Laser Processing of Hard and Ultra-Hard Materials for Micro-Machining and Surface Engineering Applications

Abstract

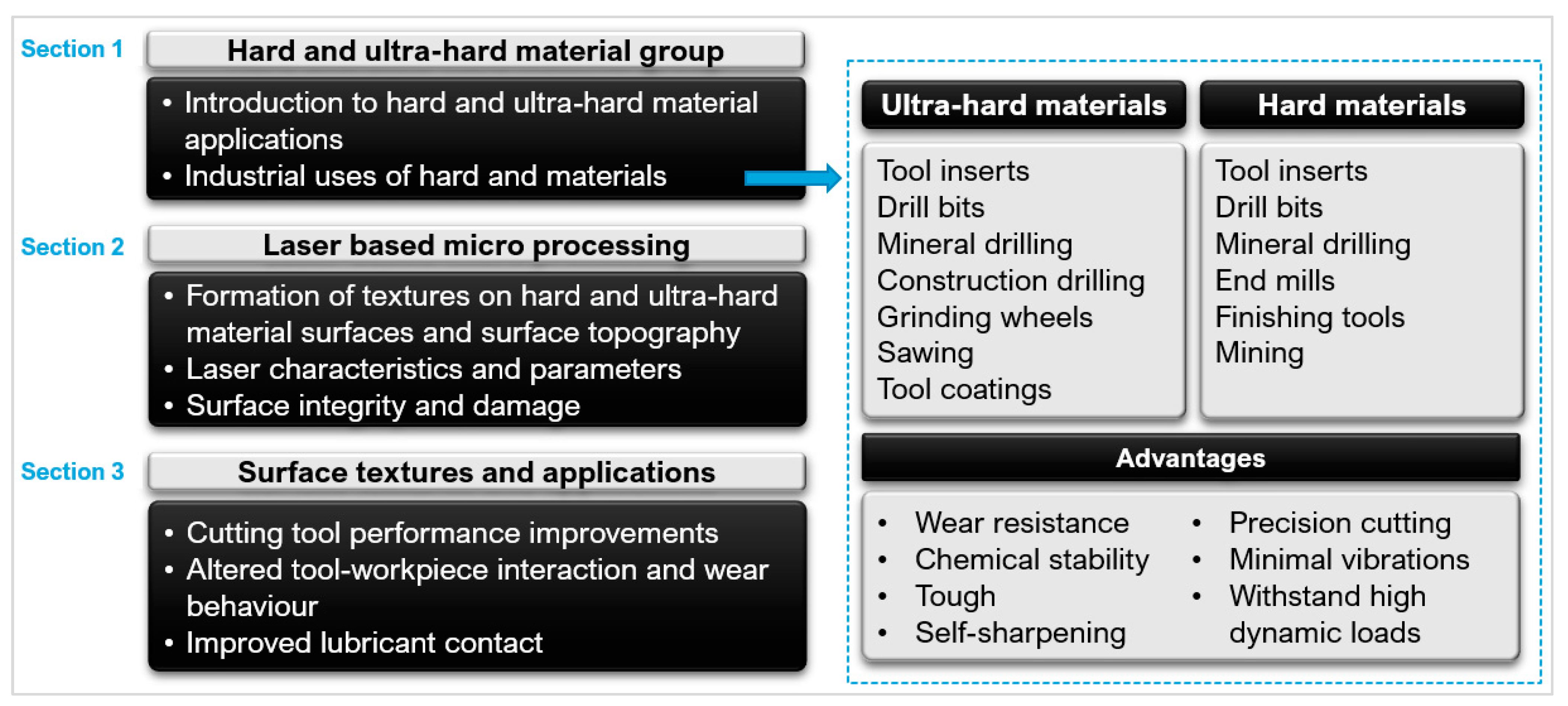

:1. Introduction

- (1)

- What laser mechanisms are required for the fabrication of surface textures on hard and ultra-hard materials?

- (2)

- What are the main laser parameters involved in processing hard and ultra-hard materials to produce surface textures?

- (3)

- What are the tribological improvements achievable with textured tools, the limitations, and the emerging techniques?

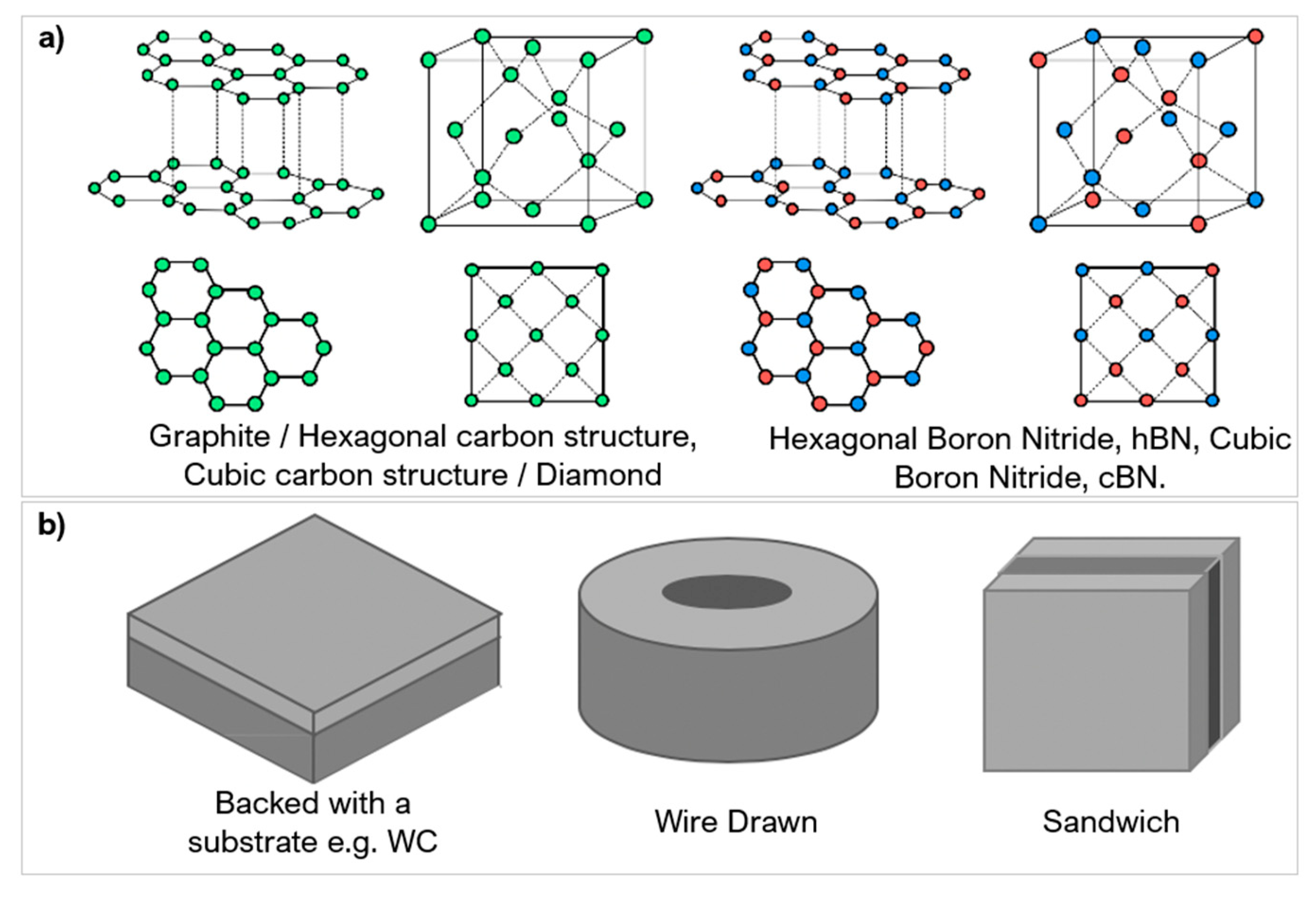

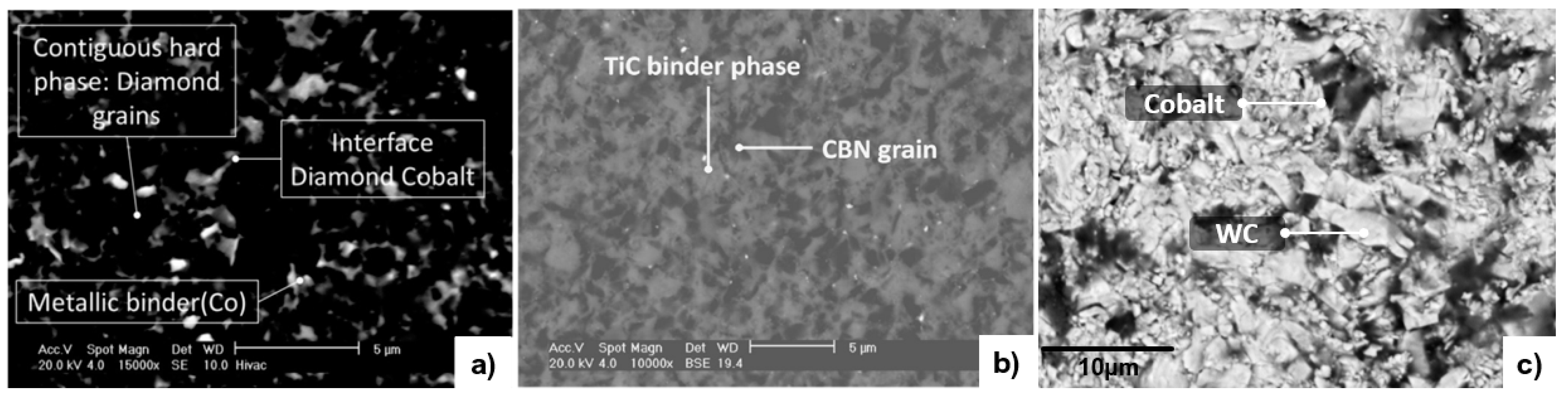

Introduction to Hard and Ultra-Hard Materials

| Properties | Diamond | Graphite | PCD | PcBN | WC | TiN | Co | Ni | Al |

|---|---|---|---|---|---|---|---|---|---|

| Density (kgm−3) | 3520 | 2230 | 4100 | 3450 | 15000 | 5220 | 8900 | 8900 | 2700 |

| Young Modulus (GPa) | 1220 | / | 840 | 865 | 660 | 450 | 220 | 200 | 74 |

| Compressive strength (GPa) | 20 | 20–200 | 7.4 | 20 | 5 | 0.97 | / | / | / |

| Knoop hardness (GPa) | 50–100 | / | / | 45 | 11 | 17 | / | / | 2.9 |

| Melting temperature (K) | Theoretical melting point as sublimation to vapour occurs at atmospheric pressures. | 3246 | 2870 | 3200 | 1495 | 1455 | 933 | ||

| Thermal conductivity (Wm−1K−1) | 540 | 25–470 | 800 | 740 | 110 | 8.36 | 100 | 90.7 | 237 |

| Thermal expansion coefficient (10−6K−1) | 3.8 | 1.2 | 0.7 | 1.2 | 5.5 | 9.35 | 12.3 | 13.4 | 23.1 |

2. Fabrication of Surface Textures

2.1. Effect of Laser Parameters on Surface Engineered Composites

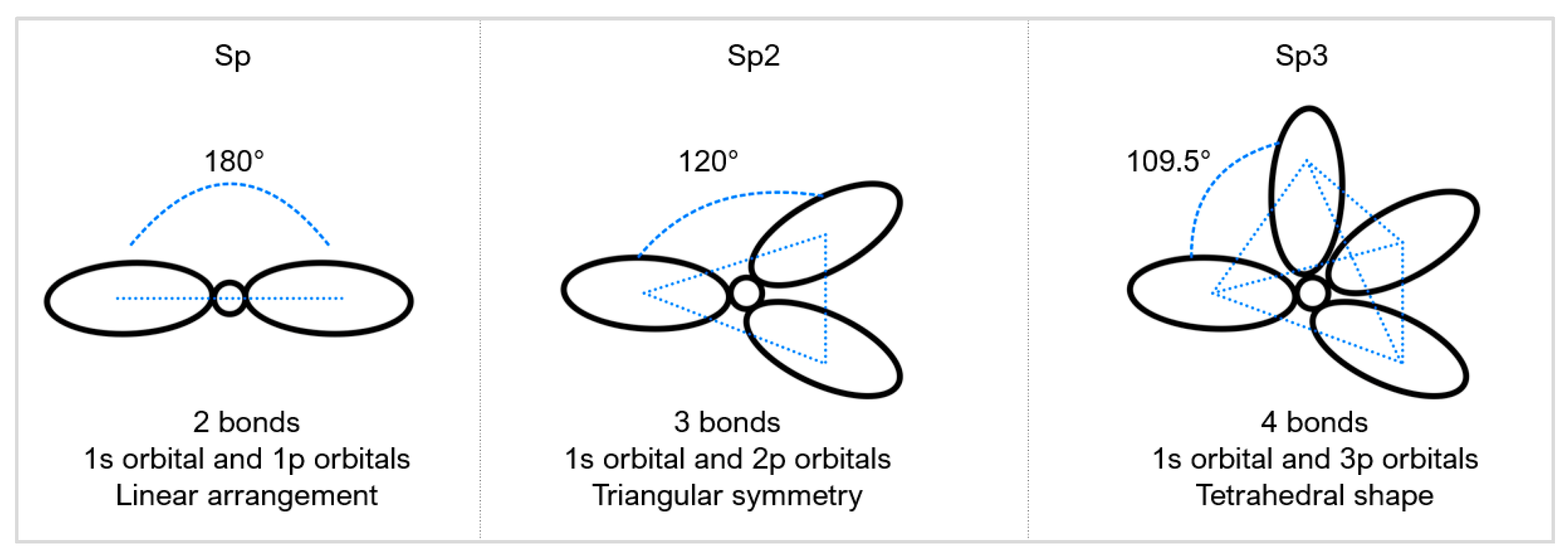

2.1.1. Effect of Wavelength and Laser Type on Ablation Mechanism

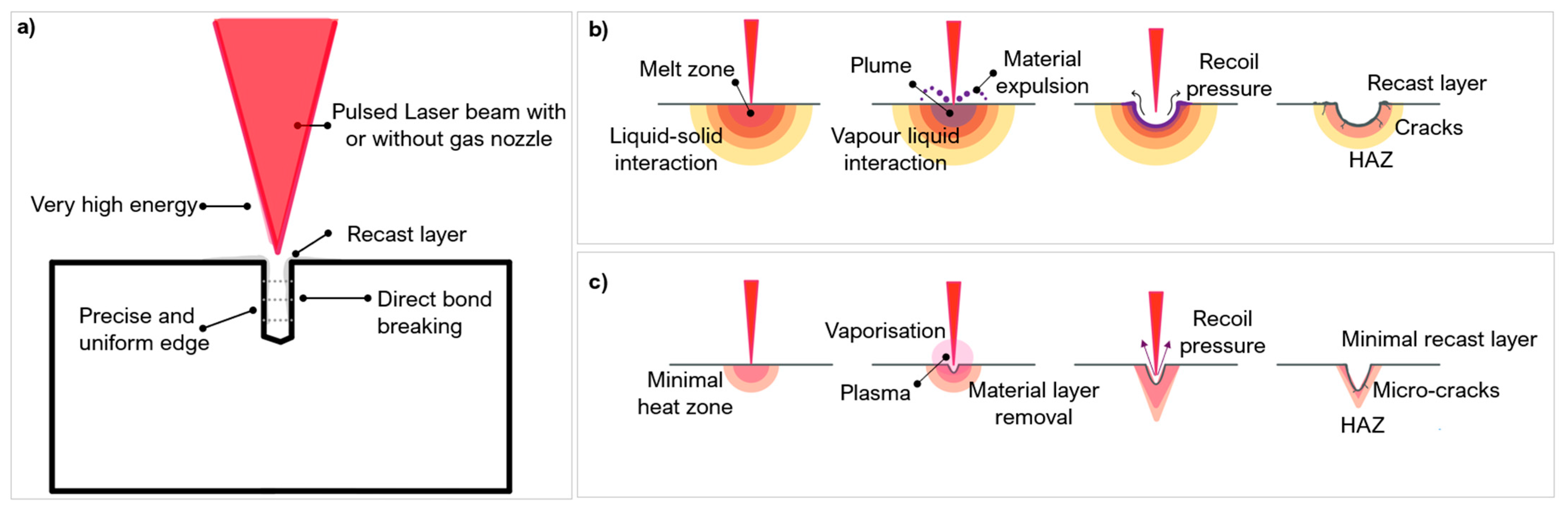

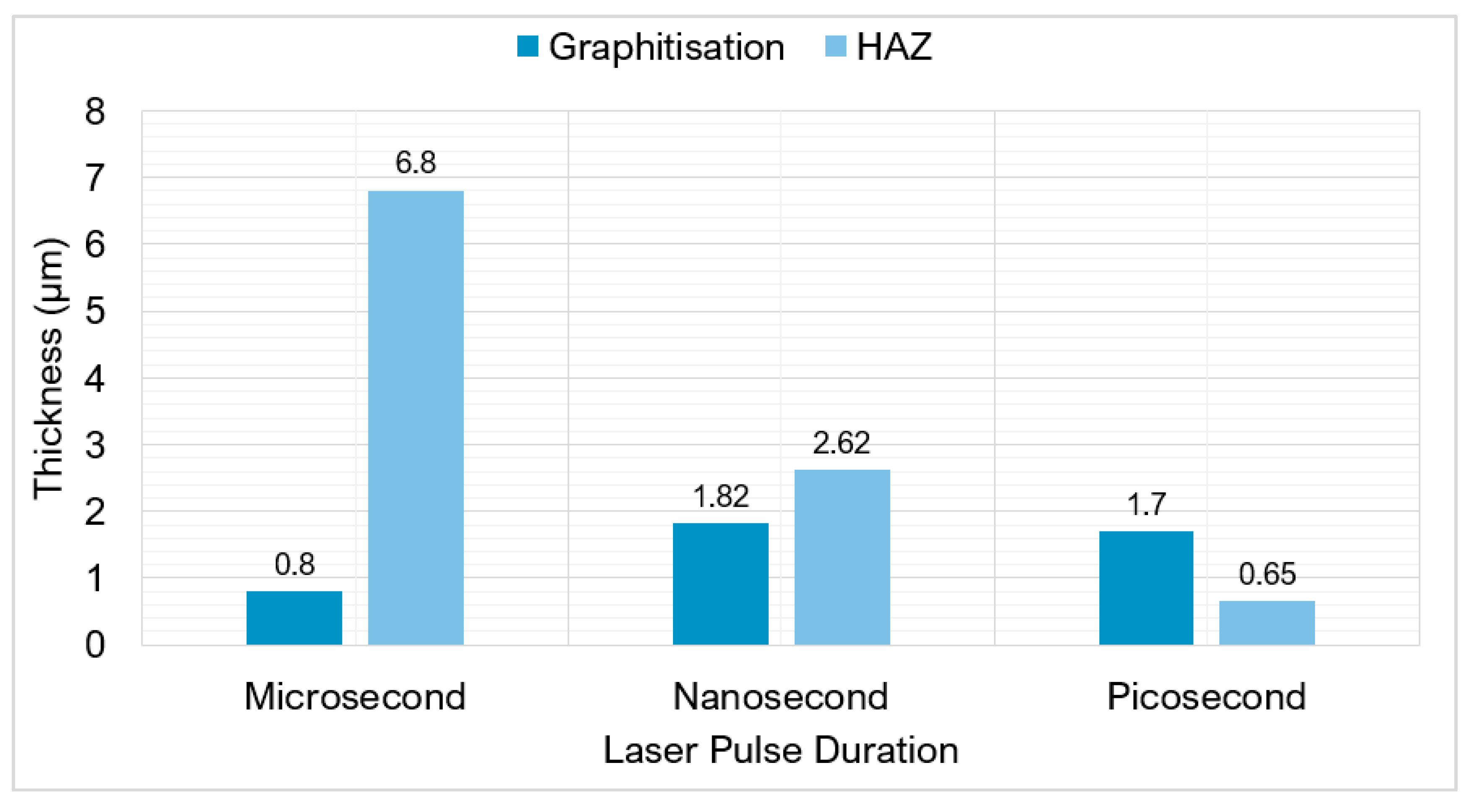

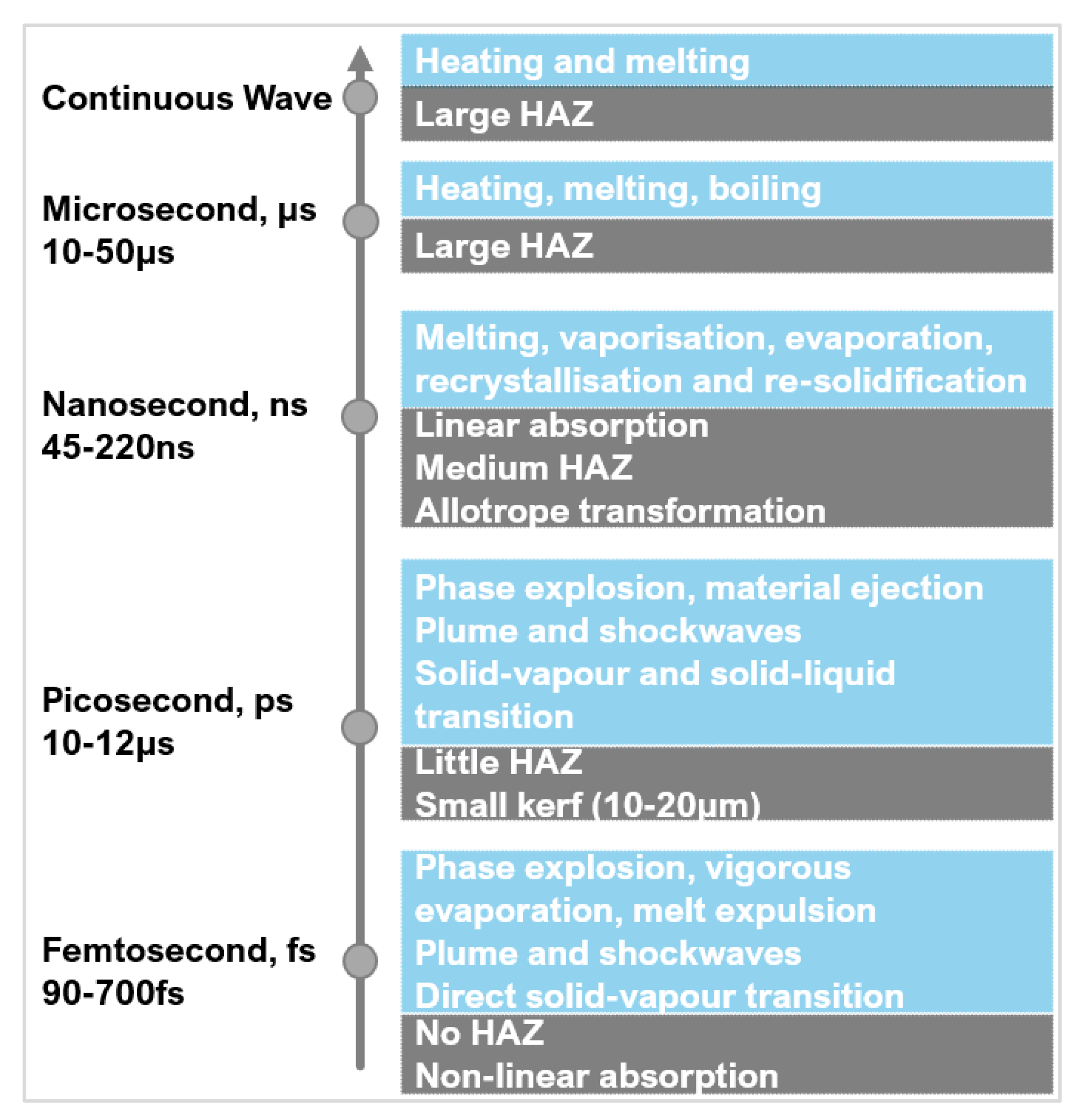

2.1.2. Impact of Pulse Duration on Surface Integrity

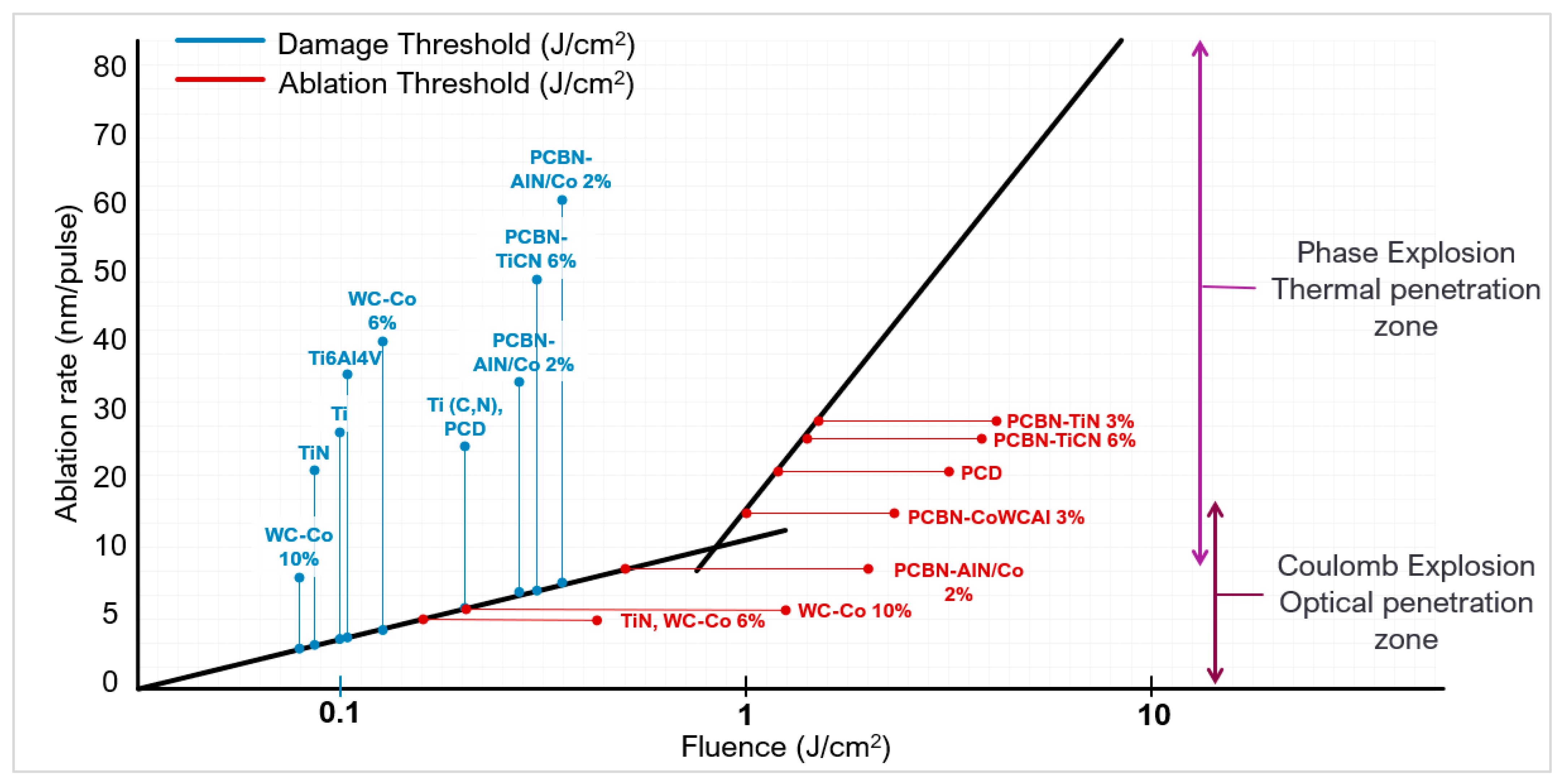

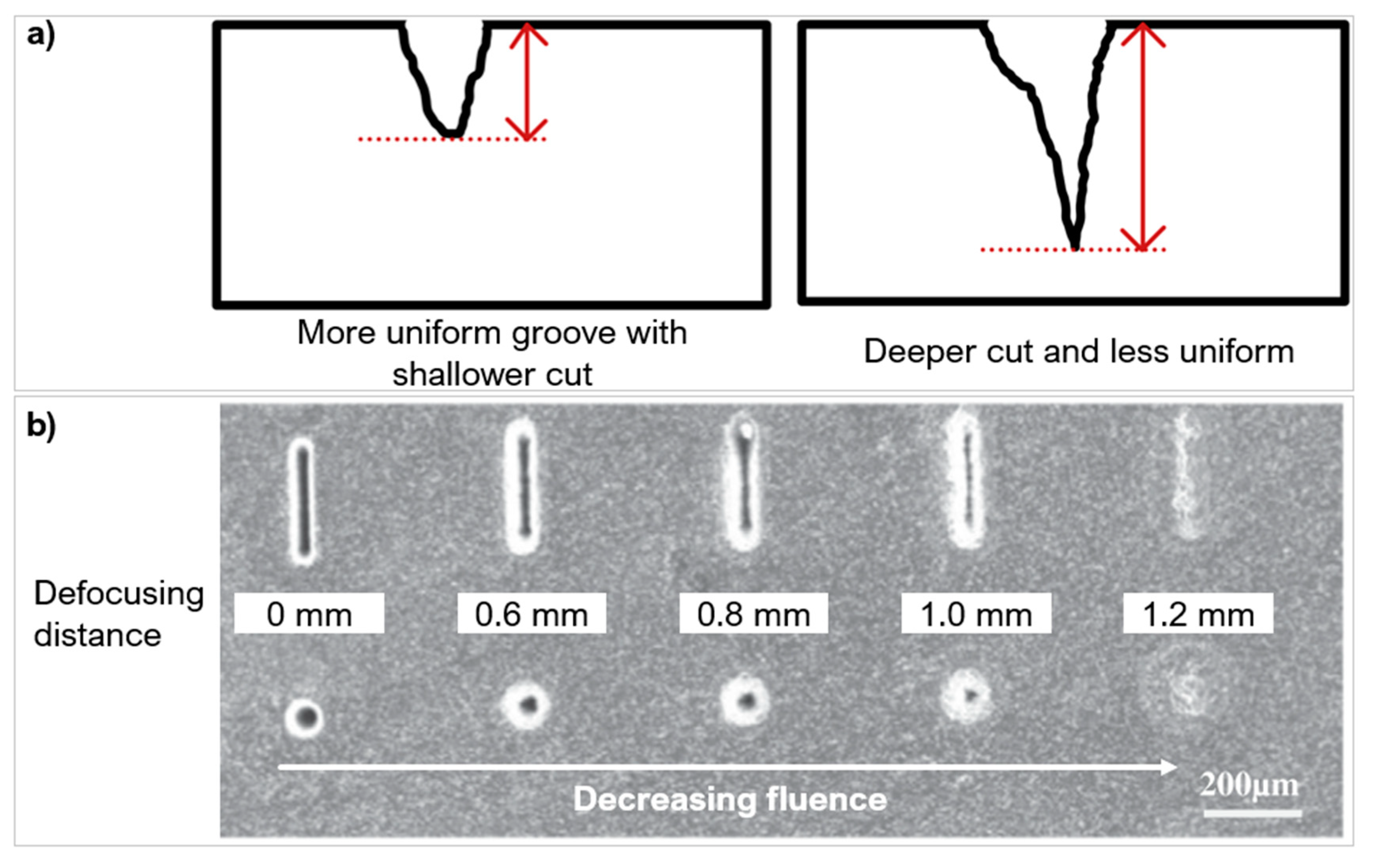

2.1.3. Effect of Fluence on Allotropic Transition of Hard and Ultra-Hard Composites

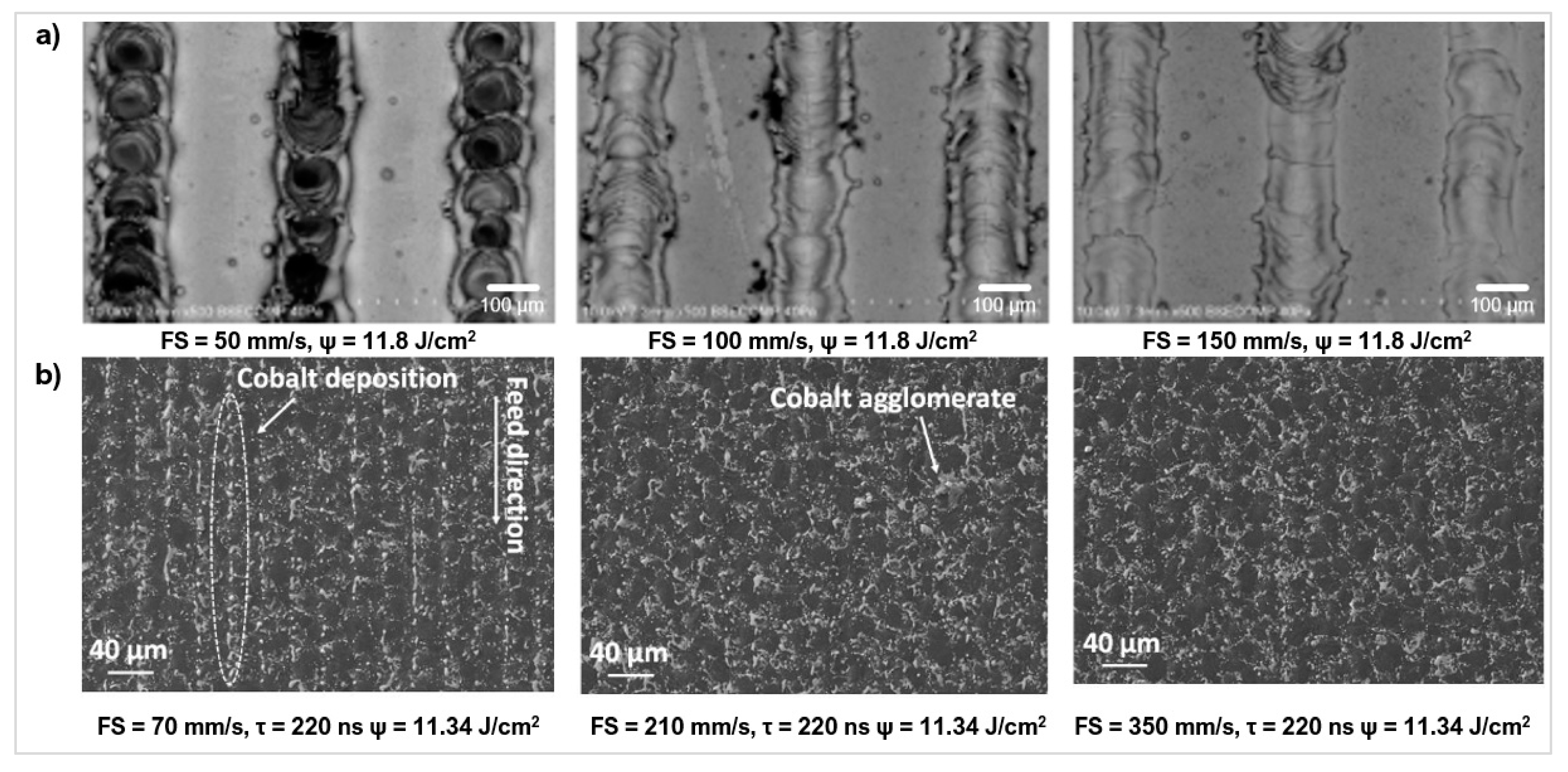

2.1.4. Impact of Scanning Speed on Texture Generation

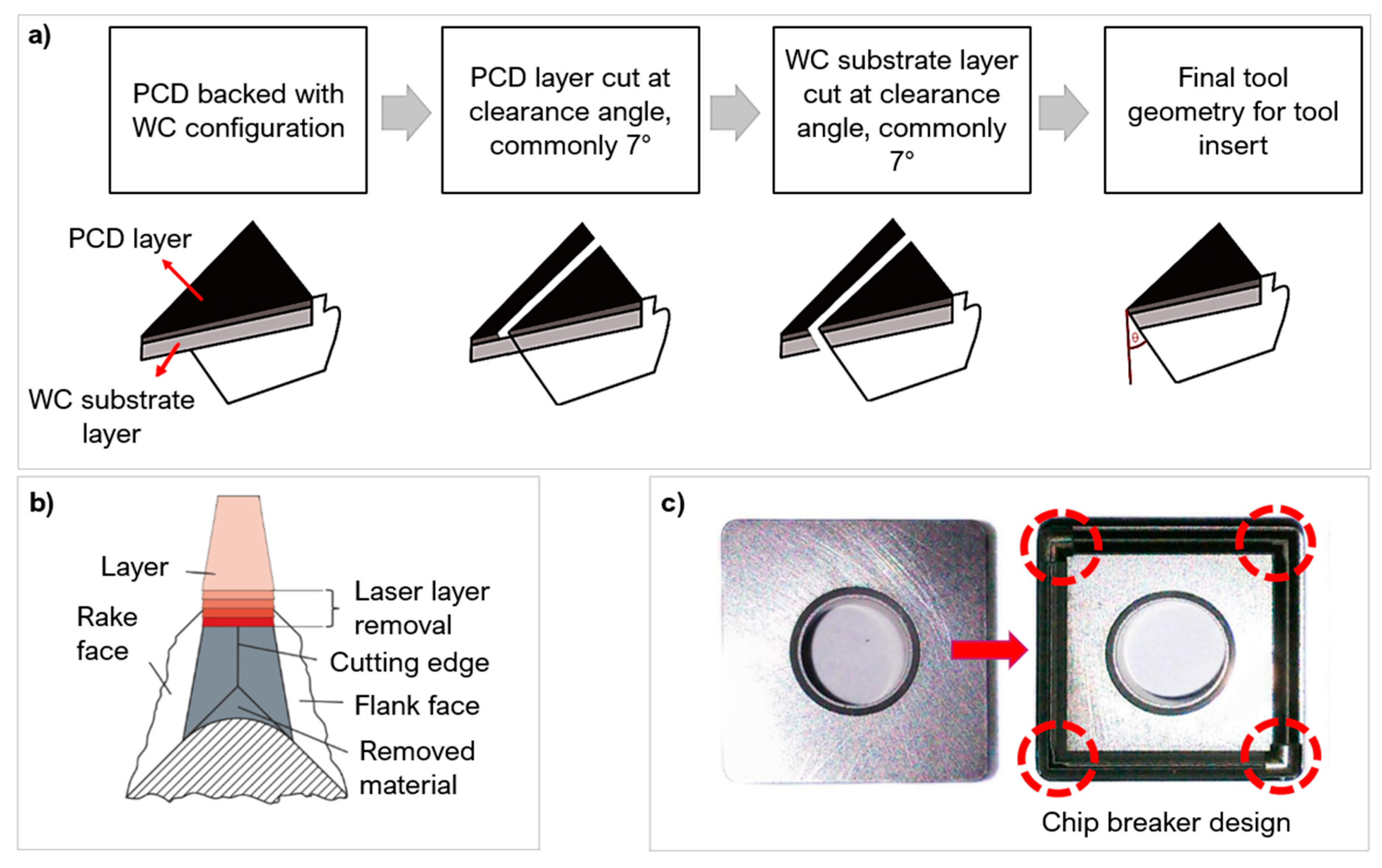

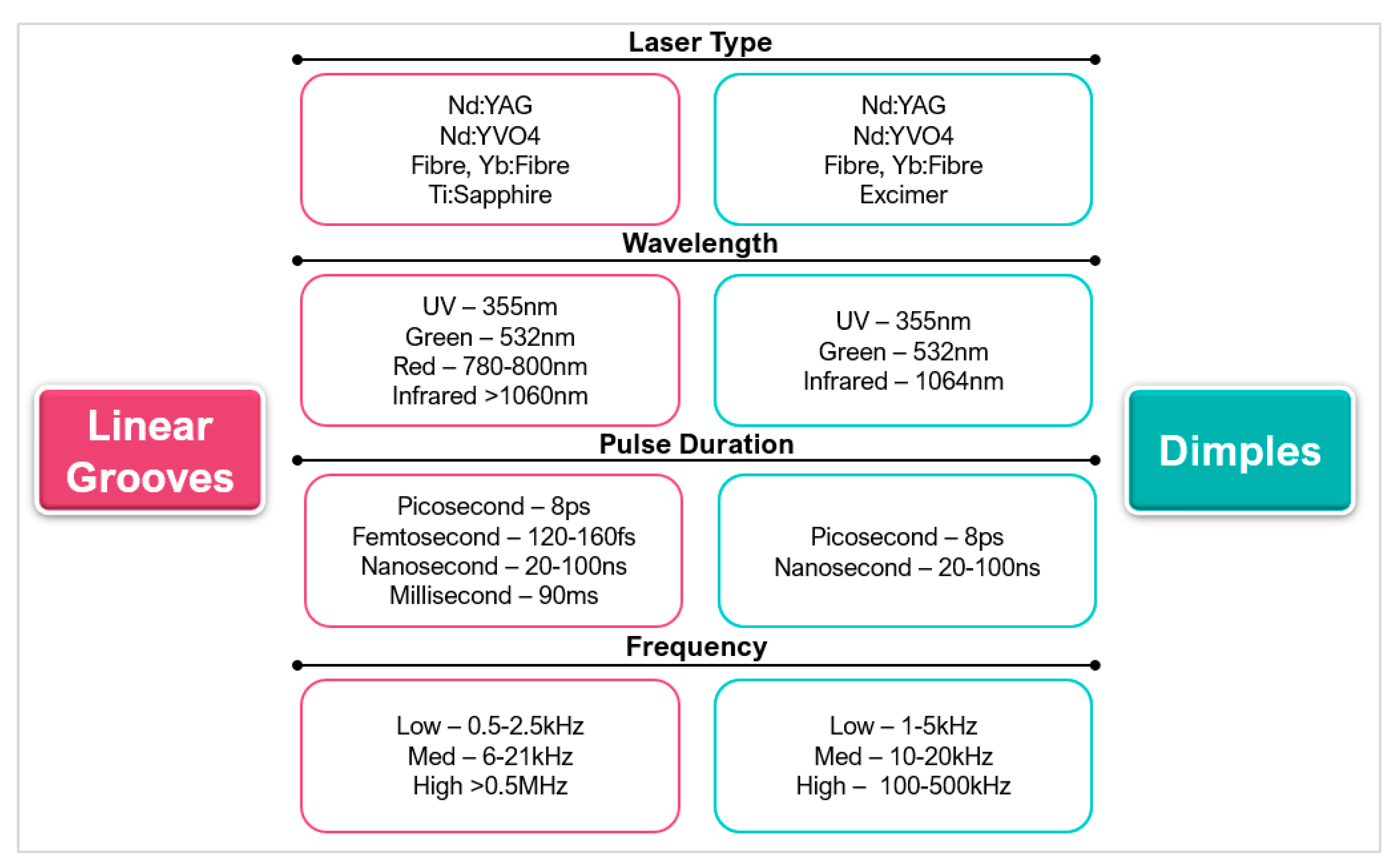

2.2. Cutting Tool Surface Textures

3. Surface Texture Performance

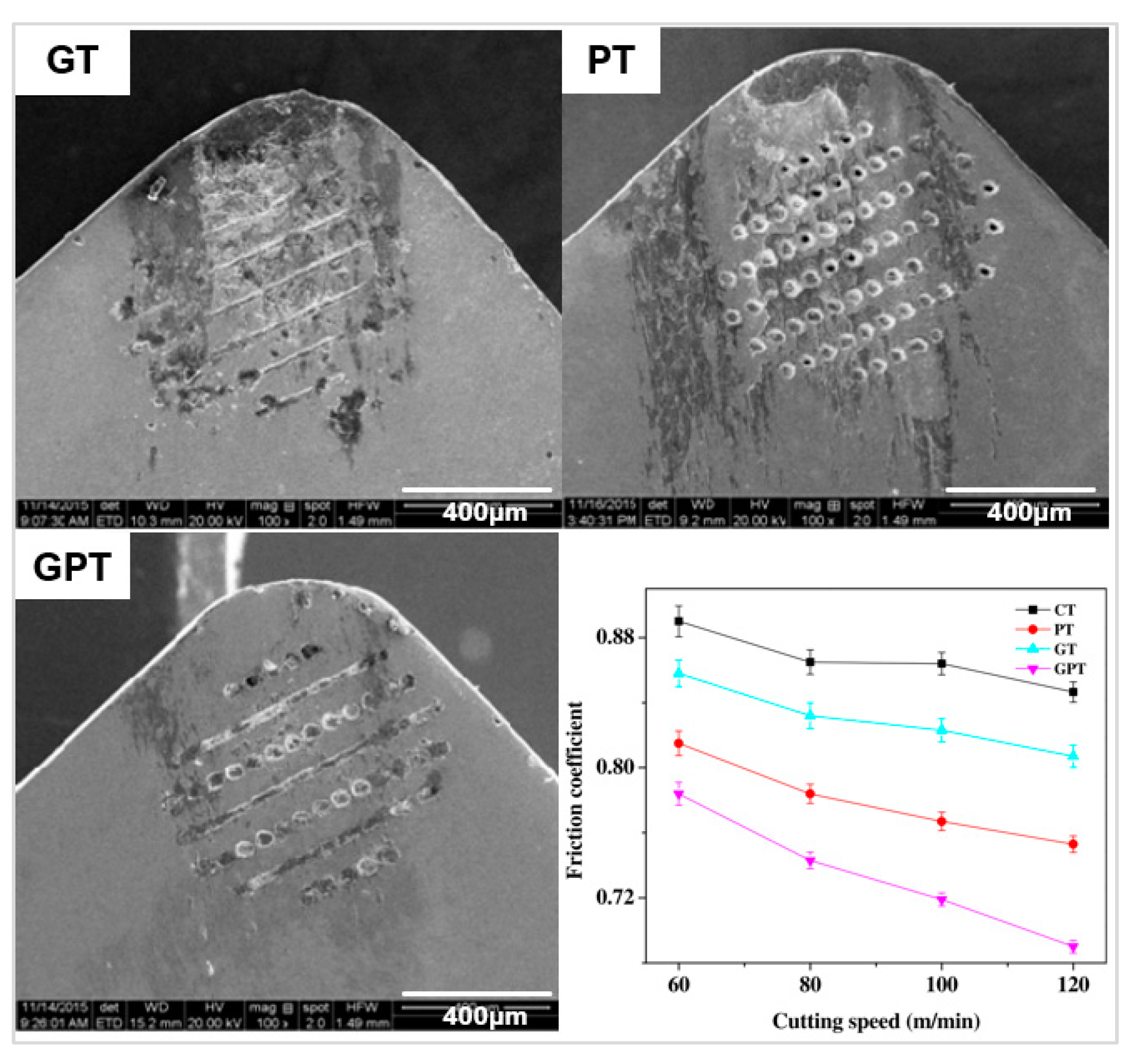

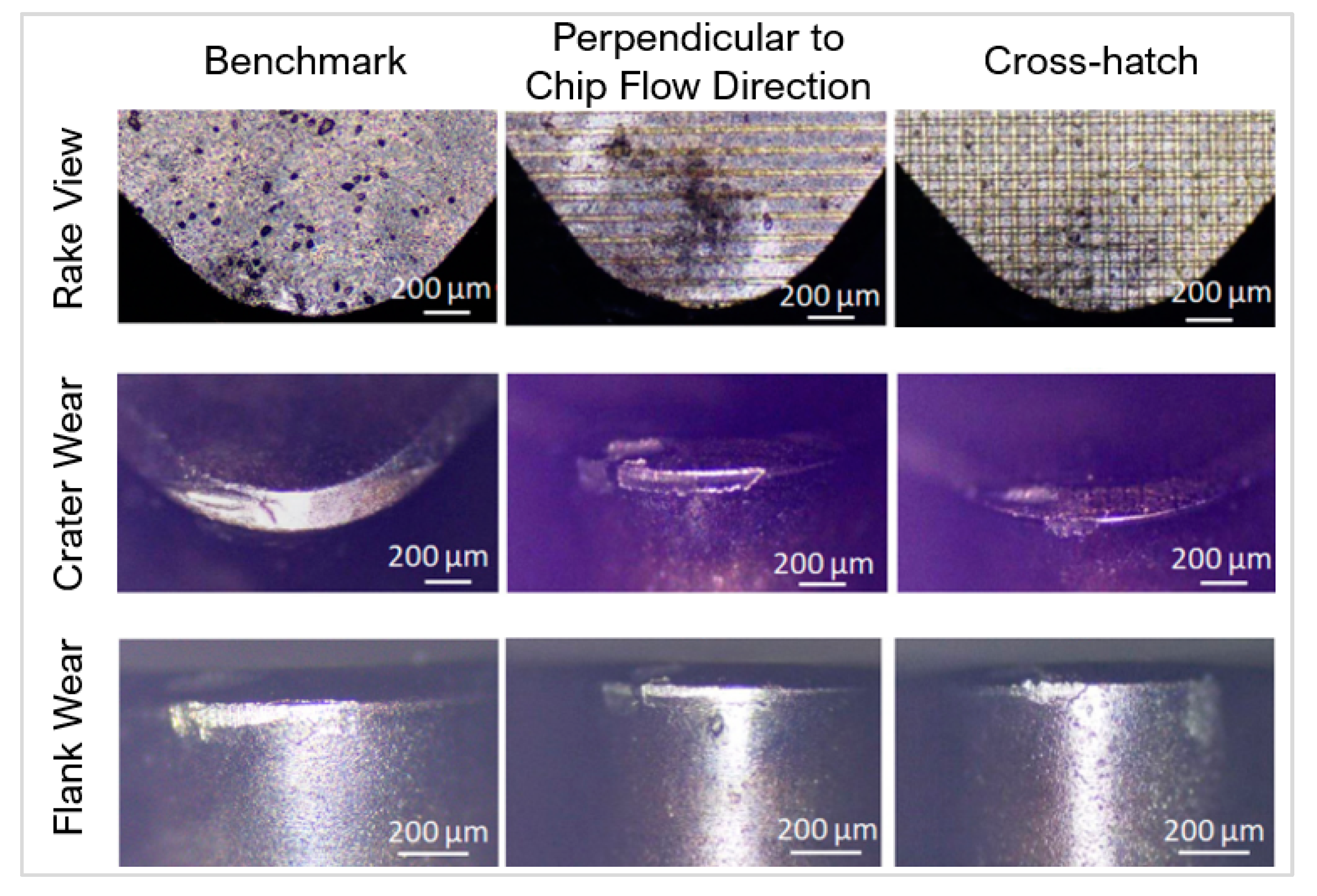

3.1. Effect of Textures on Friction Properties

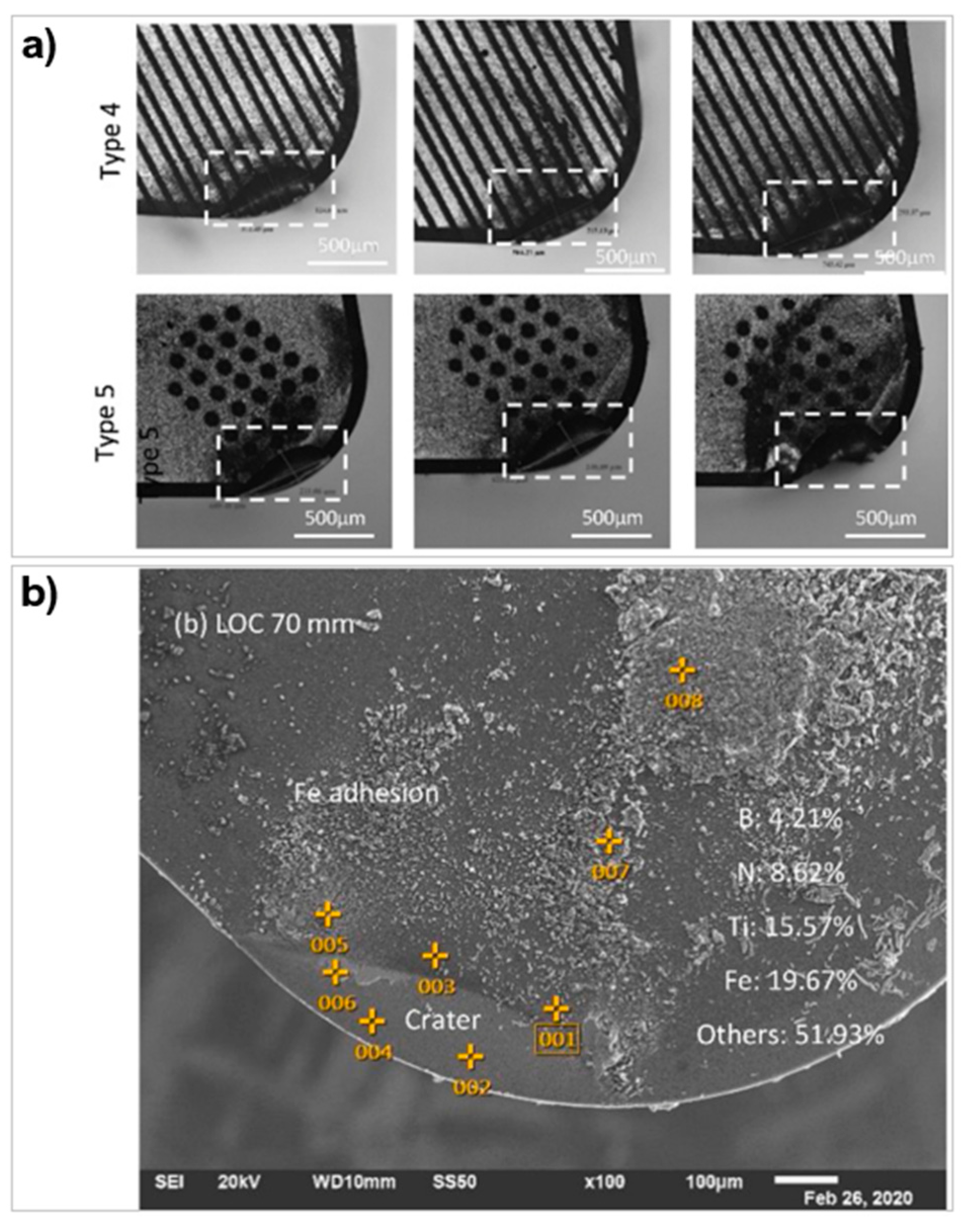

3.2. Effect of Textures on Wear Performance

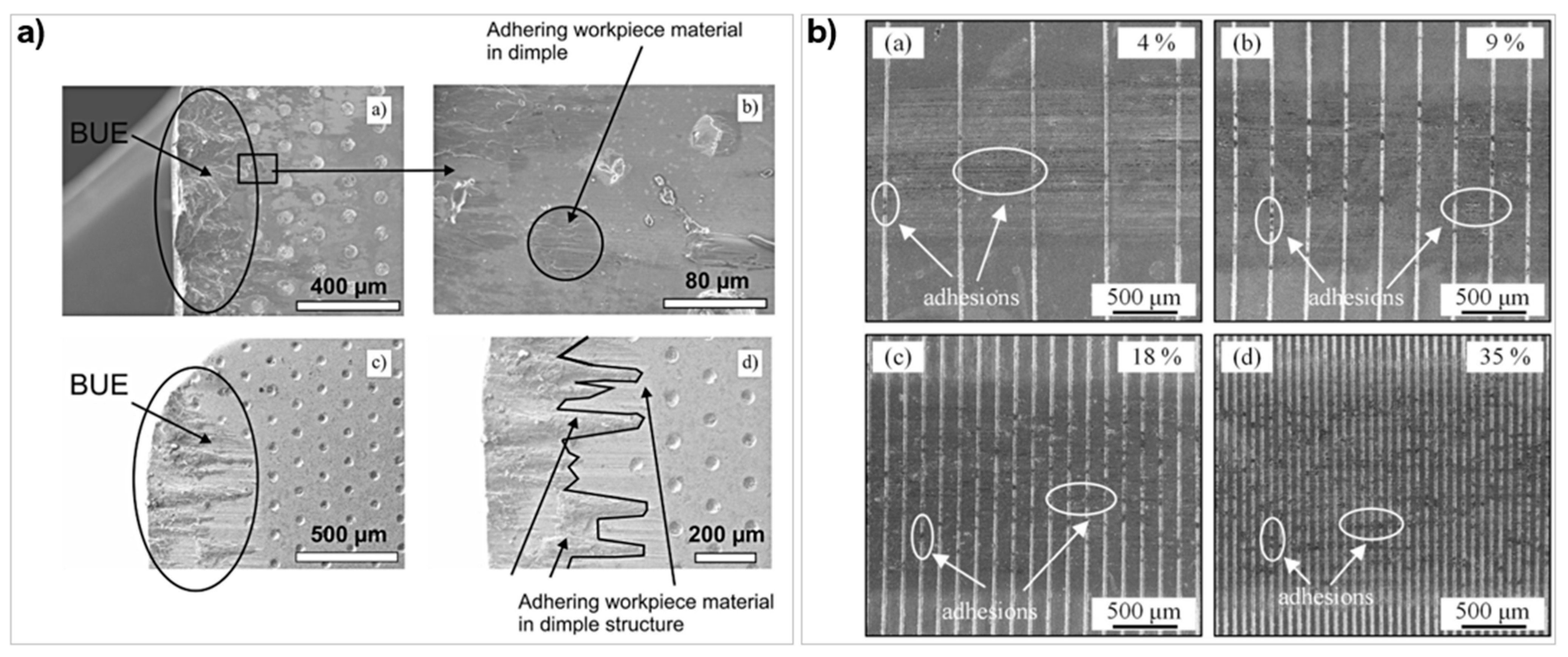

3.3. Effect of Textures on Adhesion Properties

3.4. Lubricants

4. Conclusions

- Pulsed laser ablation is an established surface texturing technique, providing a relatively accurate, non-contact, and flexible method for machining difficult to machine materials. Material removal occurs via melting, vaporisation, and sublimation of the processing region. Laser parameters have a direct impact on the physical mechanisms governing the texturing process, the material removal rate, the surface integrity, the microstructure, and the quality on textures generated.

- Processing at near IR wavelengths (1064 nm) can ablate hard and ultra-hard materials; however, the absorptivity and optical breakdown efficiency of laser processing is improved with shorter wavelengths (<532 nm) as these have higher energy pulses. This is ideal for ablation as it creates an efficient medium for molecular bond breaking, limiting thermal conduction to surrounding regions and minimising the size of thermal defects such as HAZ to as small as 1 μm regions.

- Pulse duration significantly dictates the material photon absorption. From the microsecond to the femtosecond regime, the photon absorption progressively changes from linear to multiphoton. Multiphoton absorption increases the energy transfer to the microstructure. Textures processed in the nanosecond range exhibited allotropic transitions, melting, and recrystallisation of the binder phase. Towards the picosecond range, there is a reduced risk of thermally induced defects like melt debris and recast layer, but thermal defects (such as HAZ and phase transitions) were still evident due to the superheating of the processing region. The femtosecond pulse duration resulted in least amount of these defects, leaving smoother and uniform texture profiles.

- Ablation threshold is dependent on the material composition (binder composition, binder percentage, and hard grain size) and fluence. The fluence alters the ablation mechanism with a noticeable shift towards material sublimation from melting as the fluence passes the ablation threshold. At low fluence (close to the ablation threshold), texture surfaces are smoother but shallower, requiring multiple passes to achieve the desired depth and shape, often leading to less precise material removal, cracking, and melt debris. Higher fluences cause deeper features, made in fewer passes, but can be accompanied with an increased surface roughness and distinct boundaries of allotropic transitions.

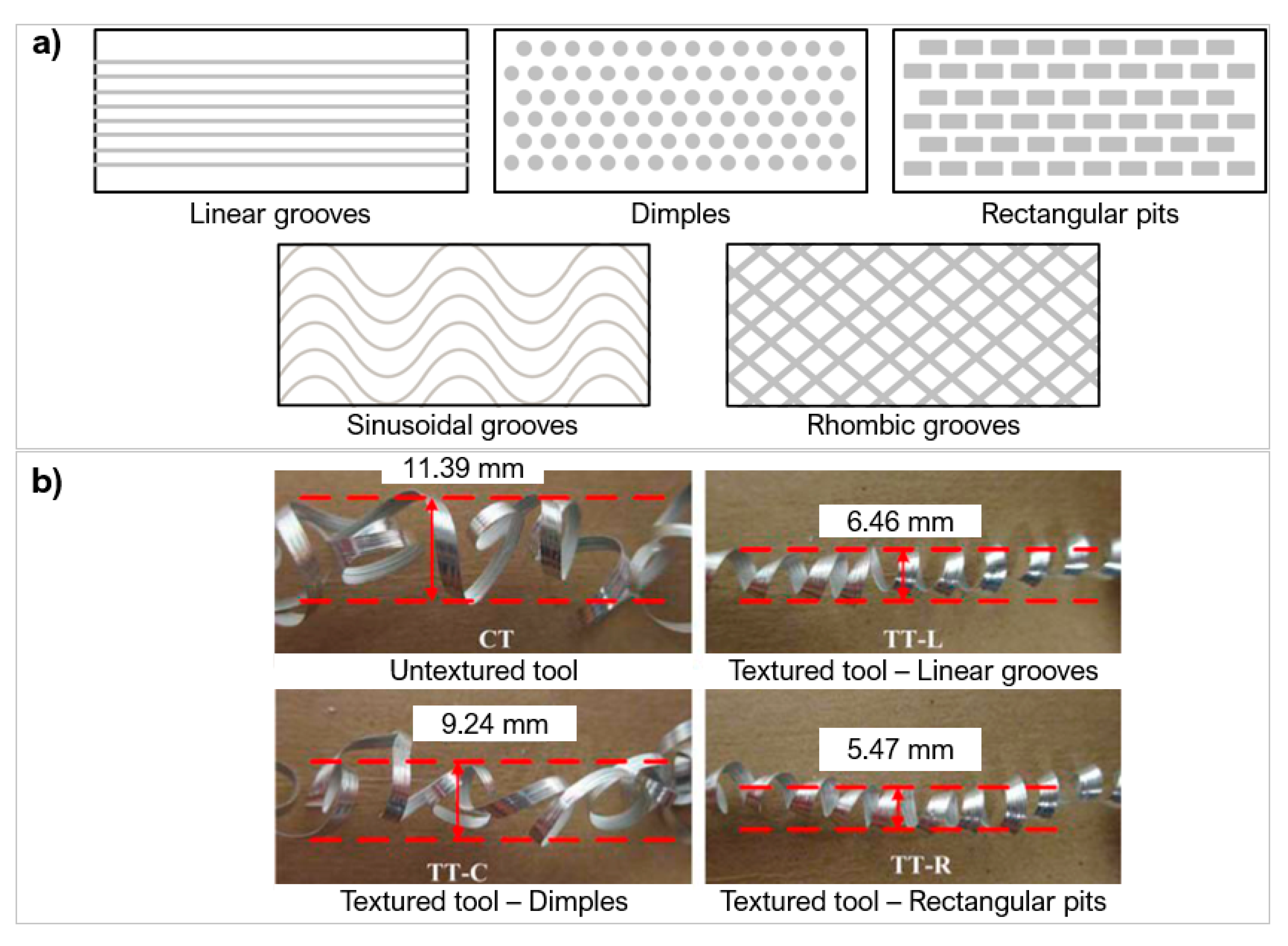

- A range of surface textures can be produced using lasers; however, the complexity and configuration of textures must be selected carefully to limit prolonged and unnecessary laser processing and avoid defects discussed in this review. Textures are typically made to widths between 50 and 100 μm and depths of 0–100 μm. The majority of studies manufactured linear grooves, dimples, and rectangular pits to shallower depths to minimise thermal damage and maintain the surface integrity of the tool region. The optimisation of laser parameters highlighted can generate an array of uniform surface textures with consistent geometric tolerances and microstructures.

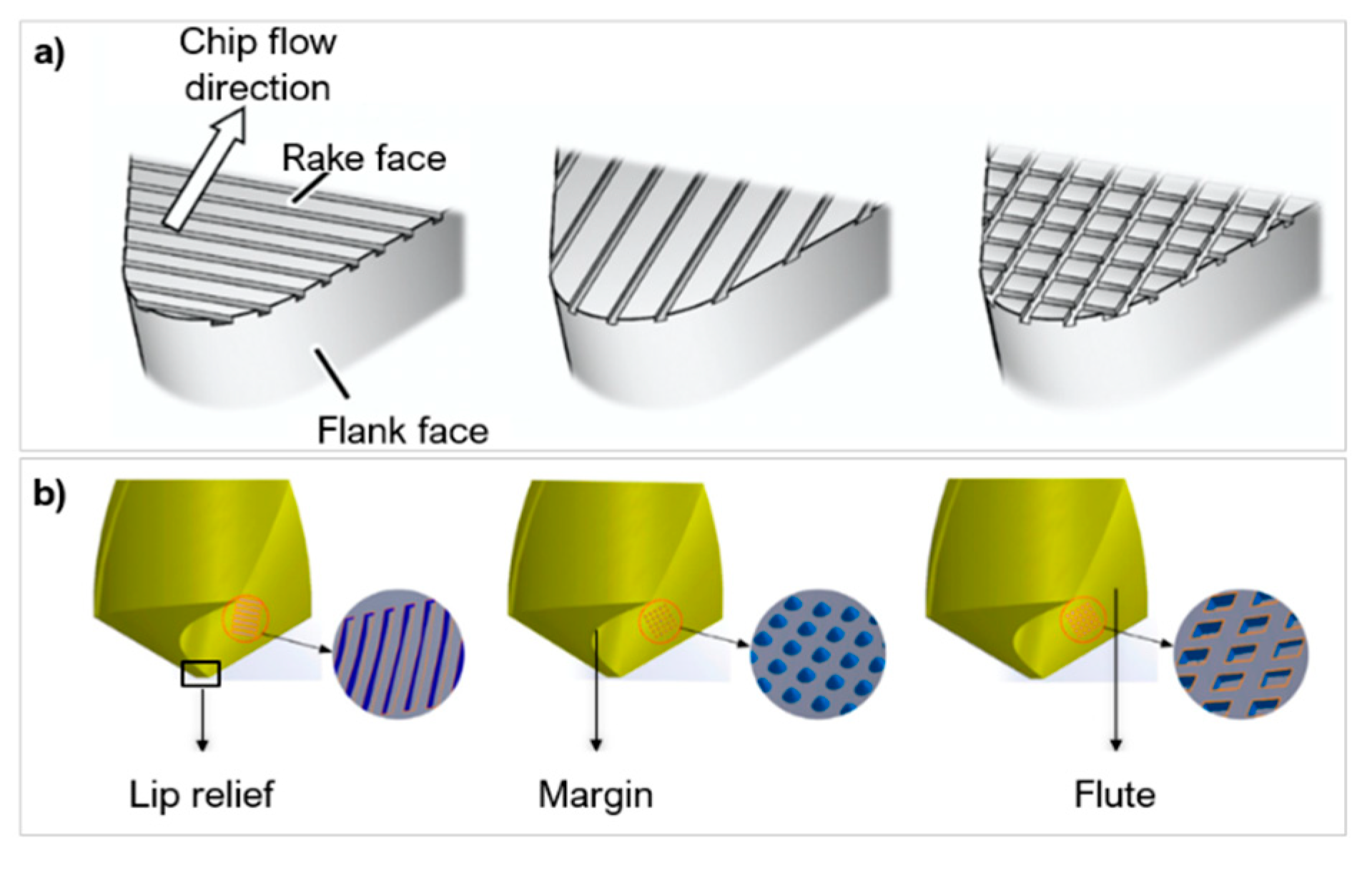

- Laser surface texturing creates of textures in various sizes, geometries, area ratios, and orientations in different locations of a tool. Commonly, the rake face (single point cutting) and the flute (multi-point cutting) are textured as these are regions of initial contact and chip-tool interaction. Texturing these regions alters the contact length and chip flow behaviour; furthermore, the textures act as reservoirs for lubricant and debris. The tribological performance of textured tools was reviewed in this paper, concluding that textures are effective in reducing COF, cutting forces, reducing wear debris, decreasing adhesion, and allowing for better heat dissipation at the cutting interface. The performance of textures is dependent on texture characteristics (texture size, orientation, geometry, area ratio, and density) and conditions of machining (workpiece material, feed speed). Textures that are transverse to the chip flow demonstrate a greater ability to reduce friction and cutting forces because of the reduced contact length.

- The geometry of texture affects the chip formation mechanism: rectangular and linear shapes are more likely to generate smaller and more uniform chips throughout the cutting process. A higher width to depth ratio or area ratio also plays a factor in this, but there are limited studies that fully investigate why. Non-conventional texture geometries have shown promise in improving tool chip interactions. The improvements with hybrid or combination textures were linked to chips progressively moving over different textures which changed the pressure distribution during the cutting process.

- The texture density dictates the texture coverage on the tool; this has a direct impact on cutting force and on the COF because it changes the amount of secondary shear zones. Texture density around 10–20% can stabilise adhesion and BUE but density over 30% increases tool wear and adhesion. This is because the proximity of textures causes additional cutting zones as chips flow, leading to abrasive wear. Adhesion build-up between textures is also greater with higher densities, burying textures at a quicker rate.

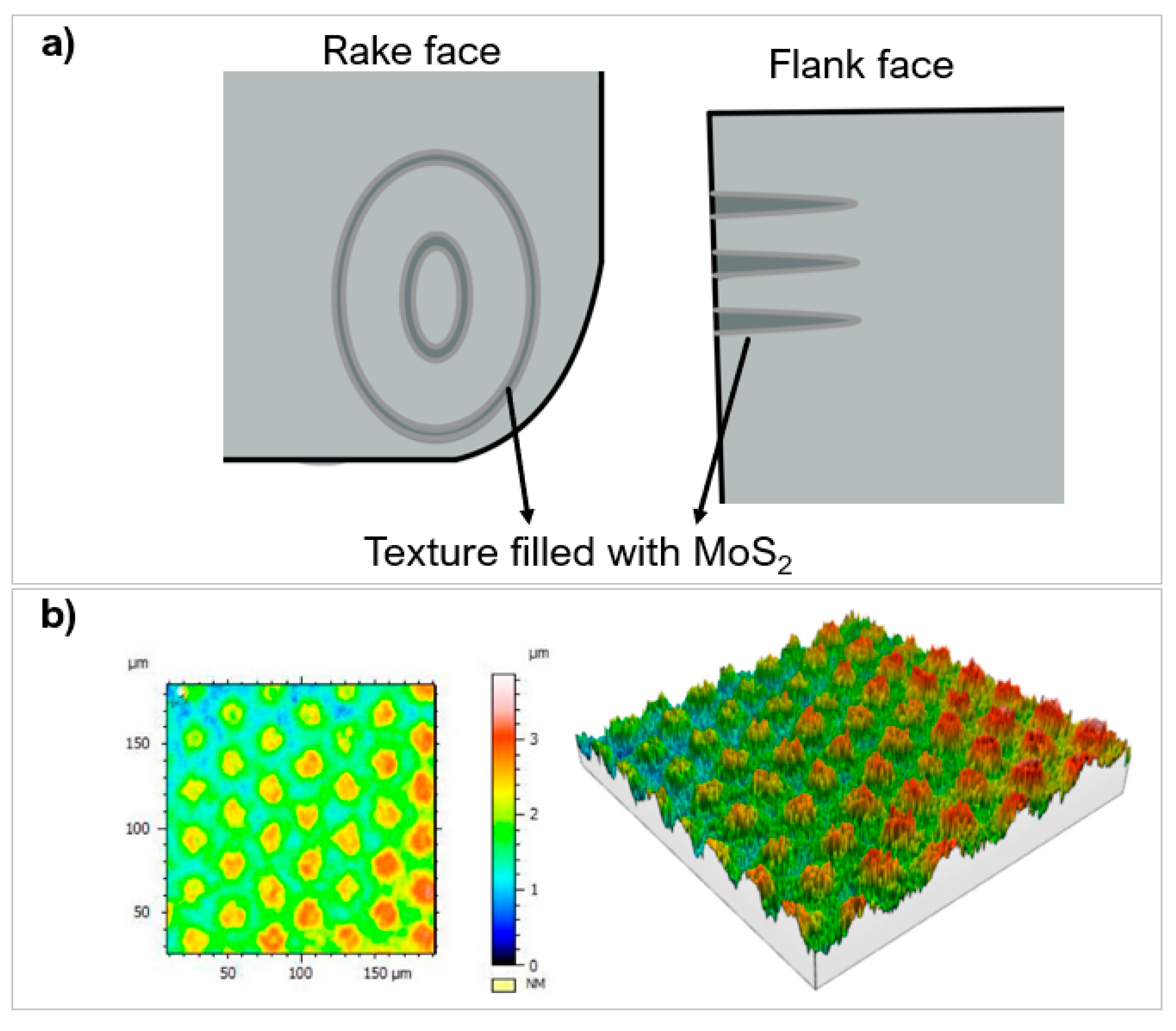

- Texture geometry influences the tool behaviour with solid lubricants. A smearing effect is created, helping to lubricate the area and distribute forces. Though a systematic comparison is not available due to limited available studies, dimples and elliptical grooves show the best interaction with lubricants; these shapes make it easier for lubricant to be expelled from the texture and smear lubricant onto the tool surface.

- Cutting conditions (workpiece material, feed speed) have a primary role in the performance of textured tools. With aluminium alloy workpieces, lower cutting speeds cause large amounts of adhesion; this quickly buries the textures making the performance comparable to an untextured tool, whereas titanium alloy workpieces are more likely to cause adhesion at higher speeds. Despite this, textured tools have consistently shown better tribological performance at very high speeds up until a point, beyond which the improvement in COF starts to diminish. This point varies for different tools and workpiece materials; in some cases, this can be as low as 125 m/min (PCD tool and Ti6Al4V workpiece) and as high as 250 m/min (WC-Ti/Co tool and hardened steel workpiece).

- Specific to hard and ultra-hard material composites, the binder is also an influential factor in the wear behaviour of surface textures. Textures on tools with harder binder compositions are less likely to show wear in the form of binder breakdown and binder diffusion.

5. Future Trends

- Studies in literature have reported the generation of allotropic transitions as a result of laser processing in PCD and PcBN materials, the extent is dependent on the energy density used during processing. Formation of graphite and hexagonal boron nitride in selected areas of the tool can be used to introduce these allotropes as solid lubricants within the manufacturing process rather than in the material design. Investigating the ability to control the amount of hBN/graphite in specific regions of the textures to customise the tool performance in a low cost and accessible way, could provide an innovative method of inducing lubricant properties to extend the performance of one the most used cutting tool materials.

- The minimum sizes of textures able to produce a noticeable cutting tool performance were 1–2 μm in depth and 1–3 μm in width. Biological structures (shark skin, frog toe pad, snakeskin) have shown that the use of even smaller textures can alter wet/dry adhesion, friction, and strengthen selected regions. Recently, LIPSS have been used to generate surface structures smaller than 1 μm. There is scarce literature on the generation of LIPSS with cutting tool materials in collaboration with micro-textures. The addition of nano-textures within micro-textures could show a similar pattern to nature where significant improved tribological performance is achieved with a slight strengthening effect.

- One interesting area to explore is the use of more hybrid combination and non-uniform textures, for example, varying density of texture based on the tool location. These irregular structures seem to have a greater effect than uniform structures on the type of chip formation mechanism, to control BUE and cutting force stability. It is not clear why this is the case, but fundamental research is needed to understand the cause and inform improvement of the configuration of textures.

- The current rationale of laser parameter selection for the fabrication of surface textures is still based on a trial and error or statical approach. However, the laser/material interaction during laser processing is stochastic and complex. It is difficult to predict the material’s response even employing thermal modelling. Advances in modelling and artificial intelligence are beginning to show their value in understanding the effects of laser parameters, giving users the ability to optimise texture microstructure. From literature, it is not clear if the choice of laser parameters should be dependent on the texture characteristics (e.g., geometry, area ratio, tool location). Using AI would be beneficial in quickly discerning this and tailoring the microstructure to achieve bespoke tribological performance in a range of cutting tool conditions.

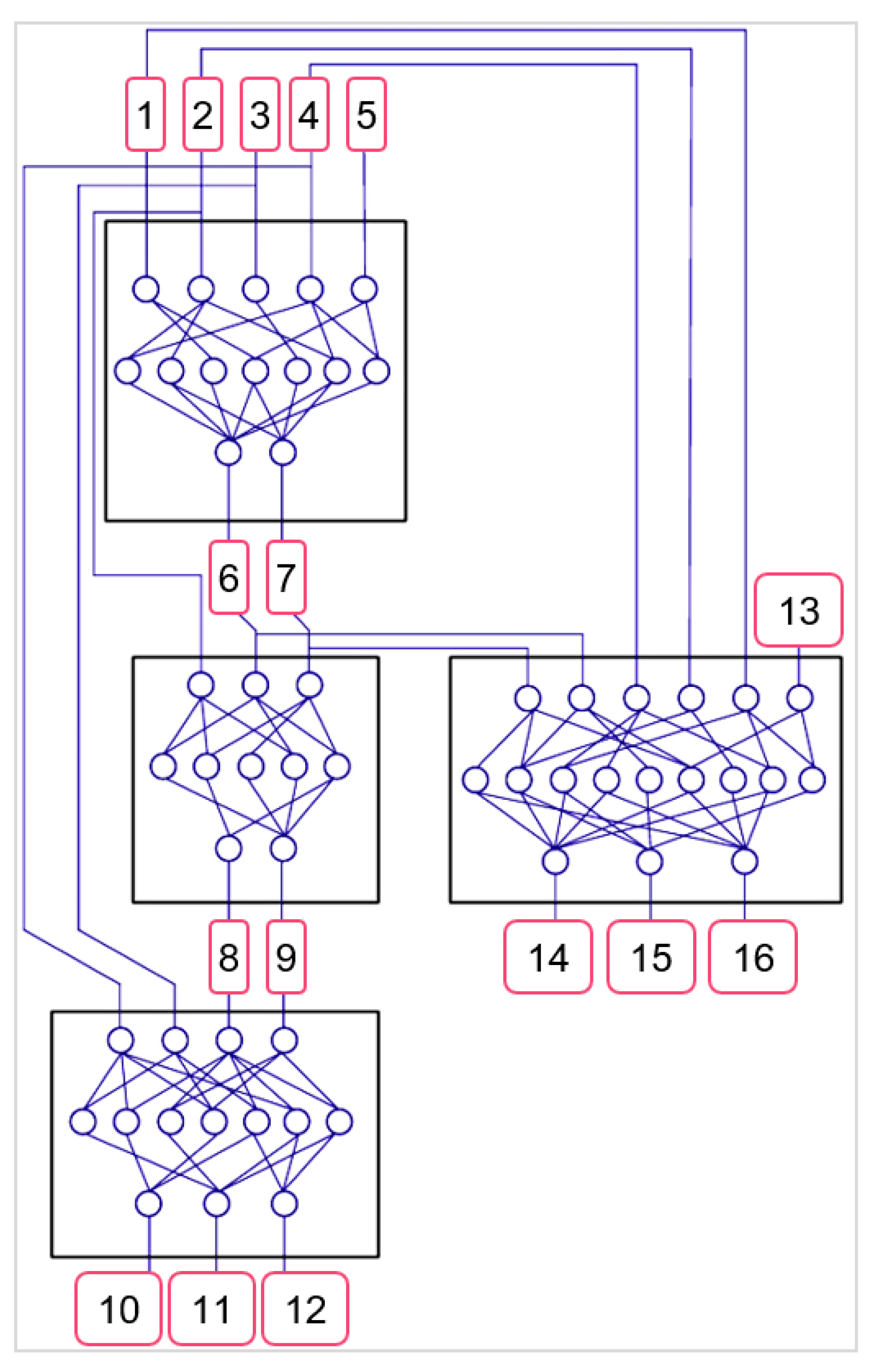

- Although there is a clear consensus that the fabrication of micro-textures on cutting tools does improve the cutting performance, the amount of improvement is a multi-factorial decision (texture geometry, texture dimension, density, location, tool material, and machining application). There is a lack of research in the choice of the optimal texture characteristics for a specific machining application to maximise texture performance, promoting the need for advanced modelling. Similar to the recommendation in laser processing, the use of AI and optimisation modelling would be beneficial to create systems that can accurately identify ideal textures and predict the performance of textured tools (wear rate, COF, adhesion). This could allow for the functionalisation of micro-textures for given operational conditions. Figure 29 shows an example proposal with these characteristics in a multi-level ANN structure to demonstrate different dependencies described in this critical review.

- Changes to cutting tool performance are not limited to surface texturing. Studies have shown that any tool edge modification changes chip interaction and the resultant frictional behaviour at the tool-chip interaction. More work is needed in understanding the different types of tool edge modifications (rounding, chamfering, chip breaker designs) possible with laser processing and the potential value in creating these structures for cutting tool performance.

- After use, textures suffer from material shredding, ploughing marks, and texture damage; however, the main structural integrity of the tool is preserved, and there is little indication that there is significant damage beneath texture structures. Research has yet to investigate how to refresh these textures to allow for future use as a cutting tool and further reconditioning methods to extend tool life.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Paul, S.; Singh, R.; Yan, W. Lasers Based Manufacturin; Springer: New Delhi, India, 2015. [Google Scholar] [CrossRef]

- Wu, Z.; Bao, H.; Xing, Y.; Liu, L. Tribological characteristics and advanced processing methods of textured surfaces: A review. Int. J. Adv. Manuf. Technol. 2021, 114, 1241–1277. [Google Scholar] [CrossRef]

- Denyer, D.; Tranfield, D. Producing a systematic review.pdf. In The SAGE Handbook of Organisational Research Methods; Sage: London, UK, 2009; pp. 671–689. [Google Scholar]

- Sumiya, H.; Harano, K. Innovative ultra-hard materials: Binderless nanopolycrystalline diamond and nano-polycrystalline cubic boron nitride. SEI Tech. Rev. 2016, 82, 21–26. [Google Scholar]

- McKie, A.; Winzer, J.; Sigalas, I.; Herrmann, M.; Weiler, L.; Rodel, J.; Can, N. Mechanical properties of cBN-Al composite materials. Ceram. Int. 2011, 37, 1–8. [Google Scholar] [CrossRef]

- Novikov, N.V.; Dub, S.N. Hardness and fracture toughness of CVD diamond film. Diam. Relat. Mater. 1996, 5, 1026–1030. [Google Scholar] [CrossRef]

- Chang, F.; Gu, D.; Dai, D.; Yuan, P. Selective laser melting of in-situ Al4SiC4 + SiC hybrid reinforced Al matrix composites: Influence of starting SiC particle size. Surf. Coatings Technol. 2015, 272, 15–24. [Google Scholar] [CrossRef]

- Pacella, M.; Butler-Smith, P.W.; Axinte, D.A.; Fay, M.W. The allotropic transformation of polycrystalline cubic boron nitride structures resulting from the thermal effects of pulsed laser ablation. Diam. Relat. Mater. 2015, 59, 62–68. [Google Scholar] [CrossRef]

- Smith, G.T. Cutting Tool Technology; Springer: London, UK, 2008. [Google Scholar]

- Sugano, T.; Ohashi, N.; Tsurumi, T.; Fukunaga, O. Pressure and temperature region of diamond formation in systems graphite and Fe containing alloy. Diam. Relat. Mater. 1996, 5, 29–33. [Google Scholar] [CrossRef]

- Chandran, M. Synthesis, characterization, and applications of diamond films. In Carbon-Based Nanofillers and Their Rubber Nanocomposites; Elsevier: Amsterdam, The Netherlands, 2019; pp. 183–224. [Google Scholar]

- Matzel, J. Nanosims studies of δ15N and δ 13Cin nitrides inclusions in coesite from a Tibetan massive cromitite ore. Geochim. Cosmochim. Acta 2010, 74, A649–A743. [Google Scholar] [CrossRef] [Green Version]

- Heath, P.J. Ultra-hard Materials. Eur. J. Eng. Educ. 1987, 12, 5–20. [Google Scholar] [CrossRef]

- Crompton, D.; Hirst, W.; Howse, M.G.W. The wear of diamond. Proc. R. Soc. London. Ser. A Math. Phys. Sci. 1973, 333, 435–454. [Google Scholar] [CrossRef]

- Lindgren, K.; Kauppi, A.; Falk, L. Development of matrix microstructure in polycrystalline cubic boron nitride ceramics. J. Eur. Ceram. Soc. 2017, 37, 3017–3026. [Google Scholar] [CrossRef]

- Jones, B.L. Properties of Natural and Synthetic Diamond; Field, J.E., Ed.; Academic Press: London, UK, 1992; Volume XIV, p. 710, hardcover, £ 90, ISBN 01 2-255352-7. Adv. Mater. 1993, 5, 681–682. [Google Scholar] [CrossRef]

- Pacella, M.; Butler-Smith, P.; Axinte, D.; Fay, M. FIB/TEM/EELS micro/nanometric investigations of the effects of laser ablation on the diamond/binder structure in polycrystalline diamond composites. J. Mater. Process. Technol. 2014, 214, 1153–1161. [Google Scholar] [CrossRef]

- Wang, Z.; Li, Y.; Zou, Q.; Dai, L.; Yu, Q.; Luo, Y.; Luo, W.; Yin, Y. Effect of sintering parameters on microstructure and properties of nanopolycrystalline diamond bulks synthesized from onion-like carbon. Diam. Relat. Mater. 2021, 111, 108233. [Google Scholar] [CrossRef]

- Lu, J.; Kou, Z.; Liu, T.; Yan, X.; Liu, F.; Ding, W.; Zhang, Q.; Zhang, L.; Liu, J.; He, D. Submicron binderless polycrystalline diamond sintering under ultra-high pressure. Diam. Relat. Mater. 2017, 77, 41–45. [Google Scholar] [CrossRef]

- Berman, R.; Simon, F. Zeitschrift fur Elecktrochemie. Wliey Oline Libr. 1955, 59, 333–338. [Google Scholar]

- Wilks, E.; Wilks, J. Properties and Applications of Diamonds; Butterworth-Heinemann Ltd.: Cambridge, UK, 1991. [Google Scholar]

- Kalpakjian, S.; Schmid, S.R.; Schmind, S.R.; Sekar, K.S.V. Manufacturing Engineering and Technology, 7th ed.; Pearson Educaton: London, UK, 2014. [Google Scholar]

- Byrne, G.; Dornfeld, D.; Denkena, B. Advancing Cutting Technology. CIRP Ann. 2003, 52, 483–507. [Google Scholar] [CrossRef] [Green Version]

- Neves, A.; Nazaré, M.H. Properties, Growth and Applications of Diamond; IET: London, UK, 2001. [Google Scholar]

- Bundy, F.P. Pressure-temperature phase diagram of elemental carbon. Phys. A: Stat. Mech. Appl. 1989, 156, 169–178. [Google Scholar] [CrossRef]

- Boland, J.N.; Li, X.S. Microstructural Characterisation and Wear Behaviour of Diamond Composite Materials. Materials 2010, 3, 1390–1419. [Google Scholar] [CrossRef] [Green Version]

- Hasan, M.; Zhao, J.; Jiang, Z. Micromanufacturing of composite materials: A review. Int. J. Extreme Manuf. 2019, 1, 012004. [Google Scholar] [CrossRef]

- Sandvik, C. Cutting Tool Materials. 2020. Available online: https://www.sandvik.coromant.com/en-gb/knowledge/materials/pages/cutting-tool-materials.aspx (accessed on 20 October 2020).

- Dold, C.; Henerichs, M.; Gilgen, P.; Wegener, K. Laser Processing of Coarse Grain Polycrystalline Diamond (PCD) Cutting Tool Inserts using Picosecond Laser Pulses. Phys. Procedia 2013, 41, 610–616. [Google Scholar] [CrossRef] [Green Version]

- Zimmermann, M.; Kirsch, B.; Kang, Y.; Herrmann, T.; Aurich, J.C. Influence of the laser parameters on the cutting edge preparation and the performance of cemented carbide indexable inserts. J. Manuf. Process. 2020, 58, 845–856. [Google Scholar] [CrossRef]

- Pacella, M. A new low-feed chip breaking tool and its effect on chip morphology. Int. J. Adv. Manuf. Technol. 2019, 104, 1145–1157. [Google Scholar] [CrossRef] [Green Version]

- Zaitsev, A. Optical Properties of Diamond: A Data Handbook; Springer: Bochum, Germany, 2001. [Google Scholar]

- USSynthetic. Diamond Bearings 101; US Synthetic: Orem, UT, USA, 2020. [Google Scholar]

- Leyendecker, T.; Lemmer, O.; Jurgens, A.; Esser, S.; Ebberink, J. Industrial application of crystalline diamond-coated tools. Surf. Coat. Technol. 1991, 48, 253–260. [Google Scholar] [CrossRef]

- Azarhoushang, B.; Soltani, B.; Daneshi, A. Study of the effects of laser micro structuring on grinding of silicon nitride ceramics. CIRP Ann. 2018, 67, 329–332. [Google Scholar] [CrossRef]

- Wang, H.-J.; Lin, H.; Wang, C.; Zheng, L.; Hu, X. Laser drilling of structural ceramics—A review. J. Eur. Ceram. Soc. 2017, 37, 1157–1173. [Google Scholar] [CrossRef]

- Heath, P.J. Developments in applications of PCD tooling. J. Mater. Process. Technol. 2001, 116, 31–38. [Google Scholar] [CrossRef]

- Petrovic, M.; Ivanković, A.; Murphy, N. High Rate and High Temperature Fracture Behaviour of Polycrystalline Diamond. Key Eng. Mater. 2011, 488-489, 670–673. [Google Scholar] [CrossRef]

- Slocombe, A.; Li, L. Laser ablation machining of metal/polymer composite materials. Appl. Surf. Sci. 2000, 154-155, 617–621. [Google Scholar] [CrossRef]

- Pacella, M.; Nekouie, V.; Badiee, A. Surface engineering of ultra-hard polycrystalline structures using a Nanosecond Yb fibre laser: Effect of process parameters on microstructure, hardness and surface finish. J. Mater. Process. Technol. 2019, 266, 311–328. [Google Scholar] [CrossRef]

- Steen, W.M.; Mazumder, J. Laser Material Processing, 3rd ed.; Springer: London, UK, 2005. [Google Scholar]

- Machado, A.R.; da Silva, L.R.; de Souza, F.C.; Davis, R.; Pereira, L.C.; Sales, W.F.; de Rossi, W.; Ezugwu, E.O. State of the art of tool texturing in machining. J. Mater. Process. Technol. 2021, 293, 117096. [Google Scholar] [CrossRef]

- Shi, Q.; Gu, D.; Xia, M.; Cao, S.; Rong, T. Effects of laser processing parameters on thermal behavior and melting/solidification mechanism during selective laser melting of TiC/Inconel 718 composites. Opt. Laser Technol. 2016, 84, 9–22. [Google Scholar] [CrossRef]

- Eberle, G.; Jefimovs, K.; Wegener, K. Characterisation of thermal influences after laser processing polycrystalline diamond composites using long to ultrashort pulse durations. Precis. Eng. 2015, 39, 16–24. [Google Scholar] [CrossRef]

- Wu, Z.; Deng, J.; Xing, Y.; Cheng, H.; Zhao, J. Effect of surface texturing on friction properties of WC/Co cemented carbide. Mater. Des. 2012, 41, 142–149. [Google Scholar] [CrossRef]

- Leitz, K.H.; Redlingshöfer, B.; Reg, Y.; Otto, A.; Schmidt, M. Metal Ablation with Short and Ultrashort Laser Pulses. Phys. Procedia 2011, 12, 230–238. [Google Scholar] [CrossRef] [Green Version]

- Parandoush, P.; Hossain, A. A review of modeling and simulation of laser beam machining. Int. J. Mach. Tools Manuf. 2014, 85, 135–145. [Google Scholar] [CrossRef]

- Robertson, J. Diamond-like amorphous carbon. Mater. Sci. Eng. R Rep. 2002, 37, 129–281. [Google Scholar] [CrossRef] [Green Version]

- Denkena, B.; Krödel, A.; Grove, T. Influence of pulsed laser ablation on the surface integrity of PCBN cutting tool materials. Int. J. Adv. Manuf. Technol. 2019, 101, 1687–1698. [Google Scholar] [CrossRef]

- Warhanek, M.G.; Pfaff, J.; Meier, L.; Walter, C.; Wegener, K. Picosecond pulsed laser processing of polycrystalline diamond and cubic boron nitride composite materials. Laser Based Micro. Nanoprocessing X 2016. [Google Scholar] [CrossRef]

- Mishra, S.; Yadava, V. Laser Beam MicroMachining (LBMM)—A review. Opt. Lasers Eng. 2015, 73, 89–122. [Google Scholar] [CrossRef]

- Siddiqui, A.A.; Dubey, A.K. Recent trends in laser cladding and surface alloying. Opt. Laser Technol. 2020, 134, 106619. [Google Scholar] [CrossRef]

- Gräf, S.; Kunz, C.; Müller, F.A. Formation and Properties of Laser-Induced Periodic Surface Structures on Different Glasses. Material 2017, 10, 933. [Google Scholar] [CrossRef] [Green Version]

- Kalyanasundaram, D.; Schmidt, A.; Molian, P.; Shrotriya, P. Hybrid CO2 Laser/Waterjet Machining of Polycrystalline Diamond Substrate: Material Separation Through Transformation Induced Controlled Fracture. J. Manuf. Sci. Eng. 2014, 136, 041001. [Google Scholar] [CrossRef]

- Kalyanasundaram, D.; Molian, P.; Shrotriya, P. Application of chemical transformation induced fracture for cutting of superhard materials. J. Manuf. Process. 2012, 14, 336–342. [Google Scholar] [CrossRef]

- Liang, L.; Yuan, J.; Li, X.; Yang, F.; Jiang, L. Wear behavior of the micro-grooved texture on WC-Ni 3 Al cermet prepared by laser surface texturing. Int. J. Refract. Met. Hard Mater. 2018, 72, 211–222. [Google Scholar] [CrossRef]

- Fang, S.; Pérez, V.; Salán, N.; Baehre, D.; Llanes, L. Surface Patterning of Cemented Carbides by Means of Nanosecond Laser. Mater. Manuf. Process. 2019, 35, 123–129. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, B.; Deng, Z.; Chen, J. An Experimental Study on Laser Cutting Mechanisms of Polycrystalline Diamond Compacts. CIRP Ann. 2007, 56, 201–204. [Google Scholar] [CrossRef]

- Eberle, G.; Wegener, K. Ablation Study of WC and PCD Composites Using 10 Picosecond and 1 Nanosecond Pulse Durations at Green and Infrared Wavelengths. Phys. Procedia 2014, 56, 951–962. [Google Scholar] [CrossRef] [Green Version]

- Dumitru, G.; Romano, V.; Weber, H.; Sentis, M.; Marine, W. Femtosecond ablation of ultrahard materials. Appl. Phys. A Mater. Sci. Process. 2002, 74, 729–739. [Google Scholar] [CrossRef]

- Denkena, B.; Grove, T.; Krödel, A.; Ellersiek, L. Increased performance in high speed turning of Inconel 718 by laser structuring of PcBN tools. Procedia CIRP 2018, 77, 602–605. [Google Scholar] [CrossRef]

- Okuchi, T.; Ohfuji, H.; Odake, S.; Kagi, H.; Nagatomo, S.; Sugata, M.; Sumiya, H. Micromachining and surface processing of the super-hard nano-polycrystalline diamond by three types of pulsed lasers. Appl. Phys. A Mater. Sci. Process. 2009, 96, 833–842. [Google Scholar] [CrossRef]

- Pacella, M.; Axinte, D.; Butler-Smith, P.; Daine, M. On the Topographical/Chemical Analysis of Polycrystalline Diamond Pulsed Laser Ablated Surfaces. Procedia CIRP 2014, 13, 387–392. [Google Scholar] [CrossRef] [Green Version]

- Butler-Smith, P.; Warhanek, M.; Axinte, D.; Fay, M.; Bucourt, J.-F.; Ragueneau, R.; Wegener, K. The influences of pulsed-laser-ablation and electro-discharge-grinding processes on the cutting performances of polycrystalline diamond micro-drills. CIRP Ann. Manuf. Technol. 2016, 65, 105–108. [Google Scholar] [CrossRef]

- Melookaran, R.; Melaibari, A.; Deng, C.; Molian, P. Laser shock processing on microstructure and hardness of polycrystalline cubic boron nitride tools with and without nanodiamond powders. Mater. Des. 2012, 35, 235–242. [Google Scholar] [CrossRef]

- Berthe, L.; Fabbro, R.; Peyre, P.; Bartnicki, E. Wavelength dependent of laser shock-wave generation in the water-confinement regime. J. Appl. Phys. 1999, 85, 7552–7555. [Google Scholar] [CrossRef]

- Cottrell, T. The Strengths of Chemical Bonds. Prop. At. Radic. Bond. 1958, 372, 41–53. [Google Scholar]

- LibreTexts. Bond Energies LibreTexts. 2019. Available online: https://chem.libretexts.org/Bookshelves/Physical_and_Theoretical_Chemistry_Textbook_Maps/Supplemental_Modules_(Physical_and_Theoretical_Chemistry)/Chemical_Bonding/Fundamentals_of_Chemical_Bonding/Bond_Energies (accessed on 18 July 2019).

- Omni. Photon Energy Calculator. 2020. Available online: https://www.omnicalculator.com/physics/photon-energy (accessed on 19 October 2020).

- Schaeffer, R.D. Fundamentals of Laser Micromachining; Taylor & Francis: Danvers, MA, USA, 2012. [Google Scholar]

- Wang, Y.; Molian, P.; Shrotriya, P. Crack separation mechanism in CO2 laser machining of thick polycrystalline cubic boron nitride tool blanks. Int. J. Adv. Manuf. Technol. 2013, 70, 1009–1022. [Google Scholar] [CrossRef]

- TechNavio. Breakdown of the Laser Cutting Machine Market in the U.S. in 2016, by Segment. Statista 2016. Available online: https://www.statista.com/statistics/697882/us-laser-cutting-machine-market-by-product/ (accessed on 19 February 2021).

- Pacella, M.; Axinte, D.A.; Butler-Smith, P.W.; Shipway, P.; Daine, M.; Wort, C. An Assessment of the Wear Characteristics of Microcutting Arrays Produced From Polycrystalline Diamond and Cubic Boron Nitride Composites. J. Manuf. Sci. Eng. 2016, 138, 021001. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.; Lu, W.; He, Y.; Zhou, G. Research on optimal laser texture parameters about antifriction characteristics of cemented carbide surface. Int. J. Refract. Met. Hard Mater. 2019, 82, 287–296. [Google Scholar] [CrossRef]

- Solutions, I.L. Femtosecond Laser Micromachining: A Back-to-Basics Primer. 2012. Available online: https://www.industrial-lasers.com/micromachining/article/16485321/femtosecond-laser-micromachining-a-backtobasics-primer (accessed on 14 September 2020).

- Odake, S.; Ohfuji, H.; Okuchi, T.; Kagi, H.; Sumiya, H.; Irifune, T. Pulsed laser processing of nano-polycrystalline diamond: A comparative study with single crystal diamond. Diam. Relat. Mater. 2009, 18, 877–880. [Google Scholar] [CrossRef]

- See, T.L.; Chantzis, D.; Royer, R.; Metsios, I.; Antar, M.; Marimuthu, S. A comparison of the DPSS UV laser ablation characteristic of 1024 and H10F WC-Co. Opt. Laser Technol. 2017, 92, 101–108. [Google Scholar] [CrossRef]

- See, T.; Liu, Z.; Liu, H.; Li, L.; Chippendale, J.; Cheetham, S.; Dilworth, S. Effect of geometry measurements on characteristics of femtosecond laser ablation of HR4 nickel alloy. Opt. Lasers Eng. 2015, 64, 71–78. [Google Scholar] [CrossRef]

- Ukar, E.; Lamikiz, A.; Martínez, S.; Arrizubieta, I.; Mentxaka, A.L. Laser Texturing with Conventional Fiber Laser. Procedia Eng. 2015, 132, 663–670. [Google Scholar] [CrossRef] [Green Version]

- Willmott, P.R.; Huber, J.R. Pulsed laser vaporization and deposition. Rev. Mod. Phys. 2000, 72, 315–328. [Google Scholar] [CrossRef]

- Denkena, B.; Krödel, A.; Grove, T. On the pulsed laser ablation of polycrystalline cubic boron nitride—Influence of pulse duration and material properties on ablation characteristics. J. Laser Appl. 2019, 31, 022004. [Google Scholar] [CrossRef]

- Urbina, J.C.; Daniel, C.; Emmelmann, C. Experimental and Analytical Investigation of Cemented Tungsten Carbide Ultra-Short Pulse Laser Ablation. Phys. Procedia 2013, 41, 752–758. [Google Scholar] [CrossRef] [Green Version]

- Zhao, K.; Jia, Z.; Liu, W.; Ma, J.; Wang, L. Material removal with constant depth in CNC laser milling based on adaptive control of laser fluence. Int. J. Adv. Manuf. Technol. 2014, 77, 797–806. [Google Scholar] [CrossRef]

- Canel, T.; Zeren, M.; Sınmazçelik, T. Laser parameters optimization of surface treating of Al 6082-T6 with Taguchi method. Opt. Laser Technol. 2019, 120, 105714. [Google Scholar] [CrossRef]

- Gnilitskyi, I.; Derrien, T.J.-Y.; Levy, Y.; Bulgakova, N.M.; Mocek, T.; Orazi, L. High-speed manufacturing of highly regular femtosecond laser-induced periodic surface structures: Physical origin of regularity. Sci. Rep. 2017, 7, 8485. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wee, L.M.; Li, L. An analytical model for striation formation in laser cutting. Appl. Surf. Sci. 2005, 247, 277–284. [Google Scholar] [CrossRef]

- Lickschat, P.; Metzner, D.; Weißmantel, S. Fundamental investigations of ultrashort pulsed laser ablation on stainless steel and cemented tungsten carbide. Int. J. Adv. Manuf. Technol. 2020, 109, 1167–1175. [Google Scholar] [CrossRef]

- Fang, S.; Llanes, L.; Bähre, D. Laser surface texturing of a WC-CoNi cemented carbide grade: Surface topography design for honing application. Tribol. Int. 2018, 122, 236–245. [Google Scholar] [CrossRef] [Green Version]

- Zheng, B.; Jiang, G.; Wang, W.; Wang, K.; Mei, X. Ablation experiment and threshold calculation of titanium alloy irradiated by ultra-fast pulse laser. AIP Adv. 2014, 4, 031310. [Google Scholar] [CrossRef]

- Denkena, B.; Krödel, A.; Heckemeyer, A.; Murrenhoff, M. Pulsed laser micro ablation of polycrystalline cubic boron nitride. Procedia CIRP 2020, 94, 823–828. [Google Scholar] [CrossRef]

- Kodama, S.; Yamaguchi, H.; Shimada, K.; Mizutani, M.; Kuriyagawa, T. Control of short-pulsed laser induced periodic surface structures with machining -picosecond laser nanotexturing with magnetic abrasive finishing-. Precis. Eng. 2019, 60, 428–436. [Google Scholar] [CrossRef]

- Su, Y.; Li, L.; He, N.; Zhao, W. Experimental study of fiber laser surface texturing of polycrystalline diamond tools. Int. J. Refract. Met. Hard Mater. 2014, 45, 117–124. [Google Scholar] [CrossRef]

- Breidenstein, B.; Grove, T.; Krödel, A.; Sitab, R. Influence of hexagonal phase transformation in laser prepared PcBN cutting tools on tool wear in machining of Inconel 718. Met. Powder Rep. 2019, 74, 237–243. [Google Scholar] [CrossRef]

- Pacella, M.; Brigginshaw, D. Enhanced wear performance of laser machined tools in dry turning of hardened steels. J. Manuf. Process. 2020, 56, 189–196. [Google Scholar] [CrossRef]

- Vázquez-Martínez, J.M.; Del Sol, I.; Batista, M.; Vidal, S.R.F.; Hernandez, P.M.; Salguero, J. Experimental Study of Laser Texturing Processes on the Lubricant Retention of Carbide (WC-Co) Surfaces. Key Eng. Mater. 2019, 813, 55–61. [Google Scholar] [CrossRef]

- Zhang, X.; Ni, D.; Xiao, B.; Andrä, H.; Gan, W.; Hofmann, M.; Ma, Z. Determination of macroscopic and microscopic residual stresses in friction stir welded metal matrix composites via neutron diffraction. Acta Mater. 2015, 87, 161–173. [Google Scholar] [CrossRef]

- Pacella, M.; John, M.G.J.S.; Dolatabadi, N.; Badiee, A. Microhardness and wear behaviour of polycrystalline diamond after warm laser shock processing with and without coating. Int. J. Refract. Met. Hard Mater. 2019, 82, 215–226. [Google Scholar] [CrossRef]

- Pacella, M. Pulsed Laser Ablation (PLA) of Ultra-Hard Structures: Generation of Damage-Tolerant Freeform Surfaces for Advanced Machining Applications. Ph.D. Thesis, University of Nottingham, Nottingham, UK, September 2014. [Google Scholar]

- Cadot, G.; Axinte, D.; Billingham, J. Continuous trench, pulsed laser ablation for micro-machining applications. Int. J. Mach. Tools Manuf. 2016, 107, 8–20. [Google Scholar] [CrossRef] [Green Version]

- Ghosh, P.; Pacella, M. Effect of laser texturing on the performance of ultra-hard single-point cutting tools. Int. J. Adv. Manuf. Technol. 2019, 106, 2635–2648. [Google Scholar] [CrossRef] [Green Version]

- Hermens, U.; Kirner, S.; Emonts, C.; Comanns, P.; Skoulas, E.; Mimidis, A.; Mescheder, H.; Winands, K.; Krüger, J.; Stratakis, E.; et al. Mimicking lizard-like surface structures upon ultrashort laser pulse irradiation of inorganic materials. Appl. Surf. Sci. 2017, 418, 499–507. [Google Scholar] [CrossRef]

- Ahsan, A.; Kryukov, I.; Böhm, S. Laser Surface Structuring of Cemented Carbide for improving the Strength of Induction Brazed Joints. J. Manuf. Mater. Process. 2019, 3, 44. [Google Scholar] [CrossRef] [Green Version]

- Xing, Y.; Deng, J.; Wang, X.; Ehmann, K.; Cao, J. Experimental Assessment of Laser Textured Cutting Tools in Dry Cutting of Aluminum Alloys. J. Manuf. Sci. Eng. 2016, 138, 071006. [Google Scholar] [CrossRef]

- Ling, T.D.; Liu, P.; Xiong, S.; Grzina, D.; Cao, J.; Wang, Q.J.; Xia, Z.C.; Talwar, R. Surface Texturing of Drill Bits for Adhesion Reduction and Tool Life Enhancement. Tribol. Lett. 2013, 52, 113–122. [Google Scholar] [CrossRef]

- Jianxin, D.; Ze, W.; Yunsong, L.; Ting, Q.; Jie, C. Performance of carbide tools with textured rake-face filled with solid lubricants in dry cutting processes. Int. J. Refract. Met. Hard Mater. 2012, 30, 164–172. [Google Scholar] [CrossRef]

- Orra, K.; Choudhury, S.K. Tribological aspects of various geometrically shaped micro-textures on cutting insert to improve tool life in hard turning process. J. Manuf. Process. 2018, 31, 502–513. [Google Scholar] [CrossRef]

- Ze, W.; Jianxin, D.; Yang, C.; Youqiang, X.; Jun, Z. Performance of the self-lubricating textured tools in dry cutting of Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2012, 62, 943–951. [Google Scholar] [CrossRef]

- Zhang, N.; Yang, F.; Jiang, F.; Liu, G. Study of the effect of surface laser texture on tribological properties of cemented carbide materials. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2020, 234, 993–1006. [Google Scholar] [CrossRef]

- Mishra, S.; Ghosh, S.; Aravindan, S. Characterization and machining performance of laser-textured chevron shaped tools coated with AlTiN and AlCrN coatings. Surf. Coat. Technol. 2018, 334, 344–356. [Google Scholar] [CrossRef]

- Sun, J.; Zhou, Y.; Deng, J.; Zhao, J. Effect of hybrid texture combining micro-pits and micro-grooves on cutting performance of WC/Co-based tools. Int. J. Adv. Manuf. Technol. 2016, 86, 3383–3394. [Google Scholar] [CrossRef]

- Wang, H.; Guan, Y.; Zheng, H.; Hong, M. Controllable fabrication of metallic micro/nano hybrid structuring surface for antireflection by picosecond laser direct writing. Appl. Surf. Sci. 2019, 471, 347–354. [Google Scholar] [CrossRef]

- Bertolete, M.; Barbosa, P.A.; Machado, Á.R.; Samad, R.E.; Vieira, N.D.; Vilar, R.; De Rossi, W. Effects of texturing the rake surfaces of cemented tungsten carbide tools by ultrashort laser pulses in machining of martensitic stainless steel. Int. J. Adv. Manuf. Technol. 2018, 98, 2653–2664. [Google Scholar] [CrossRef]

- Kawasegi, N.; Sugimori, H.; Morimoto, H.; Morita, N.; Hori, I. Development of cutting tools with microscale and nanoscale textures to improve frictional behavior. Precis. Eng. 2009, 33, 248–254. [Google Scholar] [CrossRef]

- Lian, Y.; Deng, J.; Yao, B.; Zhuo, Y.; Lei, S. Influence of different cemented carbides on fabricating periodic micro-nano textures by femtosecond laser processing. Surf. Coat. Technol. 2017, 317, 166–171. [Google Scholar] [CrossRef]

- Pang, M.; Nie, Y.; Ma, L. Effect of symmetrical conical micro-grooved texture on tool–chip friction property of WC-TiC/Co cemented carbide tools. Int. J. Adv. Manuf. Technol. 2018, 99, 737–746. [Google Scholar] [CrossRef]

- Xie, J.; Luo, M.-J.; He, J.-L.; Liu, X.-R.; Tan, T.-W. Micro-grinding of micro-groove array on tool rake surface for dry cutting of titanium alloy. Int. J. Precis. Eng. Manuf. 2012, 13, 1845–1852. [Google Scholar] [CrossRef]

- Suh, M.-S.; Chae, Y.-H.; Kim, S.-S.; Hinoki, T.; Kohyama, A. Effect of geometrical parameters in micro-grooved crosshatch pattern under lubricated sliding friction. Tribol. Int. 2010, 43, 1508–1517. [Google Scholar] [CrossRef] [Green Version]

- Siju, A.S.; Gajrani, K.K.; Joshi, S.S. Dual textured carbide tools for dry machining of titanium alloys. Int. J. Refract. Met. Hard Mater. 2021, 94, 105403. [Google Scholar] [CrossRef]

- Su, Y.; Li, Z.; Li, L.; Wang, J.; Gao, H.; Wang, G. Cutting performance of micro-textured polycrystalline diamond tool in dry cutting. J. Manuf. Process. 2017, 27, 1–7. [Google Scholar] [CrossRef]

- Meng, R.; Deng, J.; Liu, Y.; Duan, R.; Zhang, G. Improving tribological performance of cemented carbides by combining laser surface texturing and W-S-C solid lubricant coating. Int. J. Refract. Met. Hard Mater. 2018, 72, 163–171. [Google Scholar] [CrossRef]

- Liu, Y.; Deng, J.; Wang, W.; Duan, R.; Meng, R.; Ge, D.; Li, X. Effect of texture parameters on cutting performance of flank-faced textured carbide tools in dry cutting of green Al2O3 ceramics. Ceram. Int. 2018, 44, 13205–13217. [Google Scholar] [CrossRef]

- Sugihara, T.; Enomoto, T. Crater and flank wear resistance of cutting tools having micro textured surfaces. Precis. Eng. 2013, 37, 888–896. [Google Scholar] [CrossRef]

- Wang, Q.; Yang, Y.; Yao, P.; Zhang, Z.; Yu, S.; Zhu, H.; Huang, C. Friction and cutting characteristics of micro-textured diamond tools fabricated with femtosecond laser. Tribol. Int. 2021, 154, 106720. [Google Scholar] [CrossRef]

- Pang, K.; Wang, D. Study on the performances of the drilling process of nickel-based superalloy Inconel 718 with differently micro-textured drilling tools. Int. J. Mech. Sci. 2020, 180, 105658. [Google Scholar] [CrossRef]

- Kümmel, J.; Braun, D.; Gibmeier, J.; Schneider, J.; Greiner, C.; Schulze, V.; Wanner, A. Study on micro texturing of uncoated cemented carbide cutting tools for wear improvement and built-up edge stabilisation. J. Mater. Process. Technol. 2015, 215, 62–70. [Google Scholar] [CrossRef]

- Guimarães, B.; Fernandes, C.M.; Figueiredo, D.; Carvalho, O.; Silva, F.S.; Miranda, G. Effect of laser surface texturing on the wettability of WC-Co cutting tools. Int. J. Adv. Manuf. Technol. 2020, 111, 1991–1999. [Google Scholar] [CrossRef]

- Niketh, S.; Samuel, G. Surface texturing for tribology enhancement and its application on drill tool for the sustainable machining of titanium alloy. J. Clean. Prod. 2017, 167, 253–270. [Google Scholar] [CrossRef]

- Wakuda, M.; Yamauchi, Y.; Kanzaki, S.; Yasuda, Y. Effect of surface texturing on friction reduction between ceramic and steel materials under lubricated sliding contact. Wear 2003, 254, 356–363. [Google Scholar] [CrossRef]

- Rao, C.M.; Rao, S.S.; Herbert, M.A. Development of novel cutting tool with a micro-hole pattern on PCD insert in machining of titanium alloy. J. Manuf. Process. 2018, 36, 93–103. [Google Scholar] [CrossRef]

- Wenlong, S.; Jianxin, D.; Hui, Z.; Pei, Y.; Jun, Z.; Xing, A. Performance of a cemented carbide self-lubricating tool embedded with solid lubricants in dry machining. J. Manuf. Process. 2011, 13, 8–15. [Google Scholar] [CrossRef]

- Jianxin, D.; Wenlong, S.; Hui, Z. Design, fabrication and properties of a self-lubricated tool in dry cutting. Int. J. Mach. Tools Manuf. 2009, 49, 66–72. [Google Scholar] [CrossRef]

- Xing, Y.; Deng, J.; Feng, X.; Yu, S. Effect of laser surface texturing on Si3N4/TiC ceramic sliding against steel under dry friction. Mater. Des. 2013, 52, 234–245. [Google Scholar] [CrossRef]

- Moravčíková, J.; Moravčík, R.; Kusý, M.; Necpal, M. Influence of Laser Surface Texturing on Tribological Performance of Tool Steels. J. Mater. Eng. Perform. 2018, 27, 5417–5426. [Google Scholar] [CrossRef]

- Voevodin, A.; Zabinski, J. Laser surface texturing for adaptive solid lubrication. Wear 2006, 261, 1285–1292. [Google Scholar] [CrossRef]

- Pakuła, D.; Staszuk, M.; Dziekońska, M.; Kožmín, P.; Čermák, A. Laser Micro-Texturing of Sintered Tool Materials Surface. Materials 2019, 12, 3152. [Google Scholar] [CrossRef] [Green Version]

- De Zanet, A.; Casalegno, V.; Salvo, M. Laser surface texturing of ceramics and ceramic composite materials—A review. Ceram. Int. 2021, 47, 7307–7320. [Google Scholar] [CrossRef]

- Xing, Y.; Zhang, K.; Huang, P.; Liu, L.; Wu, Z. Assessment machining of micro-channel textures on PCD by laser-induced plasma and ultra-short pulsed laser ablation. Opt. Laser Technol. 2020, 125, 106057. [Google Scholar] [CrossRef]

- Hao, X.; Cui, W.; Li, L.; Li, H.; Khan, A.M.; He, N. Cutting performance of textured polycrystalline diamond tools with composite lyophilic/lyophobic wettabilities. J. Mater. Process. Technol. 2018, 260, 1–8. [Google Scholar] [CrossRef]

- Arulkirubakaran, D.; Senthilkumar, V.; Kumawat, V. Effect of micro-textured tools on machining of Ti–6Al–4V alloy: An experimental and numerical approach. Int. J. Refract. Met. Hard Mater. 2016, 54, 165–177. [Google Scholar] [CrossRef]

- Zhang, K.; Deng, J.; Meng, R.; Gao, P.; Yue, H. Effect of nano-scale textures on cutting performance of WC/Co-based Ti55Al45N coated tools in dry cutting. Int. J. Refract. Met. Hard Mater. 2015, 51, 35–49. [Google Scholar] [CrossRef]

- Gajrani, K.K.; Suresh, S.; Sankar, M.R. Environmental friendly hard machining performance of uncoated and MoS 2 coated mechanical micro-textured tungsten carbide cutting tools. Tribol. Int. 2018, 125, 141–155. [Google Scholar] [CrossRef]

- Xie, J.; Zhuo, Y.; Tan, T. Experimental study on fabrication and evaluation of micro pyramid-structured silicon surface using a V-tip of diamond grinding wheel. Precis. Eng. 2011, 35, 173–182. [Google Scholar] [CrossRef]

- Ke, Z.; Zheng, Y.; Zhang, G.; Wu, H.; Xu, X.; Lu, X.; Zhu, X. Fabrication of dual-grain structure WC-Co cemented carbide by in-situ carbothermal reduction of WO3 and subsequent liquid sintering. Ceram. Int. 2020, 46, 12767–12772. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, X.; Li, T.; Tian, Y. Numerical modelling and experimental study on pulsed laser surface texturing on cemented carbides. Int. J. Adv. Manuf. Technol. 2021, 114, 3137–3145. [Google Scholar] [CrossRef]

- Koshy, P.; Tovey, J. Performance of electrical discharge textured cutting tools. CIRP Ann. 2011, 60, 153–156. [Google Scholar] [CrossRef]

- Deng, J.; Lian, Y.; Wu, Z.; Xing, Y. Performance of femtosecond laser-textured cutting tools deposited with WS2 solid lubricant coatings. Surf. Coat. Technol. 2013, 222, 135–143. [Google Scholar] [CrossRef]

- Costil, S.; Lamraoui, A.; Langlade, C.; Heintz, O.; Oltra, R. Surface modifications induced by pulsed-laser texturing—Influence of laser impact on the surface properties. Appl. Surf. Sci. 2014, 288, 542–549. [Google Scholar] [CrossRef]

- Fang, S.; Klein, S. Surface structuring of polycrystalline diamond (PCD) using ultrashort pulse laser and the study of force conditions. Int. J. Refract. Met. Hard Mater. 2019, 84, 105036. [Google Scholar] [CrossRef]

- Hua, X.; Xie, X.; Yin, B.; Zhang, P.; Ji, J.; Wang, H.; Fu, Y. Tribological performance and self-lubricating mechanism of the laser-textured surface filled with solid lubricant in rolling friction pair. Ind. Lubr. Tribol. 2018, 70, 371–384. [Google Scholar] [CrossRef]

- Hazzan, K.E.; Pacella, M.; See, T.L. Understanding the surface integrity of laser surface engineered tungsten carbide. Int. J. Adv. Manuf. Technol. 2021. [Google Scholar] [CrossRef]

- Ukar, E.; Lamikiz, A.; Martínez, S.; Tabernero, I.; de Lacalle, L.N.L. Roughness prediction on laser polished surfaces. J. Mater. Process. Technol. 2012, 212, 1305–1313. [Google Scholar] [CrossRef]

- Vadali, M.; Ma, C.; Duffie, N.A.; Li, X.; Pfefferkorn, F.E. Pulsed laser micro polishing: Surface prediction model. J. Manuf. Process. 2012, 14, 307–315. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, T.H.; Lin, C.-K.; Tung, P.-C.; Nguyen-Van, C.; Ho, J.-R. Artificial intelligence-based modeling and optimization of heat-affected zone and magnetic property in pulsed laser cutting of thin nonoriented silicon steel. Int. J. Adv. Manuf. Technol. 2021, 3225–3240. [Google Scholar] [CrossRef]

- Stavridis, J.; Papacharalampopoulos, A.; Stavropoulos, P. A cognitive approach for quality assessment in laser welding. Procedia CIRP 2018, 72, 1542–1547. [Google Scholar] [CrossRef]

- Biswas, R.; Kuar, A.S.; Biswas, S.K.; Mitra, S. Artificial neural network modelling of Nd:YAG laser microdrilling on titanium nitride—alumina composite. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2010, 224, 473–482. [Google Scholar] [CrossRef]

- Phillips, T.; Ricker, T.; Fish, S.; Beaman, J. Design of a laser control system with continuously variable power and its application in additive manufacturing. Addit. Manuf. 2020, 34, 101173. [Google Scholar] [CrossRef]

- Tsai, M.-J.; Li, C.-H.; Chen, C.-C. Optimal laser-cutting parameters for QFN packages by utilizing artificial neural networks and genetic algorithm. J. Mater. Process. Technol. 2008, 208, 270–283. [Google Scholar] [CrossRef]

- Karazi, S.; Issa, A.; Brabazon, D. Comparison of ANN and DoE for the prediction of laser-machined micro-channel dimensions. Opt. Lasers Eng. 2009, 47, 956–964. [Google Scholar] [CrossRef] [Green Version]

- Stratakis, E.; Bonse, J.; Heitz, J.; Siegel, J.; Tsibidis, G.; Skoulas, E.; Papadopoulos, A.; Mimidis, A.; Joel, A.-C.; Comanns, P.; et al. Laser engineering of biomimetic surfaces. Mater. Sci. Eng. R Rep. 2020, 141, 100562. [Google Scholar] [CrossRef]

- Cui, X.; Li, Y.; Guo, J.; Ming, P. Effects of bio-inspired integration of laser-induced microstructure and coated cemented carbide on tool performance in green intermittent turning. J. Manuf. Process. 2021, 65, 228–244. [Google Scholar] [CrossRef]

- Wang, X.; Wan, W.; Zheng, H. Picosecod laser micromachining of tungsten carbide. Ind. Laser Solut. 2019. Available online: https://www.industrial-lasers.com/micromachining/article/14039508/picosecond-laser-micromachining-of-tungsten-carbide (accessed on 2 October 2020).

- Gajrani, K.K.; Sankar, M.R. State of the art on micro to nano textured cutting tools. Mater. Today Proc. 2017, 4, 3776–3785. [Google Scholar] [CrossRef]

- Gokulachandran, J.; Reddy, B.B.K. A study on the usage of current signature for tool condition monitoring of drill bit. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Law, M.; Karthik, R.; Sharma, S.; Ramkumar, J. Finish turning of hardened bearing steel using textured PcBN tools. J. Manuf. Process. 2020, 60, 144–161. [Google Scholar] [CrossRef]

- Wu, Z.; Deng, J.; Zhang, H.; Lian, Y.; Zhao, J. Tribological behavior of textured cemented carbide filled with solid lubricants in dry sliding with titanium alloys. Wear 2012, 292–293, 135–143. [Google Scholar] [CrossRef]

- Ahmad, M.I.; Yusof, Y.; Daud, E.; Latiff, K.; Kadir, A.Z.A.; Saif, Y. Machine monitoring system: A decade in review. Int. J. Adv. Manuf. Technol. 2020, 108, 3645–3659. [Google Scholar] [CrossRef]

- Herraez, M.; González, C.; Lopes, C.; De Villoria, R.G.; Llorca, J.; Varela, T.; Sánchez, J. Computational micromechanics evaluation of the effect of fibre shape on the transverse strength of unidirectional composites: An approach to virtual materials design. Compos. Part A Appl. Sci. Manuf. 2016, 91, 484–492. [Google Scholar] [CrossRef]

- Kunz, C.; Büttner, T.N.; Naumann, B.; Boehm, A.V.; Gnecco, E.; Bonse, J.; Neumann, C.; Turchanin, A.; Müller, F.A.; Gräf, S. Large-area fabrication of low- and high-spatial-frequency laser-induced periodic surface structures on carbon fibers. Carbon 2018, 133, 176–185. [Google Scholar] [CrossRef] [Green Version]

- Grzesik, W. Prediction of the Functional Performance of Machined Components Based on Surface Topography: State of the Art. J. Mater. Eng. Perform. 2016, 25, 4460–4468. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Yang, H.; Chen, S.; Tang, H. Study on the influence of micro-textures on wear mechanism of cemented carbide tools. Int. J. Adv. Manuf. Technol. 2020, 108, 1701–1712. [Google Scholar] [CrossRef]

- Duan, R.; Deng, J.; Lei, S.; Ge, D.; Liu, Y.; Li, X. Effect of derivative cutting on machining performance of micro textured tools. J. Manuf. Process. 2019, 45, 544–556. [Google Scholar] [CrossRef]

- Prakash, S.; Kumar, S. Pulse smearing and profile generation in CO2 laser micromachining on PMMA via raster scanning. J. Manuf. Process. 2018, 31, 116–123. [Google Scholar] [CrossRef]

- Sharma, V.; Pandey, P.M. Recent advances in turning with textured cutting tools: A review. J. Clean. Prod. 2016, 137, 701–715. [Google Scholar] [CrossRef]

- Savan, A.; Pflüger, E.; Voumard, P.; Schröer, A.; Simmonds, M. Modern solid lubrication: Recent developments and applications of MoS2. Lubr. Sci. 2000, 12, 185–203. [Google Scholar] [CrossRef]

- Mishra, S.K.; Ghosh, S.; Aravindan, S. Physical characterization and wear behavior of laser processed and PVD coated WC/Co in dry sliding and dry turning processes. Wear 2019, 428–429, 93–110. [Google Scholar] [CrossRef]

- Vazirisereshk, M.R.; Martini, A.; Strubbe, D.A.; Baykara, M.Z. Solid Lubrication with MoS2: A Review. Lubricants 2019, 7, 57. [Google Scholar] [CrossRef] [Green Version]

| Metallic Hard Materials >15 GPa | Covalent Hard Materials >15 GPa | Ionic Hard Materials >15 GPa | Ultra-Hard Materials >40 GPa |

|---|---|---|---|

| Tungsten carbide (WC) Titanium nitride (TiN) Titanium carbide (TiC) Chromium nitride (CrN) | Silicon carbide (SiC) Silicon nitride (SiN) Titanium boride (TiB2) | Aluminium oxide (Al2O3) Zirconium oxide (ZrO2) Titanium oxide (TiO2) | Polycrystalline diamond (PCD) Polycrystalline cubic boron nitride (PcBN) Borocarbonitrides (bxCyNz) Tetraboron carbon (B4C) Natural diamond |

| Laser Parameters | Texture Characteristics | Application Characteristics | Machining Measurements |

|---|---|---|---|

| Wavelength Pulse duration Laser speed Fluence Laser source | Texture geometry Depth Width Width/area ratio Texture density Nano structures | Depth of cut Workpiece material Surface roughness Cutting speed | Coefficient of Friction Adhesion Wear |

| Ref | Tool | Binder% | Grain Size (μm) | Laser Medium | Wavelength (nm) | Pulse Duration | Spot Size (mm) | Fluence (J/cm2) | Feed Speed (mm/s) | Frequency (kHz) | Research Findings |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Zhang et al. [58] | PCD | - | 25 | Nd:YAG KTP/Nd:YAG | 1064 532 | - | - | - | 100, 120 | 0.05, 10 |

|

| Eberle et al. [59] | PCD | - | - | EWAG | 1064 | 10 ps 125 ns | 0.025 0.03 | 2.12–9.05 | - | - |

|

| Dumitru et al. [60] | WC, TiC, TiN Diamond TiN | Co, 10 Co, 6 | - | Ti:Sapphire | 800 | 100 fs | 6 | 0.13–2.45 | - | 1.00 |

|

| Pacella et al. [17] | PCD | Co, 15 | 2 | Nd:YAG | 1064 | 20 µs | 0.03 | 848.65 | - | 100 |

|

| Denkena et al. [61] | PcBN | TiCN, 35 | 3 | Nd:YVO4 | 1064 | 85 ns | 0.04 | - | 200–800 | 60 |

|

| Denkena et al. [49] | PcBN—A PcBN—B PcBN—C | TiC W-Co-Al AlN | - | - | 1064 | 300 fs 10 ps 90 ns | - | 4.68–20.79 | - | 400, 800, 100 |

|

| Okuchi et al. [62] | NPD | - | - | NUV-Nd:YAG Yb:Fibre | 1064,355,1045 | 80 ns, 100 ns 700 fs | 0.03 0.002 0.001 | 3.18 | 0.05–2.00 | - |

|

| Pacella et al. [63] | PCD | Co, 8 Co, 15 | 25 2 | Nd:YAG | - | 10–30 µs | 0.04 | - | 100–900 | 10–50 |

|

| Pacella et al. [40] | PCD (CTB010, CTM302) | Co, 12 Co, 10 | 10, 2–30 | Yb:Fibre | 1064 | 220 ns 45 ns | 0.04 | 3.78–11.34 | 70–350 | 35, 105 |

|

| Pacella et al. [8] | PcBN | TiC, 50 | 1.5 | Nd:YAG | 1064 | 10–50 µs | 0.04 | 623.00–7369.00 | 100 | 10 |

|

| Butler-Smith et al. [64] | PCD | Co, 7 | 5 | - | 1064 | 12 ps | - | 6.70 | - | 800 |

|

| Ref | Tool/Workpiece Material | Texture Pattern | Texture Dimension d—Depth μm, w—Width μm, x—Pitch μm | Location | Lubricant | Laser | Key Findings |

|---|---|---|---|---|---|---|---|

| Breidenstein et al. [93] | PcBN-TiCN for turning Inconel 718 | Array of dimples | d = 2 w = 25, 40 | Rake face, Flank face | - | Nd:YVO4 laser, 1064 nm, 3–4.4 J/cm2, 70 ns pulse duration |

|

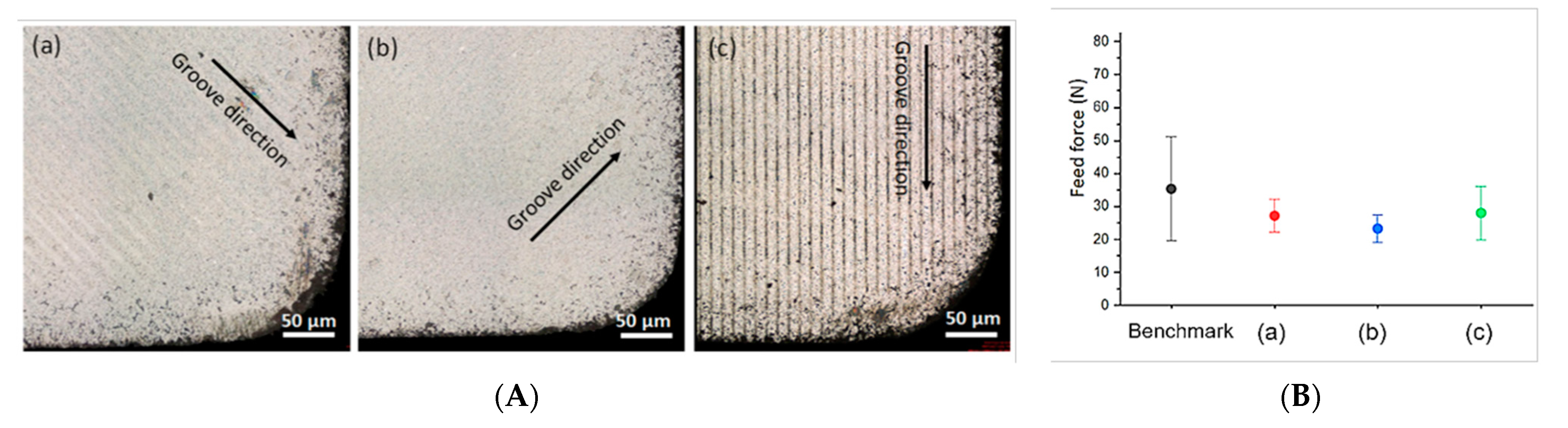

| Ghosh and Pacella [100] | PCD-Co cutting tool for turning Al 6082 | Parallel grooves to CFD, Perpendicular grooves to CFD, Parallel to MCE | d = 0.26 w = 7 x = 20 | Rake face | - | Fibre laser, 1064 nm, with 260 ns pulse duration |

|

| Pacella and Brigginshaw [94] | PcBN-TiN cutting tool for turning AISI51200 | Orthogonal grooves, Perpendicular grooves, Linear Crosshatch | d = 1–2 w = 30 x = 75 | Rake face | - | Yb:Fibre laser with 46 ns pulse duration |

|

| Xing et al. [103] | TiCN cutting tools for turning Al 6061 | Linear grooves Dimples Rectangular pits | d = 10 w = 70–200 | Rake face | - | Nd:YVO4 laser, 355 nm, with 8 ps pulse duration |

|

| Su et al. [92] | PCD cutting tool for turning Ti6Al4V | Linear grooves | d = 51.5, 55.4, 54.4 w = 60.4, 60.4, 56.5 x = 86.4, 83.9, 84.5 | Rake face | - | Fibre laser |

|

| Law et al. [164] | PcBN cutting tool for turning hardened bearing steel | Linear grooves, Dimples | d = 5–20 w = 15–60 x = 70–150 | Rake faceFlank face | - | Fibre laser, 1070 nm, 90 ns pulse duration |

|

| Jianxin et al. [146] | WC-TiC/Co cutting tool for turning #45 steel | Elliptical grooves | Rake face | WS2 | Ti laser with 120 fs pulse duration |

| |

| Jianxin et al. [105] | WC-Co cutting tool for turning #45 steel | Elliptical grooves, Parallel Linear, Linear Grooves | d = 200 w = 50 | Rake face | MoS2 | - |

|

| Zhang et al. [74] | WC-Co for ball-on-disc test on SAE 1045 steel | Linear grooves (radial around disc) | d = 26, 45, 51, 500 w = 40, 70, 100, 130 | - | WS2 | UV laser, 355 nm |

|

| Ze et al. [45] | WC-Co for ball-on-flat on Ti6Al4V | Dimples | d = 100 w = 50 x = 200, 250, 300 | Rake face | MoS2 | Nd:YAG laser, 1064 nm, 20 ns pulse duration |

|

| Mishra et al. [109] | WC-Co with AlTiN, AlCrN coatings for turning Ti6Al4V | Chevron | d = 25 | Rake face | - | Nd:YAG laser, 1064 nm, 20 ns pulse |

|

| Sugihara and Enonmoto [122] | WC-Co cutting tool for milling medium carbon steel | Linear grooves | d = 5 w = 20 x = 20 | Rake face Flank face | - | Ti:Sapphire laser, 800 nm, 150 fs pulse duration |

|

| Ze et al. [165] | WC-Co for ball-on-disk test | Linear grooves | d = 100 w = 50 | Surface | MoS2 | Nd:YAG laser, 1064 nm, 20 ns pulse |

|

| Martinez-Vazquez et al. [95] | WC for turning on Ti6Al4V | Linear grooves, Dimples, Circular grooves | w = 100–150 | Surface | - | Yb:Fibre laser, 1070 nm, 100 ns |

|

| Niketh and Samuel [127] | WC drilling tool for Ti6Al4V | Dimples Linear grooves | d = 60, 40 w = 90, 50 x = 50, 80 | Flute Margin | - | Nd:YAG laser, 1064 nm, 20 ns pulse |

|

| Liang et al. [56] | WC-Ni3Al/Co for Reciprocating sliding test Ti6Al4V | Linear grooves | d = 100, 110 x = 150 | Surface | - | Fibre laser, 1064 nm, 100 ns pulse duration |

|

| Pacella et al. [73] | PCD and PcBN for abrasion of SiO2 | Micro-array | w = 100–250 | Abrasive face | - | Nd:YAG laser, 1064 nm, 10 µs pulse duration |

|

| Kummel et al. [125] | WC-Co for turning SAE 1045 steel | Dimples, Parallel grooves, Perpendicular grooves | d = 20, 20 w = 50, 50 | Rake face | - | Yb:Fibre laser, 1040 nm |

|

| Cutting Parameter | Grooves (GT) | Dimples (PT) | Hybrid Texture (GPT) |

|---|---|---|---|

| Axial thurst force (Fx) | −4.9% | −22.0% | −39.0% |

| Radial thrust force (Fy) | −6.9% | −20.5% | −30.8% |

| Main cutting force (Fz) | −2.3% | −8.6% | −12.7% |

| Temperature | −7.4% | −21.0% | −28.4% |

| COF | −4.7% | −11.8% | −18.8% |

| Cutting Parameter | Textured Surface | Textured Surface Filled with WS2 |

|---|---|---|

| Cutting force | Reduced by 13–22% | Reduced by 25–44% |

| Cutting temperature | Reduced by 9% | Reduced by 16% |

| Coefficient of Friction | - | Reduced by 13–26% |

| Wear | Grooves buried by adhesion, but textures remain visible. | No mechanical ploughing or adhered materials. Filled textures visible. |

| Flank wear | Good resistance | Good resistance |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hazzan, K.E.; Pacella, M.; See, T.L. Laser Processing of Hard and Ultra-Hard Materials for Micro-Machining and Surface Engineering Applications. Micromachines 2021, 12, 895. https://doi.org/10.3390/mi12080895

Hazzan KE, Pacella M, See TL. Laser Processing of Hard and Ultra-Hard Materials for Micro-Machining and Surface Engineering Applications. Micromachines. 2021; 12(8):895. https://doi.org/10.3390/mi12080895

Chicago/Turabian StyleHazzan, Kafayat Eniola, Manuela Pacella, and Tian Long See. 2021. "Laser Processing of Hard and Ultra-Hard Materials for Micro-Machining and Surface Engineering Applications" Micromachines 12, no. 8: 895. https://doi.org/10.3390/mi12080895