Experimental Study and Mechanism Analysis of the Flow Boiling and Heat Transfer Characteristics in Microchannels with Different Surface Wettability

Abstract

:1. Introduction

2. Materials and Methods

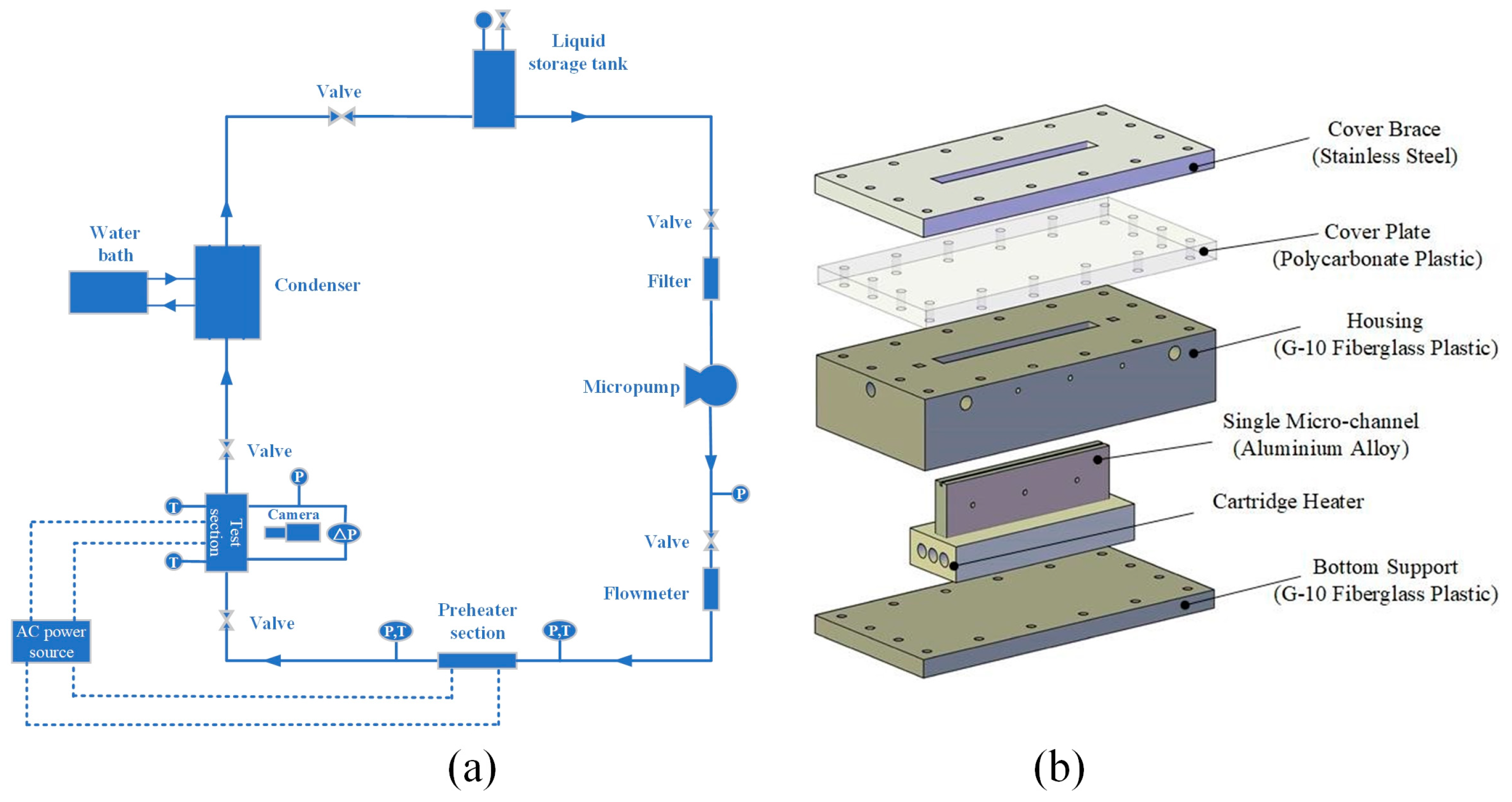

2.1. Flow Loop

2.2. Preparation and Characterization of Different Surface Wettability Microchannels

2.3. Data Processing

3. Results and Discussion

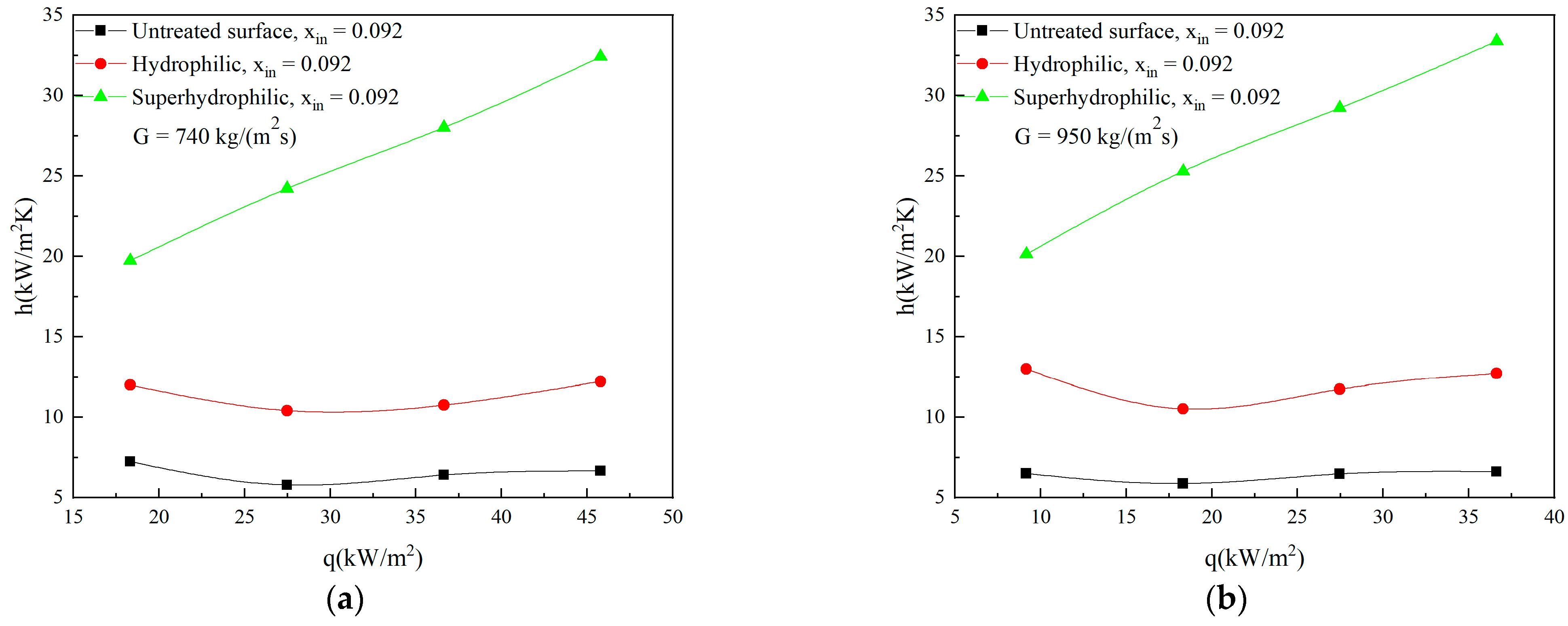

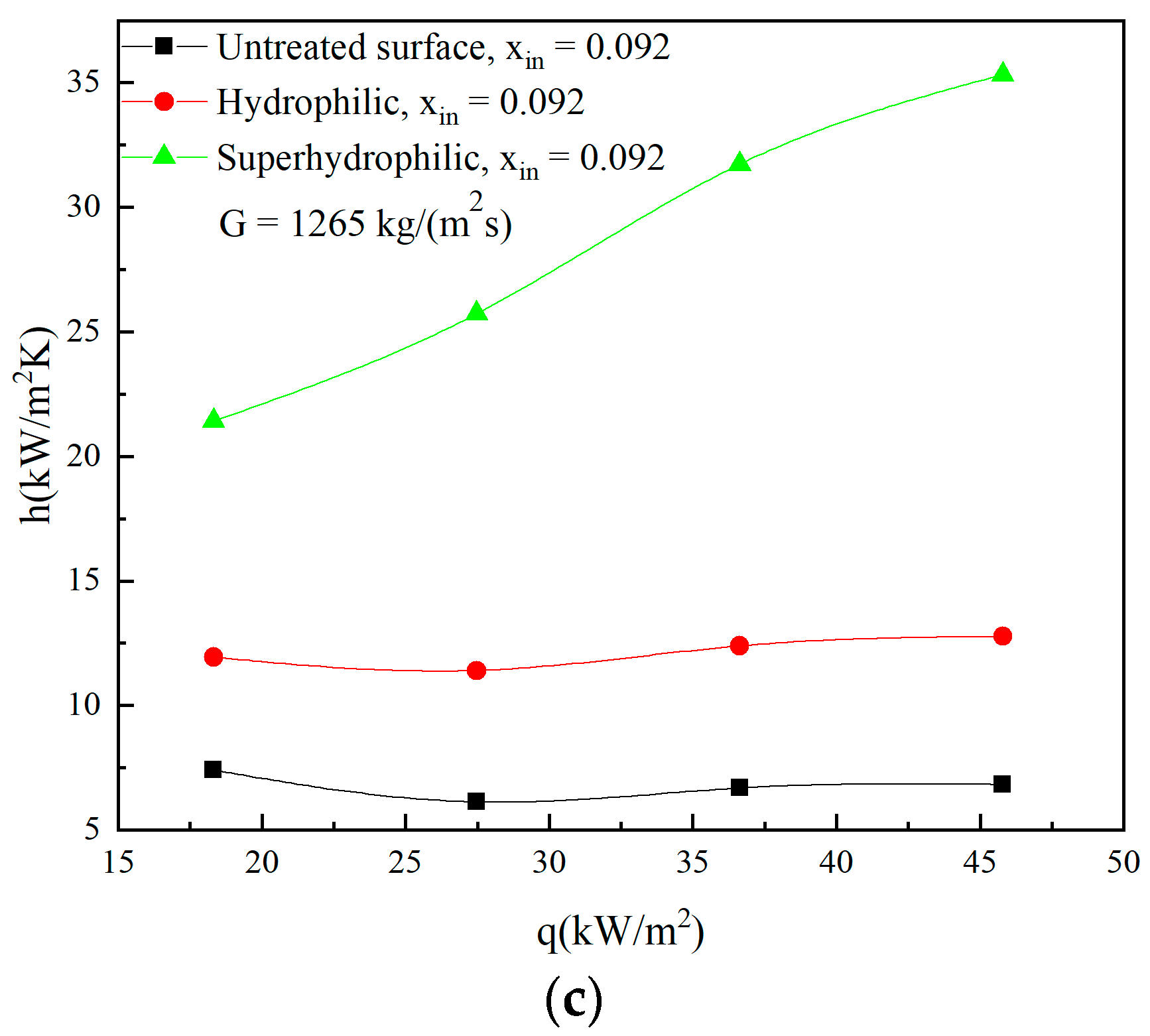

3.1. Influence of Surface Wettability on Average Heat Transfer Coefficients

3.2. Advantages of Super-Hydrophilic Microchannel

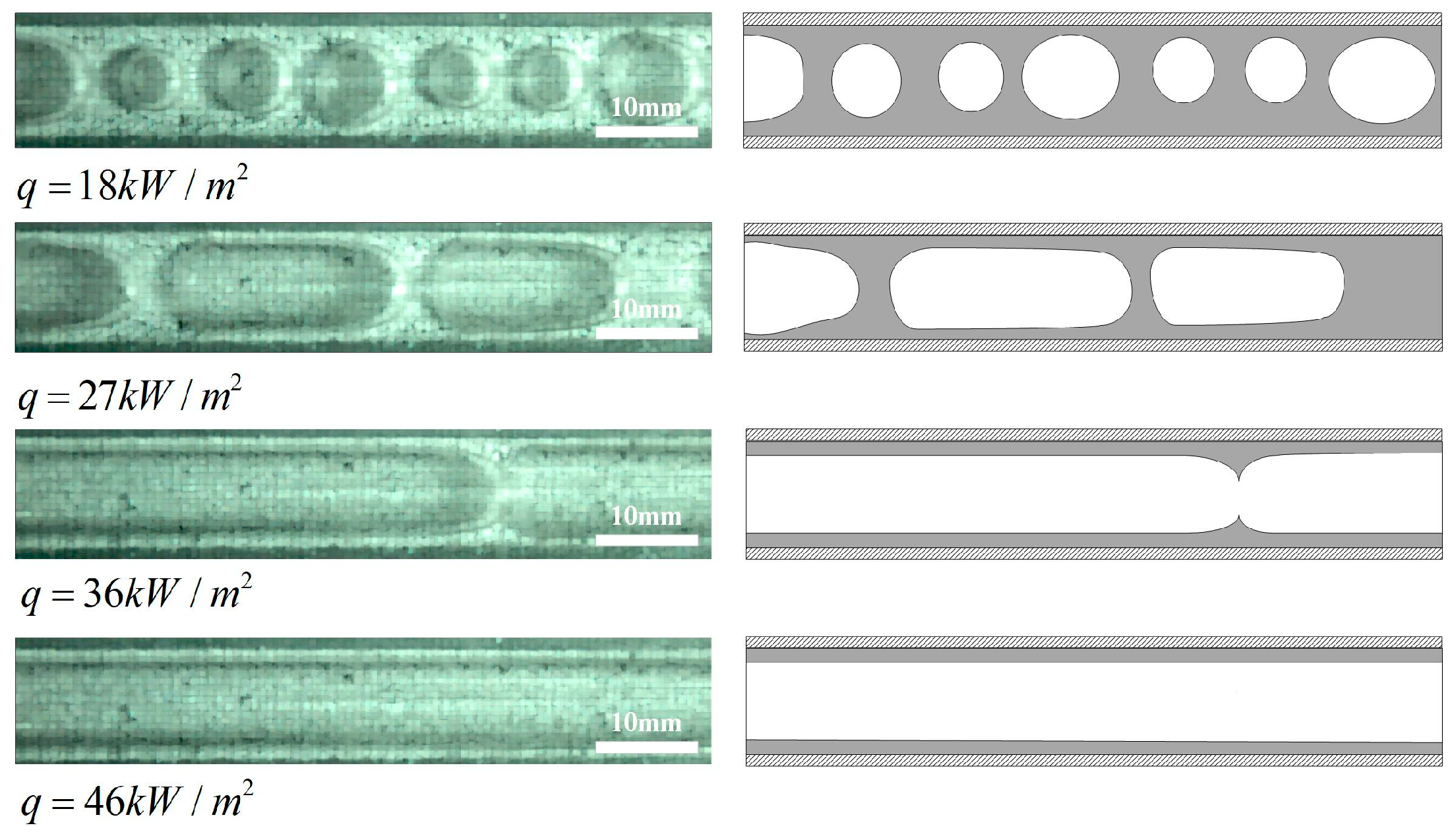

3.3. Influence of Surface Wettability on Flow Patterns

3.4. Mechanism of Heat Transfer Enhancement in Super-Hydrophilic Microchannel

3.4.1. Bubble Nucleation Rate and the Number of Nucleation

3.4.2. Bubble Departure Diameter and Departure Frequency

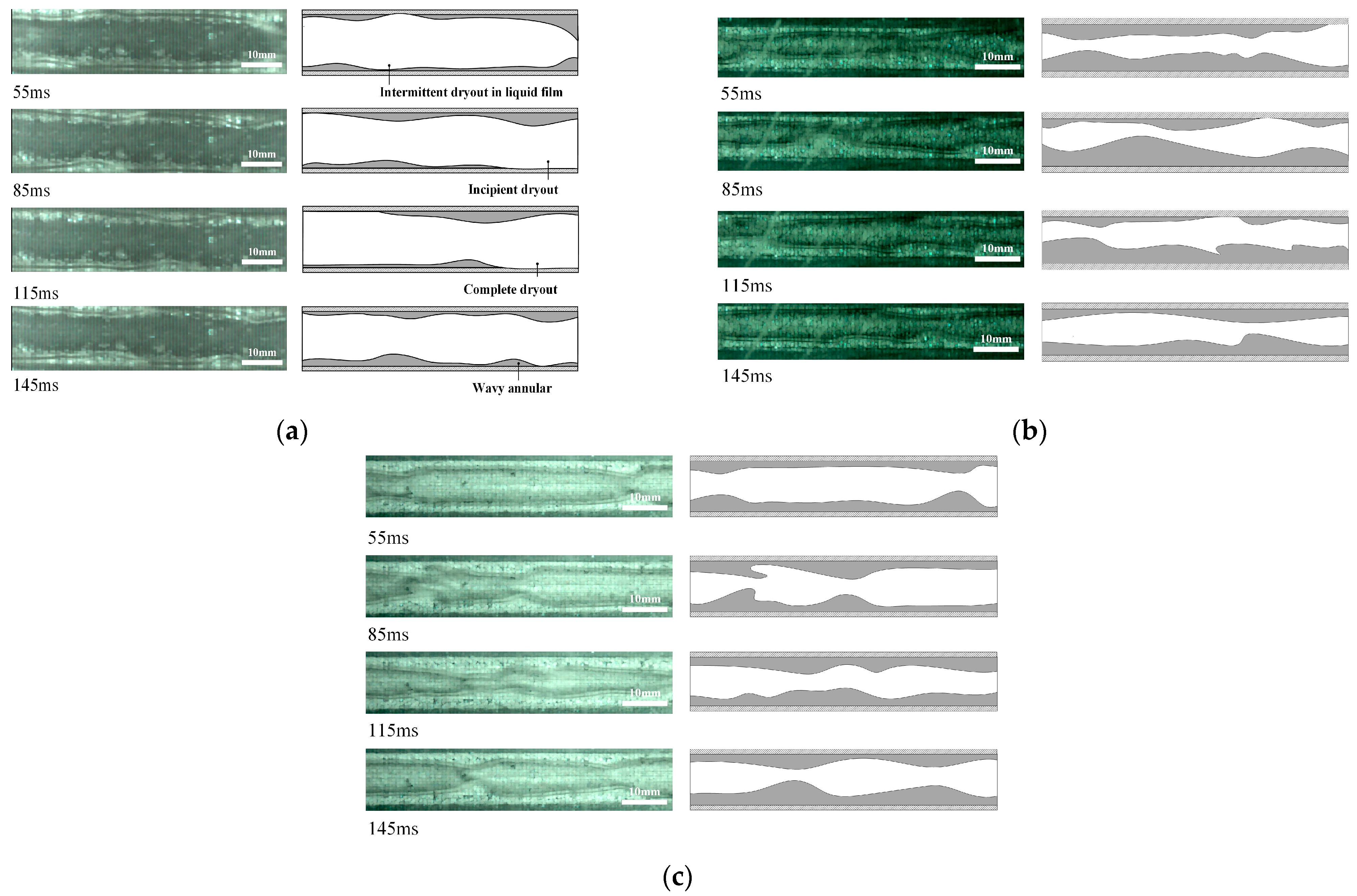

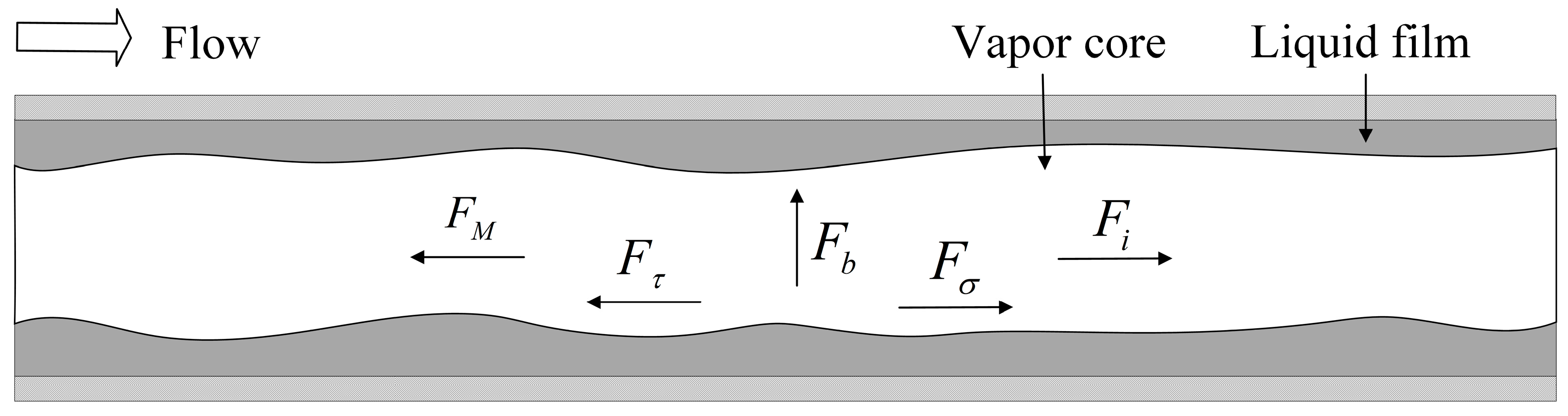

3.4.3. Force Analysis of the Vapor-Liquid Interface and Dryout Mechanism

- (a)

- The effect of high heat flux

- (b)

- The effect of high mass flux

4. Conclusions

- (1)

- The heat transfer performance of a super-hydrophilic surface microchannel is much better than that of an untreated one. At a lower mass flux of 740 kg/(m2s), the average heat transfer coefficients of the hydrophilic and super-hydrophilic microchannels are higher about 65% and 300% than those of the untreated one. At higher mass flux of 1265 kg/(m2s), the average heat transfer coefficients of the hydrophilic and the super-hydrophilic microchannels are about 85% and 325% higher than those of the untreated one.

- (2)

- The mechanism of the heat transfer performance advantages of the super-hydrophilic surface microchannel is as follows: Compared with the untreated surface, the super-hydrophilic surface is rough and has more active nucleation cavities. As a result, the number of bubble nucleation sites generated in the super-hydrophilic surface microchannel is larger, and the bubble departure diameter is smaller, so the flow and heat transfer are enhanced. On the other hand, the contact angle of the super-hydrophilic surface microchannel is very small, so the departure diameter is small and the departure frequency is high, resulting in enhanced flow and heat transfer.

- (3)

- Under high heat flux conditions, a dryout phenomenon emerges in the untreated surface microchannel, but there is no such appearance in a super-hydrophilic surface microchannel. This is because in the untreated surface microchannel, the evaporation momentum force increases and dominates at this time, causing the balance of the flow forces to be broken, the flow is blocked, the vapor-liquid interface is unevenly distributed, and dryout occurs. However, for a super-hydrophilic surface microchannel, due to its large surface tension, which can weaken the effect of the increase of evaporative momentum force, so that the sum of the surface tension force and inertial force is still greater than (or equal to) the sum of evaporation momentum force and shear force. At this time, the flow is not blocked, and the vapor-liquid interface remains uniform and stable to avoid dryout.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Ah | heated area [m2] |

| cp | specific heat at constant pressure [kJ/(kg K)] |

| Dh | hydraulic diameter [mm] |

| G | mass velocity [kg/(m2s)] |

| h | enthalpy [kJ/kg] |

| hfg | latent heat of vaporization [kJ/kg] |

| hz | local heat transfer coefficient [kW/(m2s)] |

| h | average heat transfer coefficient [kW/(m2s)] |

| Htc | distance between thermocouple and base of microchannel [m] |

| k | thermal conductivity [kW/(m K)] |

| L | length of microchannel [m] |

| p | pressure [bar] |

| power of heater [W] | |

| heat flux based on heated perimeter [kW/m2] | |

| T | Temperature [°C] |

| x | vapor quality [-] |

| z | coordinate along microchannel [m] |

| Greek symbols | |

| β | channel aspect ratio [-] |

| Δ | difference [-] |

| Subscripts | |

| f | fluid |

| in | microchannel inlet |

| res | reservoir |

| sat | saturated |

| sub | subcooling |

| test | test section |

| w | wall |

| z | coordinate along microchannel |

References

- Mudawar, I. Two-Phase Microchannel Heat Sinks: Theory, Applications, and Limitations. J. Electron. Packag. 2011, 133. [Google Scholar] [CrossRef]

- Valeh-e-Sheyda, P.; Rahimi, M.; Karimi, E.; Asadi, M. Application of two-phase flow for cooling of hybrid microchannel PV cells: A comparative study. Energy Convers. Manag. 2013, 69, 122–130. [Google Scholar] [CrossRef]

- Karayiannis, T.G.; Mahmoud, M.M. Flow boiling in microchannels: Fundamentals and applications. Appl. Therm. Eng. 2017, 115, 1372–1397. [Google Scholar] [CrossRef]

- Liang, G.; Mudawar, I. Review of channel flow boiling enhancement by surface modification, and instability suppression schemes. Int. J. Heat Mass Transf. 2020, 146. [Google Scholar] [CrossRef]

- Yang, F.; Dai, X.; Peles, Y.; Cheng, P.; Khan, J.; Li, C. Flow boiling phenomena in a single annular flow regime in microchannels (I): Characterization of flow boiling heat transfer. Int. J. Heat Mass Transf. 2014, 68, 703–715. [Google Scholar] [CrossRef]

- Yang, F.; Dai, X.; Peles, Y.; Cheng, P.; Khan, J.; Li, C. Flow boiling phenomena in a single annular flow regime in microchannels (II): Reduced pressure drop and enhanced critical heat flux. Int. J. Heat Mass Transf. 2014, 68, 716–724. [Google Scholar] [CrossRef]

- Liu, T.Y.; Li, P.L.; Liu, C.W.; Gau, C. Boiling flow characteristics in microchannels with very hydrophobic surface to super-hydrophilic surface. Int. J. Heat Mass Transf. 2011, 54, 126–134. [Google Scholar] [CrossRef]

- Anwar, Z.; Palm, B.; Khodabandeh, R. Flow boiling heat transfer and dryout characteristics of R152a in a vertical mini-channel. Exp. Therm. Fluid Sci. 2014, 53, 207–217. [Google Scholar] [CrossRef]

- Lee, S.; Mudawar, I. Transient characteristics of flow boiling in large micro-channel heat exchangers. Int. J. Heat Mass Transf. 2016, 103, 186–202. [Google Scholar] [CrossRef]

- Lee, S.; Devahdhanush, V.S.; Mudawar, I. Investigation of subcooled and saturated boiling heat transfer mechanisms, instabilities, and transient flow regime maps for large length-to-diameter ratio micro-channel heat sinks. Int. J. Heat Mass Transf. 2018, 123, 172–191. [Google Scholar] [CrossRef]

- Morisaki, M.; Minami, S.; Miyazaki, K.; Yabuki, T. Direct local heat flux measurement during water flow boiling in a rectangular minichannel using a MEMS heat flux sensor. Exp. Therm. Fluid Sci. 2021, 121. [Google Scholar] [CrossRef]

- Zhou, K.; Coyle, C.; Li, J.; Buongiorno, J.; Li, W. Flow boiling in vertical narrow microchannels of different surface wettability characteristics. Int. J. Heat Mass Transf. 2017, 109, 103–114. [Google Scholar] [CrossRef] [Green Version]

- Li, W.; Zhou, K.; Li, J.; Feng, Z.; Zhu, H. Effects of heat flux, mass flux and two-phase inlet quality on flow boiling in a vertical superhydrophilic microchannel. Int. J. Heat Mass Transf. 2018, 119, 601–613. [Google Scholar] [CrossRef]

- Li, W.; Chen, Z.; Li, J.; Sheng, K.; Zhu, J. Subcooled flow boiling on hydrophilic and super-hydrophilic surfaces in microchannel under different orientations. Int. J. Heat Mass Transf. 2019, 129, 635–649. [Google Scholar] [CrossRef]

- Bao, Z.Y.; Fletcher, D.F.; Haynes, B.S. Flow boiling heat transfer of Freon R11 and HCFC123 in narrow passages. Int. J. Heat Mass Transf. 2000, 43, 3347–3358. [Google Scholar] [CrossRef]

- Lin, S.; Kew, P.A.; Cornwell, K. Flow Boiling of Refrigerant R141B in Small Tubes. Chem. Eng. Res. Des. 2001, 79, 417–424. [Google Scholar] [CrossRef]

- Bertsch, S.S.; Groll, E.A.; Garimella, S.V. Effects of heat flux, mass flux, vapor quality, and saturation temperature on flow boiling heat transfer in microchannels. Int. J. Multiph. Flow 2009, 35, 142–154. [Google Scholar] [CrossRef] [Green Version]

- Qu, W.; Mudawar, I. Flow boiling heat transfer in two-phase micro-channel heat sinks––I. Experimental investigation and assessment of correlation methods. Int. J. Heat Mass Transf. 2003, 46, 2755–2771. [Google Scholar] [CrossRef]

- Boye, H.; Staate, Y.; Schmidt, J. Experimental investigation and modelling of heat transfer during convective boiling in a minichannel. Int. J. Heat Mass Transf. 2007, 50, 208–215. [Google Scholar] [CrossRef]

- Mortada, S.; Zoughaib, A.; Arzano-Daurelle, C.; Clodic, D. Boiling heat transfer and pressure drop of R-134a and R-1234yf in minichannels for low mass fluxes. Int. J. Refrig. 2012, 35, 962–973. [Google Scholar] [CrossRef]

- Leão, H.L.S.L.; do Nascimento, F.J.; Ribatski, G. Flow boiling heat transfer of R407C in a microchannels based heat spreader. Exp. Therm. Fluid Sci. 2014, 59, 140–151. [Google Scholar] [CrossRef]

- Lee, J.; Mudawar, I. Two-phase flow in high-heat-flux micro-channel heat sink for refrigeration cooling applications: Part II—heat transfer characteristics. Int. J. Heat Mass Transf. 2005, 48, 941–955. [Google Scholar] [CrossRef]

- Huh, C.; Kim, M.H. An experimental investigation of flow boiling in an asymmetrically heated rectangular microchannel. Exp. Therm. Fluid Sci. 2006, 30, 775–784. [Google Scholar] [CrossRef]

- Lee, P.-S.; Garimella, S.V. Saturated flow boiling heat transfer and pressure drop in silicon microchannel arrays. Int. J. Heat Mass Transf. 2008, 51, 789–806. [Google Scholar] [CrossRef] [Green Version]

- Harirchian, T.; Garimella, S.V. Microchannel size effects on local flow boiling heat transfer to a dielectric fluid. Int. J. Heat Mass Transf. 2008, 51, 3724–3735. [Google Scholar] [CrossRef] [Green Version]

- Ducoulombier, M.; Colasson, S.; Bonjour, J.; Haberschill, P. Carbon dioxide flow boiling in a single microchannel—Part II: Heat transfer. Exp. Therm. Fluid Sci. 2011, 35, 597–611. [Google Scholar] [CrossRef]

- Lee, S.; Mudawar, I. Investigation of flow boiling in large micro-channel heat exchangers in a refrigeration loop for space applications. Int. J. Heat Mass Transf. 2016, 97, 110–129. [Google Scholar] [CrossRef]

- McNeil, D.A.; Raeisi, A.H.; Kew, P.A.; Hamed, R.S. Flow boiling heat-transfer in micro to macro transition flows. Int. J. Heat Mass Transf. 2013, 65, 289–307. [Google Scholar] [CrossRef]

- Balasubramanian, K.; Jagirdar, M.; Lee, P.S.; Teo, C.J.; Chou, S.K. Experimental investigation of flow boiling heat transfer and instabilities in straight microchannels. Int. J. Heat Mass Transf. 2013, 66, 655–671. [Google Scholar] [CrossRef]

- Ren, C.; Li, W.; Ma, J.; Huang, G.; Li, C. Flow boiling in microchannels enhanced by parallel microgrooves fabricated on the bottom surfaces. Int. J. Heat Mass Transf. 2021, 166. [Google Scholar] [CrossRef]

- Yang, Q.; Shu, B.; Wang, J.; Guo, Y. Experimental investigation on flow boiling heat transfer and flow patterns in a single micro-channel with large mass velocity. Exp. Therm. Fluid Sci. 2018, 91, 283–291. [Google Scholar] [CrossRef]

- Nguyen, T.; Anh Ngo, T.; Duong Bang, D.; Wolff, A. Optimising the supercritical angle fluorescence structures in polymer microfluidic biochips for highly sensitive pathogen detection: A case study on Escherichia coli. Lab Chip 2019, 19, 3825–3833. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Parameter | Dimension |

|---|---|

| Number of channels | 1 |

| Hydraulic diameter, Dh [mm] | 0.872 |

| Channel length, L [mm] | 78 |

| Channel width, Wch [mm] | 1.6 |

| Channel depth, Hch [mm] | 0.6 |

| Experiment Parameters | Range | Unit |

|---|---|---|

| Surface contact angle | 70, 43, 0 | ° |

| Saturation temperature | 20 | ℃ |

| Inter vapor quality | 0–0.25 | 1 |

| Mass flux | 741–1267 | kg/(m2s) |

| Heat flux | 9–45 | kW/m2 |

| Parameter | Maximum Uncertainty (%) |

|---|---|

| Pressure, P [bar] | 0.5 |

| Differential pressure, ΔP [MPa] | 0.5 |

| Refrigerant temperature Tf [°C] | 0.3 |

| Wall temperature, Tw [°C] | 0.5 |

| Heat flux, q″ [kW/m2] | 0.5 |

| Mass velocity, G [kg/(m2s)] | 5.7 |

| Inlet vapor quality [–] | 5.2 |

| Local vapor quality [–] | 7.2 |

| Local heat transfer coefficient [kW/(m2K)] | 12.5 |

| Average heat transfer coefficient [kW/(m2K)] | 12.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, S.; Shu, B.; Yu, Z.; Huang, Y.; Zhang, Y. Experimental Study and Mechanism Analysis of the Flow Boiling and Heat Transfer Characteristics in Microchannels with Different Surface Wettability. Micromachines 2021, 12, 881. https://doi.org/10.3390/mi12080881

Zhou S, Shu B, Yu Z, Huang Y, Zhang Y. Experimental Study and Mechanism Analysis of the Flow Boiling and Heat Transfer Characteristics in Microchannels with Different Surface Wettability. Micromachines. 2021; 12(8):881. https://doi.org/10.3390/mi12080881

Chicago/Turabian StyleZhou, Shengnan, Bifen Shu, Zukang Yu, Yan Huang, and Yuqi Zhang. 2021. "Experimental Study and Mechanism Analysis of the Flow Boiling and Heat Transfer Characteristics in Microchannels with Different Surface Wettability" Micromachines 12, no. 8: 881. https://doi.org/10.3390/mi12080881

APA StyleZhou, S., Shu, B., Yu, Z., Huang, Y., & Zhang, Y. (2021). Experimental Study and Mechanism Analysis of the Flow Boiling and Heat Transfer Characteristics in Microchannels with Different Surface Wettability. Micromachines, 12(8), 881. https://doi.org/10.3390/mi12080881