Soft Finger Modelling and Co-Simulation Control towards Assistive Exoskeleton Hand Glove

Abstract

1. Introduction

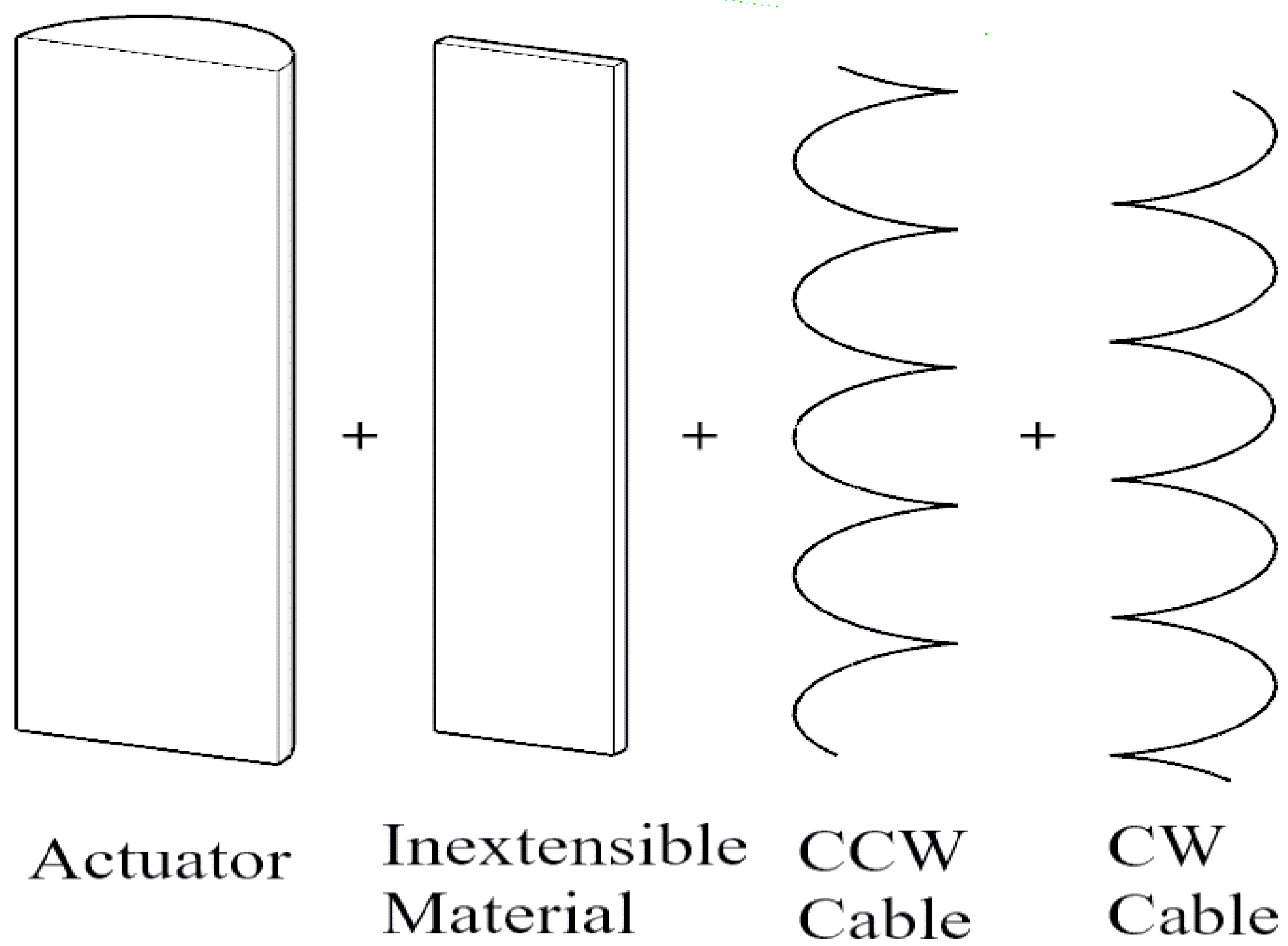

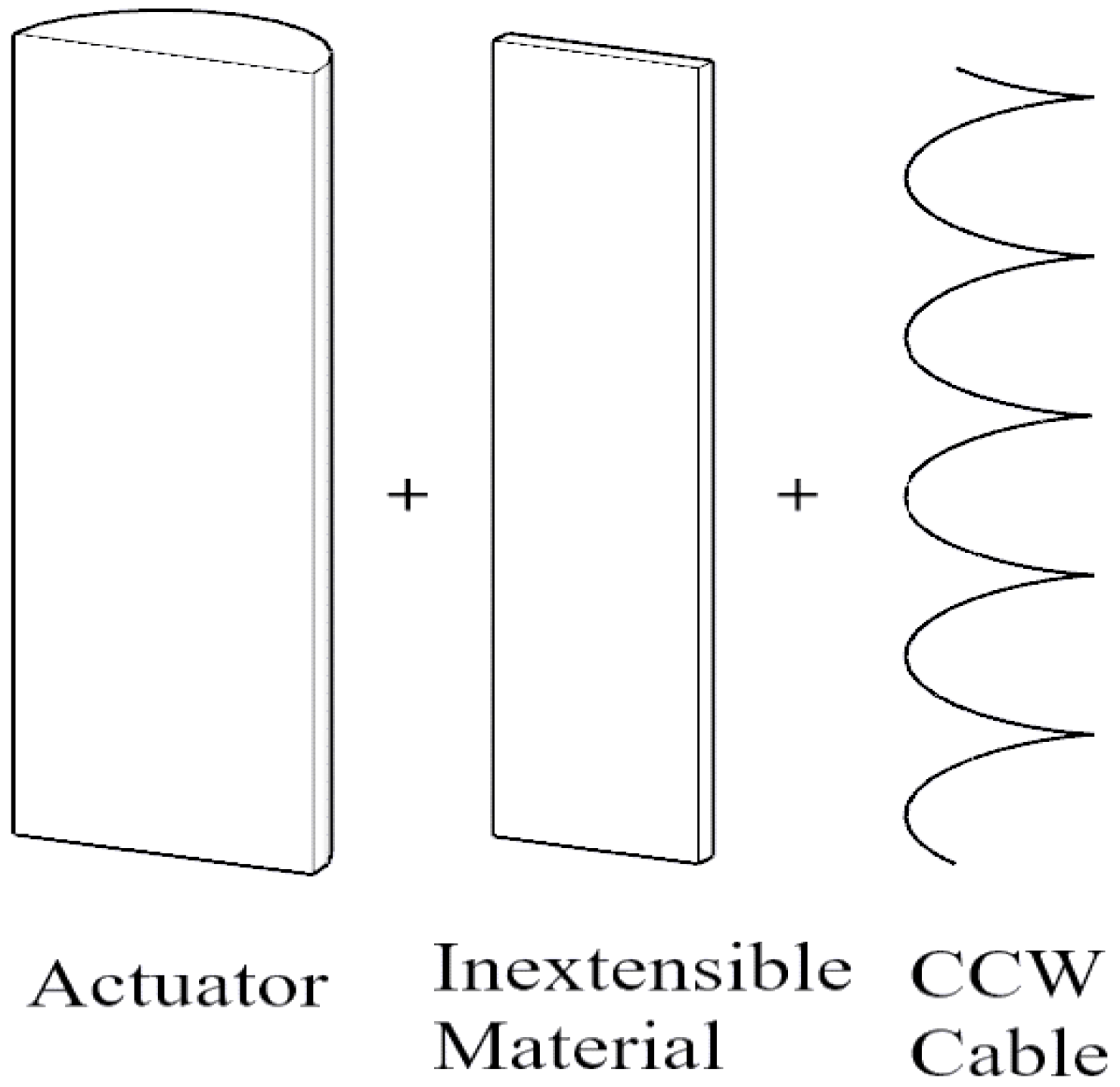

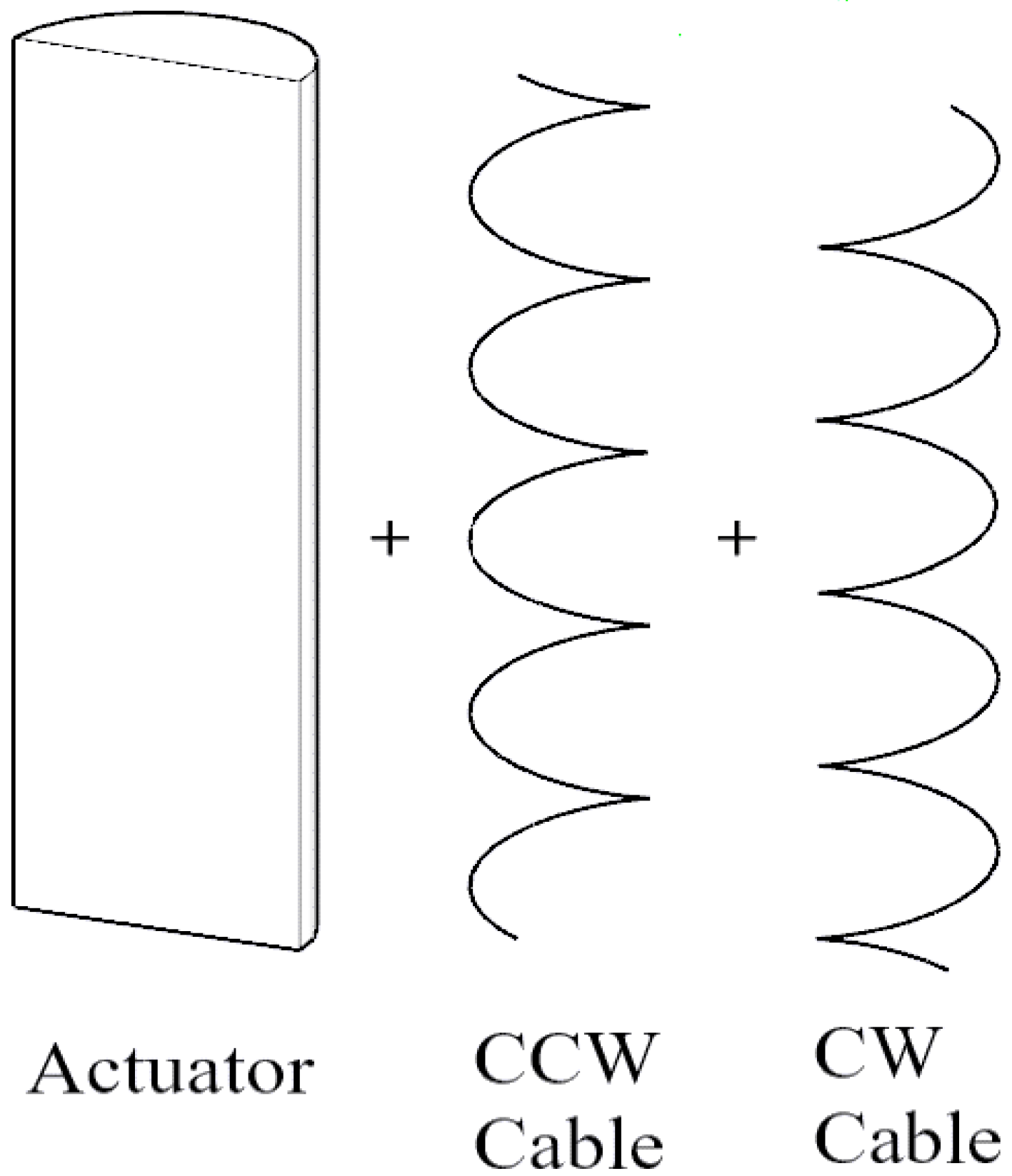

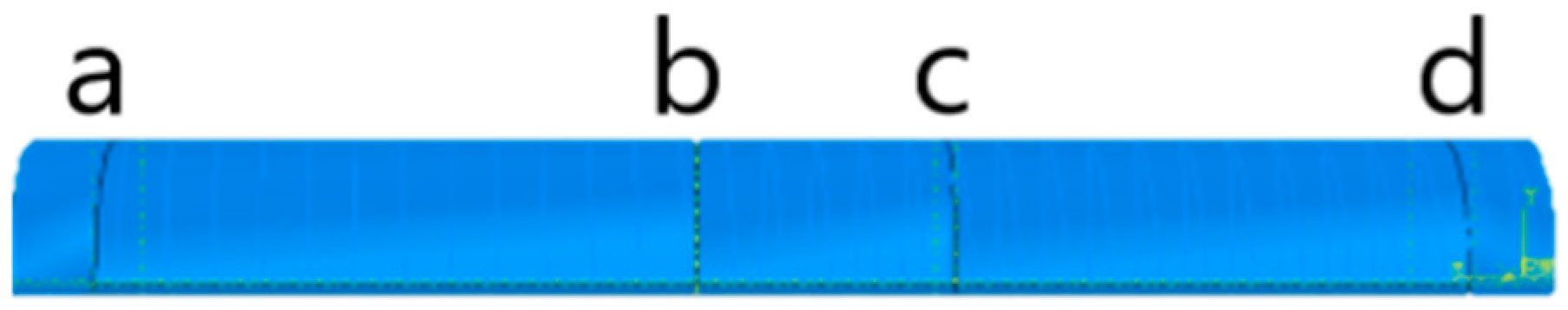

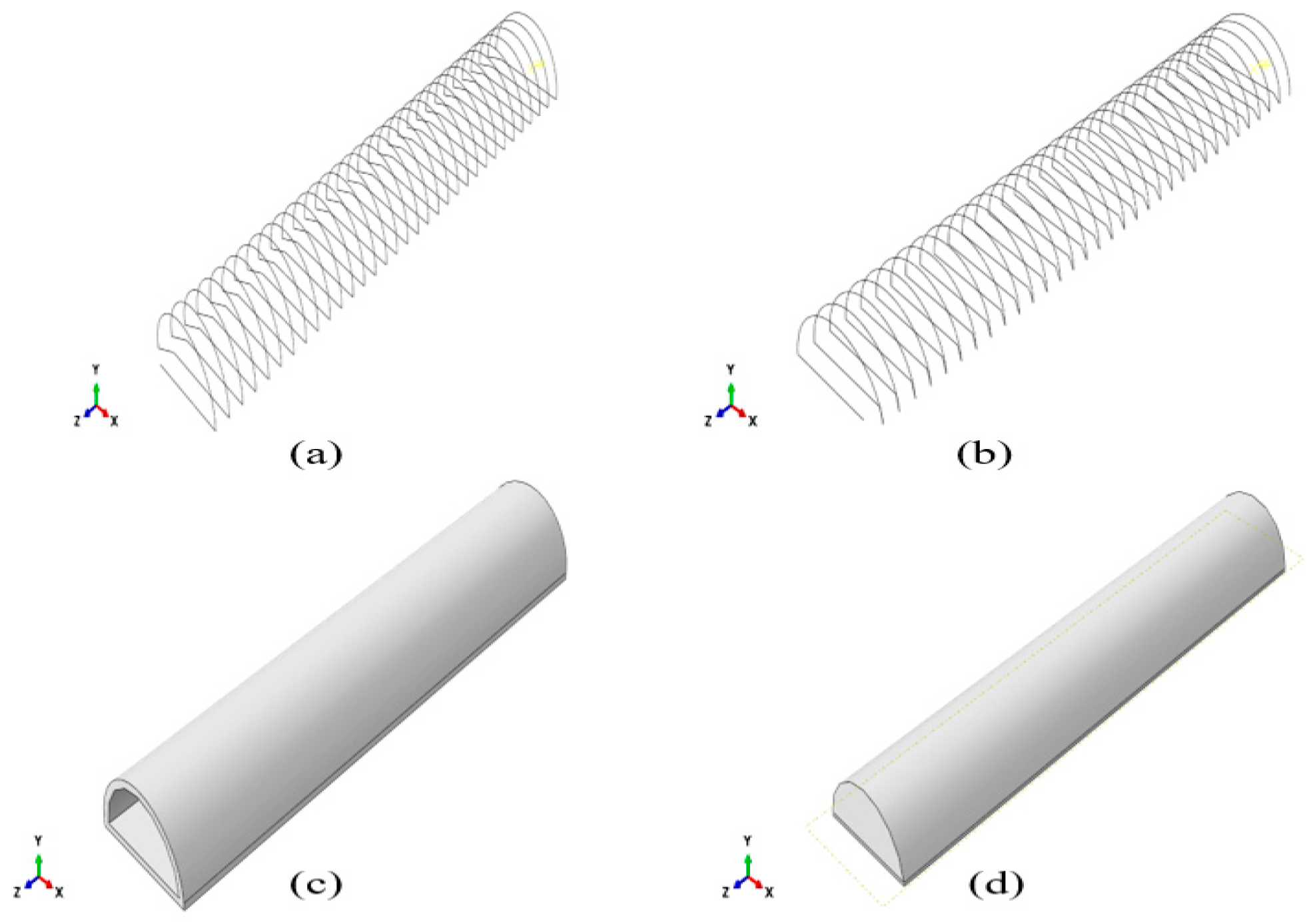

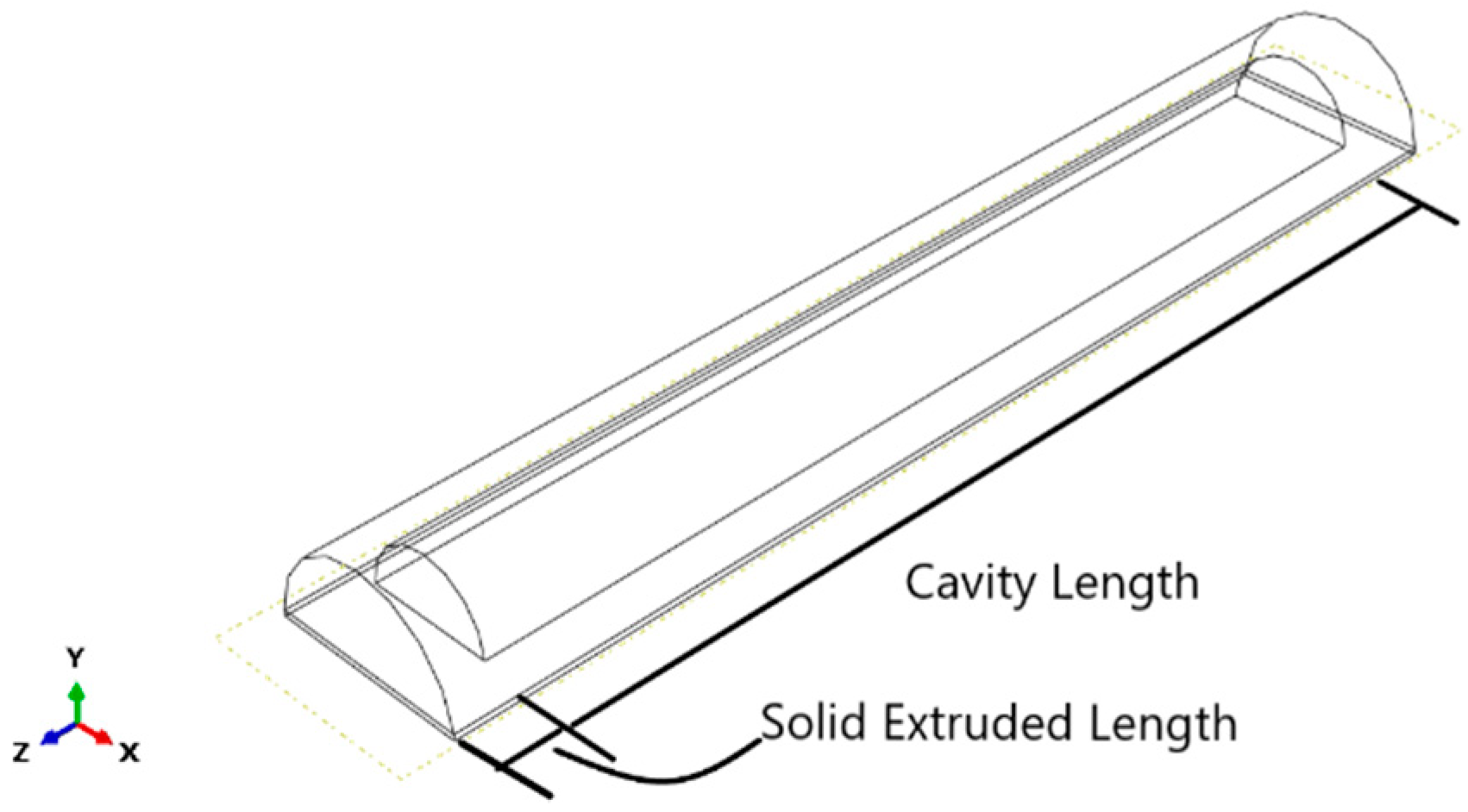

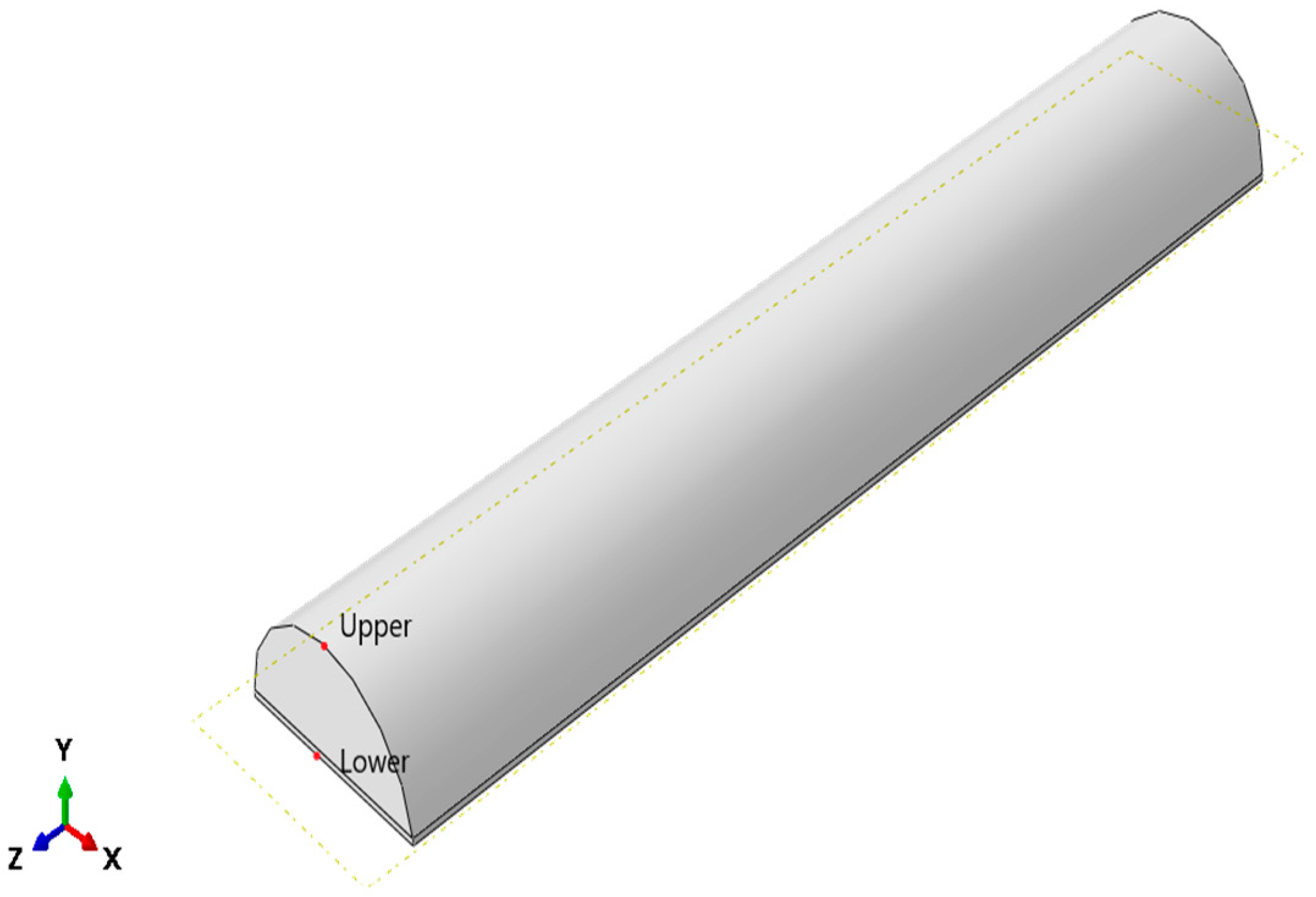

2. Materials and Method

3. Results

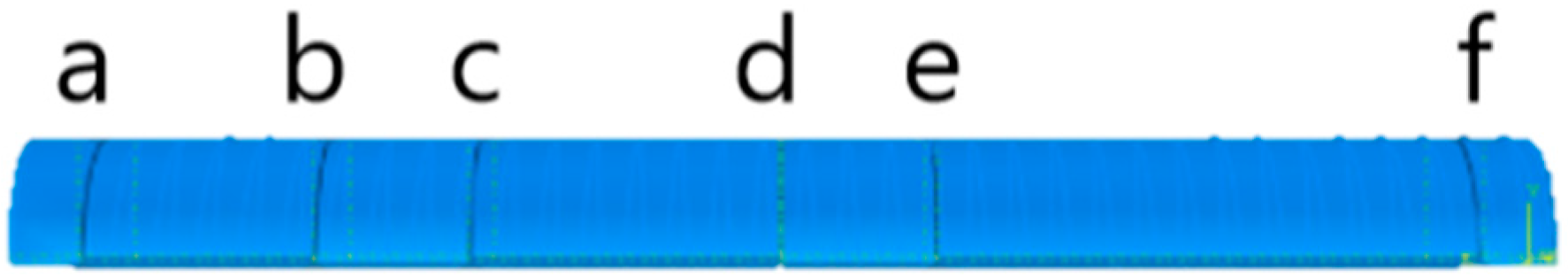

3.1. Open-Loop Simulation Results

3.2. Optimization Results

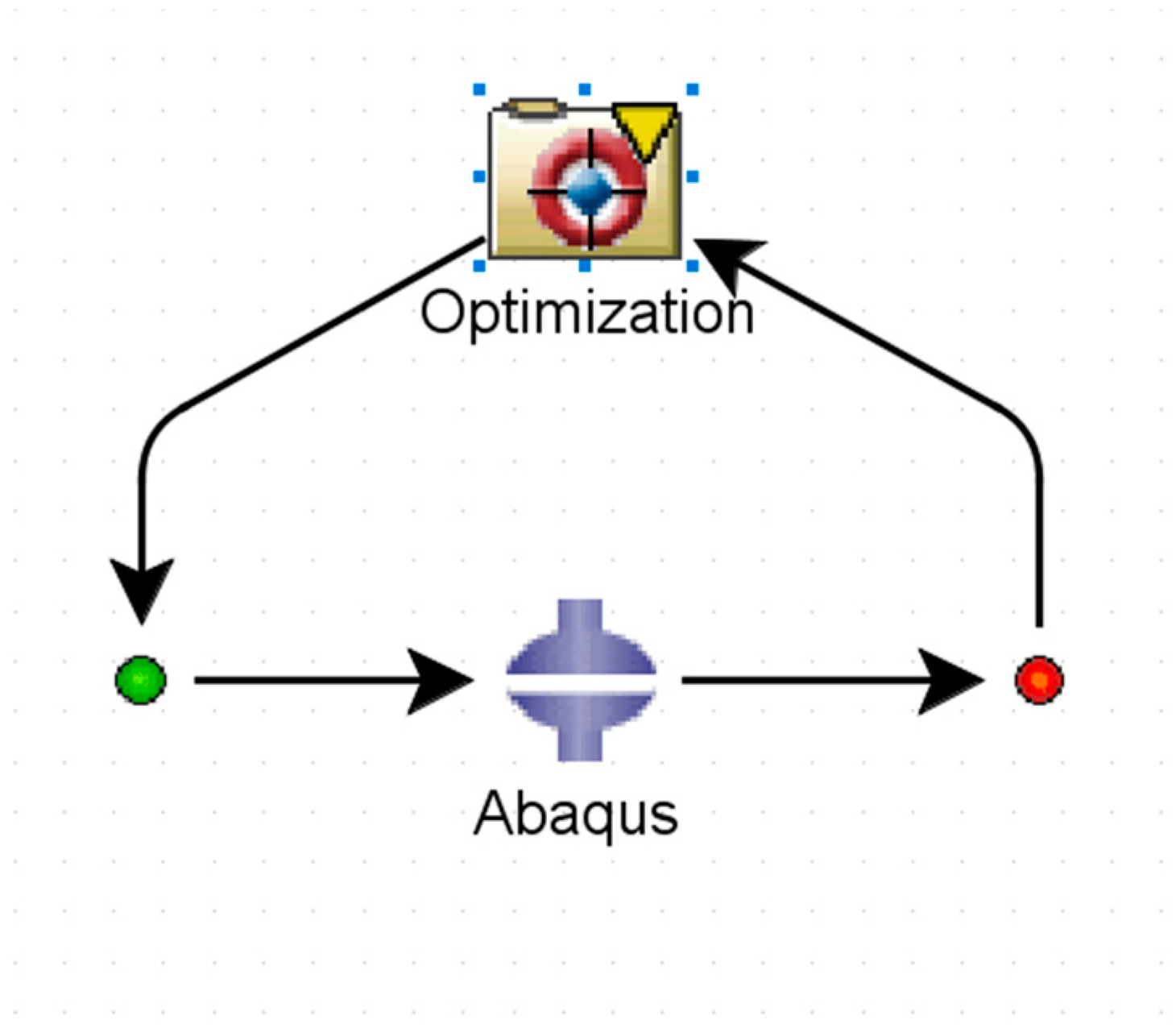

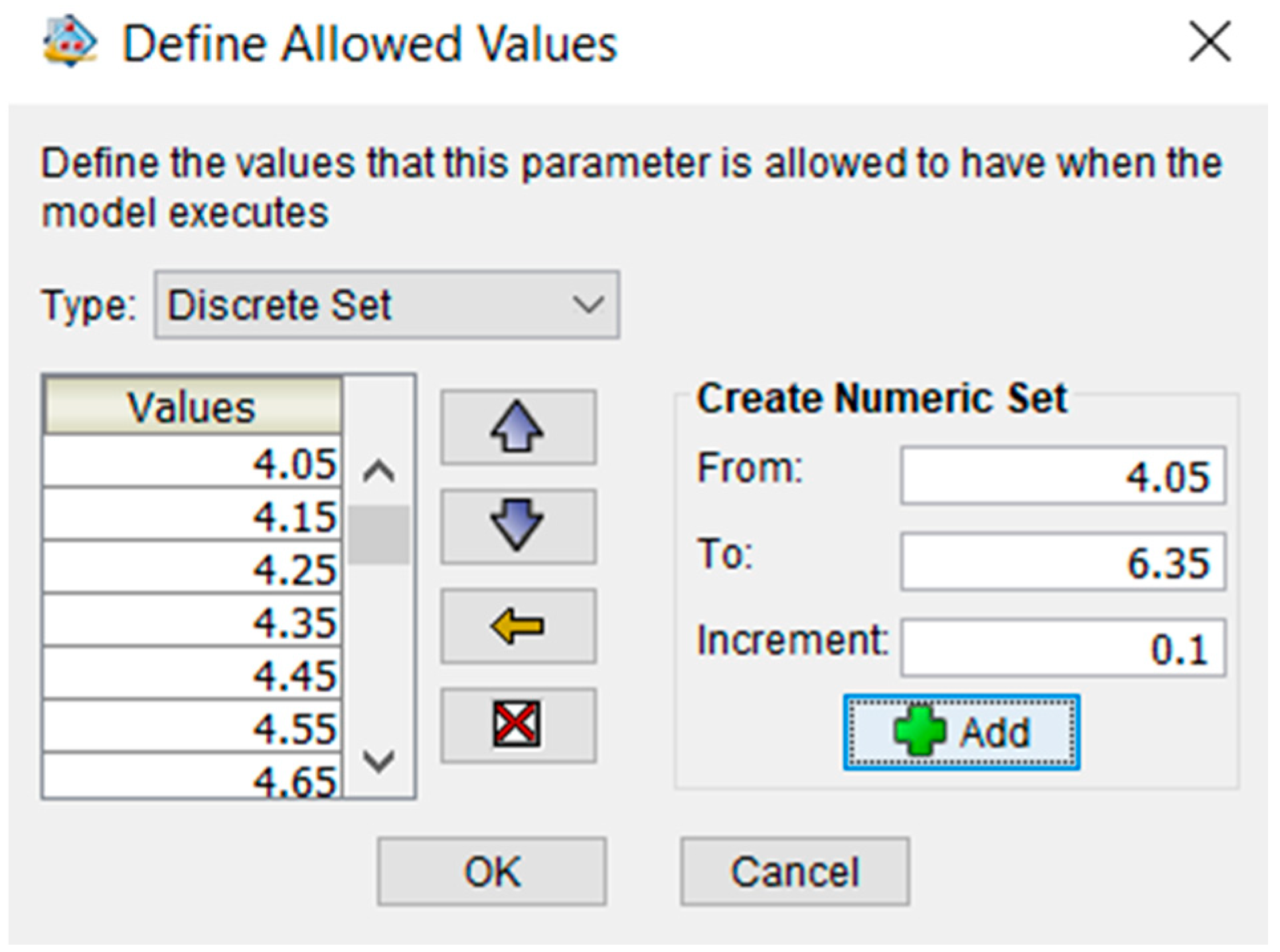

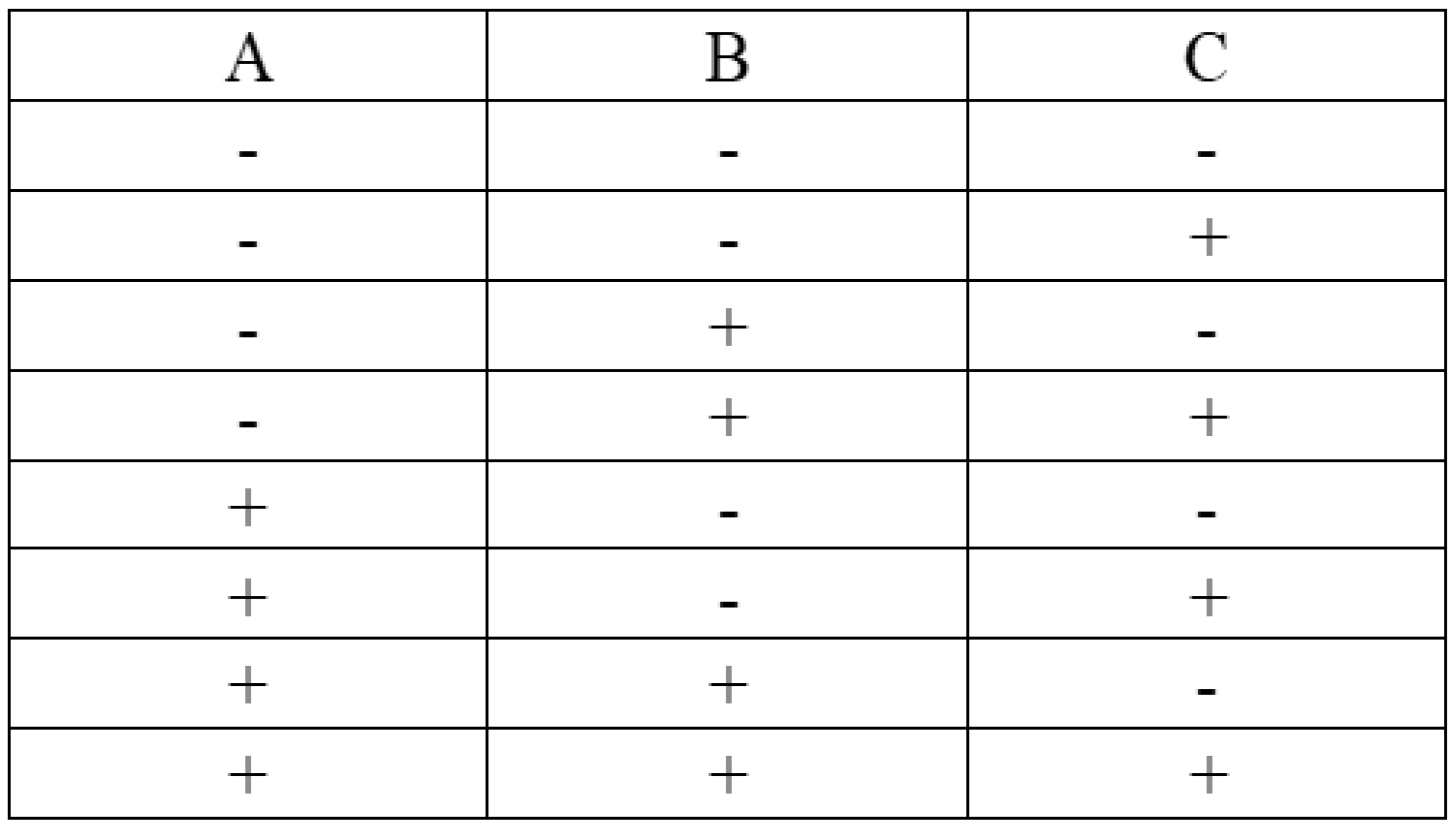

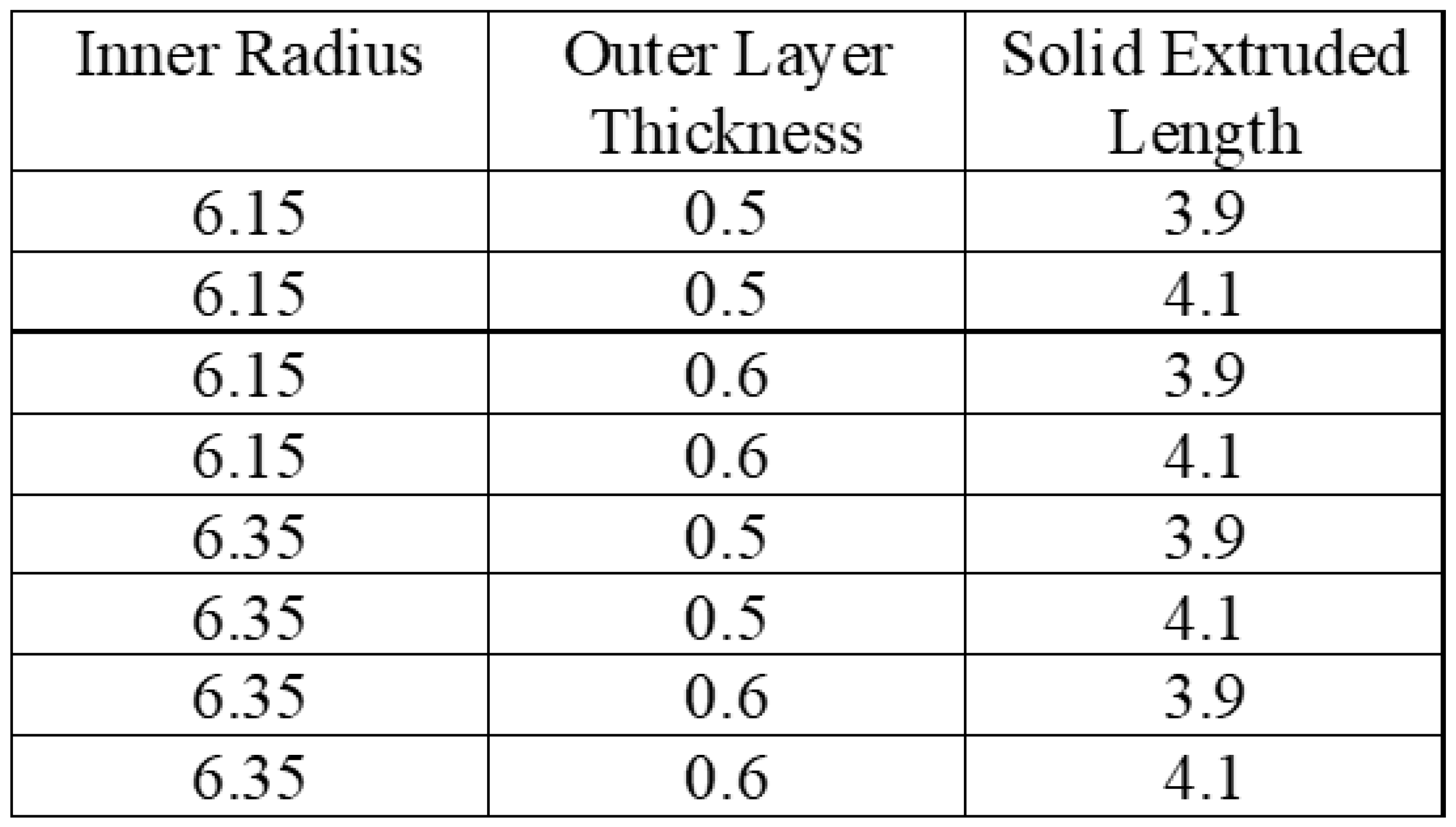

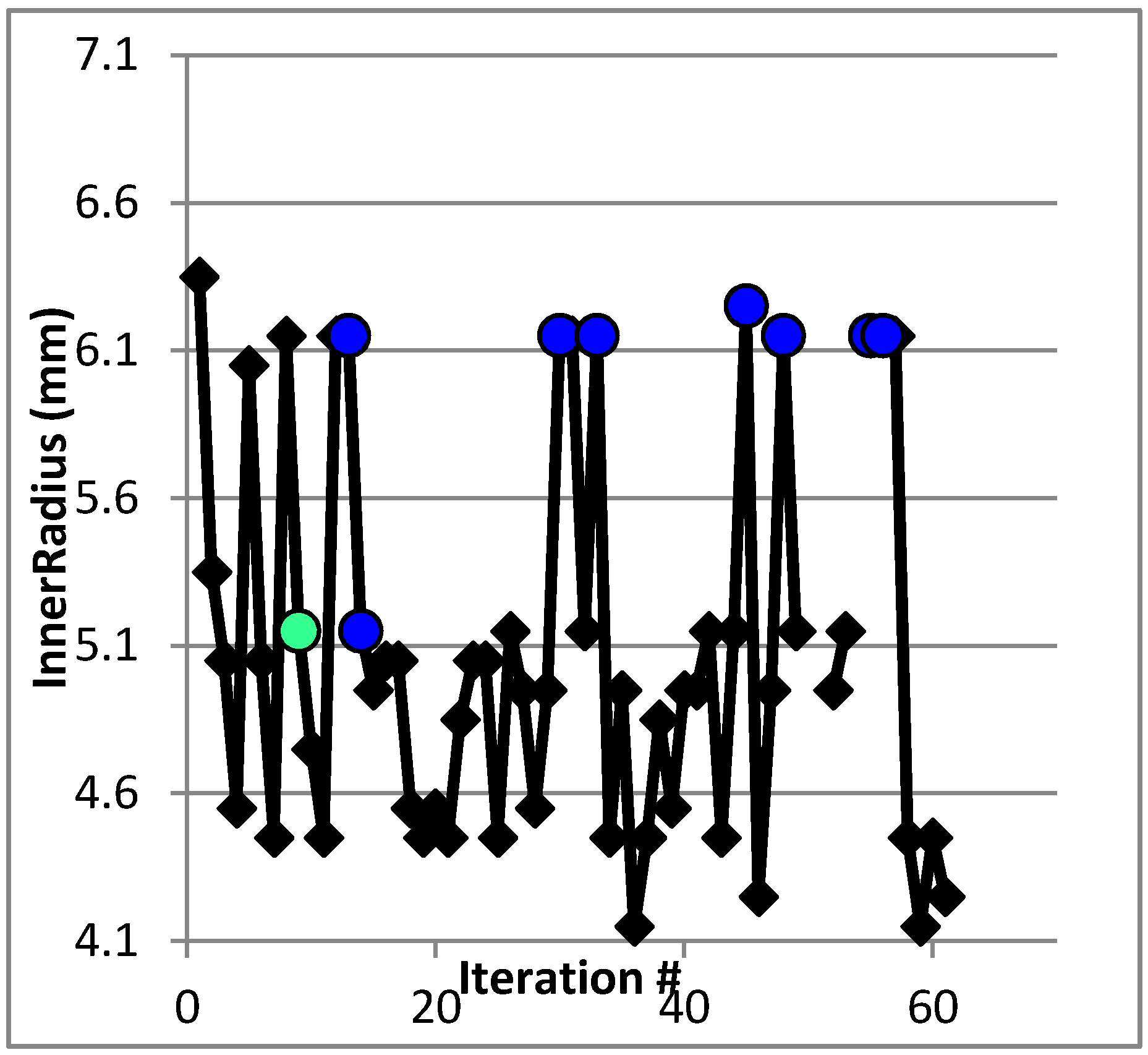

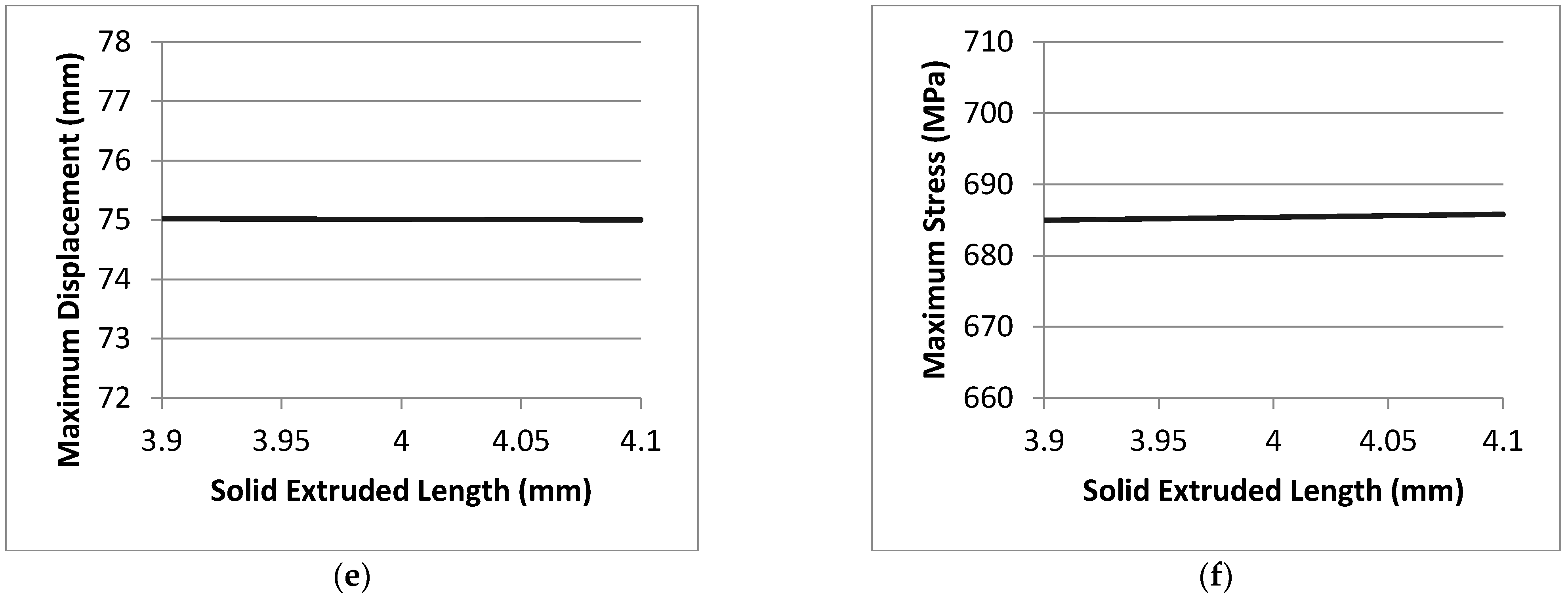

3.2.1. Dimensional Optimization Results

3.2.2. Material Optimization Results

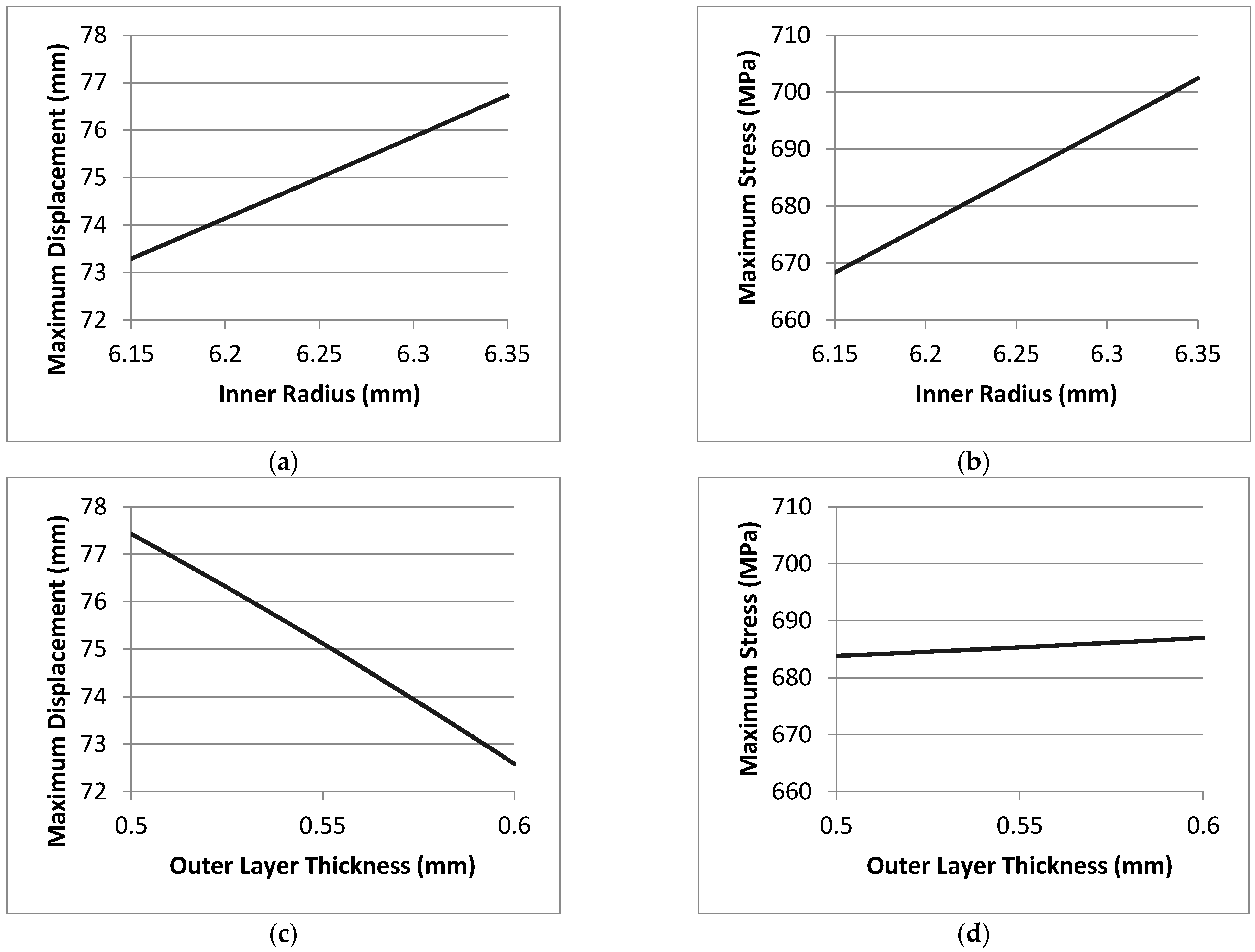

3.3. Design of Experiment Results

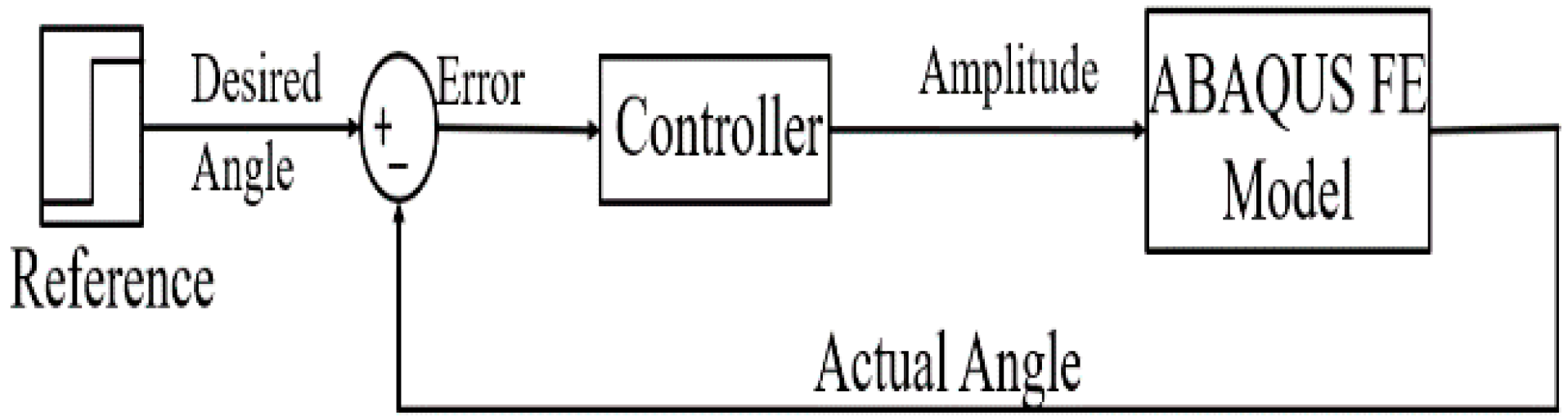

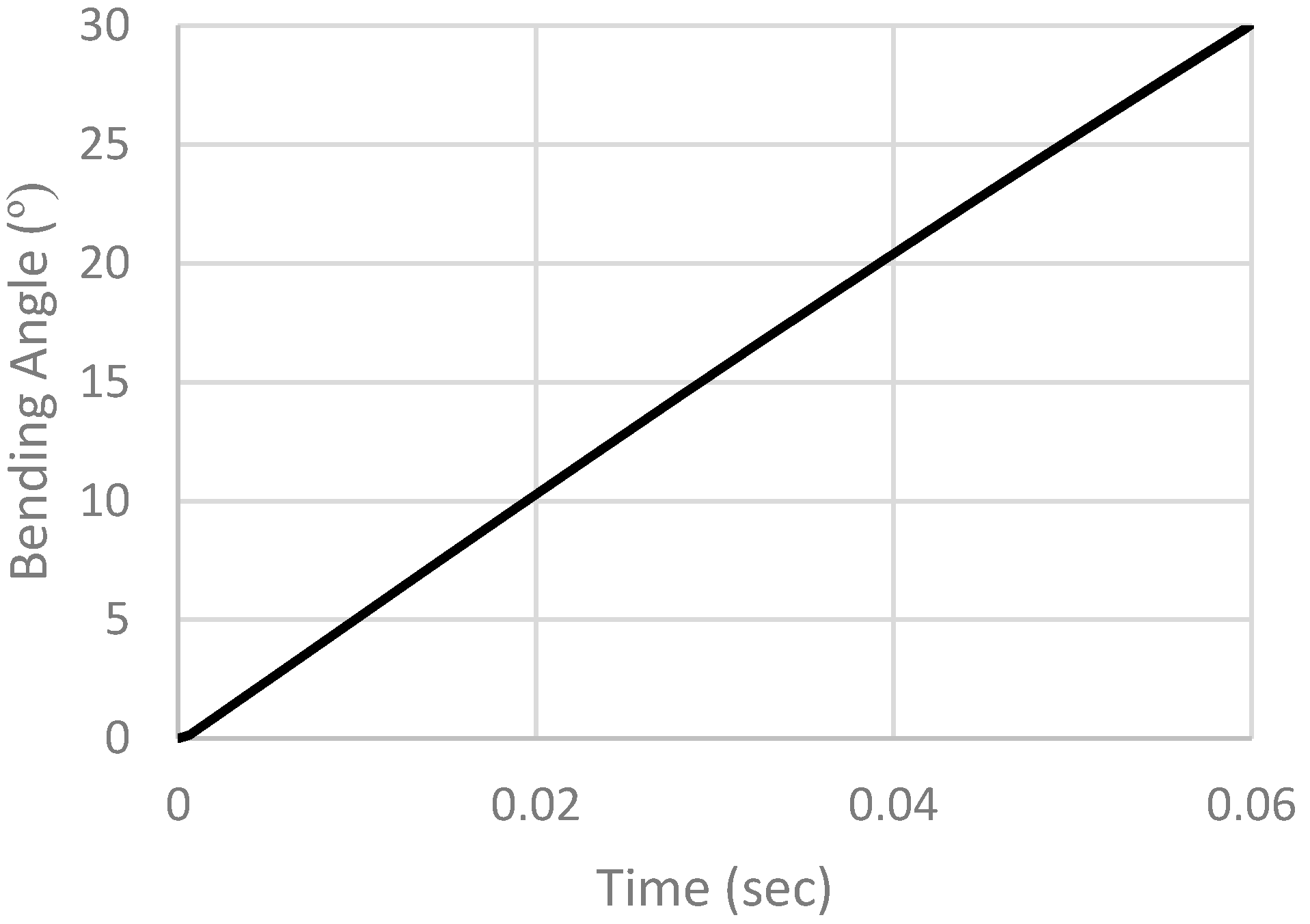

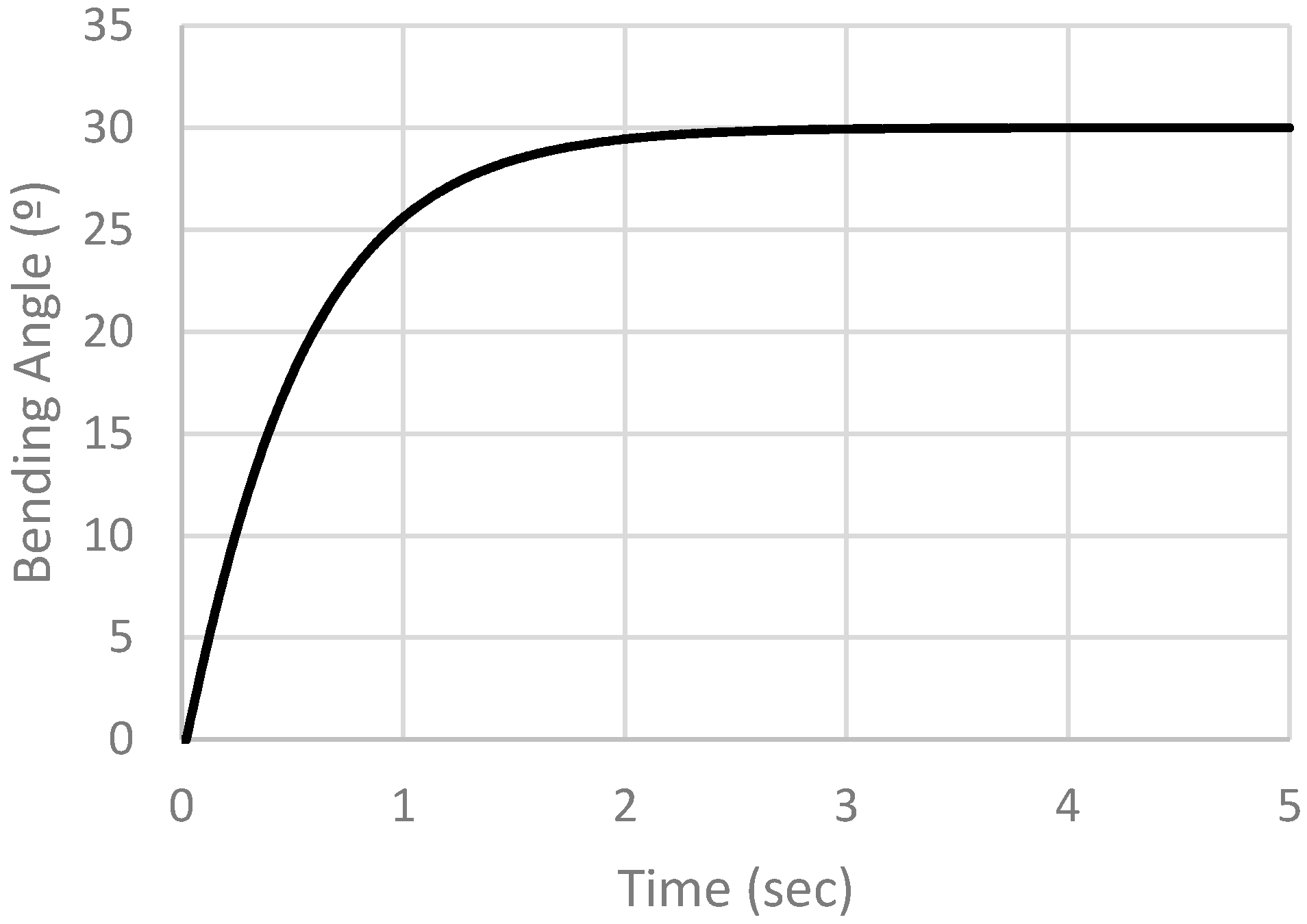

3.4. Software-In-The-Loop Results

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Findlay at Touro University, Wrist and Hand, Human Anatomy Pa 657. Available online: https://www.pinterest.com/pin/324751823112763203/ (accessed on 5 February 2021).

- Polygerinos, P.; Wang, Z.; Overvelde, J.T.; Galloway, K.C.; Wood, R.J.; Bertoldi, K.; Walsh, C.J. Modeling of soft fiber-reinforced bending actuators. IEEE Trans. Robot. 2015, 31, 778–789. [Google Scholar] [CrossRef]

- Polygerinos, P.; Galloway, K.C.; Sanan, S.; Herman, M.; Walsh, C.J. EMG controlled soft robotic glove for assistance during activities of daily living. In Proceedings of the 2015 IEEE International Conference on Rehabilitation Robotics (ICORR), Singapore, 11–14 August 2015; pp. 55–60. [Google Scholar] [CrossRef]

- Yap, H.K.; Goh, J.; Yeow, R.C.-H. Design and characterization of soft actuator for hand rehabilitation application. In IFMBE Proceedings; Springer: Berlin/Heidelberg, Germany, 2014; Volume 45. [Google Scholar] [CrossRef]

- Yap, H.K.; Lim, J.H.; Nasrallah, F.; Goh, J.C.H.; Yeow, R.C.H. A soft exoskeleton for hand assistive and rehabilitation application using pneumatic actuators with variable stiffness. In Proceedings of the 2015 IEEE International Conference on Robotics and Automation (ICRA), Seattle, WA, USA, 26–30 May 2015; pp. 4967–4972. [Google Scholar] [CrossRef]

- Moseley, P.; Florez, J.M.; Sonar, H.A.; Agarwal, G.; Curtin, W.; Paik, J. Modeling, design and development of soft pneumatic actuators with finite element method. Adv. Eng. Mater. 2016. [Google Scholar] [CrossRef]

- Oveisi, A.; Sukhairi, T.A.; Nestorović, T. Finite element-based software-in-the-loop for offline post-processing and real-time simulations. Struct. Eng. Mech. 2018, 67, 643–658. [Google Scholar] [CrossRef]

- Wang, Z.; Polygerinos, P.; Overvelde, J.T.B.; Galloway, K.C.; Bertoldi, K.; Walsh, C.J. Interaction forces of soft fiber reinforced bending actuators. IEEE/ASME Trans. Mechatron. 2017, 22, 717–727. [Google Scholar] [CrossRef]

- Elgeneidy, K.; Lohse, N.; Jackson, M. Bending angle prediction and control of soft pneumatic actuators with embedded flex sensors A data-driven approach. Mechatronics 2018, 50, 234–247. [Google Scholar] [CrossRef]

- Jiang, Y.; Chen, D.; Que, J.; Liu, Z.; Wang, Z.; Xu, Y. Soft robotic glove for hand rehabilitation based on a novel fabrication method. In Proceedings of the 2017 IEEE International Conference on Robotics and Biomimetics (ROBIO), Macau, China, 5–8 December 2017; pp. 817–822. [Google Scholar] [CrossRef]

- Maeder-York, P.; Clites, T.; Boggs, E.; Neff, R.; Polygerinos, P.; Holland, D.; Stirling, L.; Galloway, K.; Wee, C.; Walsh, C. Biologically inspired soft robot for thumb rehabilitation. J. Med Devices 2014, 8, 020934. [Google Scholar] [CrossRef]

- Holland, D.P.; Berndt, S.; Herman, M.; Walsh, C. Growing the soft robotics community through knowledge-sharing initiatives. Soft Robot. 2018, 5, 119–121. [Google Scholar] [CrossRef]

- Dassault Systèmes Simulia Corp. Available online: https://www.3ds.com/products-services/simulia/products/abaqus/ (accessed on 30 November 2020).

- Mohamed, M.H.; Wagdy, S.H.; Atalla, M.A.; Rehan Youssef, A.; Maged, S.A. A proposed soft pneumatic actuator control based on angle estimation from data-driven model. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2020, 234, 612–625. [Google Scholar] [CrossRef] [PubMed]

- El-Agroudy, M.N.; Gaber, M.; Joseph, D.; Ibrahim, M.; Amin, M.; Helmy, D.; Hanafy, M.; Hisham, S.; Awad, M.I.; Youssef, A.R.; et al. Assistive exoskeleton hand glove. In Proceedings of the 2020 International Conference on Innovative Trends in Communication and Computer Engineering (ITCE), Aswan, Egypt, 8–9 February 2020; pp. 164–169. [Google Scholar] [CrossRef]

- Smooth-on Inc. 2020. Available online: https://www.smooth-on.com/products/dragon-skin-20/ (accessed on 30 November 2020).

- Smooth-on Inc. 2020. Available online: https://www.smooth-on.com/products/dragon-skin-10-medium/ (accessed on 30 November 2020).

- Watanabe, S.; Hiroyasu, T.; Miki, M. NCGA: Neighborhood Cultivation Genetic Algorithm for Multi-Objective Optimization Problems. 2003. Available online: https://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.15.4445&rep=rep1&type=pdf (accessed on 5 February 2021).

| Name | Maximum Stress | Maximum Displacement |

|---|---|---|

| Solid Extruded Length | 0.114523212 | 0.115576479 |

| Inner Radius | 0.843821803 | 0.847783115 |

| Name | Maximum Stress | Maximum Displacement |

|---|---|---|

| Inner Radius | 0.991336239 | 0.443522174 |

| Outer Layer Thickness | −0.000547 | −0.813641802 |

| Name | Maximum Stress | Maximum Displacement |

|---|---|---|

| Outer Layer Material | −0.176361891 | −0.475591571 |

| Inner Layer Material | −0.978232335 | −0.897922165 |

| Sources | Max Displacement | Max Stress |

|---|---|---|

| Inner Radius | 40.531 | 87.472 |

| Inner Radius–Outer Layer Thickness | −2.039 | −0.32753 |

| Inner Radius–Solid Extruded Length | 0.18253 | 0.82108 |

| Outer Layer Thickness | −56.962 | 8.1345 |

| Outer Layer Thickness–Solid Extruded Length | 0.063 | 1.1223 |

| Solid Extruded Length | −0.22316 | 2.1222 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

El-Agroudy, M.N.; Awad, M.I.; Maged, S.A. Soft Finger Modelling and Co-Simulation Control towards Assistive Exoskeleton Hand Glove. Micromachines 2021, 12, 181. https://doi.org/10.3390/mi12020181

El-Agroudy MN, Awad MI, Maged SA. Soft Finger Modelling and Co-Simulation Control towards Assistive Exoskeleton Hand Glove. Micromachines. 2021; 12(2):181. https://doi.org/10.3390/mi12020181

Chicago/Turabian StyleEl-Agroudy, Mohammed N., Mohammed I. Awad, and Shady A. Maged. 2021. "Soft Finger Modelling and Co-Simulation Control towards Assistive Exoskeleton Hand Glove" Micromachines 12, no. 2: 181. https://doi.org/10.3390/mi12020181

APA StyleEl-Agroudy, M. N., Awad, M. I., & Maged, S. A. (2021). Soft Finger Modelling and Co-Simulation Control towards Assistive Exoskeleton Hand Glove. Micromachines, 12(2), 181. https://doi.org/10.3390/mi12020181