Methodologies for Fabricating Flexible Supercapacitors

Abstract

1. Introduction

2. Design Strategies for Flexible Supercapacitors

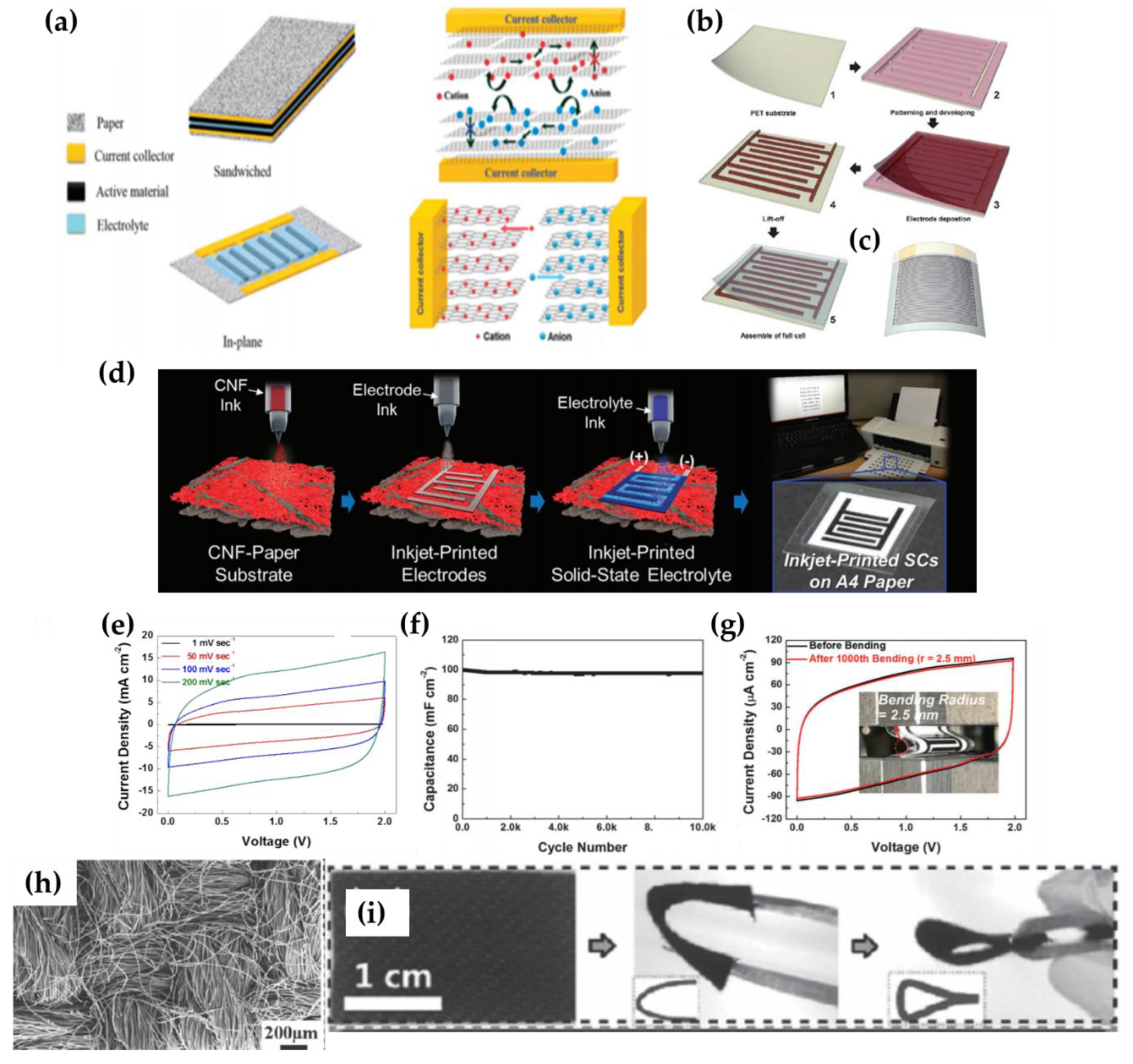

2.1. Paper and Other Paper-Thin Substrates

2.2. Textile Configuration

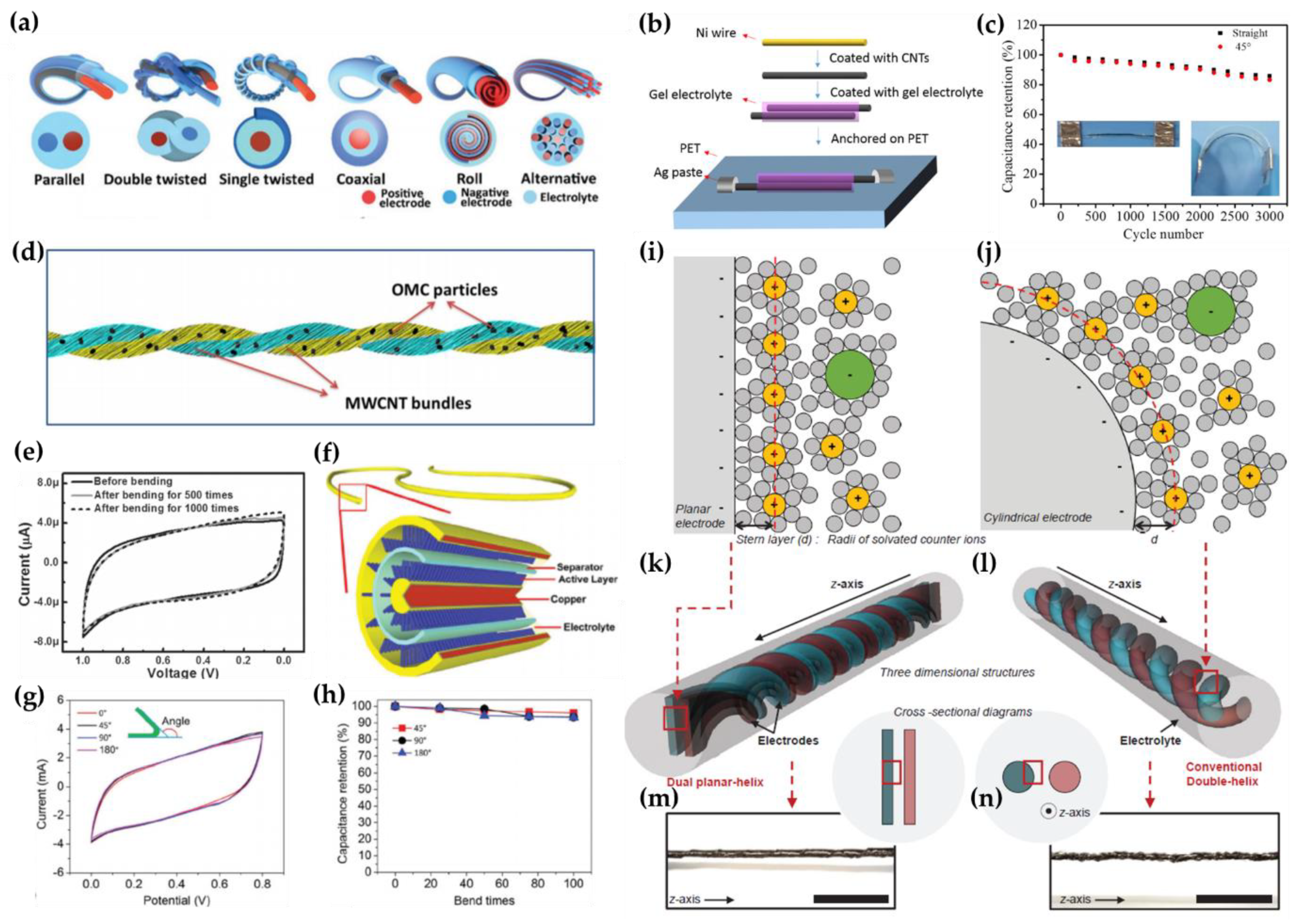

2.3. Wire Configuration

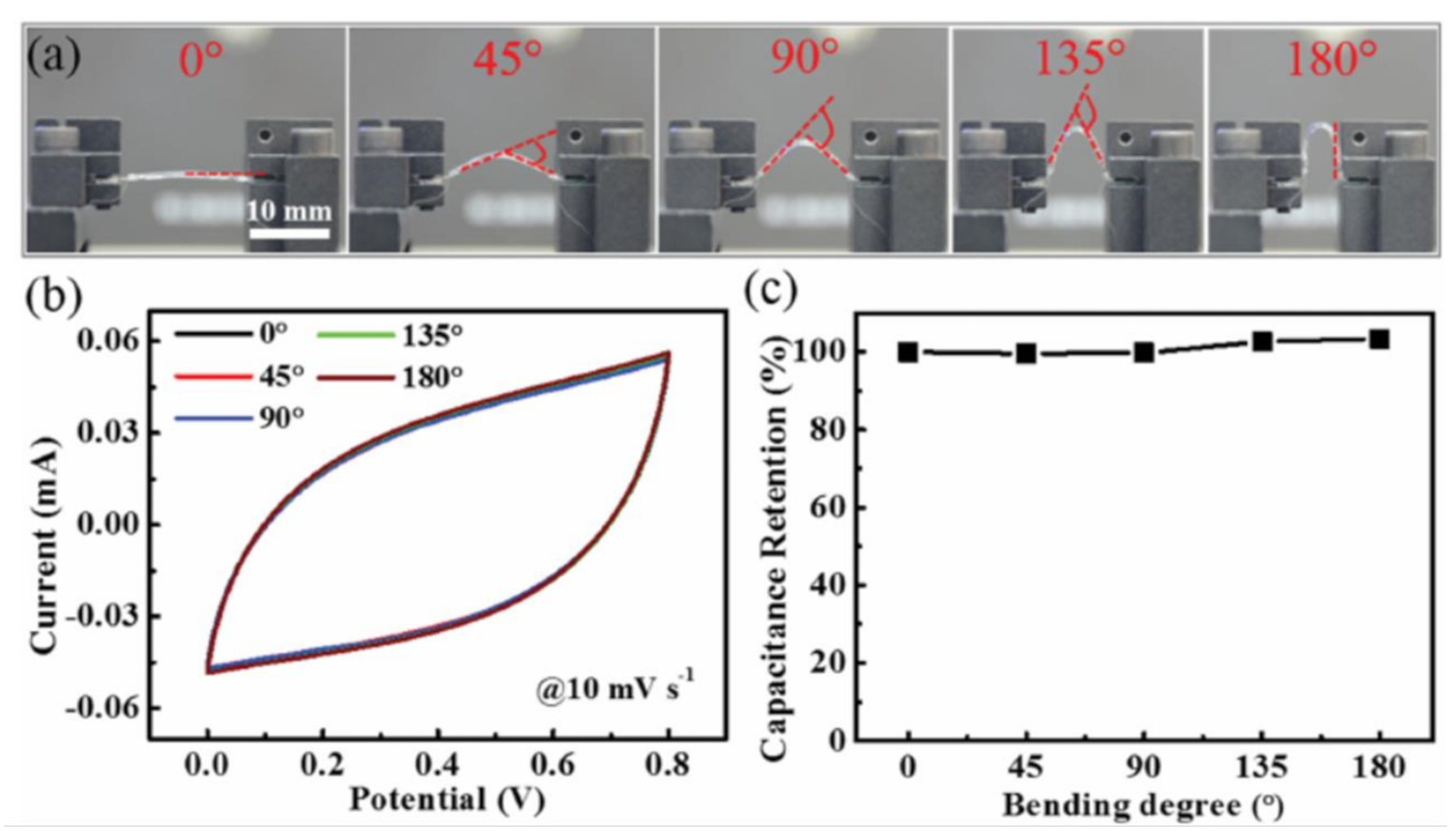

2.4. Origami-Shaped SCs

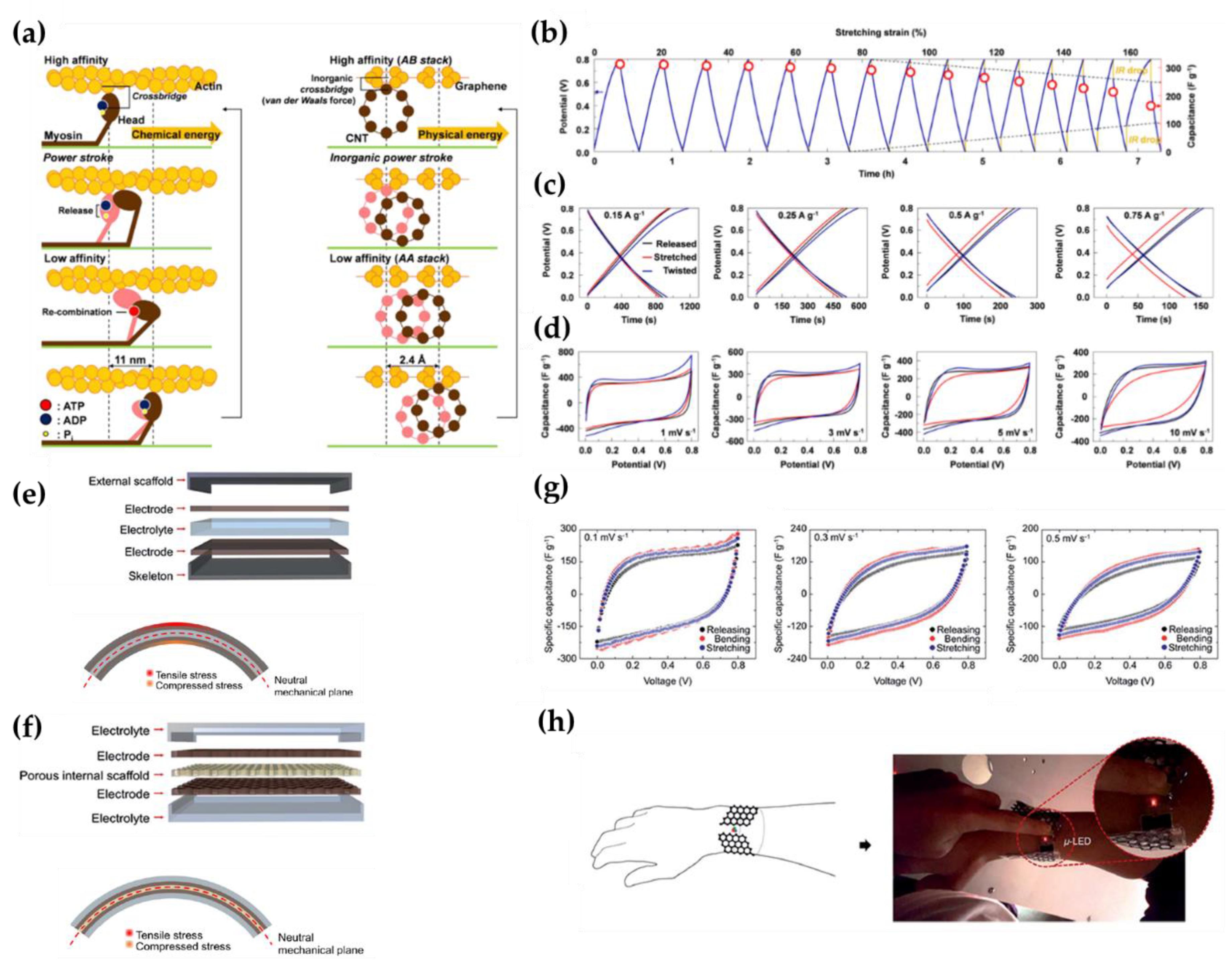

2.5. Biomimetic Configuration

2.5.1. Actin-Myosin Induced Omni-Directional Stretchable System

2.5.2. Endoskeleton Structure Energy Storage System

2.6. Micro-Supercapacitors

3. Conclusions and Future Perspectives

Author Contributions

Funding

Conflicts of Interest

References

- Hartwig, M.; Zichner, R.; Joseph, Y. Inkjet-printed wireless chemiresistive sensors—A review. Chemosensors 2018, 6, 66. [Google Scholar] [CrossRef]

- Chung, S.J.; Cho, K.J.; Lee, T. Recent progress in inkjet-printed thin-film transistors. Adv. Sci. 2019, 6, 1801445. [Google Scholar] [CrossRef] [PubMed]

- Huang, Q.; Zhu, Y. Printing conductive nanomaterials for flexible and stretchable electronics: A review of materials, processes, and applications. Adv. Mater. Technol. 2019, 4, 1800546. [Google Scholar] [CrossRef]

- Yoon, K.J.; Han, J.W.; Moon, D.I.; Seol, M.L.; Meyyappan, M.; Kim, H.J.; Hwang, C.S. Electrically-generated memristor based on inkjet printed silver nanoparticles. Nanoscale Adv. 2019, 1, 2990–2998. [Google Scholar] [CrossRef]

- Zhang, D.; Huang, T.; Duan, L. Emerging self-emissive technologies for flexible displays. Adv. Mater. 2020, 32, 1902391. [Google Scholar] [CrossRef] [PubMed]

- Koo, J.K.; Kim, D.C.; Shim, H.J.; Kim, T.H.; Kim, D.H. Flexible and stretchable smart display: Materials, fabrication, device design, and system integration. Adv. Funct. Mater. 2018, 28, 1801834. [Google Scholar] [CrossRef]

- Goncalves, S.; Serrado-Nunes, J.; Oliveira, J.; Pereira, N.; Hilliou, L.; Costa, C.M. Environmentally friendly printable piezoelectric inks and their application in the development of all-printed touch screens. ACS Appl. Electron. Mater. 2019, 1, 1678–1687. [Google Scholar] [CrossRef]

- Chmiola, J.; Largeot, C.; Taberna, P.L.; Simon, P.; Gogotsi, Y. Monolithic carbide-derived carbon films for micro-supercapacitors. Science 2010, 328, 480–483. [Google Scholar] [CrossRef]

- Yang, P.; Mai, W. Flexible solid-state electrochemical supercapacitors. Nano Energy 2014, 8, 274–290. [Google Scholar] [CrossRef]

- Dong, L.; Xu, C.; Li, Y.; Huang, Z.-H.; Kang, F.; Yang, Q.-H.; Zhao, X. Flexible electrodes and supercapacitors for wearable energy storage: A review by category. J. Mater. Chem. A 2016, 4, 4659–4685. [Google Scholar] [CrossRef]

- Kang, Y.J.; Chun, S.-J.; Lee, S.-S.; Kim, B.-Y.; Kim, J.H.; Chung, H.; Lee, S.-Y.; Kim, W. All-Solid-State Flexible Supercapacitors Fabricated with Bacterial Nanocellulose Papers, Carbon Nanotubes, and Triblock-Copolymer Ion Gels. ACS Nano 2012, 6, 6400–6406. [Google Scholar] [CrossRef]

- Yuan, L.; Lu, X.-H.; Xiao, X.; Zhai, T.; Dai, J.; Zhang, F.; Hu, B.; Wang, X.; Gong, L.; Chen, J.; et al. Flexible Solid-State Supercapacitors Based on Carbon Nanoparticles/MnO2 Nanorods Hybrid Structure. ACS Nano 2012, 6, 656–661. [Google Scholar] [CrossRef]

- Peng, X.; Peng, L.; Wu, C.; Xie, Y. Two dimensional nanomaterials for flexible supercapacitors. Chem. Soc. Rev. 2014, 43, 3303–3323. [Google Scholar] [CrossRef]

- Dubal, D.P.; Chodankar, N.R.; Kim, D.-H.; Gomez-Romero, P. Towards flexible solid-state supercapacitors for smart and wearable electronics. Chem. Soc. Rev. 2018, 47, 2065–2129. [Google Scholar] [CrossRef]

- Gwon, H.; Kim, H.-S.; Lee, K.U.; Seo, D.-H.; Park, Y.C.; Lee, Y.-S.; Ahn, B.T.; Kang, K. Flexible energy storage devices based on graphene paper. Energy Environ. Sci. 2011, 4, 1277–1283. [Google Scholar] [CrossRef]

- Zhang, Y.-Z.; Wang, Y.; Cheng, T.; Lai, W.-Y.; Pang, H.; Huang, W. Flexible supercapacitors based on paper substrates: A new paradigm for low-cost energy storage. Chem. Soc. Rev. 2015, 44, 5181–5199. [Google Scholar] [CrossRef] [PubMed]

- Nam, I.; Park, S.; Kim, G.-P.; Park, J.; Yi, J. Transparent and ultra-bendable all-solid-state supercapacitors without percolation problems. Chem. Sci. 2013, 4, 1663–1667. [Google Scholar] [CrossRef]

- King, P.J.; Higgins, T.M.; De, S.; Nicoloso, N.; Coleman, J.N. Percolation Effects in Supercapacitors with Thin, Transparent Carbon Nanotube Electrodes. ACS Nano 2012, 6, 1732–1741. [Google Scholar] [CrossRef] [PubMed]

- Yu, A.; Roes, I.; Davies, A.; Chen, Z. Ultrathin, transparent, and flexible graphene films for supercapacitor application. Appl. Phys. Lett. 2010, 96, 253105. [Google Scholar] [CrossRef]

- Ge, J.; Cheng, G.; Chen, L. Transparent and flexible electrodes and supercapacitors using polyaniline/single-walled carbon nanotube composite thin films. Nanoscale 2011, 3, 3084–3088. [Google Scholar] [CrossRef] [PubMed]

- Chen, P.-C.; Shen, G.; Sukcharoenchoke, S.; Zhou, C. Flexible and transparent supercapacitor based on In2O3 nanowire/carbon nanotube heterogeneous films. Appl. Phys. Lett. 2009, 94, 043113. [Google Scholar] [CrossRef]

- Choi, K.-H.; Yoo, J.; Lee, C.K.; Lee, S.-Y. All-inkjet-printed, solid-state flexible supercapacitors on paper. Energy Environ. Sci. 2016, 9, 2812–2821. [Google Scholar] [CrossRef]

- Decher, G. Fuzzy Nanoassemblies: Toward Layered Polymeric Multicomposites. Science 1997, 277, 1232. [Google Scholar] [CrossRef]

- Cho, J.; Char, K.; Hong, J.-D.; Lee, K.-B. Fabrication of Highly Ordered Multilayer Films Using a Spin Self-Assembly Method. Adv. Mater. 2001, 13, 1076–1078. [Google Scholar] [CrossRef]

- Ko, Y.; Kwon, M.; Bae, W.K.; Lee, B.; Lee, S.W.; Cho, J. Flexible supercapacitor electrodes based on real metal-like cellulose papers. Nat. Commun. 2017, 8, 536. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Song, M.S.; Kong, B.; Cui, Y. Flexible and Stretchable Energy Storage: Recent Advances and Future Perspectives. Adv. Mater. 2017, 29, 1603436. [Google Scholar] [CrossRef] [PubMed]

- Zhou, W.; Zhou, K.; Liu, X.; Hu, R.; Liu, H.; Chen, S. Flexible wire-like all-carbon supercapacitors based on porous core–shell carbon fibers. J. Mater. Chem. A 2014, 2, 7250–7255. [Google Scholar] [CrossRef]

- Wang, K.; Meng, Q.; Zhang, Y.; Wei, Z.; Miao, M. High-Performance Two-Ply Yarn Supercapacitors Based on Carbon Nanotubes and Polyaniline Nanowire Arrays. Adv. Mater. 2013, 25, 1494–1498. [Google Scholar] [CrossRef]

- Hsu, Y.-K.; Chen, Y.-C.; Lin, Y.-G.; Chen, L.-C.; Chen, K.-H. High-cell-voltage supercapacitor of carbon nanotube/carbon cloth operating in neutral aqueous solution. J. Mater. Chem. 2012, 22, 3383–3387. [Google Scholar] [CrossRef]

- Wang, K.-P.; Teng, H. The performance of electric double layer capacitors using particulate porous carbons derived from PAN fiber and phenol-formaldehyde resin. Carbon 2006, 44, 3218–3225. [Google Scholar] [CrossRef]

- Dong, L.; Xu, C.; Li, Y.; Wu, C.; Jiang, B.; Yang, Q.; Zhou, E.; Kang, F.; Yang, Q.-H. Simultaneous Production of High-Performance Flexible Textile Electrodes and Fiber Electrodes for Wearable Energy Storage. Adv. Mater. 2016, 28, 1675–1681. [Google Scholar] [CrossRef] [PubMed]

- Cheng, H.; Dong, Z.; Hu, C.; Zhao, Y.; Hu, Y.; Qu, L.; Chen, N.; Dai, L. Textile electrodes woven by carbon nanotube–graphene hybrid fibers for flexible electrochemical capacitors. Nanoscale 2013, 5, 3428–3434. [Google Scholar] [CrossRef] [PubMed]

- Cakici, M.; Kakarla, R.R.; Alonso-Marroquin, F. Advanced electrochemical energy storage supercapacitors based on the flexible carbon fiber fabric-coated with uniform coral-like MnO2 structured electrodes. Chem. Eng. J. 2017, 309, 151–158. [Google Scholar] [CrossRef]

- Fu, Y.; Cai, X.; Wu, H.; Lv, Z.; Hou, S.; Peng, M.; Yu, X.; Zou, D. Fiber Supercapacitors Utilizing Pen Ink for Flexible/Wearable Energy Storage. Adv. Mater. 2012, 24, 5713–5718. [Google Scholar] [CrossRef]

- Ren, J.; Bai, W.; Guan, G.; Zhang, Y.; Peng, H. Flexible and Weaveable Capacitor Wire Based on a Carbon Nanocomposite Fiber. Adv. Mater. 2013, 25, 5965–5970. [Google Scholar] [CrossRef]

- Yu, Z.; Thomas, J. Energy Storing Electrical Cables: Integrating Energy Storage and Electrical Conduction. Adv. Mater. 2014, 26, 4279–4285. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Li, Y.; Zhang, Z.; Chen, J.; Li, Y.; Ma, Y. Capillarity-driven assembly of single-walled carbon nanotubes onto nickel wires for flexible wire-shaped supercapacitors. Mater. Sci. Energy Technol. 2018, 1, 91–96. [Google Scholar] [CrossRef]

- Niu, Z.; Zhang, L.; Liu, L.; Zhu, B.; Dong, H.; Chen, X. All-Solid-State Flexible Ultrathin Micro-Supercapacitors Based on Graphene. Adv. Mater. 2013, 25, 4035–4042. [Google Scholar] [CrossRef]

- Park, J.; Kim, G.-P.; Umh, H.N.; Nam, I.; Park, S.; Kim, Y.; Yi, J. Co3O4 nanoparticles embedded in ordered mesoporous carbon with enhanced performance as an anode material for Li-ion batteries. J. Nanopart. Res. 2013, 15, 1943. [Google Scholar] [CrossRef]

- Li, X.; Chen, X.; Jin, Z.; Li, P.; Xiao, D. Recent progress in conductive polymers for advanced fiber-shaped electrochemical energy storage devices. Mater. Chem. Front. 2020. [Google Scholar] [CrossRef]

- Yu, Z.; Moore, J.; Calderon, J.; Zhai, L.; Thomas, J. Coil-Type Asymmetric Supercapacitor Electrical Cables. Small 2015, 11, 5289–5295. [Google Scholar] [CrossRef] [PubMed]

- Cheng, X.; Gui, X.; Lin, Z.; Zheng, Y.; Liu, M.; Zhan, R.; Zhu, Y.; Tang, Z. Three-dimensional α-Fe2O3/carbon nanotube sponges as flexible supercapacitor electrodes. J. Mater. Chem. A 2015, 3, 20927–20934. [Google Scholar] [CrossRef]

- Yu, D.; Qian, Q.; Wei, L.; Jiang, W.; Goh, K.; Wei, J.; Zhang, J.; Chen, Y. Emergence of fiber supercapacitors. Chem. Soc. Rev. 2015, 44, 647–662. [Google Scholar] [CrossRef] [PubMed]

- Yu, S.; Patil, B.; Ahn, H. Flexible, fiber-shaped supercapacitors with roll-type assembly. J. Ind. Eng. Chem. 2019, 71, 220–227. [Google Scholar] [CrossRef]

- Nam, I.; Park, J.; Park, S.; Bae, S.; Yoo, Y.G.; Yi, J. Dual Planar-Helix Type Energy Storage Wires to Circumvent Universal Energy Lag Effect. Adv. Energy Mater. 2016, 6, 1501812. [Google Scholar] [CrossRef]

- Nam, I.; Park, J.; Bae, S.; Park, S.; Yoo, Y.G.; Yi, J. Energy storage systems based on endoskeleton structuring. J. Mater. Chem. A 2016, 4, 13228–13234. [Google Scholar] [CrossRef]

- Guo, K.; Ma, Y.; Li, H.; Zhai, T. Flexible Wire-Shaped Supercapacitors in Parallel Double Helix Configuration with Stable Electrochemical Properties under Static/Dynamic Bending. Small 2016, 12, 1024–1033. [Google Scholar] [CrossRef]

- Song, Z.; Ma, T.; Tang, R.; Cheng, Q.; Wang, X.; Krishnaraju, D.; Panat, R.; Chan, C.K.; Yu, H.; Jiang, H. Origami lithium-ion batteries. Nat. Commun. 2014, 5, 3140. [Google Scholar] [CrossRef]

- Nam, I.; Kim, G.-P.; Park, S.; Han, J.W.; Yi, J. All-solid-state, origami-type foldable supercapacitor chips with integrated series circuit analogues. Energy Environ. Sci. 2014, 7, 1095–1102. [Google Scholar] [CrossRef]

- Junzhi, Y.; Long, W.; Min, T. A framework for biomimetic robot fish’s design and its realization. In Proceedings of the 2005, American Control Conference, Portland, OR, USA, 8–10 June 2005; American Automatic Control Council; IEEE: Evanston, IL, USA; Piscataway, NJ, USA, 2005; Volume 1593, pp. 1593–1598. [Google Scholar]

- Laschi, C.; Mazzolai, B.; Mattoli, V.; Cianchetti, M.; Dario, P. Design of a biomimetic robotic octopus arm. Bioinspir. Biomim. 2009, 4, 015006. [Google Scholar] [CrossRef] [PubMed]

- Byoung-Ho, K.; Byung-Ju, Y.; Il Hong, S.; Sang-Rok, O.; Yeh-Sun, H. A biomimetic compliance control of robot hand by considering structures of human finger. In Proceedings of the 2000 ICRA. Millennium Conference. IEEE International Conference on Robotics and Automation, Symposia Proceedings (Cat. No.00CH37065), San Francisco, CA, USA, 24–28 April 2000; IEEE: Piscataway, NJ, USA, 2000; Volume 3874, pp. 3879–3886. [Google Scholar]

- Ghaemmaghami, A.M.; Hancock, M.J.; Harrington, H.; Kaji, H.; Khademhosseini, A. Biomimetic tissues on a chip for drug discovery. Drug Discov. Today 2012, 17, 173–181. [Google Scholar] [CrossRef] [PubMed]

- Richards, D.J.; Coyle, R.C.; Tan, Y.; Jia, J.; Wong, K.; Toomer, K.; Menick, D.R.; Mei, Y. Inspiration from heart development: Biomimetic development of functional human cardiac organoids. Biomaterials 2017, 142, 112–123. [Google Scholar] [CrossRef] [PubMed]

- Nam, I.; Bae, S.; Park, S.; Yoo, Y.G.; Lee, J.M.; Han, J.W.; Yi, J. Omnidirectionally stretchable, high performance supercapacitors based on a graphene–carbon-nanotube layered structure. Nano Energy 2015, 15, 33–42. [Google Scholar] [CrossRef]

- Ginga, N.J.; Chen, W.; Sitaraman, S.K. Waviness reduces effective modulus of carbon nanotube forests by several orders of magnitude. Carbon 2014, 66, 57–66. [Google Scholar] [CrossRef]

- Lee, J.H.; Park, N.; Kim, B.G.; Jung, D.S.; Im, K.; Hur, J.; Choi, J.W. Restacking-Inhibited 3D Reduced Graphene Oxide for High Performance Supercapacitor Electrodes. ACS Nano 2013, 7, 9366–9374. [Google Scholar] [CrossRef]

- Yoo, J.J.; Balakrishnan, K.; Huang, J.; Meunier, V.; Sumpter, B.G.; Srivastava, A.; Conway, M.; Mohana Reddy, A.L.; Yu, J.; Vajtai, R.; et al. Ultrathin Planar Graphene Supercapacitors. Nano Lett. 2011, 11, 1423–1427. [Google Scholar] [CrossRef]

- Zhu, Y.; Murali, S.; Stoller, M.D.; Ganesh, K.J.; Cai, W.; Ferreira, P.J.; Pirkle, A.; Wallace, R.M.; Cychosz, K.A.; Thommes, M.; et al. Carbon-Based Supercapacitors Produced by Activation of Graphene. Science 2011, 332, 1537–1541. [Google Scholar] [CrossRef]

- Cha, W.-I.; Hyon, S.-H.; Oka, M.; Ikada, Y. Mechanical and wear properties of poly (vinyl alcohol) hydrogels. Macromol. Symp. 1996, 109, 115–126. [Google Scholar] [CrossRef]

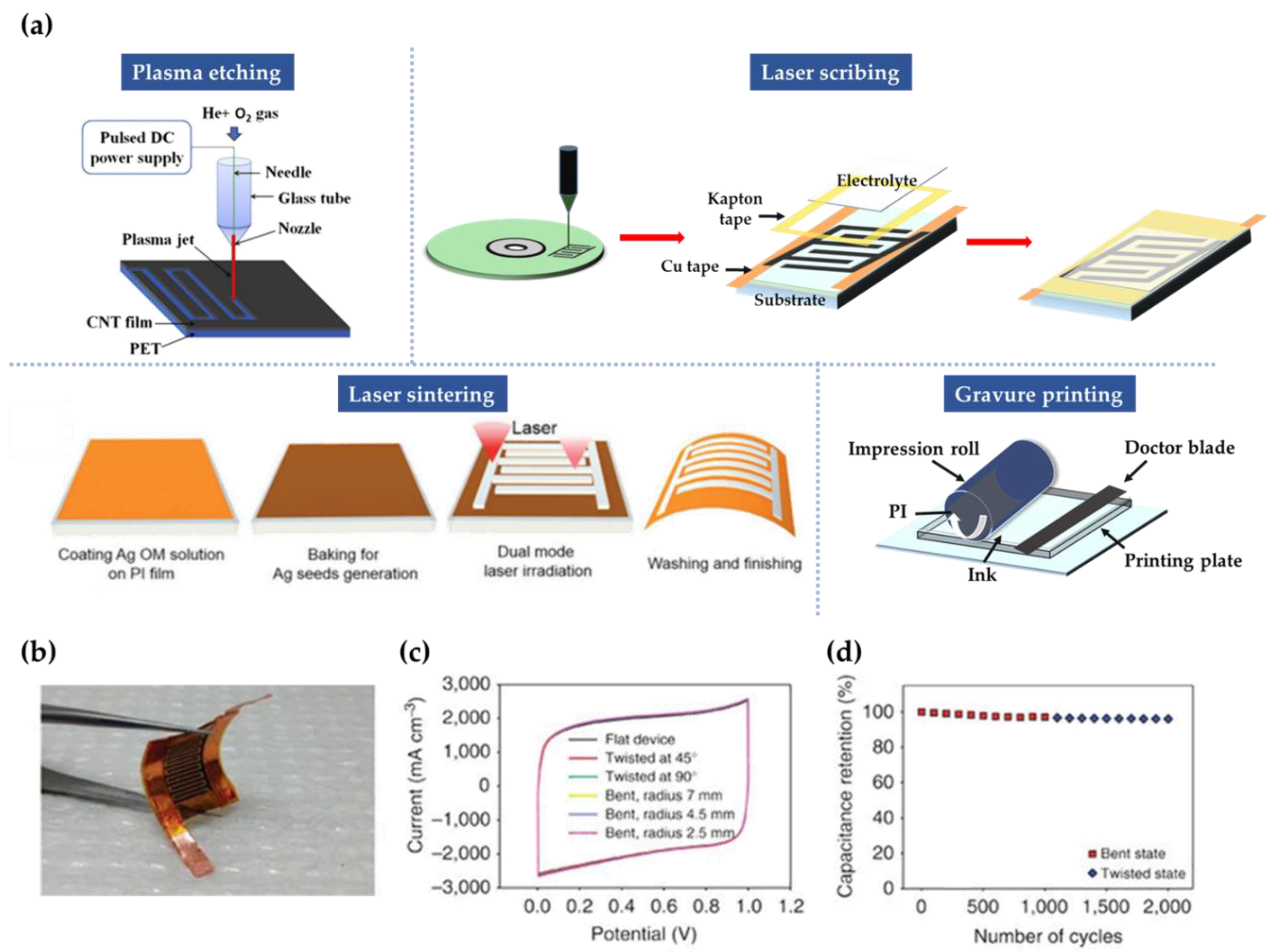

- Liu, L.; Ye, D.; Yu, Y.; Liu, L.; Wu, Y. Carbon-based flexible micro-supercapacitor fabrication via mask-free ambient micro-plasma-jet etching. Sci. Direct 2017, 111, 121–127. [Google Scholar] [CrossRef]

- Rolison, D.R.; Long, J.W.; Lytle, J.C.; Fischer, A.E.; Rhodes, C.P.; McEvoy, T.M.; Bourg, M.E.; Lubers, A.M. Multifunctional 3D nanoarchitectures for energy storage and conversion. Chem. Soc. Rev. 2009, 38, 226–252. [Google Scholar] [CrossRef] [PubMed]

- Pech, D.; Brunet, M.; Durou, H.; Huang, P.; Mochalin, V.; Gogotsi, Y.; Taberna, P.-L.; Simon, P. Ultrahigh-power micrometre-sized supercapacitors based on onion-like carbon. Nat. Nanotechnol. 2010, 5, 651–654. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.S.; Parvez, K.; Feng, X.; Müllen, K. Graphene-based in-plane micro-supercapacitors with high power and energy densities. Nat. Commun. 2013, 4, 2487. [Google Scholar] [CrossRef] [PubMed]

- Guo, G.; Huang, L.; Chang, Q.; Ji, L.; Liu, Y.; Xie, Y.; Shi, W.; Jia, N. Sandwiched nanoarchitecture of reduced graphene oxide/ZnO nanorods/reduced graphene oxide on flexible PET substrate for supercapacitor. Appl. Phys. Lett. 2011, 99, 083111. [Google Scholar] [CrossRef]

- Wang, F.; Zhan, X.; Cheng, Z.; Wang, Q.; Wang, Z.; Wang, F.; Xu, K.; Huang, Y.; Safdar, M.; He, J. A High-Energy-Density Asymmetric Microsupercapacitor for Integrated Energy Systems. Adv. Electron. Mater. 2015, 1, 1400053. [Google Scholar] [CrossRef]

- In, J.B.; Hsia, B.; Yoo, J.-H.; Hyun, S.; Carraro, C.; Maboudian, R.; Grigoropoulos, C.P. Facile fabrication of flexible all solid-state micro-supercapacitor by direct laser writing of porous carbon in polyimide. Carbon 2015, 83, 144–151. [Google Scholar] [CrossRef]

- El-Kady, M.F.; Kaner, R.B. Scalable fabrication of high-power graphene micro-supercapacitors for flexible and on-chip energy storage. Nat. Commun. 2013, 4, 1475. [Google Scholar] [CrossRef]

- Gao, W.; Singh, N.; Song, L.; Liu, Z.; Reddy, A.L.M.; Ci, L.; Vajtai, R.; Zhang, Q.; Wei, B.; Ajayan, P.M. Direct laser writing of micro-supercapacitors on hydrated graphite oxide films. Nat. Nanotechnol. 2011, 6, 496–500. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.S.; Hsia, B.; Carraro, C.; Maboudian, R. Flexible micro-supercapacitors with high energy density from simple transfer of photoresist-derived porous carbon electrodes. Carbon 2014, 74, 163–169. [Google Scholar] [CrossRef]

- Kim, D.; Yun, J.; Lee, G.; Ha, J.S. Fabrication of high performance flexible micro-supercapacitor arrays with hybrid electrodes of MWNT/V2O5 nanowires integrated with a SnO2 nanowire UV sensor. Nanoscale 2014, 6, 12034–12041. [Google Scholar] [CrossRef]

- Wang, S.; Hsia, B.; Carraro, C.; Maboudian, R. High-performance all solid-state micro-supercapacitor based on patterned photoresist-derived porous carbon electrodes and an ionogel electrolyte. J. Mater. Chem. A 2014, 2, 7997–8002. [Google Scholar] [CrossRef]

- Zhang, Q.; Huang, L.; Chang, Q.; Shi, W.; Shen, L.; Chen, Q. Gravure-printed interdigital microsupercapacitors on a flexible polyimide substrate using crumpled graphene ink. Nanotechnology 2016, 27, 105401. [Google Scholar] [CrossRef] [PubMed]

- Jung, H.; Cheah, C.V.; Jeong, N.; Lee, J. Direct printing and reduction of graphite oxide for flexible supercapacitors. Appl. Phys. Lett. 2014, 105, 053902. [Google Scholar] [CrossRef]

- Li, L.; Secor, E.B.; Chen, K.-S.; Zhu, J.; Liu, X.; Gao, T.Z.; Seo, J.-W.T.; Zhao, Y.; Hersam, M.C. High-Performance Solid-State Supercapacitors and Microsupercapacitors Derived from Printable Graphene Inks. Adv. Energy Mater. 2016, 6, 1600909. [Google Scholar] [CrossRef]

- Lee, J.; Seok, J.Y.; Son, S.; Yang, M.; Kang, B. High-energy, flexible micro-supercapacitors by one-step laser fabrication of a self-generated nanoporous metal/oxide electrode. J. Mater. Chem. A 2017, 5, 24585–24593. [Google Scholar] [CrossRef]

- Lupo, D.; Clemens, W.; Breitung, S.; Hecker, K. Applications of organic and printed electronics. In Applications of Organic and Printed Electronics: A Technology-Enabled Revolution; Springer: Boston, MA, USA, 2013; pp. 1–26. [Google Scholar]

- Secor, E.B.; Lim, S.; Zhang, H.; Frisbie, C.D.; Francis, L.F.; Hersam, M.C. Gravure Printing of Graphene for Large-area Flexible Electronics. Adv. Mater. 2014, 26, 4533–4538. [Google Scholar] [CrossRef]

- Yun, J.; Lim, Y.; Lee, H.; Lee, G.; Park, H.; Hong, S.Y.; Jin, S.W.; Lee, Y.H.; Lee, S.-S.; Ha, J.S. A Patterned Graphene/ZnO UV Sensor Driven by Integrated Asymmetric Micro-Supercapacitors on a Liquid Metal Patterned Foldable Paper. Adv. Funct. Mater. 2017, 27, 1700135. [Google Scholar] [CrossRef]

- Seol, M.-L.; Sadatian, E.; Jang, S.; Hill, C.; Nam, I.; Han, J.-W.; Meyyappan, M. Printing of a Passivation Layer for the Protection of Printed Supercapacitors. ACS Appl. Electron. Mater. 2020, 2, 3643–3649. [Google Scholar] [CrossRef]

- Meyyappan, M. Nanostructured Materials for Supercapacitors. J. Vac. Sci. Technol. A 2013, 31, 050803. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jang, S.; Kang, J.; Kwak, S.; Seol, M.-L.; Meyyappan, M.; Nam, I. Methodologies for Fabricating Flexible Supercapacitors. Micromachines 2021, 12, 163. https://doi.org/10.3390/mi12020163

Jang S, Kang J, Kwak S, Seol M-L, Meyyappan M, Nam I. Methodologies for Fabricating Flexible Supercapacitors. Micromachines. 2021; 12(2):163. https://doi.org/10.3390/mi12020163

Chicago/Turabian StyleJang, Seohyeon, Jihyeon Kang, Soyul Kwak, Myeong-Lok Seol, M. Meyyappan, and Inho Nam. 2021. "Methodologies for Fabricating Flexible Supercapacitors" Micromachines 12, no. 2: 163. https://doi.org/10.3390/mi12020163

APA StyleJang, S., Kang, J., Kwak, S., Seol, M.-L., Meyyappan, M., & Nam, I. (2021). Methodologies for Fabricating Flexible Supercapacitors. Micromachines, 12(2), 163. https://doi.org/10.3390/mi12020163