Numerical Study of the Microflow Characteristics in a V-ball Valve

Abstract

1. Introduction

2. Methods

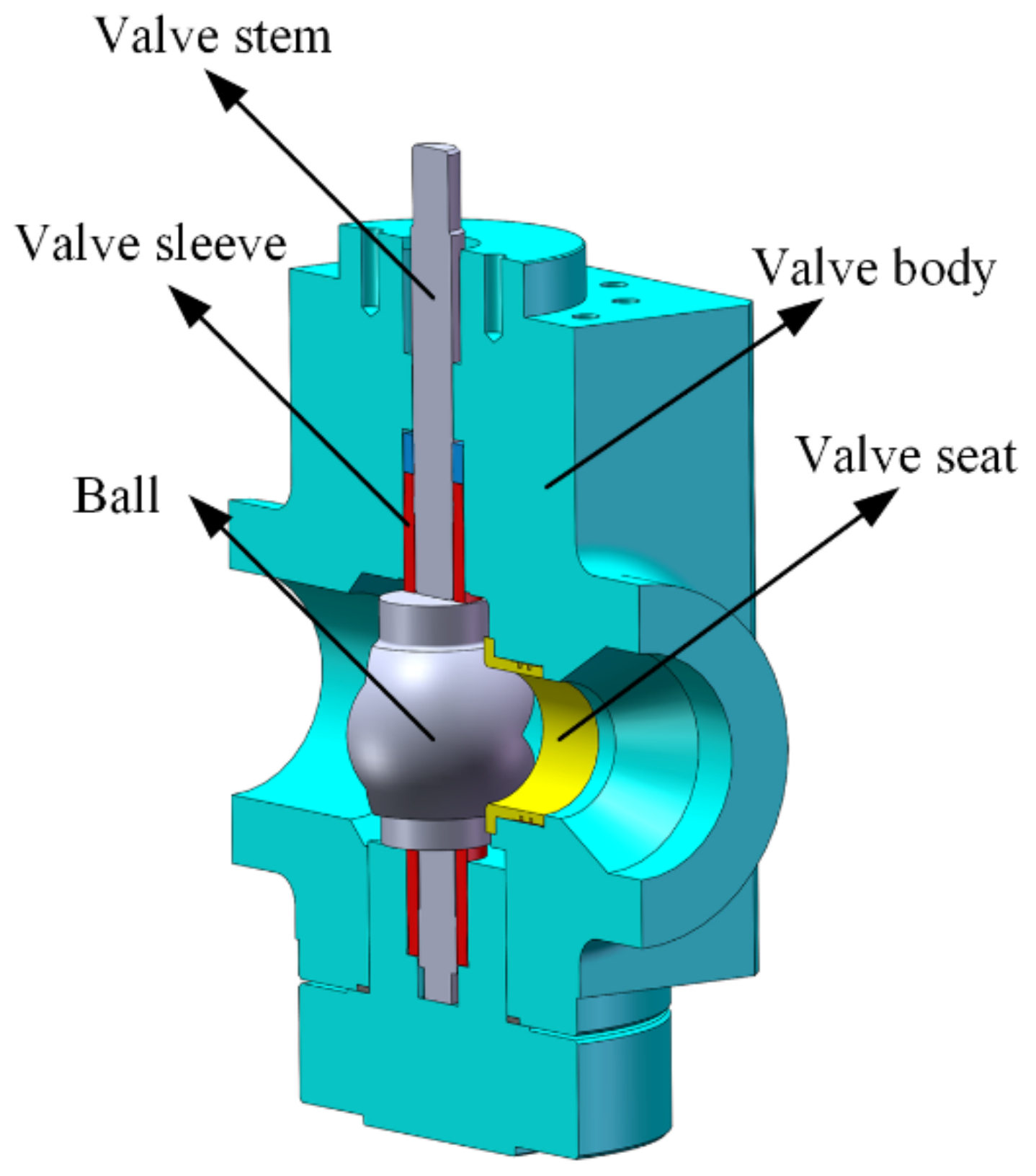

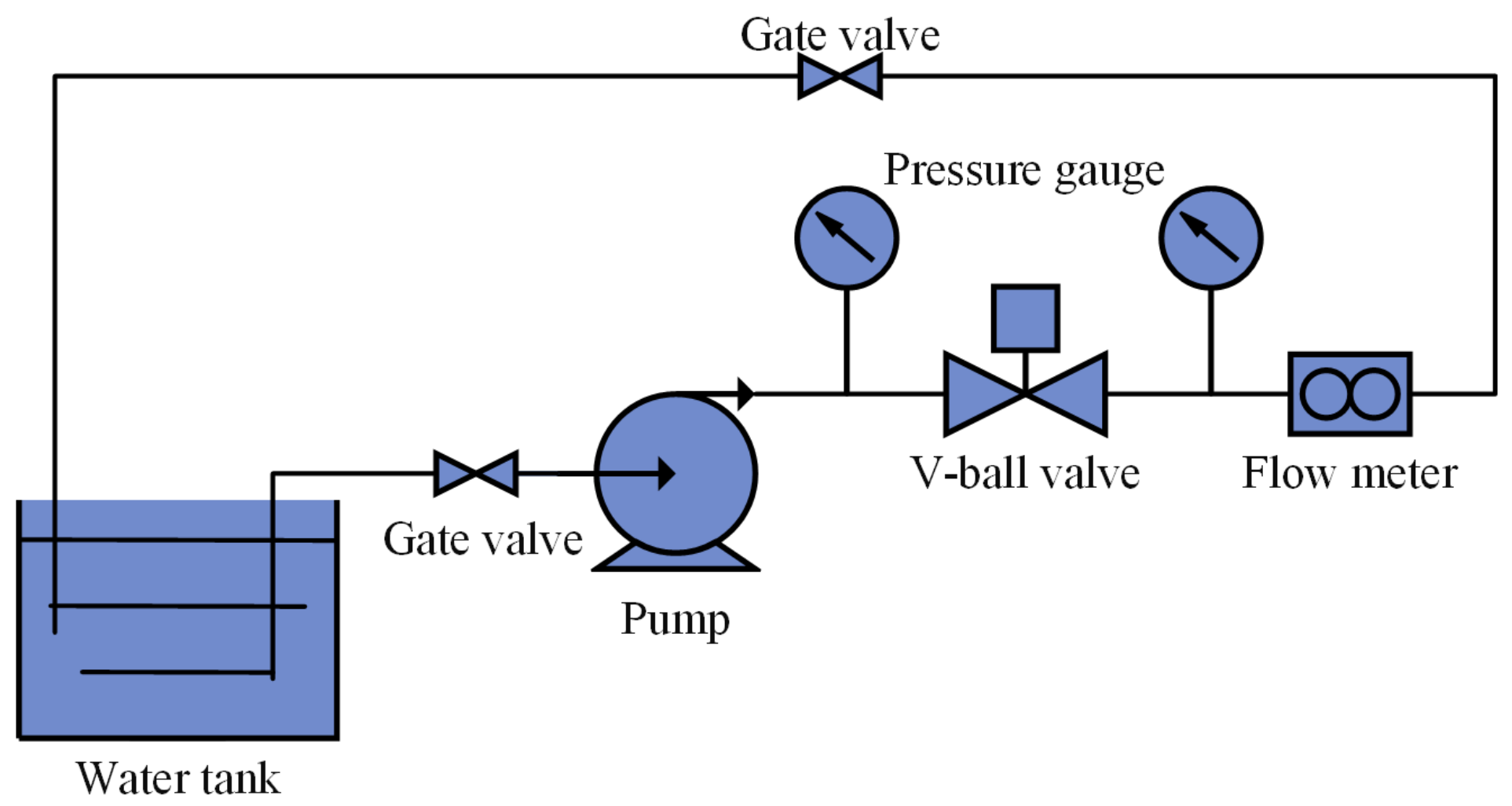

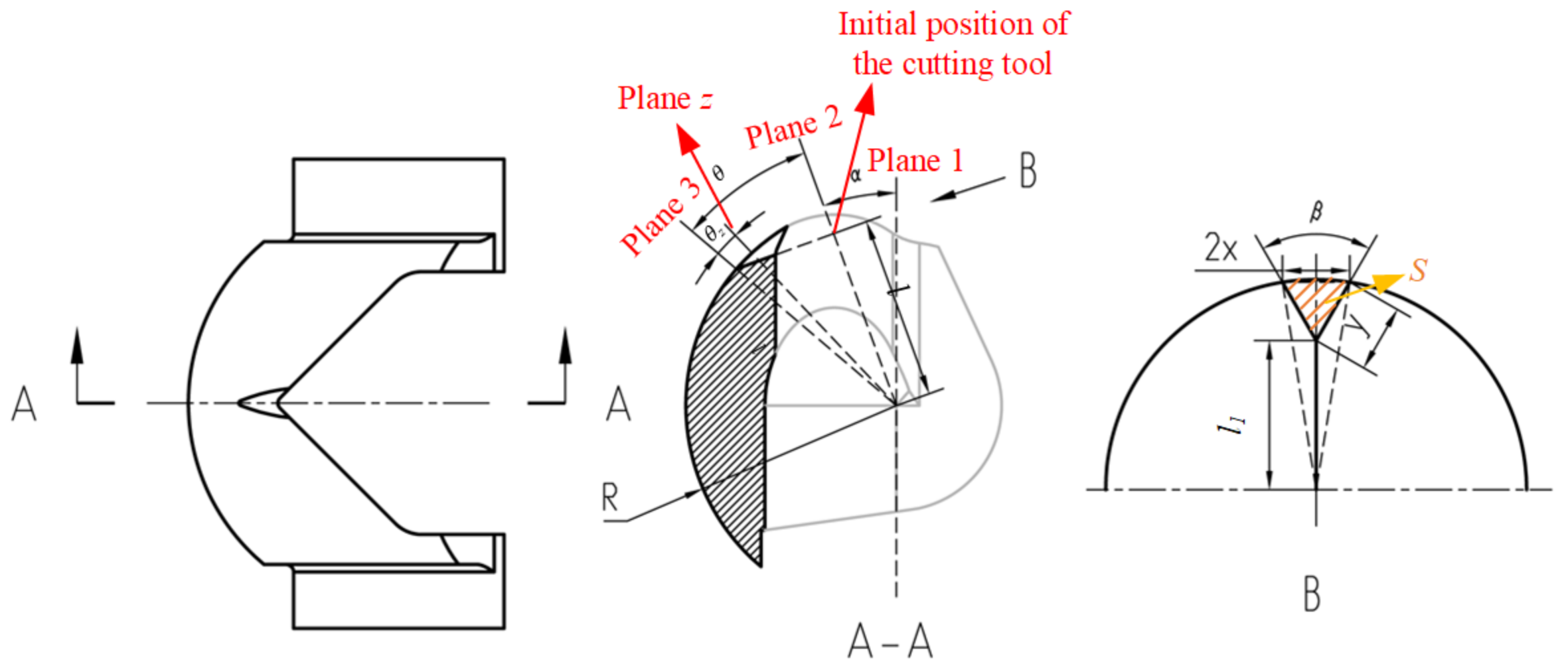

2.1. Physical Model

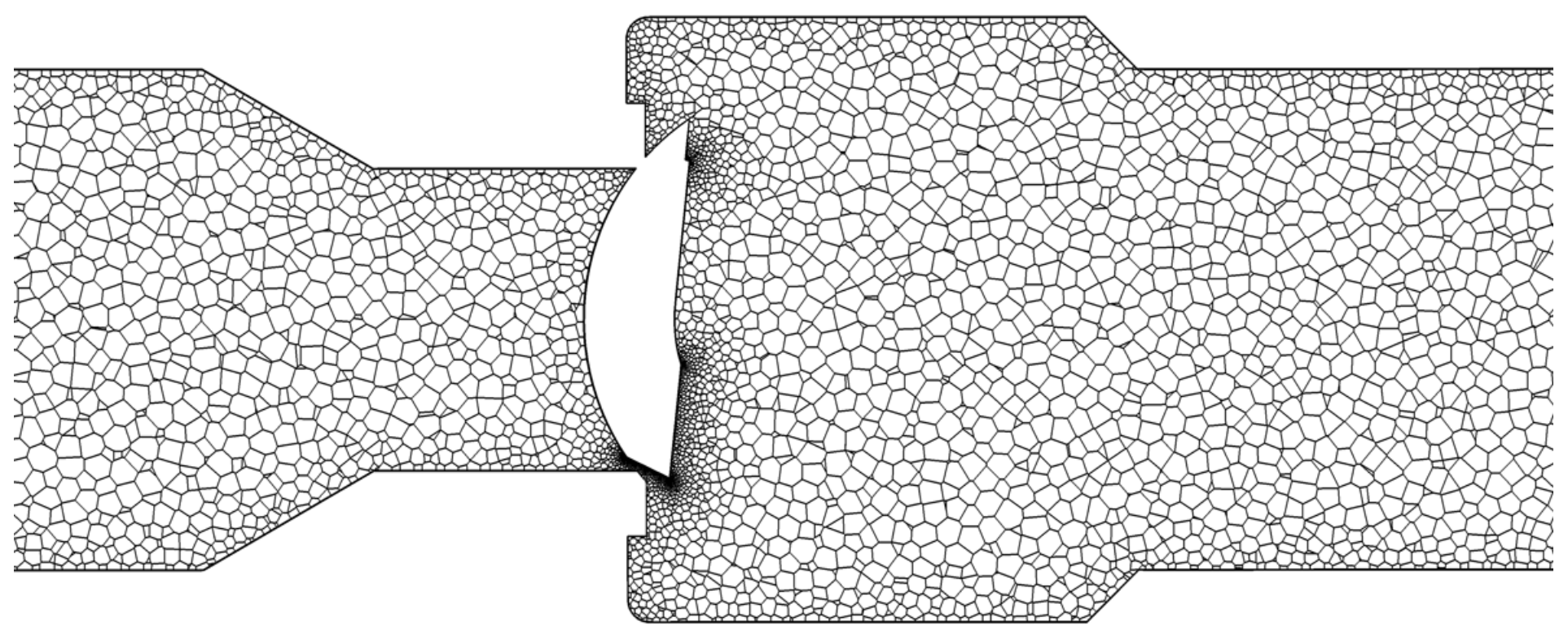

2.2. Numerical Model

2.3. Analysis Method

3. Results

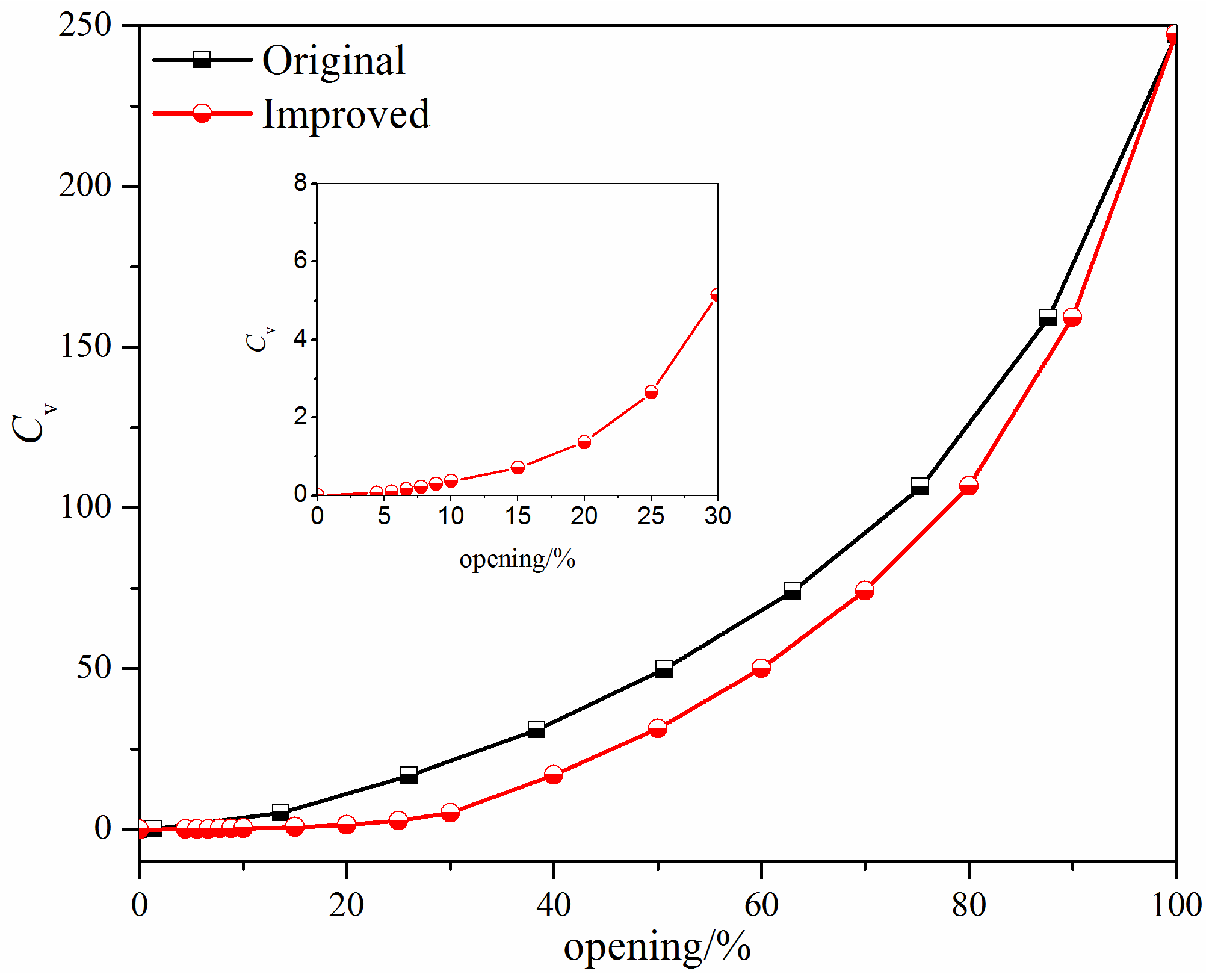

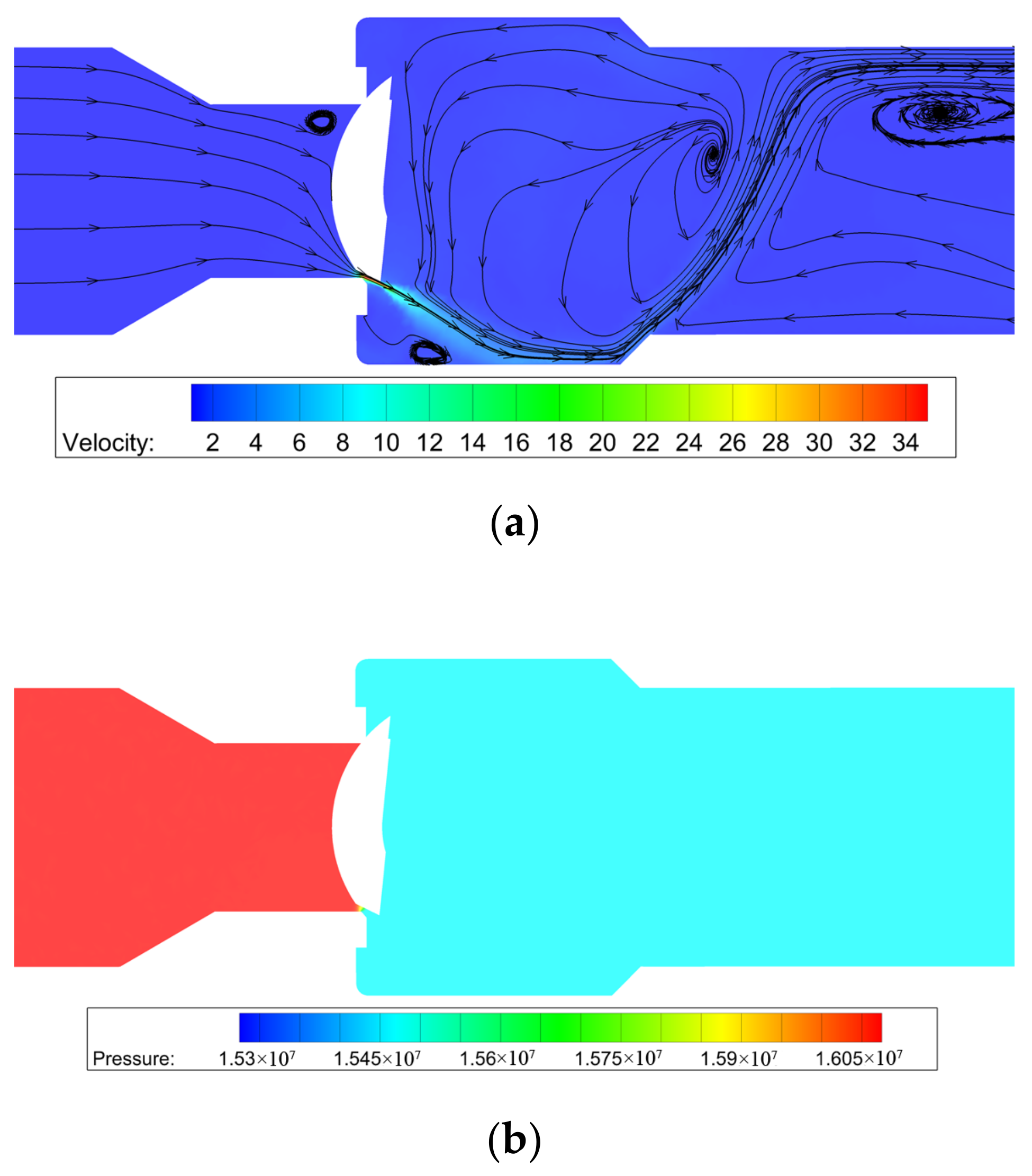

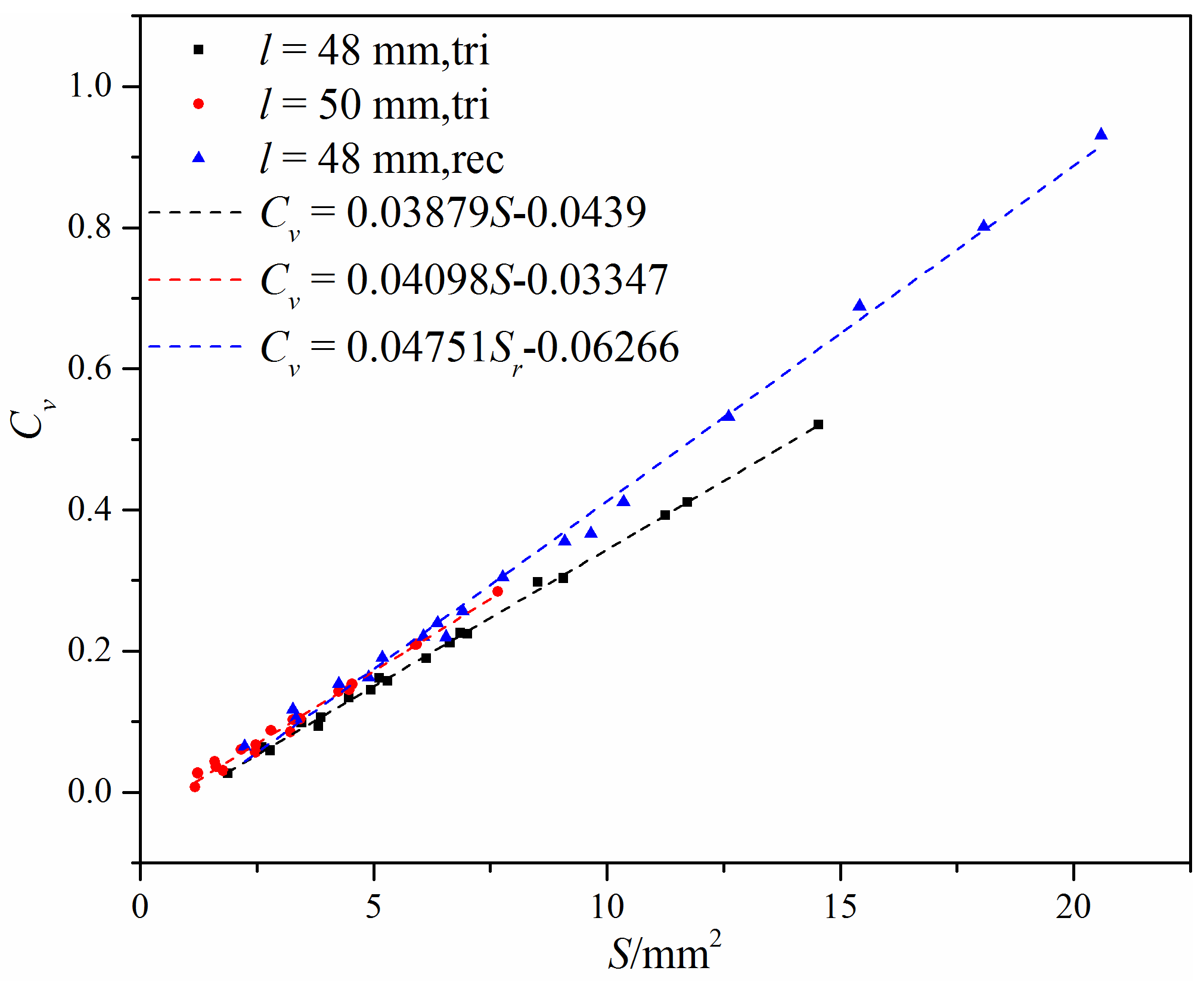

3.1. Flow Coefficient

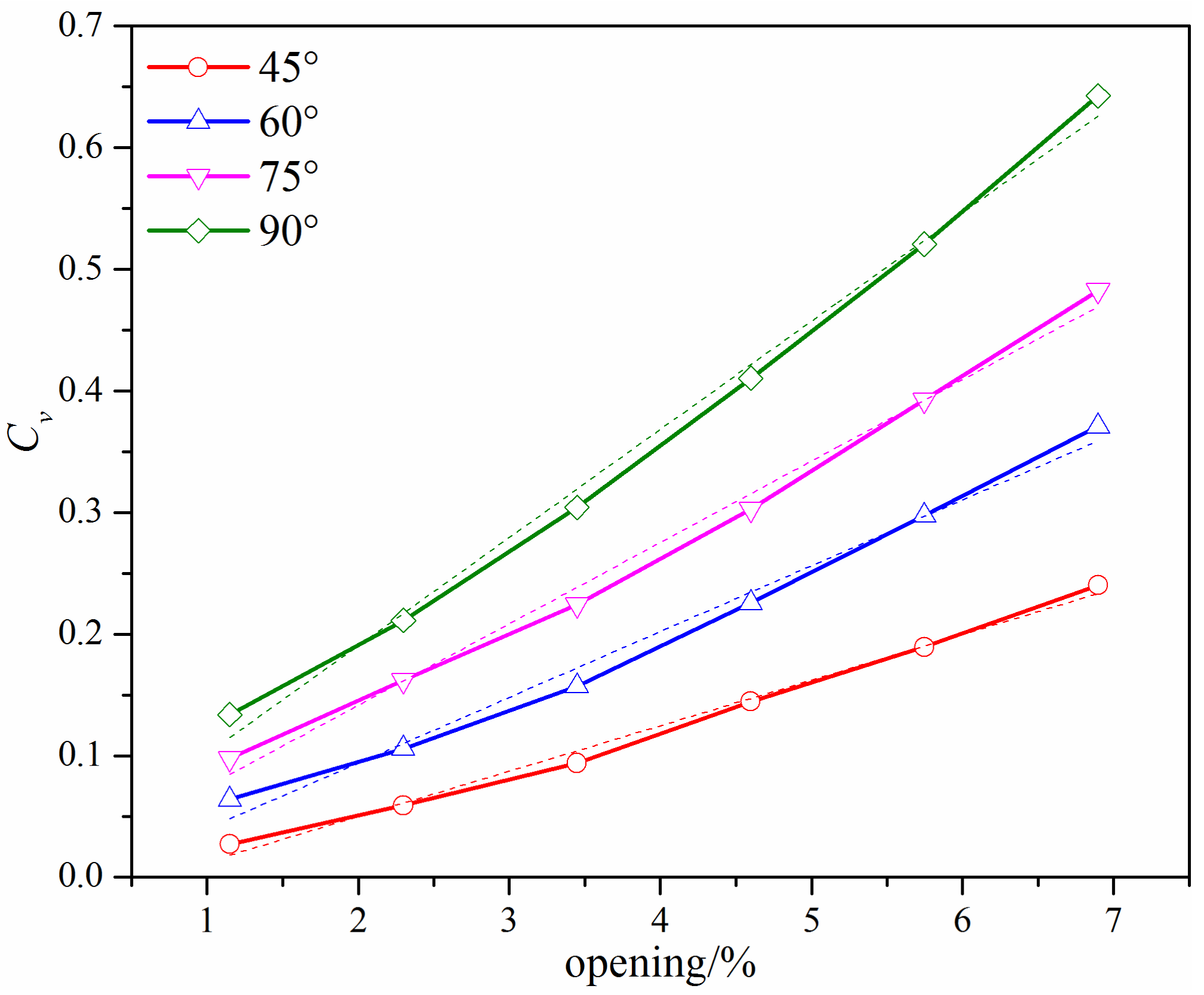

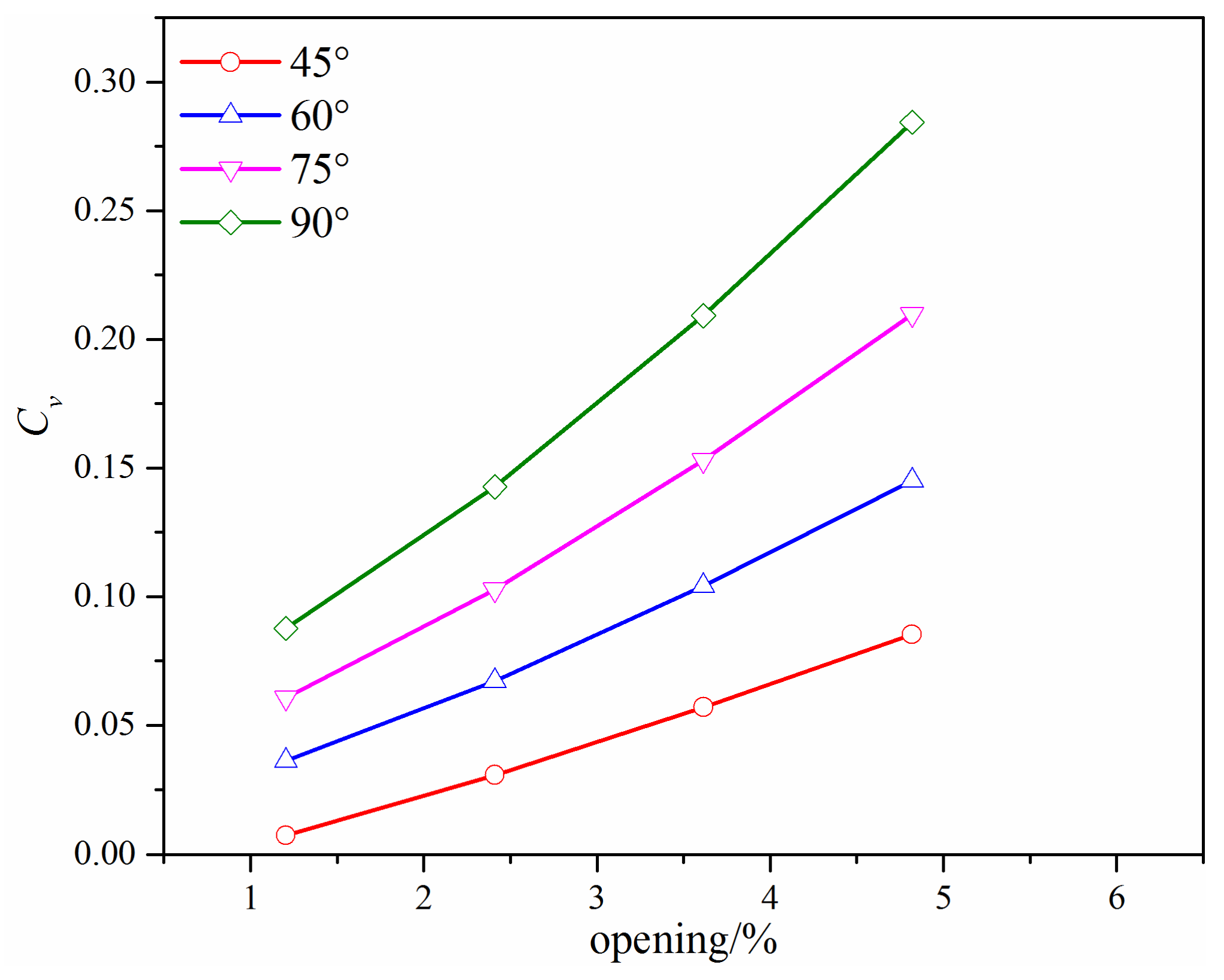

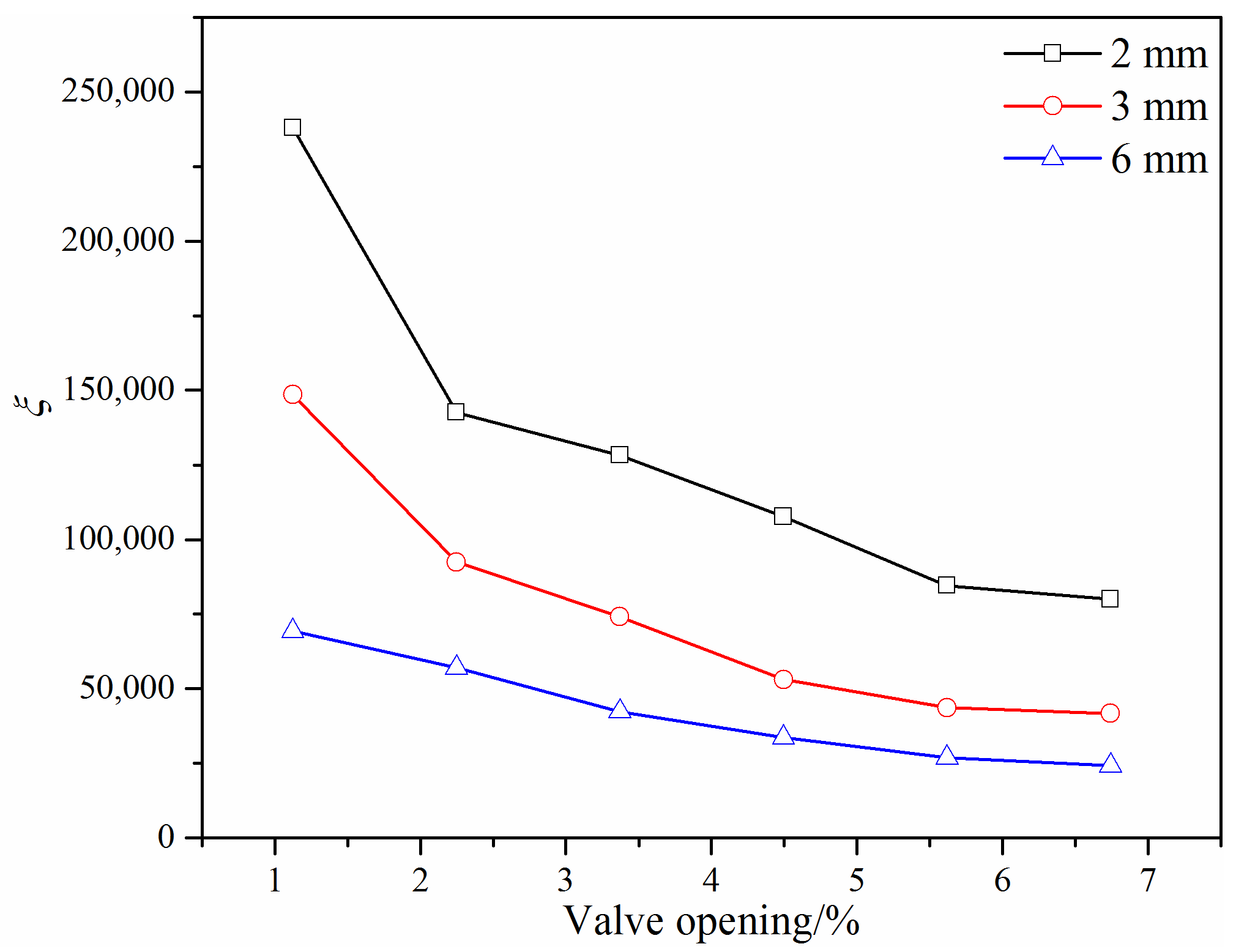

3.2. Loss Coefficient

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yonezawa, K.; Ogawa, R.; Ogi, K.; Takino, T.; Tsujimoto, Y.; Endo, T.; Tezuka, K.; Morita, R.; Inada, F. Flow-induced vibration of a steam control valve. J. Fluids Struct. 2012, 35, 76–88. [Google Scholar] [CrossRef]

- Zeng, L.F.; Liu, G.W.; Mao, J.R.; Wang, S.S.; Yuan, Q.; Yuan, H.; Wang, K.G.; Zhang, J.J.; Xu, Y.T. Flow-induced vibration and noise in control valve. Proc. Inst. Mech. Eng. Part C J. Eng. Mech. Eng. Sci. 2015, 229, 3368–3377. [Google Scholar] [CrossRef]

- Li, L.; Yan, H.; Zhang, H.; Li, J. Numerical simulation and experimental research of the flow force and forced vibration in the nozzle-flapper valve. Mech. Syst. Signal Proc. 2018, 99, 550–566. [Google Scholar] [CrossRef]

- Jin, Z.; Qiu, C.; Jiang, C.; Wu, J.; Qian, J. Effect of valve core shapes on cavitation flow through a sleeve regulating valve. J. Zhejiang Univ. Sci. A 2020, 21, 1–14. [Google Scholar] [CrossRef]

- Jin, Z.; Gao, Z.; Qian, J.; Wu, Z.; Sunden, B. A parametric study of hydrodynamic cavitation inside globe valves. ASME J. Fluids Eng. 2018, 140, 031208. [Google Scholar] [CrossRef]

- Li, J.Y.; Gao, Z.X.; Wu, H.; Jin, Z.J. Numerical Investigation of methodologies for cavitation suppression inside globe valves. Appl. Sci. 2020, 10, 5541. [Google Scholar] [CrossRef]

- Li, W.; Gao, Z.; Jin, Z.; Qian, J. Transient study of flow and cavitation inside a bileaflet mechanical heart valve. Appl. Sci. 2020, 10, 2548. [Google Scholar] [CrossRef]

- Qian, J.Y.; Gao, Z.X.; Li, W.Q.; Jin, Z.J. Cavitation suppression of bileaflet mechanical heart valves. Cardiovasc. Eng. Technol. 2020, 11, 1–12. [Google Scholar] [CrossRef]

- Sreekala, S.; Thirumalini, S. Investigation on aerodynamic noise evaluation and attenuation in a globe valve using CFD analysis. Int. J. Multiphys. 2016, 10, 43–52. [Google Scholar]

- Qian, J.; Chen, M.; Jin, Z.; Chen, L.; Sundén, B. A numerical study of heat transfer effects and aerodynamic noise reduction in superheated steam flow passing a temperature and pressure regulation valve. Numer. Heat Transf. Part A 2020, 77, 873–889. [Google Scholar] [CrossRef]

- Qian, J.; Chen, M.; Gao, Z.; Jin, Z. Mach number and energy loss analysis inside multi-stage Tesla valves for hydrogen decompression. Energy 2019, 179, 647–654. [Google Scholar] [CrossRef]

- Qian, J.Y.; Wu, J.Y.; Gao, Z.X.; Jin, Z.J. Pilot pipe and damping orifice arrangements analysis of a pilot-control globe valve. ASME J. Fluids Eng. 2020, 142, 101210. [Google Scholar] [CrossRef]

- Qian, J.Y.; Hou, C.W.; Mu, J.; Gao, Z.X.; Jin, Z.J. Valve core shapes analysis on flux through control valves in nuclear power plants. Nucl. Eng. Technol. 2020, 52, 2173–2182. [Google Scholar] [CrossRef]

- Qian, J.Y.; Wu, J.Y.; Gao, Z.X.; Jin, Z.J. Effects of throttling window on flow rate through feed-water valves. ISA Trans. 2020, 104, 393–405. [Google Scholar] [CrossRef]

- Nguyen, Q.K.; Jung, K.H.; Lee, G.N.; Suh, S.B.; To, P. Experimental study on pressure distribution and flow coefficient of globe valve. Processes 2020, 8, 875. [Google Scholar] [CrossRef]

- Singh, D.; Charlton, M.; Asim, T.; Mishra, R.; Townsend, A.; Blunt, L. Quantification of additive manufacturing induced variations in the global and local performance characteristics of a complex multi-stage control valve trim. J. Pet. Sci. Eng. 2020, 190, 107053. [Google Scholar] [CrossRef]

- Iravani, M.; Toghraie, D. Design a high-pressure test system to investigate the performance characteristics of ball valves in a compressible choked flow. Measurement 2020, 151, 107200. [Google Scholar] [CrossRef]

- Asim, T.; Mishra, R.; Oliveira, A.; Charlton, M. Effects of the geometrical features of flow paths on the flow capacity of a control valve trim. J. Pet. Sci. Eng. 2019, 172, 124–138. [Google Scholar] [CrossRef]

- Chern, M.J.; Wang, C.H.; Lu, G.T.; Tseng, P.Y.; Cheng, Y.J.; Lin, C.A.; Hu, C.M. Design of cages in globe valve. Proc. Inst. Mech. Eng. Part C J. Eng. Mech. Eng. Sci. 2015, 229, 476–484. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, M.; Xu, B. Design and experimental research of a miniature digital hydraulic valve. Micromachines 2018, 9, 283. [Google Scholar] [CrossRef]

- Qian, J.; Hou, C.; Li, X.; Jin, Z. Actuation mechanism of microvalves: A review. Micromachines 2020, 11, 172. [Google Scholar] [CrossRef]

- Qian, J.Y.; Li, X.J.; Wu, Z.; Jin, Z.J.; Sunden, B. A comprehensive review on liquid–liquid two-phase flow in microchannel: Flow pattern and mass transfer. Microfluid. Nanofluid. 2019, 23, 116. [Google Scholar] [CrossRef]

- Gao, Z.X.; Liu, P.; Yue, Y.; Li, J.Y.; Wu, H. Comparison of swing and tilting check valves flowing compressible fluids. Micromachines 2020, 11, 758. [Google Scholar] [CrossRef] [PubMed]

- Lisowski, E.; Filo, G.; Rajda, J. Analysis of flow forces in the initial phase of throttle gap opening in a proportional control valve. Flow Meas. Instrum. 2018, 59, 157–167. [Google Scholar] [CrossRef]

- Qiu, T.; Dai, H.; Lei, Y.; Liu, Y. Effects of valve needle speed on flow characteristics in control valve for unit pump fuel system. Adv. Mech. Eng. 2018, 10, 1687814018770791. [Google Scholar] [CrossRef]

- Chern, M.J.; Wang, C.C. Control of volumetric flow-rate of ball valve using V-port. ASME J. Fluids Eng. 2004, 126, 471–481. [Google Scholar] [CrossRef]

- Zhang, H.N.; Wang, G.F.; Zhao, Q.N. Design optimization of V-sector ball valve core. IOP Conf. Ser. Earth Environ. Sci. 2019, 267, 032076. [Google Scholar] [CrossRef]

- Tao, J.; Lin, Z.; Ma, C.; Ye, J.; Zhu, Z.; Li, Y.; Mao, W. An experimental and numerical study of regulating performance and flow loss in a V-port ball valve. ASME J. Fluids Eng. 2020, 142, 021207. [Google Scholar] [CrossRef]

- Industrial-Process Control Valves-Part 2-1: Flow Capacity-Sizing Equations for Fluid Flow under Installed Conditions; IEC 60534-2-1; IEC: Geneva, Switzerland, 2011.

| Grid Set | Grid Number × 105 | Flow Rate/m3h−1 | Difference/% |

|---|---|---|---|

| #1 | 5.59 | 0.378 | 7.1 |

| #2 | 9.16 | 0.353 | - |

| #3 | 21.22 | 0.363 | 2.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Z.-x.; Yue, Y.; Yang, J.-m.; Li, J.-y.; Wu, H.; Jin, Z.-j. Numerical Study of the Microflow Characteristics in a V-ball Valve. Micromachines 2021, 12, 155. https://doi.org/10.3390/mi12020155

Gao Z-x, Yue Y, Yang J-m, Li J-y, Wu H, Jin Z-j. Numerical Study of the Microflow Characteristics in a V-ball Valve. Micromachines. 2021; 12(2):155. https://doi.org/10.3390/mi12020155

Chicago/Turabian StyleGao, Zhi-xin, Yang Yue, Jia-ming Yang, Jun-ye Li, Hui Wu, and Zhi-jiang Jin. 2021. "Numerical Study of the Microflow Characteristics in a V-ball Valve" Micromachines 12, no. 2: 155. https://doi.org/10.3390/mi12020155

APA StyleGao, Z.-x., Yue, Y., Yang, J.-m., Li, J.-y., Wu, H., & Jin, Z.-j. (2021). Numerical Study of the Microflow Characteristics in a V-ball Valve. Micromachines, 12(2), 155. https://doi.org/10.3390/mi12020155