Investigation of Size Effects in Multi-Stage Cold Forming of Metallic Micro Parts from Sheet Metal

Abstract

:1. Introduction

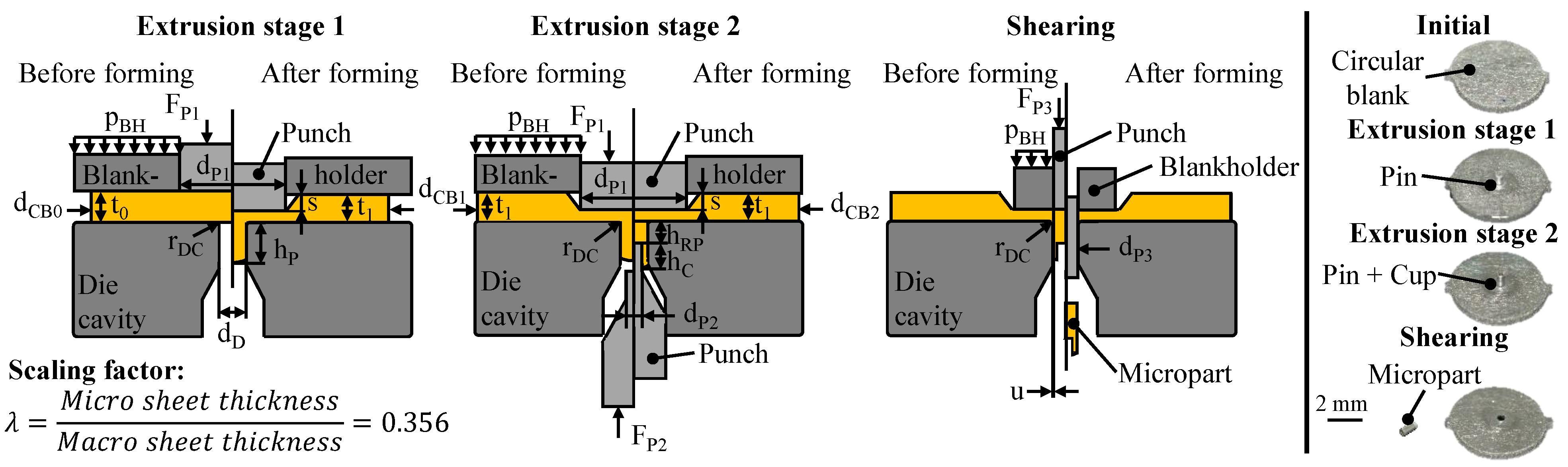

2. Experimental Setup

3. Materials

4. Results

4.1. Extrusion Stage 1 (Pin-Forming)

4.2. Extrusion Stage 2 (Cup-Forming)

4.3. Shearing (Separation of the Micro Part)

5. Summary and Outlook

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhao, J. Microforming Technology. Theory, Simulation and Practice; Elsevier: San Diego, CA, USA, 2017. [Google Scholar]

- Wang, C.; Wang, C.; Xu, J.; Zhang, P.; Shan, D.; Guo, B. Interactive effect of microstructure and cavity dimension on filling behavior in micro coining of pure nickel. Sci. Rep. 2016, 6, 23895. [Google Scholar] [CrossRef]

- Becker, E.; Ehrfeld, W.; Hagmann, P.; Maner, A.; Münchmeyer, D. Fabrication of microstructures with high aspect ratios and great structural heights by synchrotron radiation lithography, galvanoforming, and plastic moulding (LIGA process). Microelectron. Eng. 1986, 4, 35–56. [Google Scholar] [CrossRef]

- Piotter, V.; Gietzelt, T.; Merz, L. Micro powder-injection moulding of metals and ceramics. Sadhana 2003, 28, 299–306. [Google Scholar] [CrossRef] [Green Version]

- Masuzawa, T. State of the art of micromachining. In Proceedings of the 50th General Assembly of CIRP, Sydney, Australia, 20–26 August 2000; pp. 473–488. [Google Scholar]

- Geiger, M.; Kleiner, M.; Eckstein, R.; Tiesler, N.; Engel, U. Microforming. CIRP Ann. 2001, 50, 445–462. [Google Scholar] [CrossRef]

- Vollertsen, F. Categories of size effects. Prod. Eng. 2008, 2, 377–383. [Google Scholar] [CrossRef]

- Jiang, Z.; Zhao, J.; Xie, H. Chapter 3—Scaling Laws, Microforming Technology; Elsevier: San Diego, CA, USA, 2017; pp. 53–71. [Google Scholar] [CrossRef]

- Arentoft, M.; Eriksen, R.; Hansen, H.N.; Paldan, N. Towards the first generation micro bulk forming system. CIRP Ann. 2011, 60, 335–338. [Google Scholar] [CrossRef]

- Hirota, K. Fabrication of micro-billet by sheet extrusion. J. Mater. Process. Technol. 2007, 191, 283–287. [Google Scholar] [CrossRef]

- Ghassemali, E.; Tan, M.-J.; Jarfors, A.E.W.; Lim, S.C.V. Progressive microforming process: Towards the mass production of micro-parts using sheet metal. Int. J. Adv. Manuf. Technol. 2012, 66, 611–621. [Google Scholar] [CrossRef]

- Meng, B.; Fu, M.; Shi, S.-Q. Deformation characteristic and geometrical size effect in continuous manufacturing of cylindrical and variable-thickness flanged microparts. J. Mater. Process. Technol. 2018, 252, 546–558. [Google Scholar] [CrossRef]

- Rosochowski, A.; Presz, W.; Olejnik, L.; Richert, M. Micro-extrusion of ultra-fine grained aluminium. Int. J. Adv. Manuf. Technol. 2007, 33, 137–146. [Google Scholar] [CrossRef]

- Dhal, A.; Panigrahi, S.K.; Shunmugam, M.S. Achieving excellent microformability in aluminum by engineering a unique ultrafine-grained microstructure. Sci. Rep. 2019, 9, 10683. [Google Scholar] [CrossRef] [PubMed]

- Saito, Y.; Utsunomiya, H.; Tsuji, N.; Sakai, T. Novel ultra-high straining process for bulk materials—development of the accumulative roll-bonding (ARB) process. Acta Mater. 1999, 47, 579–583. [Google Scholar] [CrossRef]

- Kraus, M.; Merklein, M. (Eds.) Bulk microforming from sheet metal-A promissing approach for the mass production of cold formed metallic microparts. In Proceedings of the 13th International Conference on the Technology of Plasticity, Columbus, OH, USA, 25–30 July 2021. [Google Scholar]

- Herrmann, J.; Merklein, M. Improvement of deep drawability of ultra-fine grained 6000 series aluminum alloy by tailored heat treatment. Procedia Manuf. 2018, 15, 976–983. [Google Scholar] [CrossRef]

- Kraus, M.; Hufnagel, T.; Merklein, M. Accuracy of Conventional Finite Element Models in Bulk-Forming of Micropins From Sheet Metal. J. Micro Nano-Manuf. 2019, 7, 010902. [Google Scholar] [CrossRef]

- Hirota, K.; Michitsuji, K. Deformation behavior in boss forming with small punch/die diameter ratio. J. Mater. Process. Technol. 2015, 216, 294–301. [Google Scholar] [CrossRef]

- Merklein, M.; Stellin, T.; Engel, U. Experimental Study of a Full Forward Extrusion Process from Metal Strip. Key Eng. Mater. 2012, 504–506, 587–592. [Google Scholar] [CrossRef]

- Deng, J.; Fu, M.; Chan, W.-L. Size effect on material surface deformation behavior in micro-forming process. Mater. Sci. Eng. A 2011, 528, 4799–4806. [Google Scholar] [CrossRef]

| Parameters | Unit | Macro | Micro | |

|---|---|---|---|---|

| Relative punch stroke | s/t0 | (%) | 75 (Cu-OFE; AA6014-W); 56 (AA6014-ARB) | |

| Blankholder pressure | pBH | (MPa) | 50 MPa (Cu-OFE); 70 MPa (AA6014-W); 300 MPa (AA6014-ARB) | |

| Sheet thickness | t0 | (mm) | 1.32 | 0.47 |

| Blank diameter | dCB0 | (mm) | 15.00 | 5.34 |

| Restpin height | hRP | (mm) | 1.000 | 0.356 |

| Punch diameter 1 | dP1 | (mm) | 4.00 | 1.42 |

| Punch diameter 2 | dP2 | (mm) | 0.920; 1.120 | 0.328; 0.399 |

| Punch diameter 3 | dP3 | (mm) | - | 0.43 |

| Die diameter | dD | (mm) | 1.32 | 0.47 |

| Die radius | rDC | (mm) | 0.14 | 0.05 |

| Cu-OFE | ||||||||

| Alloying Element | Cu | |||||||

| Chemical composition (%) | min. 99.99 | |||||||

| AA6014 | ||||||||

| Alloying Element | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti |

| Chemical composition (%) | 0.30–0.60 | max. 0.35 | max. 0.25 | 0.05–0.20 | 0.40–0.80 | max. 0.20 | max. 0.10 | max. 0.10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kraus, M.; Merklein, M. Investigation of Size Effects in Multi-Stage Cold Forming of Metallic Micro Parts from Sheet Metal. Micromachines 2021, 12, 1561. https://doi.org/10.3390/mi12121561

Kraus M, Merklein M. Investigation of Size Effects in Multi-Stage Cold Forming of Metallic Micro Parts from Sheet Metal. Micromachines. 2021; 12(12):1561. https://doi.org/10.3390/mi12121561

Chicago/Turabian StyleKraus, Martin, and Marion Merklein. 2021. "Investigation of Size Effects in Multi-Stage Cold Forming of Metallic Micro Parts from Sheet Metal" Micromachines 12, no. 12: 1561. https://doi.org/10.3390/mi12121561

APA StyleKraus, M., & Merklein, M. (2021). Investigation of Size Effects in Multi-Stage Cold Forming of Metallic Micro Parts from Sheet Metal. Micromachines, 12(12), 1561. https://doi.org/10.3390/mi12121561