Atmosphere Effect in Post-Annealing Treatments for Amorphous InGaZnO Thin-Film Transistors with SiOx Passivation Layers

Abstract

:1. Introduction

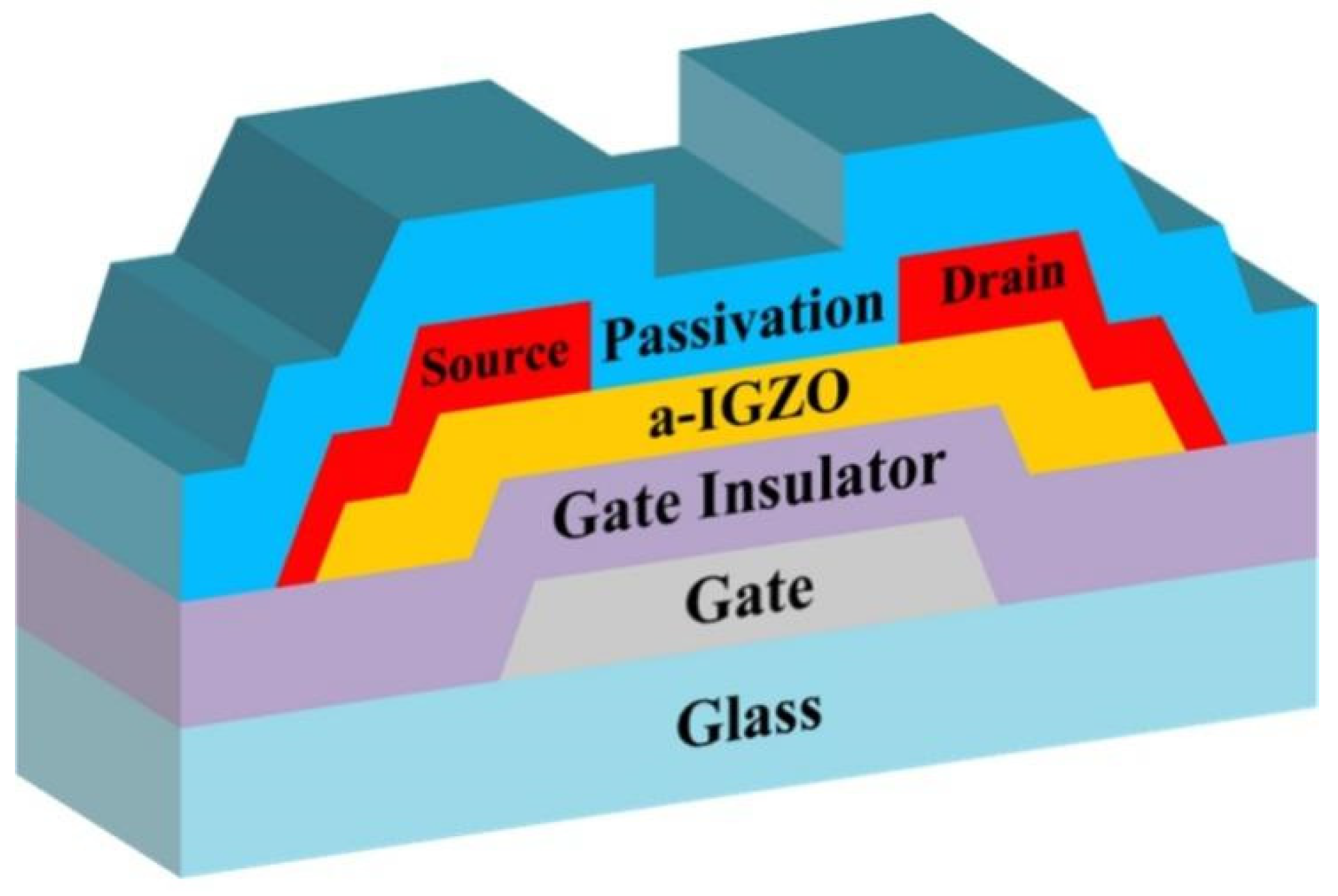

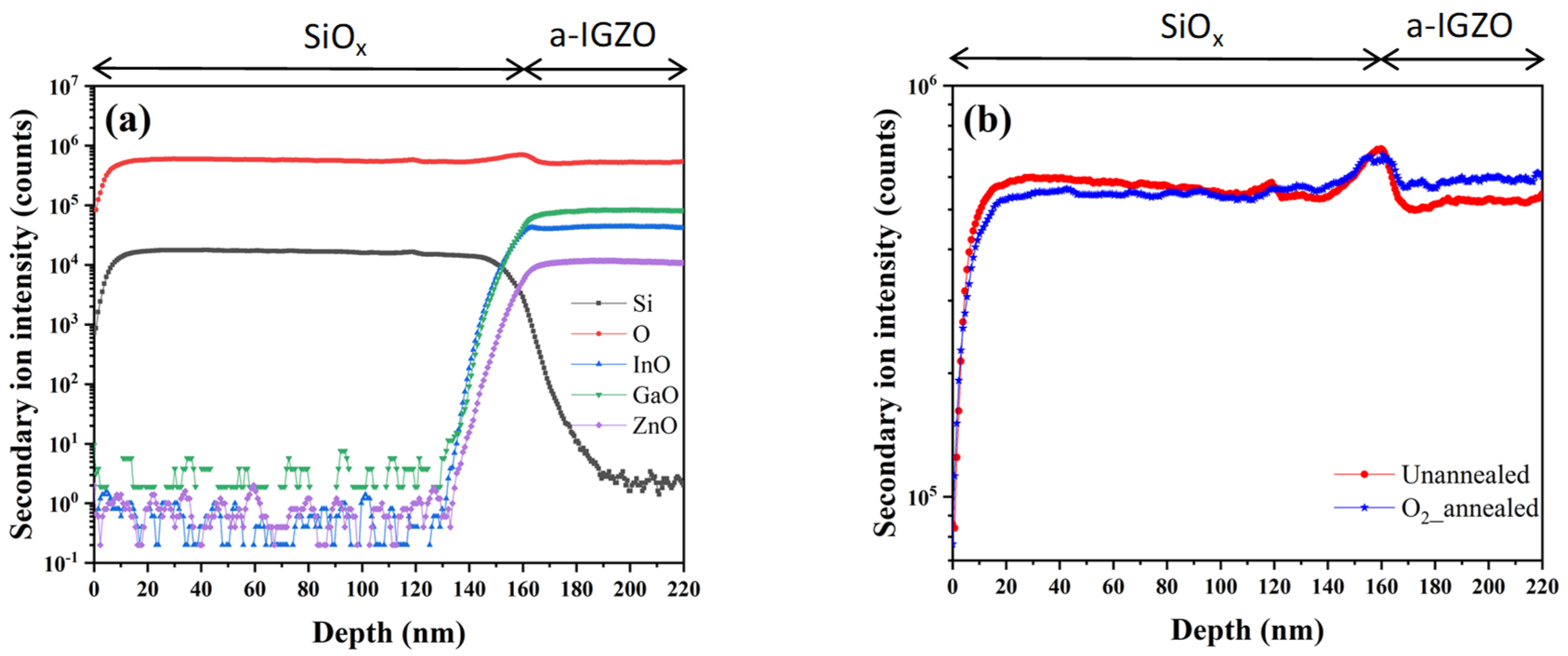

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nomura, K.; Ohta, H.; Takagi, A.; Kamiya, T.; Hirano, M.; Hosono, H. Room-temperature fabrication of transparent flexible thin-film transistors using amorphous oxide semiconductors. Nature 2004, 432, 488–492. [Google Scholar] [CrossRef]

- Kamiya, T.; Nomura, K.; Hosono, H. Present status of amorphous In–Ga–Zn–O thin-film transistors. Sci. Technol. Adv. Mater. 2010, 11, 044305. [Google Scholar] [CrossRef]

- Yabuta, H.; Sano, M.; Abe, K.; Aiba, T.; Den, T.; Kumomi, H.; Nomura, K.; Kamiya, T.; Hosono, H. High-mobility thin-film transistor with amorphous InGaZnO4 channel fabricated by room temperature rf-magnetron sputtering. Appl. Phys. Lett. 2006, 89, 112123. [Google Scholar] [CrossRef]

- Lee, J.; Kim, D.; Yang, D.; Hong, S.; Yoon, K.; Hong, P.; Jeong, C.; Park, H.; Kim, S.; Lim, S.; et al. 42.2: World’s largest (15-inch) XGA AMLCD panel using IGZO oxide TFT. SID Symp. Dig. Tech. Pap. 2008, 39, 625–628. [Google Scholar] [CrossRef]

- Jeong, J.; Jeong, J.; Choi, J.; Im, J.; Kim, S.; Yang, H.; Kang, K.; Kim, K.; Ahn, T.; Chung, H.; et al. 3.1: Distinguished Paper: 12.1-Inch WXGA AMOLED display driven by indium-gallium-zinc oxide TFTs array. SID Symp. Dig. Tech. Pap. 2008, 39, 1–4. [Google Scholar] [CrossRef]

- Kim, M.K.; Jeong, J.H.; Lee, H.J.; Ahn, T.K.; Shin, H.S.; Park, J.S.; Jeong, J.K.; Mo, Y.G.; Kim, H.D. High mobility bottom gate InGaZnO thin film transistors with SiOx etch stopper. Appl. Phys. Lett. 2007, 90, 212114. [Google Scholar] [CrossRef]

- Peng, C.; Yang, S.; Pan, C.; Li, X.; Zhang, J. Effect of two-step annealing on high stability of a-IGZO thin-film transistor. IEEE Trans. Electron Devices 2020, 67, 4262–4268. [Google Scholar] [CrossRef]

- Nag, M.; Bhoolokam, A.; Steudel, S.; Chasin, A.; Myny, K.; Maas, J.; Groeseneken, G.; Heremans, P. Back-channel-etch amorphous indium–gallium–zinc oxide thin-film transistors: The impact of source/drain metal etch and final passivation. Jpn. J. Appl. Phys. 2014, 53, 111401. [Google Scholar] [CrossRef]

- Park, Y.; Um, J.; Mativenga, M.; Jang, J. Enhanced operation of back-channel-etched a-IGZO TFTs by fluorine treatment during source/drain wet-etching. ECS J. Solid State Sci. Technol. 2017, 6, 300–303. [Google Scholar] [CrossRef]

- Ochi, M.; Hino, A.; Goto, H.; Hayashi, K.; Kugimiya, T. Improvement of stress stability in back channel etch-type amorphous In–Ga–Zn–O thin film transistors with post process annealing. ECS J. Solid State Sci. Technol. 2017, 6, 247–252. [Google Scholar] [CrossRef]

- Yu, Y.; Lv, N.; Zhang, D.; Wei, Y.; Wang, M. High-mobility amorphous InGaZnO thin-film transistors with nitrogen introduced via low-temperature annealing. IEEE Electron Device Lett. 2021, 42, 1480–1483. [Google Scholar] [CrossRef]

- Trinh, T.; Nguyen, V.; Ryu, K.; Jang, K.; Lee, W.; Baek, S.; Raja, J.; Yi, J. Improvement in the performance of an InGaZnO thin-film transistor by controlling interface trap densities between the insulator and active layer. Semicond. Sci. Technol. 2011, 26, 085012. [Google Scholar] [CrossRef]

- Jung, C.; Kim, D.; Kang, Y.; Yoon, D. Effect of heat treatment on electrical properties of amorphous oxide semiconductor In–Ga–Zn–O film as a function of oxygen flow rate. Jpn. J. Appl. Phys. 2009, 48, 08HK02. [Google Scholar] [CrossRef]

- Lin, C.; Yen, T.; Lin, H.; Huang, T.; Lee, Y. Effect of annealing ambient on the characteristics of a-IGZO thin film transistors. In Proceedings of the 4th IEEE International NanoElectronics Conference, Taiwan, China, 21–24 June 2011; pp. 1–2. [Google Scholar]

- Fuh, C.; Sze, S.; Liu, P.; Teng, L.; Chou, Y. Role of environmental and annealing conditions on the passivation–free In–Ga–Zn–O TFT. Thin Solid Films 2011, 520, 1489–1494. [Google Scholar] [CrossRef]

- Gutierrez-Heredia, G.; Maeng, J.; Conde, J.; Rodriguez-Lopez, O.; Voit, W.E. Effect of annealing atmosphere on IGZO thin film transistors on a deformable softening polymer substrate. Semicond. Sci. Technol. 2018, 33, 095001. [Google Scholar] [CrossRef]

- Huang, Y.; Yang, P.; Huang, H.; Wang, S.; Cheng, H. Effect of the annealing ambient on the electrical characteristics of the amorphous InGaZnO thin film transistors. J. Nanosci. Nanotechnol. 2012, 12, 5625–5630. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Chen, Y.; Zhou, D.; Hu, Z.; Xie, H.; Dong, C. Sputtered oxides used for passivation layers of amorphous InGaZnO thin film transistors. Mater. Sci. Semicond. Process. 2015, 29, 277–282. [Google Scholar] [CrossRef]

- Nguyen, C.; Trinh, T.; Dao, V.; Raja, J.; Jang, K.; Le, T.; Iftiquar, S.; Yi, J. Bias-stress-induced threshold voltage shift dependence of negative charge trapping in the amorphous indium tin zinc oxide thin-film transistors. Semicond. Sci. Technol. 2013, 28, 105014. [Google Scholar] [CrossRef]

- Xie, H.; Xu, J.; Liu, G.; Zhang, L.; Dong, C. Development and analysis of nitrogen-doped amorphous InGaZnO thin film transistors. Mater. Sci. Semicond. Process. 2017, 64, 1–5. [Google Scholar] [CrossRef]

- Zhou, X.; Han, D.; Dong, J.; Li, H.; Yi, Z.; Xing, Z.; Wang, Y. The effects of post annealing process on the electrical performance and stability of Al-Zn-O thin-film transistors. IEEE Electron Device Lett. 2020, 41, 569–572. [Google Scholar] [CrossRef]

- Chun, M.; Um, J.; Park, M.; Chowdhury, M.; Jang, J. Effect of top gate potential on bias-stress for dual gate amorphous indium-gallium-zinc-oxide thin film transistor. AIP Adv. 2016, 6, 075217. [Google Scholar] [CrossRef] [Green Version]

- Nomura, K.; Kamiya, T.; Hosono, H. Effects of diffusion of hydrogen and oxygen on electrical properties of amorphous oxide semiconductor, In-Ga-Zn-O. ECS J. Solid State Sci. Technol. 2012, 2, 5–8. [Google Scholar] [CrossRef]

- Yang, J.; Cao, D.; Lin, D.; Liu, F. Effect of annealing ambient gases on the bias stability of amorphous SnSiO thin-film transistors. Semicond. Sci. Technol. 2020, 35, 115003. [Google Scholar] [CrossRef]

- Su, J.; Yang, H.; Ma, Y.; Li, R.; Jia, L.; Liu, D.; Zhang, X. Annealing atmosphere-dependent electrical characteristics and bias stability of N-doped InZnSnO thin film transistors. Mater. Sci. Semicond. Process. 2020, 113, 105040. [Google Scholar] [CrossRef]

- Chen, Y.; Chang, T.; Li, H.; Chen, S.; Chung, W.; Chen, Y.; Tai, Y.; Tseng, T.; Huang, F. Surface states related the bias stability of amorphous In–Ga–Zn–O thin film transistors under different ambient gasses. Thin Solid Films 2011, 520, 1432–1436. [Google Scholar] [CrossRef]

- Dong, C.; Xu, J.; Zhou, Y.; Zhang, Y.; Xie, H. Light-illumination stability of amorphous InGaZnO thin film transistors in oxygen and moisture ambience. Solid-State Electron. 2019, 153, 74–78. [Google Scholar] [CrossRef]

- Pearton, S.; Cho, H.; LaRoche, J.; Ren, F.; Wilson, R.; Lee, J. Oxygen diffusion into SiO2-capped GaN during annealing. Appl. Phys. Lett. 1999, 75, 2939–2941. [Google Scholar] [CrossRef]

- Nguyen, T.; Renault, O.; Aventurier, B.; Rodriguez, G.; Barnes, J.; Templier, F. Analysis of IGZO thin-film transistors by XPS and relation with electrical characteristics. J. Disp. Technol. 2013, 9, 770–774. [Google Scholar] [CrossRef]

- Chen, W.; Lo, S.; Kao, S.; Zan, H.; Tsai, C.; Lin, J.; Fang, C. Oxygen-dependent instability and annealing/passivation effects in amorphous In–Ga–Zn–O thin-film transistors. IEEE Electron Device Lett. 2011, 32, 1552–1554. [Google Scholar] [CrossRef]

- Qu, M.; Chang, C.; Meng, T.; Zhang, Q.; Liu, P.; Shieh, H. Stability study of indium tungsten oxide thin-film transistors annealed under various ambient conditions. Phys. Status Solidi 2016, 214, 1600465. [Google Scholar] [CrossRef]

- Nomura, K.; Kamiya, T.; Hirano, M.; Hosono, H. Origins of threshold voltage shifts in room-temperature deposited and annealed a-In–Ga–Zn–O thin-film transistors. Appl. Phys. Lett. 2009, 95, 013502. [Google Scholar] [CrossRef]

- Zhou, Y.; Dong, C. Influence of passivation layers on positive gate bias-stress stability of amorphous InGaZnO thin-film transistors. Micromachines 2018, 9, 603. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.; Cho, W. Effects of vacuum rapid thermal annealing on the electrical characteristics of amorphous indium gallium zinc oxide thin films. AIP Adv. 2018, 8, 015007. [Google Scholar] [CrossRef]

- Park, Y.; Um, J.; Mativenga, M.; Jang, J. Thermal stability improvement of back channel etched a-IGZO TFTs by using fluorinated organic passivation. ECS J. Solid State Sci. Technol. 2018, 7, 123–126. [Google Scholar] [CrossRef]

- Kim, C.; Kim, E.; Lee, M.; Park, J.; Seol, M.; Bae, H.; Bang, T.; Jeon, S.; Jun, S.; Park, S.; et al. Electrothermal annealing (ETA) method to enhance the electrical performance of amorphous-oxide-semiconductor (AOS) thin-film transistors (TFTs). ACS Appl. Mater. Interfaces 2016, 8, 23820–23826. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Fan, Z.; Shen, A.; Dong, C. Atmosphere Effect in Post-Annealing Treatments for Amorphous InGaZnO Thin-Film Transistors with SiOx Passivation Layers. Micromachines 2021, 12, 1551. https://doi.org/10.3390/mi12121551

Zhang W, Fan Z, Shen A, Dong C. Atmosphere Effect in Post-Annealing Treatments for Amorphous InGaZnO Thin-Film Transistors with SiOx Passivation Layers. Micromachines. 2021; 12(12):1551. https://doi.org/10.3390/mi12121551

Chicago/Turabian StyleZhang, Wen, Zenghui Fan, Ao Shen, and Chengyuan Dong. 2021. "Atmosphere Effect in Post-Annealing Treatments for Amorphous InGaZnO Thin-Film Transistors with SiOx Passivation Layers" Micromachines 12, no. 12: 1551. https://doi.org/10.3390/mi12121551

APA StyleZhang, W., Fan, Z., Shen, A., & Dong, C. (2021). Atmosphere Effect in Post-Annealing Treatments for Amorphous InGaZnO Thin-Film Transistors with SiOx Passivation Layers. Micromachines, 12(12), 1551. https://doi.org/10.3390/mi12121551