Analysis of the Influence of Ferromagnetic Material on the Output Characteristics of Halbach Array Energy-Harvesting Structure

Abstract

:1. Introduction

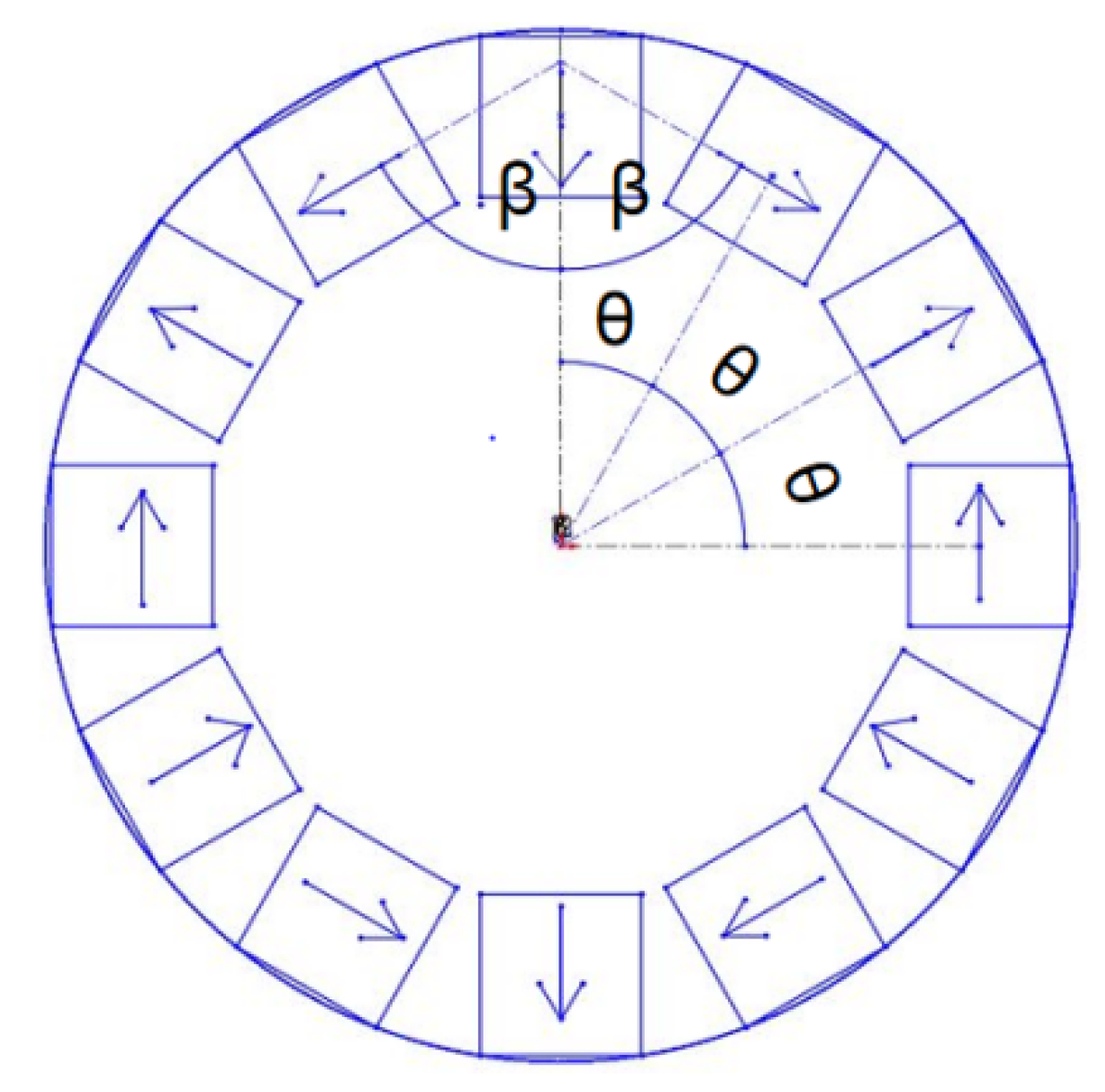

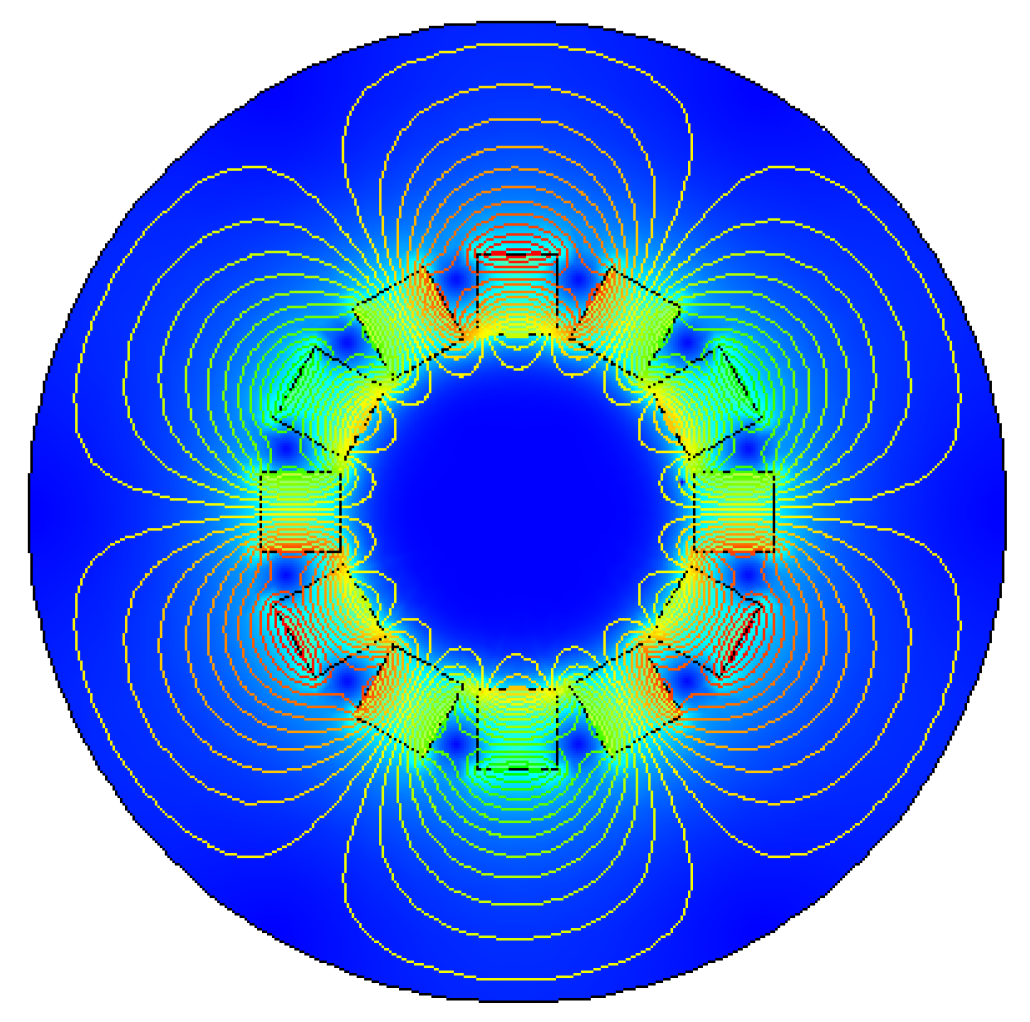

2. The Principle of Halbach Array and Ferromagnetic Magnetization

3. The Effect of Iron Sheet on Halbach Array

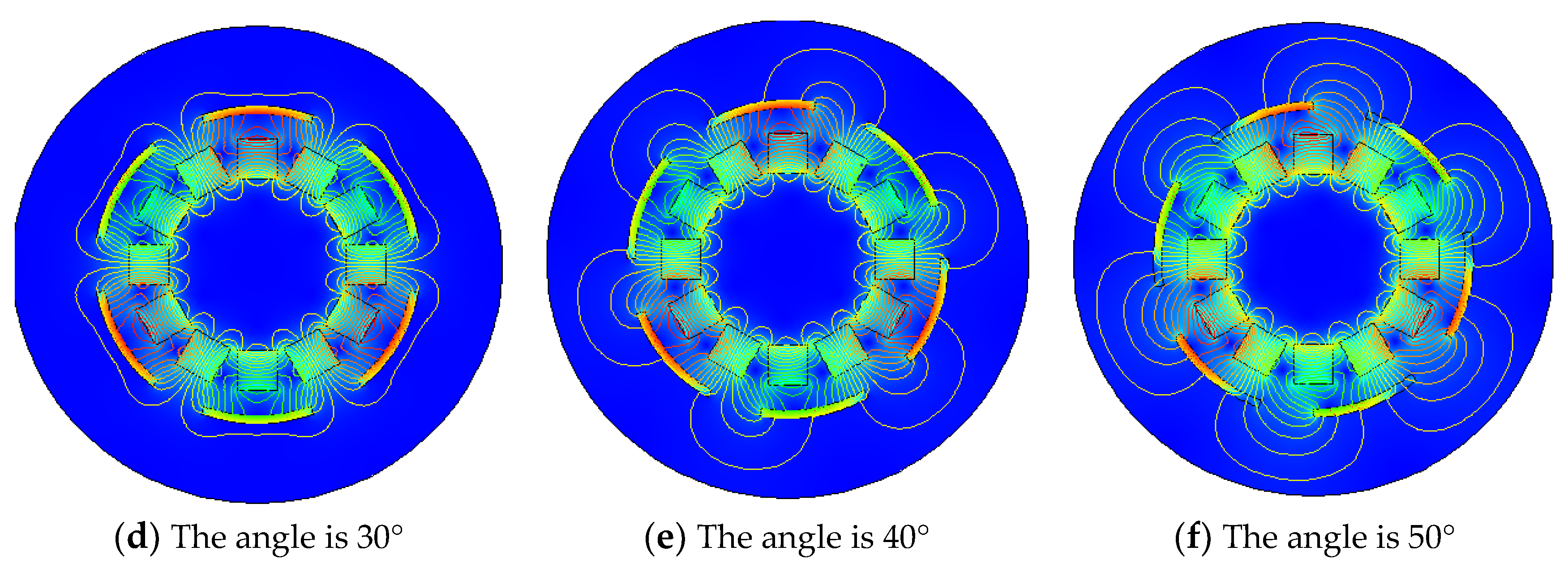

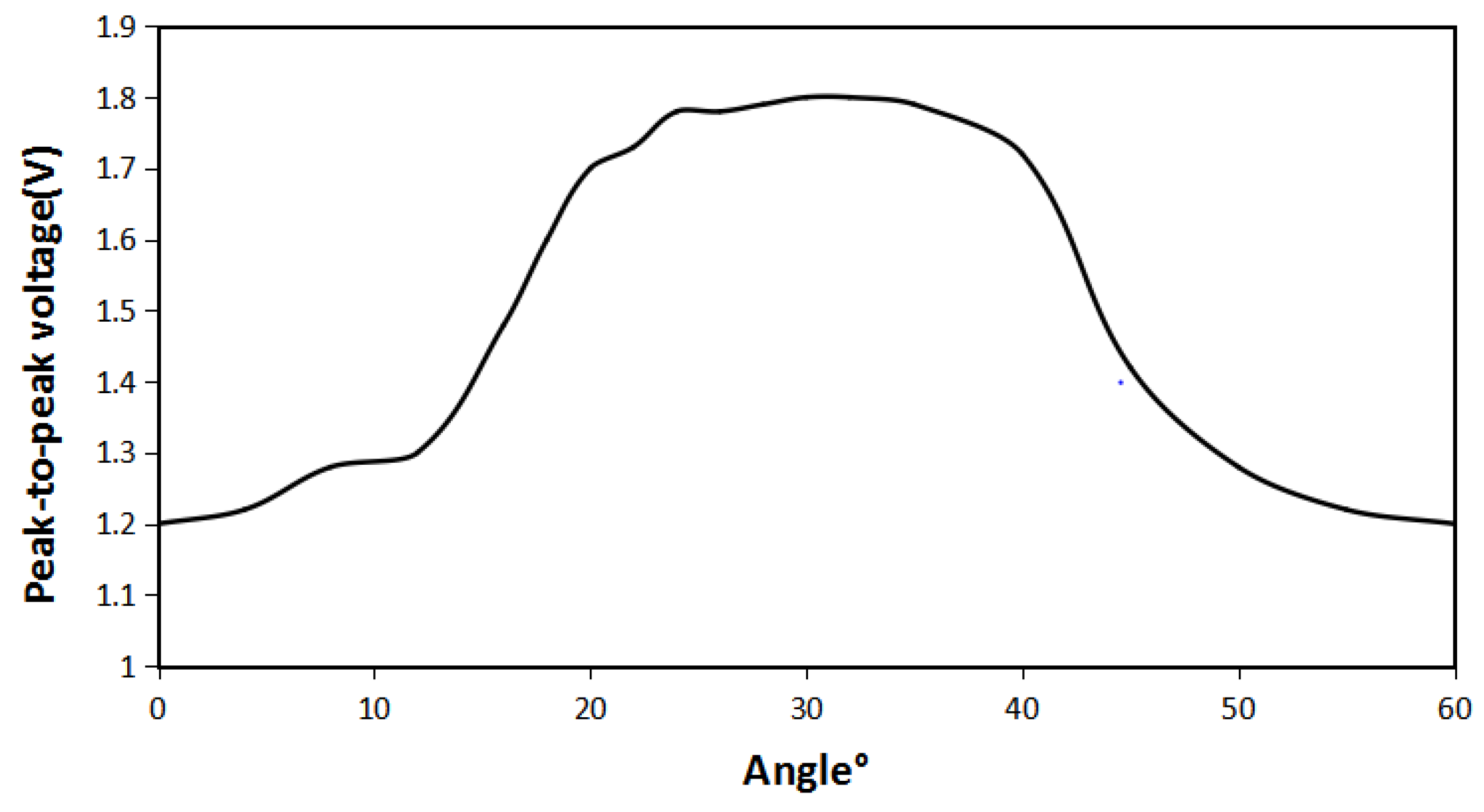

3.1. The Influence of the Angle between Halbach Array and Iron Sheet

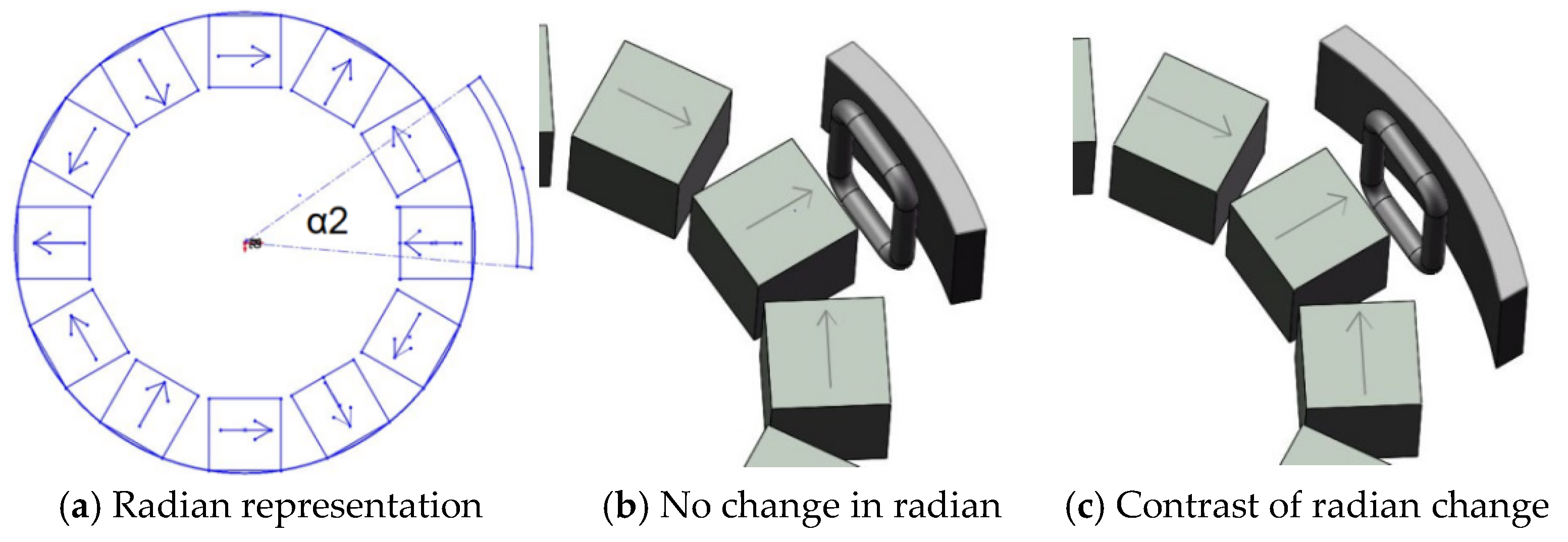

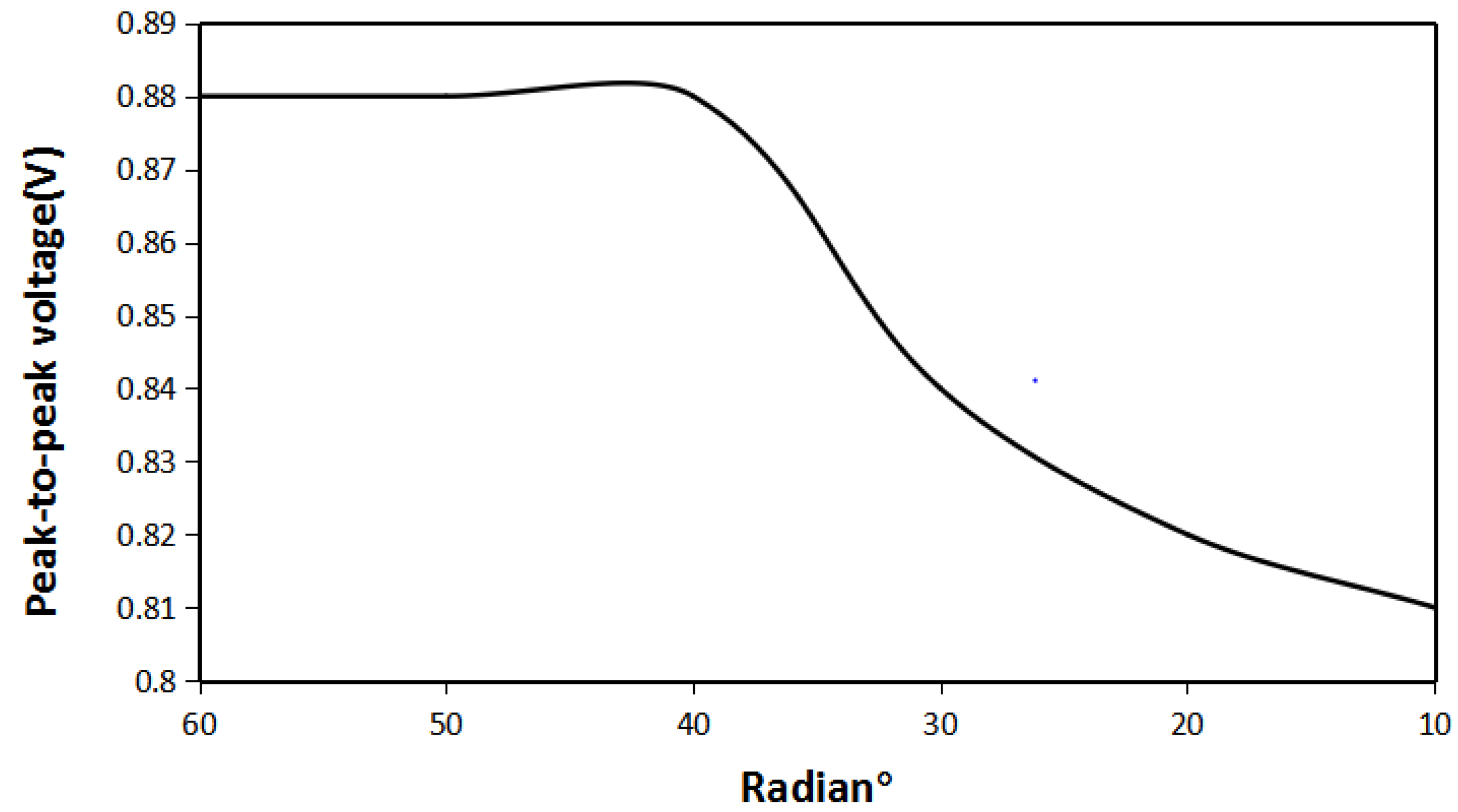

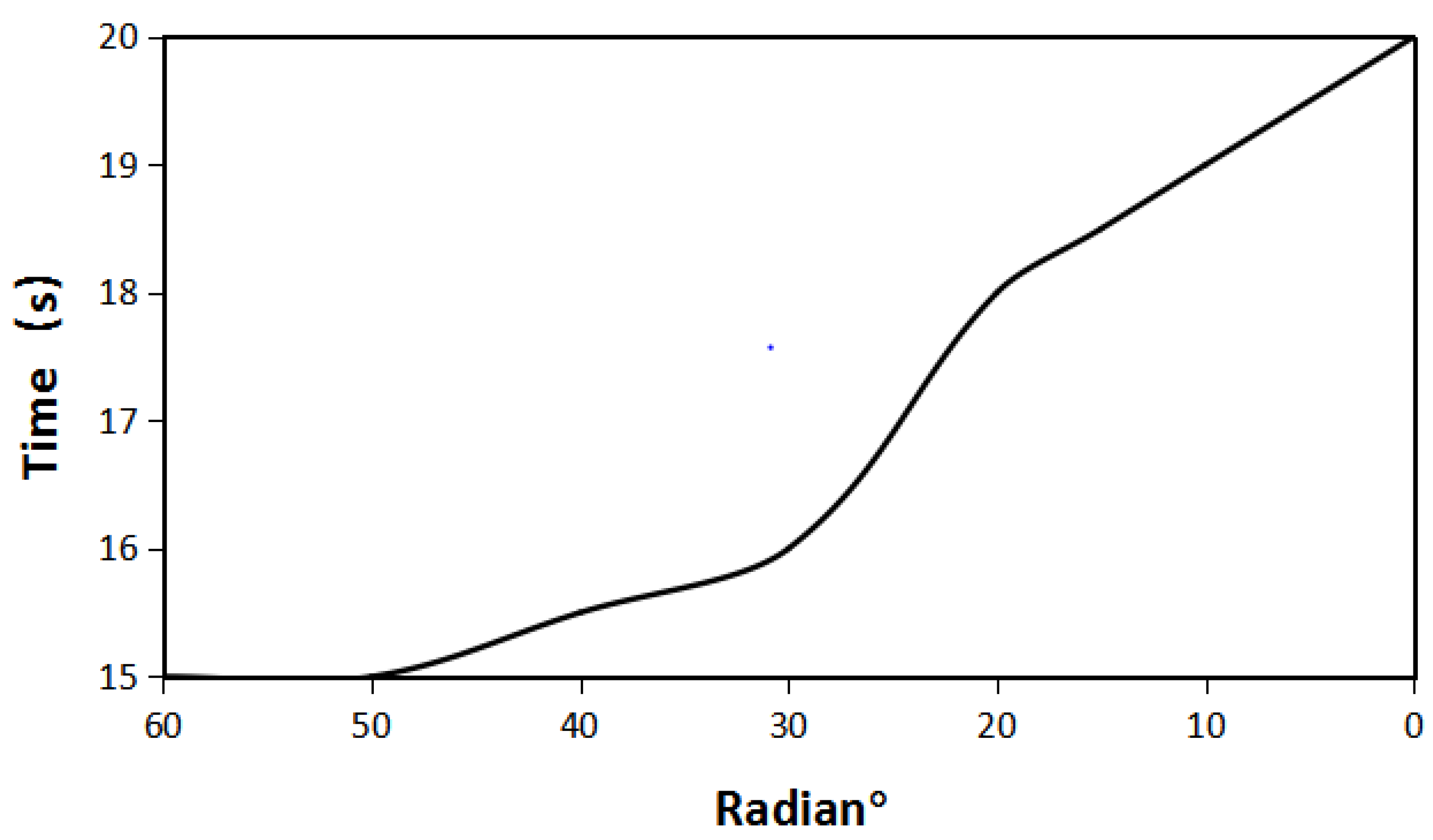

3.2. The Influence of the Radian Size of the Iron Sheet and the Halbach Array

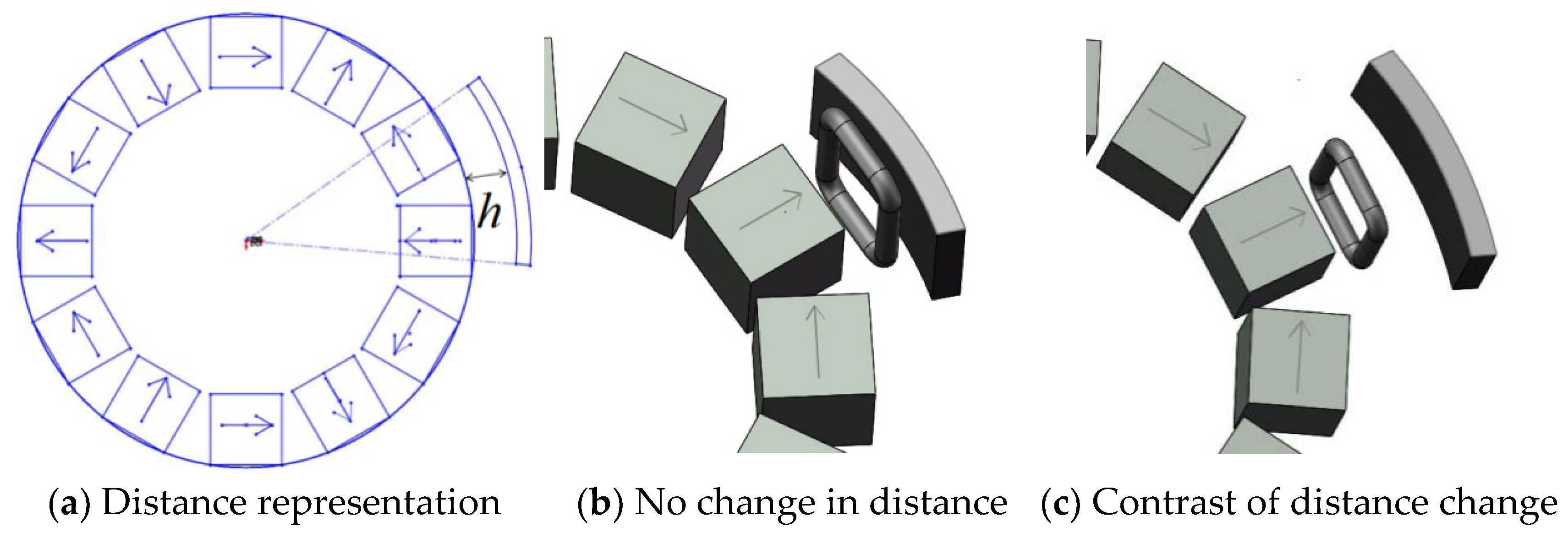

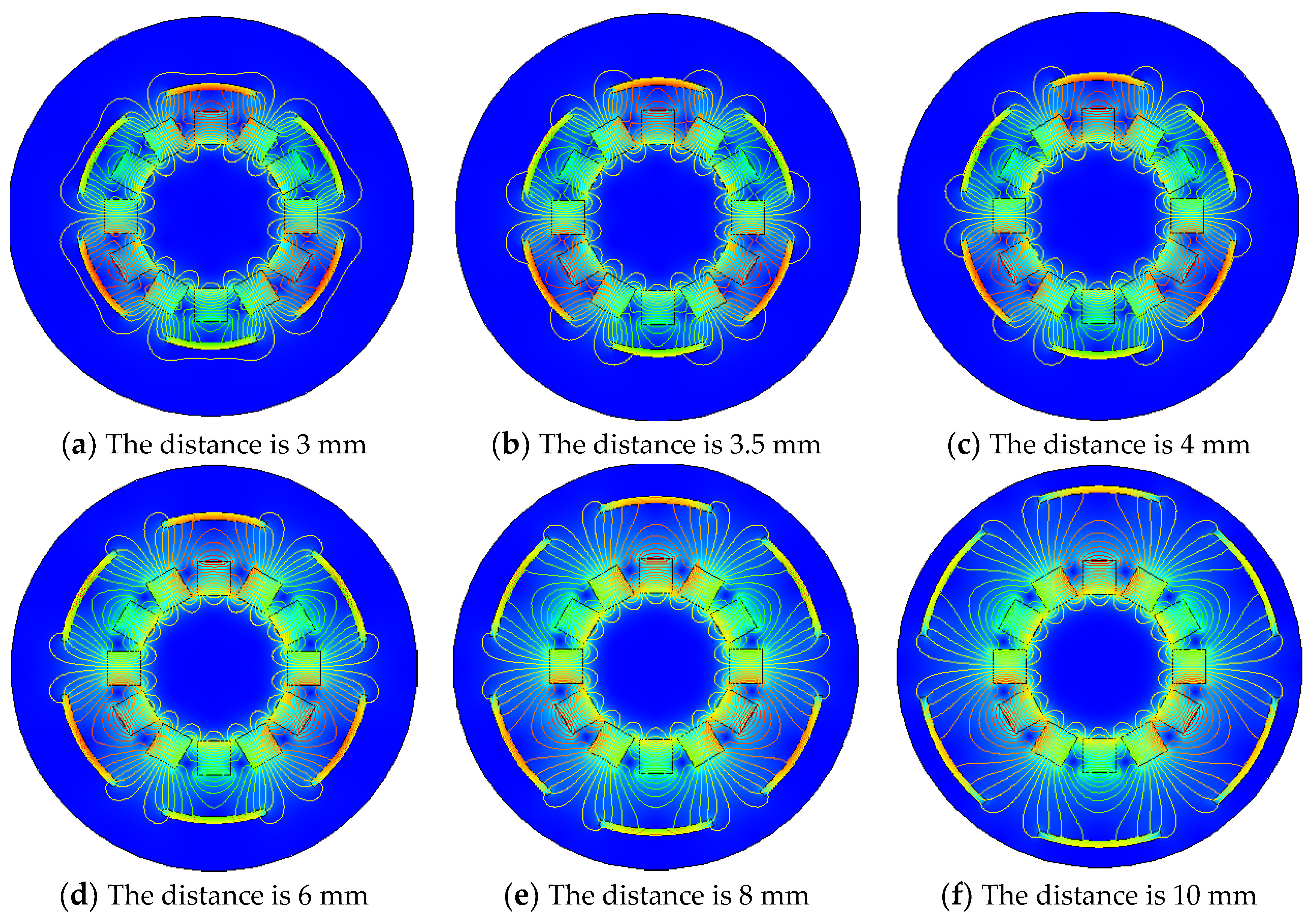

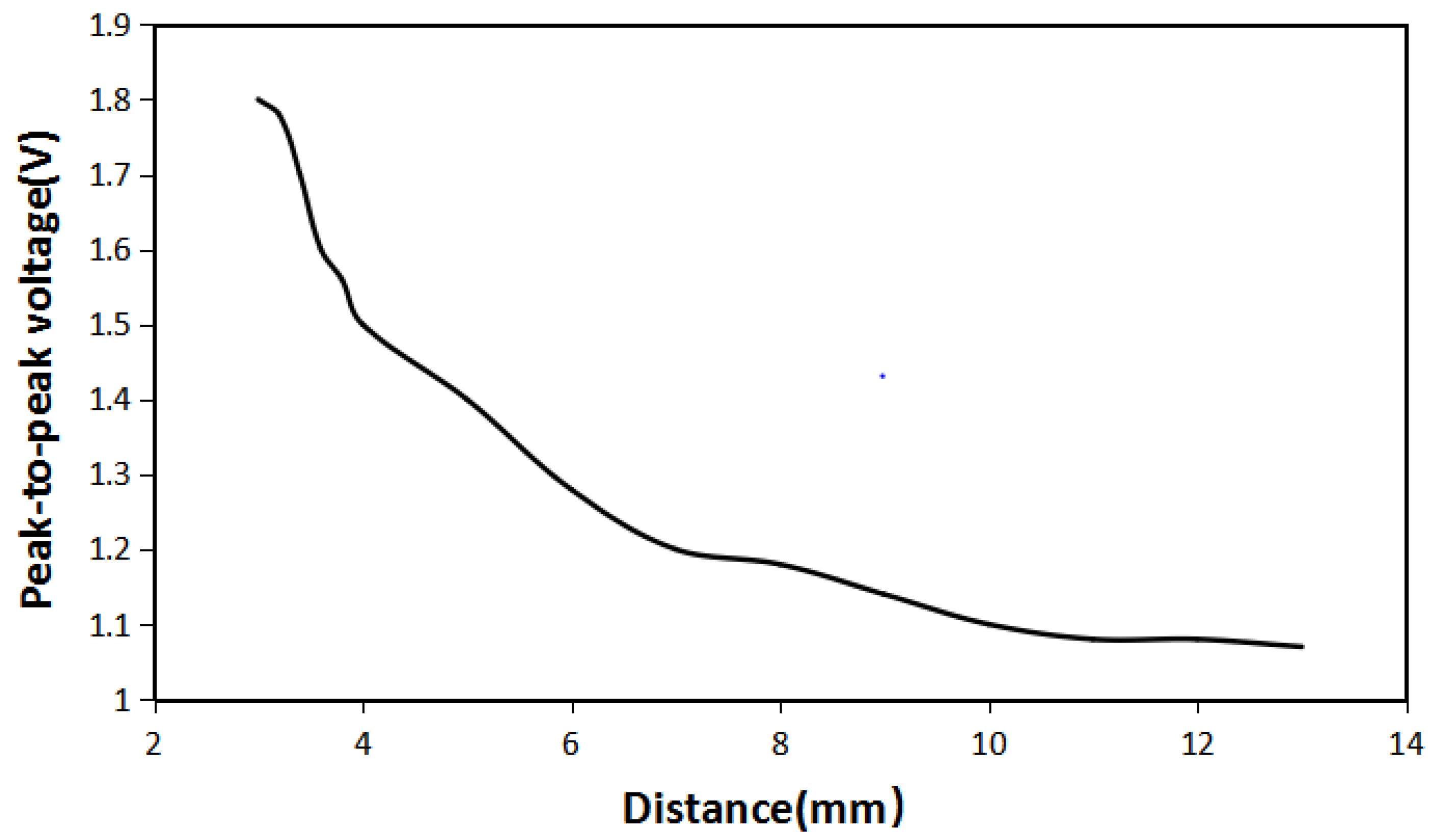

3.3. The Influence of the Distance between the Iron Sheet and the Halbach Array

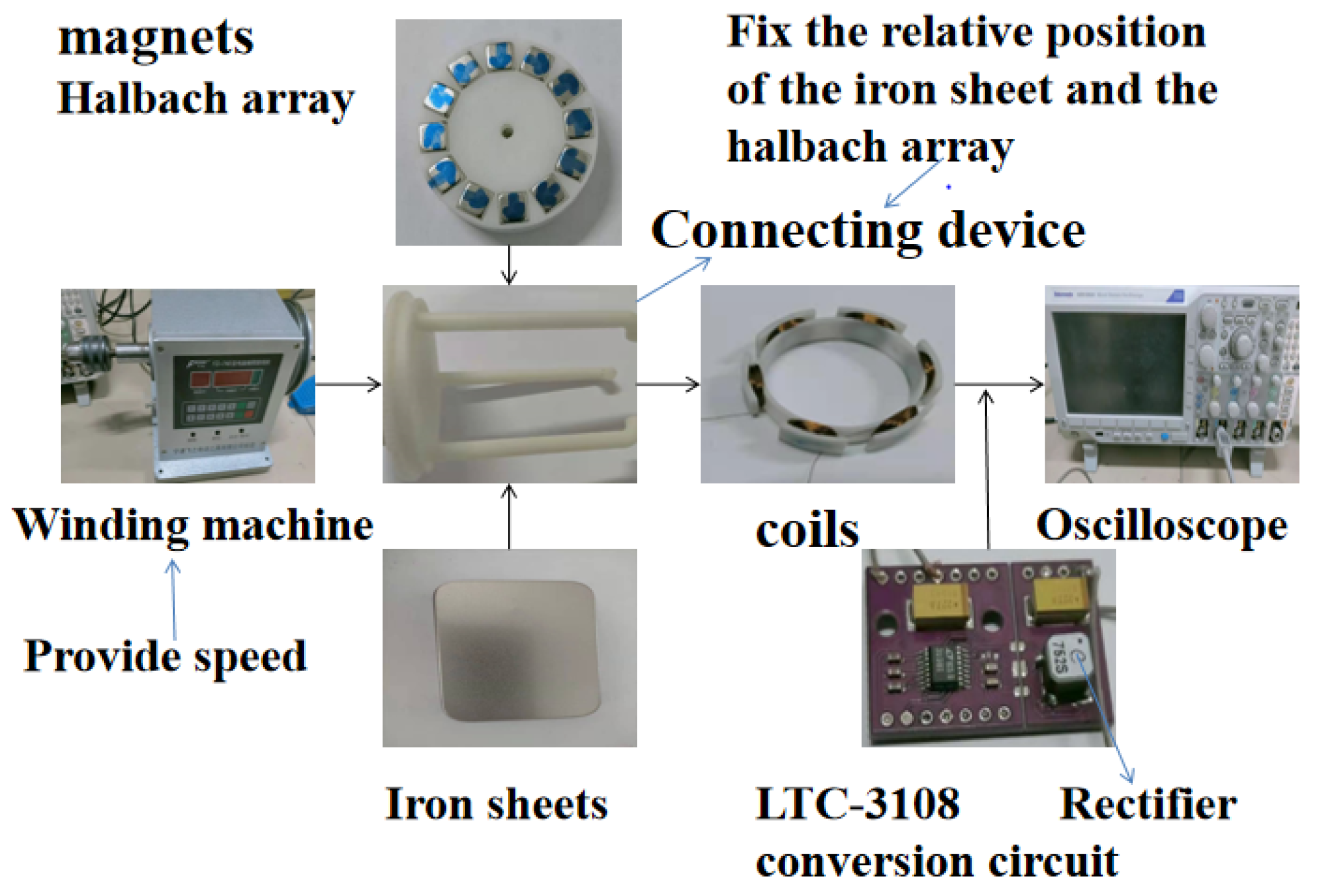

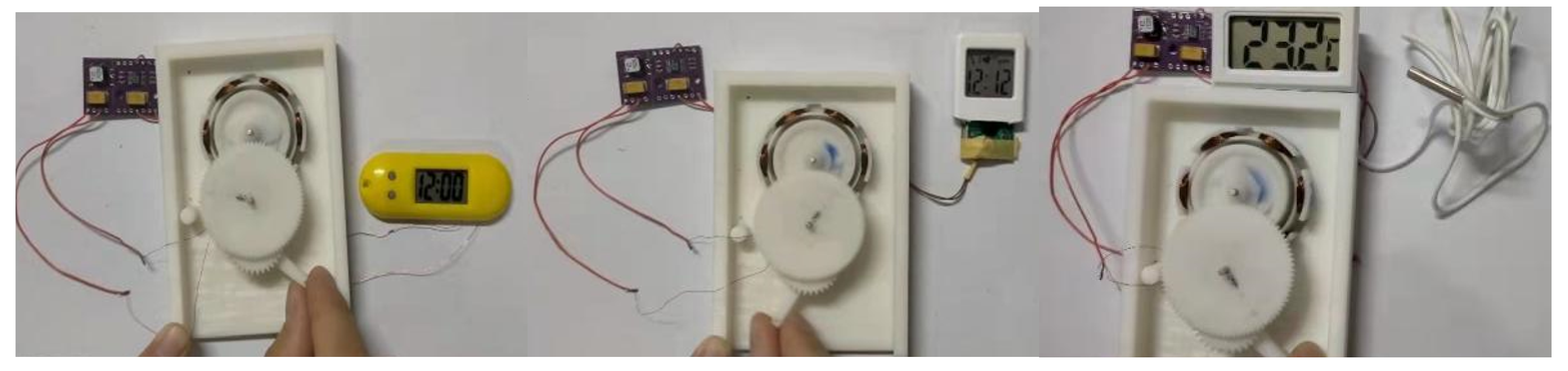

4. Experimental Verification

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ren, Z.; Xu, J.; Le, X.; Lee, C. Heterogeneous wafer bonding technology and thin-film transfer technology-enabling platform for the next generation applications beyond 5G. Micromachines 2021, 12, 946. [Google Scholar] [CrossRef] [PubMed]

- Lu, X.; Xi, X.; Lu, K.; Wang, C.; Chen, X.; Wu, Y.; Wu, X.; Xiao, D. Miniature ultralight deformable squama mechanics and skin based on piezoelectric actuation. Micromachines 2021, 12, 696. [Google Scholar] [CrossRef]

- He, R.; Li, J. Optimized design and performance analysis of a magnetic-field modulated brushless dual-mechanical port motor with Halbach array permanent magnets. Adv. Mech. Eng. 2020, 12, 168781402095775. [Google Scholar] [CrossRef]

- Sim, M.S.; Ro, J.S. Semi-analytical modeling and analysis of Halbach array. Energies 2020, 13, 1252. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.S.; Deng, Z.X.; Yang, M.L.; Zhang, Y.; Tuo, J.Y.; Xu, J. Analytical prediction of Halbach array permanent magnet machines considering finite tooth permeability. IEEE Trans. Magn. 2020, 56, 1–10. [Google Scholar] [CrossRef]

- Ni, Y.; Jiang, X.; Xiao, B.; Wang, Q. Analytical modeling and optimization of dual-layer segmented halbach permanent magnet machines. IEEE Trans. Magn. 2020, 56, 1–10. [Google Scholar] [CrossRef]

- Xu, L.; Zhu, X.; Zhang, C.; Zhang, L.; Quan, L. Power oriented design and optimization of dual stator linear-rotary generator with halbach pm array for ocean energy conversion. IEEE Trans. Energy Convers. 2021, 36, 3414–3426. [Google Scholar] [CrossRef]

- Jing, L.; Gong, J.; Chen, J.; Huang, Z.; Qu, R. A novel coaxial magnetic gear with unequal Halbach arrays and non-uniform air gap. IEEE Trans. Appl. Supercond. 2020, 30, 1–5. [Google Scholar] [CrossRef]

- Chunsheng, E.; Smith, D.; Wolfe, J.; Weller, D.; Khizroev, S.; Litvinov, D. Physics of patterned magnetic medium recording: Design considerations. J. Appl. Phys. 2005, 98, 978–979. [Google Scholar]

- Kou, B.; Zhang, L.; Zhao, B.; Zhang, C. Analysis and Optimization of a Linear Synchronous Motor with Novel Halbach Magnet Array. Appl. Mech. Mater. 2013, 2698, 416–417. [Google Scholar] [CrossRef]

- Zhu, Z.Q.; Howe, D.; Chan, C.C. Improved analytical model for predicting the magnetic field distribution in brushless permanent-magnet machines. IEEE Trans. Magn. 2002, 38, 229–238. [Google Scholar] [CrossRef] [Green Version]

- Sun, S. Monodisperse FePt nanoparticles and ferromagnetic FePt nanocrystal superlattices. Cheminform 2000, 287, 1989–1992. [Google Scholar] [CrossRef]

- Zarko, D.; Ban, D.; Lipo, T.A. Analytical calculation of magnetic field distribution in the slotted air gap of a surface permanent-magnet motor using complex relative air-gap permeance. IEEE Trans. Magn. 2006, 42, 1828–1837. [Google Scholar] [CrossRef]

- Gao, L.; Zhuang, J.; Nie, L.; Zhang, J.; Zhang, Y.; Gu, N.; Wang, T.; Feng, J.; Yang, D.; Perrett, S.; et al. Intrinsic peroxidase-like activity of ferromagnetic nanoparticles. Nat. Nanotechnol. 2007, 2, 577–583. [Google Scholar] [CrossRef]

- Schmidt, G.; Ferrand, D.; Molenkamp, L.W.; Filip, A.T.; Van Wees, B.J. Fundamental obstacle for electrical spin injection from a ferromagnetic metal into a diffusive semiconductor. Phys. Rev. B 2000, 62, R4790. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Z.Q.; Xia, Z.P.; Atallah, K.; Jewell, G.W.; Howe, D. Powder alignment system for anisotropic bonded NdFeB Halbach cylinders. IEEE Trans. Magn. 2000, 36, 3349–3352. [Google Scholar] [CrossRef]

- Xia, C.; Guo, L.; Wang, H. Modeling and analyzing of magnetic field of segmented Halbach array permanent magnet machine considering gap between segment. IEEE Trans. Magn. 2014, 50, 1–9. [Google Scholar] [CrossRef]

- Tewari, S.; O’Reilly, T.; Webb, A. Improving the field homogeneity of fixed- and variable-diameter discrete Halbach magnet arrays for MRI via optimization of the angular magnetization distribution. J. Magn. Reson. 2021, 324, 106923. [Google Scholar] [CrossRef] [PubMed]

- Žežulka, V.; Straka, P. Linear Halbach Structures:The Influence of Different Arrangement and Dimensions on the Resulting Magnetic Field. J. Magn. 2018, 23, 229–237. [Google Scholar] [CrossRef]

- Lesnak, M.; Ciprian, D.; Les, M.; Lu, J. The effect of magnet magnetization vector orientation in Halbach arrays on the effectiveness of separation. Acta Phys. Pol. A 2014, 126, 158–159. [Google Scholar]

- Liu, G.D.; Zhou, Y.F.; Zhou, R.G.; Huo, L.G. Modeling of the 2D Halbach array with different dimensions of magnets based on magnetization direction. Appl. Mech. Mater. 2015, 752, 396–401. [Google Scholar] [CrossRef]

| Rectangular permanent magnet | 5 mm × 5 mm × 5 mm |

| The radius of the Halbach array rotor | 16 mm |

| The thickness of the iron sheet | 1 mm |

| Permanent magnet residual magnetic flux density | 0.84 T |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Liu, H.; He, Y.; Peng, T.; Su, B.; Guan, H. Analysis of the Influence of Ferromagnetic Material on the Output Characteristics of Halbach Array Energy-Harvesting Structure. Micromachines 2021, 12, 1541. https://doi.org/10.3390/mi12121541

Zhang X, Liu H, He Y, Peng T, Su B, Guan H. Analysis of the Influence of Ferromagnetic Material on the Output Characteristics of Halbach Array Energy-Harvesting Structure. Micromachines. 2021; 12(12):1541. https://doi.org/10.3390/mi12121541

Chicago/Turabian StyleZhang, Xiangyong, Haipeng Liu, Yunli He, Tingrui Peng, Bin Su, and Huiyuan Guan. 2021. "Analysis of the Influence of Ferromagnetic Material on the Output Characteristics of Halbach Array Energy-Harvesting Structure" Micromachines 12, no. 12: 1541. https://doi.org/10.3390/mi12121541

APA StyleZhang, X., Liu, H., He, Y., Peng, T., Su, B., & Guan, H. (2021). Analysis of the Influence of Ferromagnetic Material on the Output Characteristics of Halbach Array Energy-Harvesting Structure. Micromachines, 12(12), 1541. https://doi.org/10.3390/mi12121541