State of the Art of Non-Invasive Electrode Materials for Brain–Computer Interface

Abstract

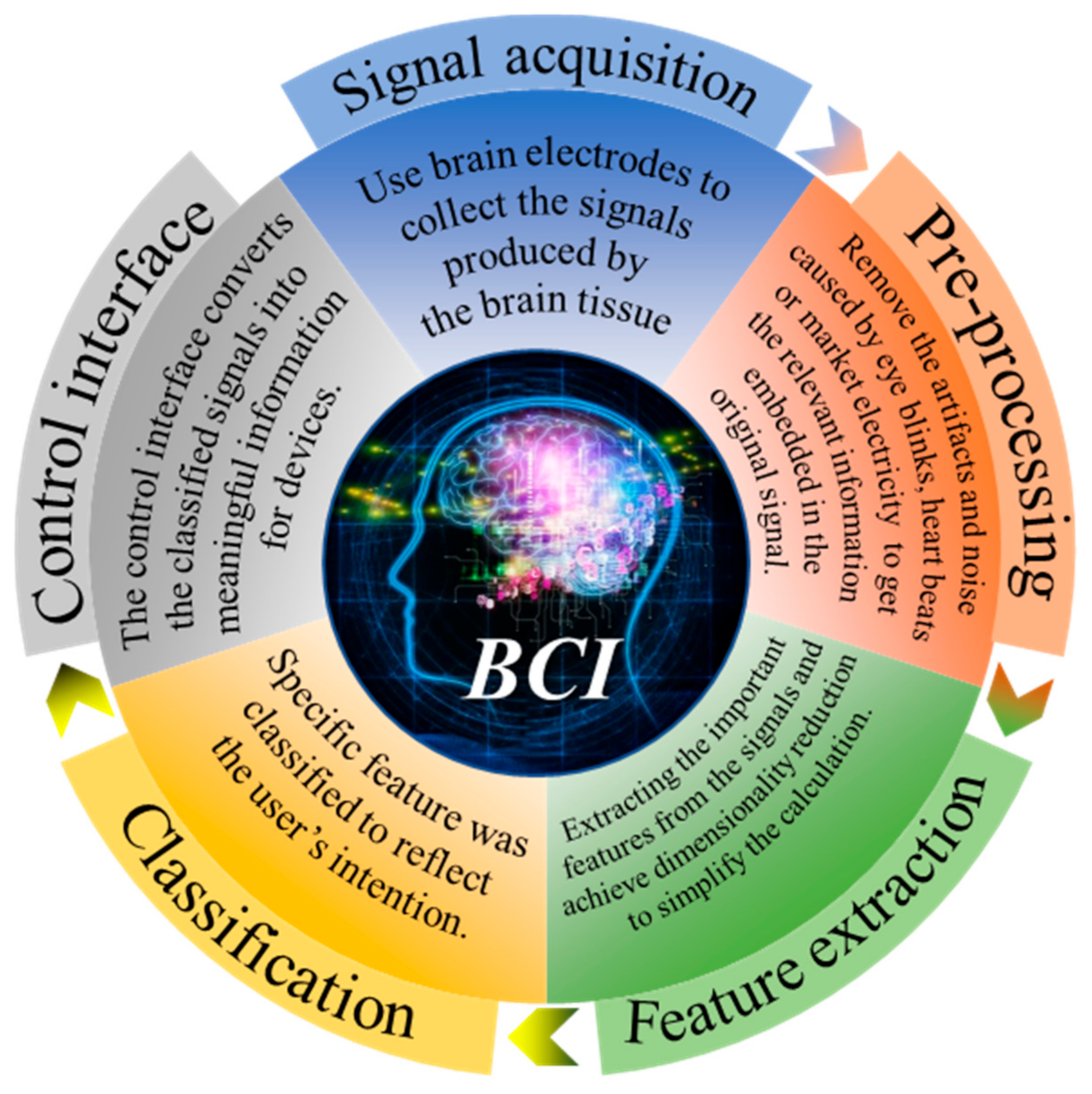

:1. Introduction

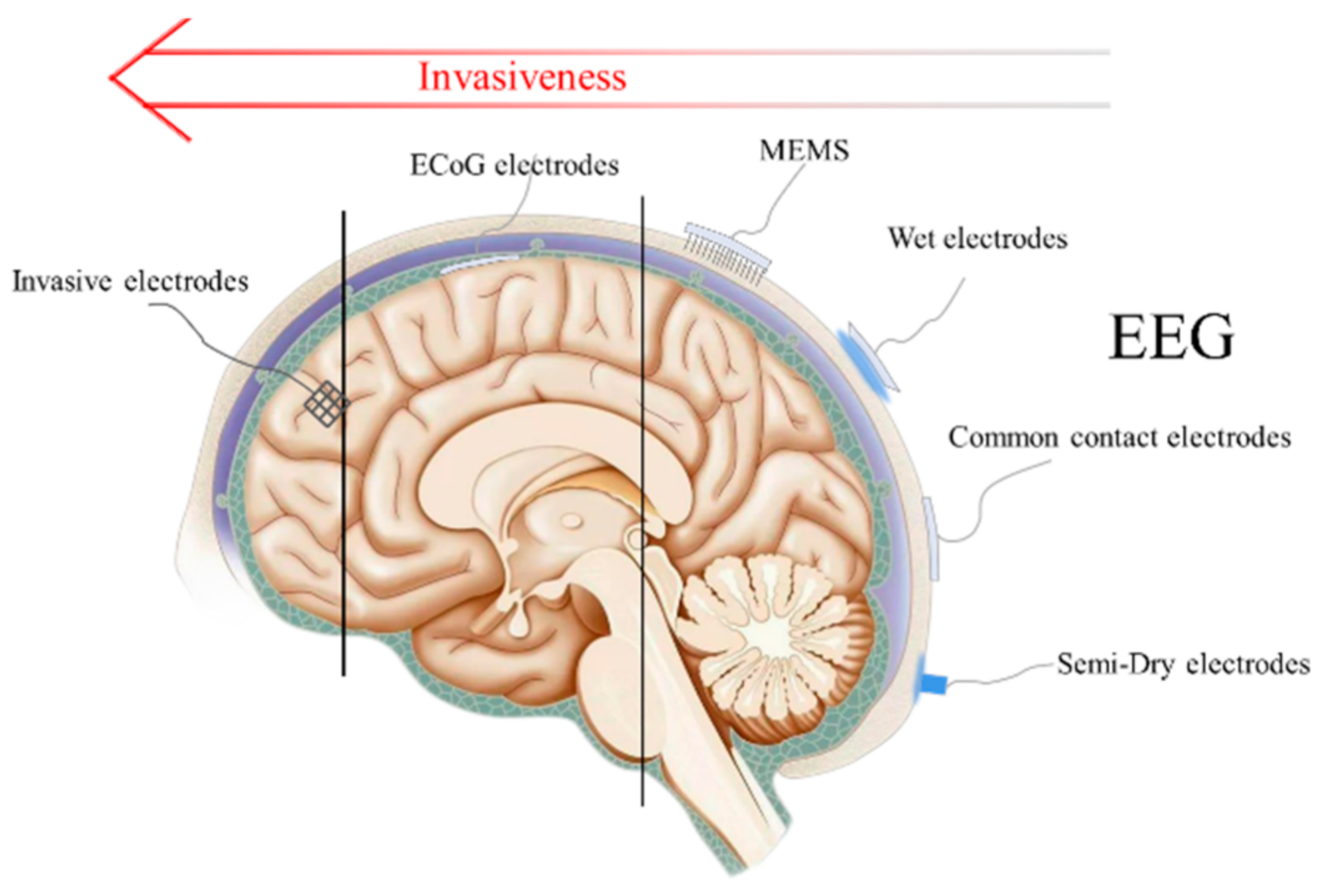

2. EEG Electrodes

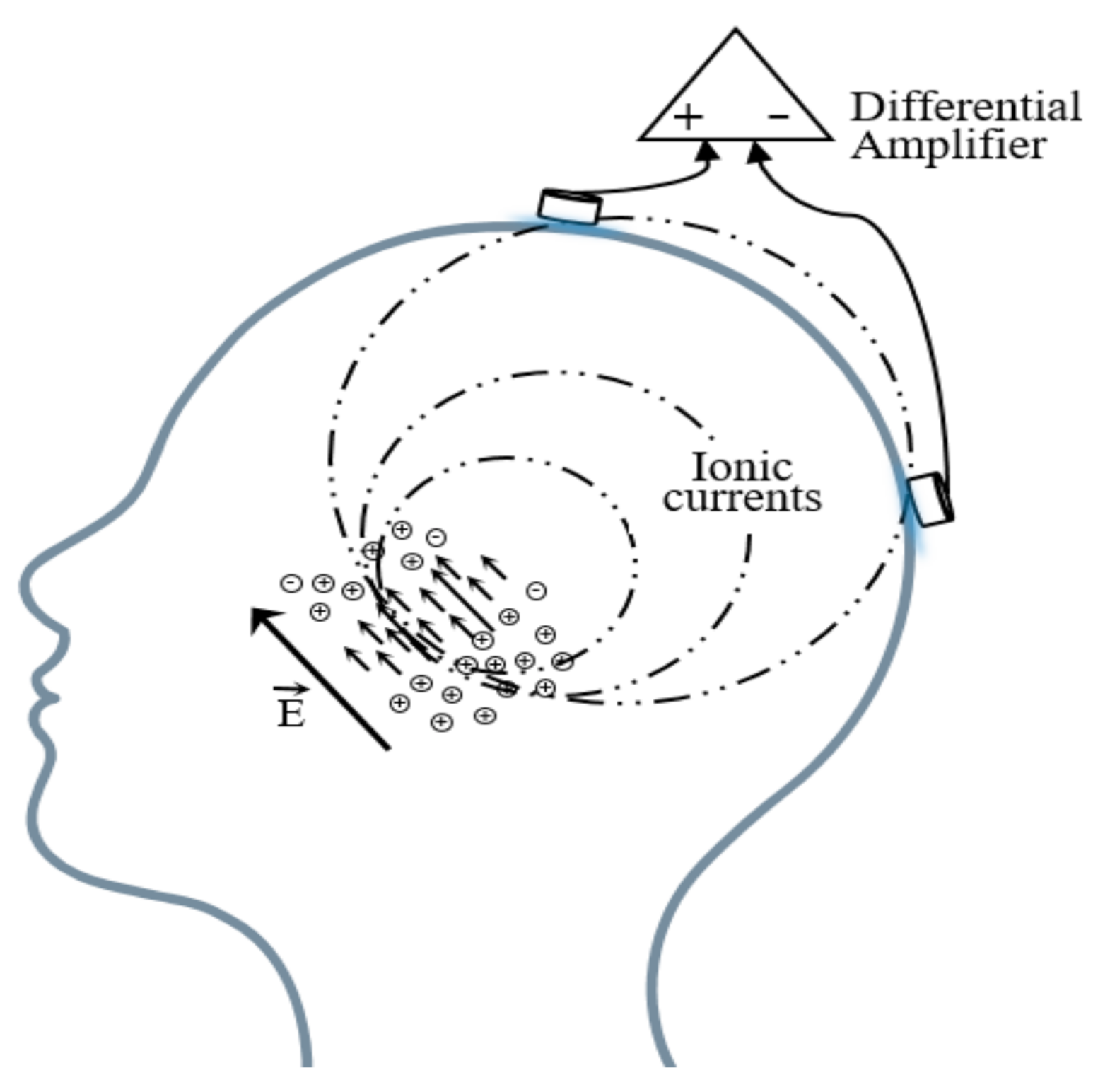

2.1. Principle of EEG Acquisition

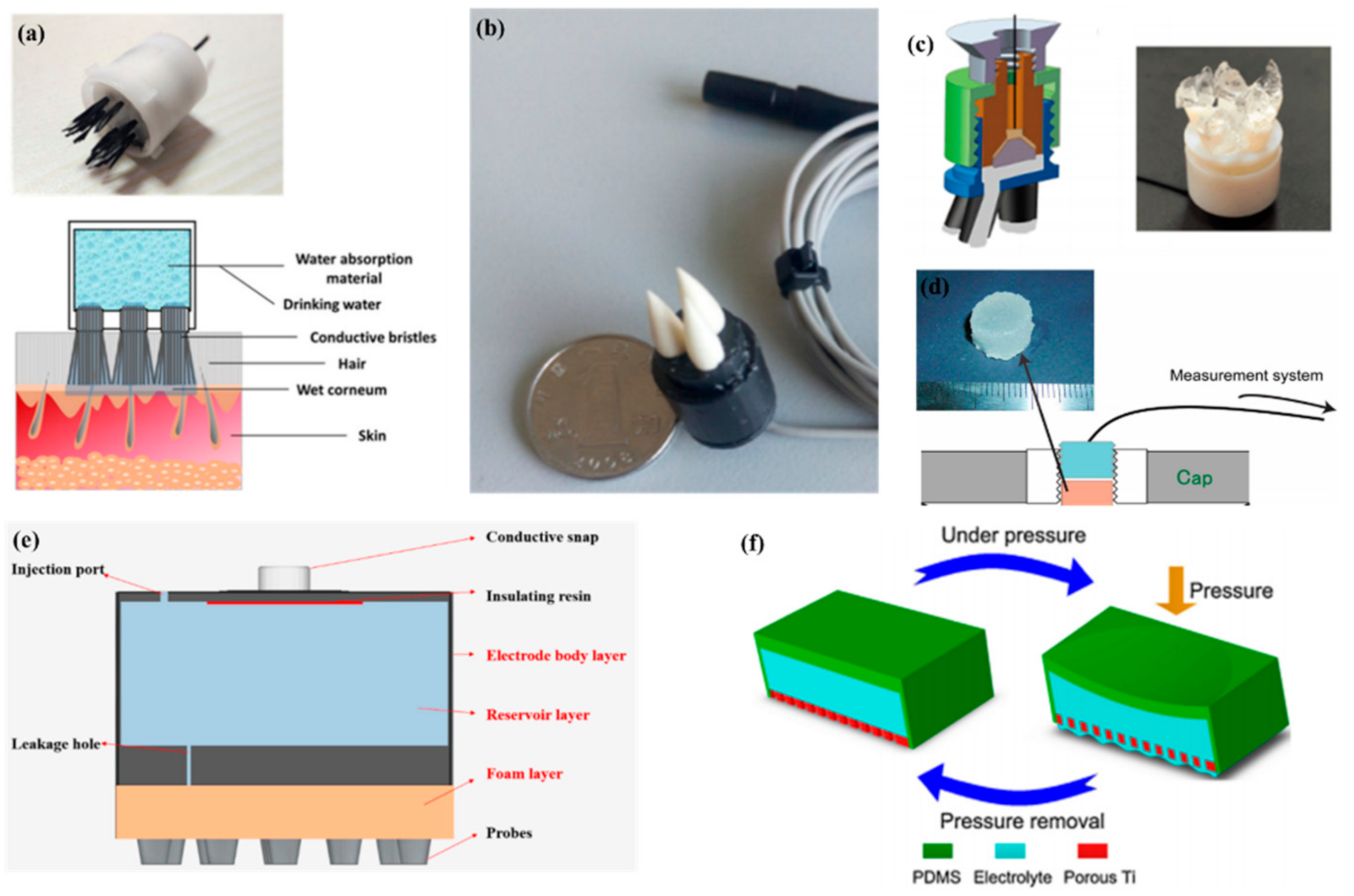

2.2. Wet Electrodes

2.3. Dry Electrodes

2.3.1. MEMS Dry Electrodes

2.3.2. Non-Contacted Electrodes

2.3.3. Common-Contact Dry Electrodes

2.4. Semi-Dry Electrodes

3. Evaluation Methods for EEG Electrodes

3.1. Evaluation of Chemical Characteristics

3.2. Simulation of Actual Application Scenarios

3.2.1. Antioxidant Performance

3.2.2. Sweat Resistance

3.2.3. Moisture Retention

3.2.4. Structural Stability

3.3. Electrochemical Performance

3.3.1. Impedance

3.3.2. Electrode Polarization and Electrochemical Noise

3.4. Mechanical Performance

3.5. Biocompatibility

3.6. Operation Difficulty and Comfort

4. Challenges for EEG Electrodes and Expectations

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nicolelis, M.A.L. Brain-to-Brain Interfaces: When Reality Meets Science Fiction. Cerebrum Dana Forum Brain Sci. 2014, 2014, 13. [Google Scholar]

- Vidal, J.J. Toward direct brain-computer communication. Annu. Rev. Biophys. Bio. 1973, 2, 157–180. [Google Scholar] [CrossRef] [PubMed]

- Vidal, J.J. Real-time detection of brain events in EEG. Proc. IEEE 1977, 65, 633–641. [Google Scholar] [CrossRef]

- Wolpaw, J.R.; Birbaumer, N.; Heetderks, W.J.; Mcfarland, D.J.; Peckham, P.H.; Schalk, G.; Donchin, E.; Quatrano, L.A.; Robinson, C.J.; Vaughan, T.M. Brain-computer interface technology: A review of the first international meeting. IEEE Trans. Rehabil. Eng. 2000, 8, 164–173. [Google Scholar] [CrossRef]

- Machado, S.; Arauro, F.; Paes, F.; Velasques, B.; Cunha, M.; Budde, H.; Basile, L.; Anghinah, R.; Arias-Carrión, O.; Cagy, M.; et al. EEG-based Brain-Computer Interfaces: An Overview of Basic Concepts and Clinical Applications in Neurorehabilitation. Rev. Neurosci. 2010, 21, 451–468. [Google Scholar] [CrossRef]

- Moghimi, S.; Kushki, A.; Guerguerian, A.M.; Chau, T. A review of EEG-based brain-computer interfaces as access pathways for individuals with severe disabilities. Assist. Technol. 2013, 25, 99–110. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Yan, F.; Xu, T.; Yin, H.; Chen, P.; Yue, H.; Chen, C.; Zhang, H.; Xu, L.; He, Y.; et al. Brain-Controlled Wheelchair Review: From Wet Electrode to Dry Electrode, From Single Modal to Hybrid Modal, From Synchronous to Asynchronous. IEEE Access 2021, 9, 55920–55938. [Google Scholar] [CrossRef]

- Geronimo, A.; Stephens, H.E.; Schiff, S.J.; Simmons, Z. Acceptance of brain-computer interfaces in amyotrophic lateral sclerosis. Amyotroph. Lateral Scler. Front. Degener. 2015, 16, 258–264. [Google Scholar] [CrossRef]

- Cervera, M.A.; Soekadar, S.R.; Ushiba, J.; Millan, J.D.R.; Liu, M.; Birbaumer, N.; Garipelli, G. Brain-computer interfaces for post-stroke motor rehabilitation: A meta-analysis. Ann. Clin. Transl. Neurol. 2018, 5, 651–663. [Google Scholar] [CrossRef]

- Ramos-Murguialday, A.; Broetz, D.; Rea, M.; Laer, L.; Yilmaz, O.; Brasil, F.L.; Liberati, G.; Curado, M.R.; Garcia-Cossio, E.; Vyziotis, A.; et al. Brain-machine interface in chronic stroke rehabilitation: A controlled study. Ann. Neurol. 2013, 74, 100–108. [Google Scholar] [CrossRef]

- Widge, A.S.; Malone, D.A., Jr.; Dougherty, D.D. Closing the Loop on Deep Brain Stimulation for Treatment-Resistant Depression. Front. Neurosci. 2018, 12, 175. [Google Scholar] [CrossRef] [PubMed]

- Stawicki, P.; Gembler, F.; Volosyak, I. A User-Friendly Dictionary-Supported SSVEP-Based BCI Application. In Proceedings of the Symbiotic Interaction: 5th International Workshop, Symbiotic 2016, Padua, Italy, 29–30 September 2016; Springer: Berlin/Heidelberg, Germany, 2017; pp. 168–180. [Google Scholar]

- Zander, T.O.; Shetty, K.; Lorenz, R.; Leff, D.R.; Krol, L.R.; Darzi, A.W.; Gramann, K.; Yang, G.-Z. Automated Task Load Detection with Electroencephalography: Towards Passive Brain–Computer Interfacing in Robotic Surgery. J. Med. Robot. Res. 2017, 2, 1750003. [Google Scholar] [CrossRef] [Green Version]

- Hung, S.H.; Chang, C.J.; Chao, C.F.; Wang, I.J.; Lin, B.S. Development of real-time wireless brain computer interface for drowsiness detection. In Proceedings of the 2010 IEEE International Symposium on Circuits and Systems (ISCAS), Paris, France, 30 May–2 June 2010; pp. 1380–1383. [Google Scholar]

- Ko, L.W.; Komarov, O.; Hairston, W.D.; Jung, T.P.; Lin, C.T. Sustained Attention in Real Classroom Settings: An EEG Study. Front. Hum. Neurosci. 2017, 11, 388. [Google Scholar] [CrossRef]

- Coyle, D.; Principe, J.; Lotte, F.; Nijholt, A. Guest Editorial: Brain/neuronal—Computer game interfaces and interaction. IEEE Trans. Comput. Intell. AI Games 2013, 5, 77–81. [Google Scholar] [CrossRef] [Green Version]

- Liao, L.D.; Chen, C.Y.; Wang, I.J.; Chen, S.F.; Lin, C.T. Gaming control using a wearable and wireless EEG-based brain-computer interface device with novel dry foam-based sensors. J. Neuroeng. Rehabili. 2012, 9, 1–12. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yeh, S.-C.; Hou, C.-L.; Peng, W.-H.; Wei, Z.-Z.; Huang, S.; Kung, E.Y.-C.; Lin, L.; Liu, Y.-H. A multiplayer online car racing virtual-reality game based on internet of brains. J. Syst. Archit. 2018, 89, 30–40. [Google Scholar] [CrossRef]

- Park, K.; Kihl, T.; Park, S.; Kim, M.-J.; Chang, J. Fairy tale directed game-based training system for children with ADHD using BCI and motion sensing technologies. Behav. Inf. Technol. 2018, 38, 564–577. [Google Scholar] [CrossRef]

- Rezeika, A.; Benda, M.; Stawicki, P.; Gembler, F.; Saboor, A.; Volosyak, I. Brain-Computer Interface Spellers: A Review. Brain Sci. 2018, 8, 57. [Google Scholar] [CrossRef] [Green Version]

- Abiri, R.; Borhani, S.; Sellers, E.W.; Jiang, Y.; Zhao, X. A comprehensive review of EEG-based brain-computer interface paradigms. J. Neural Eng. 2019, 16, 011001. [Google Scholar] [CrossRef] [PubMed]

- Ilyas, M.Z.; Saad, P.; Ahmad, M.I. A survey of analysis and classification of EEG signals for brain-computer interfaces. In Proceedings of the 2015 2nd International Conference on Biomedical Engineering (ICoBE), Penang, Malaysia, 30–31 March 2015; pp. 30–31. [Google Scholar]

- Lotte, F.; Bougrain, L.; Cichocki, A.; Clerc, M.; Congedo, M.; Rakotomamonjy, A.; Yger, F. A review of classification algorithms for EEG-based brain-computer interfaces: A 10 year update. J. Neural Eng. 2018, 15, 31005. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lotte, F.; Guan, C. Regularizing common spatial patterns to improve BCI designs: Unified theory and new algorithms. IEEE Trans. Biomed. Eng. 2011, 58, 355–362. [Google Scholar] [CrossRef] [Green Version]

- Motamedi-Fakhr, S.; Moshrefi-Torbati, M.; Hill, M.; Hill, C.M.; White, P.R. Signal processing techniques applied to human sleep EEG signals—A review. Biomed. Signal Process. 2014, 10, 21–33. [Google Scholar] [CrossRef]

- Zhang, Y.; Nam, C.S.; Zhou, G.; Jin, J.; Wang, X.; Cichocki, A. Temporally Constrained Sparse Group Spatial Patterns for Motor Imagery BCI. IEEE Trans. Cybern. 2019, 49, 3322–3332. [Google Scholar] [CrossRef] [PubMed]

- Martini, M.L.; Oermann, E.K.; Opie, N.L.; Panov, F.; Oxley, T.; Yaeger, K. Sensor Modalities for Brain-Computer Interface Technology: A Comprehensive Literature Review. Neurosurgery 2020, 86, E108–E117. [Google Scholar] [CrossRef]

- Renshaw, B.; Forbes, A.; Morison, B.R. Activity of isocortex and hippocampus: Electrical studies with micro-electrodes. J. Neurophysiol. 1940, 3, 74–105. [Google Scholar] [CrossRef]

- Worrell, G.A.; Gardner, A.B.; Stead, S.M.; Hu, S.; Goerss, S.; Cascino, G.J.; Meyer, F.B.; Marsh, R.; Litt, B. High-frequency oscillations in human temporal lobe: Simultaneous microwire and clinical macroelectrode recordings. Brain 2008, 131, 928–937. [Google Scholar] [CrossRef] [Green Version]

- Prasad, A.; Xue, Q.S.; Sankar, V.; Nishida, T.; Shaw, G.; Streit, W.J.; Sanchez, J.C. Comprehensive characterization and failure modes of tungsten microwire arrays in chronic neural implants. J. Neural Eng. 2012, 9, 56015. [Google Scholar] [CrossRef]

- Prasad, A.; Xue, Q.S.; Dieme, R.; Sankar, V.; Mayrand, R.C.; Nishida, T.; Streit, W.J.; Sanchez, J.C. Abiotic-biotic characterization of Pt/Ir microelectrode arrays in chronic implants. Front. Neuroeng. 2014, 7, 2. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Obaid, A.; Hanna, M.E.; Wu, Y.W.; Kollo, M.; Melosh, N.A. Massively parallel microwire arrays integrated with CMOS chips for neural recording. Sci. Adv. 2020, 6, eaay2789. [Google Scholar] [CrossRef] [Green Version]

- Jorfi, M.; Skousen, J.L.; Weder, C.; Capadona, J.R. Progress towards biocompatible intracortical microelectrodes for neural interfacing applications. J. Neural Eng. 2015, 12, 11001. [Google Scholar] [CrossRef]

- Wise, K.D.; Angell, J.B.; Starr, A. An Integrated-Circuit Approach to Extracellular Microelectrodes. IEEE Trans. Biomed. Eng. 1970, BME-17, 238–247. [Google Scholar] [CrossRef] [Green Version]

- Campbell, P.K.; Jones, K.E. A silicon-based, three-dimensional neural interface: Manufacturing processes for an intracortical electrode array. IEEE Trans. Biomed. Eng. 1991, 38, 758–768. [Google Scholar] [CrossRef]

- Hetke, J.F.; Williams, J.C.; Pellinen, D.S.; Vetter, R.J.; Kipke, D.R. 3-D silicon probe array with hybrid polymer interconnect for chronic cortical recording. In Proceedings of the 1st International IEEE EMBS Conference on Neural Engineering, Capri Island, Italy, 20–22 March 2003; pp. 181–184. [Google Scholar]

- Xu, C.; Lemon, W.; Liu, C. Design and fabrication of a high-density metal microelectrode array for neural recording. Sens. Actuator A Phys. 2002, 96, 78–85. [Google Scholar] [CrossRef]

- Jones, K.E.; Campbell, P.K.; Normann, R.A. A glass/silicon composite intracortical electrode array. Ann. Biomed. Eng. 1992, 20, 423–437. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Du, M.; Wang, L.; Li, S.; Wang, G.; Yang, X.; Zhang, L.; Fang, Y.; Zheng, W.; Yang, G.; et al. Bacterial Cellulose as a Supersoft Neural Interfacing Substrate. ACS Appl. Mater. Interfaces 2018, 10, 33049–33059. [Google Scholar] [CrossRef]

- Wang, L.; Chen, D.; Jiang, K.; Shen, G. New insights and perspectives into biological materials for flexible electronics. Chem. Soc. Rev. 2017, 46, 6764–6815. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.M.; Hong, G.; Lin, D.; Schuhmann, T.G., Jr.; Sullivan, A.T.; Viveros, R.D.; Park, H.G.; Lieber, C.M. Nanoenabled Direct Contact Interfacing of Syringe-Injectable Mesh Electronics. Nano Lett. 2019, 19, 5818–5826. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Fu, T.M.; Cheng, Z.; Hong, G.; Zhou, T.; Jin, L.; Duvvuri, M.; Jiang, Z.; Kruskal, P.; Xie, C.; et al. Syringe-injectable electronics. Nat. Nanotechnol. 2015, 10, 629–636. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Viveros, R.D.; Zhou, T.; Hong, G.; Fu, T.M.; Lin, H.G.; Lieber, C.M. Advanced One- and Two-Dimensional Mesh Designs for Injectable Electronics. Nano Lett. 2019, 19, 4180–4187. [Google Scholar] [CrossRef]

- Xie, C.; Liu, J.; Fu, T.M.; Dai, X.; Zhou, W.; Lieber, C.M. Three-dimensional macroporous nanoelectronic networks as minimally invasive brain probes. Nat. Mater. 2015, 14, 1286–1292. [Google Scholar] [CrossRef] [Green Version]

- Teplan, M. Fundamentals of EEG Measurement. Meas. Sci. Rev. 2002, 2, 1–11. [Google Scholar]

- Nicolas-Alonso, L.F.; Gomez-Gil, J. Brain computer interfaces, a review. Sensors 2012, 12, 1211–1279. [Google Scholar] [CrossRef]

- Kappenman, E.S.; Luck, S.J. The effects of electrode impedance on data quality and statistical significance in ERP recordings. Psychophysiology 2010, 47, 888–904. [Google Scholar] [CrossRef] [Green Version]

- Fowles, D.C.; Venables, P.H. The reduction of palmar skin potential by epidermal hydration. Psychophysiology 1970, 7, 254–261. [Google Scholar] [CrossRef]

- Tregear, R.T. Physical Functions of Skin; Academic Press, Inc.: New York, NY, USA, 1966; pp. 1–52. [Google Scholar]

- Yao, S.; Zhu, Y. Nanomaterial-Enabled Dry Electrodes for Electrophysiological Sensing: A Review. JOM 2016, 68, 1145–1155. [Google Scholar] [CrossRef]

- Chi, Y.M.; Wang, Y.T.; Wang, Y.; Maier, C.; Jung, T.P.; Cauwenberghs, G. Dry and noncontact EEG sensors for mobile brain-computer interfaces. IEEE Trans. Neural Syst. Rehabil. Eng. 2012, 20, 228–235. [Google Scholar] [CrossRef]

- Li, G.; Wang, S.; Duan, Y.Y. Towards gel-free electrodes: A systematic study of electrode-skin impedance. Sens. Actuators B Chem. 2017, 241, 1244–1255. [Google Scholar] [CrossRef]

- Fiedler, P.; Griebel, S.; Pedrosa, P.; Fonseca, C.; Vaz, F.; Zentner, L.; Zanow, F.; Haueisen, J. Multichannel EEG with novel Ti/TiN dry electrodes. Sens. Actuator A Phys. 2015, 221, 139–147. [Google Scholar] [CrossRef]

- Guger, C.; Daban, S.; Sellers, E.; Holzner, C.; Krausz, G.; Carabalona, R.; Gramatica, F.; Edlinger, G. How many people are able to control a P300-based brain-computer interface (BCI)? Neurosci. Lett. 2009, 462, 94–98. [Google Scholar] [CrossRef]

- Merletti, R. The electrode-skin interface and optimal detection of bioelectric signals. Physiol. Meas. 2010, 31. [Google Scholar] [CrossRef] [PubMed]

- Tallgren, P.; Vanhatalo, S.; Kaila, K.; Voipio, J. Evaluation of commercially available electrodes and gels for recording of slow EEG potentials. Clin. Neurophysiol. 2005, 116, 799–806. [Google Scholar] [CrossRef]

- Miller, J.W.; Kim, W.; Holmes, M.D.; Vanhatalo, S. Ictal localization by source analysis of infraslow activity in DC-coupled scalp EEG recordings. NeuroImage 2007, 35, 583–597. [Google Scholar] [CrossRef]

- Scanlon, J.E.M.; Townsend, K.A.; Cormier, D.L.; Kuziek, J.W.P.; Mathewson, K.E. Taking off the training wheels: Measuring auditory P3 during outdoor cycling using an active wet EEG system. Brain Res. 2019, 1716, 50–61. [Google Scholar] [CrossRef]

- Kim, D.Y.; Ku, Y.; Ahn, J.W.; Kwon, C.; Kim, H.C. Electro-deposited Nanoporous Platinum Electrode for EEG Monitoring. J. Korean Med. Sci. 2018, 33, e154. [Google Scholar] [CrossRef] [Green Version]

- Ng, W.C.; Seet, H.L.; Lee, K.S.; Ning, N.; Tai, W.X.; Sutedja, M.; Fuh, J.Y.H.; Li, X.P. Micro-spike EEG electrode and the vacuum-casting technology for mass production. J. Mater. Process. Technol. 2009, 209, 4434–4438. [Google Scholar] [CrossRef]

- Tseghai, G.B.; Malengier, B.; Fante, K.A.; Langenhove, L.V. The Status of Textile-Based Dry EEG Electrodes. Autex Res. J. 2021, 21, 63–70. [Google Scholar] [CrossRef]

- Huigen, E.; Peper, A.; Grimbergen, C.A. Investigation into the origin of the noise of surface electrodes. Med. Biol. Eng. Comput. 2002, 40, 332–338. [Google Scholar] [CrossRef]

- Pedrosa, P.; Fiedler, P.; Schinaia, L.; Vasconcelos, B.; Martins, A.C.; Amaral, M.H.; Comani, S.; Haueisen, J.; Fonseca, C. Alginate-based hydrogels as an alternative to electrolytic gels for rapid EEG monitoring and easy cleaning procedures. Sens. Actuators B Chem. 2017, 247, 273–283. [Google Scholar] [CrossRef]

- Goulart, L.A.; Guaraldo, T.T.; Lanza, M.R.V. A Novel Electrochemical Sensor Based on Printex L6 Carbon Black Carrying CuO/Cu2O Nanoparticles for Propylparaben Determination. Electroanalysis 2018, 30, 2967–2976. [Google Scholar] [CrossRef]

- Sheng, X.; Qin, Z.; Xu, H.; Shu, X.; Gu, G.; Zhu, X. Soft ionic-hydrogel electrodes for electroencephalography signal recording. Sci. China Technol. Sci. 2020, 64, 273–282. [Google Scholar] [CrossRef]

- Liao, L.D.; Wang, I.J.; Chen, S.F.; Chang, J.Y.; Lin, C.T. Design, fabrication and experimental validation of a novel dry-contact sensor for measuring electroencephalography signals without skin preparation. Sensors 2011, 11, 5819–5834. [Google Scholar] [CrossRef]

- Spelman, F.A. Cochlear electrode arrays: Past, present and future. Audiol. Neurotol. 2006, 11, 77–85. [Google Scholar] [CrossRef]

- Bai, Q.; Wise, K.D.; Anderson, D.J. A high-yield microassembly structure for three-dimensional microelectrode arrays. IEEE Trans. Biomed. Eng. 2000, 47, 281. [Google Scholar]

- Griss, P.; Enoksson, P.; Stemme, G. Micromachined barbed spikes for mechanical chip attachment. Sens. Actuator A Phys. 2002, 95, 94–99. [Google Scholar] [CrossRef]

- Chiou, J.C.; Ko, L.W.; Lin, C.T.; Hong, C.T.; Jung, T.P. Using Novel MEMS EEG Sensors in Detecting Drowsiness Application. In Proceedings of the IEEE Biomedical Circuits and Systems Conference, London, UK, 29 November–1 December 2006; pp. 33–36. [Google Scholar]

- Nakazaki, N.; Takao, Y.; Eriguchi, K.; Ono, K. Molecular dynamics simulations of silicon chloride ion incidence during Si etching in Cl-based plasmas. Jpn. J. Appl. Phys. 2014, 53, 56201. [Google Scholar] [CrossRef]

- Hsu, L.S.; Tung, S.W.; Kuo, C.H.; Yang, Y.J. Developing barbed microtip-based electrode arrays for biopotential measurement. Sensors 2014, 14, 12370–12386. [Google Scholar] [CrossRef] [Green Version]

- Griss, P.; Enoksson, P.; Tolvanen-Laakso, H.K.; Merilainen, P.; Ollmar, S.; Stemme, G. Micromachined electrodes for biopotential measurements. J. Microelectromech. Syst. 2001, 10, 10–16. [Google Scholar] [CrossRef]

- Sun, Y.; Ren, L.; Jiang, L.; Tang, Y.; Liu, B. Fabrication of Composite Microneedle Array Electrode for Temperature and Bio-Signal Monitoring. Sensors 2018, 18, 1193. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhou, W.; Song, R.; Pan, X.; Peng, Y.; Qi, X.; Peng, J.; Hui, K.S.; Hui, K.N. Fabrication and impedance measurement of novel metal dry bioelectrode. Sens. Actuator A Phys. 2013, 201, 127–133. [Google Scholar] [CrossRef]

- Zhou, W.; Ling, W.-S.; Liu, W.; Peng, Y.; Peng, J. Laser direct micromilling of copper-based bioelectrode with surface microstructure array. Opt. Lasers Eng. 2015, 73, 7–15. [Google Scholar] [CrossRef]

- Yan, X.-X.; Liu, J.-Q.; Jiang, S.-D.; Yang, B.; Yang, C.-S. Tapered metal microneedles fabricated by the hybrid process of mechanical dicing and electrochemical corrosion for drug delivery. Micro Nano Lett. 2012, 7, 1313–1315. [Google Scholar] [CrossRef]

- Dias, N.S.; Carmo, J.P.; da Silva, A.F.; Mendes, P.M.; Correia, J.H. New dry electrodes based on iridium oxide (IrO) for non-invasive biopotential recordings and stimulation. Sens. Actuator A Phys. 2010, 164, 28–34. [Google Scholar] [CrossRef] [Green Version]

- Yu, Y.H.; Chen, S.H.; Chang, C.L.; Lin, C.T.; Hairston, W.D.; Mrozek, R.A. New Flexible Silicone-Based EEG Dry Sensor Material Compositions Exhibiting Improvements in Lifespan, Conductivity, and Reliability. Sensors 2016, 16, 1826. [Google Scholar] [CrossRef] [Green Version]

- Stavrinidis, G.; Michelakis, K.; Kontomitrou, V.; Giannakakis, G.; Sevrisarianos, M.; Sevrisarianos, G.; Chaniotakis, N.; Alifragis, Y.; Konstantinidis, G. SU-8 microneedles based dry electrodes for Electroencephalogram. Microelectron. Eng. 2016, 159, 114–120. [Google Scholar] [CrossRef]

- Mansoor, I.; Liu, Y.; Hafeli, U.O.; Stoeber, B. Fabrication of hollow microneedle arrays using electrodeposition of metal onto solvent cast conductive polymer structures. In Proceedings of the 2013 Transducers & Eurosensors XXVII: The 17th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS & EUROSENSORS XXVII), Barcelona, Spain, 16–20 June 2013; pp. 373–376. [Google Scholar]

- Luttge, R.; Bystrova, S.N.; Putten, M. Microneedle array electrode for human EEG recording. In Proceedings of the 4th European Conference of the International Federation for Medical and Biological Engineering, Antwerp, Belgium, 23–27 November 2008; Springer: Berlin/Heidelberg, Germany, 2009; Volume 22, pp. 1246–1249. [Google Scholar]

- Cha, K.J.; Kim, T.; Park, S.J.; Kim, D.S. Simple and cost-effective fabrication of solid biodegradable polymer microneedle arrays with adjustable aspect ratio for transdermal drug delivery using acupuncture microneedles. J. Micromech. Microeng. 2014, 24, 115015. [Google Scholar] [CrossRef]

- Ami, Y. Formation of polymer microneedle arrays using soft lithography. Micro/Nanolith. Mems Moems 2011, 10, 011503. [Google Scholar] [CrossRef]

- Zhu, J.; Shen, Q.; Cao, Y.; Wang, H.; Chen, X.; Chen, D. Characterization of out-of-plane cone metal microneedles and the function of transdermal delivery. Microsyst. Technol. 2012, 19, 617–621. [Google Scholar] [CrossRef]

- Lee, S.M.; Kim, J.H.; Byeon, H.J.; Choi, Y.Y.; Park, K.S.; Lee, S.H. A capacitive, biocompatible and adhesive electrode for long-term and cap-free monitoring of EEG signals. J. Neural Eng. 2013, 10, 036006. [Google Scholar] [CrossRef]

- Liu, S.; Liu, X.; Jiang, Y.; Wang, X.; Huang, P.; Wang, H.; Zhu, M.; Tan, J.; Li, P.; Lin, C.; et al. Flexible Non-contact Electrodes for Bioelectrical Signal Monitoring. In Proceedings of the 2018 40th Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), Honolulu, HI, USA, 18–21 July 2018; pp. 4305–4308. [Google Scholar]

- Chen, Y.-C.; Lin, B.-S.; Pan, J.-S. Novel Noncontact Dry Electrode With Adaptive Mechanical Design for Measuring EEG in a Hairy Site. IEEE Trans. Instrum. Meas. 2015, 64, 3361–3368. [Google Scholar] [CrossRef]

- Dabbaghian, A.; Yousefi, T.; Fatmi, S.Z.; Shafia, P.; Kassiri, H. A 9.2-g Fully-Flexible Wireless Ambulatory EEG Monitoring and Diagnostics Headband With Analog Motion Artifact Detection and Compensation. IEEE Trans. Biomed. Circuits Syst. 2019, 13, 1141–1151. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Yu, X.B. Capacitive Biopotential Measurement for Electrophysiological Signal Acquisition: A Review. IEEE Sens. J. 2016, 16, 2832–2853. [Google Scholar] [CrossRef]

- Liu, J.; Liu, X.; He, E.; Gao, F.; Li, Z.; Xiao, G.; Xu, S.; Cai, X. A novel dry-contact electrode for measuring electroencephalography signals. Sens. Actuator A Phys. 2019, 294, 73–80. [Google Scholar] [CrossRef]

- Fiedler, P.; Pedrosa, P.; Griebel, S.; Fonseca, C.; Haueisen, J. Novel flexible dry PU/TiN-multipin electrodes: First application in EEG measurements. In Proceedings of the International Conference of the IEEE Engineering in Medicine & Biology Society, Boston, MA, USA, 30 August–3 September 2011; pp. 55–58. [Google Scholar]

- Krachunov, S.; Casson, A.J. 3D Printed Dry EEG Electrodes. Sensors 2016, 16, 1635. [Google Scholar] [CrossRef]

- Kitoko, V.; Nguyen, T.N.; Nguyen, J.S.; Tran, Y.; Nguyen, H.T. Performance of dry electrode with bristle in recording EEG rhythms across brain state changes. In Proceedings of the International Conference of the IEEE Engineering in Medicine & Biology Society, Boston, MA, USA, 30 August–3 September 2011; pp. 59–62. [Google Scholar]

- Grozea, C.; Voinescu, C.D.; Fazli, S. Bristle-sensors-low-cost flexible passive dry EEG electrodes for neurofeedback and BCI applications. J. Neural Eng. 2011, 8, 025008. [Google Scholar] [CrossRef] [PubMed]

- Gao, K.-P.; Yang, H.-J.; Wang, X.-L.; Yang, B.; Liu, J.-Q. Soft pin-shaped dry electrode with bristles for EEG signal measurements. Sens. Actuator A Phys. 2018, 283, 348–361. [Google Scholar] [CrossRef]

- Lee, J.S.; Han, C.M.; Kim, J.H.; Park, K.S. Reverse-curve-arch-shaped dry EEG electrode for increased skin–electrode contact area on hairy scalps. Electron. Lett. 2015, 51, 1643–1645. [Google Scholar] [CrossRef]

- Krishnan, A.; Kumar, R.; Venkatesh, P.; Kelly, S.; Grover, P. Low-cost carbon fiber-based conductive silicone sponge EEG electrodes. In Proceedings of the 2018 40th Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), Honolulu, HI, USA, 18–21 July 2018; pp. 1287–1290. [Google Scholar]

- Chen, Y.H.; Op de Beeck, M.; Vanderheyden, L.; Carrette, E.; Mihajlovic, V.; Vanstreels, K.; Grundlehner, B.; Gadeyne, S.; Boon, P.; Van Hoof, C. Soft, comfortable polymer dry electrodes for high quality ECG and EEG recording. Sensors 2014, 14, 23758–23780. [Google Scholar] [CrossRef] [Green Version]

- Lofhede, J.; Seoane, F.; Thordstein, M. Textile electrodes for EEG recording—A pilot study. Sensors 2012, 12, 16907–16919. [Google Scholar] [CrossRef] [PubMed]

- Kumar, N.M.; Thilagavathi, G. Design and Development of Textile Electrodes for EEG Measurement using Copper Plated Polyester Fabrics. J. Text. Appar. Technol. Manag. 2014, 8, 80–85. [Google Scholar]

- Lin, C.T.; Liao, L.D.; Liu, Y.H.; Wang, I.J.; Lin, B.S.; Chang, J.Y. Novel dry polymer foam electrodes for long-term EEG measurement. IEEE. Trans. Biomed. Eng. 2011, 58, 1200–1207. [Google Scholar] [CrossRef] [PubMed]

- Yapici, M.K.; Alkhidir, T.; Samad, Y.A.; Liao, K. Graphene-clad textile electrodes for electrocardiogram monitoring. Sens. Actuators B Chem. 2015, 221, 1469–1474. [Google Scholar] [CrossRef]

- Muthukumar, N.; Thilagavathi, G.; Kannaian, T. Polyaniline-coated foam electrodes for electroencephalography (EEG) measurement. J. Text. Inst. 2015, 107, 283–290. [Google Scholar] [CrossRef]

- Li, G.; Wu, J.; Xia, Y.; Wu, Y.; Tian, Y.; Liu, J.; Chen, D.; He, Q. Towards emerging EEG applications: A novel printable flexible Ag/AgCl dry electrode array for robust recording of EEG signals at forehead sites. J. Neural Eng. 2020, 17, 026001. [Google Scholar] [CrossRef]

- Jiang, Y.; Liu, L.; Chen, L.; Zhang, Y.; He, Z.; Zhang, W.; Zhao, J.; Lu, D.; He, J.; Zhu, H.; et al. Flexible and Stretchable Dry Active Electrodes with PDMS and Silver Flakes for Bio-potentials Sensing Systems. IEEE Sens. J. 2021, 21, 12255–12268. [Google Scholar] [CrossRef]

- Lee, J.H.; Hwang, J.Y.; Zhu, J.; Hwang, H.R.; Lee, S.M.; Cheng, H.; Lee, S.H.; Hwang, S.W. Flexible Conductive Composite Integrated with Personal Earphone for Wireless, Real-Time Monitoring of Electrophysiological Signs. ACS Appl. Mater. Interfaces 2018, 10, 21184–21190. [Google Scholar] [CrossRef]

- Kappel, S.L.; Rank, M.L.; Toft, H.O.; Andersen, M.; Kidmose, P. Dry-Contact Electrode Ear-EEG. IEEE. Trans. Biomed. Eng. 2019, 66, 150–158. [Google Scholar] [CrossRef] [PubMed]

- Mota, A.R.; Duarte, L.; Rodrigues, D.; Martins, A.C.; Machado, A.V.; Vaz, F.; Fiedler, P.; Haueisen, J.; Nóbrega, J.M.; Fonseca, C. Development of a quasi-dry electrode for EEG recording. Sens. Actuator A Phys. 2013, 199, 310–317. [Google Scholar] [CrossRef]

- Li, G.; Zhang, D.; Wang, S.; Duan, Y.Y. Novel passive ceramic based semi-dry electrodes for recording electroencephalography signals from the hairy scalp. A Sens. Actuators B Chem. 2016, 237, 167–178. [Google Scholar] [CrossRef] [Green Version]

- Hua, H.; Tang, W.; Xu, X.; Feng, D.D.; Shu, L. Flexible Multi-Layer Semi-Dry Electrode for Scalp EEG Measurements at Hairy Sites. Micromachines 2019, 10, 518. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gao, K.P.; Yang, H.J.; Liao, L.L.; Jiang, C.P.; Zhao, N.; Wang, X.L.; Li, X.Y.; Chen, X.; Yang, B.; Liu, J. A Novel Bristle-Shaped Semi-Dry Electrode With Low Contact Impedance and Ease of Use Features for EEG Signal Measurements. IEEE. Trans. Biomed. Eng. 2020, 67, 750–761. [Google Scholar] [CrossRef] [PubMed]

- Xing, X.; Pei, W.; Wang, Y.; Guo, X.; Zhang, H.; Xie, Y.; Gui, Q.; Wang, F.; Chen, H. Assessing a novel micro-seepage electrode with flexible and elastic tips for wearable EEG acquisition. Sens. Actuator A Phys. 2018, 270, 262–270. [Google Scholar] [CrossRef]

- Peng, H.-L.; Jing-Quan, L.; Tian, H.-C.; Dong, Y.-Z.; Yang, B.; Chen, X.; Yang, C.-S. A novel passive electrode based on porous Ti for EEG recording. Sens. Actuators B Chem. 2016, 226, 349–356. [Google Scholar] [CrossRef]

- Lin, S.; Liu, J.; Li, W.; Wang, D.; Huang, Y.; Jia, C.; Li, Z.; Murtaza, M.; Wang, H.; Song, J.; et al. A Flexible, Robust, and Gel-Free Electroencephalogram Electrode for Noninvasive Brain-Computer Interfaces. Nano Lett. 2019, 19, 6853–6861. [Google Scholar] [CrossRef]

- Toyama, S.; Takano, K.; Kansaku, K. A non-adhesive solid-gel electrode for a non-invasive brain-machine interface. Front. Neurol. 2012, 3, 114. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sang, Z.; Ke, K.; Manas-Zloczower, I. Design Strategy for Porous Composites Aimed at Pressure Sensor Application. Small 2019, 15, e1903487. [Google Scholar] [CrossRef]

- Besio, W.; Prasad, A. Analysis of skin-electrode impedance using concentric ring electrode. Conf. Proc. IEEE Eng. Med. Biol. Soc. 2006, 1, 6414–6417. [Google Scholar]

- Pinto, A.M.R.; Bertemes-Filho, P.; Paterno, A. Gelatin: A skin phantom for bioimpedance spectroscopy. Biomed. Phys. Eng. Express. 2015, 1, 035001. [Google Scholar] [CrossRef]

- Guger, C.; Krausz, G.; Allison, B.Z.; Edlinger, G. Comparison of dry and gel based electrodes for p300 brain-computer interfaces. Front. Neurosci. 2012, 6, 60. [Google Scholar] [CrossRef] [Green Version]

| Electrode Type | Materials (Structure) | Contact Impedance | Correlation | Ref. |

|---|---|---|---|---|

| MEMS electrodes | Ti/Pt @ Si substrate | — | 83~86% | [70] |

| Ti/Ag @ Si substrate | 12.5 kΩ~20 kΩ (@ 10 hz) | 91.63% (@ forehead) | [72] | |

| Au/SU-8 @ Ti substrate | 40 kΩ (@ 10 hz on the inner forearm) | — | [74] | |

| Cu | 1.9 kΩ (@ 50 kHz on the inner forearm) | — | [75] | |

| IrO | Lower than Ag/AgCl wet electrode | — | [78] | |

| Ag flakes in silicone | — | 97.85% | [79] | |

| Ag @ flexible polyimide organic layer | 3 kΩ (@ Fp1) and 2.7 kΩ (@ Cz) | — | [80] | |

| Non-contacted electrodes | A layer of 30 μm polyimide, 30 nm titanium, 10 μm Cu, 30 μm Ni and 100 nm Au | — | 91% (eye closed) and 83% (eyes open) | [86] |

| Cu | — | 92.05% | [88] | |

| Cu | — | — | [87] | |

| Common-contact electrode | BeCu plungers coated with Au | 9 kΩ (@ forehead) 16 kΩ (@ hariy sites) | 95.26% (@ forehead) and 91.47% (@ hairy sites) | [66] |

| Spring probes coated with a platinum nanoporous layer | 11.5 ± 4.9 kΩ | 81.79~96.77% | [91] | |

| PU multpin coated with TiN | 65~76 kΩ (@ Fp2) | — | [92] | |

| Fingered PLA plastic coated with Ag | 3 kΩ (@ 10 hz) | 86.2~99.5% | [93] | |

| Bristles made of Ag/AgCl | 5~10 kΩ | — | [94] | |

| Bristles coated with Ag | 80 kΩ | — | [95] | |

| Pin-shaped PDMS embedded with carbon fiber and coated with Au | 13 kΩ~417 kΩ (Average 133 kΩ) | >90% at most of the frequencies | [96] | |

| Reverse-curve arch made of 92.5% Ag and 7.5%Cu | 70 kΩ (@ forehead) and 125 kΩ (@ hairy sites) | — | [97] | |

| Fingered EPDM embedded with carbon fiber stainless steel fiber and CNT (finger-shaped) | — | 90% | [99] | |

| Ti/TiN | About 250 kΩ | — | [53] | |

| PU foam coated with Ni/Cu | 7 kΩ~15 kΩ (0.5 Hz~1000 Hz on the forehead) | 95.56% (@ forehead) | [17] | |

| TYPE I: A yarn containing 78% polyamide and 22% elastomer and plated with 99% pure silver TYPE II: 15% nylon, 30% silver plated conductive fibers, 20% Spandex and 35% polypropylene. | — | 82~88% | [100] | |

| PU foam with electrically conductive taffeta fabric and Ni/Cu coating | 9 kΩ (@ forehead) and 16 kΩ (@ hairy sites) | 96.14% (@ forehead) and 90.12% (@ hairy sites) | [102] | |

| PU foam coated with PANI | — | — | [104] | |

| Ag/AgCl screen printed on a sweat-absorbable sponge layer | 2325 ± 1025 Ω (wet skin) and 36,366 ± 17,286 Ω (dry skin) | 90.8 ± 6.2% (dry skin) 96.2 ± 3.2% (wet skin) | [105] | |

| Semi-dry electrodes | PAAm hydrogel containing NaCl | 17.4 kΩ | 93.65% (@ F10) and 95.64% (@ Pz). | [65] |

| Thermoset PU foam coated with an Ag/AgCl chemically deposited layer | — | 61~94% | [109] | |

| Plungers made of Al2O3 porous ceramic | 22.2 ± 8.5 kΩ | 93.8 ± 3.7% | [110] | |

| Silver nanoparticles distributed in PDMS matrix | 18.18 ± 7.51 kΩ (@ Fpz) and 23.89 ± 7.44 kΩ (@ Oz) | 90.65~94.25% | [111] | |

| Nylon coated with carbon | 15 kΩ | 90.89% at FCz, 92.61% at Cz and 92.62% at Pz | [112] | |

| PU foam | 25 kΩ to 8 kΩ (@ 10 Hz) from 0.3 N to 10 N | — | [113] | |

| Porous Ti | 2.4 kΩ on forehead 10 hz | 95.55% (semi-dry) and 90.18% (dry) | [114] | |

| Melamine foam coated with Ag nanowires | <10 kΩ | — | [115] | |

| A solid-gel electrode containing CMC sodium salt, calcium chloride dihydrate, glycerol, and pure water. | From 3 to 25 kΩ (typically 10 kΩ) | — | [116] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, H.; Li, Y.; Yang, J.; Li, H.; Yang, Q.; Guo, C.; Zhu, S.; Shu, X. State of the Art of Non-Invasive Electrode Materials for Brain–Computer Interface. Micromachines 2021, 12, 1521. https://doi.org/10.3390/mi12121521

Yuan H, Li Y, Yang J, Li H, Yang Q, Guo C, Zhu S, Shu X. State of the Art of Non-Invasive Electrode Materials for Brain–Computer Interface. Micromachines. 2021; 12(12):1521. https://doi.org/10.3390/mi12121521

Chicago/Turabian StyleYuan, Haowen, Yao Li, Junjun Yang, Hongjie Li, Qinya Yang, Cuiping Guo, Shenmin Zhu, and Xiaokang Shu. 2021. "State of the Art of Non-Invasive Electrode Materials for Brain–Computer Interface" Micromachines 12, no. 12: 1521. https://doi.org/10.3390/mi12121521

APA StyleYuan, H., Li, Y., Yang, J., Li, H., Yang, Q., Guo, C., Zhu, S., & Shu, X. (2021). State of the Art of Non-Invasive Electrode Materials for Brain–Computer Interface. Micromachines, 12(12), 1521. https://doi.org/10.3390/mi12121521