An Investigation of Cutting Performance and Action Mechanism in Ultrasonic Vibration-Assisted Milling of Ti6Al4V Using a PCD Tool

Abstract

:1. Introduction

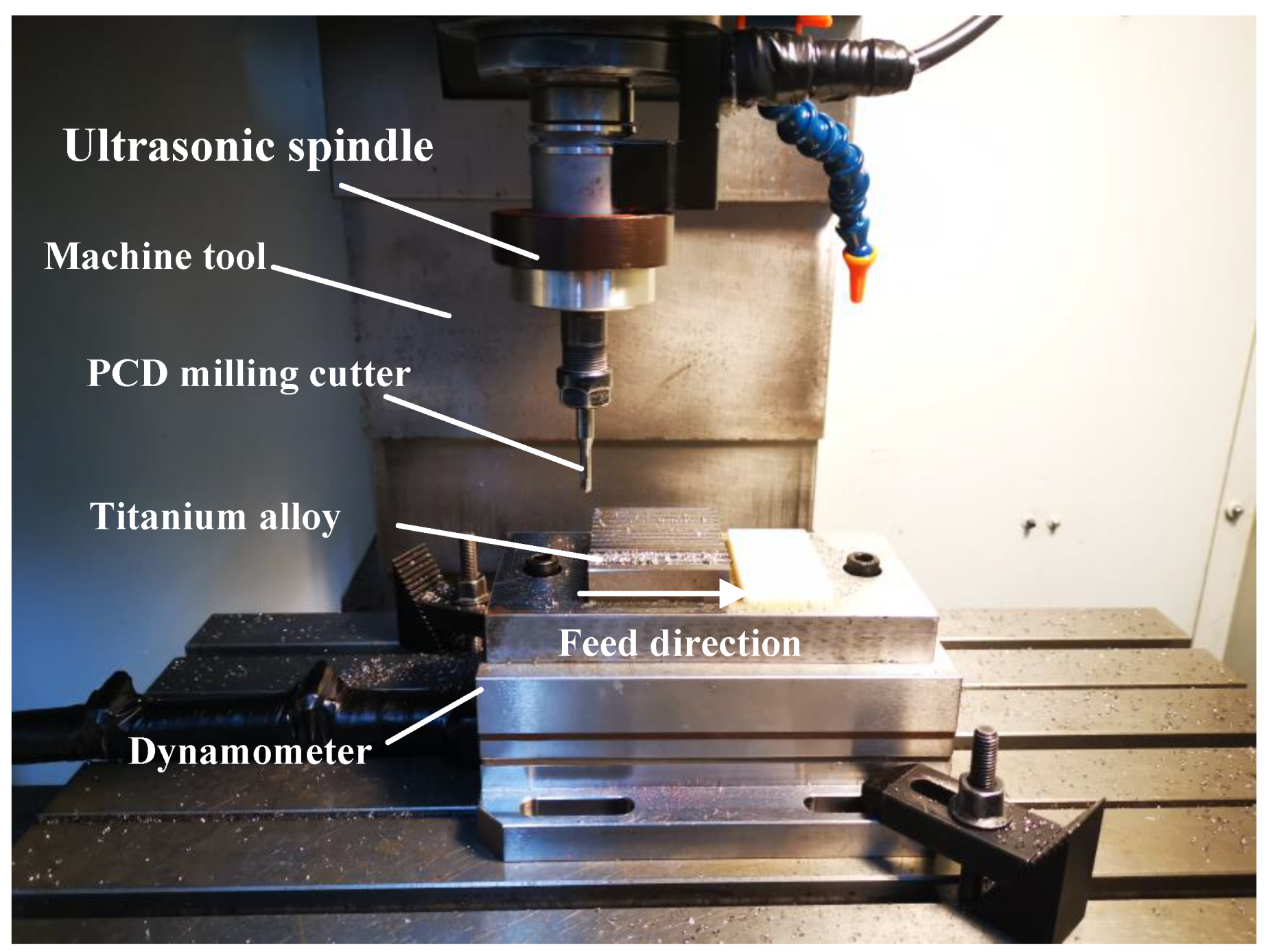

2. Experimental Methods and Materials

3. Results and Discussion

3.1. The Influence of UVAM on Cutting Force

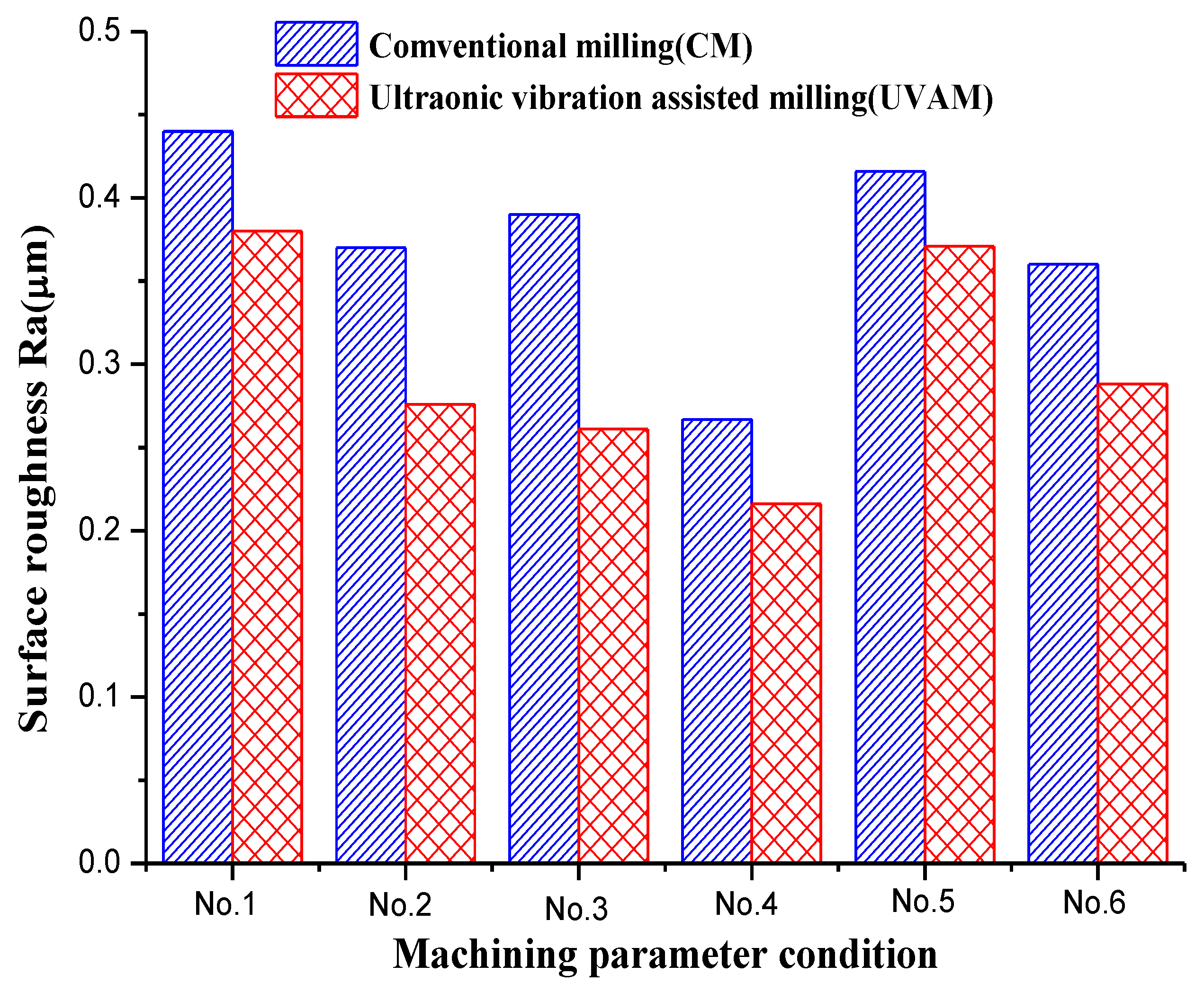

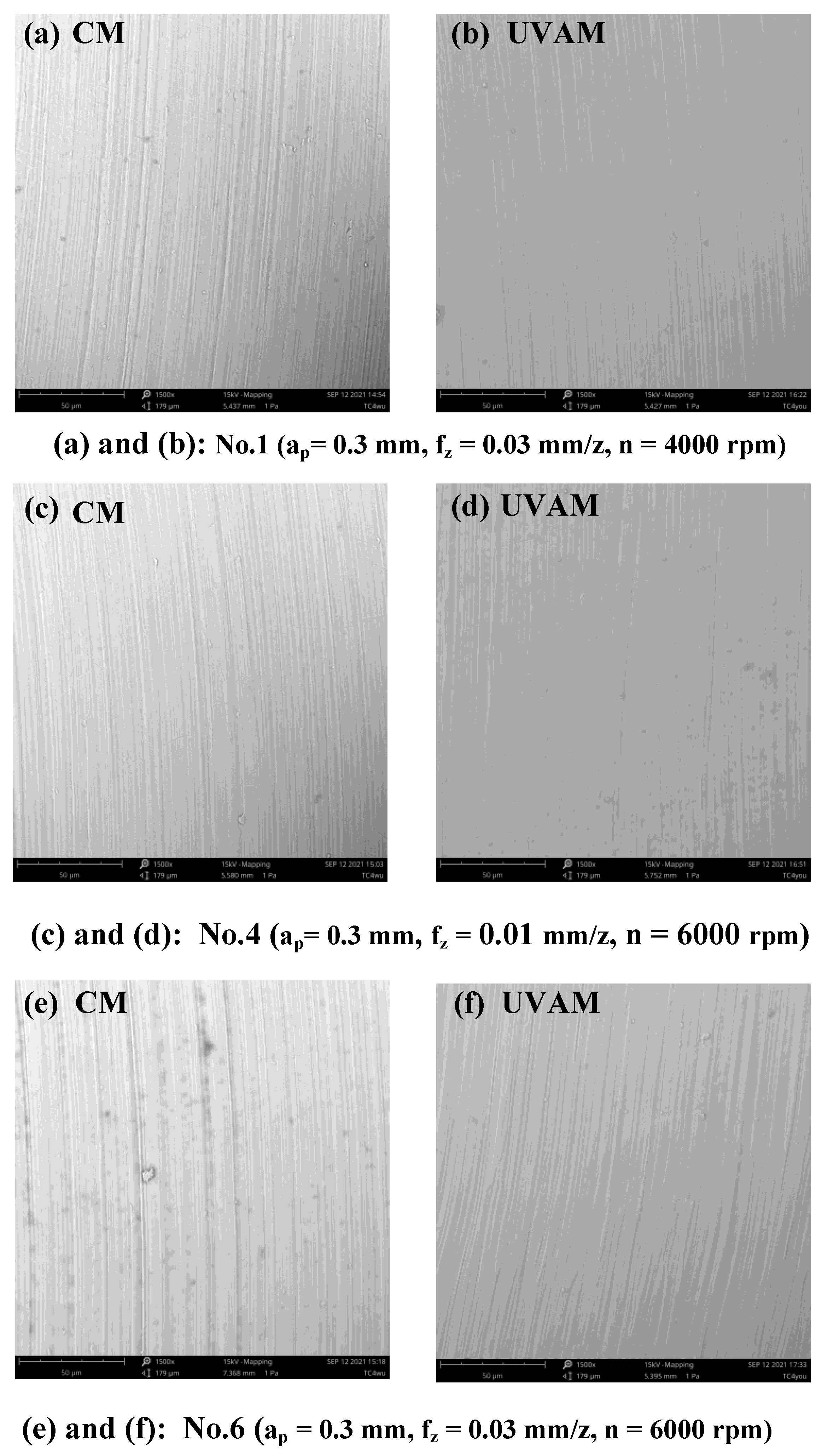

3.2. The Influence of UVAM on Surface Quality

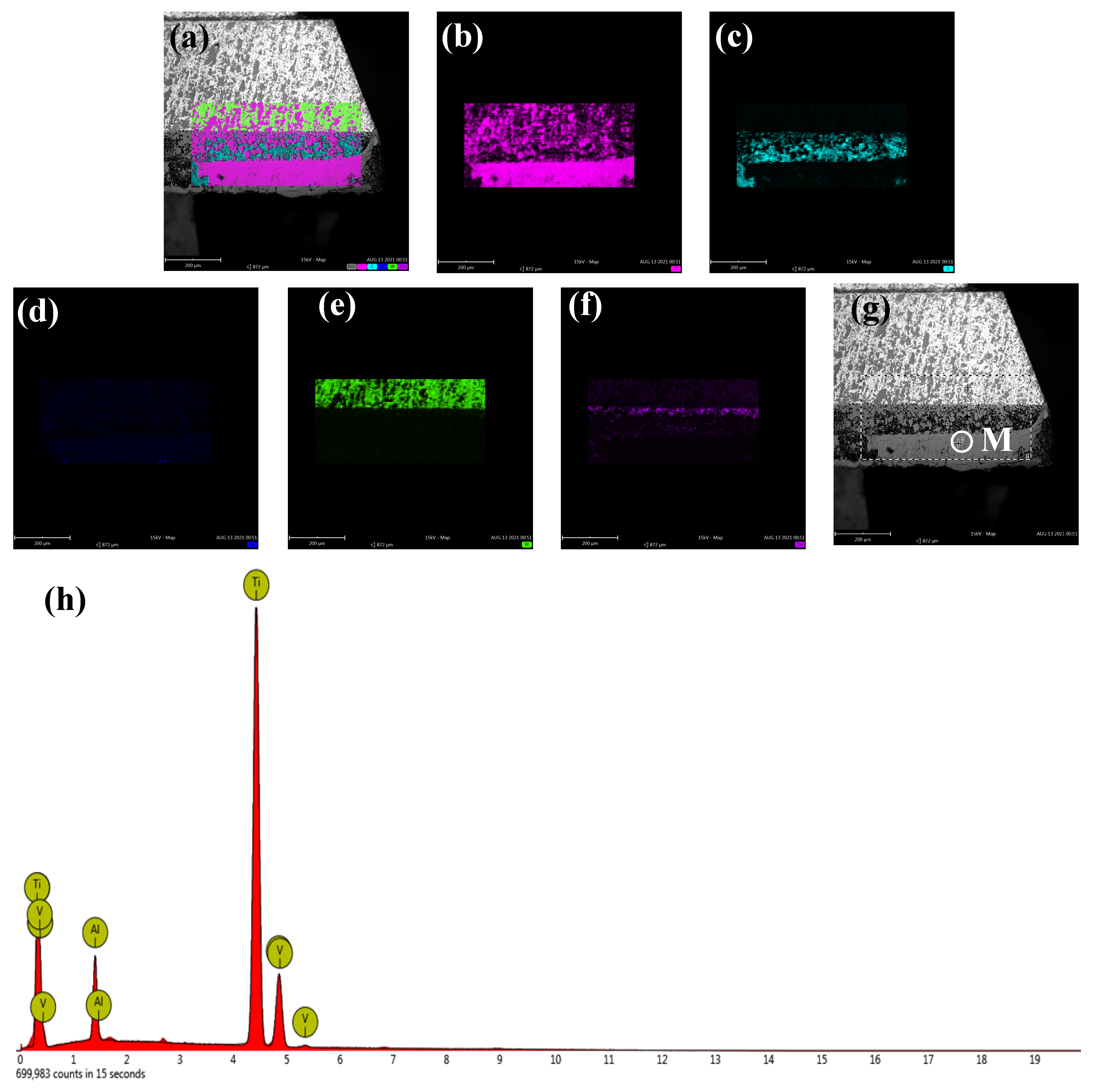

3.3. Surface Adhesion of UVAM

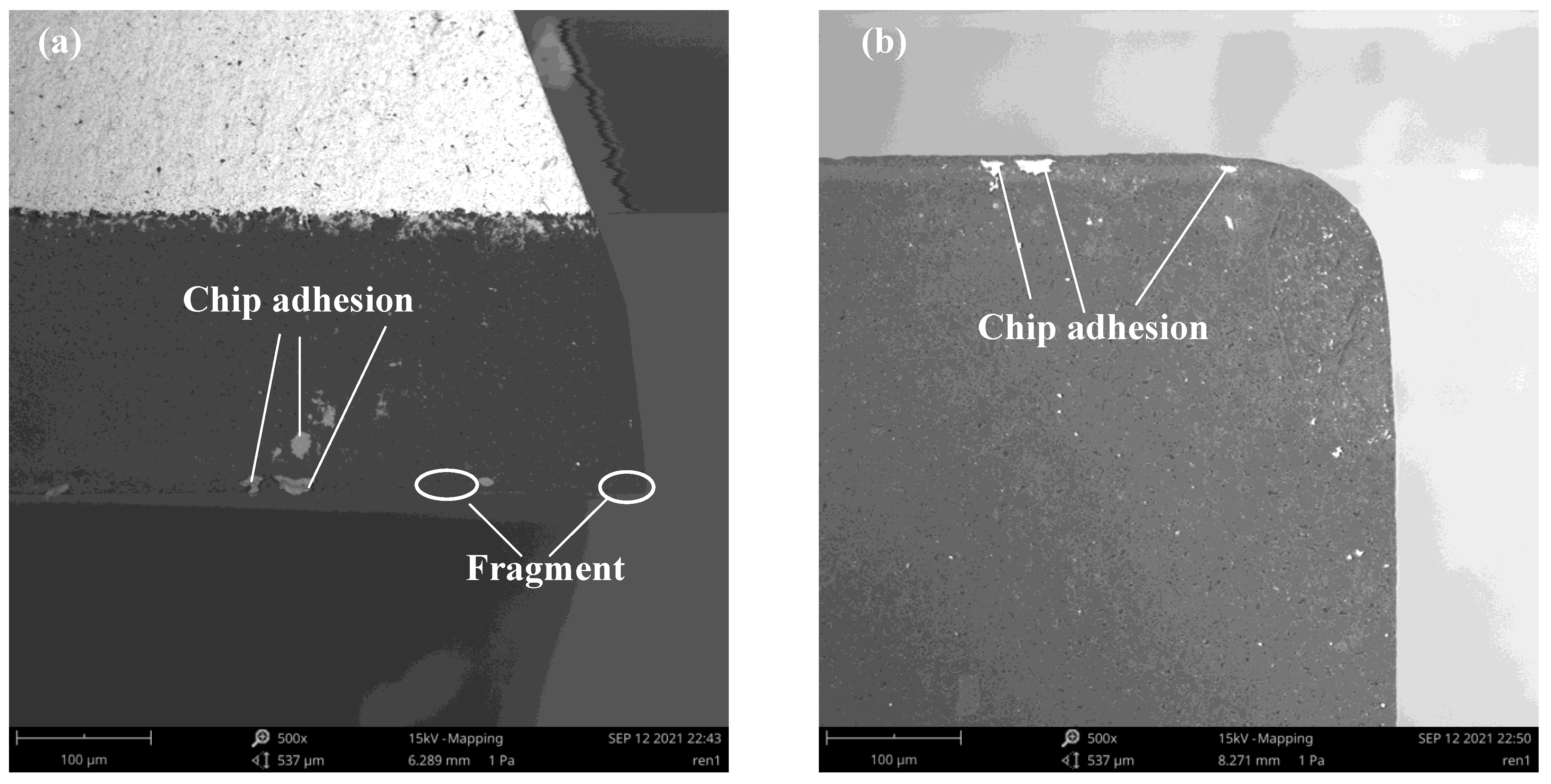

3.4. Tool Wear of UVAM

3.5. Discussion on Effect of UVAM

4. Conclusions

- Compared with the CM method, the UVAM method can effectively decrease the cutting force even under dry milling, and when the selected value of fz and ap ranged from low to high, respectively, the corresponding cutting force of UVAM was reduced by up to 0.8–42% and 5.3–65%, respectively.

- Compared to CM, UVAM can effectively reduce surface roughness, Ra, and the surface roughness can be reduced by 10.82–37.97% under the cutting condition of this study. The results demonstrate that UVAM is superior to CM in improving surface quality even under the dry milling condition.

- Under the condition of UVAM, the experimental results indicate that there is serious adhesion on the PCD tool, and there is only wear of tiny fragment on its flank face.

- The machining mechanism of UVAM can be mainly explained from the perspective of a reduction in actual contact time and an increase in separation time between the tool-workpiece and tool-chip owing to ultrasonic vibration with the characteristic of intermittent cutting.

Author Contributions

Funding

Conflicts of Interest

References

- Liang, X.L.; Liu, Z.Q.; Wang, B. State-of-the-art of surface integrity induced by tool wear effects in machining process of titanium and nickel alloys: A review. Measurement 2018, 132, 150–181. [Google Scholar] [CrossRef]

- Ezugwu, E.O.; Bonney, J.; Yamane, Y. An overview of the machinability of aeroengine alloys. J. Mater. Process. Technol. 2003, 134, 233–253. [Google Scholar] [CrossRef]

- Hourmand, M.; Sarhan, A.A.D.; Sayuti, M.; Hamdi, M. A Comprehensive Review on Machining of Titanium Alloys. Arab. J. Sci. Eng. 2021, 46, 7087–7123. [Google Scholar] [CrossRef]

- Lei, S.; Liu, W. High-speed machining of titanium alloys using the driven rotary tool. Int. J. Mach. Tools Manuf. 2002, 42, 653–661. [Google Scholar] [CrossRef]

- Jawaid, A.; Koksal, S.; Sharif, S. Cutting performance and wear characteristics of PVD coated and uncoated Carbide tools in face milling Inconel 718 aerospace alloy. J. Mater. Process. 2001, 116, 2–9. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.G.; Rahman, M.; Wong, Y.S. Tool wear characteristics of binderless CBN tools used in high-speed milling of titanium alloys. Wear 2005, 258, 752–758. [Google Scholar] [CrossRef]

- Lü, W.Z.; Li, G.J.; Zhou, Y.Y.; Liu, S.Y.; Wang, K.; Wang, Q. Effect of high hardness and adhesion of gradient TiAlSiN coating on cutting performance of titanium alloy. J. Alloy. Compd. 2020, 820, 153137. [Google Scholar] [CrossRef]

- Lindvall, R.; Lenrick, F.; Persson, H.; M’Saoubi, R.; Ståhl, J.E.; Bushlya, V. Performance and wear mechanisms of PCD and pcBN cutting tools during machining titanium alloy Ti6Al4V. Wear 2020, 454–455, 1–16. [Google Scholar] [CrossRef]

- Kumar, U.; Senthil, P. A comparative machinability study on titanium alloy Ti-6Al-4V during dry turning by cryogenic treated and untreated condition of uncoated WC inserts. Mater. Today Proc. 2020, 27, 2324–2328. [Google Scholar] [CrossRef]

- Denkena, B.; Lucas, A.; Bassett, E. Effects of the cutting edge microgeometry on tool wear and its thermo-mechanical load. CIRP Ann. 2011, 60, 73–76. [Google Scholar] [CrossRef]

- Yang, Y.F.; Su, Y.S.; Li, L.; He, N.; Zhao, W. Performance of cemented carbide tools with micro-grooves in Ti-6Al-4V titanium alloy cutting. Int. J. Adv. Manuf. Technol. 2015, 76, 1731–1738. [Google Scholar] [CrossRef]

- Wu, X.; Zeng, K.; Zhong, L.; Shen, J.Y.; Li, L. Hybrid micro-milling assisted with laser oxidation based on the hardness reduction that caused by cemented carbide oxidation. Ceram. Int. 2021, in press. [Google Scholar] [CrossRef]

- Chen, N.; Li, H.N.; Wu, J.M.; Li, Z.J.; Li, L.; Liu, G.Y.; He, N. Advances in micro milling: From tool fabrication to process outcomes. Int. J. Mach. Tools Manuf. 2021, 160, 103670. [Google Scholar] [CrossRef]

- Chen, N.; Li, L.; Wu, J.; Qian, J.; He, N.; Reynaerts, D. Research on the ploughing force in micro milling of soft-brittle crystals. Int. J. Mech. Sci. 2019, 155, 315–322. [Google Scholar] [CrossRef]

- Gao, G.F.; Xia, Z.W.; Su, T.T.; Xiang, D.H.; Zhao, B. Cutting force model of longitudinal-torsional ultrasonic-assisted milling Ti-6Al-4V based on tool flank wear. J. Mater. Process. Technol. 2021, 291, 1–16. [Google Scholar] [CrossRef]

- Chen, J.; Ming, W.W.; An, Q.L.; Chen, M. Mechanism and feasibility of ultrasonic-assisted milling to improve the machined surface quality of 2D Cf/SiC composites. Ceram. Int. 2020, 46, 15122–15136. [Google Scholar] [CrossRef]

- Ni, C.B.; Zhu, L.D. Investigation on machining characteristics of TC4 alloy by simultaneous application of ultrasonic vibration assisted milling (UVAM) and economical-environmental MQL technology. J. Mater. Process. Technol. 2020, 278, 116518. [Google Scholar] [CrossRef]

- Ni, C.B.; Zhu, L.D.; Yang, Z.C. Comparative investigation of tool wear mechanism and corresponding machined surface characterization in feed-direction ultrasonic vibration assisted milling of Ti-6Al-4V from dynamic view. Wear 2019, 436–437, 203006. [Google Scholar] [CrossRef]

- Lu, Z.H.; Zhang, D.Y.; Zhang, X.Y.; Peng, Z.L. Effects of high-pressure coolant on cutting performance of high-speed ultrasonic vibration cutting titanium alloy. J. Mater. Process. Technol. 2020, 279, 116584. [Google Scholar] [CrossRef]

- Su, Y.S.; Li, L.; Wang, G.; Zhong, X.Q. Cutting mechanism and performance of high-speed machining of a titanium alloy using a super-hard textured tool. J. Manuf. Process. 2018, 34, 706–712. [Google Scholar] [CrossRef]

- Su, Y.S.; Li, Z.; Li, L.; Wang, J.B.; Gao, H.; Wang, G. Cutting performance of micro-textured polycrystalline diamond tool in dry cutting. J. Manuf. Process. 2017, 27, 1–7. [Google Scholar] [CrossRef]

- Nabhani, F. Machining of aerospace titanium alloys. Robot. Comput. -Integr. Manuf. 2001, 17, 99–106. [Google Scholar] [CrossRef]

- da Silva, R.B.; Álisson, R.M.; Ezugwu, E.O.; Bonney, J.; Sales, W.F. Tool life and wear mechanisms in high speed machining of Ti-6Al-4V alloy with PCD tools under various coolant pressures. J. Mater. Process. Technol. 2013, 213, 1459–1464. [Google Scholar] [CrossRef] [Green Version]

- Ezugwu, E.O.; Bonney, J.; da Silva, R.B.; Çakir, O. Surface integrity of finished turned Ti-6Al-4V alloy with PCD tools using conventional and high pressure coolant supplies. Int. J. Mach. Tools Manuf. 2007, 47, 884–891. [Google Scholar] [CrossRef]

- Ramirez, C.; Ismail, A.I.; Gendarme, C.; Dehmas, M.; Aeby-Gautier, E.; Poulachon, G.; Rossi, F. Understanding the diffusion wear mechanisms of WC-10% Co carbide tools during dry machining of titanium alloys. Wear 2017, 390–391, 61–70. [Google Scholar] [CrossRef] [Green Version]

- Shi, Q.; Li, L.; He, N.; Zhao, W.; Liu, X.L. Experimental study in high speed milling of titanium alloy TC21. Int. J. Adv. Manuf. Technol. 2013, 64, 49–54. [Google Scholar] [CrossRef]

- Krishnaraj, V.; Samsudeensadham, S.; Sindhumathi, R.; Kuppan, P. A study on high speed end milling of titanium alloy. Procedia Eng. 2014, 97, 251–257. [Google Scholar] [CrossRef] [Green Version]

- Shen, X.H.; Zhang, J.H.; Li, H.; Wang, J.J.; Wang, X.C. Ultrasonic vibration-assisted milling of aluminum alloy. Int. J. Adv. Manuf. Technol. 2012, 63, 41–49. [Google Scholar] [CrossRef]

- Vermaa, G.C.; Pandey, P.M. Machining forces in ultrasonic-vibration assisted end milling. Ultrasonics 2019, 94, 350–363. [Google Scholar] [CrossRef]

- Peng, Z.L.; Zhang, X.Y.; Zhang, D.Y. Effect of radial high-speed ultrasonic vibration cutting on machining performance during finish turning of hardened steel. Ultrasonics 2021, 111, 106340. [Google Scholar] [CrossRef] [PubMed]

| Milling Machine | HAAS OM-2A |

|---|---|

| Workpiece | Conventional Ti6Al4V |

| PCD tool | Rake angle 0°, relief angle 15° |

| Tool diameter | 4 mm |

| Flutes | 2 |

| Spindle speed | 4000~10,000 rpm |

| Depth of cut ap | 0.1~0.5 mm |

| Feed per tooth fz | 0.01~0.08 mm/z |

| Lubrication method | Dry milling |

| Cutting length | 612 mm |

| Ultrasonic vibration direction | Axial direction |

| Ultrasonic frequency | 30 kHz |

| Ultrasonic amplitude | 6 μm |

| Number | ap (mm) | fz (mm/z) | n (rpm) |

|---|---|---|---|

| No. 1 | 0.3 | 0.03 | 4000 |

| No. 2 | 0.3 | 0.03 | 8000 |

| No. 3 | 0.3 | 0.03 | 10,000 |

| No. 4 | 0.3 | 0.01 | 6000 |

| No. 5 | 0.3 | 0.05 | 6000 |

| No. 5 | 0.3 | 0.03 | 6000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, Y.; Li, L. An Investigation of Cutting Performance and Action Mechanism in Ultrasonic Vibration-Assisted Milling of Ti6Al4V Using a PCD Tool. Micromachines 2021, 12, 1319. https://doi.org/10.3390/mi12111319

Su Y, Li L. An Investigation of Cutting Performance and Action Mechanism in Ultrasonic Vibration-Assisted Milling of Ti6Al4V Using a PCD Tool. Micromachines. 2021; 12(11):1319. https://doi.org/10.3390/mi12111319

Chicago/Turabian StyleSu, Yongsheng, and Liang Li. 2021. "An Investigation of Cutting Performance and Action Mechanism in Ultrasonic Vibration-Assisted Milling of Ti6Al4V Using a PCD Tool" Micromachines 12, no. 11: 1319. https://doi.org/10.3390/mi12111319

APA StyleSu, Y., & Li, L. (2021). An Investigation of Cutting Performance and Action Mechanism in Ultrasonic Vibration-Assisted Milling of Ti6Al4V Using a PCD Tool. Micromachines, 12(11), 1319. https://doi.org/10.3390/mi12111319