A Novel Triboelectric Material Based on Deciduous Leaf for Energy Harvesting

Abstract

:1. Introduction

2. Materials and Methods

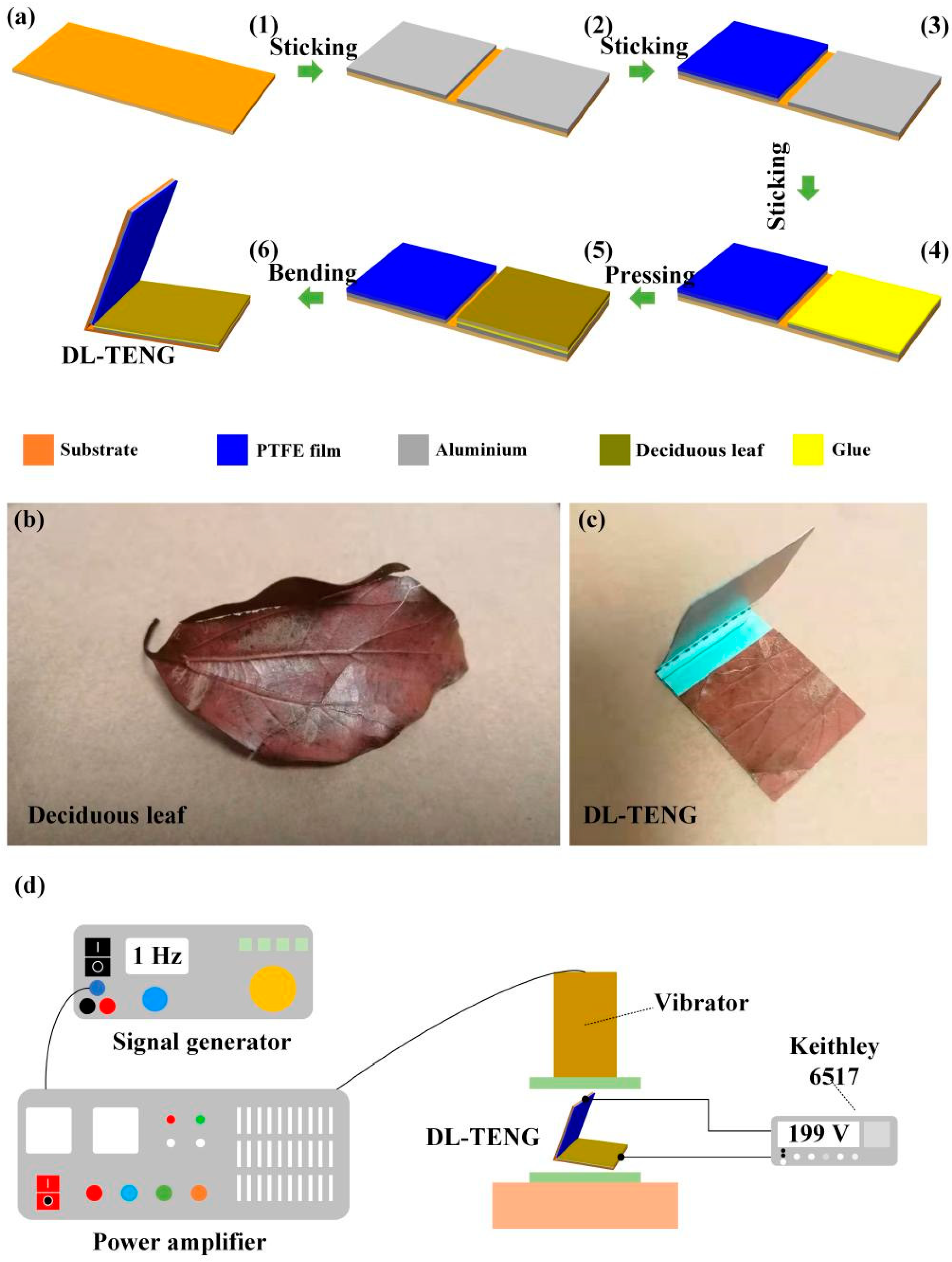

2.1. Preparation Process and Measurement

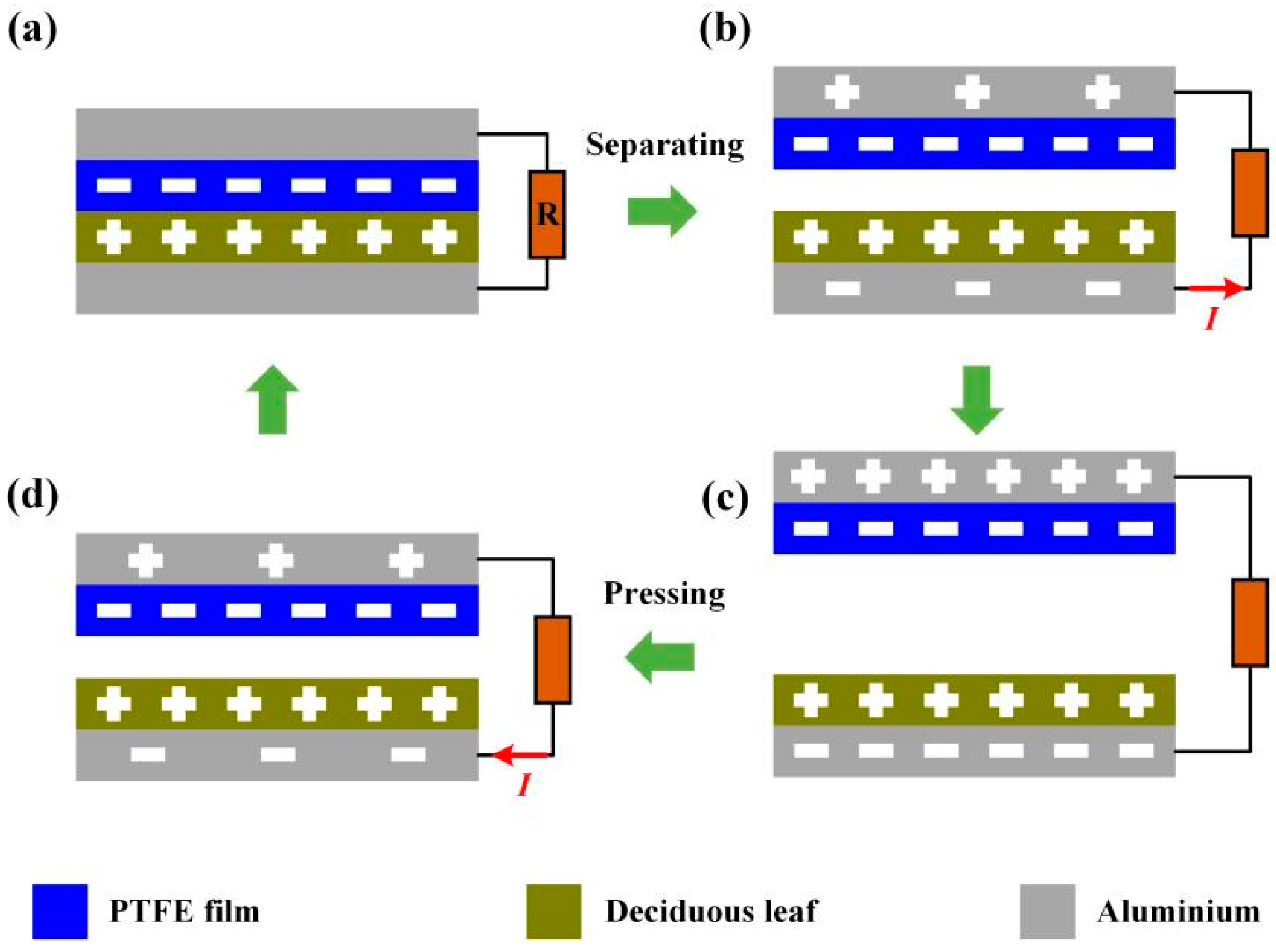

2.2. Working Mechanism

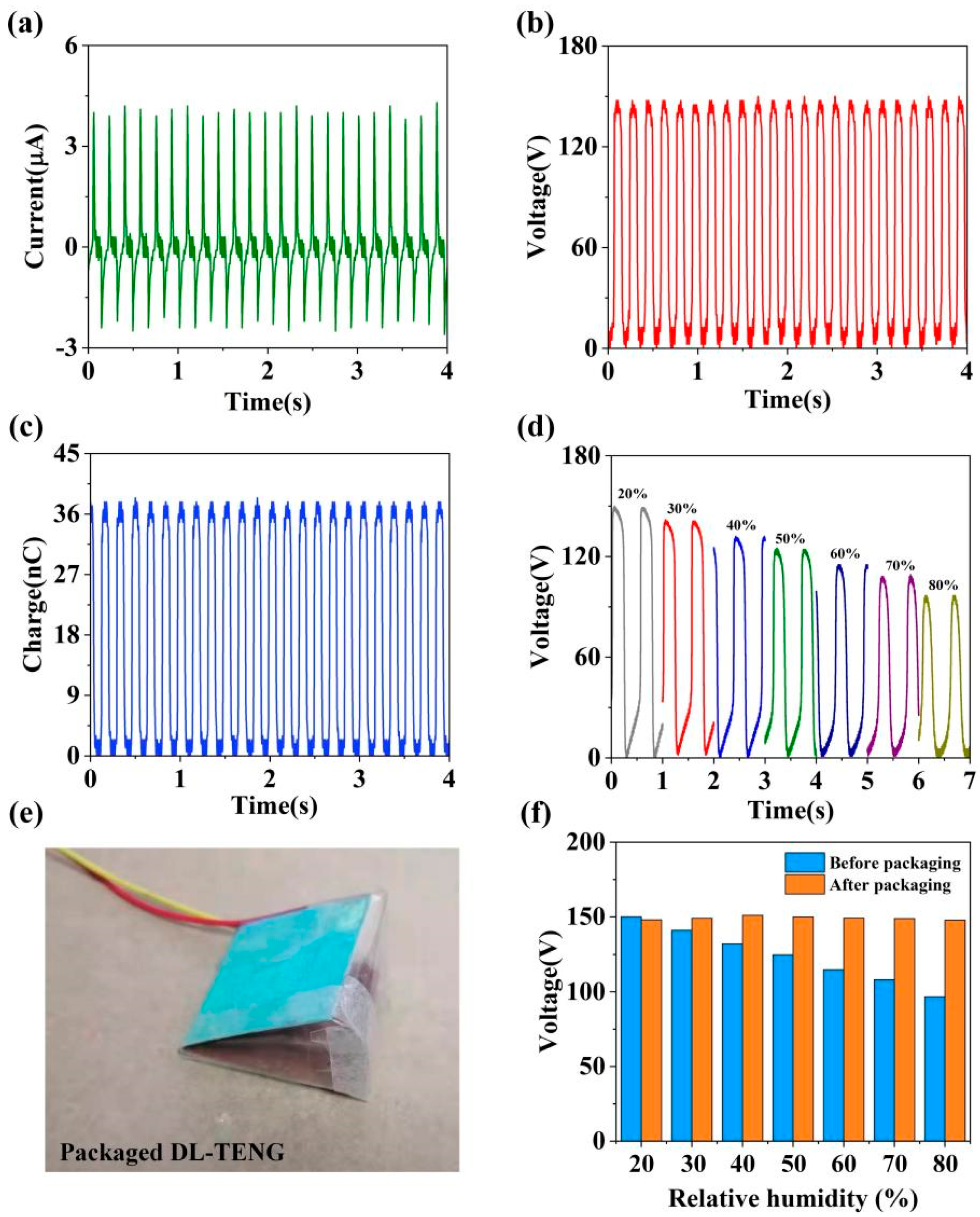

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Obara, S.; Kawai, M.; Kawae, O.; Morizane, Y. Operational planning of an independent microgrid containing tidal power generators, SOFCs, and photovoltaics. Appl. Energy 2013, 102, 1343–1357. [Google Scholar] [CrossRef]

- Champier, D. Thermoelectric generators: A review of applications. Energy Convers. Manag. 2017, 140, 167–181. [Google Scholar] [CrossRef]

- Yan, J.; Liao, X.; Ji, S.; Zhang, S. MEMS-based thermoelectric–photoelectric integrated power generator. J. Microelectromech. Syst. 2018, 28, 1–3. [Google Scholar] [CrossRef]

- Jin, X.; Xu, Z.; Qiao, W. Condition monitoring of wind turbine generators using SCADA data analysis. IEEE Trans. Sustain. Energy 2020, 12, 202–210. [Google Scholar] [CrossRef]

- Wang, Z.L. Triboelectric nanogenerator (TENG)—Sparking an energy and sensor revolution. Adv. Energy Mater. 2020, 10, 2000137. [Google Scholar] [CrossRef] [Green Version]

- He, W.; Liu, W.; Chen, J.; Wang, Z.; Liu, Y.; Pu, X.; Yang, H.; Tang, Q.; Yang, H.; Guo, H.; et al. Boosting output performance of sliding mode triboelectric nanogenerator by charge space-accumulation effect. Nat. Commun. 2020, 11, 1–8. [Google Scholar]

- Lei, R.; Shi, Y.; Ding, Y.; Nie, J.; Li, S.; Wang, F.; Zhai, H.; Chen, X.; Wang, Z.L. Sustainable high-voltage source based on triboelectric nanogenerator with a charge accumulation strategy. Energy Environ. Sci. 2020, 13, 2178–2190. [Google Scholar] [CrossRef]

- Chen, C.; Guo, H.; Chen, L.; Wang, Y.-C.; Pu, X.; Yu, W.; Wang, F.; Du, Z.; Wang, Z.L. Direct current fabric triboelectric nanogenerator for biomotion energy harvesting. ACS Nano 2020, 14, 4585–4594. [Google Scholar] [CrossRef]

- Nie, S.; Fu, Q.; Lin, X.; Zhang, C.; Lu, Y.; Wang, S. Enhanced performance of a cellulose nanofibrils-based triboelectric nanogenerator by tuning the surface polarizability and hydrophobicity. Chem. Eng. J. 2021, 404, 126512. [Google Scholar] [CrossRef]

- Zhu, Y.; Lin, S.; Gao, W.; Zhang, M.; Li, D.; Feng, P.; Xu, C.; Wang, Z.L. Reversal of triboelectric charges on sol–gel oxide films annealed at different temperatures. Appl. Phys. Lett. 2021, 118, 243902. [Google Scholar] [CrossRef]

- Zhao, D.; Yu, X.; Wang, Z.; Wang, J.; Li, X.; Wang, Z.L.; Cheng, T. Universal equivalent circuit model and verification of current source for triboelectric nanogenerator. Nano Energy 2021, 89, 106335. [Google Scholar] [CrossRef]

- Sun, J.; Zhang, L.; Li, Z.; Tang, Q.; Chen, J.; Huang, Y.; Hu, C.; Guo, H.; Peng, Y.; Wang, Z.L. A Mobile and Self-Powered Micro-Flow Pump Based on Triboelectricity Driven Electroosmosis. Adv. Mater. 2021, 33, 2102765. [Google Scholar] [CrossRef]

- Shu, S.; An, J.; Chen, P.; Liu, D.; Wang, Z.; Li, C.; Zhang, S.; Liu, Y.; Luo, J.; Zu, L.; et al. Active-Sensing Epidermal Stretchable Bioelectronic Patch for Noninvasive, Conformal, and Wireless Tendon Monitoring. Research 2021, 2021, 9783432. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Chen, B.; Li, W.; Zu, L.; Tang, W.; Wang, Z.L. Bioinspired Triboelectric Soft Robot Driven by Mechanical Energy. Adv. Funct. Mater. 2021, 31, 2104770. [Google Scholar] [CrossRef]

- Lu, P.; Pang, H.; Ren, J.; Feng, Y.; An, J.; Liang, X.; Jiang, T.; Wang, Z.L. Swing-Structured Triboelectric–Electromagnetic Hybridized Nanogenerator for Breeze Wind Energy Harvesting. Adv. Mater. Technol. 2021, 2100496. [Google Scholar] [CrossRef]

- Luo, X.; Zhu, L.; Wang, Y.C.; Li, J.; Nie, J.; Wang, Z.L. A Flexible Multifunctional Triboelectric Nanogenerator Based on MXene/PVA Hydrogel. Adv. Funct. Mater. 2021, 31, 2104928. [Google Scholar] [CrossRef]

- Zhang, P.; Guo, W.; Guo, Z.H.; Ma, Y.; Gao, L.; Cong, Z.; Zhao, X.J.; Qiao, L.; Pu, X.; Wang, Z.L. Dynamically Crosslinked Dry Ion-Conducting Elastomers for Soft Iontronics. Adv. Mater. 2021, 33, 2101396. [Google Scholar] [CrossRef] [PubMed]

- Lin, S.; Chen, X.; Wang, Z.L. Contact Electrification at the Liquid–Solid Interface. Chem. Rev. 2021. [Google Scholar] [CrossRef] [PubMed]

- Xu, F.; Dong, S.; Liu, G.; Pan, C.; Guo, Z.H.; Guo, W.; Li, L.; Liu, Y.; Zhang, C.; Pu, X.; et al. Scalable fabrication of stretchable and washable textile triboelectric nanogenerators as constant power sources for wearable electronics. Nano Energy 2021, 88, 106247. [Google Scholar] [CrossRef]

- Xia, K.; Fu, J.; Xu, Z. Multiple-frequency high-output triboelectric nanogenerator based on a water balloon for all-weather water wave energy harvesting. Adv. Energy Mater. 2020, 10, 2000426. [Google Scholar] [CrossRef]

- Chen, P.; An, J.; Cheng, R.; Shu, S.; Berbille, A.; Jiang, T.; Wang, Z.L. Rationally Segmented Triboelectric Nanogenerator with Constant Direct-Current Output and Low Crest Factor. Energy Environ. Sci. 2021, 14, 4523–4532. [Google Scholar] [CrossRef]

- Xia, K.; Wu, D.; Fu, J.; Hoque, N.A.; Ye, Y.; Xu, Z. A high-output triboelectric nanogenerator based on nickel–copper bimetallic hydroxide nanowrinkles for self-powered wearable electronics. J. Mater. Chem. A 2020, 8, 25995–26003. [Google Scholar] [CrossRef]

- Wu, C.; Wang, A.; Ding, W.; Guo, H.; Wang, Z.L. Triboelectric nanogenerator: A foundation of the energy for the new era. Adv. Energy Mater. 2019, 9, 1802906. [Google Scholar] [CrossRef]

- Wang, Z.L.; Jiang, T.; Xu, L. Toward the blue energy dream by triboelectric nanogenerator networks. Nano Energy 2017, 39, 9–23. [Google Scholar] [CrossRef]

- Bai, P.; Zhu, G.; Liu, Y.; Chen, J.; Jing, Q.; Yang, W.; Ma, J.; Zhang, G.; Wang, Z.L. Cylindrical rotating triboelectric nanogenerator. ACS Nano 2013, 7, 6361–6366. [Google Scholar] [CrossRef]

- Wang, S.; Niu, S.; Yang, J.; Lin, L.; Wang, Z.L. Quantitative measurements of vibration amplitude using a contact-mode freestanding triboelectric nanogenerator. ACS Nano 2014, 8, 12004–12013. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Yang, Y.; Zhong, X.; Su, Y.; Zhou, Y.; Chung, A.; Wang, Z.L. Single-electrode-based rotating triboelectric nanogenerator for harvesting energy from tires. ACS Nano 2014, 8, 680–689. [Google Scholar] [CrossRef] [PubMed]

- Bai, P.; Zhu, G.; Lin, Z.-H.; Jing, Q.; Chen, J.; Zhang, G.; Ma, J.; Wang, Z.L. Integrated multilayered triboelectric nanogenerator for harvesting biomechanical energy from human motions. ACS Nano 2013, 7, 3713–3719. [Google Scholar] [CrossRef] [PubMed]

- Guo, H.; Yeh, M.-H.; Lai, Y.-C.; Zi, Y.; Wu, C.; Wen, Z.; Hu, C.; Wang, Z.L. All-in-one shape-adaptive self-charging power package for wearable electronics. ACS Nano 2016, 10, 10580–10588. [Google Scholar] [CrossRef]

- Wen, Z.; Yeh, M.-H.; Guo, H.; Wang, J.; Zi, Y.; Xu, W.; Deng, J.; Zhu, L.; Wang, X.; Hu, C.; et al. Self-powered textile for wearable electronics by hybridizing fiber-shaped nanogenerators, solar cells, and supercapacitors. Sci. Adv. 2016, 2, e1600097. [Google Scholar] [CrossRef] [Green Version]

- Zhang, M.; Jie, Y.; Cao, X.; Bin, J.; Li, T.; Wang, N.; Wang, Z.L. Robust design of unearthed single-electrode TENG from three-dimensionally hybridized copper/polydimethylsiloxane film. Nano Energy 2016, 30, 155–161. [Google Scholar] [CrossRef]

- Feng, Y.; Zhang, L.; Zheng, Y.; Wang, D.; Zhou, F.; Liu, W. Leaves based triboelectric nanogenerator (TENG) and TENG tree for wind energy harvesting. Nano Energy 2019, 55, 260–268. [Google Scholar] [CrossRef]

- Chen, Y.; Jie, Y.; Wang, J.; Ma, J.; Jia, X.; Dou, W.; Cao, X. Triboelectrification on natural rose petal for harvesting environmental mechanical energy. Nano Energy 2018, 50, 441–447. [Google Scholar] [CrossRef]

- Khandelwal, G.; Minocha, T.; Yadav, S.K.; Chandrasekhar, A.; Raj, N.P.M.J.; Gupta, S.C.; Kim, S.-J. All edible materials derived biocompatible and biodegradable triboelectric nanogenerator. Nano Energy 2019, 65, 104016. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, Z.; Zou, M.; Yao, P.; Zhu, Z.; Fan, L. A Novel Triboelectric Material Based on Deciduous Leaf for Energy Harvesting. Micromachines 2021, 12, 1314. https://doi.org/10.3390/mi12111314

Ding Z, Zou M, Yao P, Zhu Z, Fan L. A Novel Triboelectric Material Based on Deciduous Leaf for Energy Harvesting. Micromachines. 2021; 12(11):1314. https://doi.org/10.3390/mi12111314

Chicago/Turabian StyleDing, Zhuyu, Ming Zou, Peng Yao, Zhiyuan Zhu, and Li Fan. 2021. "A Novel Triboelectric Material Based on Deciduous Leaf for Energy Harvesting" Micromachines 12, no. 11: 1314. https://doi.org/10.3390/mi12111314

APA StyleDing, Z., Zou, M., Yao, P., Zhu, Z., & Fan, L. (2021). A Novel Triboelectric Material Based on Deciduous Leaf for Energy Harvesting. Micromachines, 12(11), 1314. https://doi.org/10.3390/mi12111314