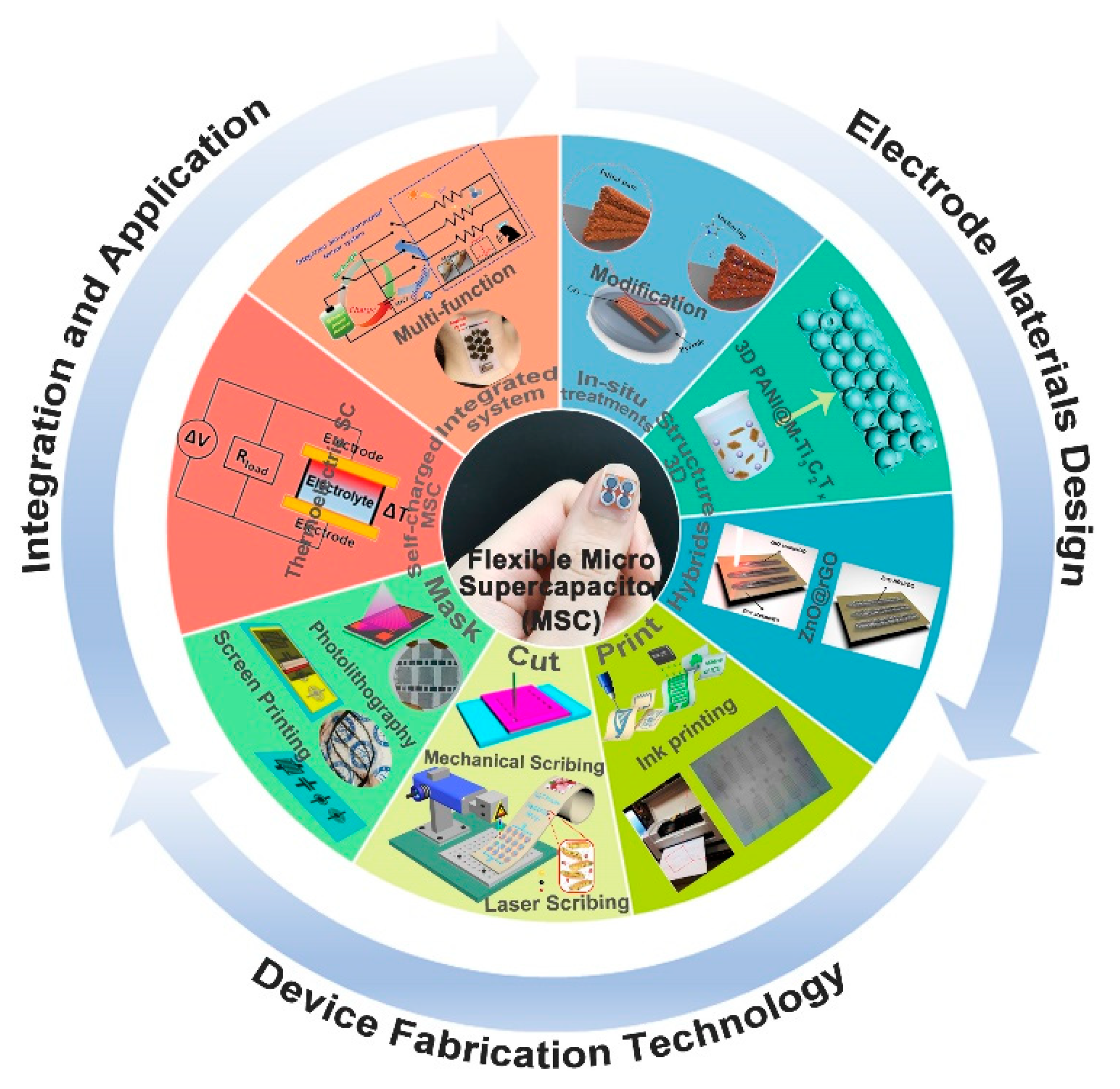

Progress and Perspectives in Designing Flexible Microsupercapacitors

Abstract

:1. Introduction

2. Electrode Materials Design

2.1. Calculation Formulas of the On-Chip MSC

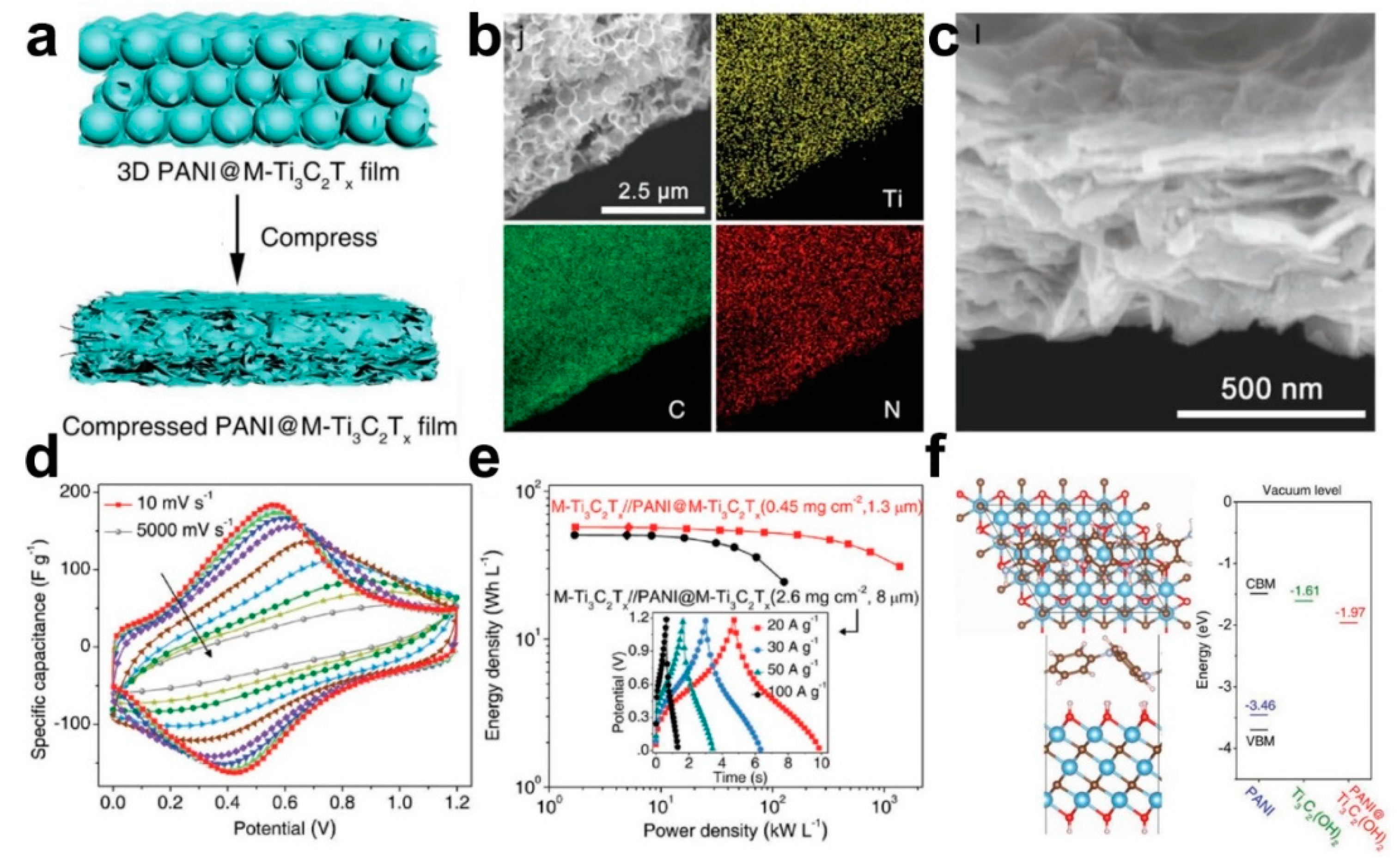

2.2. Hybrid Electrode Materials

3D Architecture Electrodes

2.3. In Situ Treatment

3. Device Fabrication Technology

3.1. Mask

3.1.1. Photolithography

3.1.2. Screen Printing

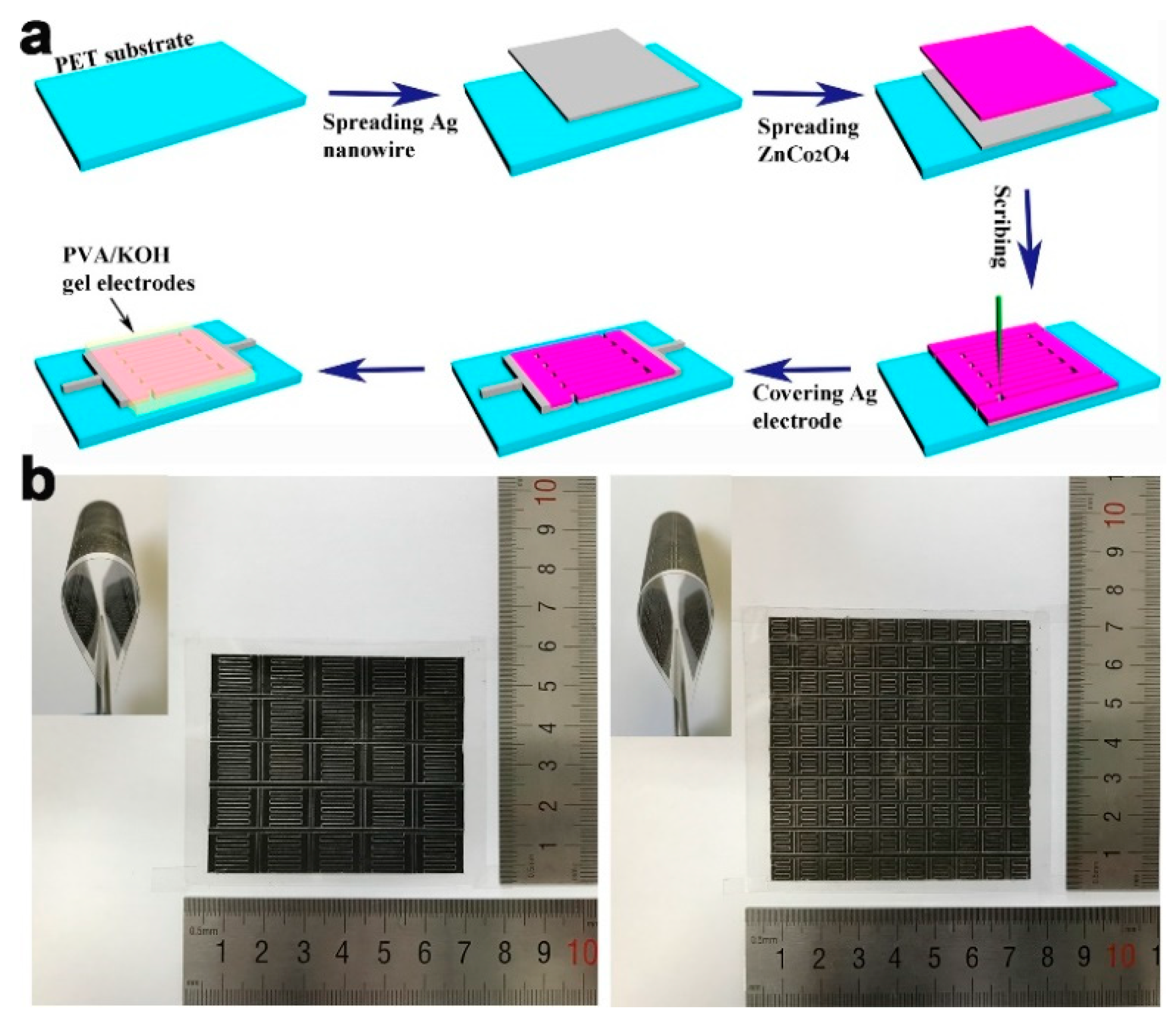

3.2. Cut

3.2.1. Mechanical Scribing

3.2.2. Laser Scribing

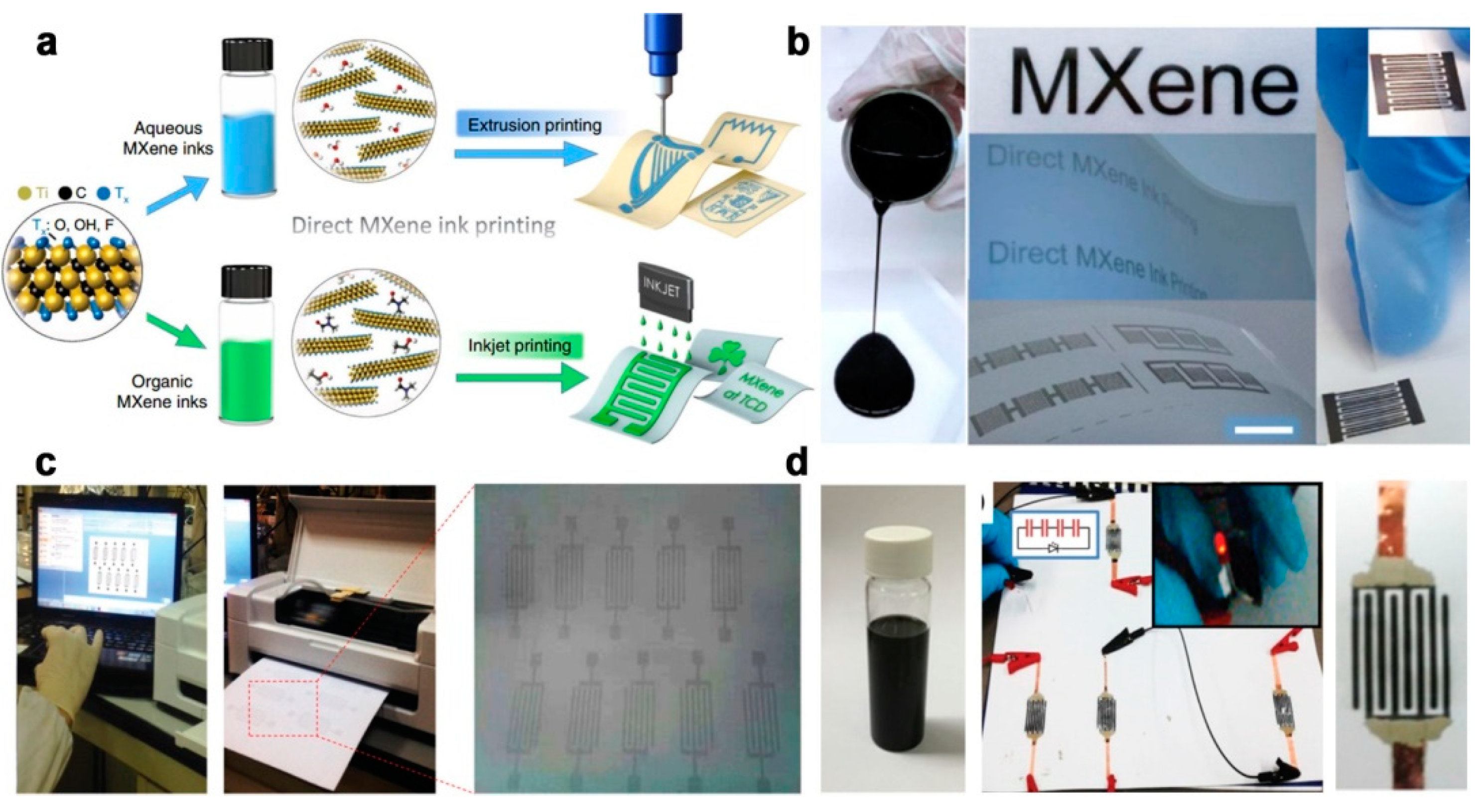

3.3. Ink Printing

4. Integration and Application

4.1. Self-Charged MSC

4.2. Integrated System

5. Conclusions

- The electrochemical performance with high energy density still requires to be improved. Many of the composites electrode materials have been developed to fabricate high-performance flexible MSC devices, but the guideline to reveal the selection basis of the electrode materials in composites is rarely available. More attention should be focused on the establishment of a selective standard.

- Although constructing 3D architecture could improve the electrochemical performance, the pore morphology and size control needs to be considered in further work. The template used to build 3D architecture are expensive and the procedures are complicated. More facile methods and template-free synthesis processes should be developed to get scalable electrode materials with 3D architecture.

- The exploration of novel technologies may lead to a new achievement in the field of large scale and low-cost fabrication of flexible on-chip MSC. The MSC devices with natures of self-healing, biodegradability, and biocompatibility are expected in the implantable self-powered medical devices and health monitoring devices.

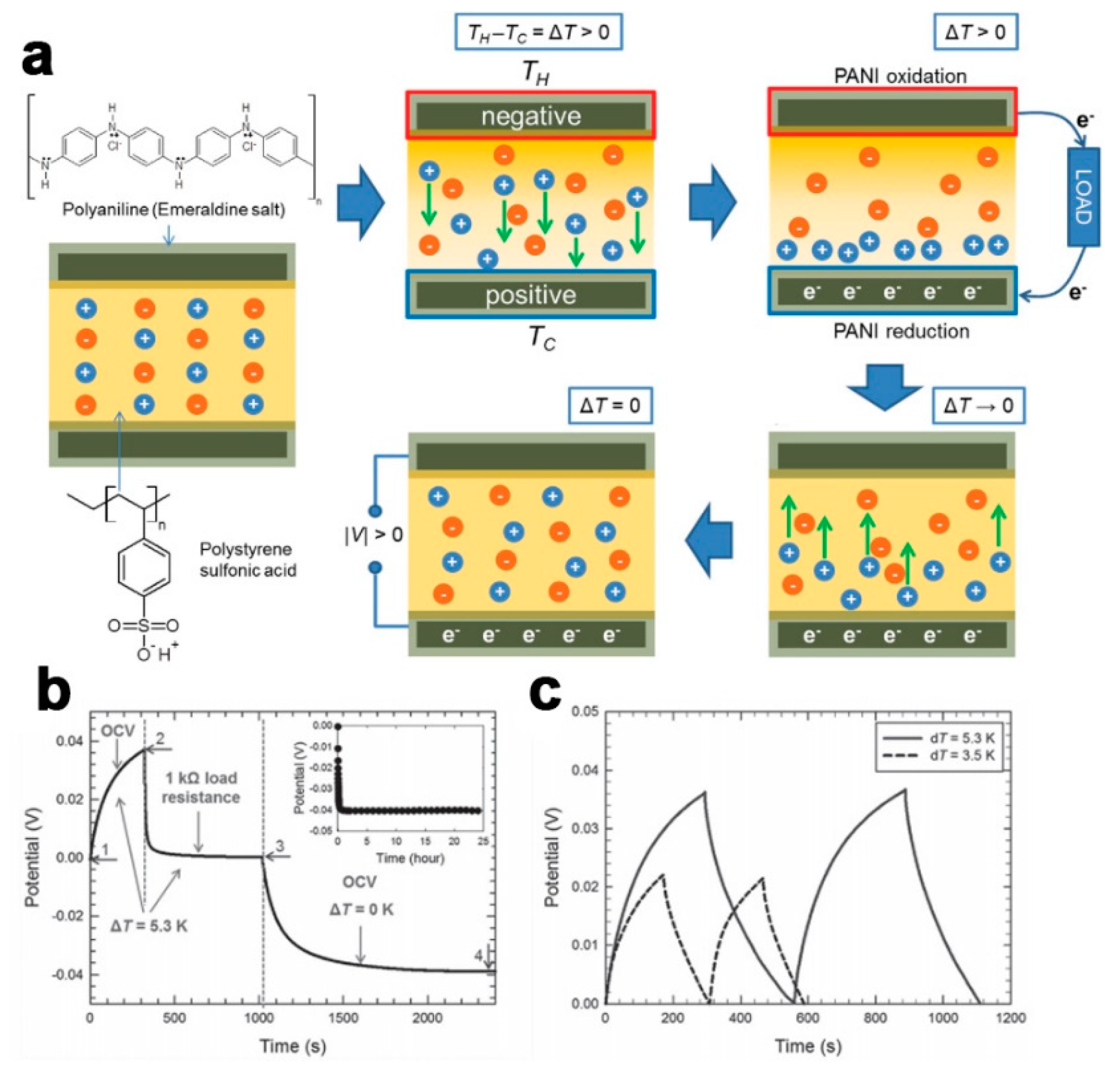

- For the self-powered systems integrated with functional sensors, the thermal charged MSC could simplify the structure of the integrated system and reduce the energy lost in the energy transformation. Thermal charged on-chip MSC will become an important future direction for direct charging the MSC using the temperature gradient between the human body and the environment.

Author Contributions

Funding

Conflicts of Interest

References

- Li, L.; Lou, Z.; Chen, D.; Jiang, K.; Han, W.; Shen, G.Z. Recent Advances in Flexible/Stretchable Supercapacitors for Wearable Electronics. Small 2018, 14, 1702829. [Google Scholar] [CrossRef]

- Li, R.; Li, L.; Jia, R.; Jiang, K.; Shen, G.Z.; Chen, D. A Flexible Concentric Circle Structured Zinc-Ion Micro-Battery with Electrodeposited Electrodes. Small Methods 2020, 4, 2000363. [Google Scholar] [CrossRef]

- Lu, Y.; Li, L.; Wang, X.D.; Chen, D. Directly transfer-printing tailored micro-supercapacitors. Mater. Today Commun. 2021, 27, 102342. [Google Scholar] [CrossRef]

- Lee, H.U.; Kim, S.W. Pen lithography for flexible microsupercapacitors with layer-by-layer assembled graphene flake/PEDOT nanocomposite electrodes. J. Mater. Chem. A 2017, 5, 13581–13590. [Google Scholar] [CrossRef]

- Ma, X.Y.; Feng, S.X.; He, L.; Yan, M.Y.; Tian, X.C.; Li, Y.X.; Tang, C.J.; Hong, X.F.; Mai, L.Q. Rapid, all dry microfabrication of three-dimensional Co3O4/Pt nanonetworks for high-performance microsupercapacitors. Nanoscale 2017, 9, 11765–11772. [Google Scholar] [CrossRef]

- Mao, X.L.; Xu, J.H.; He, X.; Yang, W.Y.; Yang, Y.J.; Xu, L.; Zhao, Y.T.; Zhou, Y.J. All-solid-state flexible microsupercapacitors based on reduced graphene oxide/multi-walled carbon nanotube composite electrodes. Appl. Surf. Sci. 2018, 435, 1228–1236. [Google Scholar] [CrossRef]

- Pan, H.; Wang, D.W.; Peng, Q.F.; Ma, J.; Meng, X.; Zhang, Y.P.; Ma, Y.N.; Zhu, S.M.; Zhang, D. High-Performance Microsupercapacitors Based on Bioinspired Graphene Microfibers. ACS Appl. Mater. Interfaces 2018, 10, 10157–10164. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.S.; Viola, W.; Andrew, T.L. High Energy Density, Super-Deformable, Garment-Integrated Microsupercapacitors for Powering Wearable Electronics. ACS Appl. Mater. Interfaces 2018, 10, 36834–36840. [Google Scholar] [CrossRef] [PubMed]

- Siddique, A.H.; Bokhari, S.W.; Butt, R.; Jiang, S.Q.; Chen, W.; Zhou, X.F.; Liu, Z.P. Flexible asymmetric microsupercapacitor with high energy density based on all-graphene electrode system. J. Mater. Sci. 2020, 55, 309–318. [Google Scholar] [CrossRef]

- Nasir, F.; Mohammad, M.A. Investigation of Device Dimensions on Electric Double Layer Microsupercapacitor Performance and Operating Mechanism. IEEE Access 2020, 8, 28367–28374. [Google Scholar] [CrossRef]

- Feng, X.; Ning, J.; Wang, B.Y.; Guo, H.B.; Xia, M.Y.; Wang, D.; Zhang, J.C.; Wu, Z.S.; Hao, Y. Functional integrated electromagnetic interference shielding in flexible micro-supercapacitors by cation-intercalation typed Ti3C2Tx MXene. Nano Energy 2020, 72, 104741. [Google Scholar] [CrossRef]

- Wang, Y.; Tu, Y.; Peng, F. The Energy Conversion behind Micro-and Nanomotors. Micromachines 2021, 12, 222. [Google Scholar] [CrossRef]

- Qiu, M.J.; Sun, P.; Cui, G.F.; Tong, Y.X.; Mai, W. A Flexible Microsupercapacitor with Integral Photocatalytic Fuel Cell for Self-Charging. ACS Nano 2019, 13, 8246–8255. [Google Scholar] [CrossRef]

- Tang, W.; Han, C.B.; Zhang, C.; Wang, Z.L. Cover-sheet-based nanogenerator for charging mobile electronics using low-frequency body motion/vibration. Nano Energy 2014, 9, 121–127. [Google Scholar] [CrossRef]

- Chen, X.B.; Li, C.; Gratzel, M.; Kostecki, R.; Mao, S.S. Nanomaterials for renewable energy production and storage. Chem. Soc. Rev. 2012, 41, 7909–7937. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.L.; Song, J.H. Piezoelectric nanogenerators based on zinc oxide nanowire arrays. Science 2006, 312, 242–246. [Google Scholar] [CrossRef]

- Zhu, G.; Peng, B.; Chen, J.; Jing, Q.; Wang, Z.L. Triboelectric nanogenerators as a new energy technology: From fundamentals, devices, to applications. Nano Energy 2015, 14, 126–138. [Google Scholar] [CrossRef] [Green Version]

- Zi, Y.; Lin, L.; Wang, J.; Wang, S.; Chen, J.; Fan, X.; Yang, P.K.; Yi, F.; Wang, Z.L. Triboelectric-pyroelectric-piezoelectric hybrid cell for high-efficiency energy-harvesting and self-powered sensing. Adv. Mater. 2015, 27, 2340–2347. [Google Scholar] [CrossRef]

- Cao, X.; Jie, Y.; Wang, N.; Wang, Z.L. Triboelectric Nanogenerators Driven Self-Powered Electrochemical Processes for Energy and Environmental Science. Adv. Energy Mater. 2016, 6, 1600665. [Google Scholar] [CrossRef]

- Fan, F.R.; Tang, W.; Wang, Z.L. Flexible Nanogenerators for Energy Harvesting and Self-Powered Electronics. Adv. Mater. 2016, 28, 4283–4305. [Google Scholar] [CrossRef] [PubMed]

- Gu, S.; Lou, Z.; Li, L.; Chen, Z.; Ma, X.; Shen, G. Fabrication of flexible reduced graphene oxide/Fe2O3 hollow nanospheres based on-chip micro-supercapacitors for integrated photodetecting applications. Nano Res. 2015, 9, 424–434. [Google Scholar] [CrossRef]

- Xu, J.; Shen, G. A flexible integrated photodetector system driven by on-chip microsupercapacitors. Nano Energy 2015, 13, 131–139. [Google Scholar] [CrossRef]

- Kim, D.; Keum, K.; Lee, G.; Kim, D.; Lee, S.-S.; Ha, J.S. Flexible, water-proof, wire-type supercapacitors integrated with wire-type UV/NO2 sensors on textiles. Nano Energy 2017, 35, 199–206. [Google Scholar] [CrossRef]

- Kim, D.; Yun, J.; Lee, G.; Ha, J.S. Fabrication of high performance flexible micro-supercapacitor arrays with hybrid electrodes of MWNT/V2O5 nanowires integrated with a SnO2 nanowire UV sensor. Nanoscale 2014, 6, 12034–12041. [Google Scholar] [CrossRef]

- Staaf, L.G.H.; Lundgren, P.; Enoksson, P. Present and future supercapacitor carbon electrode materials for improved energy storage used in intelligent wireless sensor systems. Nano Energy 2014, 9, 128–141. [Google Scholar] [CrossRef]

- Wang, X.; Liu, B.; Liu, R.; Wang, Q.; Hou, X.; Chen, D.; Wang, R.; Shen, G. Fiber-based flexible all-solid-state asymmetric supercapacitors for integrated photodetecting system. Angew. Chem. Int. Ed. Engl. 2014, 53, 1849–1853. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Q.; Xie, C.; Li, H.; Yang, C.; Zeng, D. A novel planar integration of all-solid-state capacitor and photodetector by an ultra-thin transparent sulfated TiO2 film. Nano Energy 2014, 9, 252–263. [Google Scholar] [CrossRef]

- Akhtar, F.; Rehmani, M.H. Energy replenishment using renewable and traditional energy resources for sustainable wireless sensor networks: A review. Renew. Sustain. Energy Rev. 2015, 45, 769–784. [Google Scholar] [CrossRef]

- Ramadoss, A.; Saravanakumar, B.; Kim, S.J. Vanadium Pentoxide/Reduced Graphene Oxide Composite as an Efficient Electrode Material for High-Performance Supercapacitors and Self-Powered Systems. Energy Technol. 2015, 3, 913–924. [Google Scholar] [CrossRef]

- Sun, L.; Wang, X.; Zhang, K.; Zou, J.; Yan, Z.; Hu, X.; Zhang, Q. Bi-functional electrode for UV detector and supercapacitor. Nano Energy 2015, 15, 445–452. [Google Scholar] [CrossRef]

- Kirubasankar, B.; Balan, B.; Yan, C.; Angaiah, S. Recent Progress in Graphene-Based Microsupercapacitors. Energy Technol. 2021, 9, 2000844. [Google Scholar] [CrossRef]

- Lee, Y.A.; Lim, J.; Cho, Y.; Lee, H.; Park, S.; Lee, G.W.; Yoo, C.Y.; Park, S.H.; Murukeshan, V.M.; Kim, S.; et al. Attachable micropseudocapacitors using highly swollen laser-induced-graphene electrodes. Chem. Eng. J. 2020, 386, 123972. [Google Scholar] [CrossRef]

- Jiang, Q.; Lei, Y.J.; Liang, H.F.; Xi, K.; Xia, C.; Alshareef, H.N. Review of MXene electrochemical microsupercapacitors. Energy Storage Mater. 2020, 27, 78–95. [Google Scholar] [CrossRef]

- Zhou, C.; Hong, M.; Yang, Y.; Yang, C.; Hu, N.T.; Zhang, L.Y.; Yang, Z.; Zhang, Y.F. Laser-induced bi-metal sulfide/graphene nanoribbon hybrid frameworks for high-performance all-in-one fiber supercapacitors. J. Power Sources 2019, 438, 227044. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Zhao, W.; Wei, L.; Jin, Y.Y.; Hou, J.; Wang, X.X.; Guo, X. In-plane flexible solid-state microsupercapacitors for on-chip electronics. Energy 2019, 170, 338–348. [Google Scholar] [CrossRef]

- Boruah, B.D.; Maji, A.; Misra, A. Flexible Array of Microsupercapacitor for Additive Energy Storage Performance Over a Large Area. ACS Appl. Mater. Interfaces 2018, 10, 15864–15872. [Google Scholar] [CrossRef]

- Boonpakdee, D.; Yevenes, C.F.G.; Surareungchai, W.; La-o-vorakiat, C. Exploring non-linearities of carbon-based microsupercapacitors from an equivalent circuit perspective. J. Mater. Chem. A 2018, 6, 7162–7167. [Google Scholar] [CrossRef]

- Shao, Y.L.; Li, J.M.; Li, Y.G.; Wang, H.Z.; Zhang, Q.H.; Kaner, R.B. Flexible quasi-solid-state planar micro-supercapacitor based on cellular graphene films. Mater. Horiz. 2017, 4, 1145–1150. [Google Scholar] [CrossRef]

- Yoonessi, M.; Borenstein, A.; El-Kady, M.F.; Turner, C.L.; Wang, H.S.; Stieg, A.Z.; Pilon, L. Hybrid Transparent PEDOT:PSS Molybdenum Oxide Battery-like Supercapacitors. ACS Appl. Energy Mater. 2019, 2, 4629–4639. [Google Scholar] [CrossRef]

- Yin, Q.; Li, D.P.; Zhang, J.; Zhao, Y.J.; Wang, C.; Han, J.B. CoNi-layered double hydroxide array on graphene-based fiber as a new electrode material for microsupercapacitor. Appl. Surf. Sci. 2019, 487, 1–8. [Google Scholar] [CrossRef]

- Wang, J.Y.; Wang, X.H.; Lee, S.W.; Zhang, Q. Enhanced Performance of an Electric Double Layer Microsupercapacitor Based on Novel Carbon-Encapsulated Cu Nanowire Network Structure As the Electrode. ACS Appl. Mater. Interfaces 2019, 11, 40481–40489. [Google Scholar] [CrossRef]

- Kamboj, N.; Purkait, T.; Das, M.; Sarkar, S.; Hazra, K.S.; Dey, R.S. Ultralong cycle life and outstanding capacitive performance of a 10.8 V metal free micro-supercapacitor with highly conducting and robust laser-irradiated graphene for an integrated storage device. Energy Environ. Sci. 2019, 12, 2507–2517. [Google Scholar] [CrossRef]

- Li, X.Q.; Cai, W.H.; Teh, K.S.; Qi, M.J.; Zang, X.N.; Ding, X.R.; Cui, Y.; Xie, Y.X.; Wu, Y.C.; Ma, H.Y.; et al. High-Voltage Flexible Microsupercapacitors Based on Laser-Induced Graphene. ACS Appl. Mater. Interfaces 2018, 10, 26357–26364. [Google Scholar] [CrossRef]

- Li, P.; Shi, W.H.; Liu, W.X.; Chen, Y.F.; Xu, X.L.; Ye, S.F.; Yin, R.L.; Zhang, L.; Xu, L.X.; Cao, X.H. Fabrication of high-performance MXene-based all-solid-state flexible microsupercapacitor based on a facile scratch method. Nanotechnology 2018, 29, 445401. [Google Scholar] [CrossRef]

- Jiang, Q.; Wu, C.S.; Wang, Z.J.; Wang, A.C.; He, J.H.; Wang, Z.L.; Alshareef, H.N. MXene electrochemical microsupercapacitor integrated with triboelectric nanogenerator as a wearable self-charging power unit. Nano Energy 2018, 45, 266–272. [Google Scholar] [CrossRef] [Green Version]

- Duy, L.X.; Peng, Z.W.; Li, Y.L.; Zhang, J.B.; Ji, Y.S.; Tour, J.M. Laser-induced graphene fibers. Carbon 2018, 126, 472–479. [Google Scholar] [CrossRef]

- Boruah, B.D.; Nandi, S.; Misra, A. Layered Assembly of Reduced Graphene Oxide and Vanadium Oxide Heterostructure Supercapacitor Electrodes with Larger Surface Area for Efficient Energy-Storage Performance. ACS Appl. Energy Mater. 2018, 1, 1567–1574. [Google Scholar] [CrossRef]

- Kumar, R.; Sahoo, S.; Joanni, E.; Singh, R.K.; Tan, W.K.; Kar, K.K.; Matsuda, A. Recent progress in the synthesis of graphene and derived materials for next generation electrodes of high performance lithium ion batteries. Prog. Energy Combust. Sci. 2019, 75, 100786. [Google Scholar] [CrossRef]

- Velasco, A.; Ryu, Y.K.; Bosca, A.; Ladron-de-Guevara, A.; Hunt, E.; Zuo, J.H.; Pedros, J.; Calle, F.; Martinez, J. Recent trends in graphene supercapacitors: From large area to microsupercapacitors. Sustain. Energy Fuels 2021, 5, 1235–1254. [Google Scholar] [CrossRef]

- Li, P.; Shang, T.X.; Dong, X.M.; Li, H.; Tao, Y.; Yang, Q.H. A Review of Compact Carbon Design for Supercapacitors with High Volumetric Performance. Small 2021, 3, 2007548. [Google Scholar] [CrossRef]

- Kumar, R.; Savu, R.; Joanni, E.; Vaz, A.R.; Canesqui, M.A.; Singh, R.K.; Timm, R.A.; Kubota, L.T.; Moshkalev, S.A. Fabrication of interdigitated micro-supercapacitor devices by direct laser writing onto ultra-thin, flexible and free-standing graphite oxide films. RSC Adv. 2016, 6, 84769–84776. [Google Scholar] [CrossRef] [Green Version]

- Shahrokhian, S.; Naderi, L.; Mohammadi, R. High-Performance Fiber-Shaped Flexible Asymmetric Microsupercapacitor Based on Ni(OH)(2) Nanoparticles-Decorated Porous Dendritic Ni-Cu Film/Cu Wire and Reduced Graphene Oxide/Carbon Fiber Electrodes. ACS Sustain. Chem. Eng. 2018, 6, 14574–14588. [Google Scholar] [CrossRef]

- Rao, J.Y.; Liu, N.S.; Zhang, Z.; Su, J.; Li, L.Y.; Xiong, L.; Gao, Y.H. All-fiber-based quasi-solid-state lithium-ion battery towards wearable electronic devices with outstanding flexibility and self-healing ability. Nano Energy 2018, 51, 425–433. [Google Scholar] [CrossRef]

- Patil, S.J.; Park, J.S.; Kim, Y.B.; Lee, D.W. A Quasi 2D Flexible Micro-Supercapacitor Based on MnO2//NiCoO4 as a Miniaturized Energy-Storage Device. Energy Technol. 2018, 6, 1380–1391. [Google Scholar] [CrossRef]

- Li, K.; Liang, M.; Wang, H.; Wang, X.; Huang, Y.; Coelho, J.; Pinilla, S.; Zhang, Y.; Qi, F.; Nicolosi, V.; et al. 3D MXene Architectures for Efficient Energy Storage and Conversion. Adv. Funct. Mater. 2020, 30, 2000842. [Google Scholar] [CrossRef]

- Jung, J.; Jeong, J.R.; Lee, J.; Lee, S.H.; Kim, S.Y.; Kim, M.J.; Nah, J.; Lee, M.H. In situ formation of graphene/metal oxide composites for high-energy microsupercapacitors. NPG Asia Mater. 2020, 12, 50. [Google Scholar] [CrossRef]

- Li, K.; Wang, X.; Li, S.; Urbankowski, P.; Li, J.; Xu, Y.; Gogotsi, Y. An Ultrafast Conducting Polymer@MXene Positive Electrode with High Volumetric Capacitance for Advanced Asymmetric Supercapacitors. Small 2020, 16, e1906851. [Google Scholar] [CrossRef]

- Chen, Y.; Guo, M.; Xu, L.; Cai, Y.; Tian, X.; Liao, X.; Wang, Z.; Meng, J.; Hong, X.; Mai, L. In-situ selective surface engineering of graphene micro-supercapacitor chips. Nano Res. 2021, 1–8. [Google Scholar]

- Li, L.; Lou, Z.; Han, W.; Shen, G. Flexible in-plane microsupercapacitors with electrospun NiFe2O4 nanofibers for portable sensing applications. Nanoscale 2016, 8, 14986–14991. [Google Scholar] [CrossRef]

- Shi, X.; Pei, S.; Zhou, F.; Ren, W.; Cheng, H.-M.; Wu, Z.-S.; Bao, X. Ultrahigh-voltage integrated micro-supercapacitors with designable shapes and superior flexibility. Energy Environ. Sci. 2019, 12, 1534–1541. [Google Scholar] [CrossRef]

- Huang, T.T.; Jiang, K.; Li, L.; Chen, S.; Li, R.; Shen, G.Z.; Chen, D. Large-Scale Fabrication of Flexible On-Chip Micro-Supercapacitors by a Mechanical Scribing Process. Chemelectrochem 2018, 5, 1652–1657. [Google Scholar] [CrossRef]

- Li, L.; Liu, W.J.; Jiang, K.; Chen, D.; Qu, F.Y.; Shen, G.Z. In-Situ Annealed Ti3C2Tx MXene Based All-Solid-State Flexible Zn-Ion Hybrid Micro Supercapacitor Array with Enhanced Stability. Nano-Micro Lett. 2021, 13, 100. [Google Scholar] [CrossRef]

- Zhang, C.J.; McKeon, L.; Kremer, M.P.; Park, S.H.; Ronan, O.; Seral-Ascaso, A.; Barwich, S.; Coileain, C.O.; McEvoy, N.; Nerl, H.C.; et al. Additive-free MXene inks and direct printing of micro-supercapacitors. Nat. Commun. 2019, 10, 1795. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Wu, Z.S.; Yang, S.; Dong, R.; Feng, X.; Mullen, K. Ultraflexible In-Plane Micro-Supercapacitors by Direct Printing of Solution-Processable Electrochemically Exfoliated Graphene. Adv. Mater. 2016, 28, 2217–2222. [Google Scholar] [CrossRef]

- Wang, H.; Zhao, D.; Khan, Z.U.; Puzinas, S.; Jonsson, M.P.; Berggren, M.; Crispin, X. Ionic Thermoelectric Figure of Merit for Charging of Supercapacitors. Adv. Electron. Mater. 2017, 3, 1700013. [Google Scholar] [CrossRef]

- Kim, D.; Kim, D.; Lee, H.; Jeong, Y.R.; Lee, S.J.; Yang, G.; Kim, H.; Lee, G.; Jeon, S.; Zi, G.; et al. Body-Attachable and Stretchable Multisensors Integrated with Wirelessly Rechargeable Energy Storage Devices. Adv. Mater. 2016, 28, 748–756. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Lou, Z.; Han, W.; Chen, D.; Jiang, K.; Shen, G. Highly Stretchable Micro-Supercapacitor Arrays with Hybrid MWCNT/PANI Electrodes. Adv. Mater. Technol. 2017, 2, 1600282. [Google Scholar] [CrossRef]

- Chen, D.; Lu, M.J.; Li, L.; Cai, D.; Li, J.Z.; Cao, J.M.; Han, W. Hierarchical core-shell structural NiMoO4@NiS2/MoS2 nanowires fabricated via an in situ sulfurization method for high performance asymmetric supercapacitors. J. Mater. Chem. A 2019, 7, 21759–21765. [Google Scholar] [CrossRef]

- Li, L.; Fu, C.; Lou, Z.; Chen, S.; Han, W.; Jiang, K.; Chen, D.; Shen, G. Flexible planar concentric circular micro-supercapacitor arrays for wearable gas sensing application. Nano Energy 2017, 41, 261–268. [Google Scholar] [CrossRef]

- Kumar, R.; Sahoo, S.; Joanni, E.; Singh, R.K.; Yadav, R.M.; Verma, R.K.; Singh, D.P.; Tan, W.K.; del Pino, A.P.; Moshkalev, S.A.; et al. A review on synthesis of graphene, h-BN and MoS2 for energy storage applications: Recent progress and perspectives. Nano Res. 2019, 12, 2655–2694. [Google Scholar] [CrossRef]

- Kumar, R.; Sahoo, S.; Joanni, E.; Singh, R.K.; Maegawa, K.; Tan, W.K.; Kawamura, G.; Kar, K.K.; Matsuda, A. Heteroatom doped graphene engineering for energy storage and conversion. Mater. Today 2020, 39, 47–65. [Google Scholar] [CrossRef]

- Lu, Y.; Li, L.; Chen, D.; Shen, G.Z. Nanowire-assembled Co3O4@NiCo2O4 architectures for high performance all-solid-state asymmetric supercapacitors. J. Mater. Chem. A 2017, 5, 24981–24988. [Google Scholar] [CrossRef]

- Li, L.; Lou, Z.; Chen, D.; Han, W.; Shen, G.Z. Hollow Polypyrrole Sleeve Based Coaxial Fiber Supercapacitors for Wearable Integrated Photosensing System. Adv. Mater. Technol. 2018, 3, 1800115. [Google Scholar] [CrossRef]

- Jia, R.; Li, L.; Ai, Y.F.; Du, H.; Zhang, X.D.; Chen, Z.J.; Shen, G.Z. Self-healable wire-shaped supercapacitors with two twisted NiCo2O4 coated polyvinyl alcohol hydrogel fibers. Sci. China-Mater. 2018, 61, 254–262. [Google Scholar] [CrossRef] [Green Version]

- Hwang, J.Y.; Li, M.; El-Kady, M.F.; Kaner, R.B. Next-Generation Activated Carbon Supercapacitors: A Simple Step in Electrode Processing Leads to Remarkable Gains in Energy Density. Adv. Funct. Mater. 2017, 27, 1605745. [Google Scholar] [CrossRef]

- Jia, L.M.; Zheng, L.T.; Wang, W.J.; Shi, Y.H.; Zhang, Q.; Xu, X.H. Controllable design of coaxial MnO2/polyaniline for asymmetric supercapacitors and stamping flexible micro-device. Mater. Lett. 2019, 252, 80–83. [Google Scholar] [CrossRef]

- Zhao, F.F.; Liu, W.H.; Qiu, T.L.; Gong, W.B.; Ma, W.; Li, Q.W.; Li, F.; Geng, F.X. All Two-Dimensional Pseudocapacitive Sheet Materials for Flexible Asymmetric Solid-State Planar Microsupercapacitors with High Energy Density. ACS Nano 2020, 14, 603–610. [Google Scholar] [CrossRef] [PubMed]

- Zaccagnini, P.; di Giovanni, D.; Gomez, M.G.; Passerini, S.; Varzi, A.; Lamberti, A. Flexible and high temperature supercapacitor based on laser-induced graphene electrodes and ionic liquid electrolyte, a de-rated voltage analysis. Electrochim. Acta 2020, 357, 136838. [Google Scholar] [CrossRef]

- Naderi, L.; Shahrokhian, S. Nickel vanadium sulfide grown on nickel copper phosphide Dendrites/Cu fibers for fabrication of all-solid-state wire-type micro-supercapacitors. Chem. Eng. J. 2020, 392, 124880. [Google Scholar] [CrossRef]

- Li, X.X.; Ma, Y.N.; Shen, P.Z.; Zhang, C.K.; Cao, M.L.; Xiao, S.J.; Yan, J.F.; Luo, S.J.; Gao, Y.H. An Ultrahigh Energy Density Flexible Asymmetric Microsupercapacitor Based on Ti3C2Tx and PPy/MnO2 with Wide Voltage Window. Adv. Mater. Technol. 2020, 5, 2000272. [Google Scholar] [CrossRef]

- Chen, D.; Lu, M.J.; Wang, B.R.; Chai, R.Q.; Li, L.; Cai, D.; Yang, H.; Liu, B.K.; Zhang, Y.P.; Han, W. Uncover the mystery of high-performance aqueous zinc-ion batteries constructed by oxygen-doped vanadium nitride cathode: Cationic conversion reaction works. Energy Storage Mater. 2021, 35, 679–686. [Google Scholar] [CrossRef]

- Chen, D.; Li, L.; Xi, Y.L.; Li, J.Z.; Lu, M.J.; Cao, J.M.; Han, W. Self-assembly of biomass microfibers into 3D layer-stacking hierarchical porous carbon for high performance supercapacitors. Electrochim. Acta 2018, 286, 264–270. [Google Scholar] [CrossRef]

- Cai, D.; Lu, M.J.; Li, L.; Cao, J.M.; Chen, D.; Tu, H.R.; Li, J.Z.; Han, W. A Highly Conductive MOF of Graphene Analogue Ni-3(HITP)(2) as a Sulfur Host for High-Performance Lithium-Sulfur Batteries. Small 2019, 15, 1902605. [Google Scholar] [CrossRef] [PubMed]

- Ai, Y.F.; Lou, Z.; Li, L.; Chen, S.; Park, H.S.; Wang, Z.M.M.; Shen, G.Z. Meters-Long Flexible CoNiO2-Nanowires@Carbon-Fibers Based Wire-Supercapacitors for Wearable Electronics. Adv. Mater. Technol. 2016, 1, 1600142. [Google Scholar] [CrossRef]

- Zhang, B.; He, J.K.; Zheng, G.F.; Huang, Y.Y.; Wang, C.H.; He, P.S.; Sui, F.P.; Meng, L.C.; Lin, L.W. Electrohydrodynamic 3D printing of orderly carbon/nickel composite network as supercapacitor electrodes. J. Mater. Sci. Technol. 2021, 82, 135–143. [Google Scholar] [CrossRef]

- Ye, B.R.; Xiao, S.H.; Cao, X.J.; Chen, J.S.; Zhou, A.J.; Zhao, Q.; Huang, W.; Wang, J.S. Interface engineering for enhancing performance of additive-free NiTe@NiCoSe2 core/shell nanostructure for asymmetric supercapacitors. J. Power Sources 2021, 506, 230056. [Google Scholar] [CrossRef]

- Wang, R.; Xuan, H.C.; Yang, J.; Zhang, G.H.; Xie, Z.G.; Liang, X.H.; Han, P.D.; Wu, Y.C. Controllable Synthesis of complex nickel-vanadium selenide three dimensional flower-like structures as an attractive battery-type electrode material for high-performance hybrid supercapacitors. Electrochim. Acta 2021, 388, 138649. [Google Scholar] [CrossRef]

- Tu, D.; Wu, Z.K.; Xu, J.H.; Zhou, Y.J.; Yang, W.Y.; Yang, Y.J.; Zha, X.T.; Shi, L.W. Direct Assembly of 3D-BCN Microspheres as a Microsupercapacitor Electrode for Wearable Energy Storage. ACS Appl. Mater. Interfaces 2020, 12, 47416–47424. [Google Scholar] [CrossRef]

- Liu, B.K.; Cao, J.M.; Li, J.Z.; Li, L.; Chen, D.; Zhang, S.Q.; Cai, D.; Han, W. Highly conductive Co3Se4 embedded in N-doped 3D interconnected carbonaceous network for enhanced lithium and sodium storage. J. Colloid Interface Sci. 2021, 586, 630–639. [Google Scholar] [CrossRef]

- Dong, Y.; Wang, L.; Ban, L.; Du, W.; Feng, X.J.; Chen, P.; Xiao, F.; Wang, S.; Liu, B.F. Selective vacuum filtration-induced microelectrode patterning on paper for high-performance planar microsupercapacitor. J. Power Sources 2018, 396, 632–638. [Google Scholar] [CrossRef]

- He, L.; Hong, T.J.; Huang, Y.; Xiong, B.; Hong, X.F.; Tahir, M.; Haider, W.A.; Han, Y.L. Surface Engineering of Carbon-Based Microelectrodes for High-Performance Microsupercapacitors. Micromachines 2019, 10, 307. [Google Scholar] [CrossRef] [Green Version]

- Smith, E.A.M.; Liu, Y.Q.; Stirling, C.; Watson, D.J.; Slade, R.C.T.; Chen, J.; Crean, C. Plasma functionalisation of few-layer graphenes and carbon nanotubes for graphene microsupercapacitors. Electrochim. Acta 2019, 317, 348–357. [Google Scholar] [CrossRef]

- Lin, N.; Chen, H.N.; Wang, W.T.; Lu, L.S. Laser-Induced Graphene/MoO2 Core-Shell Electrodes on Carbon Cloth for Integrated, High-Voltage, and In-Planar Microsupercapacitors. Adv. Mater. Technol. 2021, 6, 2000991. [Google Scholar] [CrossRef]

- Kim, H.R.; Lee, J.H.; Lee, S.K.; Chun, Y.; Park, C.; Jin, J.H.; Lee, H.U.; Kim, S.W. Fabricating a modified biochar-based all-solid-state flexible microsupercapacitor using pen lithography. J. Clean. Prod. 2021, 284, 125449. [Google Scholar] [CrossRef]

- Hu, C.Q.; Li, L.; Shen, G.Z. Flexible Transparent Near-Infrared Photodetector Based on 2D Ti3C2 MXene-Te Van Der Waals Heterostructures(dagger). Chin. J. Chem. 2021, 39, 2141–2146. [Google Scholar] [CrossRef]

- Li, L.; Fu, X.Y.; Chen, S.; Uzun, S.; Levitt, A.S.; Shuck, C.E.; Han, W.; Gogotsi, Y. Hydrophobic and Stable MXene-Polymer Pressure Sensors for Wearable Electronics. ACS Appl. Mater. Interfaces 2020, 12, 15362–15369. [Google Scholar] [CrossRef] [PubMed]

- Chu, X.; Zhu, Z.; Huang, H.; Xie, Y.; Xu, Z.; Wang, Y.; Yan, C.; Jin, L.; Wang, Y.; Zhang, H.; et al. Conducting polymer ink for flexible and printable micro-supercapacitors with greatly-enhanced rate capability. J. Power Sources 2021, 513, 230555. [Google Scholar] [CrossRef]

- Zhang, Q.; Huang, L.; Chang, Q.H.; Shi, W.Z.; Shen, L.; Chen, Q. Gravure-printed interdigital microsupercapacitors on a flexible polyimide substrate using crumpled graphene ink. Nanotechnology 2016, 27, 105401. [Google Scholar] [CrossRef]

- Xiao, Y.X.; Huang, L.; Zhang, Q.; Xu, S.H.; Chen, Q.; Shi, W.Z. Gravure printing of hybrid MoS2@S-rGO interdigitated electrodes for flexible microsupercapacitors. Appl. Phys. Lett. 2015, 107, 013906. [Google Scholar] [CrossRef]

- Li, L.; Chen, D.; Shen, G.Z. All-Ti3C2Tx MXene Based Flexible On-chip Microsupercapacitor Array. Chem. Res. Chin. Univ. 2020, 36, 694–698. [Google Scholar] [CrossRef]

- Cai, J.G.; Lv, C.; Watanabe, A. Laser Direct Writing and Selective Metallization of Metallic Circuits for Integrated Wireless Devices. ACS Appl. Mater. Interfaces 2018, 10, 915–924. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.Z.; Zhang, Q.M. Recent progress on laser fabrication of on-chip microsupercapacitors. J. Energy Storage 2021, 34, 101994. [Google Scholar] [CrossRef]

- Wang, W.T.; Lu, L.S.; Xie, Y.X.; Li, Z.H.; Wu, W.B.; Liang, R.X.; Tang, Y. One-step laser induced conversion of a gelatin-coated polyimide film into graphene: Tunable morphology, surface wettability and microsupercapacitor applications. Sci. China-Technol. Sci. 2021, 64, 1030–1040. [Google Scholar] [CrossRef]

- Rao, Y.F.; Yuan, M.; Luo, F.; Wang, Z.P.; Li, H.; Yu, J.B.; Chen, X.P. One-step laser fabrication of phosphorus-doped porous graphene electrodes for high-performance flexible microsupercapacitor. Carbon 2021, 180, 56–66. [Google Scholar] [CrossRef]

- Kwon, S.; Lee, T.S.; Choi, H.J.; Ahn, J.Y.; Lim, H.J.; Kim, G.H.; Choi, K.B.; Lee, J.J. Scalable fabrication of inkless, transfer-printed graphene-based textile microsupercapacitors with high rate capabilities. J. Power Sources 2021, 481, 228939. [Google Scholar] [CrossRef]

- Wang, Y.L.; Zhang, Y.; Liu, J.M.; Wang, G.L.; Pu, F.Z.; Ganesh, A.; Tang, C.; Shi, X.W.; Qiao, Y.D.; Chen, Y.Z.; et al. Boosting areal energy density of 3D printed all-solid-state flexible microsupercapacitors via tailoring graphene composition. Energy Storage Mater. 2020, 30, 412–419. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Y.Z.; Dubbink, D.; ten Elshof, J.E. Inkjet printing of delta-MnO2 nanosheets for flexible solid-state micro-supercapacitor. Nano Energy 2018, 49, 481–488. [Google Scholar] [CrossRef]

- Zhong, Y.; Cheng, G.G.; Chen, C.; Tang, Z.R.; Xi, S.; Ding, J.N. In-Plane Flexible Microsystems Integrated with High-Performance Microsupercapacitors and Photodetectors. J. Electron. Mater. 2021, 50, 3517–3526. [Google Scholar] [CrossRef]

- Gao, C.; Huang, J.C.; Xiao, Y.K.; Zhang, G.Q.; Dai, C.L.; Li, Z.L.; Zhao, Y.; Jiang, L.; Qu, L.T. A seamlessly integrated device of micro-supercapacitor and wireless charging with ultrahigh energy density and capacitance. Nat. Commun. 2021, 12, 2647. [Google Scholar] [CrossRef]

- Cai, C.Y.; Zhou, W.B.; Fu, Y. Bioinspired MXene nacre with mechanical robustness for highly flexible all-solid-state photothermo-supercapacitor. Chem. Eng. J. 2021, 418, 129275. [Google Scholar] [CrossRef]

- Secor, E.B.; Lim, S.; Zhang, H.; Frisbie, C.D.; Francis, L.F.; Hersam, M.C. Gravure Printing of Graphene for Large-Area Flexible Electronics. Adv. Mater. 2014, 26, 4533–4538. [Google Scholar] [CrossRef] [PubMed]

- Choi, D.; Choi, M.Y.; Choi, W.M.; Shin, H.J.; Park, H.K.; Seo, J.S.; Park, J.; Yoon, S.M.; Chae, S.J.; Lee, Y.H.; et al. Fully Rollable Transparent Nanogenerators Based on Graphene Electrodes. Adv. Mater. 2010, 22, 2187–2192. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Wang, Z.L. Tribotronics—A new field by coupling triboelectricity and semiconductor. Nano Today 2016, 11, 521–536. [Google Scholar] [CrossRef]

- Kim, S.L.; Lin, H.T.; Yu, C. Thermally Chargeable Solid-State Supercapacitor. Adv. Energy Mater. 2016, 6, 1600546. [Google Scholar] [CrossRef]

- Zhao, D.; Wang, H.; Khan, Z.U.; Chen, J.C.; Gabrielsson, R.; Jonsson, M.P.; Berggren, M.; Crispin, X. Ionic thermoelectric supercapacitors. Energy Environ. Sci. 2016, 9, 1450–1457. [Google Scholar] [CrossRef] [Green Version]

- Lu, Y.; Jiang, K.; Chen, D.; Shen, G.Z. Wearable sweat monitoring system with integrated micro-supercapacitors. Nano Energy 2019, 58, 624–632. [Google Scholar] [CrossRef]

| Electrodes | Specific Capacitance | Energy Density | Power Density | Ref. |

|---|---|---|---|---|

| PANI//Zn | 250 µAh/cm2 | 0.25 mWh/cm2 | 0.99 mW/cm2 | [2] |

| Active carbon | 0.32 mF/cm2 | 0.3 μWh/cm2 | 66.5 μW/cm2 | [3] |

| rGO/PEDOT | 7.7 F/cm3 at 0.02 A/cm3 | 5 mWh/cm3 | 141 W/cm3 | [4] |

| Co3O4/Pt | 35.7 F/cm3 at 20 mV/s | 3.17 mWh/cm3 | 47.4 W/cm3 | [5] |

| rGO/MWCNT | 49.35 F/cm3 at 20 mA/cm3 | 47 mWh/cm3 | 10 mW/cm3 | [6] |

| rGO fiber | 121 F/cm3 below 1 V/s | 0.01 Wh/cm3 | 100 W/cm3 | [7] |

| rGO | 10.38 mF/cm2 | 1.08 mWh/cm3 | 83.5 mW/cm3 | [32] |

| MoO3-x nanorod | 41.7 mF/cm2 | 5.8 μWh/cm2 | - | [35] |

| carbon/Cu nanowire | 7.43 F/cm3 at 0.17 mA/cm2 | 0.66 mWh/cm3 | 0.36 W/cm3 | [41] |

| ZnO/rGO | 3.9 F/cm3 | 0.43 mWh/cm3 | 0.13 mWh/cm3 | [56] |

| Ti3C2Tx MXene/ PANI@MXene | 1632 F/cm3 at 10 mV/s | 50.6 Wh/L | 127 kW/L | [57] |

| NiFe2O4 | 2.23 F/cm3 at 100 mV/s | 0.197 mWh/cm3 | 2.07 W/cm3 | [59] |

| rGO | 1.0 mF/cm3 at 5 mV/s | 1.81 mWh/cm3 | 297 mW/cm3 | [60] |

| ZnCo2O4 | 0.065 μWh/cm2 | 0.092 mW/cm2 | [61] | |

| Ti3C2Tx//Zn | 662.53 F/cm3 | 0.02 mWh/cm2 | 0.50 mW/cm2 | [62] |

| Ti3C2Tx | 562 F/cm3 | 0.32 µWh/cm2 | 11.4 µW/cm2 | [63] |

| rGO | 2 mF/cm2 at 5 mV/s | - | - | [64] |

| CNT/PANI | 44.13 mF/cm2 | 0.004 mWh/cm2 | 0.07 mW/cm2 | [67] |

| NoMoO4@NiS2/MoS2 | 970 F/g | 26.8 Wh/kg | 700 W/kg | [68] |

| Ppy | 47.42 mF/cm2 | 0.004 mWh/cm2 | 0.185 mW/cm2 | [69] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Hu, C.; Liu, W.; Shen, G. Progress and Perspectives in Designing Flexible Microsupercapacitors. Micromachines 2021, 12, 1305. https://doi.org/10.3390/mi12111305

Li L, Hu C, Liu W, Shen G. Progress and Perspectives in Designing Flexible Microsupercapacitors. Micromachines. 2021; 12(11):1305. https://doi.org/10.3390/mi12111305

Chicago/Turabian StyleLi, La, Chuqiao Hu, Weijia Liu, and Guozhen Shen. 2021. "Progress and Perspectives in Designing Flexible Microsupercapacitors" Micromachines 12, no. 11: 1305. https://doi.org/10.3390/mi12111305

APA StyleLi, L., Hu, C., Liu, W., & Shen, G. (2021). Progress and Perspectives in Designing Flexible Microsupercapacitors. Micromachines, 12(11), 1305. https://doi.org/10.3390/mi12111305