A Novel Dielectric Barrier Discharge (DBD) Reactor with Streamer and Glow Corona Discharge for Improved Ozone Generation at Atmospheric Pressure

Abstract

:1. Introduction

2. Materials and Methods

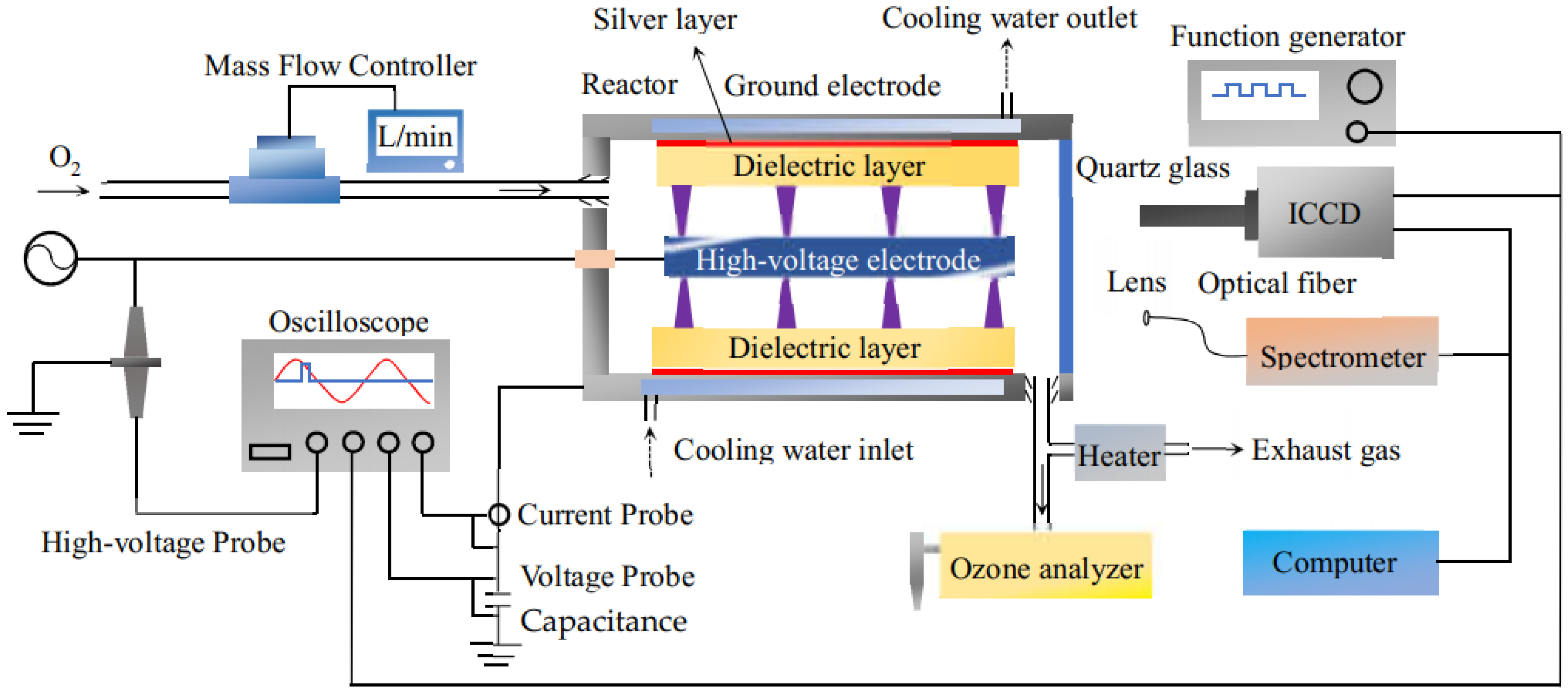

2.1. Experimental System

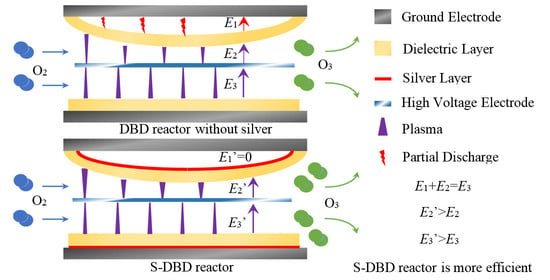

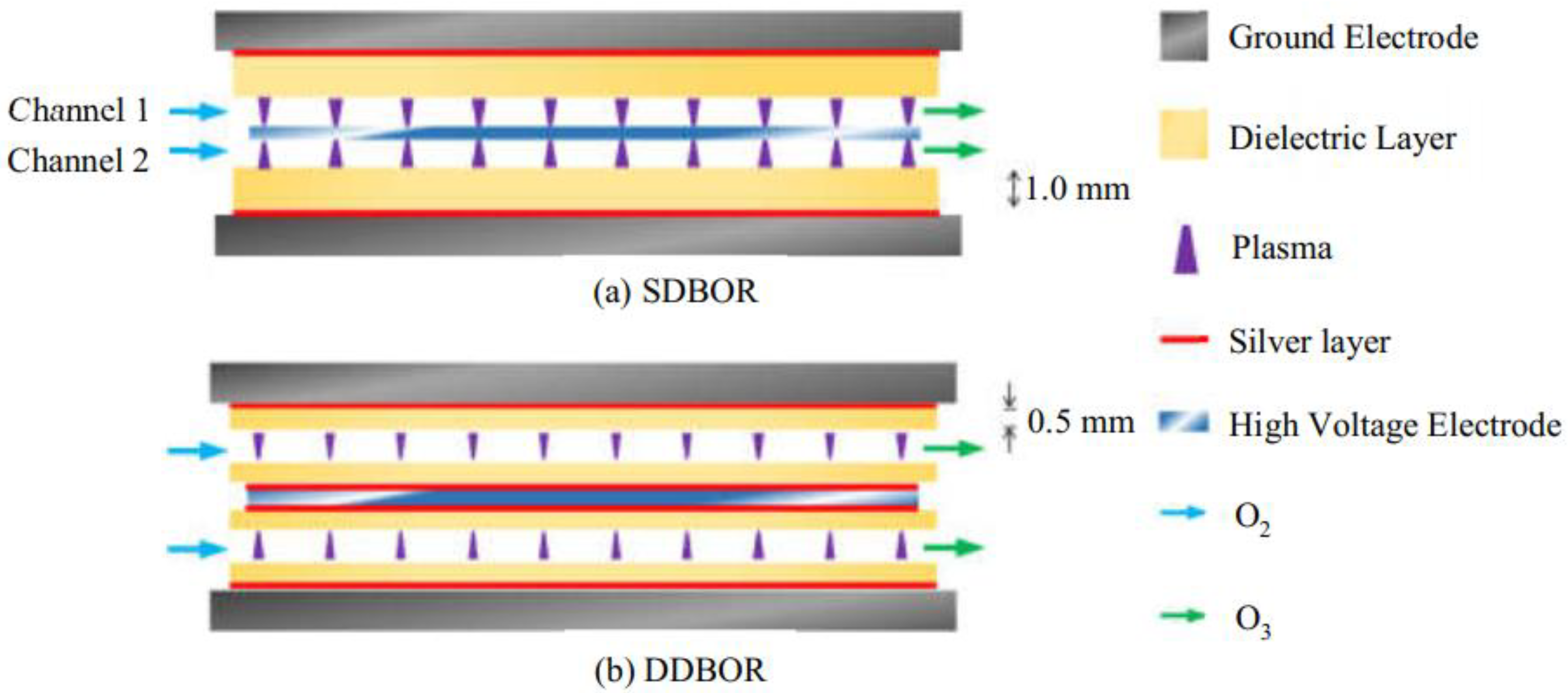

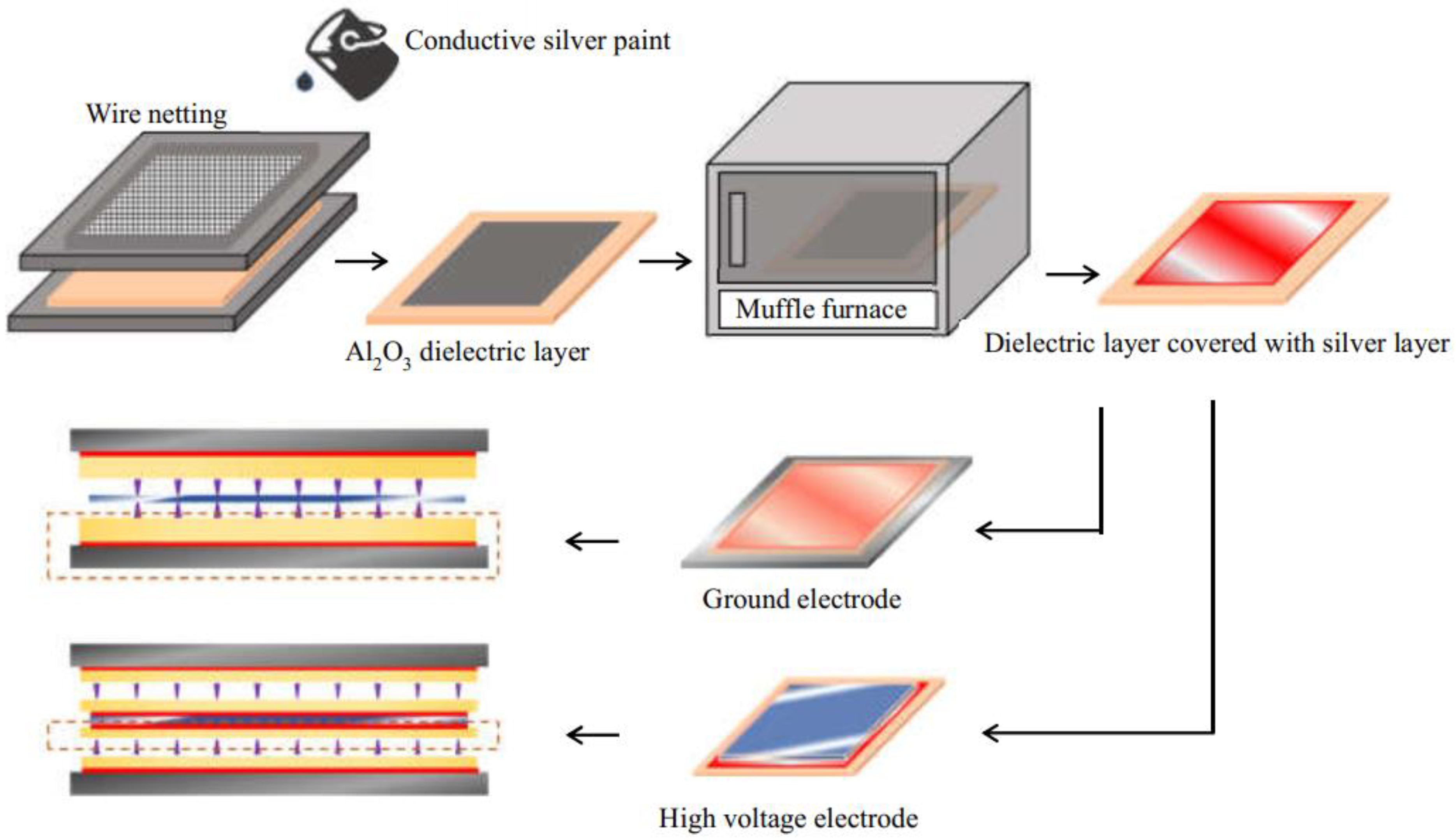

2.2. Structure and Fabrication of the Reactors

2.3. Experimental Procedures

3. Results and Discussion

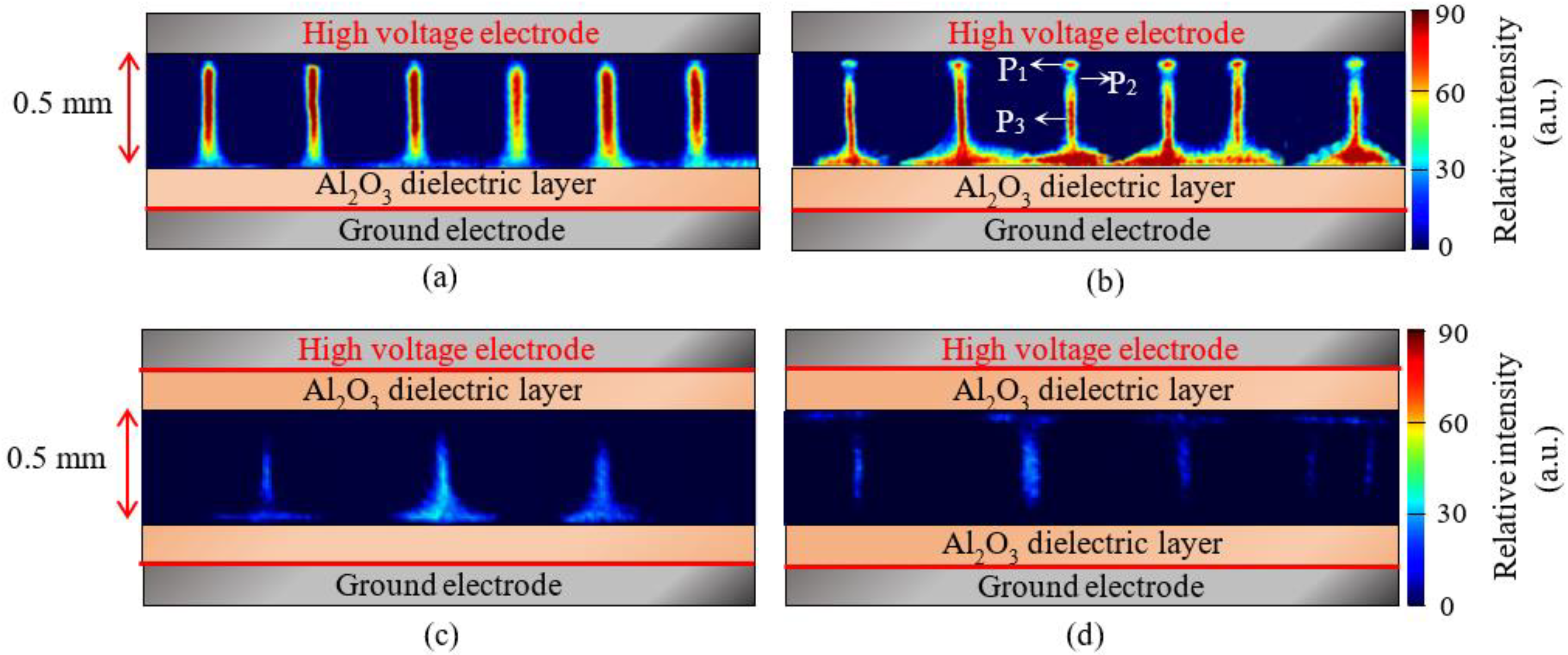

3.1. Discharge Modes

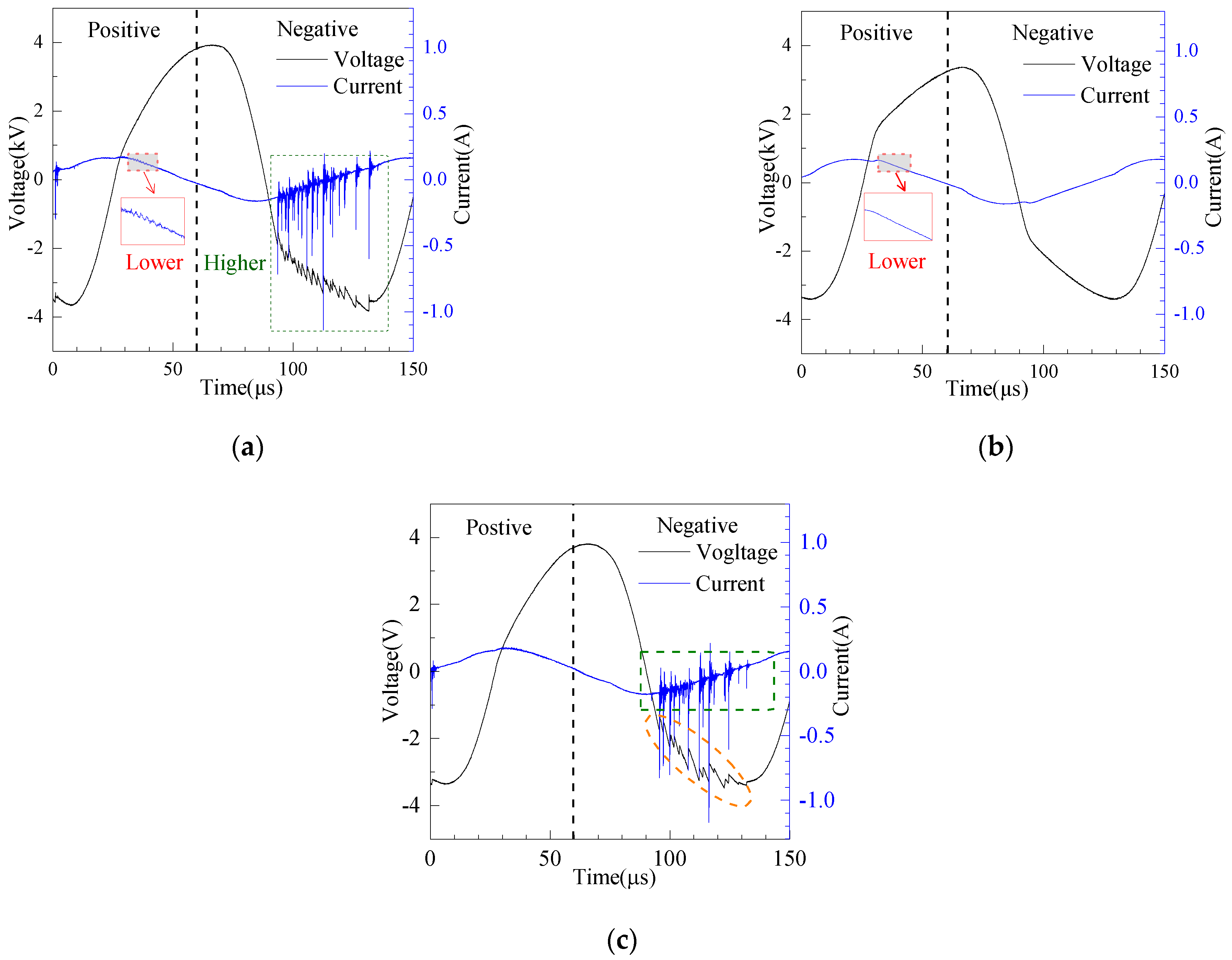

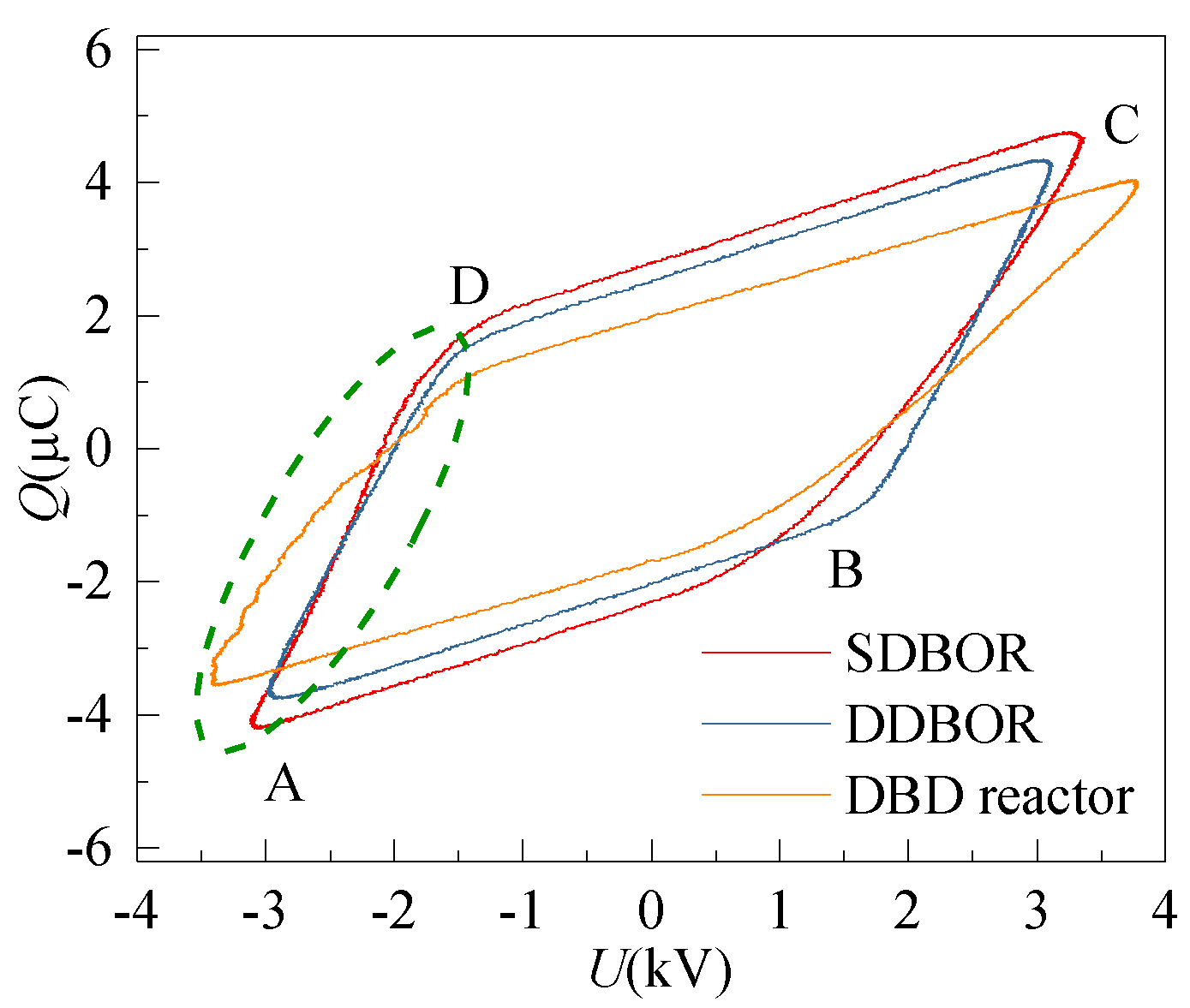

3.2. Effect of Discharge Modes on Current-Voltage Waveforms and Lissajous Figure

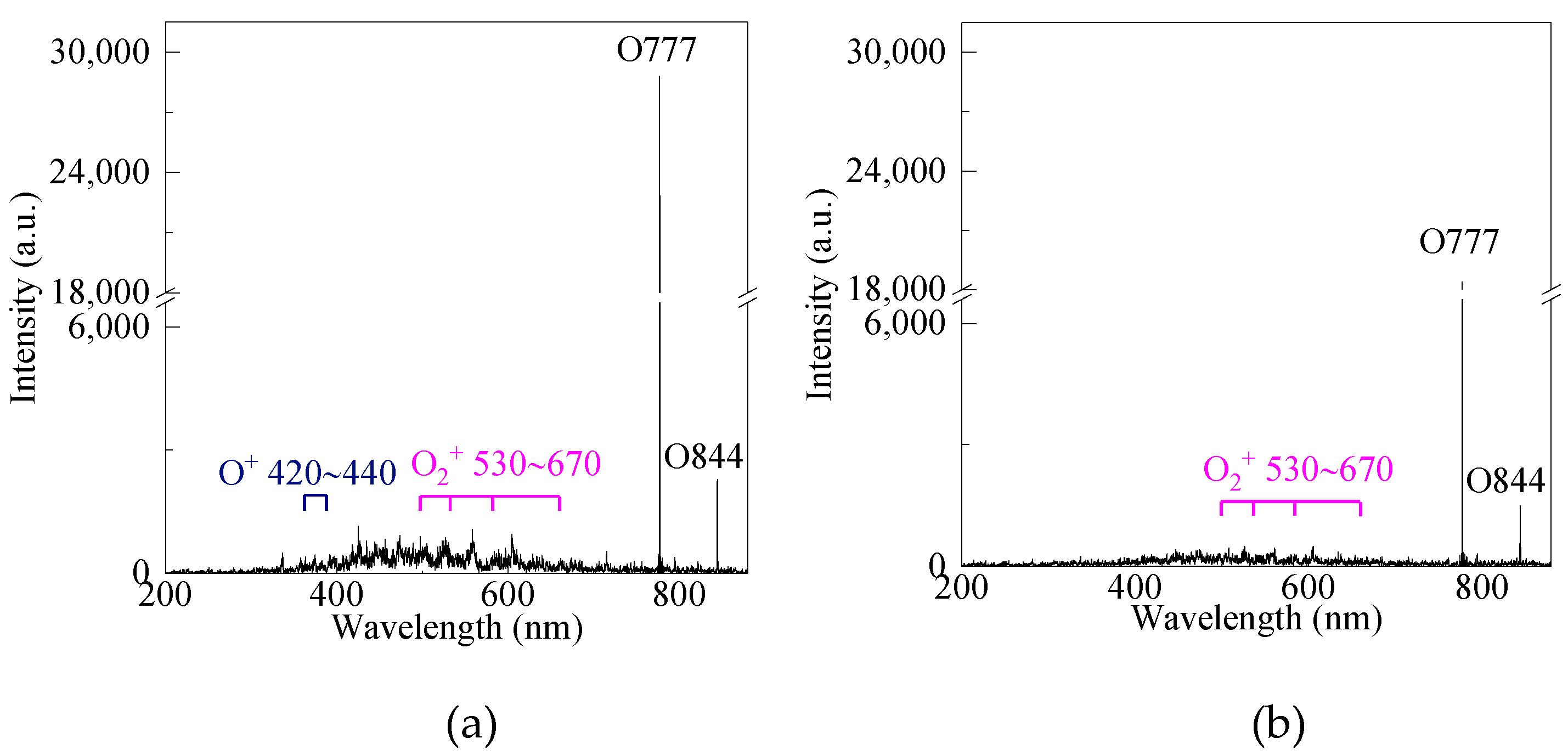

3.3. Effect of Discharge Modes on Electric Field Strength

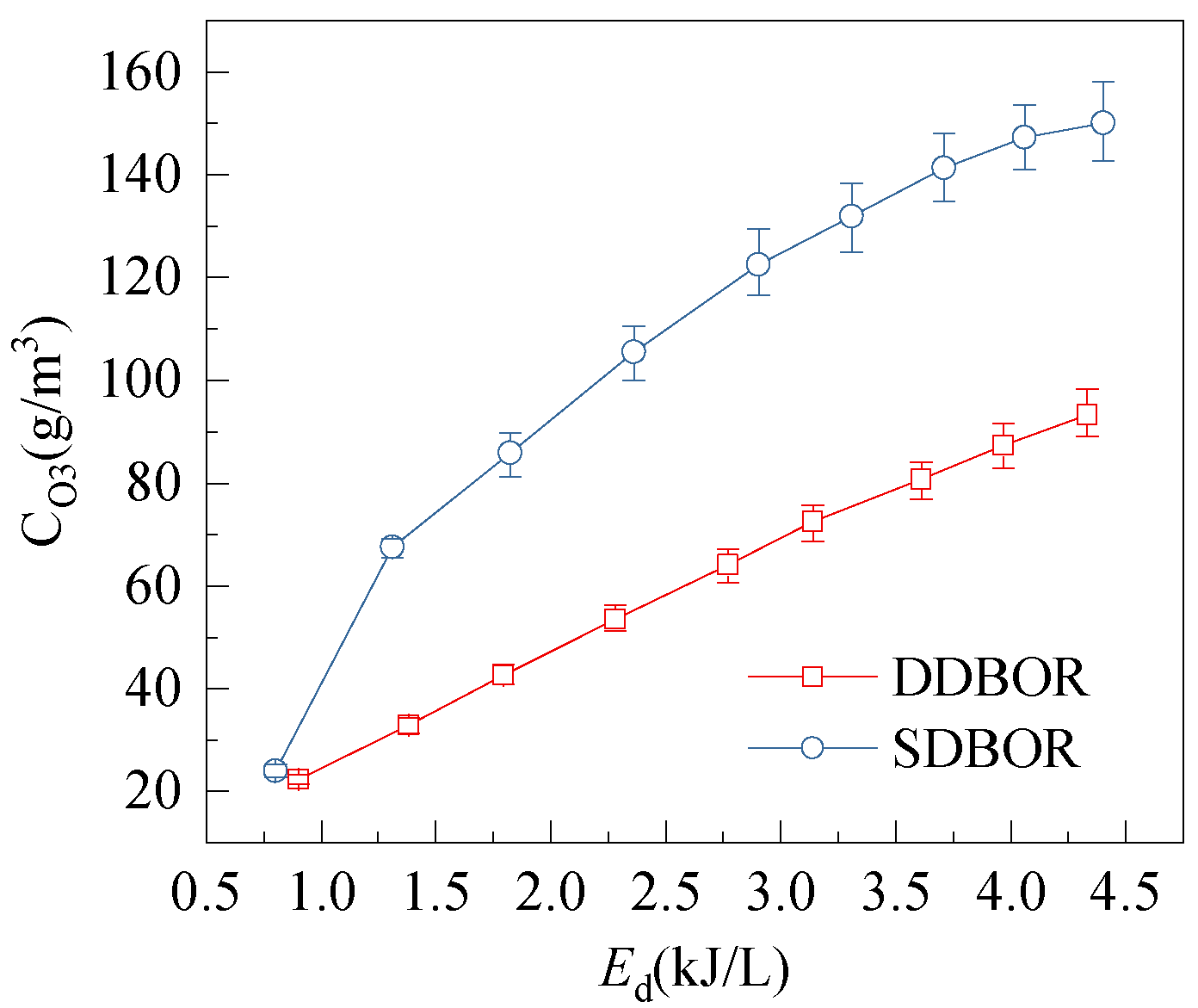

3.4. Effect of Energy Density on Ozone Concentration

3.5. Discussions on Discharge Mechanism

- Stage 1When a new discharge begins in SDBOR, electrons start to move from the surface of the dielectric layer to the high-voltage electrode, as shown in Figure 10a [29]. The electrons collide with oxygen particles in the process of movement and produce a weak discharge. This process corresponds to section A-B in Figure 6. Normally, this process is called an electronic avalanche [30]. When electrons reach the high-voltage electrode, they are absorbed by the electrode [31]. However, in DDBOR, as shown in Figure 10d, the surface of the anode is covered with a dielectric layer so that electrons cannot be absorbed by the anode. This causes the number of displaced charges by SDBOR to be higher than that of DDBOR. The discharge parameters are the same, and the difference is the discharge mode. It can be seen from Figure 4 that the discharge intensity of SDBOR is higher than that of DDBOR.

- Stage 2The second stage is the formation of streamer discharge. After the first stage, a large amount of cation is formed in the discharge gap. When the excitation electric field increases, the intensity of the electric field increases. The electric field formed by the charge and the excitation electric field are superimposed. The strong electric field ionizes the ambient gas and emits a large number of photons, causing photoionization, and forming a streamer discharge [32], as shown in Figure 10b. The arrow points to the direction of streamer discharge. This process corresponds to Figure 4a, the lower magnitude current plus in Figure 5a, and section B-C in Figure 6.

- Stage 3When the negative high voltage is applied, the electric field near the high voltage electrode is distorted, which is caused by the superposition of the electric field. Due to the small mass, electrons quickly leave the strong electric field area and adhere to oxygen particles to form negative ions. After the electrons leave, the positive ions slowly approach the high-voltage electrode to form high-density positive ion clusters. The electric field between the positive ions and the high-voltage electrode is enhanced, forming the cathode potential drop region. A bright negative glow is formed behind the cathode potential drop region, forming a corona glow discharge [33], as shown in Figure 10c. During this process, the electric field intensity in the negative glow region is the highest, which corresponds to the P1 region in Figure 4b. This process corresponds to Figure 4b, the higher magnitude current plus in Figure 5a, and section D-A in Figure 6.

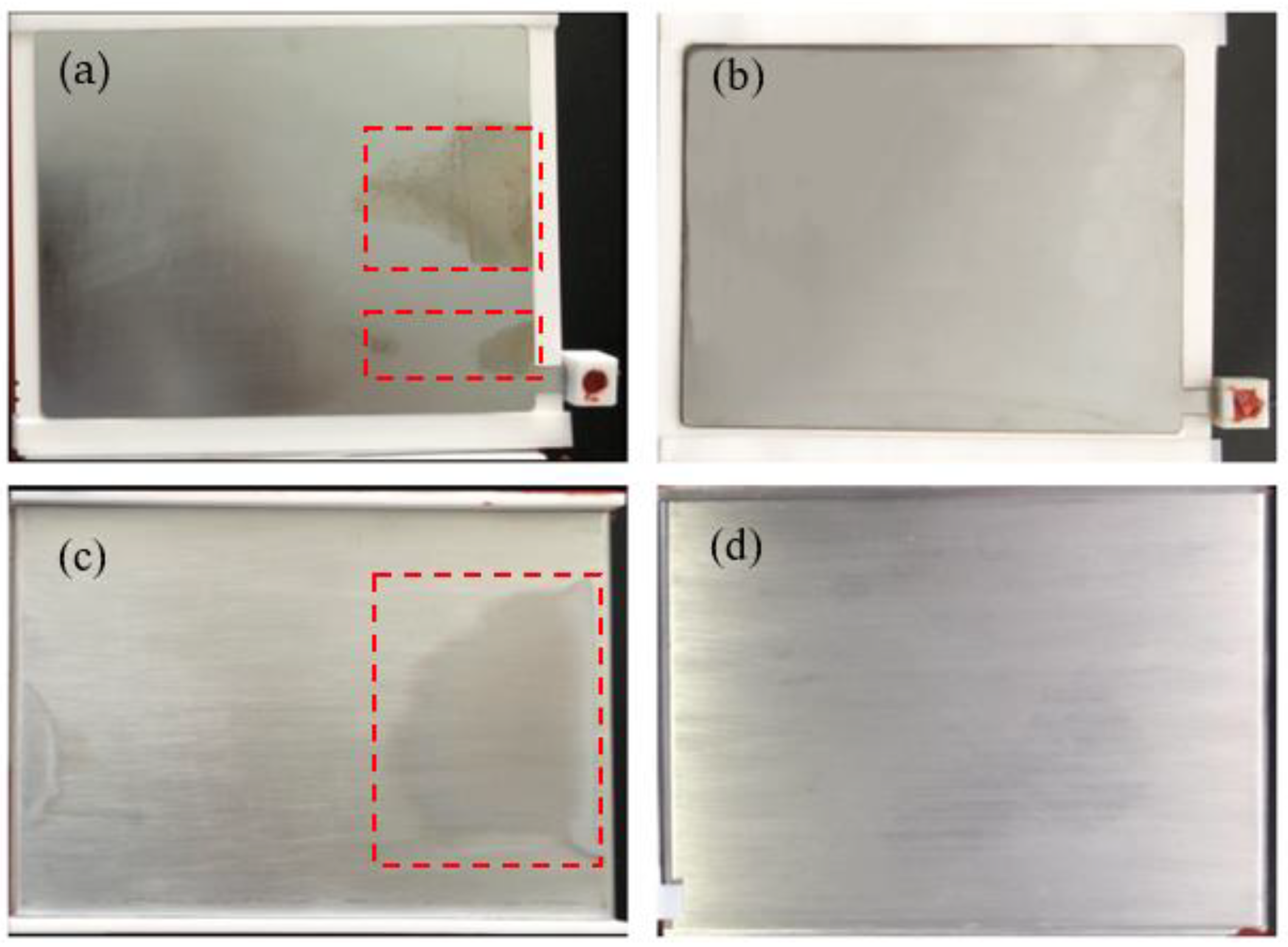

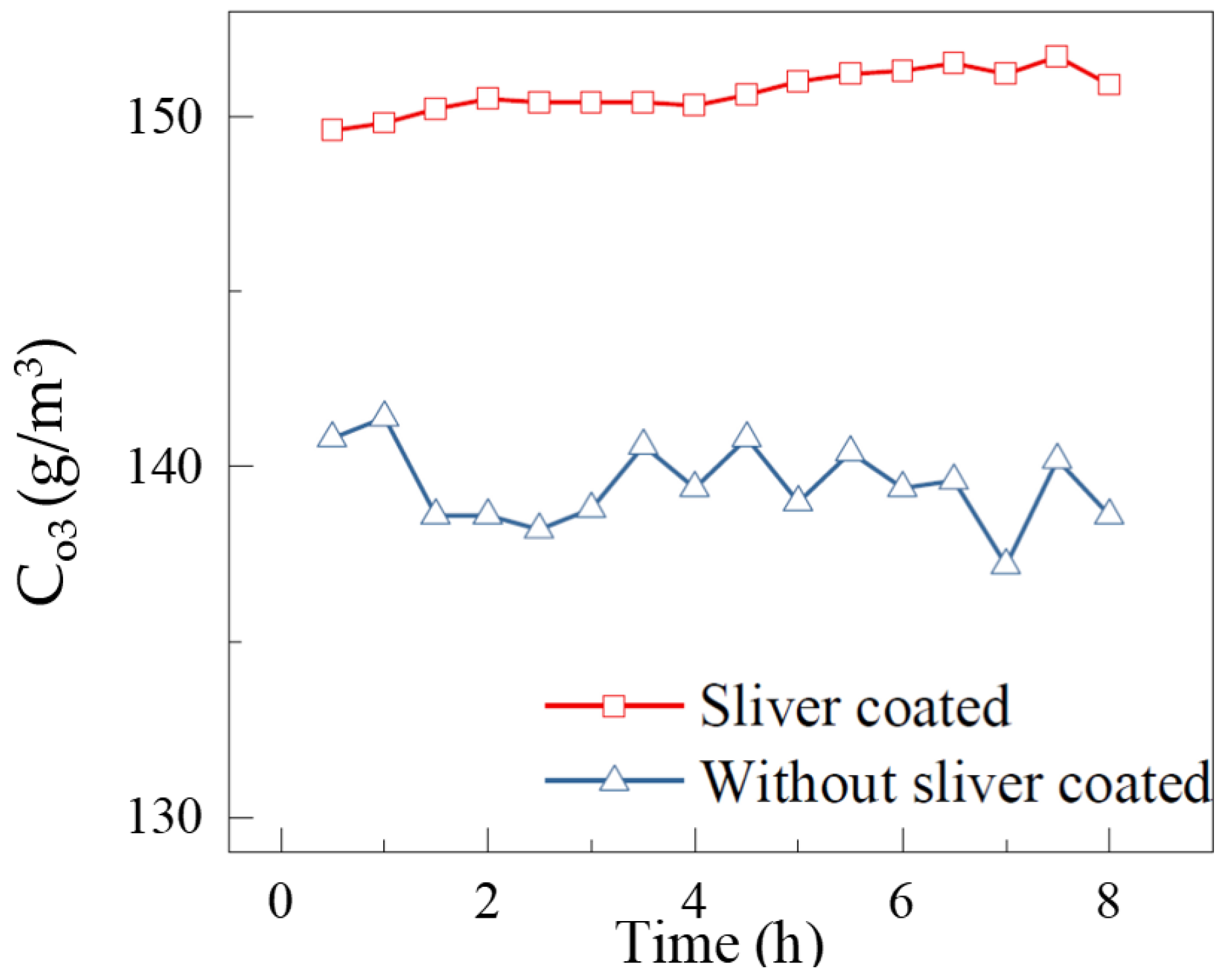

3.6. Reliability Evaluation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Malik, M.A.; Schoenbach, K.H.; Abdel-Fattah, T.M.; Heller, R.; Jiang, C. Low Cost Compact Nanosecond Pulsed Plasma System for Environmental and Biomedical Applications. Plasma Chem. Plasma Process. 2016, 37, 59–76. [Google Scholar] [CrossRef]

- Kramer, B.; Hasse, D.; Guist, S.; Schmitt-John, T.; Muranyi, P. Inactivation of bacterial endospores on surfaces by plasma processed air. J. Appl. Microbiol. 2020, 128, 920–933. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Schoenbach, K.H.; Malik, M.A. Scaling of Shielded Sliding Discharges for Environmental Applications. Plasma Chem. Plasma Process. 2013, 34, 39–54. [Google Scholar] [CrossRef]

- Zadi, T.; Assadi, A.A.; Nasrallah, N.; Bouallouche, R.; Tri, P.N.; Bouzaza, A.; Azizi, M.M.; Maachi, R.; Wolbert, D. Treatment of hospital indoor air by a hybrid system of combined plasma with photocatalysis: Case of trichloromethane. Chem. Eng. J. 2018, 349, 276–286. [Google Scholar] [CrossRef]

- Molaie, S.; Lino, P. Review of the Newly Developed, Mobile Optical Sensors for Real-Time Measurement of the Atmospheric Particulate Matter Concentration. Micromachines 2021, 12, 416. [Google Scholar] [CrossRef]

- Jin, Y.S.; Cho, C.; Kim, D.; Sohn, C.H.; Ha, C.-S.; Han, S.-T. Mass production of plasma activated water by an atmospheric pressure plasma. Jpn. J. Appl. Phys. 2020, 59, SHHF05. [Google Scholar] [CrossRef]

- Esquerdo, A.A.; Gadea, I.S.; Galvan, P.J.V.; Rico, D.P. Efficacy of atrazine pesticide reduction in aqueous solution using activated carbon, ozone and a combination of both. Sci. Total Environ. 2021, 764, 144301. [Google Scholar] [CrossRef]

- Jabesa, A.; Ghosh, P. A comparative study on the removal of dimethyl sulfoxide from water using microbubbles and millibubbles of ozone. J. Water Process Eng. 2021, 40, 101937. [Google Scholar] [CrossRef]

- Jhunkeaw, C.; Khongcharoen, N.; Rungrueng, N.; Sangpo, P.; Panphut, W.; Thapinta, A.; Senapin, S.; St-Hilaire, S.; Dong, H.T. Ozone nanobubble treatment in freshwater effectively reduced pathogenic fish bacteria and is safe for Nile tilapia (Oreochromis niloticus). Aquaculture 2021, 534, 736286. [Google Scholar] [CrossRef]

- Kiele, P.; Hergesell, J.; Buhler, M.; Boretius, T.; Suaning, G.; Stieglitz, T. Reliability of Neural Implants-Effective Method for Cleaning and Surface Preparation of Ceramics. Micromachines 2021, 12, 209. [Google Scholar] [CrossRef]

- Starikovskiy, A.Y.; Aleksandrov, N.L.; Shneider, M.N. Simulation of decelerating streamers in inhomogeneous atmosphere with implications for runaway electron generation. J. Appl. Phys. 2021, 129, 063301. [Google Scholar] [CrossRef]

- Shahid, M.A.; Khan, T.M.; Zafar, T.; Hashmi, M.F.; Amir, F. Novel Health Diagnostics Schemes Analyzing Corona Discharge of Operational Aerial Bundled Cables in Coastal Regions. IEEE Trans. Power Deliv. 2021, 36, 84–91. [Google Scholar] [CrossRef]

- Liu, F.C.; Guo, X.; Zhou, Z.X.; He, Y.F.; Fan, W.L. Numerical simulations of the effects of the level of nitrogen impurities in atmospheric helium Townsend discharge. Phys. Plasmas 2019, 26, 123502. [Google Scholar] [CrossRef]

- Yehia, A. Characteristics of the dielectric barrier corona discharges. AIP Adv. 2019, 9, 045214. [Google Scholar] [CrossRef]

- Gutsol, K.; Nunnally, T.; Rabinovich, A.; Fridman, A.; Starikovskiy, A.; Gutsol, A.; Kemoun, A. Plasma assisted dissociation of hydrogen sulfide. Int. J. Hydrogen Energy 2012, 37, 1335–1347. [Google Scholar] [CrossRef]

- Ran, J.X.; Zhang, X.X.; Ge, D.Y.; Li, X.W.; Li, X.C. Effect of Dielectric Surface Morphology on Dielectric Barrier Discharge Mode in Air at Atmospheric Pressure. IEEE Trans. Plasma Sci. 2021, 49, 214–218. [Google Scholar] [CrossRef]

- Elkholy, A.; Nijdam, S.; van Veldhuizen, E.; Dam, N.; van Oijen, J.; Ebert, U.; de Goey, L.P.H. Characteristics of a novel nanosecond DBD microplasma reactor for flow applications. Plasma Soureces Sci. Technol. 2018, 27, 055014. [Google Scholar] [CrossRef] [Green Version]

- Li, M.; Zhu, B.; Yan, Y.; Li, T.; Zhu, Y.M. A High-Efficiency Double Surface Discharge and Its Application to Ozone Synthesis. Plasma Chem. Plasma Process. 2018, 38, 1063–1080. [Google Scholar] [CrossRef]

- Lu, N.; Hui, Y.; Shang, K.F.; Jiang, N.; Li, J.; Wu, Y. Diagnostics of Plasma Behavior and TiO2 Properties Based on DBD/TiO2 Hybrid System. Plasma Chem. Plasma Process. 2018, 38, 1239–1258. [Google Scholar] [CrossRef]

- Zhao, D.; Yu, F.; Zhou, A.M.; Ma, C.H.; Dai, B. High-efficiency removal of NOx using dielectric barrier discharge nonthermal plasma with water as an outer electrode. Plasma Sci. Technol. 2018, 20, 014020. [Google Scholar] [CrossRef]

- Abdelaziz, A.A.; Ishijima, T.; Seto, T.; Osawa, N.; Wedaa, H.; Otani, Y. Characterization of surface dielectric barrier discharge influenced by intermediate frequency for ozone production. Plasma Sources Sci. Technol. 2016, 25, 035012. [Google Scholar] [CrossRef]

- Li, X.; Liu, R.; Jia, P.; Wu, K.; Ren, C.; Kang, P.; Jia, B.; Li, Y. Influence of voltage duty ratio on current asymmetry and mode of a helium dielectric-barrier discharge excited by a modulated voltage. Phys. Plasmas 2018, 25, 073510. [Google Scholar] [CrossRef]

- Hao, Y.; Han, Y.; Huang, Z.; Yang, L.; Dai, D.; Li, L. Transitions between patterned discharges and diffuse discharges in atmospheric helium under applied voltages far below the discharge inception voltage. Phys. Plasmas 2018, 25, 013516. [Google Scholar] [CrossRef]

- Zhe, Y.; Zhitao, Z.; Qingxuan, Y.; Shaojie, X.; Jing, Y.; Mindong, B.; Yiping, T.; Kaiying, L. Atmospheric Pressure Streamer and Glow discharge Generated alternately by Pin-to-plane Dielectric Barrier Discharge in Air. Acta Phys. Sin. 2012, 61, 195202. [Google Scholar] [CrossRef]

- Takaki, K.; Hatanaka, Y.; Arima, K.; Mukaigawa, S.; Fujiwara, T. Influence of Electrode Configuration on Ozone Synthesis and Microdischarge Property in Dielectric Barrier Discharge Reactor. Vacuum 2008, 83, 128–132. [Google Scholar] [CrossRef]

- Yuan, D.; Wang, Z.; Ding, C.; He, Y.; Whiddon, R.; Cen, K. Ozone production in parallel multichannel dielectric barrier discharge from oxygen and air: The influence of gas pressure. J. Phys. D Appl. Phys. 2016, 49, 455203. [Google Scholar] [CrossRef]

- Malik, M.A. Ozone Synthesis Using Shielded Sliding Discharge: Effect of Oxygen Content and Positive versus Negative Streamer Mode. Ind. Eng. Chem. Res. 2014, 53, 12305–12311. [Google Scholar] [CrossRef]

- Al-Abduly, A.; Christensen, P.; Harvey, A. The characterization of a packed bed plasma reactor for ozone generation. Plasma Sources Sci. Technol. 2020, 29, 035002. [Google Scholar] [CrossRef]

- Kogelschatz, U. Dielectric-barrier discharges: Their history, discharge physics, and industrial applications. Plasma Chem. Plasma Process. 2003, 23, 1–46. [Google Scholar] [CrossRef]

- Lin, X.; Tyl, C.; Naude, N.; Gherardi, N.; Popov, N.A.; Dap, S. The role of associative ionization reactions in the memory effect of atmospheric pressure Townsend discharges in N-2 with a small O-2 addition. J. Phys. D Appl. Phys. 2020, 53, 205201. [Google Scholar] [CrossRef]

- Kogelschatz, U. Filamentary, patterned, and diffuse barrier discharges. IEEE Trans. Plasma Sci. 2002, 30, 1400–1408. [Google Scholar] [CrossRef]

- Li, J.; Lei, B.Y.; Wang, J.; Xu, B.P.; Ran, S.; Wang, Y.S.; Zhang, T.Y.; Tang, J.; Zhao, W.; Duan, Y.X. Atmospheric diffuse plasma jet formation from positive-pseudo-streamer and negative pulseless glow discharges. Commun. Phys. 2021, 4, 64. [Google Scholar] [CrossRef]

- Jia, P.Y.; Gao, K.; Zhou, S.; Chen, J.Y.; Wu, J.C.; Wu, K.Y.; Li, X.C. Morphology evolution of an atmospheric pressure glow discharge in-itiated in the air gap between a liquid cathode and a needle anode. Plasma Sources Sci. Technol. 2021, 30, 095021. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, P.; Song, Y.; Zhang, Z. A Novel Dielectric Barrier Discharge (DBD) Reactor with Streamer and Glow Corona Discharge for Improved Ozone Generation at Atmospheric Pressure. Micromachines 2021, 12, 1287. https://doi.org/10.3390/mi12111287

Liu P, Song Y, Zhang Z. A Novel Dielectric Barrier Discharge (DBD) Reactor with Streamer and Glow Corona Discharge for Improved Ozone Generation at Atmospheric Pressure. Micromachines. 2021; 12(11):1287. https://doi.org/10.3390/mi12111287

Chicago/Turabian StyleLiu, Pu, Yongxin Song, and Zhitao Zhang. 2021. "A Novel Dielectric Barrier Discharge (DBD) Reactor with Streamer and Glow Corona Discharge for Improved Ozone Generation at Atmospheric Pressure" Micromachines 12, no. 11: 1287. https://doi.org/10.3390/mi12111287

APA StyleLiu, P., Song, Y., & Zhang, Z. (2021). A Novel Dielectric Barrier Discharge (DBD) Reactor with Streamer and Glow Corona Discharge for Improved Ozone Generation at Atmospheric Pressure. Micromachines, 12(11), 1287. https://doi.org/10.3390/mi12111287