Edge Control in the Computer-Controlled Optical Surface

Abstract

:1. Introduction

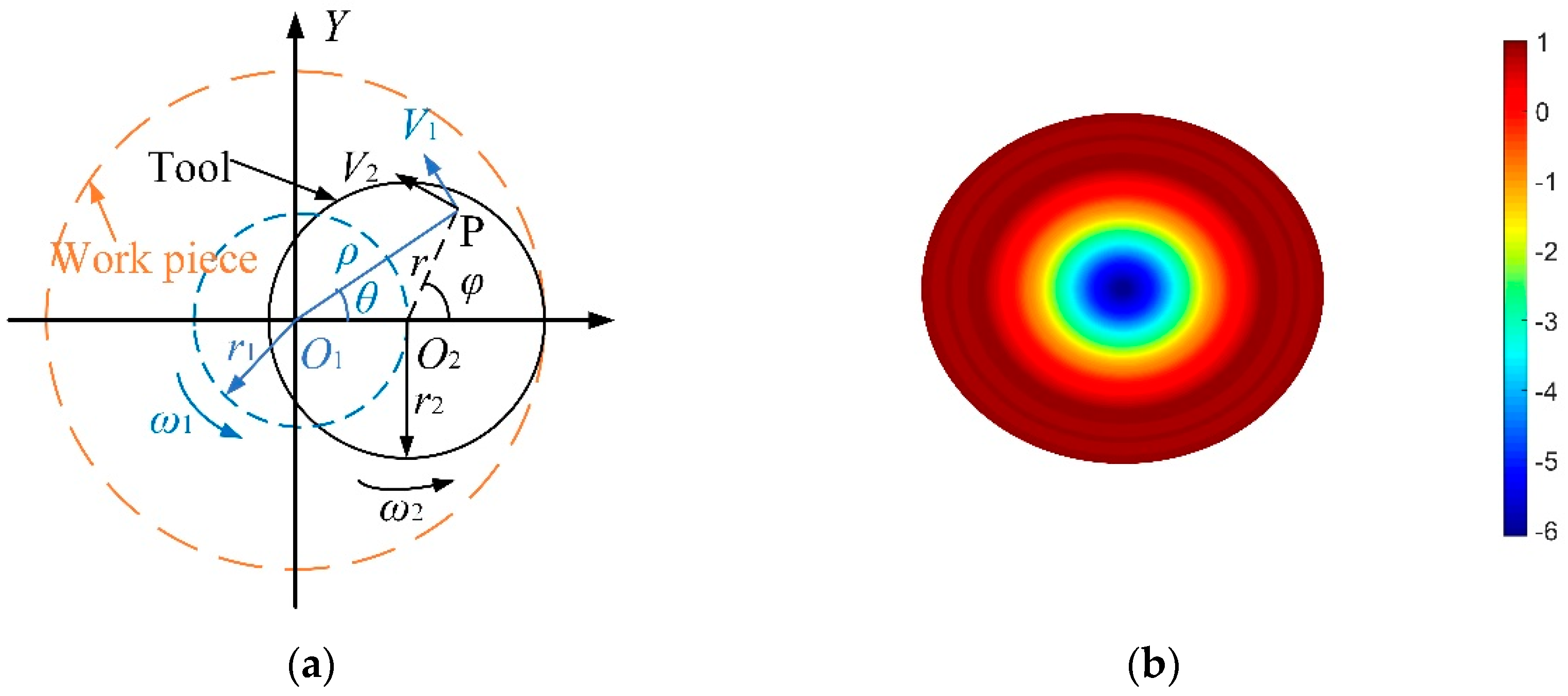

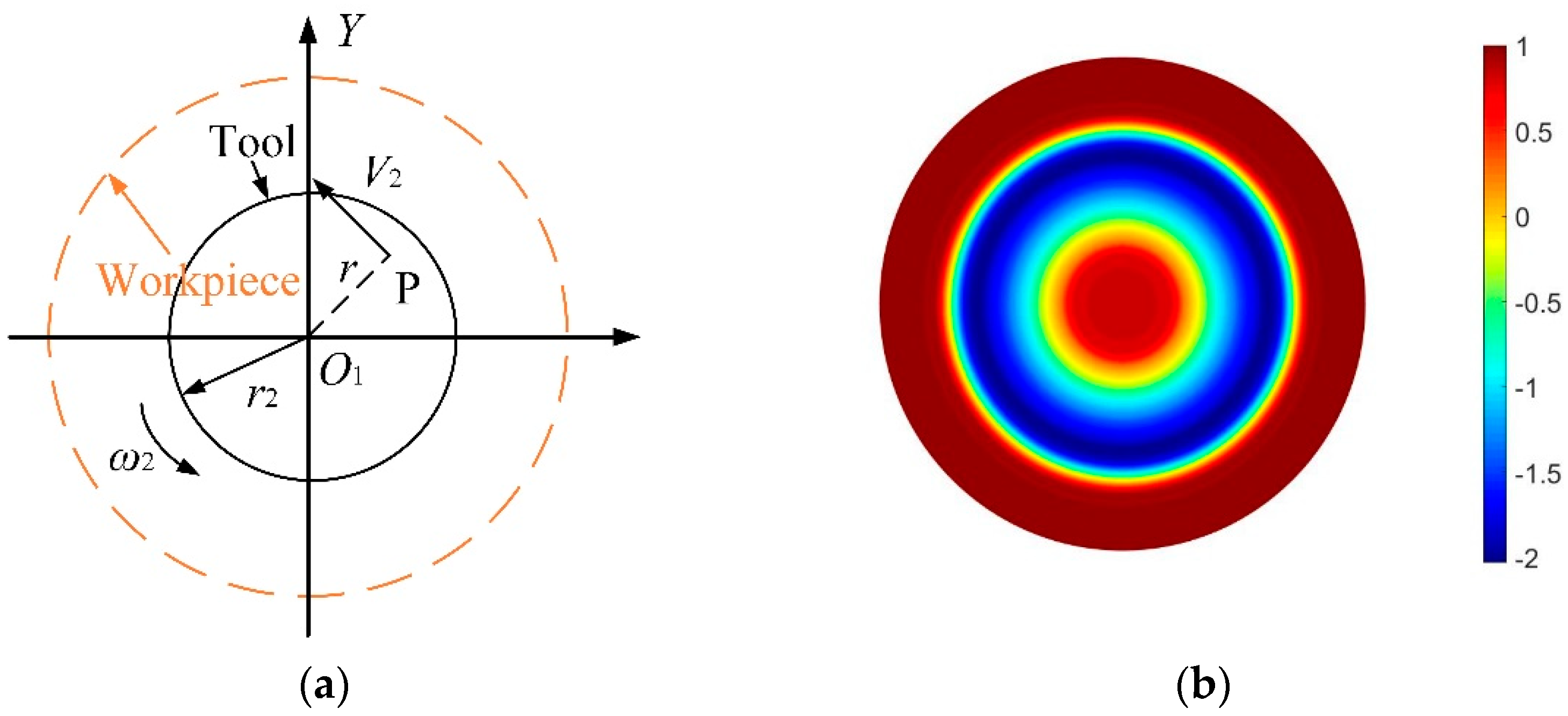

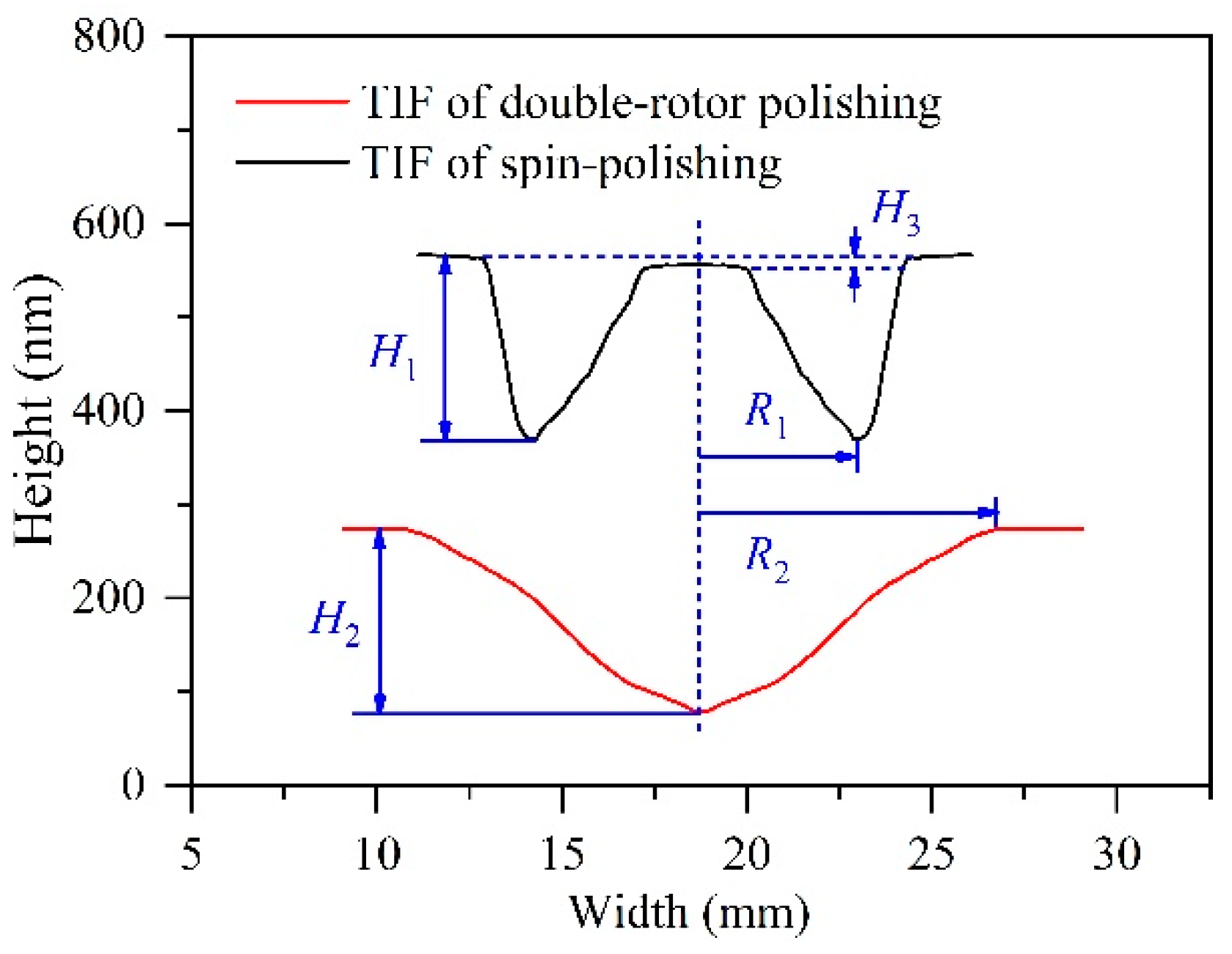

2. Theory of Combined Polishing Process

2.1. Basic Polishing Theory

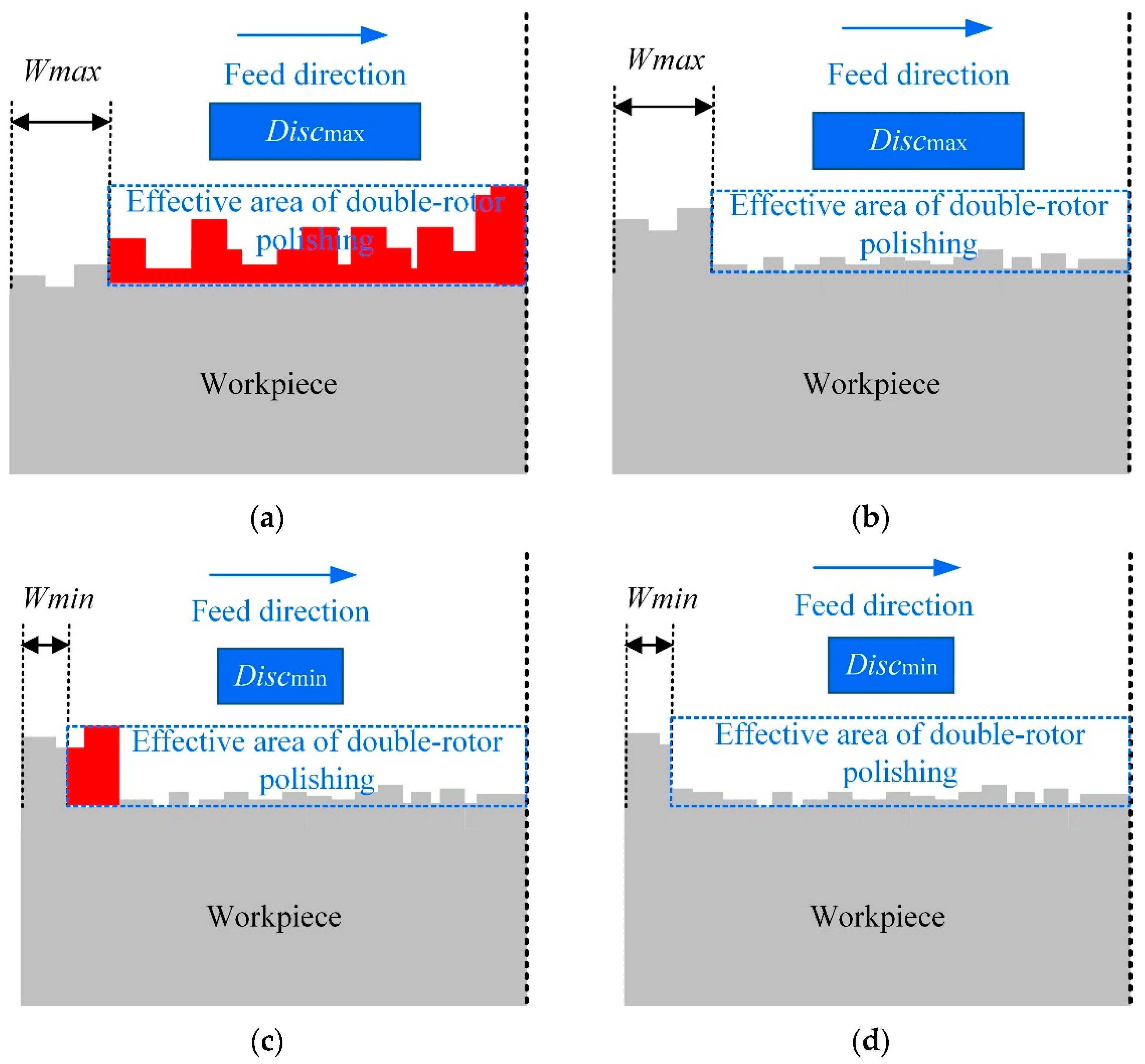

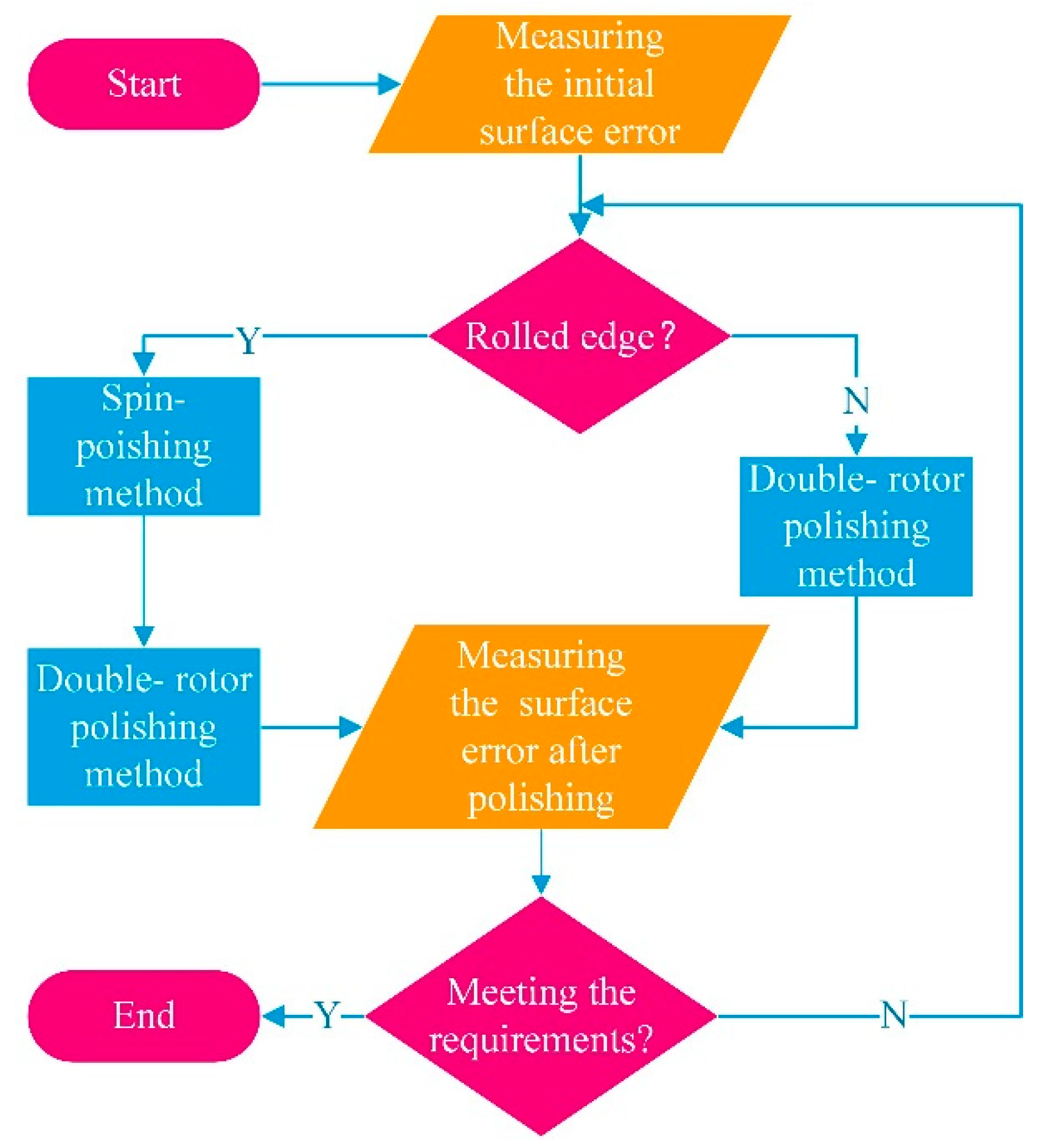

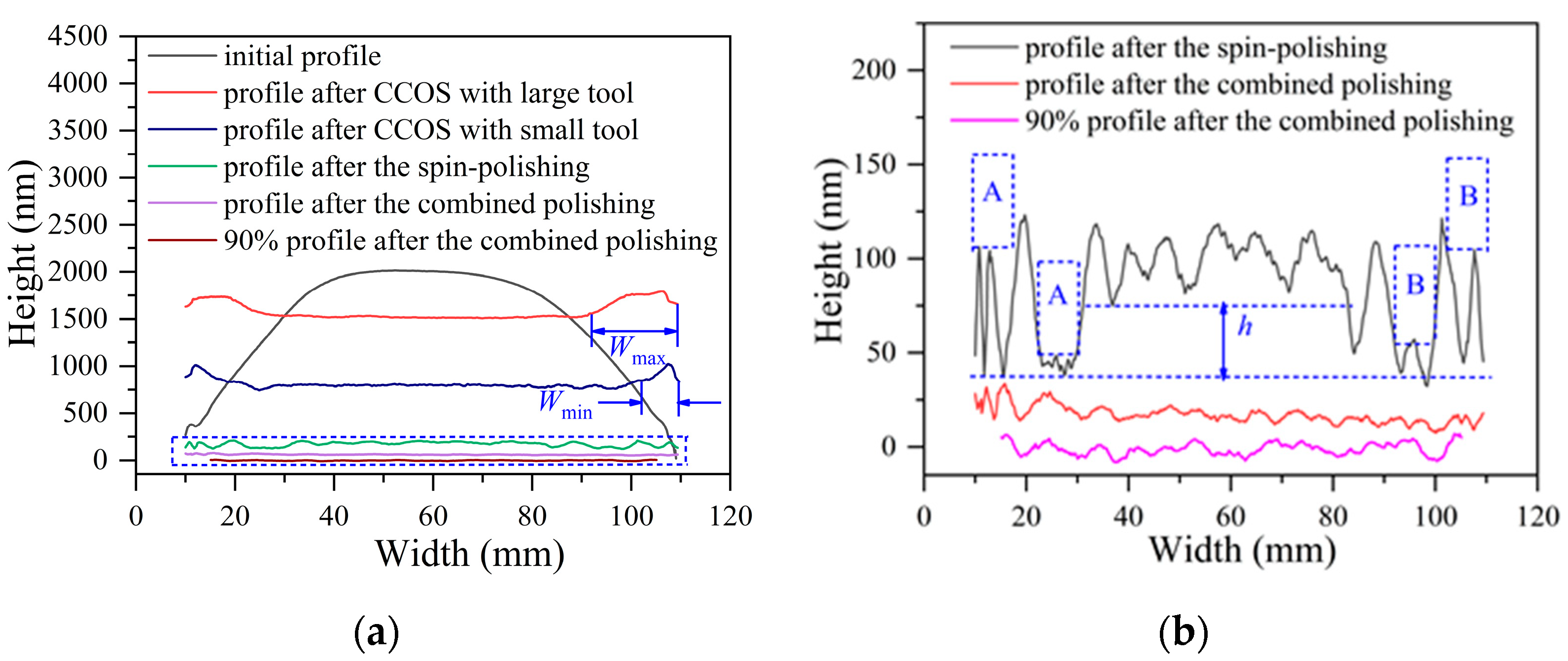

2.2. Combined Polishing Method

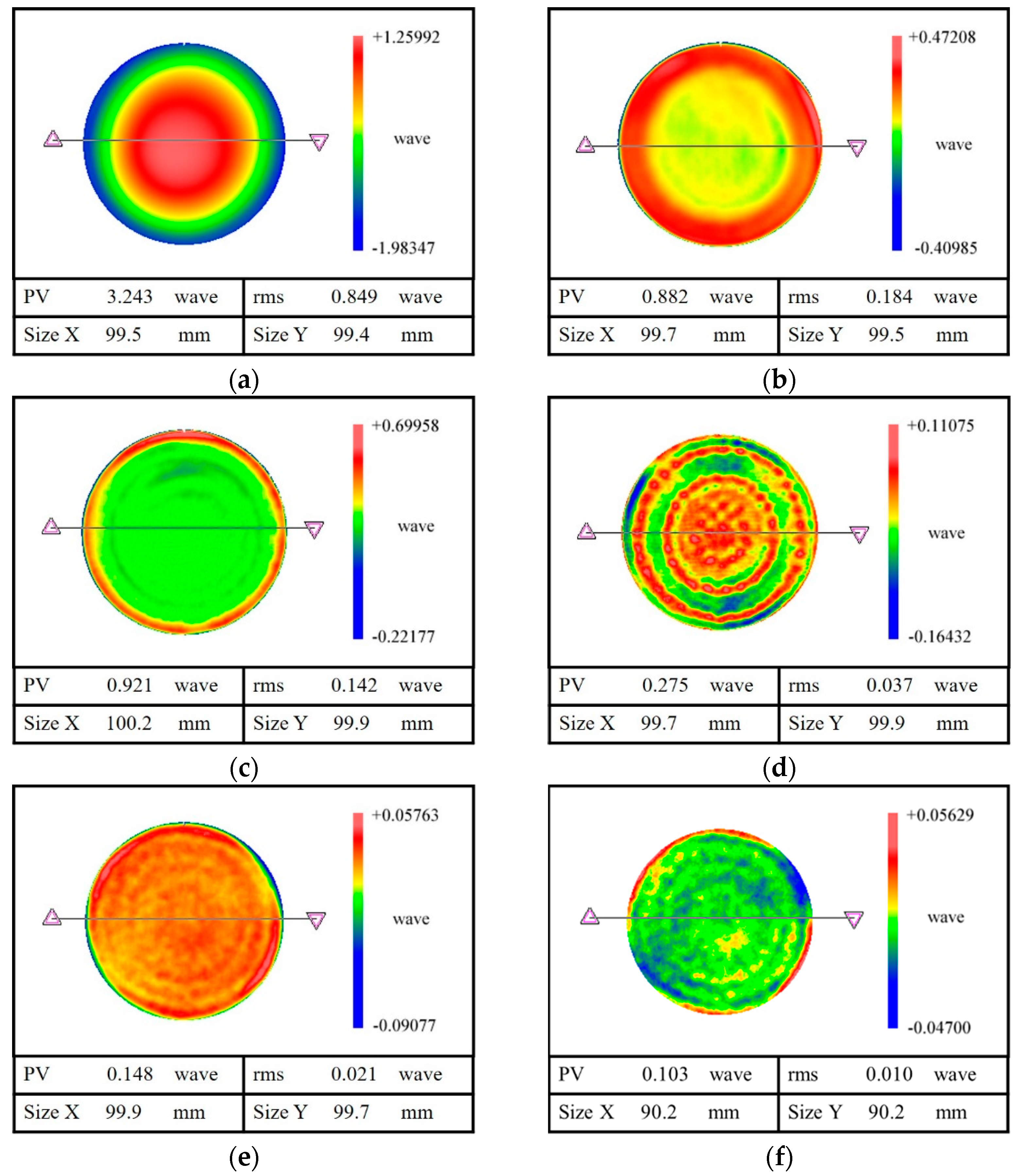

3. Edge Processing Experiment

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, Y.; Wang, T.; Zhang, G. Research on Parameter Optimization of Micro-Milling Al7075 Based on Edge-Size-Effect. Micromachines 2020, 11, 197. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Deja, M. Simulation Model for the Shape Error Estimation During Machining With Flat Lapping Kinematics, ASME 2010. Int. Manuf. Sci. Eng. Conf. 2010, 49460, 291–299. [Google Scholar]

- Zhang, X.H.; Pei, Z.J.; Fisher, G.R. A grinding-based manufacturing method for silicon wafers: Generation mechanisms of central dimples on ground wafers. Int. J. Mach. Tools Manuf. 2006, 46, 397–403. [Google Scholar] [CrossRef]

- Huang, J.; Hu, Q., II; Xie, L., III; Ma, P., IV. Research on surface extension process technology for restraining edge effect in CNC polishing. In Proceedings of the Second Target Recognition and Artificial Intelligence Summit Forum, Shenyang, China, 28–30 August 2019; p. 114270C. [Google Scholar]

- Liu, H.; Wu, F.; Zeng, Z.; Fan, B.; Wan, Y. Edge effect modeling and experiments on active lap processing. Opt. Express 2014, 22, 10761–10774. [Google Scholar] [CrossRef] [PubMed]

- Lu, A.; Jin, T.; Guo, Z.; Qu, M.; Chang, Y.; Liu, Q.; Zhang, C. Characterization of the tool influence function in a dual-axis wheel polishing process to achieve high material removal rates. Precis. Eng. 2018, 52, 276–290. [Google Scholar] [CrossRef]

- Walker, D.; Beaucamp, A.; Dunn, C.; Evans, R.; Freeman, R.; Morton, R.; Wei, S.; Yu, G. Active control of edges and global microstructure on segmented mirrors. In Advanced Optical and Mechanical Technologies in Telescopes and Instrumentation; International Society for Optics and Photonics: Bellingham, WA, USA, 2008; p. 701812. [Google Scholar]

- Wagner, R.; Shannon, R. Fabrication of aspherics using a mathematical model for material removal. Appl. Opt. 1974, 13, 1683–1689. [Google Scholar] [CrossRef] [PubMed]

- Luna-Aguilar, E.; Cordero-Davila, A.; Gonzalez, J.; Nunez-Alfonso, M.; Cabrera, V.; Robledo-Sanchez, C.I.; Cuautle-Cortez, J.; Pedrayes, M.H. Edge effects with the Preston equation. In Future Giant Telescopes; International Society for Optics and Photonics: Bellingham, WA, USA, 2003; pp. 598–603. [Google Scholar]

- Nam, H.-S.; Kim, G.-C.; Kim, H.-S.; Rhee, H.-G.; Ghim, Y.-S. Modeling of edge tool influence functions for computer controlled optical surfacing process. Int. J. Adv. Manuf. Technol. 2016, 83, 911–917. [Google Scholar] [CrossRef]

- Wan, S.; Zhang, X.; Wang, W.; Xu, M.; Jiang, X. Edge control in precision robotic polishing based on space-variant deconvolution. Precis. Eng. 2019, 55, 110–118. [Google Scholar] [CrossRef]

- Yu, G.; Walker, D.; Li, H.; Zheng, X.; Beaucamp, A. Research on edge-control methods in CNC polishing. J. Eur. Opt. Soc. Rapid Publ. 2017, 13, 1–13. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ke, X.; Qiu, L.; Wang, C.; Wang, Z. Tentative Investigations on Reducing the Edge Effects in Pre-Polishing the Optics. Appl. Sci. 2020, 10, 5286. [Google Scholar] [CrossRef]

- Li, H.; Walker, D.; Yu, G.; Sayle, A.; Messelink, W.; Evans, R.; Beaucamp, A. Edge control in CNC polishing, paper 2: Simulation and validation of tool influence functions on edges. Opt. Express 2013, 21, 370–381. [Google Scholar] [CrossRef] [PubMed]

- Walker, D.; Yu, G.; Li, H.; Messelink, W.; Evans, R.; Beaucamp, A. Edges in CNC polishing: From mirror-segments towards semiconductors, paper 1: Edges on processing the global surface. Opt. Express 2012, 20, 19787–19798. [Google Scholar] [CrossRef] [PubMed]

- Hu, H.; Zhang, X.; Ford, V.; Luo, X.; Qi, E.; Zeng, X.; Zhang, X. Edge control in a computer controlled optical surfacing process using a heterocercal tool influence function. Opt. Express 2016, 24, 26809–26824. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Du, H.; Song, C.; Li, S.; Xu, M.; Peng, X. Optimization technique for rolled edge control process based on the acentric tool influence functions. Appl. Opt. 2017, 56, 4330–4337. [Google Scholar] [CrossRef] [PubMed]

- Preston, F. The theory and design of plate glass polishing machines. J. Glass Technol. 1927, 11, 214–256. [Google Scholar]

- Xusheng, Z.; Shengyi, L.; Ziwen, Z. Optimization of Plane Polishing Parameters Based on Maximum Entropy Principle. Chin. Mech. Eng. 2005, 16, 1001–1004. [Google Scholar]

| Category | Parameter |

|---|---|

| The material of the polishing pad | Polyurethane |

| The size of tools | ϕ10, 20 and 30 mm |

| Polishing slurry | Silica(Φ50 nm) |

| Pressure | 0.06~0.1 MPa |

| Rotating speed | 80~120 r/min |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, L.; Hu, H.; Guan, C.; Dai, Y.; Li, Z. Edge Control in the Computer-Controlled Optical Surface. Micromachines 2021, 12, 1154. https://doi.org/10.3390/mi12101154

Yin L, Hu H, Guan C, Dai Y, Li Z. Edge Control in the Computer-Controlled Optical Surface. Micromachines. 2021; 12(10):1154. https://doi.org/10.3390/mi12101154

Chicago/Turabian StyleYin, Lianmin, Hao Hu, Chaoliang Guan, Yifan Dai, and Zelong Li. 2021. "Edge Control in the Computer-Controlled Optical Surface" Micromachines 12, no. 10: 1154. https://doi.org/10.3390/mi12101154

APA StyleYin, L., Hu, H., Guan, C., Dai, Y., & Li, Z. (2021). Edge Control in the Computer-Controlled Optical Surface. Micromachines, 12(10), 1154. https://doi.org/10.3390/mi12101154