High Aspect Ratio Thin-Walled Structures in D2 Steel through Wire Electric Discharge Machining (EDM)

Abstract

:1. Introduction

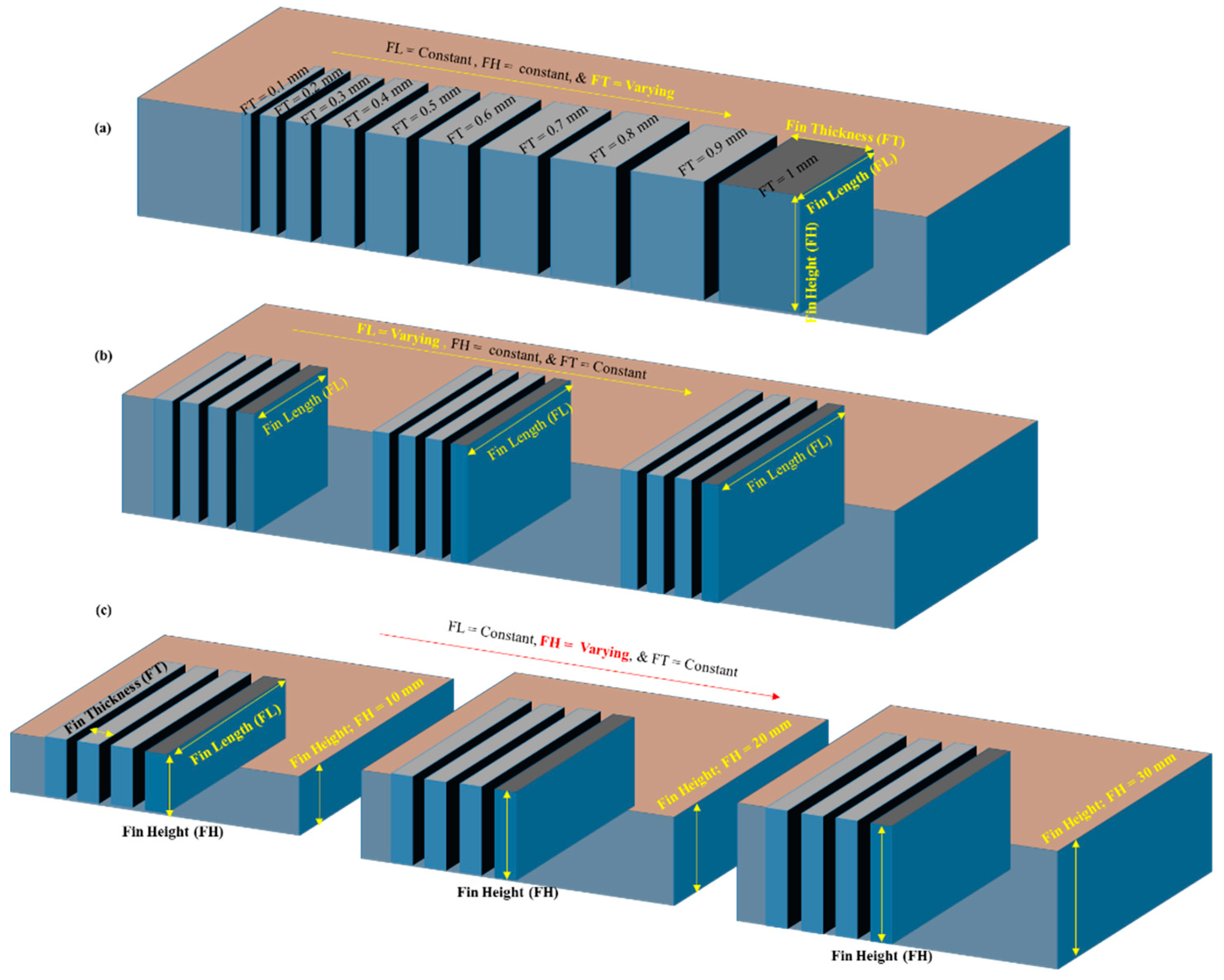

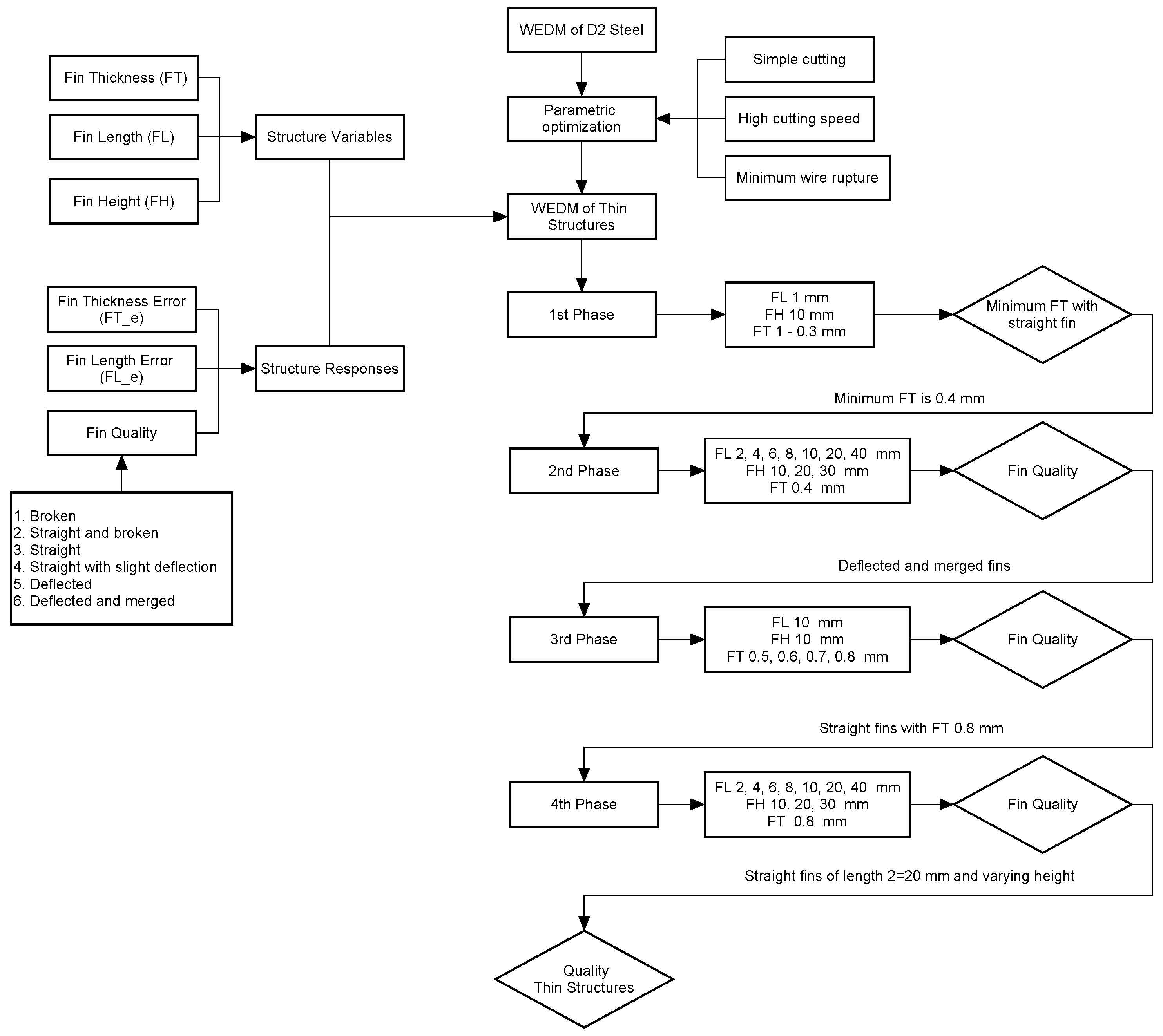

2. Materials and Methods

3. Results and Discussion

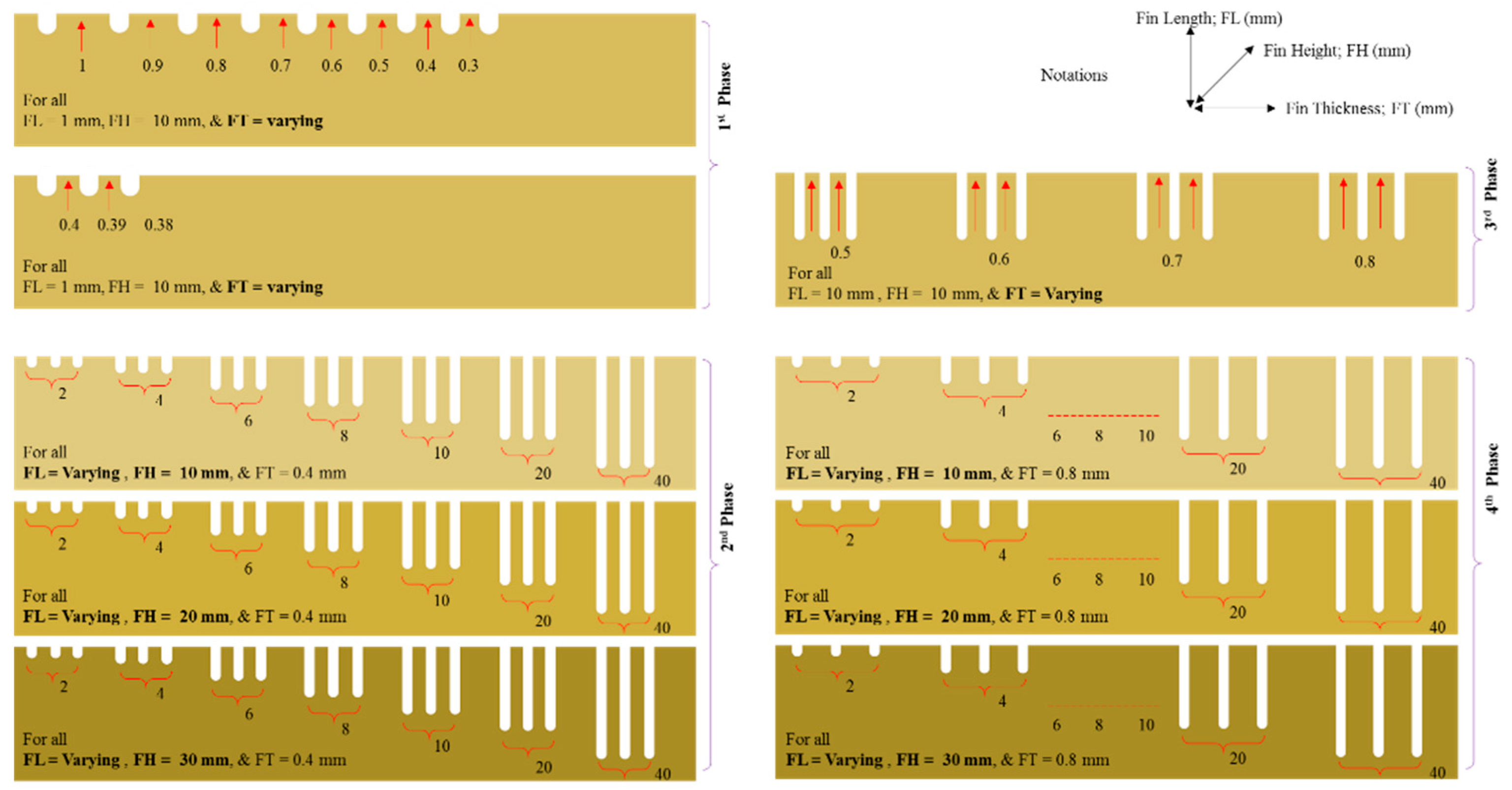

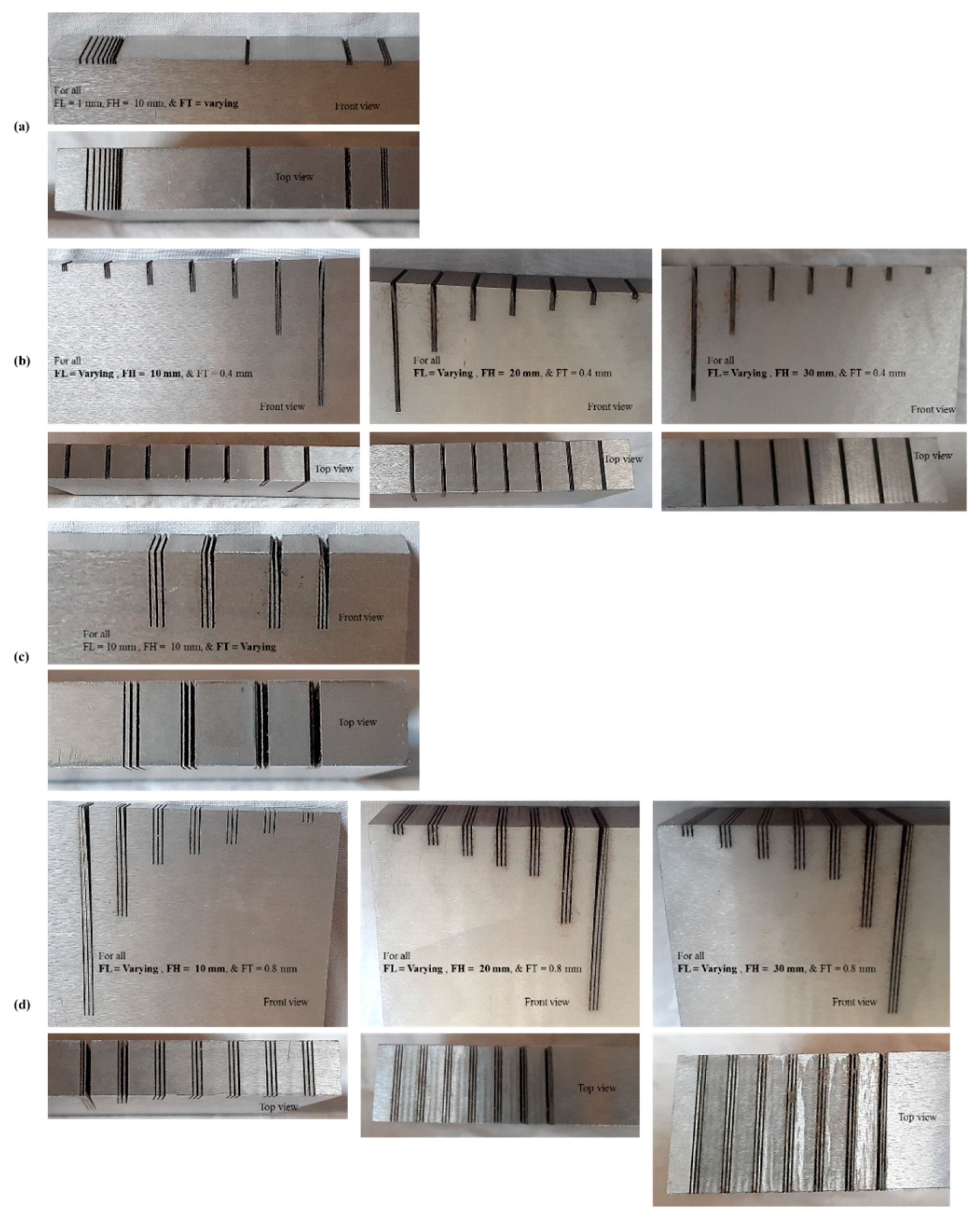

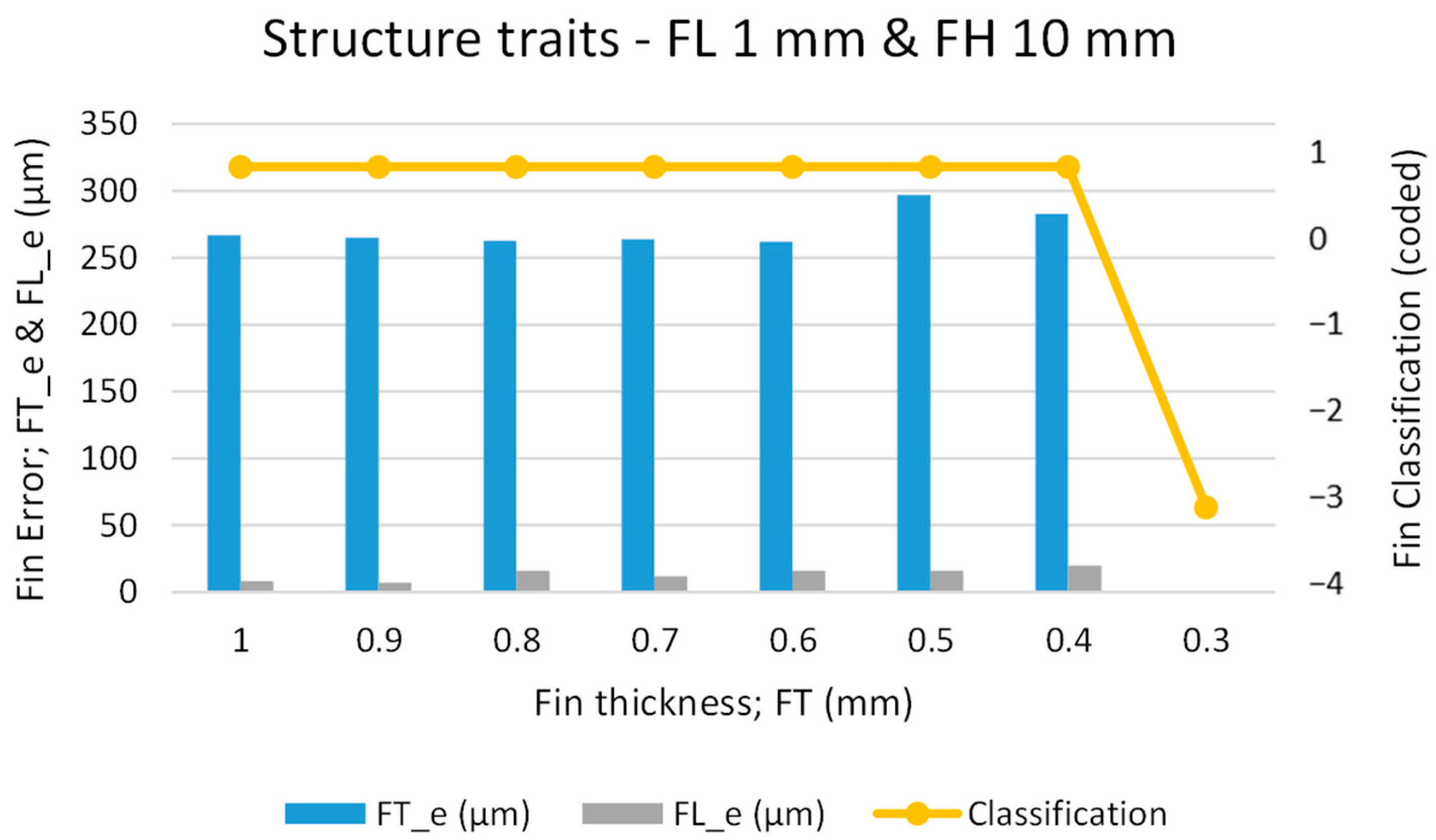

3.1. Analysis of First Phase

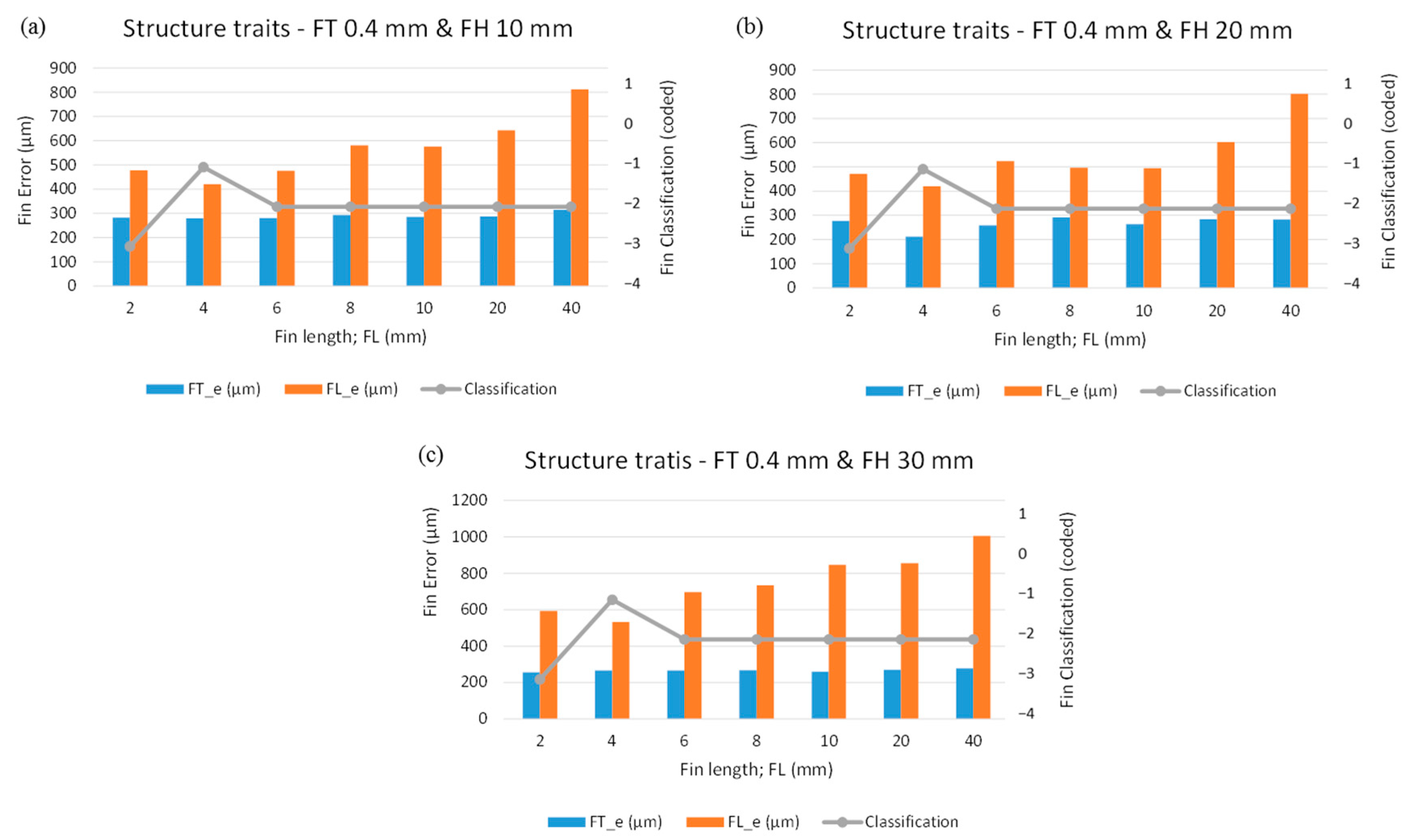

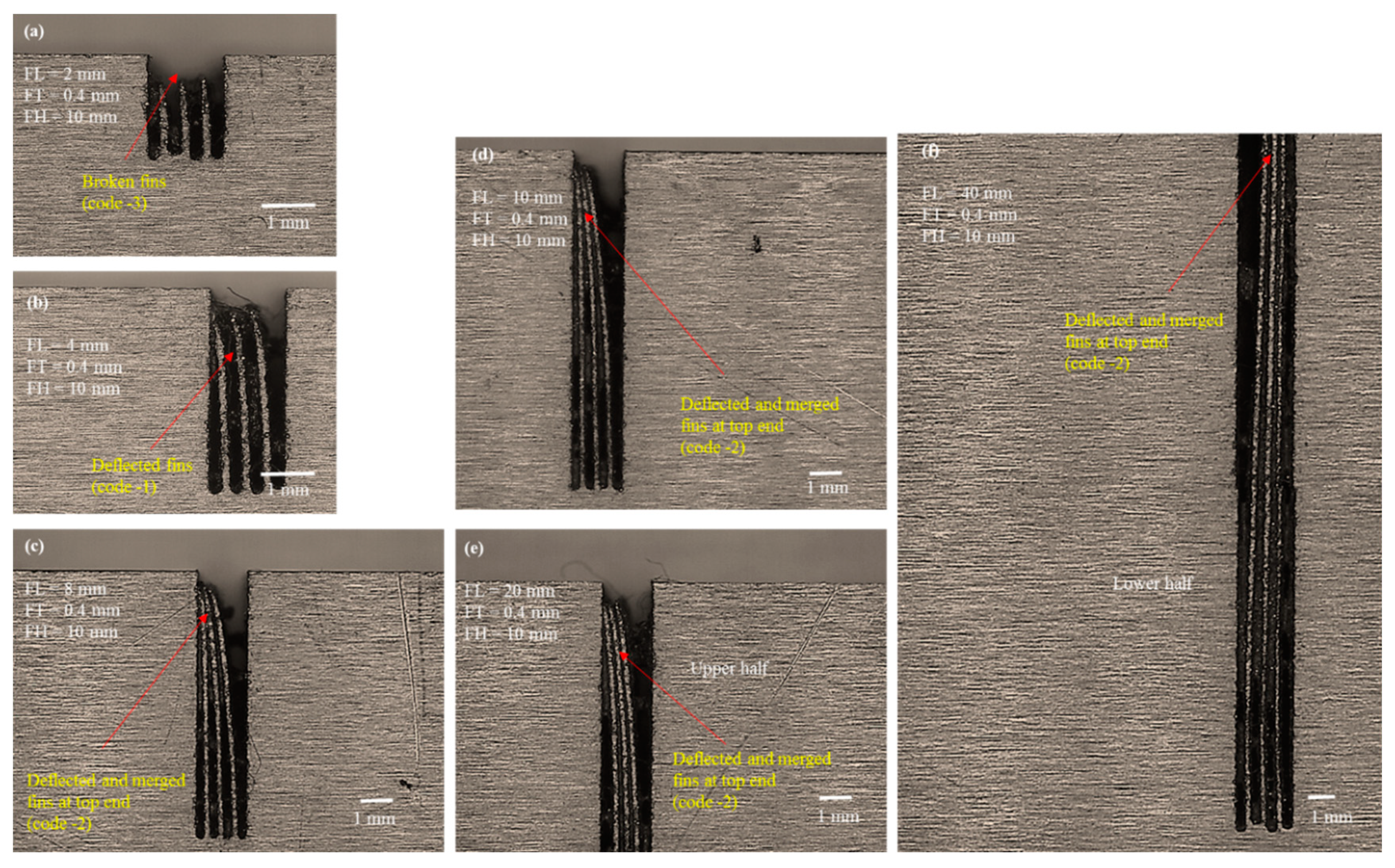

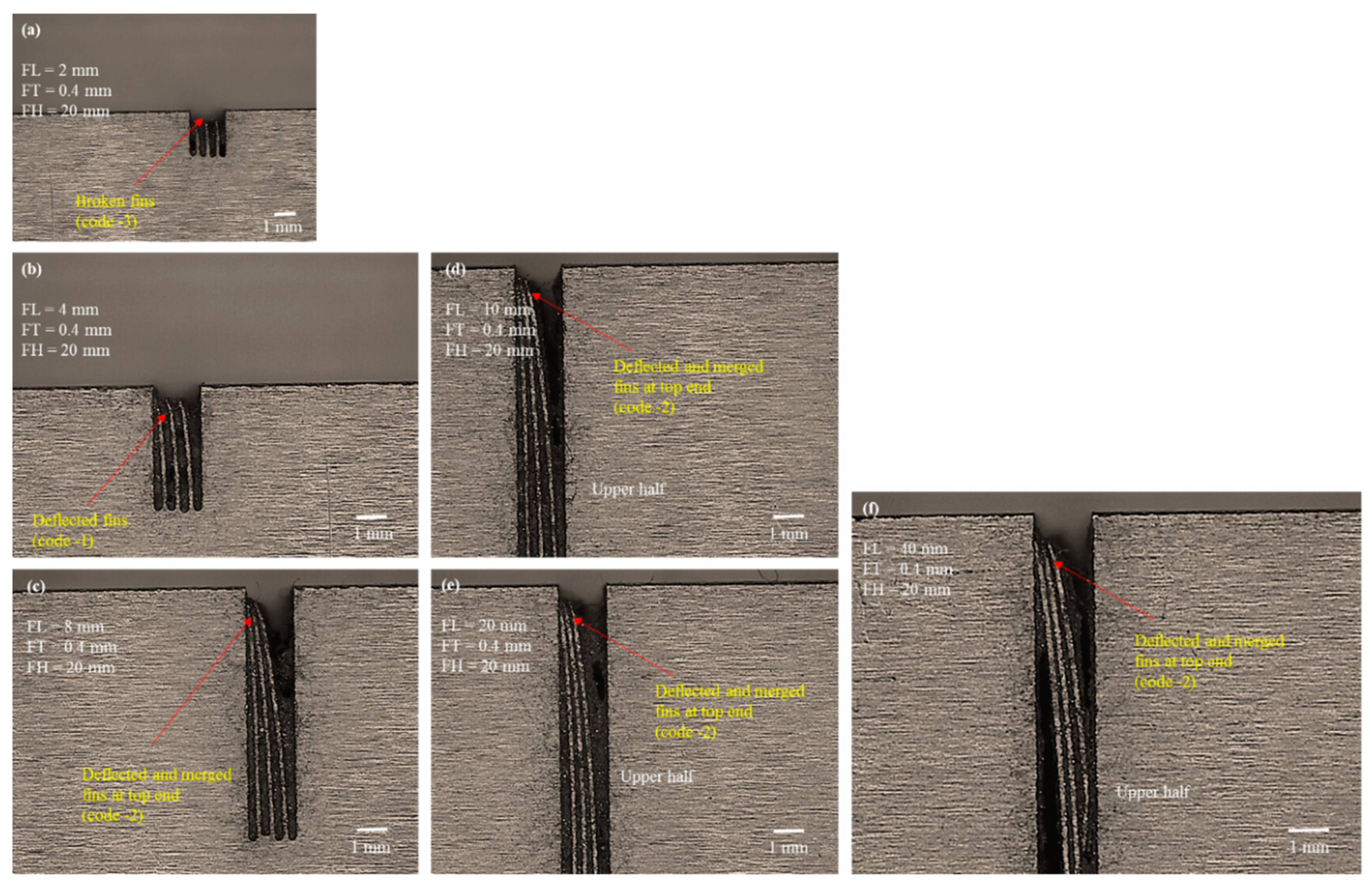

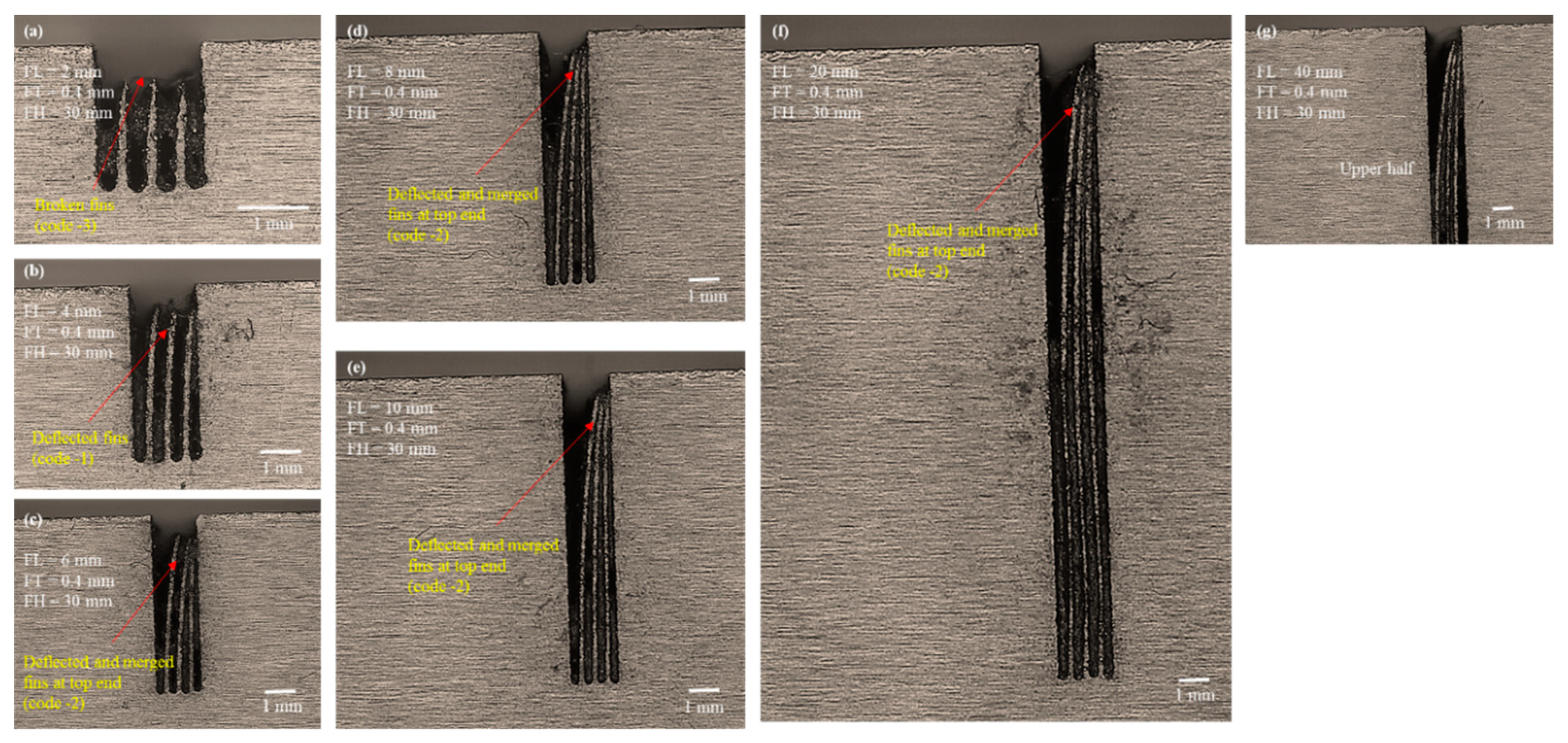

3.2. Analysis of Second Phase

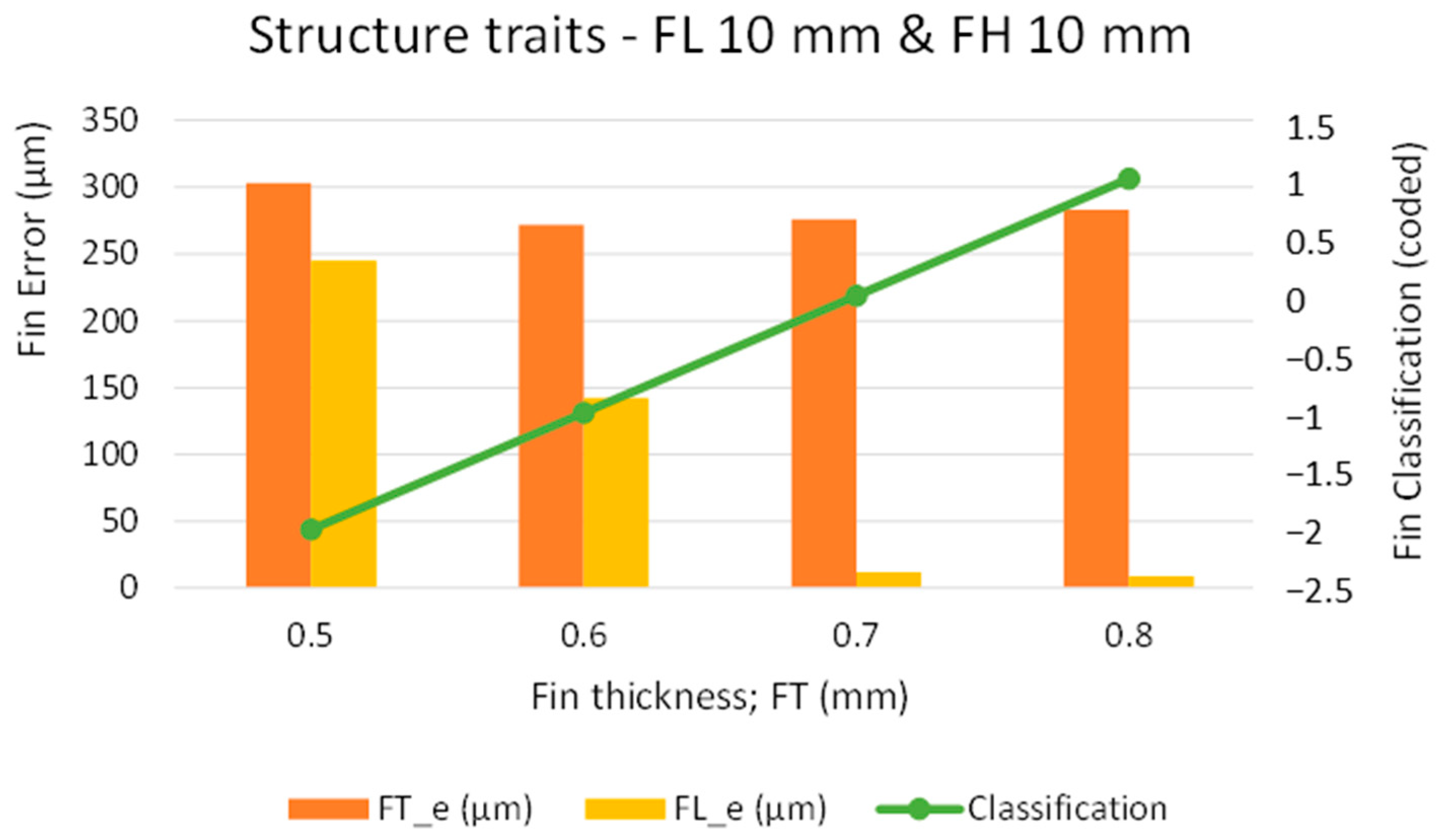

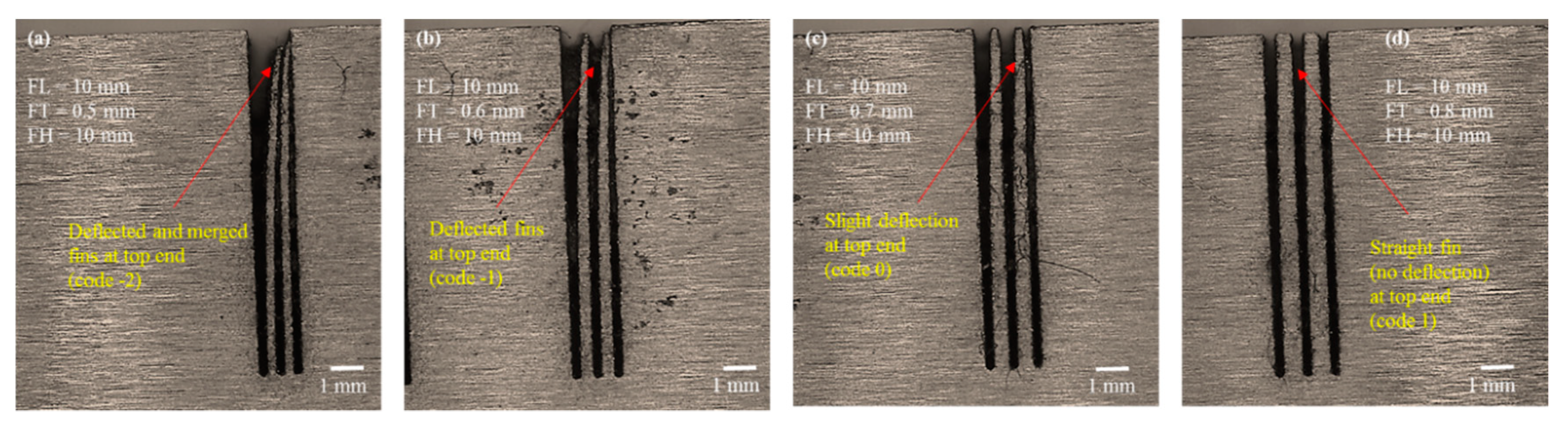

3.3. Analysis of the Third Phase

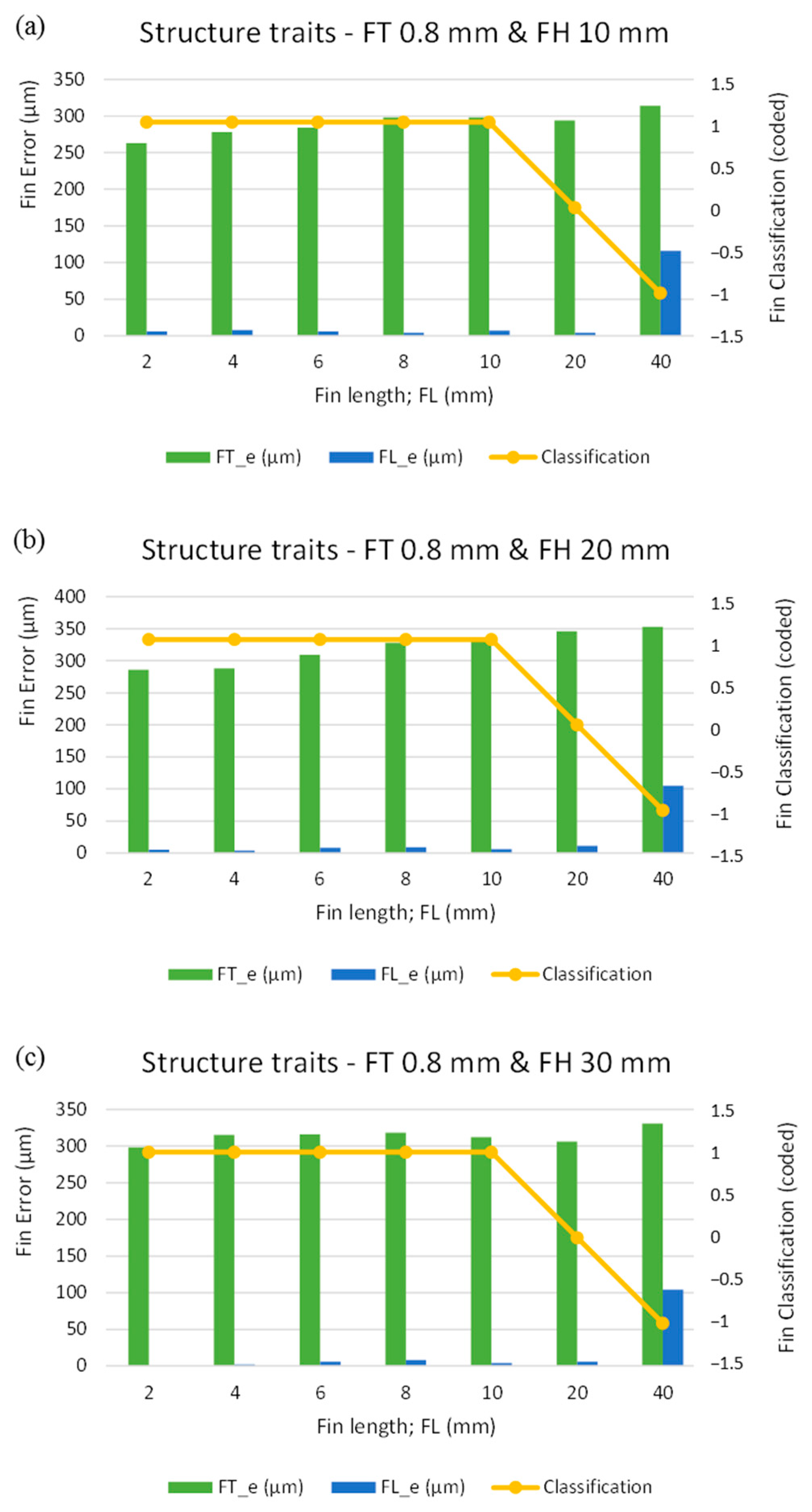

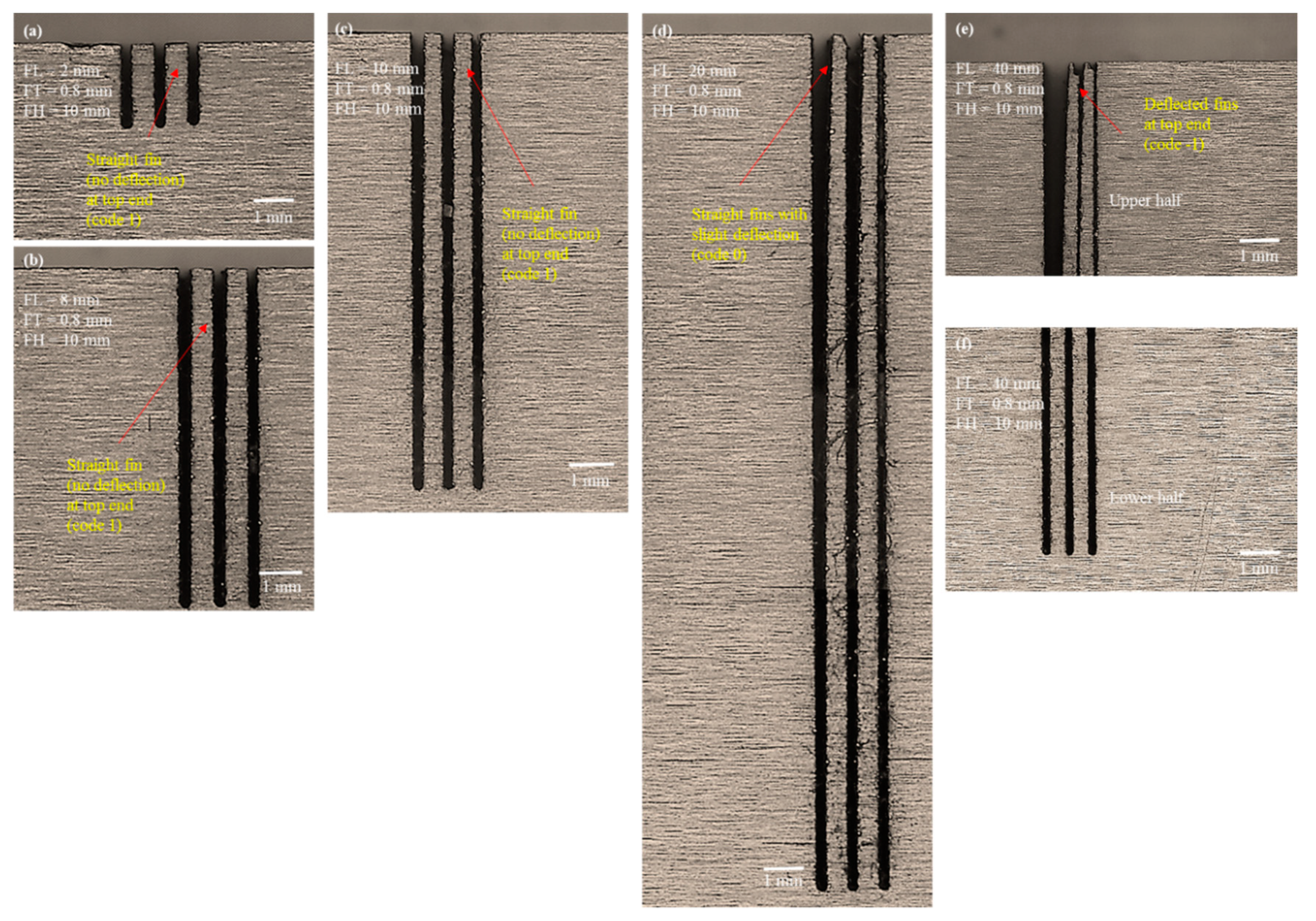

3.4. Analysis of the Fourth Phase

4. Conclusions

- Fabrication of thin structures through WEDM is possible, but the structure formation largely depends on its thickness and length provided that the WEDM conditions remained constant. Thin structures are relatively more difficult to fabricate as compared to thick structures (FT > 600 µm). It is even more difficult to fabricate thin structures if the structure length is increased i.e., to have high aspect ratio structures.

- On the whole, the formation of thin structures takes four forms. The structures are either: (1) broken at the tip point with needle-like spikes, (2) largely deflected, (3) deflected and merged at the upper ends, (4) slightly deflected, and (5) perfectly straight with square ends.

- With zero offset, constant machining conditions (as used in this study), and 1 mm structure length (FL 1 mm), the minimum designed thickness of the structure to ensure that it is straight without deflection is 0.4 mm, and the corresponding actual machined fins are 117 µm thick (aspect ratio of 8.5).

- For structures longer than 1 mm under the designed fin thickness (FT_d) of 0.4 mm, the fins are broken at the apex and a sound thermal deflection is experienced. The deflection is proportional to the FLs. Fins longer than 4 mm not only deflect but also merge at their free standing ends.

- Under the FT_d of 0.8 mm with zero offset and constant machining conditions (as used in this study), approximately 500 µm thin structures can be produced successfully from D2 steel (aspect ratio of 80). Under this designed fin thickness, the structures are:

- Straight and uniform throughout the length, if the FL ≤ 10 mm;

- Slightly deflected at the top end, if the FL is 10 mm < FL ≤ 20 mm;

- Straight at the lower half and deflected at the upper half, if the FL ≥ 40 mm.

- The microscopic evidence for each of the three FHs (10, 20, and 30 mm) are similar, irrespective of whether the fins are broken, deflected, or straight. Thus, the formation of thin structures (cross-section) is independent of their heights (FH) during the WEDM of D2 steel plates of 10–30 mm thickness.

- In general, fins longer than 20 mm experience relatively more machining errors (FT_e and FL_e) as compared to errors associated with fins of less than 20 mm in length. However, more specifically:

- The error in fin thickness (FT_e) increases with the increase in fin length (FL) and fin height (FH).

- The error in fin length (FL_e) only increases with the increase in fin length (FL). The fin height (FH) does not show a considerable effect on the fin length error (FL_e).

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yin, H.; Xiao, Y.; Wen, G.; Qing, Q.; Wu, X. Crushing analysis and multi-objective optimization design for bionic thin-walled structure. Mater. Des. 2015, 87, 825–834. [Google Scholar] [CrossRef]

- Martin, J.H.; Ashby, D.S.; Schaedler, T.A. Thin-walled high temperature alloy structures fabricated from additively manufactured polymer templates. Mater. Des. 2017, 120, 291–297. [Google Scholar] [CrossRef]

- Heidari, M.; Yan, J. Material removal mechanism and surface integrity in ultraprecision cutting of porous titanium. Precis. Eng. 2018, 52, 356–369. [Google Scholar] [CrossRef]

- Xia, H.; Zhao, G.; Li, L.; Hu, M.; He, N.; Ochengo, D. Fabrication of high aspect ratio microgroove on Ti6Al4V by laser-induced oxidation assisted micro milling. J. Manuf. Process. 2019, 45, 419–428. [Google Scholar] [CrossRef]

- Alves, L.M.; Afonso, R.M.; Silva, C.M.A.; Martins, P.A.F. Boss forming of annular flanges in thin-walled tubes. J. Mater. Process. Technol. 2017, 250, 182–189. [Google Scholar] [CrossRef]

- Lin, J.J.; Lv, Y.H.; Liu, Y.X.; Xu, B.S.; Sun, Z.; Li, Z.G.; Wu, Y.X. Microstructural evolution and mechanical properties of Ti-6Al-4V wall deposited by pulsed plasma arc additive manufacturing. Mater. Des. 2016, 102, 30–40. [Google Scholar] [CrossRef]

- Mollicone, P.; Camilleri, D.; Gray, T. Procedural influences on non-linear distortions in welded thin-plate fabrication. Thin-Walled Struct. 2008, 46, 1021–1034. [Google Scholar] [CrossRef]

- Tang, W.; Liu, H.; Zhu, L.; Shi, J.; Li, Z.; Xiang, N.; Yang, J. Fabrication of Different Microchannels by Adjusting the Extrusion Parameters for Sacrificial Molds. Micromachines 2019, 10, 544. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Zhao, E.; Kong, F.; Xiao, S. Fabrication of Thin-Walled High-Temperature Titanium Alloy Component by Investment Casting. Mater. Manuf. Process. 2013, 28, 605–609. [Google Scholar] [CrossRef]

- Yi, J.; Wang, X.; Jiao, L.; Xiang, J.; Yi, F. Research on deformation law and mechanism for milling micro thin wall with mixed boundaries of titanium alloy in mesoscale. Thin-Walled Struct. 2019, 144, 106329. [Google Scholar] [CrossRef]

- Thepsonthi, T.; Özel, T. Experimental and finite element simulation based investigations on micro-milling Ti-6Al-4V titanium alloy: Effects of cBN coating on tool wear. J. Mater. Process. Technol. 2013, 213, 532–542. [Google Scholar] [CrossRef]

- Miranda, G.; Faria, S.; Bartolomeu, F.; Pinto, E.; Alves, N.; Peixinho, N.; Gasik, M.; Silva, F.S. A study on the production of thin-walled Ti6Al4V parts by selective laser melting. J. Manuf. Process. 2019, 39, 346–355. [Google Scholar] [CrossRef]

- Sudarsan, C.; Sajun Prasad, K.; Hazra, S.; Panda, S.K. Forming of serpentine micro-channels on SS304 and AA1050 ultra-thin metallic sheets using stamping technology. J. Manuf. Process. 2020, 56, 1099–1113. [Google Scholar] [CrossRef]

- Malapati, M.; Bhattacharyya, B. Investigation into Electrochemical Micromachining Process during Micro-Channel Generation. Mater. Manuf. Process. 2011, 26, 1019–1027. [Google Scholar] [CrossRef]

- Oh, K.H.; Lee, M.K.; Jeong, S.H. Laser micromachining of high-aspect-ratio metallic grooves for application to microthermal devices. J. Micromech. Microeng. 2006, 16, 1958–1966. [Google Scholar] [CrossRef]

- Zhou, W.; Deng, W.; Lu, L.; Zhang, J.; Qin, L.; Ma, S.; Tang, Y. Laser micro-milling of microchannel on copper sheet as catalyst support used in microreactor for hydrogen production. Int. J. Hydrog. Energy 2014, 39, 4884–4894. [Google Scholar] [CrossRef]

- Darwish, S.; Ahmed, N.; Alahmari, A.M.; Mufti, N.A. A study of micro-channel size and spatter dispersion for laser beam micro-milling. Mater. Manuf. Process. 2017, 32, 171–184. [Google Scholar] [CrossRef]

- Ghazavi, A.; Papini, M. An inverse method for the abrasive jet micro-machining of high aspect ratio channels of desired topography—Part II, experiments. Precis. Eng. 2019, 58, 25–34. [Google Scholar] [CrossRef]

- Ho, K.H.; Newman, S.T.; Rahimifard, S.; Allen, R.D. State of the art in wire electrical discharge machining (WEDM). Int. J. Mach. Tools Manuf. 2004, 44, 1247–1259. [Google Scholar] [CrossRef]

- Cheng, X.; Yang, X.; Zheng, G.; Huang, Y.; Li, L. Fabrication accuracy analysis of micromilling tools with complicated geometries by wire EDM. J. Mech. Sci. Technol. 2014, 28, 2329–2335. [Google Scholar] [CrossRef]

- Naveed, R.; Mufti, N.A.; Mughal, M.P.; Saleem, M.Q.; Ahmed, N. Machining of curved profiles on tungsten carbide-cobalt composite using wire electric discharge process. Int. J. Adv. Manuf. Technol. 2017, 93, 1367–1378. [Google Scholar] [CrossRef]

- Sharma, S.; Kumar Vates, U.; Bansal, A. Parametric optimization in wire EDM of D2 tool steel using Taguchi method. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Ugrasen, G.; Ravindra, H.V.; Prakash, G.V.N.; Keshavamurthy, R. Comparison of Machining Performances Using Multiple Regression Analysis and Group Method Data Handling Technique in Wire EDM of Stavax Material. Procedia Mater. Sci. 2014, 5, 2215–2223. [Google Scholar] [CrossRef] [Green Version]

- Oßwald, K.; Lochmahr, I.; Schulze, H.-P.; Kröning, O. Automated Analysis of Pulse Types in High Speed Wire EDM. Procedia CIRP 2018, 68, 796–801. [Google Scholar] [CrossRef]

- Kirwin, R.M.; Mahbub, M.R.; Jahan, M.P. Investigating the effect of wire feed rate and wire tension on the corner and profile accuracies during wire-EDM of TI-6AL-4V. In Proceedings of the ASME 13th International Manufacturing Science and Engineering Conference, College Station, TX, USA, 18–22 June 2018; p. V004T03A057. [Google Scholar]

- Gupta, K.; Jain, N.K. On Micro-Geometry of Miniature Gears Manufactured by Wire Electrical Discharge Machining. Mater. Manuf. Process. 2013, 28, 1153–1159. [Google Scholar] [CrossRef]

- Liao, Q.; Zhou, C.; Lu, Y.; Wu, X.; Chen, F.; Lou, Y. Efficient and Precise Micro-Injection Molding of Micro-Structured Polymer Parts Using Micro-Machined Mold Core by WEDM. Polymers 2019, 11, 1591. [Google Scholar] [CrossRef] [Green Version]

- Hourmand, M.; Sarhan, A.A.D.; Noordin, M.Y. Development of new fabrication and measurement techniques of micro-electrodes with high aspect ratio for micro EDM using typical EDM machine. Measurement 2017, 97, 64–78. [Google Scholar] [CrossRef]

- Zahiruddin, M.; Kunieda, M. Analysis of Micro Fin Deformation Due to Micro EDM. Procedia CIRP 2016, 42, 569–574. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Z.; Huang, H.; Huang, Y.; Zhang, G.; Li, W.; Liu, C. Study on thermal deformation behavior and microstructural characteristics of wire electrical discharge machining thin-walled components. J. Manuf. Process. 2018, 31, 9–19. [Google Scholar] [CrossRef]

- Rajamanickam, S.; Prasanna, J. TOPSIS on High Aspect Ratio Electric Discharge Machining (EDM) of Ti-6Al-4V using 300 µm brass rotary tube electrodes. Mater. Today Proc. 2018, 5, 18489–18501. [Google Scholar] [CrossRef]

- Ahmed, N.; Mughal, M.P.; Shoaib, W.; Farhan Raza, S.; Alahmari, A.M. WEDM of Copper for the Fabrication of Large Surface-Area Micro-Channels: A Prerequisite for the High Heat-Transfer Rate. Micromachines 2020, 11, 173. [Google Scholar] [CrossRef] [Green Version]

- Kumar, K.; Batra, U. Fabrication of High Aspect Ratio WC-Co Micro Electrodes for µ-EDM Application. Mater. Today Proc. 2019, 18, 2970–2976. [Google Scholar] [CrossRef]

- Azarsa, E.; Cinco, L.; Papini, M. Fabrication of high aspect ratio free-standing structures using abrasive water jet micro-machining. J. Mater. Process. Technol. 2020, 275, 116318. [Google Scholar] [CrossRef]

- Guu, Y.H. AFM surface imaging of AISI D2 tool steel machined by the EDM process. Appl. Surf. Sci. 2005, 242, 245–250. [Google Scholar] [CrossRef]

- D2 Tool Steel—High-Carbon, High-Chromium, Cold-Work Steel (UNS T30402). Available online: https://www.azom.com/article.aspx?ArticleID=6214 (accessed on 27 January 2020).

- Karidkar, S.S.; Dabade, U.A. Finite Element Modeling and Simulation of Inconel 718 Using WEDM. Am. Soc. Mech. Eng. Digit. Collect. 2017. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Z.; Zhang, G.; Li, W. Reduction of Energy Consumption and Thermal Deformation in WEDM by Magnetic Field Assisted Technology. Int. J. Precis. Eng. Manuf. Green Tech. 2019. [Google Scholar] [CrossRef]

- Miller, S.F.; Kao, C.-C.; Shih, A.J.; Qu, J. Investigation of wire electrical discharge machining of thin cross-sections and compliant mechanisms. Int. J. Mach. Tools Manuf. 2005, 45, 1717–1725. [Google Scholar] [CrossRef]

- Ali, M.Y.; Mohammad, A.S. Experimental Study of Conventional Wire Electrical Discharge Machining for Microfabrication. Mater. Manuf. Process. 2008, 23, 641–645. [Google Scholar] [CrossRef]

| Elements | C | Si | Mn | Mo | Cr | Ni | V | Co | Fe |

| Contents % | 1.5 | 0.3 | 0.3 | 1 | 12 | 0.3 | 0.8 | 1 | Balance |

| Physical Properties | Mechanical Properties | Thermal Properties | |||

|---|---|---|---|---|---|

| Properties | Value (Units) | Properties | Value (Units) | Properties | Value (Units) |

| Density | 7.7 × 1000 kg/m3 | Hardness, Rockwell C | 62 | Thermal expansion (20 °C) | 10.5 × 10−6 °C−1 |

| Melting point | 1421 °C | Hardness, Vickers | 748 | Thermal conductivity | 20 W/mK |

| Poisson’s ratio | 0.27–0.30 | ||||

| Elastic modulus | 190–210 GPa | ||||

| Constant Machining Conditions | Parameter | Value | |||||||

| Machine | EDM E-7735 | ||||||||

| Wire | Molybdenum | ||||||||

| Wire diameter (mm) | 0.2 | ||||||||

| Discharge current; I (A) | 2 | ||||||||

| Spark voltage (V) | 160 | ||||||||

| Wire feed | 37 | ||||||||

| Pulse on time (µs) | 40 | ||||||||

| Pulse off time (µs) | 40 | ||||||||

| Variables | Variable name | Levels | |||||||

| Fin thickness; FT (mm) | 1 | 0.9 | 0.8 | 0.7 | 0.6 | 0.5 | 0.4 | 0.3 | |

| Fin height; FH (mm) | 10 | 20 | 30 | ||||||

| Fin length; FL (mm) | 1 | 2 | 4 | 6 | 8 | 10 | 20 | 40 | |

| Responses | Response name | ||||||||

| Fin thickness error; FT_e (µm) | |||||||||

| Fin length error; FL_e (µm) | |||||||||

| Fin quality | Classification | Code | |||||||

| Straight | 1 | ||||||||

| Straight with slight deflection | 0 | ||||||||

| Deflected | −1 | ||||||||

| Deflected and merged at the top end | −2 | ||||||||

| Straight but broken at the top end | −3 | ||||||||

| Broken | −4 | ||||||||

| Exp. No | FH (mm) | FT_d (mm) | FL_d (mm) | FT_m (mm) | FL_m (mm) | FT_e (µm) | FL_e (µm) | Classification and Code | |

|---|---|---|---|---|---|---|---|---|---|

| First Phase | |||||||||

| 1 | 10 | 1 | 1 | 0.733 | 0.992 | 267 | 8 | Straight | 1 |

| 2 | 0.9 | 0.635 | 0.993 | 265 | 7 | Straight | 1 | ||

| 3 | 0.8 | 0.537 | 0.984 | 263 | 16 | Straight | 1 | ||

| 4 | 0.7 | 0.436 | 0.988 | 264 | 12 | Straight | 1 | ||

| 5 | 0.6 | 0.338 | 0.984 | 262 | 16 | Straight | 1 | ||

| 6 | 0.5 | 0.203 | 0.984 | 297 | 16 | Straight | 1 | ||

| 7 | 0.4 | 0.117 | 0.98 | 283 | 20 | Straight | 1 | ||

| 8 | 0.3 | Straight and broken | −3 | ||||||

| 9 | 0.39 | Broken | −4 | ||||||

| 10 | 0.38 | Broken | −4 | ||||||

| Second Phase (FH 10 mm) | |||||||||

| 1 | 10 | 0.4 | 2 | 0.118 | 1.522 | 282 | 478 | Straight and broken | −3 |

| 2 | 4 | 0.12 | 3.579 | 280 | 421 | Deflected | −1 | ||

| 3 | 6 | 0.119 | 5.524 | 281 | 476 | Deflected and merged | −2 | ||

| 4 | 8 | 0.107 | 7.42 | 293 | 580 | Deflected and merged | −2 | ||

| 5 | 10 | 0.115 | 9.424 | 285 | 576 | Deflected and merged | −2 | ||

| 6 | 20 | 0.113 | 19.358 | 287 | 642 | Deflected and merged | −2 | ||

| 7 | 40 | 0.086 | 39.188 | 314 | 812 | Deflected and merged | −2 | ||

| Second Phase (FH 20 mm) | |||||||||

| 1 | 20 | 0.4 | 2 | 0.123 | 1.529 | 277 | 471 | Straight and broken | −3 |

| 2 | 4 | 0.188 | 3.58 | 212 | 420 | Deflected | −1 | ||

| 3 | 6 | 0.141 | 5.476 | 259 | 524 | Deflected and merged | −2 | ||

| 4 | 8 | 0.109 | 7.503 | 291 | 497 | Deflected and merged | −2 | ||

| 5 | 10 | 0.137 | 9.505 | 263 | 495 | Deflected and merged | −2 | ||

| 6 | 20 | 0.116 | 19.398 | 284 | 602 | Deflected and merged | −2 | ||

| 7 | 40 | 0.117 | 39.199 | 283 | 801 | Deflected and merged | −2 | ||

| Second Phase (FH 30 mm) | |||||||||

| 1 | 30 | 0.4 | 2 | 0.145 | 1.407 | 255 | 593 | Straight and broken | −3 |

| 2 | 4 | 0.135 | 3.467 | 265 | 533 | Deflected | −1 | ||

| 3 | 6 | 0.135 | 5.304 | 265 | 696 | Deflected and merged | −2 | ||

| 4 | 8 | 0.133 | 7.266 | 267 | 734 | Deflected and merged | −2 | ||

| 5 | 10 | 0.141 | 9.154 | 259 | 846 | Deflected and merged | −2 | ||

| 6 | 20 | 0.131 | 19.145 | 269 | 855 | Deflected and merged | −2 | ||

| 7 | 40 | 0.123 | 38.996 | 277 | 1004 | Deflected and merged | −2 | ||

| Third Phase | |||||||||

| 1 | 10 | 0.5 | 10 | 0.197 | 9.755 | 303 | 245 | Deflected and merged | −2 |

| 2 | 0.6 | 0.328 | 9.858 | 272 | 142 | Deflected | −1 | ||

| 3 | 0.7 | 0.424 | 9.988 | 276 | 12 | Slight Deflection | 0 | ||

| 4 | 0.8 | 0.517 | 9.991 | 283 | 9 | Straight | 1 | ||

| Fourth phase (FH 10 mm) | |||||||||

| 1 | 10 | 0.8 | 2 | 0.537 | 1.994 | 263 | 6 | Straight | 1 |

| 2 | 4 | 0.522 | 3.992 | 278 | 8 | Straight | 1 | ||

| 3 | 6 | 0.516 | 5.994 | 284 | 6 | Straight | 1 | ||

| 4 | 8 | 0.502 | 7.996 | 298 | 4 | Straight | 1 | ||

| 5 | 10 | 0.502 | 9.993 | 298 | 7 | Straight | 1 | ||

| 6 | 20 | 0.506 | 19.996 | 294 | 4 | Straight (Slight Deflection) | 0 | ||

| 7 | 40 | 0.486 | 39.884 | 314 | 116 | Deflected | −1 | ||

| Fourth phase (FH 20 mm) | |||||||||

| 1 | 20 | 0.8 | 2 | 0.514 | 1.995 | 286 | 5 | Straight | 1 |

| 2 | 4 | 0.512 | 3.996 | 288 | 4 | Straight | 1 | ||

| 3 | 6 | 0.491 | 5.992 | 309 | 8 | Straight | 1 | ||

| 4 | 8 | 0.472 | 7.991 | 328 | 9 | Straight | 1 | ||

| 5 | 10 | 0.466 | 9.994 | 334 | 6 | Straight | 1 | ||

| 6 | 20 | 0.454 | 19.989 | 346 | 11 | Straight (Slight Deflection) | 0 | ||

| 7 | 40 | 0.447 | 39.895 | 353 | 105 | Deflected | −1 | ||

| Fourth phase (FH 30 mm) | |||||||||

| 1 | 30 | 0.8 | 2 | 0.502 | 2 | 298 | 0 | Straight | 1 |

| 2 | 4 | 0.485 | 3.998 | 315 | 2 | Straight | 1 | ||

| 3 | 6 | 0.484 | 5.994 | 316 | 6 | Straight | 1 | ||

| 4 | 8 | 0.482 | 7.992 | 318 | 8 | Straight | 1 | ||

| 5 | 10 | 0.488 | 9.996 | 312 | 4 | Straight | 1 | ||

| 6 | 20 | 0.494 | 19.994 | 306 | 6 | Straight (Slight Deflection) | 0 | ||

| 7 | 40 | 0.469 | 39.896 | 331 | 104 | Deflected | −1 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmed, N.; Naeem, M.A.; Rehman, A.U.; Rafaqat, M.; Umer, U.; Ragab, A.E. High Aspect Ratio Thin-Walled Structures in D2 Steel through Wire Electric Discharge Machining (EDM). Micromachines 2021, 12, 1. https://doi.org/10.3390/mi12010001

Ahmed N, Naeem MA, Rehman AU, Rafaqat M, Umer U, Ragab AE. High Aspect Ratio Thin-Walled Structures in D2 Steel through Wire Electric Discharge Machining (EDM). Micromachines. 2021; 12(1):1. https://doi.org/10.3390/mi12010001

Chicago/Turabian StyleAhmed, Naveed, Muhammad Ahmad Naeem, Ateekh Ur Rehman, Madiha Rafaqat, Usama Umer, and Adham E. Ragab. 2021. "High Aspect Ratio Thin-Walled Structures in D2 Steel through Wire Electric Discharge Machining (EDM)" Micromachines 12, no. 1: 1. https://doi.org/10.3390/mi12010001

APA StyleAhmed, N., Naeem, M. A., Rehman, A. U., Rafaqat, M., Umer, U., & Ragab, A. E. (2021). High Aspect Ratio Thin-Walled Structures in D2 Steel through Wire Electric Discharge Machining (EDM). Micromachines, 12(1), 1. https://doi.org/10.3390/mi12010001