Comparison of Swing and Tilting Check Valves Flowing Compressible Fluids

Abstract

1. Introduction

2. Numerical Methods

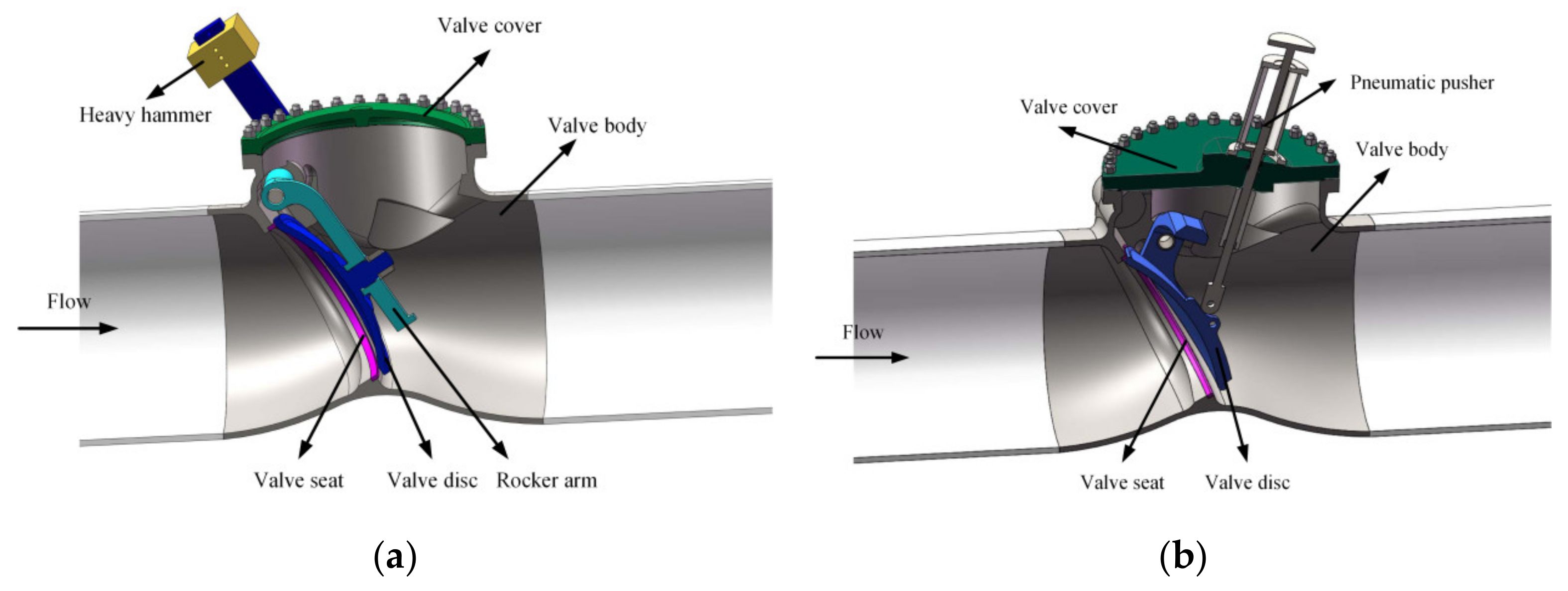

2.1. Physic Model

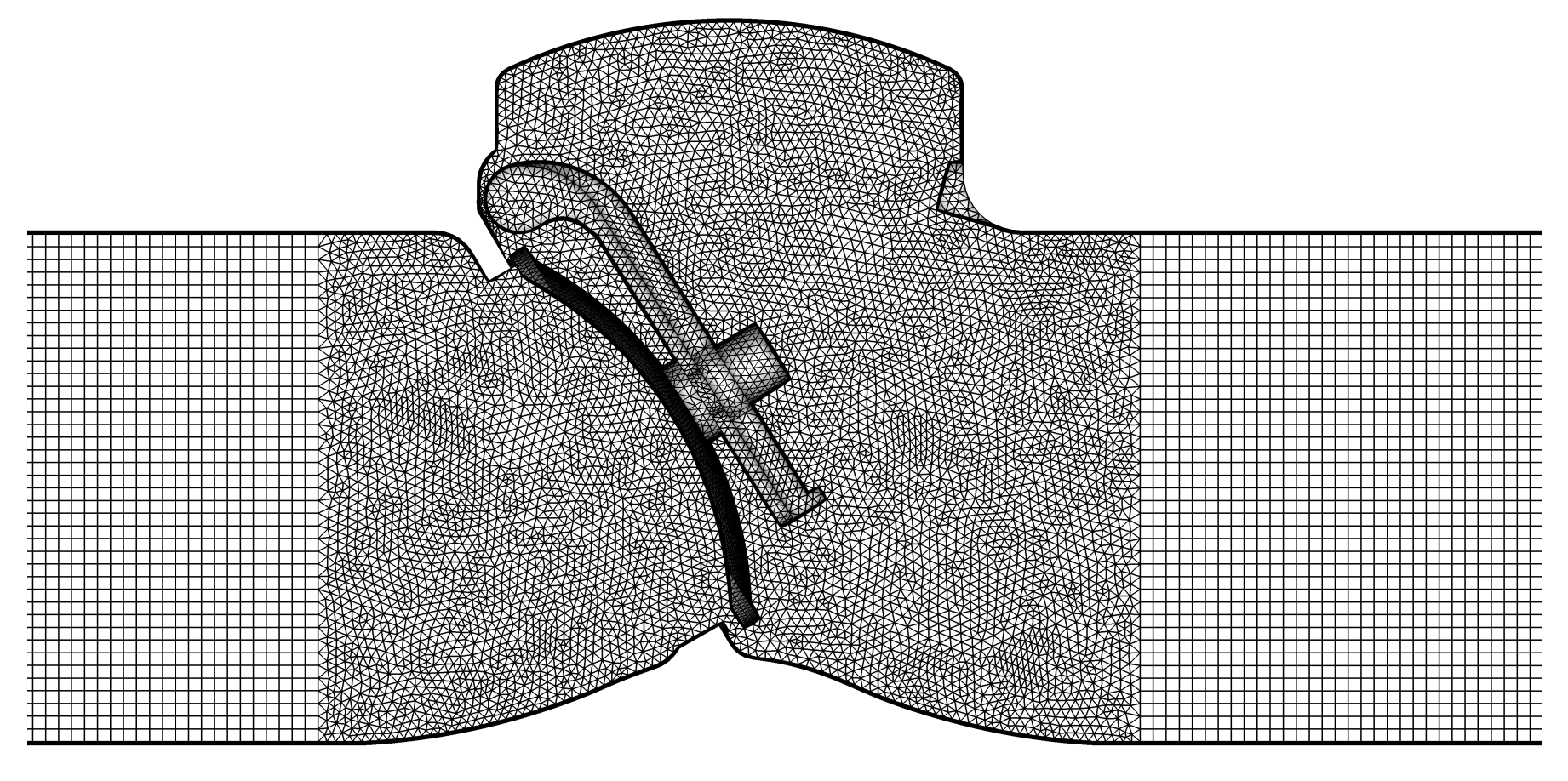

2.2. Numerical Model

3. Results

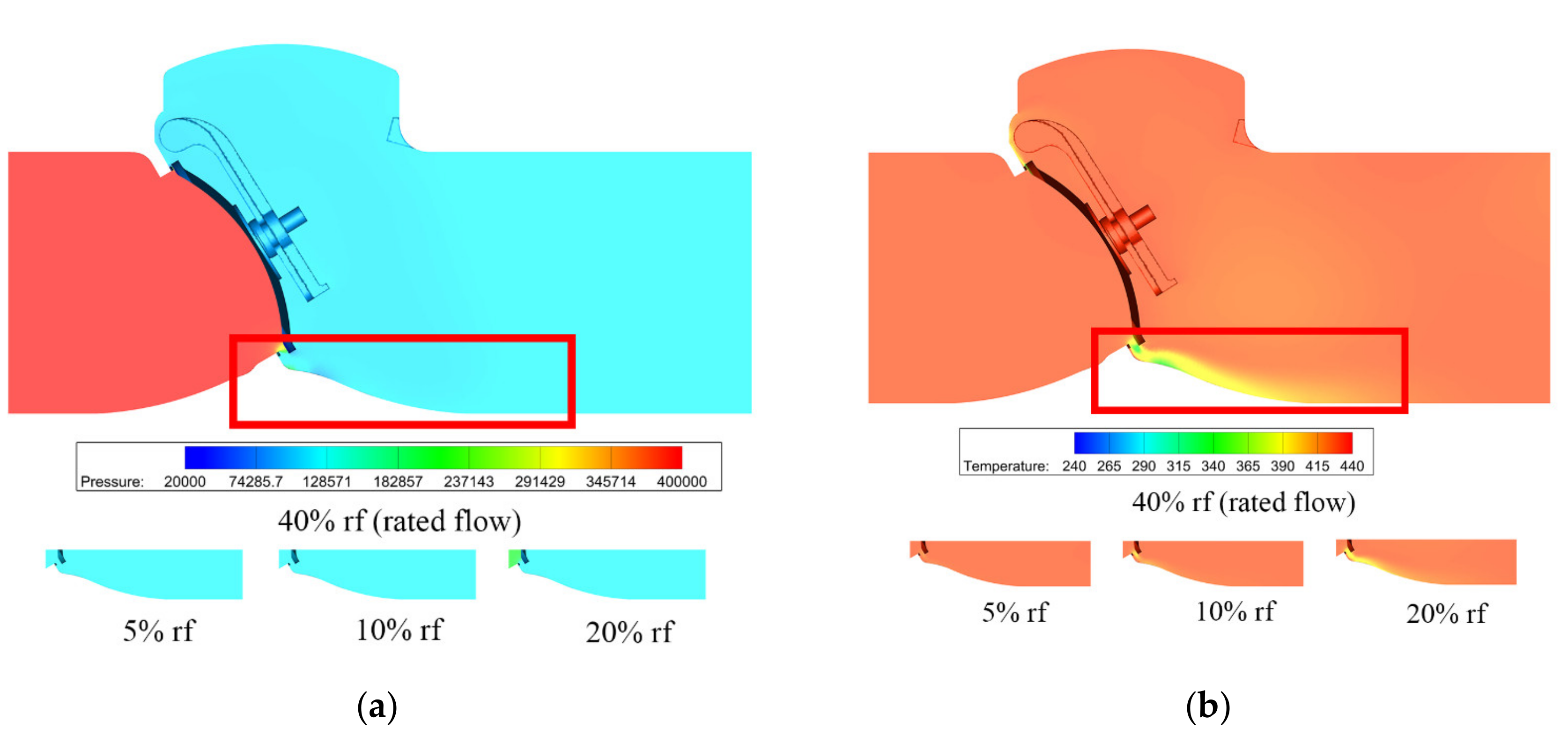

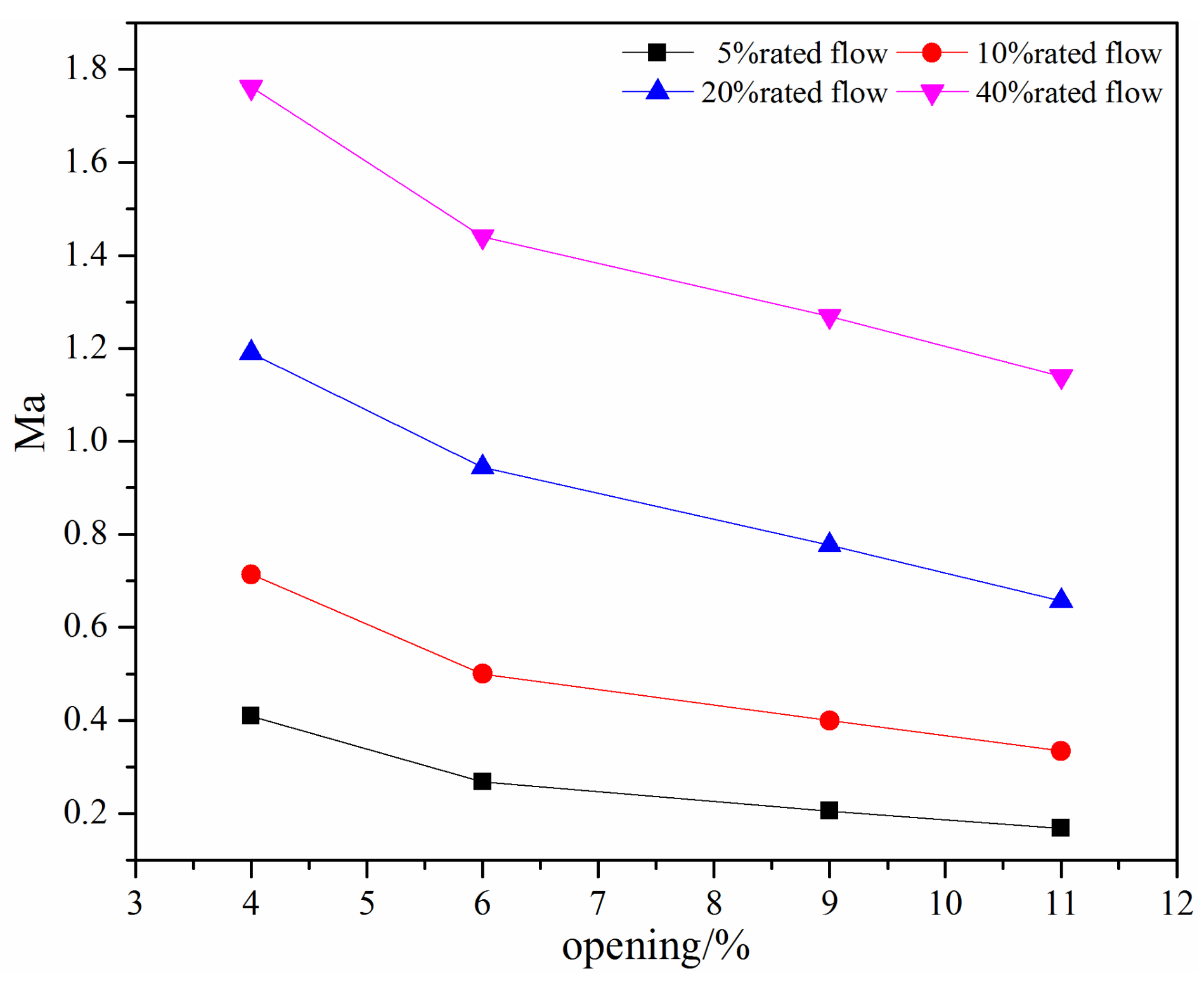

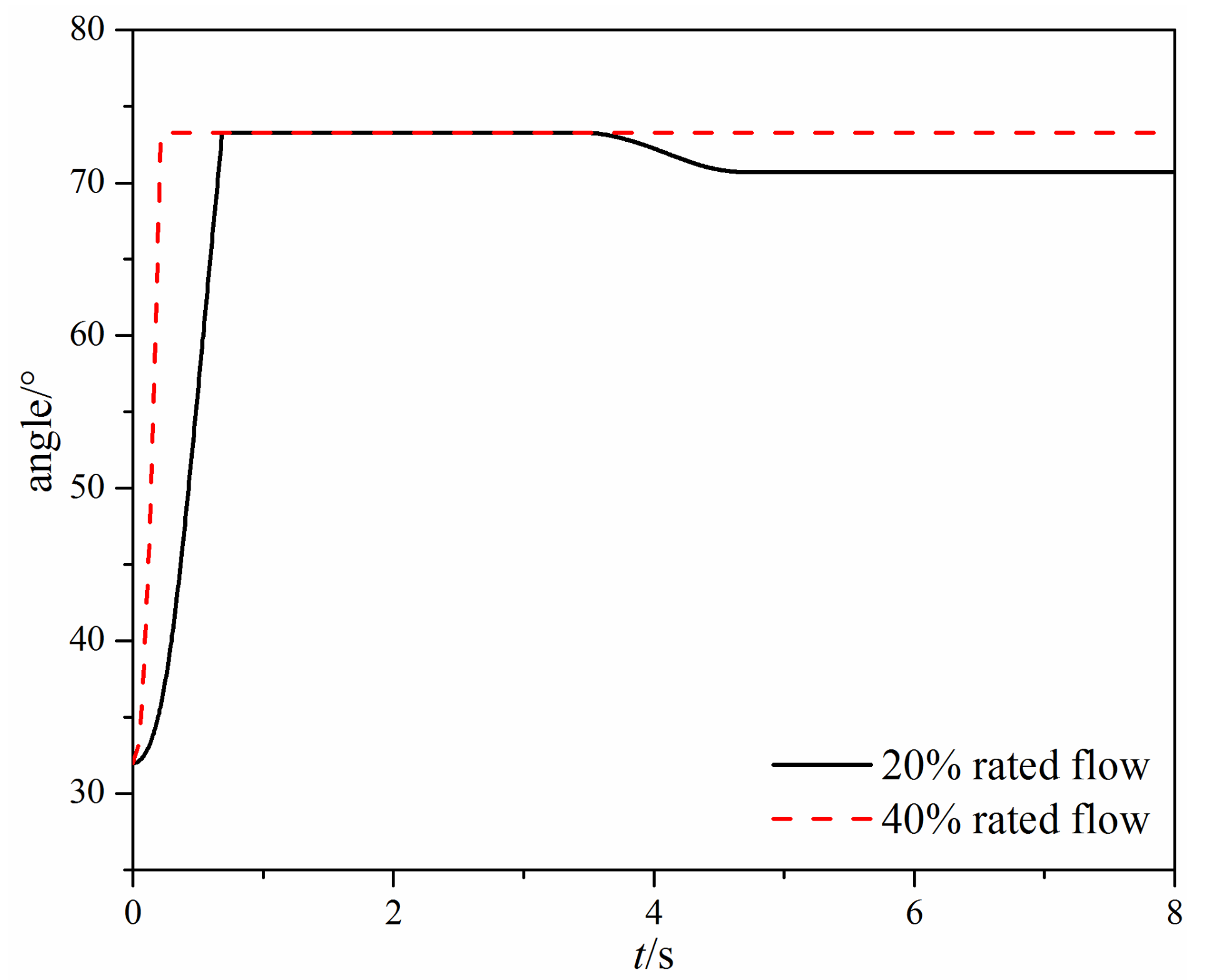

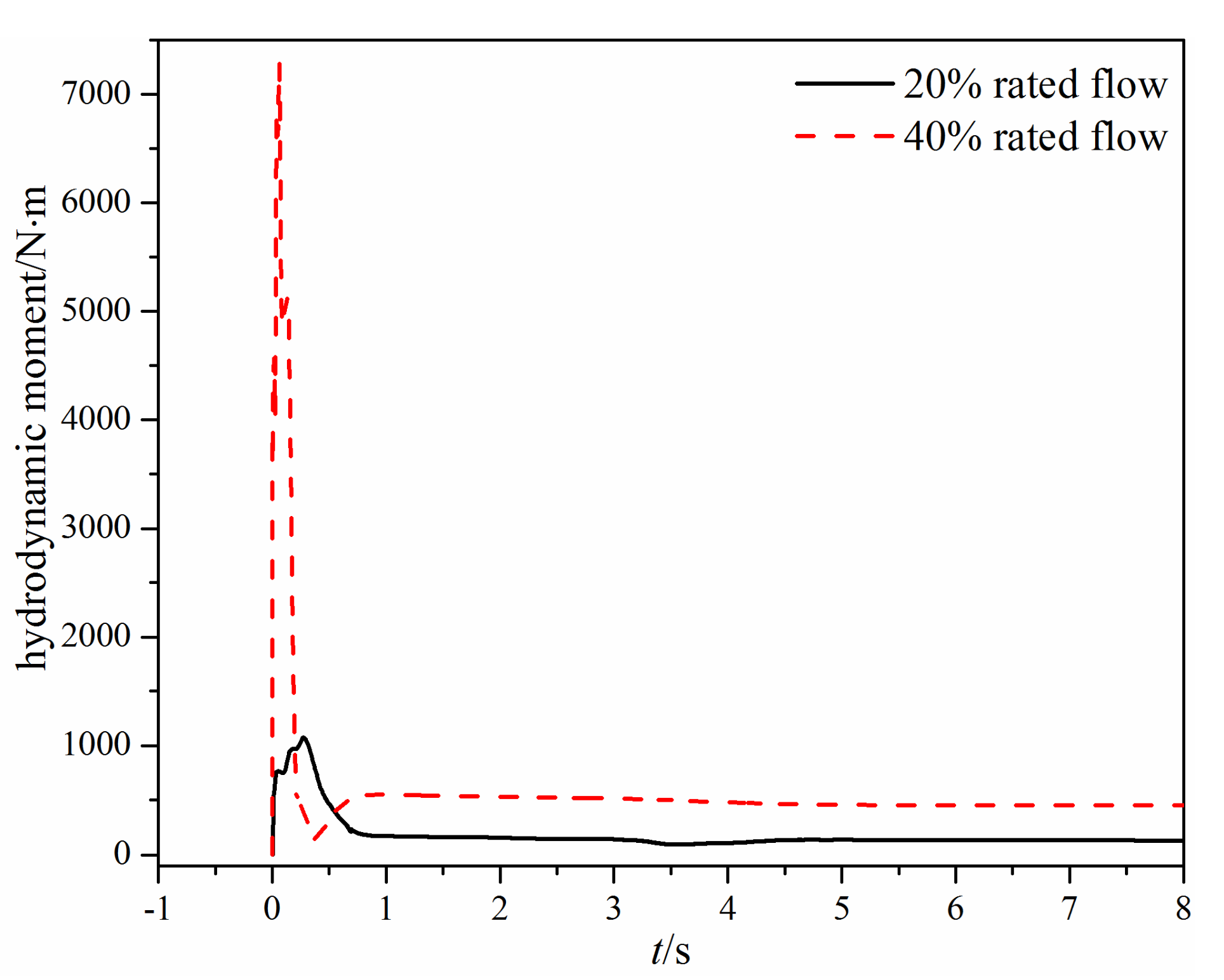

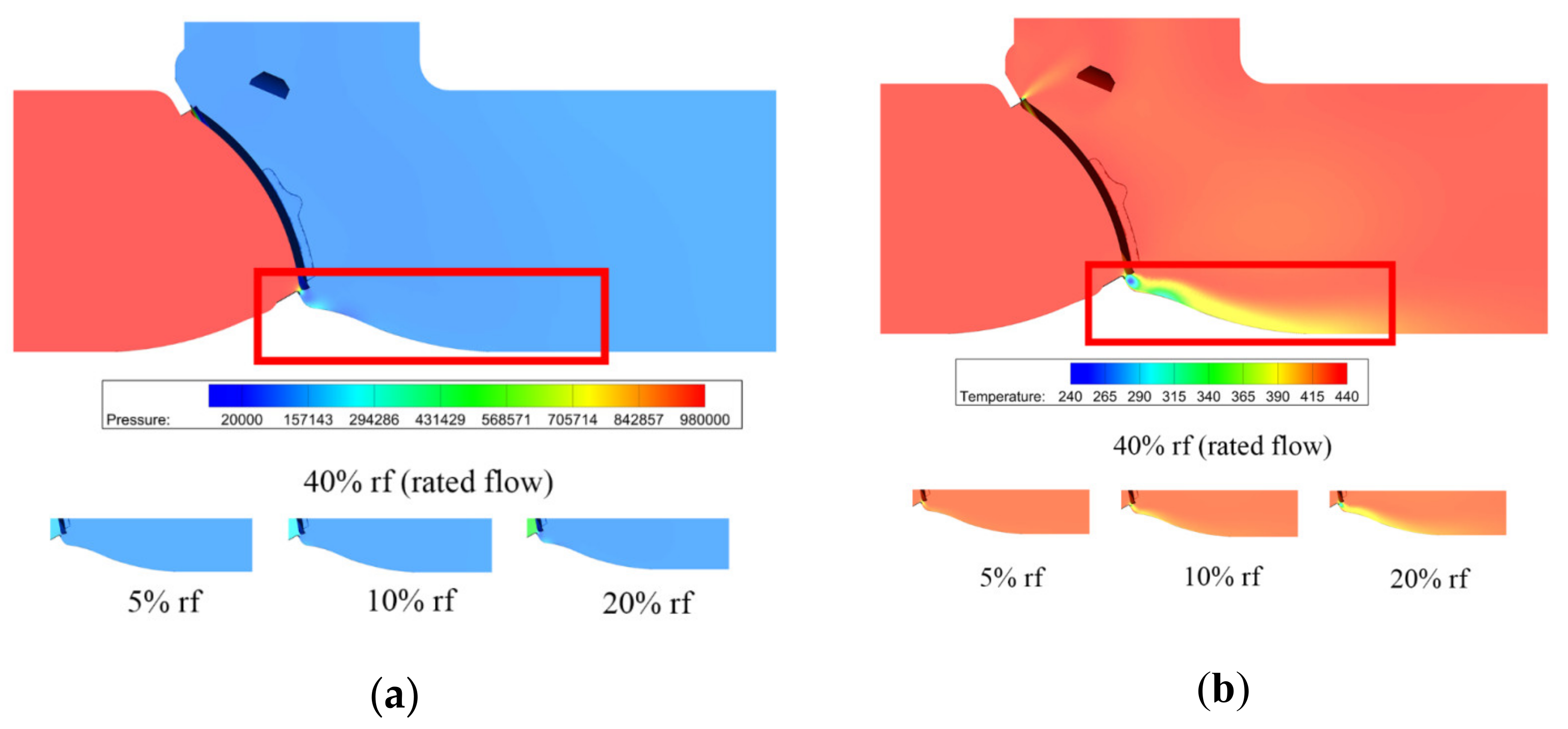

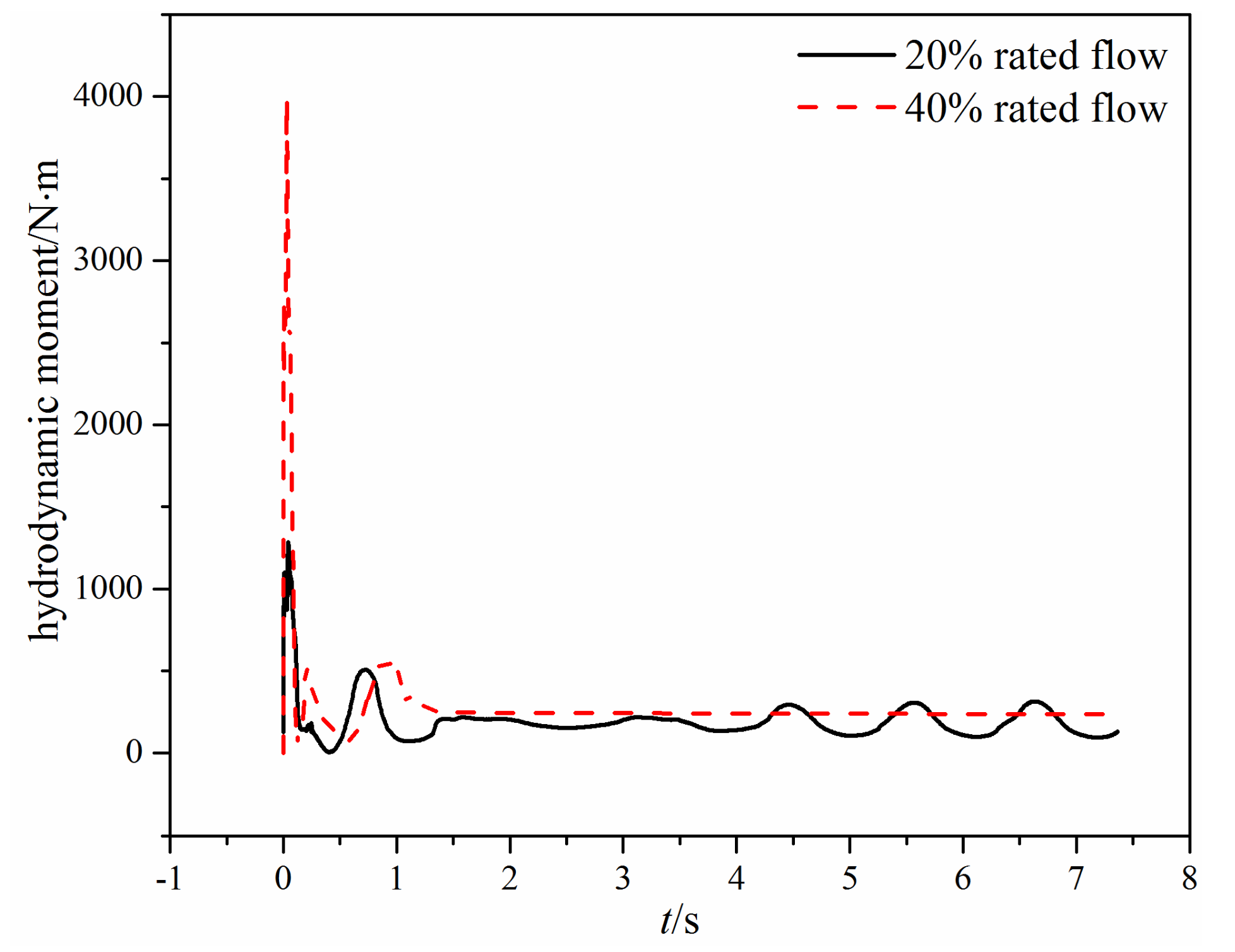

3.1. The Swing Check Valve

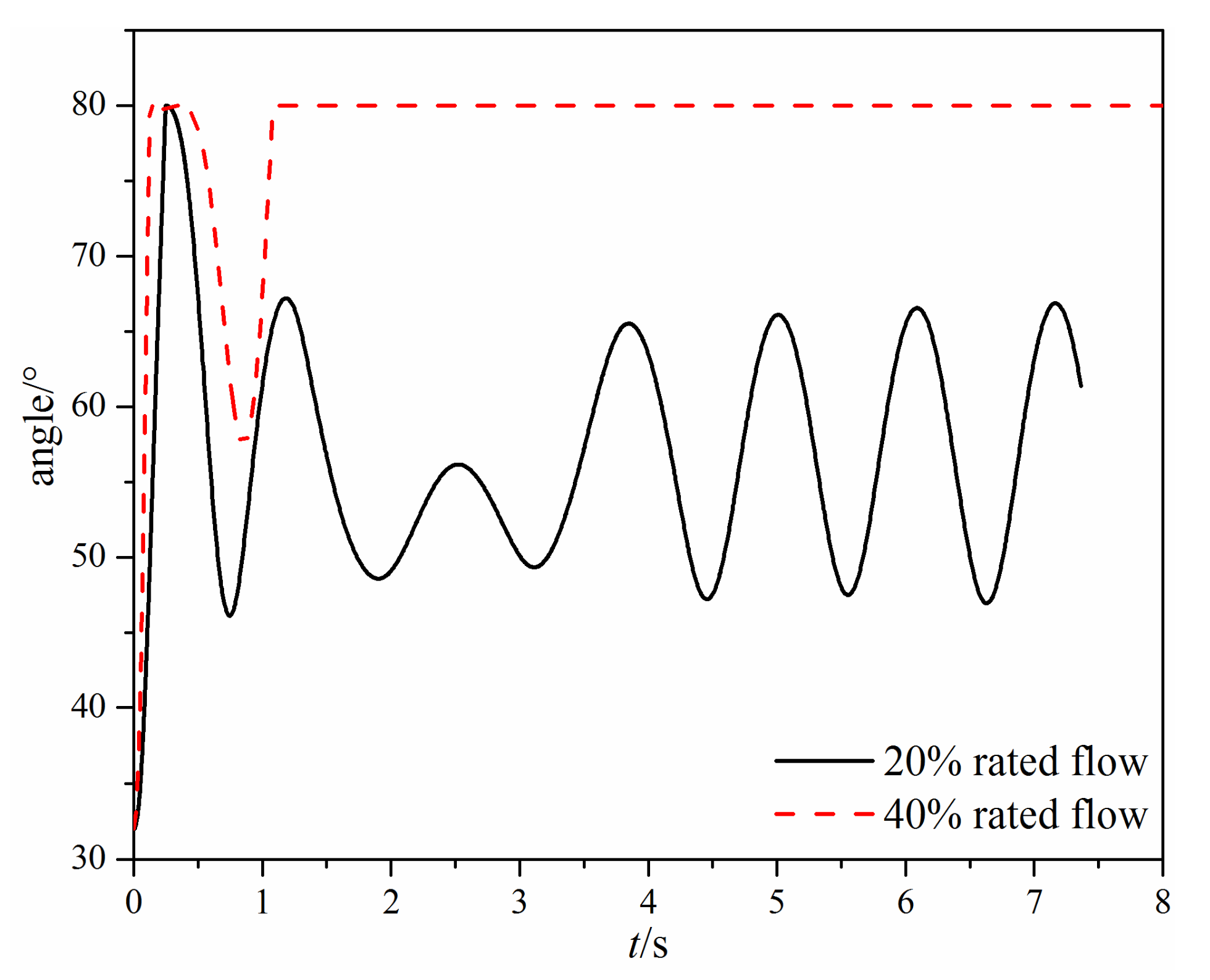

3.2. The Tilting Check Valve

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lai, Z.; Li, Q.; Karney, B.W.; Yang, S.; Wu, D.; Zhang, F. Numerical Simulation of a Check Valve Closure Induced by Pump Shutdown. J. Hydraul. Eng. 2018, 144, 06018013. [Google Scholar] [CrossRef]

- Yu, J.; Yu, S. Numerical and experimental research of flow and sound fields in an axial-flow check valve and its optimization. Adv. Mech. Eng. 2015, 7, 168781401561982. [Google Scholar] [CrossRef]

- Yang, Z.; Zhou, L.; Dou, H.; Lu, C.; Luan, X. Water hammer analysis when switching of parallel pumps based on contra-motion check valve. Ann. Nucl. Energy 2020, 139, 107275. [Google Scholar] [CrossRef]

- Yang, Z.; Chen, B.; Huang, W.; Han, W. Sensitivity Analysis and Design Improvement of Contra-Motion Check Valve. In Proceedings of the 2013 21st International Conference on Nuclear Engineering. Chengdu, China, 29 July–2 August 2013. [Google Scholar]

- Xu, H.; Guang, Z.M.; Qi, Y.Y. Hydrodynamic characterization and optimization of Contra-push check valve by numerical simulation. Ann. Nucl. Energy 2011, 38, 1427–1437. [Google Scholar] [CrossRef]

- Ballun, J.V. A methodology for predicting check valve slam. J. Am. Water Works Assoc. 2007, 99, 60–65. [Google Scholar] [CrossRef]

- Lee, S.; Kim, T.; Lee, S.; Park, S. Degradation mechanism of check valves in nuclear power plants. Ann. Nucl. Energy 2010, 37, 621–627. [Google Scholar] [CrossRef]

- Lee, T.S.; Leow, L.C. Numerical study on effects of check valve closure flow conditions on pressure surges in pumping station with air entrainment. Int. J. Numer. Methods Fluids 2001, 35, 117–124. [Google Scholar] [CrossRef]

- Marcinkiewicz, J.; Adamkowski, A.; Lewandowski, M.; Janicki, W. Experimental investigation of static characteristics of swing and tilting disc check valves. In Proceedings of the 2016 24th International Conference on Nuclear Engineering, Charlotte, NC, USA, 26–30 June 2016. [Google Scholar]

- Dokoupil, P.; Himr, D.; Habán, V. Experimental analysis of static and dynamic properties of the check valves. EPJ Web Conf. 2019, 213, 2013. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, T.; Hou, Y.; Zhu, K.; Huang, Z.; Wu, K. Local loss model of dividing flow in a bifurcate tunnel with a small angle. J. Zhejiang Univ. Sci. A 2019, 20, 21–35. [Google Scholar] [CrossRef]

- Liu, G.; Lin, Y.; Guan, G.; Yu, Y. Numerical research on the anti-sloshing effect of a ring baffle in an independent type C LNG tank. J. Zhejiang Univ. Sci. 2018, 19, 758–773. [Google Scholar] [CrossRef]

- Leati, E.; Scheidl, R.; Ploeckinger, A. On the Dynamic Behavior of Check Valves for High Frequency Oscillation Pumps. In Proceedings of the ASME/BATH 2013 Symposium on Fluid Power and Motion Control, Sarasota, FL, USA, 6–9 October 2013. [Google Scholar]

- Knutson, A.L.; Van de Ven, J.D. Modeling and Experimental Validation of a Reed Check Valve for Hydraulic Applications. In Proceedings of the BATH/ASME 2016 Symposium on Fluid Power and Motion Control, Bath, UK, 7–9 September 2016. [Google Scholar]

- Zhang, J.; Wang, D.; Xu, B.; Gan, M.; Pan, M.; Yang, H. Experimental and numerical investigation of flow forces in a seat valve using a damping sleeve with orifices. J. Zhejiang Univ. Sci. 2018, 19, 417–430. [Google Scholar] [CrossRef]

- Jin, Z.; Gao, Z.; Chen, M.; Qian, J. Parametric study on Tesla valve with reverse flow for hydrogen decompression. Int. J. Hydrogen Energy 2018, 43, 8888–8896. [Google Scholar] [CrossRef]

- Qian, J.; Chen, M.; Gao, Z.; Jin, Z. Mach number and energy loss analysis inside multi-stage Tesla valves for hydrogen decompression. Energy 2019, 179, 647–654. [Google Scholar] [CrossRef]

- Qian, J.; Wu, J.; Gao, Z.; Wu, A.; Jin, Z. Hydrogen decompression analysis by multi-stage Tesla valves for hydrogen fuel cell. Int. J. Hydrogen Energy 2019, 44, 13666–13674. [Google Scholar] [CrossRef]

- Leutwyler, Z.; Dalton, C. A Computational Study of Torque and Forces Due to Compressible Flow on a Butterfly Valve Disk in Mid-stroke Position. ASME J. Fluids Eng. 2006, 128, 1074–1082. [Google Scholar] [CrossRef]

- Sibilla, S.; Gallati, M. Hydrodynamic Characterization of a Nozzle Check Valve by Numerical Simulation. ASME J. Fluids Eng. 2008, 130, 121101. [Google Scholar] [CrossRef]

- Li, G.; Liou, J.C.P. Swing Check Valve Characterization and Modeling during Transients. ASME J. Fluids Eng. 2003, 125, 1043–1050. [Google Scholar] [CrossRef]

- Lai, Z.; Karney, B.; Yang, S.; Wu, D.; Zhang, F. Transient performance of a dual disc check valve during the opening period. Ann. Nucl. Energy 2017, 101, 15–22. [Google Scholar] [CrossRef]

- Li, W.; Gao, Z.; Jin, Z.; Qian, J. Transient Study of Flow and Cavitation Inside a Bileaflet Mechanical Heart Valve. Appl. Sci. 2020, 10, 2548. [Google Scholar] [CrossRef]

- Farrell, R.; Ezekoye, L.I.; Rain, M. Check valve flow and disk lift simulation using CFD. In Proceedings of the ASME 2017 Pressure Vessels and Piping Conference, Volume 7: Operations, Applications and Components, Waikoloa, HI, USA, 16–20 July 2017. [Google Scholar]

- Tran, P.D. Pressure Transients Caused by Tilting-Disk Check-Valve Closure. J. Hydraul. Eng. 2015, 141, 4014081. [Google Scholar] [CrossRef]

- Qian, J.; Hou, C.; Li, X.; Jin, Z. Actuation Mechanism of Microvalves: A Review. Micromachines 2020, 11, 172. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, M.; Xu, B. Design and experimental research of a miniature digital hydraulic valve. Micromachines 2018, 9, 283. [Google Scholar] [CrossRef] [PubMed]

- Qian, J.Y.; Li, X.J.; Wu, Z.; Jin, Z.J.; Sunden, B. A comprehensive review on liquid–liquid two-phase flow in microchannel: Flow pattern and mass transfer. Microfluid. Nanofluid. 2019, 23, 116. [Google Scholar] [CrossRef]

- Qian, J.Y.; Li, X.J.; Wu, Z.; Jin, Z.J.; Zhang, J.; Sunden, B. Slug formation analysis of liquid–liquid two-phase flow in T-junction microchannels. J. Therm. Sci. Eng. Appl. 2019, 11, 051017. [Google Scholar] [CrossRef]

- Bui, G.T.; Wang, J.; Lin, J. Optimization of micropump performance utilizing a single membrane with an active check valve. Micromachines 2017, 9, 1. [Google Scholar] [CrossRef]

- Ou, K.; Jackson, J.; Burt, H.; Chiao, M. Microspheres as resistive elements in a check valve for low pressure and low flow rate conditions. Lab Chip 2012, 12, 4372. [Google Scholar] [CrossRef]

- Qian, J.; Chen, M.; Liu, X.; Jin, Z. A numerical investigation of the flow of nanofluids through a micro Tesla valve. J. Zhejiang Univ. Sci. A 2019, 20, 50–60. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, Z. Microfluidic Passive Flow Regulatory Device with an Integrated Check Valve for Enhanced Flow Control. Micromachines 2019, 10, 653. [Google Scholar] [CrossRef]

- Jin, Z.; Gao, Z.; Zhang, M.; Liu, B.; Qian, J. Computational fluid dynamics analysis on orifice structure inside valve core of pilot-control angle globe valve. Proc. Inst. Mech. Eng. Part C 2018, 232, 2419–2429. [Google Scholar] [CrossRef]

- Jin, Z.; Qiu, C.; Jiang, C.; Wu, J.; Qian, J. Effect of valve core shapes on cavitation flow through a sleeve regulating valve. J. Zhejiang Univ. Sci. A 2020, 21, 1–14. [Google Scholar] [CrossRef]

- Jin, Z.; Gao, Z.; Zhang, M.; Qian, J. Pressure Drop Analysis of Pilot-Control Globe Valve With Different Structural Parameters. ASME J. Fluids Eng. 2017, 139, 091102. [Google Scholar] [CrossRef]

- Barton, P.T.; Obadia, B.; Drikakis, D. A conservative level-set based method for compressible solid/fluid problems on fixed grids. J. Comput. Phys. 2011, 230, 7867–7890. [Google Scholar] [CrossRef]

- Tsoutsanis, P.; Titarev, V.A.; Drikakis, D. WENO schemes on arbitrary mixed-element unstructured meshes in three space dimensions. J. Comput. Phys. 2011, 230, 1585–1601. [Google Scholar] [CrossRef]

- Chen, F.; Qian, J.; Chen, M.; Zhang, M.; Chen, L.; Jin, Z. Turbulent compressible flow analysis on multi-stage high pressure reducing valve. Flow Meas. Instrum. 2018, 61, 26–37. [Google Scholar] [CrossRef]

- Qian, J.; Wei, L.; Zhang, M.; Chen, F.; Chen, L.; Jiang, W.; Jin, Z. Flow rate analysis of compressible superheated steam through pressure reducing valves. Energy 2017, 135, 650–658. [Google Scholar] [CrossRef]

| Grid Number × 106 | Pressure Difference/Pa | Error/% |

|---|---|---|

| 0.8 | 1419.20 | −1.6% |

| 1.8 | 1442.69 | - |

| 3.7 | 1433.62 | −0.63% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Z.-x.; Liu, P.; Yue, Y.; Li, J.-y.; Wu, H. Comparison of Swing and Tilting Check Valves Flowing Compressible Fluids. Micromachines 2020, 11, 758. https://doi.org/10.3390/mi11080758

Gao Z-x, Liu P, Yue Y, Li J-y, Wu H. Comparison of Swing and Tilting Check Valves Flowing Compressible Fluids. Micromachines. 2020; 11(8):758. https://doi.org/10.3390/mi11080758

Chicago/Turabian StyleGao, Zhi-xin, Ping Liu, Yang Yue, Jun-ye Li, and Hui Wu. 2020. "Comparison of Swing and Tilting Check Valves Flowing Compressible Fluids" Micromachines 11, no. 8: 758. https://doi.org/10.3390/mi11080758

APA StyleGao, Z.-x., Liu, P., Yue, Y., Li, J.-y., & Wu, H. (2020). Comparison of Swing and Tilting Check Valves Flowing Compressible Fluids. Micromachines, 11(8), 758. https://doi.org/10.3390/mi11080758