Shaping Soft Robotic Microactuators by Wire Electrical Discharge Grinding

Abstract

1. Introduction

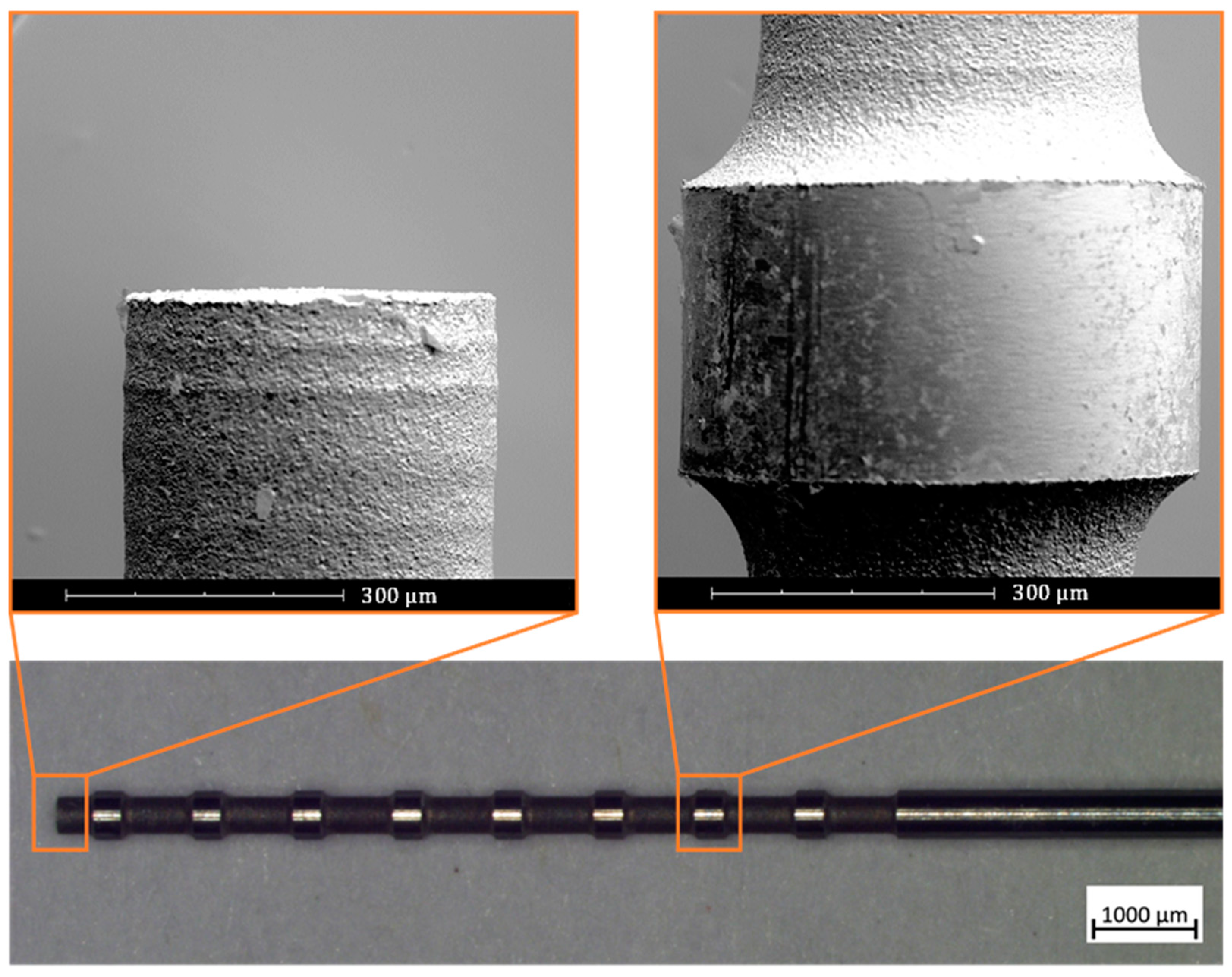

2. Materials and Methods

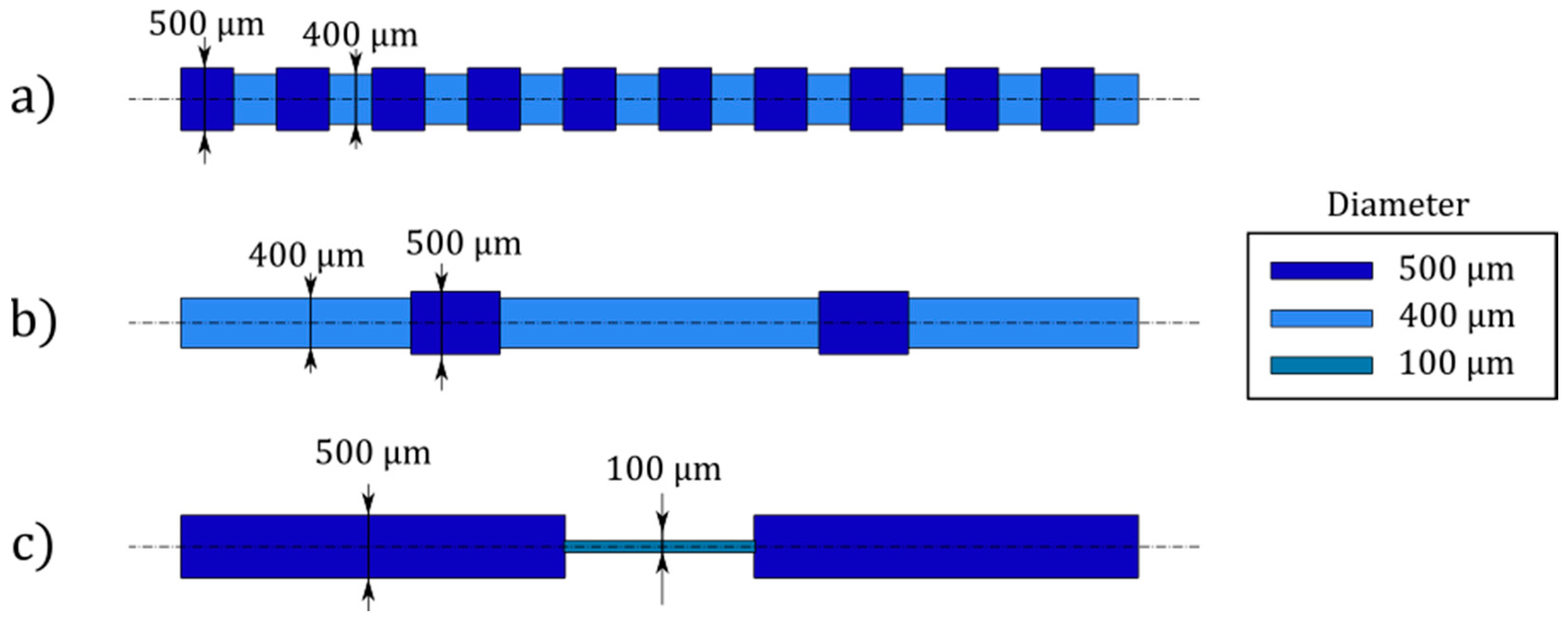

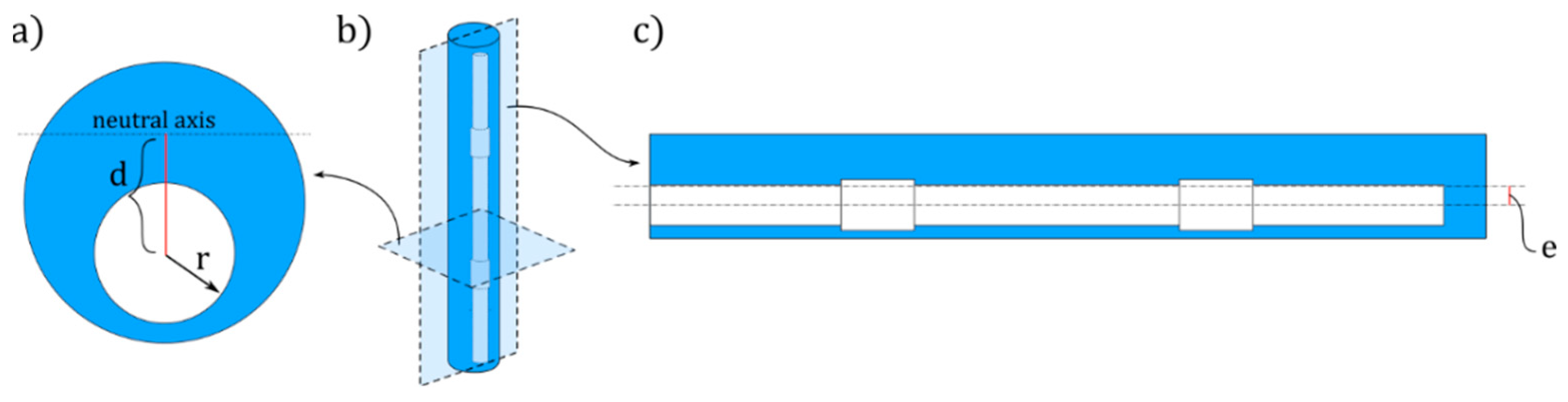

2.1. Inflatable Cavity Morphologies

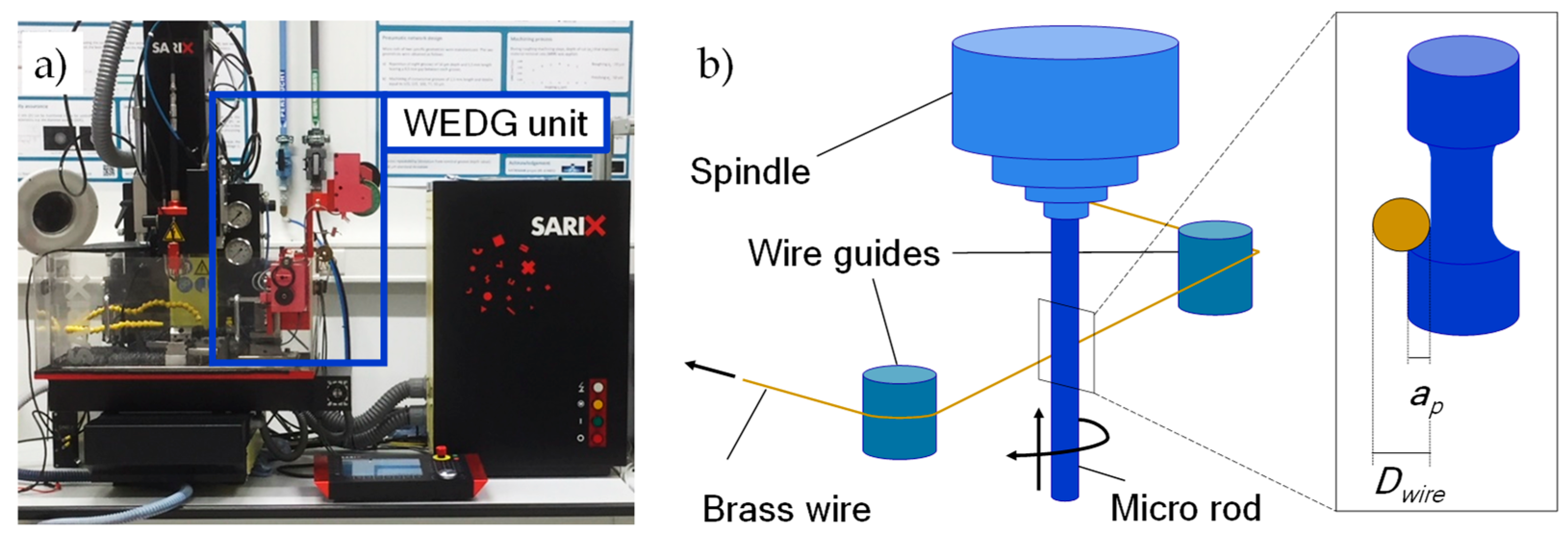

2.2. WEDG Process

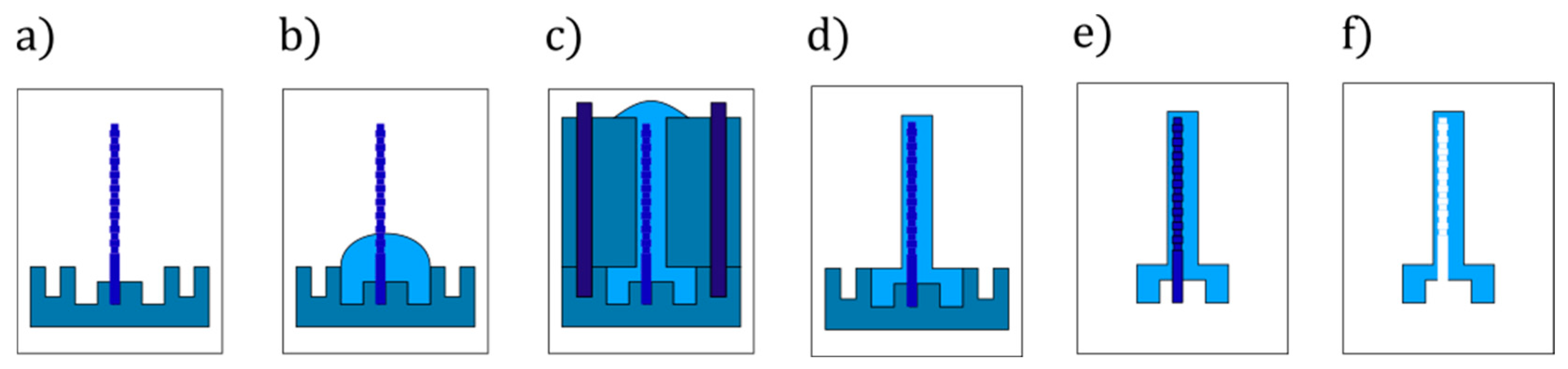

2.3. Moulding

2.4. Analytical Model

2.5. Microactuators Experimental Setup

3. Results and Discussions

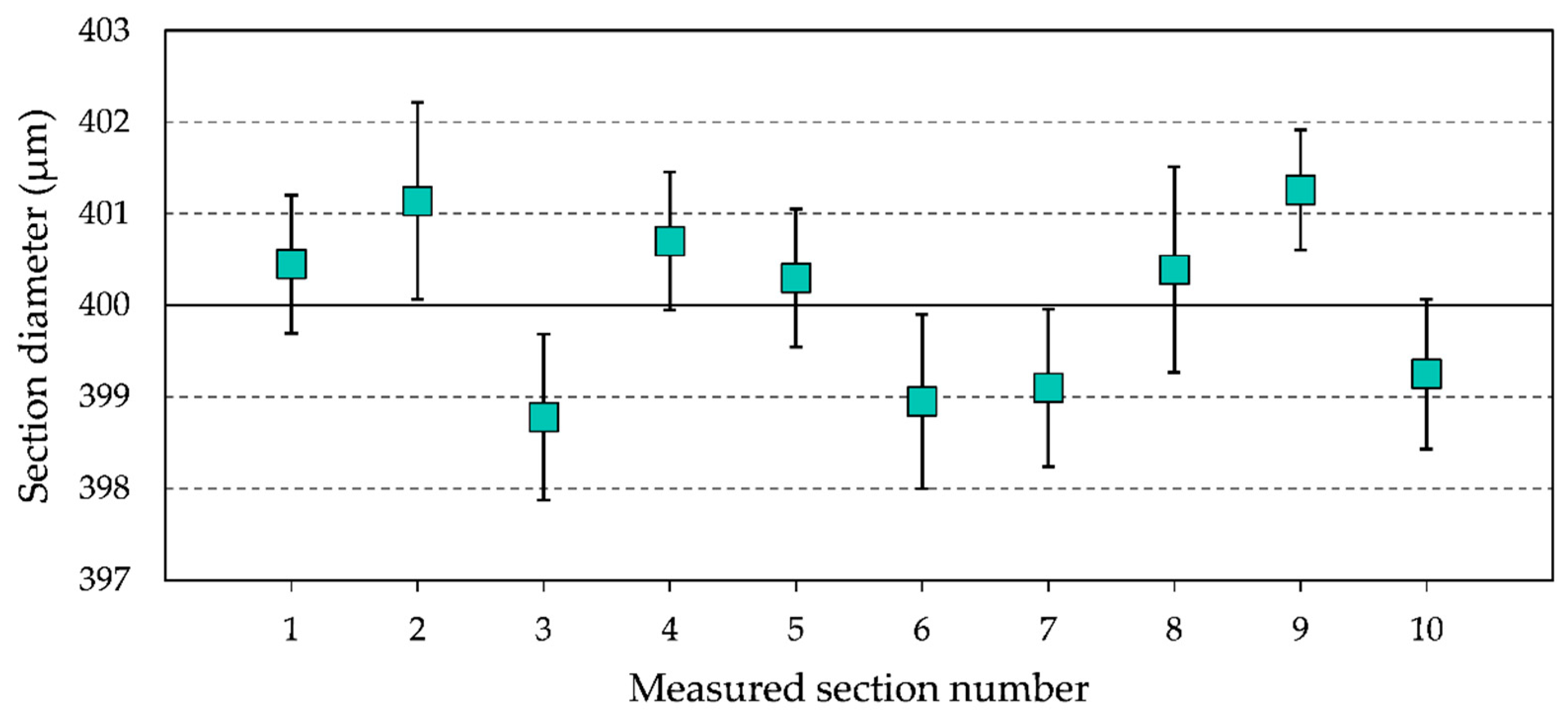

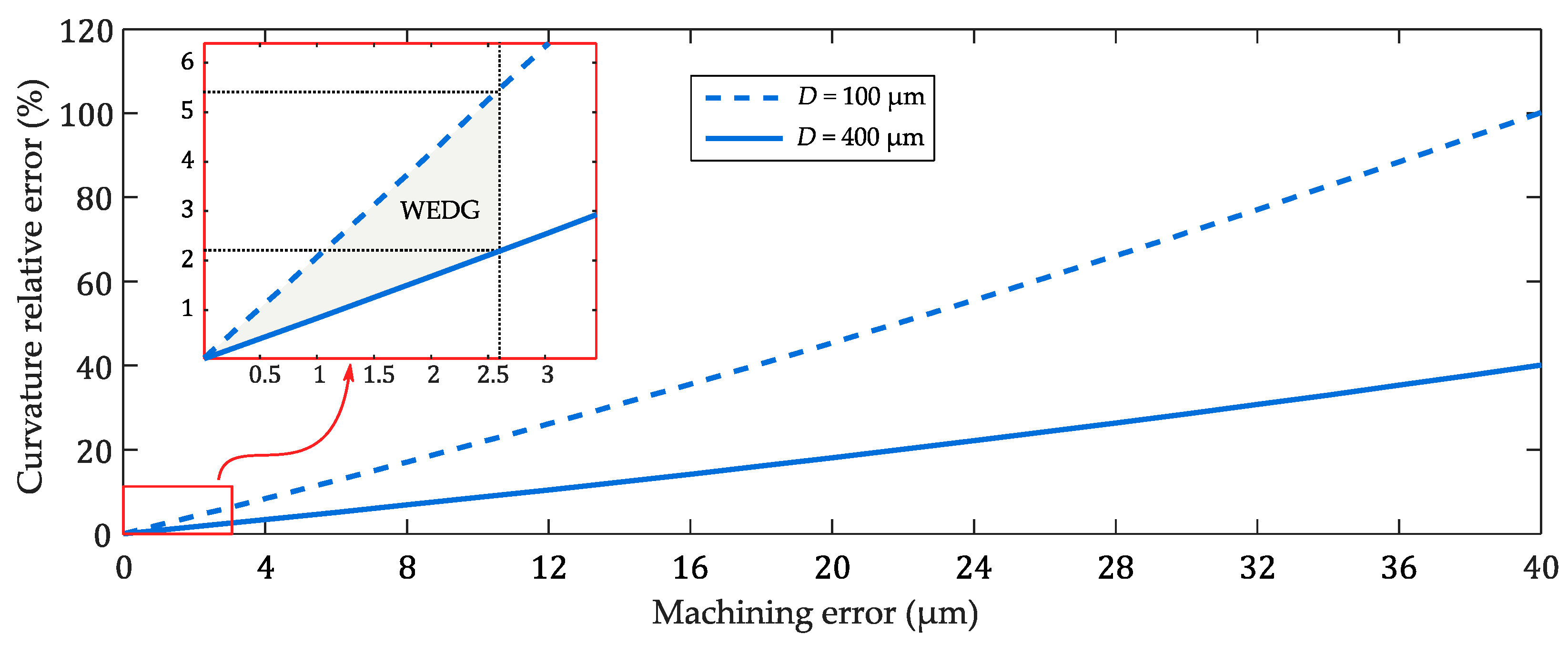

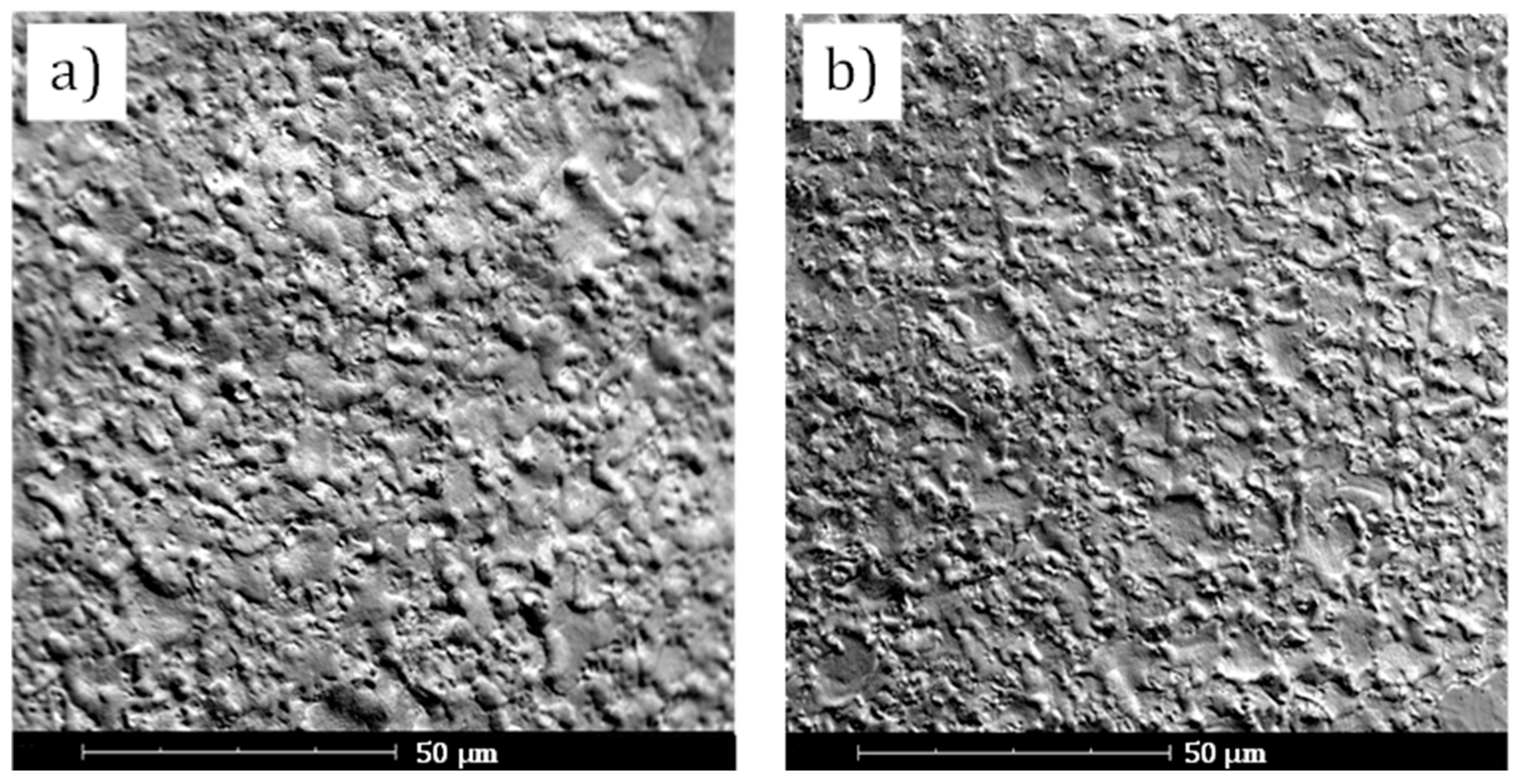

3.1. WEDG Accuracy and Quality

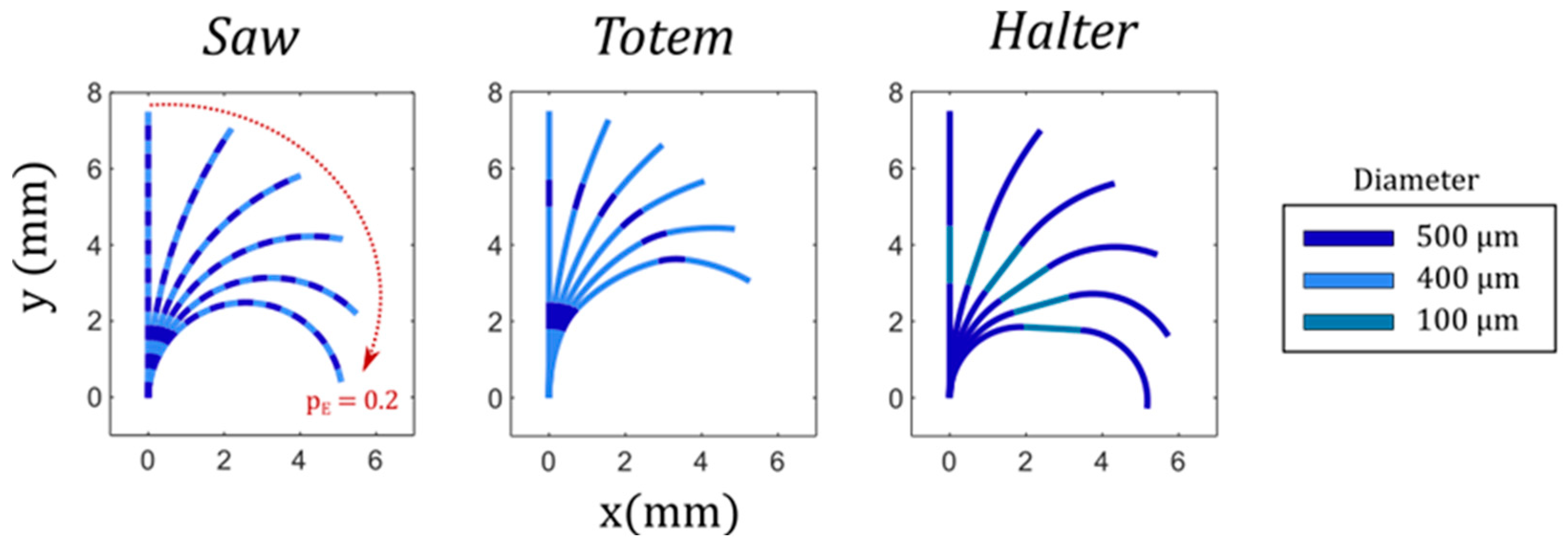

3.2. Microactuators Analytical Model

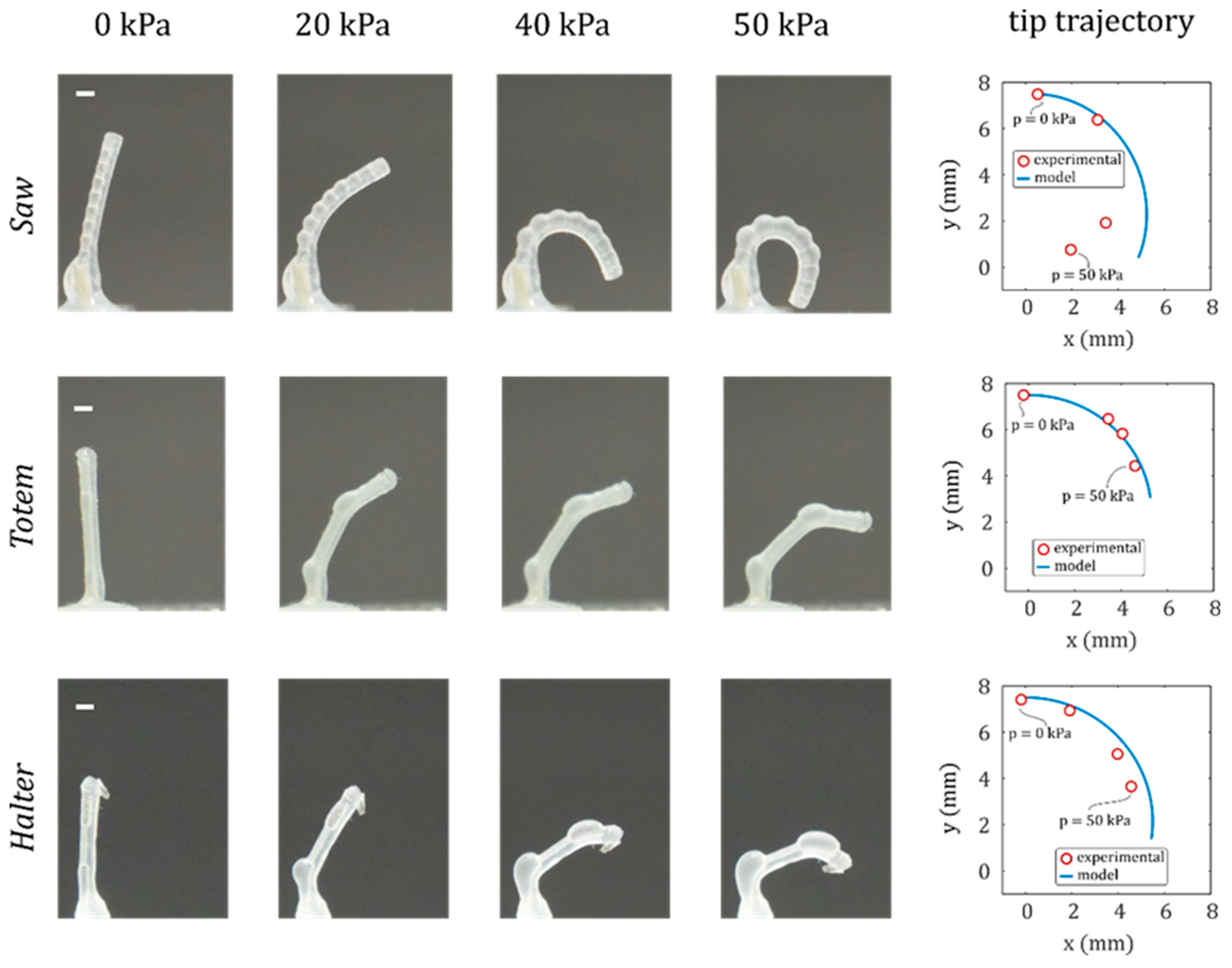

3.3. Microactuators’ Characterisation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Rus, D.; Tolley, M.T. Design, fabrication and control of soft robots. Nature 2015, 521, 467–475. [Google Scholar] [CrossRef]

- Kim, S.; Laschi, C.; Trimmer, B. Soft robotics: A bioinspired evolution in robotics. Trends Biotechnol. 2013, 31, 287–294. [Google Scholar] [CrossRef]

- Shintake, J.; Cacucciolo, V.; Floreano, D.; Shea, H. Soft Robotic Grippers. Adv. Mater. 2018, 30, 1707035. [Google Scholar] [CrossRef]

- Soft Robotics Inc. Available online: https://www.softroboticsinc.com (accessed on 5 March 2020).

- Hawkes, E.W.; Blumenschein, L.H.; Greer, J.D.; Okamura, A.M. A soft robot that navigates its environment through growth. Sci. Robot. 2017, 2, eaan3028. [Google Scholar] [CrossRef]

- Shepherd, R.F.; Ilievski, F.; Choi, W.; Morin, S.A.; Stokes, A.A.; Mazzeo, A.D.; Chen, X.; Wang, M.; Whitesides, G.M. Multigait soft robot. Proc. Natl. Acad. Sci. USA 2011, 108, 20400–20403. [Google Scholar] [CrossRef]

- Wehner, M.; Truby, R.L.; Fitzgerald, D.J.; Mosadegh, B.; Whitesides, G.M.; Lewis, J.A.; Wood, R.J. An integrated design and fabrication strategy for entirely soft, autonomous robots. Nature 2016, 536, 451–455. [Google Scholar] [CrossRef]

- Hines, L.; Petersen, K.; Lum, G.Z.; Sitti, M. Soft Actuators for Small-Scale Robotics. Adv. Mater. 2017, 29, 1603483. [Google Scholar] [CrossRef] [PubMed]

- Konishi, S. Small, soft, safe micromachine for minimally invasive surgery. In Proceedings of the IMFEDK International Meeting for Future of Electron Devices, Osaka, Japan, 9–11 May 2012. [Google Scholar]

- De Greef, A.; Lambert, P.; Delchambre, A. Towards flexible medical instruments: Review of flexible fluidic actuators. Precis. Eng. 2009, 33, 311–321. [Google Scholar] [CrossRef]

- Mosadegh, B.; Tavana, H.; Lesher-Perez, S.C.; Takayama, S. High-density fabrication of normally closed microfluidic valves by patterned deactivation of oxidized polydimethylsiloxane. Lab Chip 2011, 11, 738–742. [Google Scholar] [CrossRef] [PubMed]

- Den Toonder, J.M.J.; Onck, P.R. Microfluidic manipulation with artificial/bioinspired cilia. Trends Biotechnol. 2013, 31, 85–91. [Google Scholar] [CrossRef] [PubMed]

- Gorissen, B.; Reynaerts, D.; Konishi, S.; Yoshida, K.; Kim, J.-W.; De Volder, M. Elastic Inflatable Actuators for Soft Robotic Applications. Adv. Mater. 2017, 1604977. [Google Scholar] [CrossRef] [PubMed]

- Suzumori, K.; Iikura, S.; Tanaka, H. Development of flexible microactuator and its applications to robotic mechanisms. In Proceedings of the IEEE International Conference on Robotics and Automation, Sacramento, CA, USA, 9–11 April 1991; pp. 1622–1627. [Google Scholar]

- Wakimoto, S.; Ogura, K.; Suzumori, K.; Nishioka, Y. Miniature soft hand with curling rubber pneumatic actuators. In Proceedings of the IEEE International Conference on Robotics and Automation, Kobe, Japan, 12–17 May 2009; pp. 556–561. [Google Scholar]

- Konishi, S.; Kawai, F.; Cusin, P. Thin flexible end-effector using pneumatic balloon actuator. Sens. Actuators A Phys. 2001, 89, 28–35. [Google Scholar] [CrossRef]

- Polygerinos, P.; Correll, N.; Morin, S.A.; Mosadegh, B.; Onal, C.D.; Petersen, K.; Cianchetti, M.; Tolley, M.T.; Shepherd, R.F. Soft Robotics: Review of Fluid-Driven Intrinsically Soft Devices; Manufacturing, Sensing, Control, and Applications in Human-Robot Interaction. Adv. Eng. Mater. 2017, 19, 1–22. [Google Scholar] [CrossRef]

- Gorissen, B.; Vincentie, W.; Al-Bender, F.; Reynaerts, D.; De Volder, M. Modeling and bonding-free fabrication of flexible fluidic microactuators with a bending motion. J. Micromech. Microeng. 2013, 23, 45012. [Google Scholar] [CrossRef]

- Connolly, F.; Walsh, C.J.; Bertoldi, K. Automatic design of fiber-reinforced soft actuators for trajectory matching. Proc. Natl. Acad. Sci. USA 2016, 114, 51–56. [Google Scholar] [CrossRef]

- Chou, C.P.; Hannaford, B. Measurement and modeling of McKibben pneumatic artificial muscles. IEEE Trans. Robot. Autom. 1996, 12, 90–102. [Google Scholar] [CrossRef]

- Overvelde, J.T.B.; Kloek, T.; D’haen, J.J.; Bertoldi, K. Amplifying the response of soft actuators by harnessing snap-through instabilities. Proc. Natl. Acad. Sci. USA 2015, 112, 10863–10868. [Google Scholar] [CrossRef]

- Mosadegh, B.; Polygerinos, P.; Keplinger, C.; Wennstedt, S.; Shepherd, R.F.; Gupta, U.; Shim, J.; Bertoldi, K.; Walsh, C.J.; Whitesides, G.M. Pneumatic networks for soft robotics that actuate rapidly. Adv. Funct. Mater. 2014, 24, 2163–2170. [Google Scholar] [CrossRef]

- Gorissen, B.; De Volder, M.; De Greef, A.; Reynaerts, D. Theoretical and experimental analysis of pneumatic balloon microactuators. Sens. Actuators A Phys. 2011, 168, 58–65. [Google Scholar] [CrossRef]

- Milana, E.; Gorissen, B.; Peerlinck, S.; De Volder, M.; Reynaerts, D. Artificial Soft Cilia with Asymmetric Beating Patterns for Biomimetic Low-Reynolds-Number Fluid Propulsion. Adv. Funct. Mater. 2019, 29, 1900462. [Google Scholar] [CrossRef]

- Gorissen, B.; De Volder, M.; Reynaerts, D. Chip-on-tip endoscope incorporating a soft robotic pneumatic bending microactuator. Biomed. Microdevices 2018, 20, 73. [Google Scholar] [CrossRef] [PubMed]

- Masuzawa, T.; Fujino, M.; Kobayashi, K.; Suzuki, T.; Kinoshita, N. Wire Electro-Discharge Grinding for Micro-Machining. CIRP Ann. Manuf. Technol. 1985, 34, 431–434. [Google Scholar] [CrossRef]

- Fleischer, J.; Masuzawa, T.; Schmidt, J.; Knoll, M. New applications for micro-EDM. J. Mater. Process. Technol. 2004, 149, 246–249. [Google Scholar] [CrossRef]

- Wang, Y.-Q.; Bellotti, M.; Li, Z.; Qian, J.; Reynaerts, D. Twin-wire electrical discharge grinding for shaping tapered micro rods. In Proceedings of the 19th International Conference and Exhibition of the European Society for Precision Engineering and Nanotechnology, EUSPEN 2019, Bilbao, Spain, 3–7 June 2019. [Google Scholar]

- Wang, Y.; Chen, X.; Gan, W.; Wang, Z.; Guo, C. Complex Rotary Structures Machined by Micro-WEDM. Procedia CIRP 2016, 42, 743–747. [Google Scholar]

- Sheu, D.Y. Study on an evaluation method of micro CMM spherical stylus tips by µ-EDM on-machine measurement. J. Micromech. Microeng. 2010, 20, 075003. [Google Scholar] [CrossRef]

- Diver, C.; Atkinson, J.; Helml, H.J.; Li, L. Micro-EDM drilling of tapered holes for industrial applications. J. Mater. Process. Technol. 2004, 149, 296–303. [Google Scholar] [CrossRef]

- Zhang, L.; Tong, H.; Li, Y. Precision machining of micro tool electrodes in micro EDM for drilling array micro holes. Precis. Eng. 2015, 39, 100–106. [Google Scholar] [CrossRef]

- De Volder, M.; Peirs, J.; Reynaerts, D.; Coosemans, J.; Puers, R.; Smal, O.; Raucent, B. Production and characterization of a hydraulic microactuator. J. Micromech. Microeng. 2005, 15, S15. [Google Scholar] [CrossRef]

- Bellotti, M.; Milana, E.; Gorissen, B.; Qian, J.; Reynaerts, D. Wire electrical discharge grinding of micro rods for bonding-free fabrication of soft pneumatic microactuators. In Proceedings of the 18th International Conference and Exhibition of the European Society for Precision Engineering and Nanotechnology, EUSPEN 2018, Venice, Italy, 4–8 June 2018. [Google Scholar]

- Bellotti, M.; Qian, J.; Reynaerts, D. Enhancement of the micro-EDM process for drilling through-holes. Procedia CIRP 2018, 68, 610–615. [Google Scholar] [CrossRef]

- Milana, E.; Bellotti, M.; Gorissen, B.; De Volder, M.; Reynaerts, D. Precise bonding-free micromoulding of miniaturized elastic inflatable actuators. In Proceedings of the RoboSoft 2019–2019 IEEE International Conference on Soft Robotics, Seoul, Korea, 14–18 April 2019; pp. 768–773. [Google Scholar]

- Paek, J.; Cho, I.; Kim, J. Microrobotic tentacles with spiral bending capability based on shape-engineered elastomeric microtubes. Sci. Rep. 2015, 5, 10768. [Google Scholar] [CrossRef]

- Polygerinos, P.; Wang, Z.; Overvelde, J.T.B.; Galloway, K.C.; Wood, R.J.; Bertoldi, K.; Walsh, C.J. Modeling of Soft Fiber-Reinforced Bending Actuators. IEEE Trans. Robot. 2015, 31, 778–789. [Google Scholar] [CrossRef]

- Jahan, M.P.; Rahman, M.; Wong, Y.S. A review on the conventional and micro-electrodischarge machining of tungsten carbide. Int. J. Mach. Tools Manuf. 2011, 51, 837–858. [Google Scholar] [CrossRef]

- Delaney, K.D.; Bissacco, G.; Kennedy, D. Demoulding force prediction for micro polymer replication: A review of relevant literature. In Proceedings of the 6th International Conference on Multi Material Micro Manufacture (4M), Bourg en Bresse and Oyonnax, France, 17–19 November 2010. [Google Scholar]

- Gent, A.N. Elastic instabilities in rubber. Int. J. Non-Linear Mech. 2005, 40, 165–175. [Google Scholar] [CrossRef]

- Moseley, P.; Florez, J.M.; Sonar, H.A.; Agarwal, G.; Curtin, W.; Paik, J. Modeling, Design, and Development of Soft Pneumatic Actuators with Finite Element Method. Adv. Eng. Mater. 2016, 18, 978–988. [Google Scholar] [CrossRef]

| Morphology | Segments | Lengths (mm) |

|---|---|---|

| Saw | 20 | 0.4–0.35 (×10) |

| Totem | 5 | 1.8–0.7–2.5–0.7–1.8 |

| Halter | 3 | 3–1.5–3 |

| Parameter | Symbol | Unit | Machining Regime | |

|---|---|---|---|---|

| Roughing | Finishing | |||

| Open voltage | U0 | V | 120 | 85 |

| Capacitance 1 | C | nF | 5 | 1.5 |

| Pulse-on time | TON | μs | 5 | 4 |

| Pulse-off time | TOFF | μs | 3 | 2 |

| Reference voltage | Ue | V | 85 | 72 |

| Spindle rotation | R | rev/min | 850 | 700 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Milana, E.; Bellotti, M.; Gorissen, B.; Qian, J.; De Volder, M.; Reynaerts, D. Shaping Soft Robotic Microactuators by Wire Electrical Discharge Grinding. Micromachines 2020, 11, 661. https://doi.org/10.3390/mi11070661

Milana E, Bellotti M, Gorissen B, Qian J, De Volder M, Reynaerts D. Shaping Soft Robotic Microactuators by Wire Electrical Discharge Grinding. Micromachines. 2020; 11(7):661. https://doi.org/10.3390/mi11070661

Chicago/Turabian StyleMilana, Edoardo, Mattia Bellotti, Benjamin Gorissen, Jun Qian, Michaël De Volder, and Dominiek Reynaerts. 2020. "Shaping Soft Robotic Microactuators by Wire Electrical Discharge Grinding" Micromachines 11, no. 7: 661. https://doi.org/10.3390/mi11070661

APA StyleMilana, E., Bellotti, M., Gorissen, B., Qian, J., De Volder, M., & Reynaerts, D. (2020). Shaping Soft Robotic Microactuators by Wire Electrical Discharge Grinding. Micromachines, 11(7), 661. https://doi.org/10.3390/mi11070661