Developing a Novel Miniature 3D-Printed TLBS with High Mechanical Efficiency and Better Controllability

Abstract

1. Introduction

2. TLBS Modeling

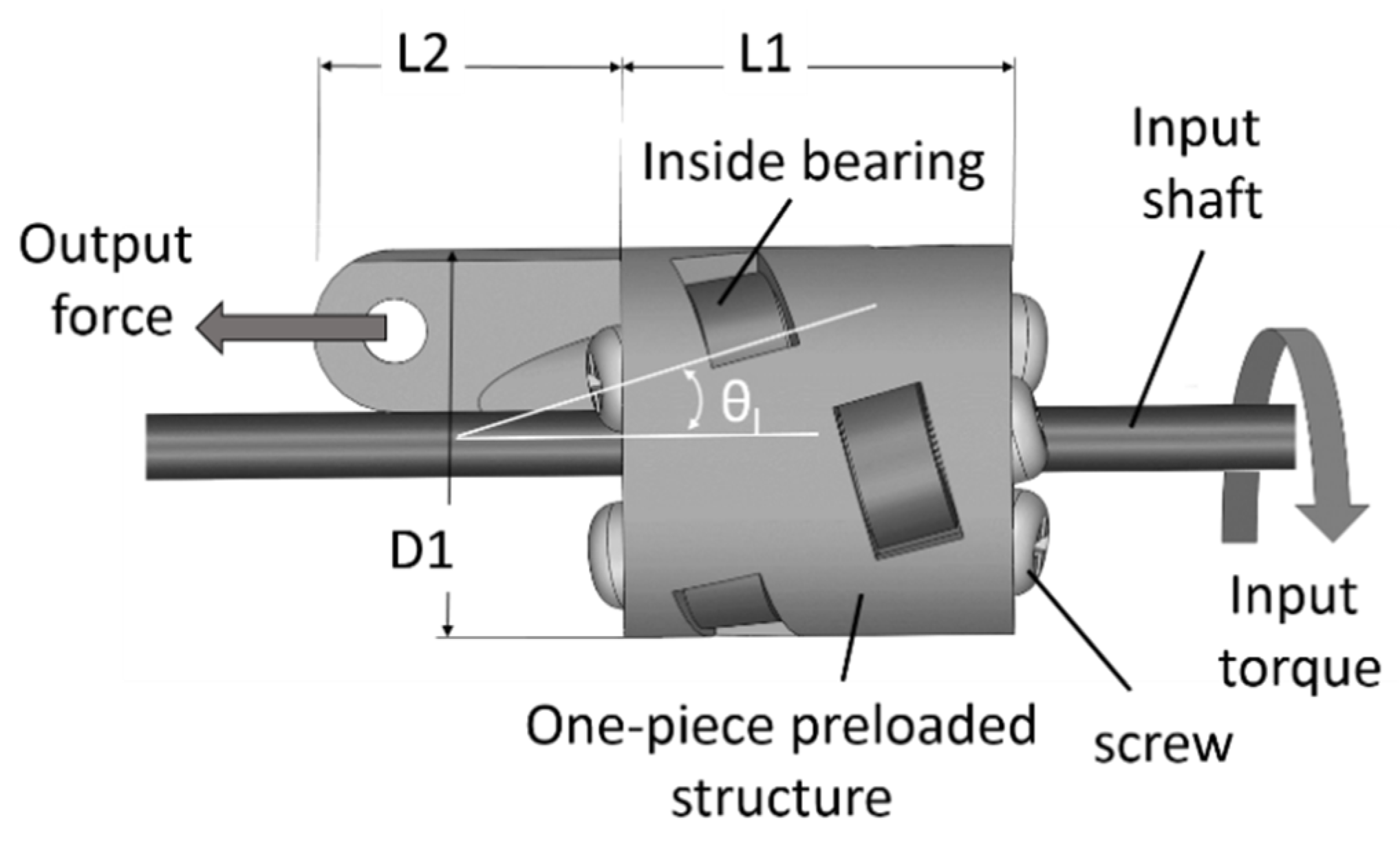

2.1. Design Parameters for Fabrication and Other Variables

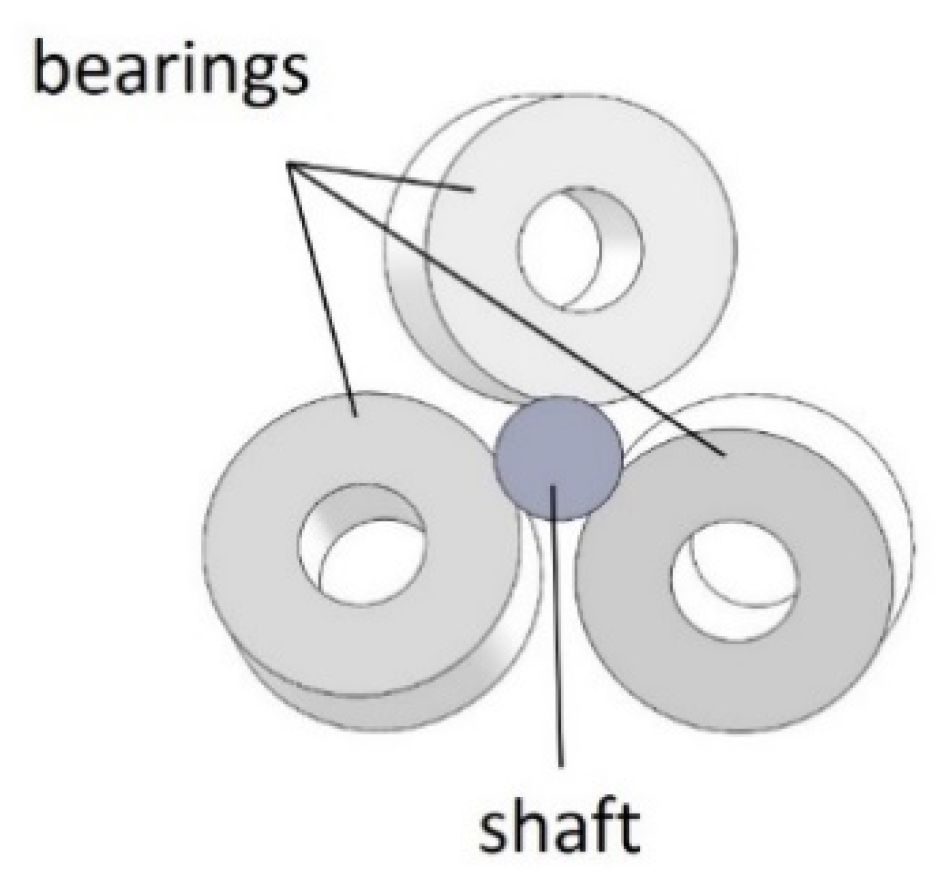

2.2. Basic Working Principle

2.3. Analysis of Mechanical Efficiency

3. Design and Implementation

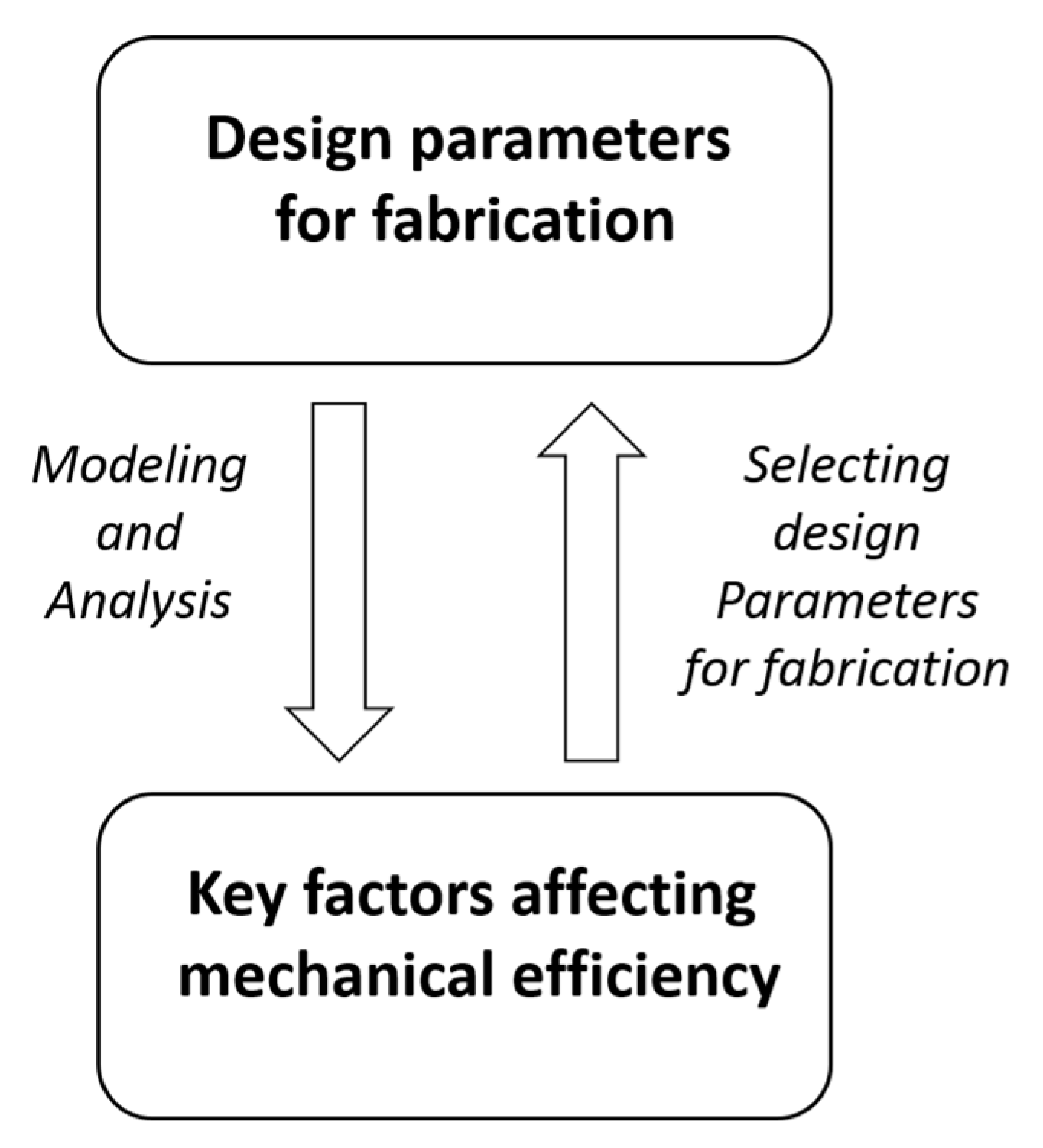

3.1. Key Factors Affecting Mechanical Efficiency and Design Parameters for Fabrication

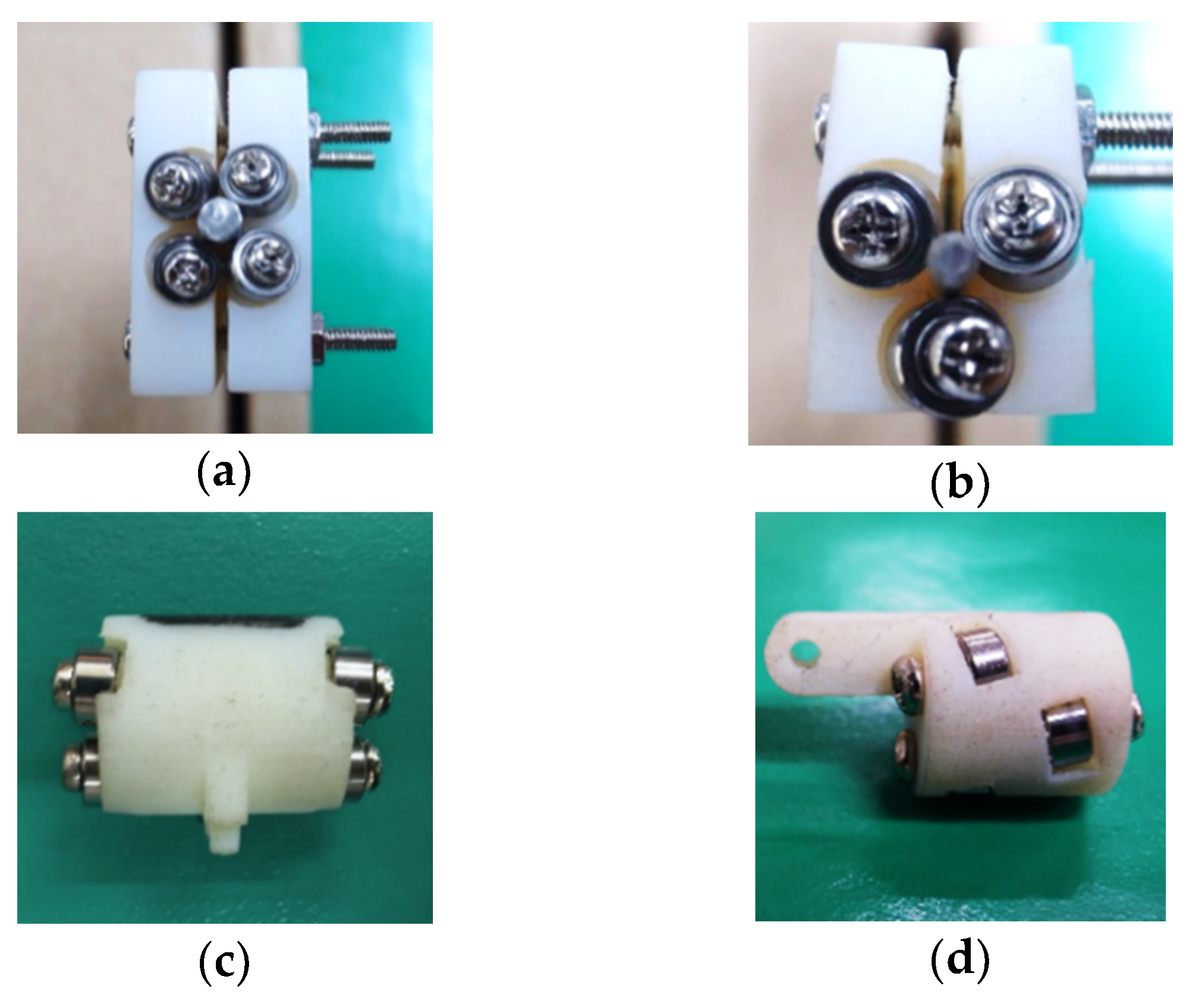

3.2. Design and Implementation of the Novel Miniature 3D Printed TLBS

4. Experimental Results and Discussion

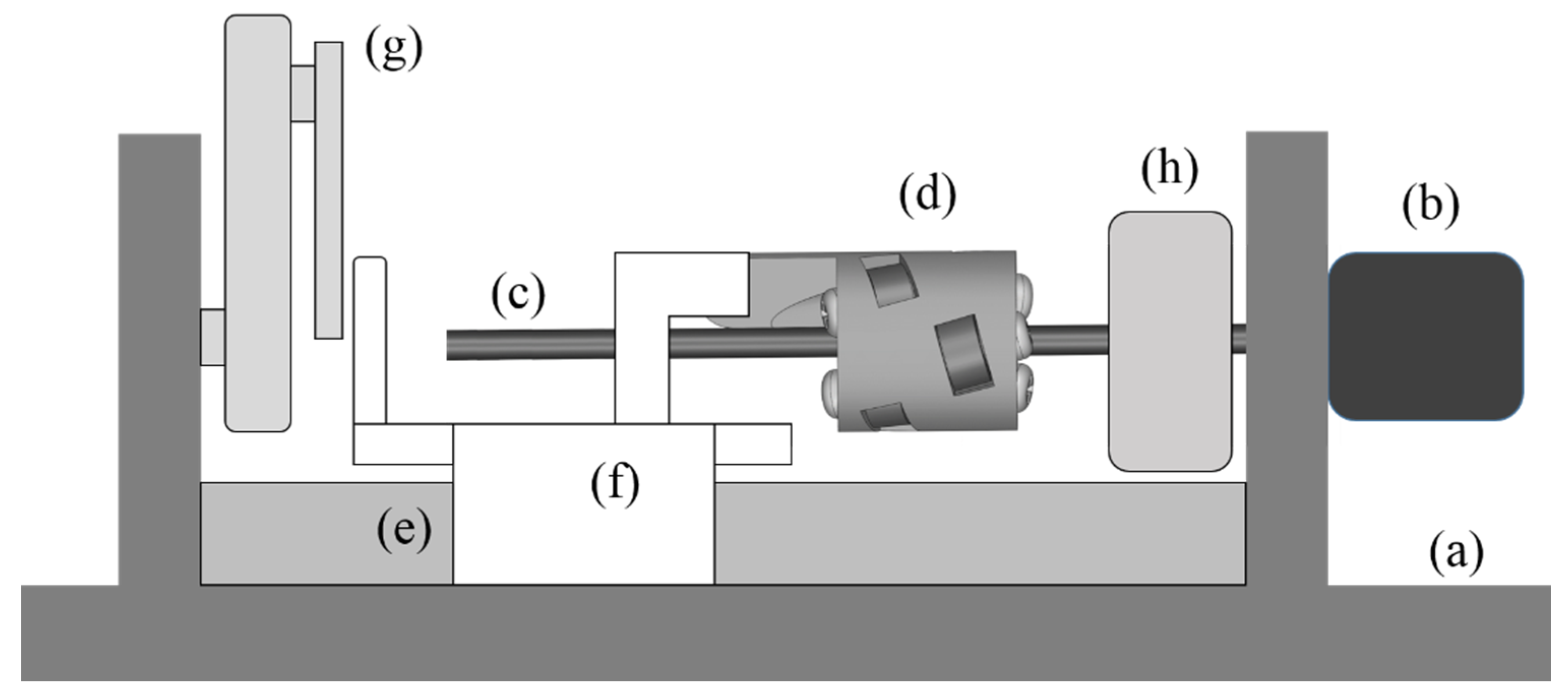

4.1. Experiment Set-Up

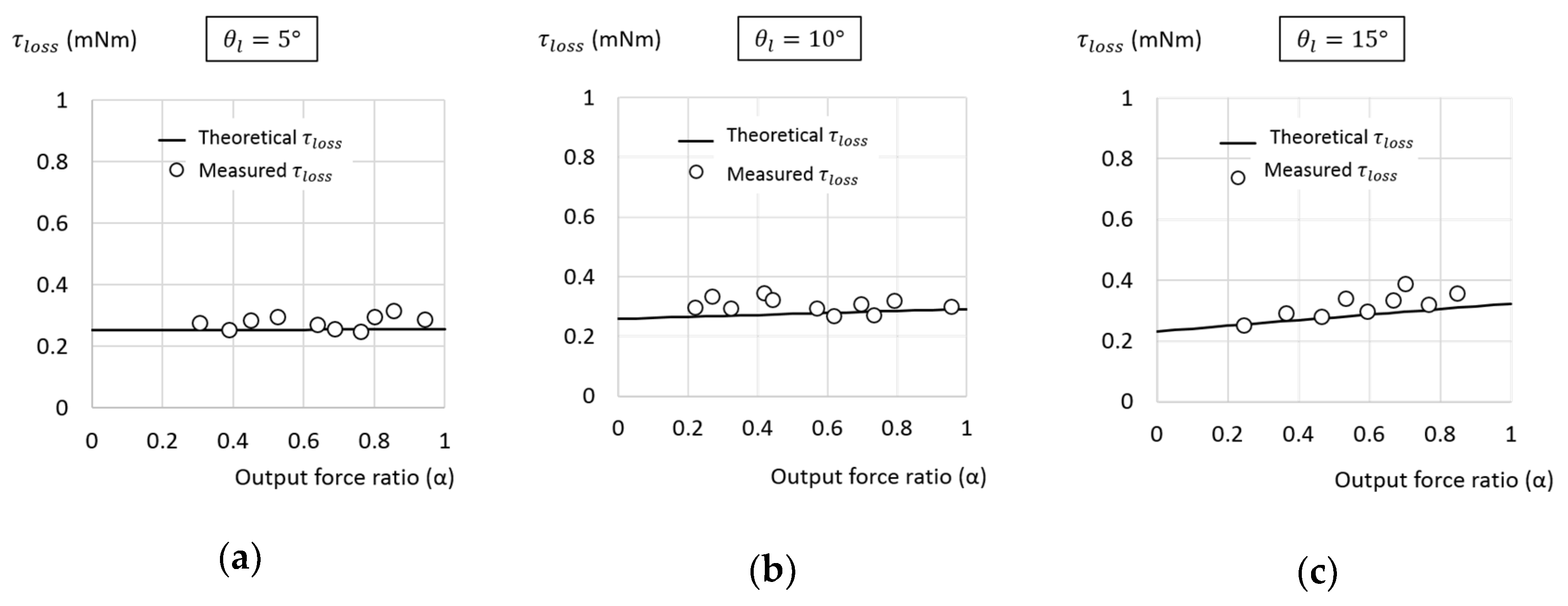

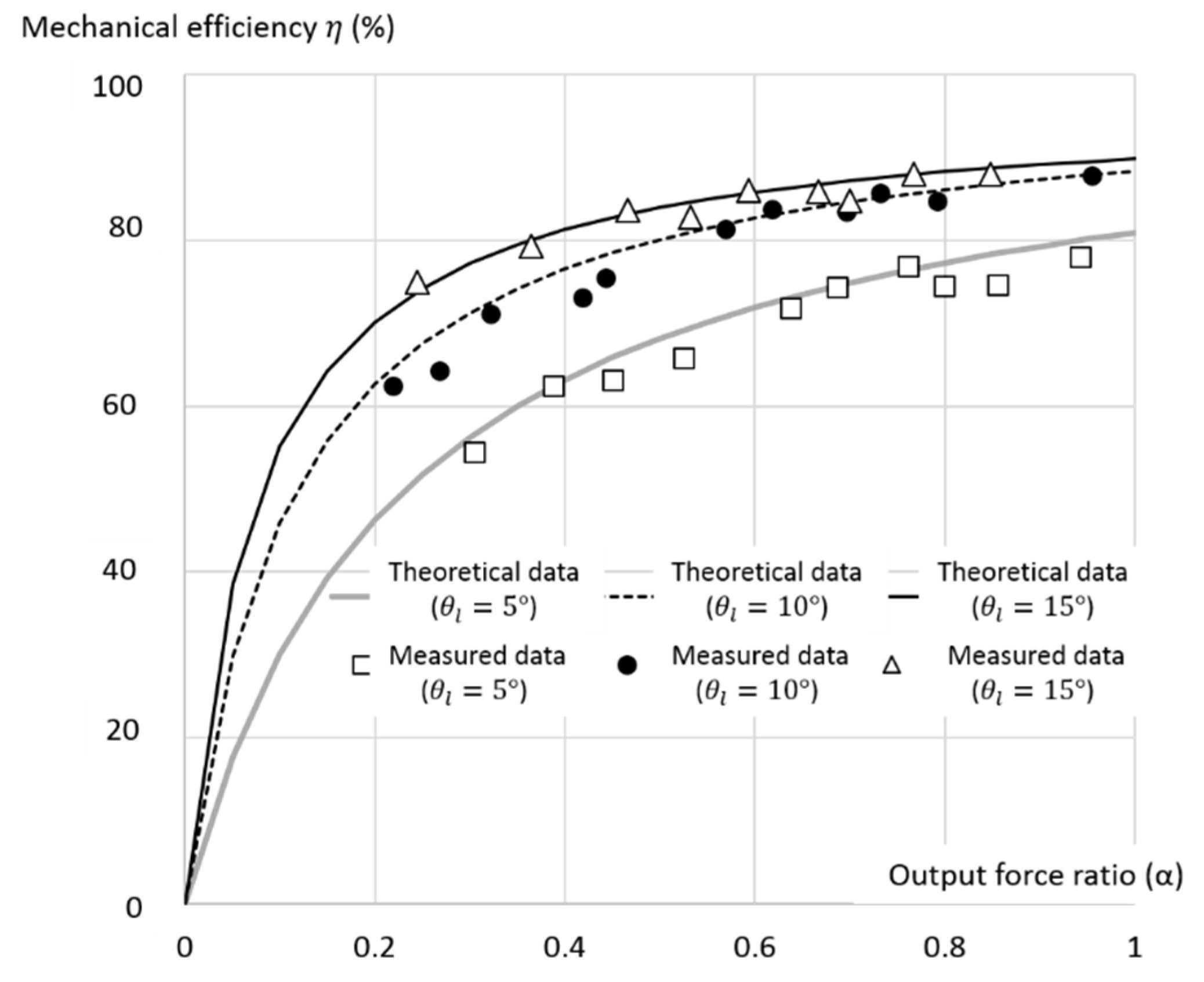

4.2. Results and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.L.; Gibson, L.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. CIRP Ann. Manuf. Technol. 2016, 65, 737–760. [Google Scholar] [CrossRef]

- Melenka, G.W.; Schofield, J.S.; Dawson, M.R.; Carey, J.P. Evaluation of dimensional accuracy and material properties of the MakerBot 3D desktop printer. Rapid Prototyp. J. 2015, 21, 618–627. [Google Scholar] [CrossRef]

- Farré-Lladós, J.; Casals-Terré, J.; Voltas, J.; Westerberg, L.G. The use of rapid prototyping techniques (RPT) to manufacture micro channels suitable for high operation pressures and μPIV. Rapid Prototyp. J. 2016, 22, 67–76. [Google Scholar] [CrossRef]

- Fernandez-Vicente, M.; Chust, A.E.; Conejero, A. Low cost digital fabrication approach for thumb orthoses. Rapid Prototyp. J. 2017, 23, 1020–1031. [Google Scholar] [CrossRef]

- Dahake, S.W.; Kuthe, A.M.; Mawale, M.B.; Bagde, A.D. Applications of medical rapid prototyping assisted customized surgical guides in complex surgeries. Rapid Prototyp. J. 2016, 22, 934–946. [Google Scholar] [CrossRef]

- Jansen, B.; Doubrovski, E.L.; Verlinden, J.C. Animaris Geneticus Parvus: Design of a complex multi-body walking mechanism. Rapid Prototyp. J. 2014, 20, 311–319. [Google Scholar] [CrossRef]

- Stöckli, F.; Modica, F.; Shea, K. Designing passive dynamic walking robots for additive manufacture. Rapid Prototyp. J. 2016, 22, 842–847. [Google Scholar] [CrossRef]

- Wei, X.; Tian, Y.; Joneja, A. A study on revolute joints in 3D-printed non-assembly mechanisms. Rapid Prototyp. J. 2016, 22, 901–933. [Google Scholar] [CrossRef]

- Tovmachenko, O.; Feng, L.; Mousa, A.M.; Ullah, Z.; Masoud, M.A. A Capsule-Type Device for Soft Tissue Cutting Using a Threadless Ballscrew Actuator. In Proceedings of the International Conference on Manipulation, Automation and Robotics at Small Scales (MARSS), Helsinki, Finland, 1 July 2019; pp. 1–6. [Google Scholar]

- Dudek, K.K.; Gatt, R.; Mizzi, L.; Dudek, M.R.; Attard, D.J.; Grima, N. Global rotation of mechanical metamaterials induced by their internal deformation. AIP Adv. 2017, 7, 095121. [Google Scholar] [CrossRef]

- Lin, M.C.; Ravani, B.; Velinsky, S.A. Design of the ball screw mechanism for optimal efficiency. J. Mech. Des. 1994, 116, 856–861. [Google Scholar] [CrossRef]

- Hung, J.P.; Wu, J.S.S.; Chiu, J.Y. Impact failure analysis of re-circulating mechanism in ball screw. Eng. Fail. Anal. 2004, 11, 561–573. [Google Scholar] [CrossRef]

- Xu, X.; Song, X.; Zhang, Z.; Jiang, H. A Novel Design Method to Reduce the Impact between Ball and Re-circulating Mechanism in Ball Screws. In Proceedings of the IEEE 10th International Conference on Computer-Aided Industrial Design & Conceptual Design, Wenzhou, China, 26 November 2009; pp. 682–685. [Google Scholar]

- Uhing, J. Arrangement for Transforming a Rotary Movement of a Smooth Shaft into a Thrust Movement of a Rolling Nut. U.S. Patent No. 4253342, 3 March 1981. [Google Scholar]

- Hu, J.; Wang, M.; Zan, T. The kinematics of ball-screw mechanisms via the slide-roll ratio. Mech. Mach. Theory 2014, 79, 158–172. [Google Scholar] [CrossRef]

- Xu, N.; Tang, W.; Chen, Y.; Bao, D.; Guo, Y. Modeling analysis and experimental study for the friction of a ball screw. Mech. Mach. Theory 2015, 87, 57–69. [Google Scholar] [CrossRef]

- Zhou, C.-G.; Feng, H.-T.; Ou, Y. A new model for predicting the mechanical efficiency of ball screws based on the empirical equations for the friction torque of rolling bearings. Adv. Mech. Eng. 2018, 10. [Google Scholar] [CrossRef]

- Tsai, P.C.; Cheng, C.C.; Hwang, Y.C. Ball screw preload loss detection using ball pass frequency. Mech. Syst. Signal. Process. 2014, 48, 77–91. [Google Scholar] [CrossRef]

- Dodds, K.J.; Kaminer, I. Rotational to Linear Actuator. U.S. Patent No. 4947698, 14 August 1990. [Google Scholar]

- Swanberg, M.E. Linear Actuator. U.S. Patent No.3777578, 11 December 1973. [Google Scholar]

- Rasmussen, J.; Hauberg, O. Friction Drive Mechanism for Converting a Rotational Movement Into an Axial Movement, or Vice Versa. U.S. Patent No.4246802, 27 January 1981. [Google Scholar]

- Barrett, R.T. Fastener Design Manual; NASA Reference Publication 1228; Lewis Research Center: Cleveland, OH, USA, 1990. [Google Scholar]

- Armillotta, A.; Cavallaro, M. Edge quality in fused deposition modeling: I. Definition and analysis. Rapid Prototyp. J. 2017, 23, 1079–1087. [Google Scholar] [CrossRef]

- Lifton, V.A.; Lifton, G.; Simon, S. Options for additive rapid prototyping methods (3D printing) in MEMS technology. Prototyp. J. 2014, 20, 403–412. [Google Scholar] [CrossRef]

- Chockalingam, K.; Jawahar, N.; Chandrasekhar, U. Influence of layer thickness on mechanical properties in stereolithography. Prototyp. J. 2006, 12, 106–113. [Google Scholar] [CrossRef]

- Objet Eden 250 3D Printing System Specifications. Available online: www.cati.com/3d-printing/objet-eden-printers/eden-250/ (accessed on 24 June 2020).

- Kingssel 3040 Specification. Available online: www.mastech3d.squarespace.com/model-kingssel3040/ (accessed on 24 June 2020).

- MakeItFrom, Material Properties Database. Overview of Materials for Polylactic Acid (PLA). Available online: www.makeitfrom.com/material-properties/Polylactic-Acid-PLA-Polylactide (accessed on 24 June 2020).

- MatWeb, Your Source for Materials Information. Overview of Materials for RGD525 High Temperature Material 2018. Available online: www.matweb.com/ (accessed on 20 February 2018).

- The Precision Alliance, Ball Screw Efficiency. Available online: www.tpa-us.com/ball-screws.html (accessed on 20 February 2018).

- Rolling Ring Linear Drive. Available online: https://www.uhing.com/en/products/linear-drive-nut (accessed on 24 June 2020).

| Symbol | Description |

|---|---|

| Preload of TLBS, the total normal forces. | |

| The normal forces between the shaft and the preloaded bearings, i is the ith bearing. | |

| The output force of the TLBS nut. | |

| The maximum output force of the TLBS nut. | |

| Lead of TLBS; design parameter for fabrication. | |

| Radius of shaft; design parameter for fabrication. | |

| The output force ratio. | |

| Mechanical efficiency of TLBS. | |

| Maximum mechanical efficiency of TLBS. | |

| Lead angle: the angle between the shaft coordinate and the preloaded bearing coordinate; design parameter for fabrication. | |

| The rolling resistance coefficient. | |

| The static friction coefficient. | |

| The rolling-static ratio. | |

| The friction loss torque of bearings. | |

| The input torque of the shaft. | |

| The maximum input torque of the shaft. | |

| Total torque loss of TLBS. |

| Method | FDM | Polyjet |

| Machine | kingssel 3040 | Objet EDEN 250 |

| Layer thickness | 50–100 μm | 16 μm |

| Material | Polylactic Acid (PLA) | RGD525 |

| Density | 1.3 g/cm3 | 1.17–1.18 g/cm3 |

| Modulus of Elasticity | 3.5 GPa | 3.2–3.5 GPa |

| Tensile Strength | 50 MPa | 70–80 MPa |

| TLBS Nut | Designed Dimensions | Measured Dimensions |

| L1 | 12 mm | 12.047 ± 0.05 mm |

| L2 | 9.5 mm | 9.502 ± 0.022 mm |

| D1 | 12 mm | 12.06 ± 0.051 mm |

| Lead angle () | 15° | 14.5 ± 0.173° |

| 10° | 9.66 ± 0.152° | |

| 5° | 4.83 ± 0.321° |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, C.-W.; Chou, J.-H. Developing a Novel Miniature 3D-Printed TLBS with High Mechanical Efficiency and Better Controllability. Micromachines 2020, 11, 662. https://doi.org/10.3390/mi11070662

Lee C-W, Chou J-H. Developing a Novel Miniature 3D-Printed TLBS with High Mechanical Efficiency and Better Controllability. Micromachines. 2020; 11(7):662. https://doi.org/10.3390/mi11070662

Chicago/Turabian StyleLee, Chung-Wei, and Jung-Hua Chou. 2020. "Developing a Novel Miniature 3D-Printed TLBS with High Mechanical Efficiency and Better Controllability" Micromachines 11, no. 7: 662. https://doi.org/10.3390/mi11070662

APA StyleLee, C.-W., & Chou, J.-H. (2020). Developing a Novel Miniature 3D-Printed TLBS with High Mechanical Efficiency and Better Controllability. Micromachines, 11(7), 662. https://doi.org/10.3390/mi11070662