Design of Graphene Phononic Crystals for Heat Phonon Engineering

Abstract

1. Introduction

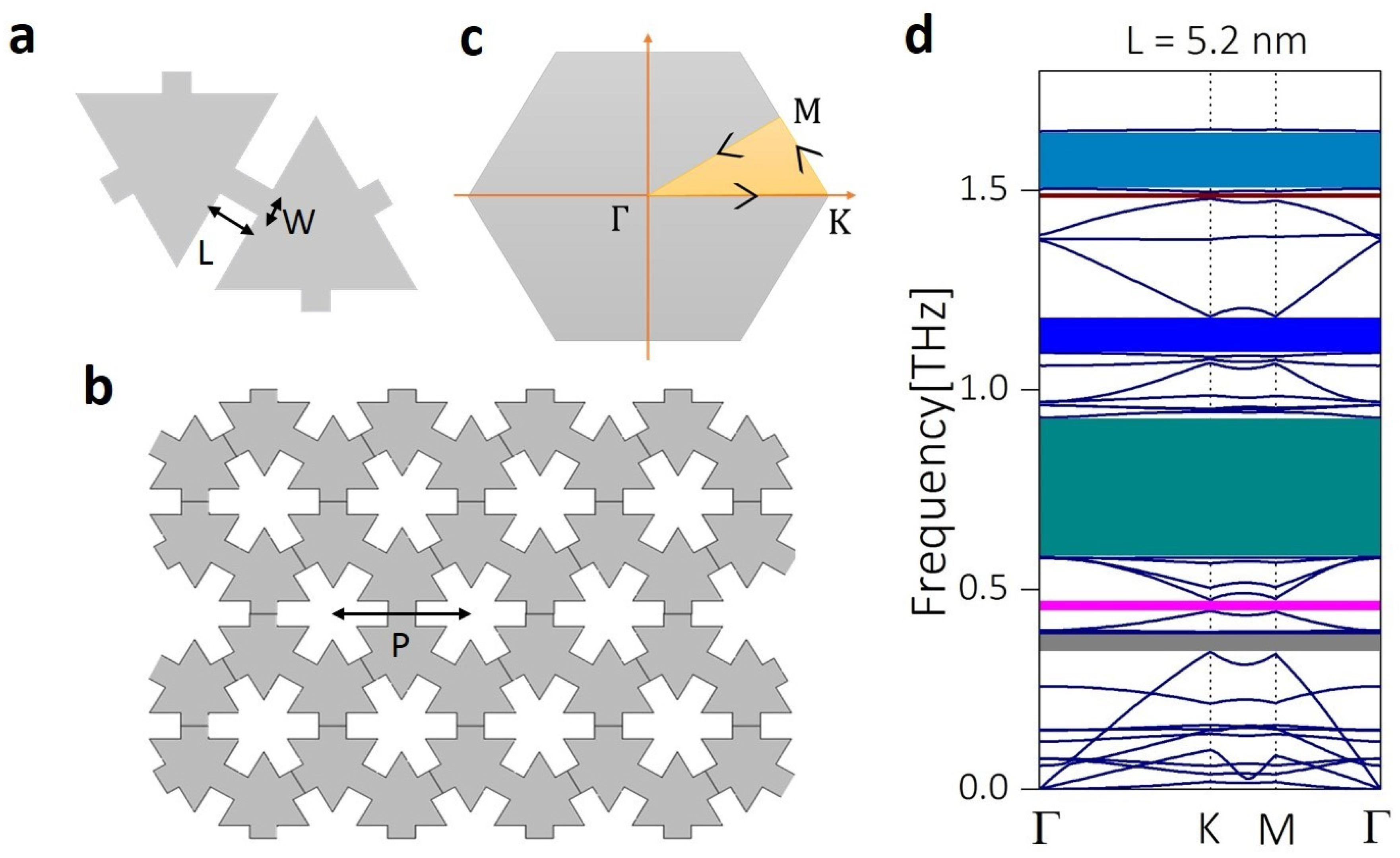

2. Computational Method

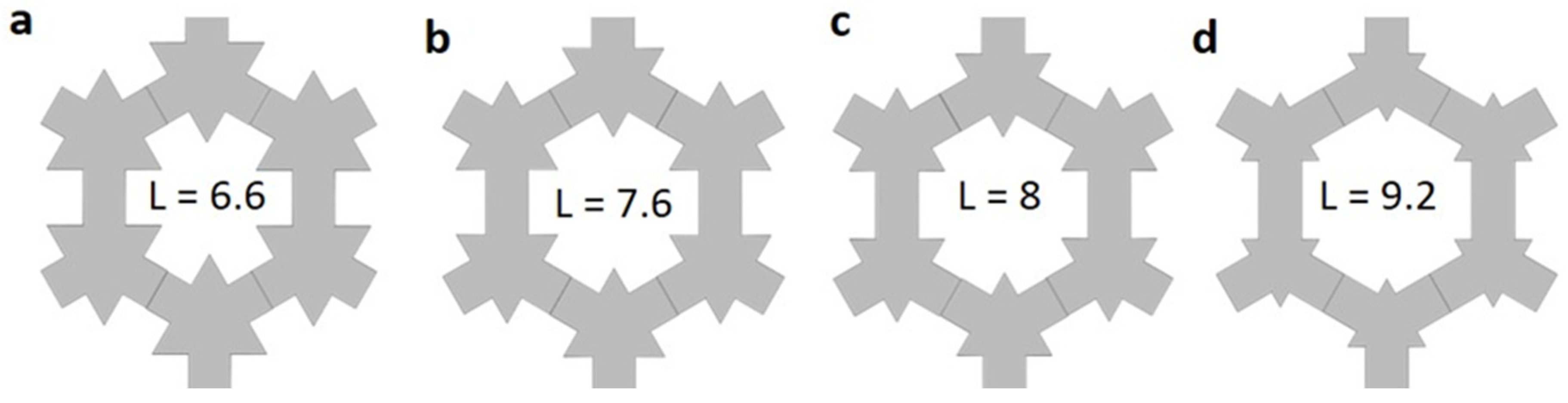

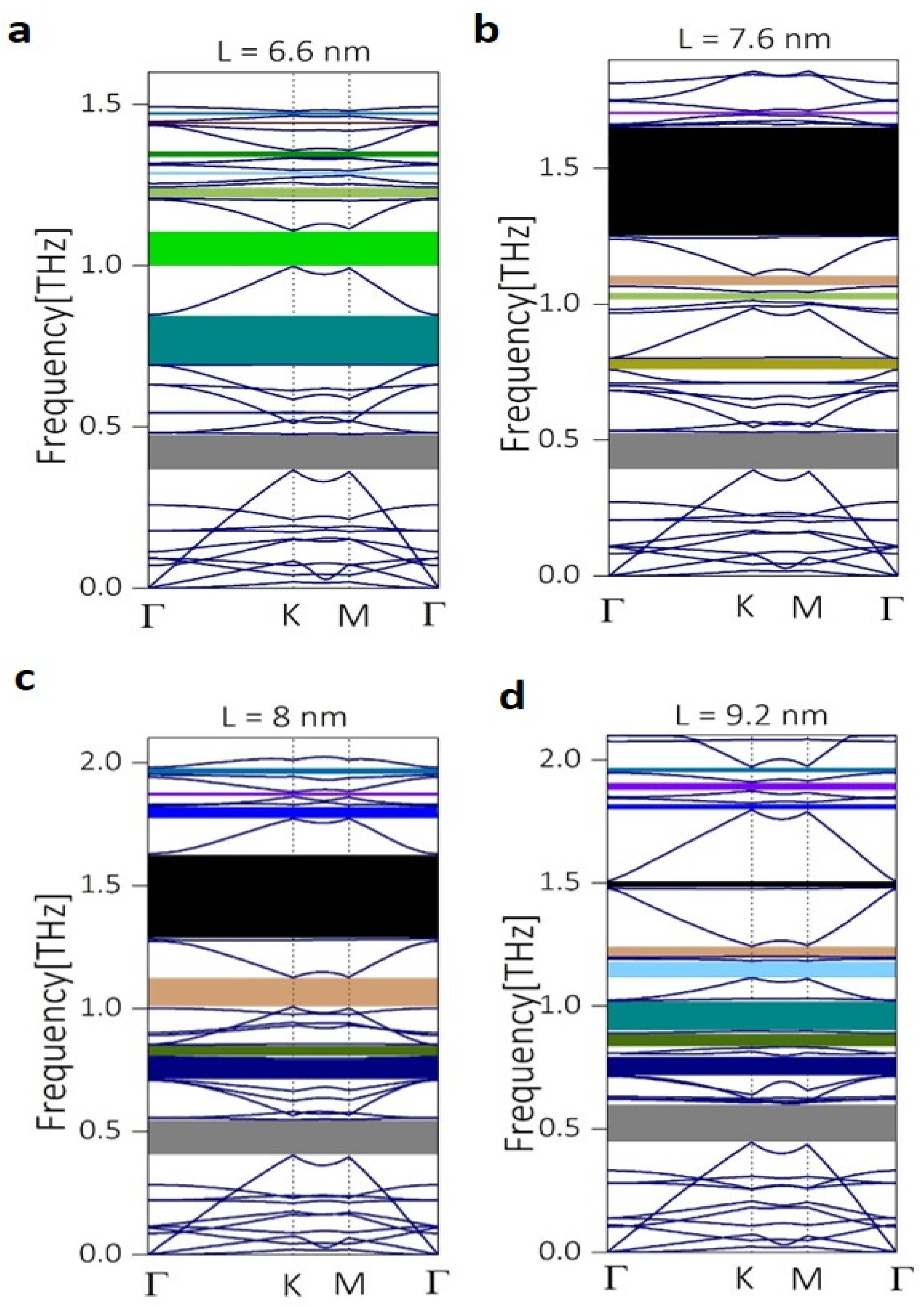

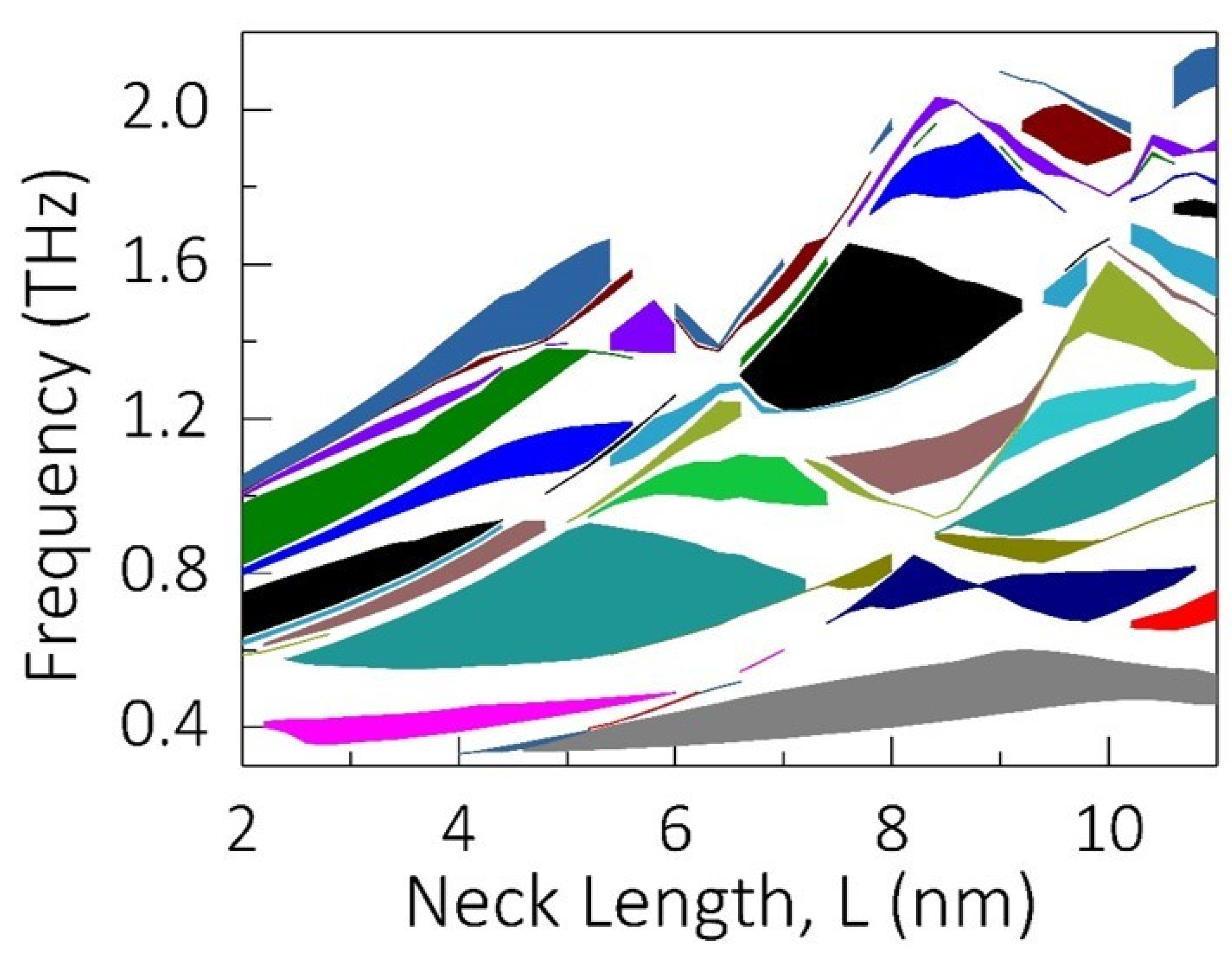

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tian, B.; Zheng, X.; Kempa, T.J.; Fang, Y.; Yu, N.; Yu, G.; Huang, J.; Lieber, C.M. Coaxial silicon nanowires as solar cells and nanoelectronic power sources. Nature 2007, 449, 885–889. [Google Scholar] [CrossRef]

- Hsu, K.F.; Loo, S.; Guo, F.; Chen, W.; Dyck, J.S.; Uher, C.; Hogan, T.; Polychroniadis, E.K.; Kanatzidis, M.G. Cubic AgPbmSbTe2+m: Bulk Thermoelectric Materials with High Figure of Merit. Science 2004, 303, 818–821. [Google Scholar] [CrossRef] [PubMed]

- Poudel, B.; Hao, Q.; Ma, Y.; Lan, Y.; Minnich, A.; Yu, B.; Yan, X.; Wang, D.; Muto, A.; Vashaee, D.; et al. High-Thermoelectric Performance of Nanostructured Bismuth Antimony Telluride Bulk Alloys. Science 2008, 320, 634–638. [Google Scholar] [CrossRef] [PubMed]

- Venkatasubramanian, R.; Siivola, E.; Colpitts, T.; O’Quinn, B. Thin-film thermoelectric devices with high room-temperature figures of merit. Nature 2001, 413, 597–602. [Google Scholar] [CrossRef] [PubMed]

- Costescu, R.M.; Cahill, D.G.; Fabreguette, F.H.; Sechrist, Z.A.; George, S.M. Ultra-Low Thermal Conductivity in W/Al2O3 Nanolaminates. Science 2004, 303, 989–990. [Google Scholar] [CrossRef] [PubMed]

- Chiritescu, C.; Cahill, D.G.; Nguyen, N.; Johnson, D.; Bodapati, A.; Keblinski, P.; Zschack, P. Ultralow Thermal Conductivity in Disordered, Layered WSe2 Crystals. Science 2007, 315, 351–353. [Google Scholar] [CrossRef]

- Hochbaum, A.I.; Chen, R.; Delgado, R.D.; Liang, W.; Garnett, E.C.; Najarian, M.; Majumdar, A.; Yang, P. Enhanced thermoelectric performance of rough silicon nanowires. Nature 2008, 451, 163–167. [Google Scholar] [CrossRef]

- Bell, L.E. Cooling, heating, generating power, and recovering waste heat with thermoelectric systems. Science 2008, 5895, 1457–1461. [Google Scholar] [CrossRef]

- Snyder, G.J.; Toberer, E.S. Complex thermoelectric materials. Nat. Mater. 2008, 7, 105–114. [Google Scholar] [CrossRef]

- Biswas, K.; He, J.; Blum, I.D.; Wu, C.-I.; Hogan, T.P.; Seidman, D.N.; Dravid, V.P.; Kanatzidis, M.G. High-performance bulk thermoelectrics with all-scale hierarchical architectures. Nature 2012, 489, 414–418. [Google Scholar] [CrossRef]

- Vineis, C.J.; Shakouri, A.; Majumdar, A.; Kanatzidis, M.G. Nanostructured Thermoelectrics: Big Efficiency Gains from Small Features. Adv. Mater. 2010, 22, 3970–3980. [Google Scholar] [CrossRef]

- Zebarjadi, M.; Esfarjani, K.; Dresselhaus, M.S.; Ren, Z.F.; Chen, G. Perspectives on thermoelectrics: From fundamentals to device applications. Bolin Liao 2012, 5, 5147–5162. [Google Scholar] [CrossRef]

- Cahill, D.G. Thermal conductivity measurement from 30 to 750 K: The 3ω method. Rev. Sci. Instrum. 1990, 61, 802–808. [Google Scholar] [CrossRef]

- Maldovan, M. Phonon wave interference and thermal bandgap materials. Nat. Mater. 2015, 14, 667–674. [Google Scholar] [CrossRef] [PubMed]

- Volz, S.; Ordonez-Miranda, J.; Shchepetov, A.; Prunnila, M.; Ahopelto, J.; Pezeril, T.; Vaudel, G.; Gusev, V.; Ruello, P.; Weig, E.M.; et al. Nanophononics: State of the art and perspectives. Eur. Phys. J. B 2016, 89, 15. [Google Scholar] [CrossRef]

- Maldovan, M. Sound and heat revolutions in phononics. Nature 2013, 503, 209–217. [Google Scholar] [CrossRef]

- Kushwaha, M.S.; Halevi, P.; Dobrzynski, L.; Djafari-Rouhani, B. Acoustic band structure of periodic elastic composites. Phys. Rev. Lett. 1993, 71, 2022–2025. [Google Scholar] [CrossRef]

- Hopkins, P.E.; Reinke, C.M.; Su, M.F.; Olsson, R.H.; Shaner, E.A.; Leseman, Z.C.; Serrano, J.R.; Phinney, L.M.; El-Kady, I. Reduction in the Thermal Conductivity of Single Crystalline Silicon by Phononic Crystal Patterning. Nano Lett. 2011, 11, 107–112. [Google Scholar] [CrossRef]

- Zen, N.; Puurtinen, T.A.; Isotalo, T.J.; Chaudhuri, S.; Maasilta, I.J. Engineering thermal conductance using a two-dimensional phononic crystal. Nat. Commun. 2014, 5, 3435. [Google Scholar] [CrossRef]

- Yang, L.; Yang, N.; Li, B. Extreme Low Thermal Conductivity in Nanoscale 3D Si Phononic Crystal with Spherical Pores. Nano Lett. 2014, 14, 1734–1738. [Google Scholar] [CrossRef]

- Wagner, M.R.; Graczykowski, B.; Reparaz, J.S.; El Sachat, A.; Sledzinska, M.; Alzina, F.; Sotomayor Torres, C.M. Two-Dimensional Phononic Crystals: Disorder Matters. Nano Lett. 2016, 16, 5661–5668. [Google Scholar] [CrossRef]

- Maire, J.; Anufriev, R.; Yanagisawa, R.; Ramiere, A.; Volz, S.; Nomura, M. Heat conduction tuning by wave nature of phonons. Sci. Adv. 2017, 3, e1700027. [Google Scholar] [CrossRef]

- Anufriev, R.; Ramiere, A.; Maire, J.; Nomura, M. Heat guiding and focusing using ballistic phonon transport in phononic nanostructures. Nat. Commun. 2017, 8, 15505. [Google Scholar] [CrossRef] [PubMed]

- Safavi-Naeini, A.H.; Painter, O. Design of optomechanical cavities and waveguides on a simultaneous bandgap phononic-photonic crystal slab. Opt. Express 2010, 18, 14926–14943. [Google Scholar] [CrossRef]

- Cahill, D.G.; Ford, W.K.; Goodson, K.E.; Mahan, G.D.; Majumdar, A.; Maris, H.J.; Merlin, R.; Phillpot, S.R. Nanoscale thermal transport. J. Appl. Phys. 2003, 93, 793–818. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Jiang, D.; Schedin, F.; Booth, T.J.; Khotkevich, V.V.; Morozov, S.V.; Geim, A.K. Two-dimensional atomic crystals. Proc. Natl. Acad. Sci. USA 2005, 102, 10451–10453. [Google Scholar] [CrossRef]

- Wang, W.; Muruganathan, M.; Kulothungan, J.; Mizuta, H. Study of dynamic contacts for graphene nano-electromechanical switches. Jpn. J. Appl. Phys. 2017, 56, 04CK05. [Google Scholar] [CrossRef]

- Kulothungan, J.; Muruganathan, M.; Mizuta, H. 3D Finite Element Simulation of Graphene Nano-Electro-Mechanical Switches. Micromachines 2016, 7, 143. [Google Scholar] [CrossRef] [PubMed]

- Muruganathan, M.; Seto, F.; Mizuta, H. Graphene Nanomechanical Resonator Mass Sensing of Mixed H2/Ar Gas. Int. J. Autom. Technol. 2018, 12, 24–28. [Google Scholar] [CrossRef]

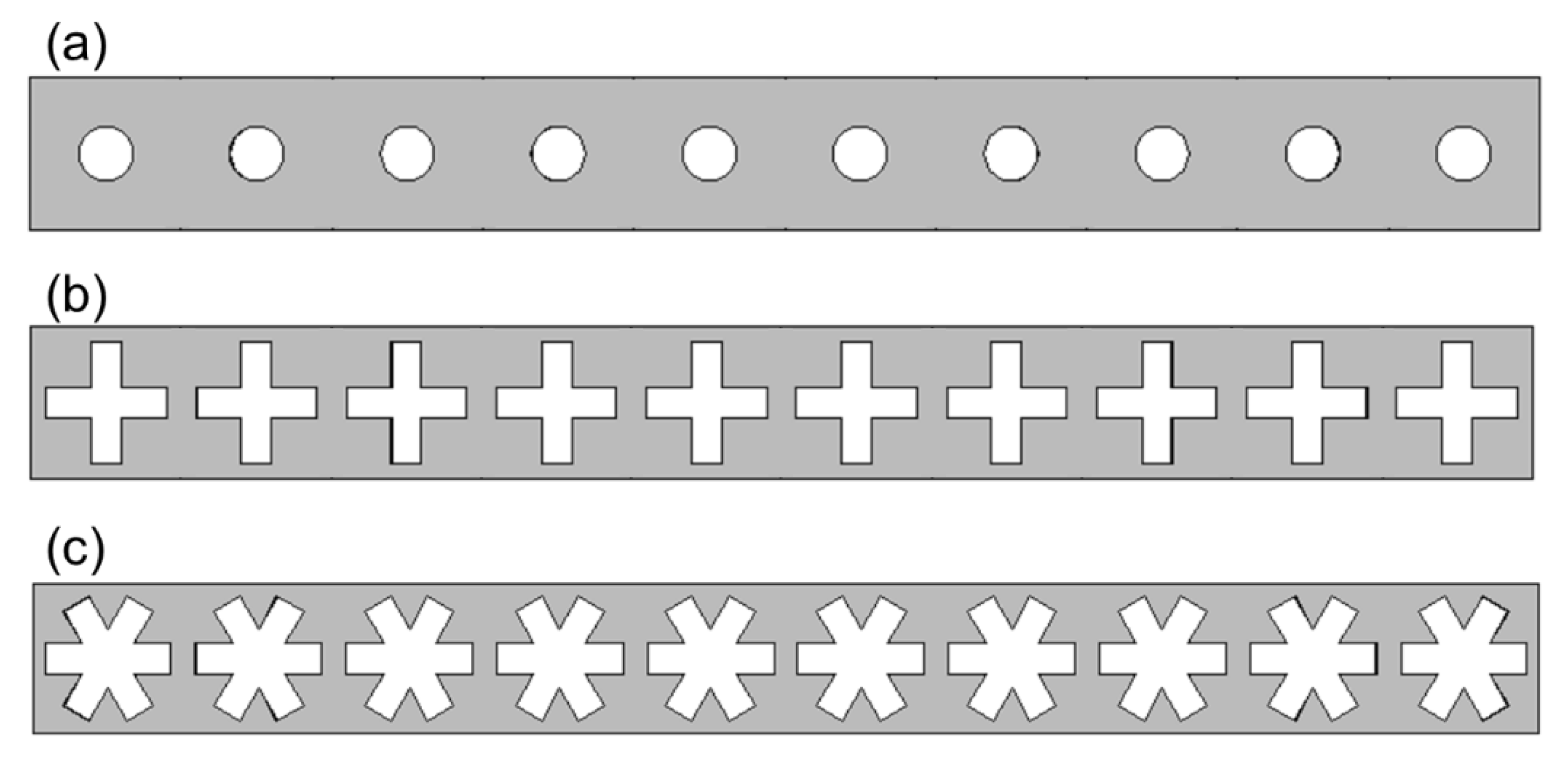

- Kubo, S.; Schimidt, M.E.; Muruganathan, M.; Mizuta, H. Finite element method simulation of graphene phononic crystals with cross-shaped nanopores. In Proceedings of the 2019 20th International Conference on Thermal, Mechanical and Multi-Physics Simulation and Experiments in Microelectronics and Microsystems (EuroSimE), Niedersachsen, Germany, 24–27 March 2019; pp. 1–5. [Google Scholar]

- Huynh Van, N.; Muruganathan, M.; Kulothungan, J.; Mizuta, H. Fabrication of a three-terminal graphene nanoelectromechanical switch using two-dimensional materials. Nanoscale 2018, 10, 12349–12355. [Google Scholar] [CrossRef]

- Sun, J.; Muruganathan, M.; Kanetake, N.; Mizuta, H. Locally-Actuated Graphene-Based Nano-Electro-Mechanical Switch. Micromachines 2016, 7, 124. [Google Scholar] [CrossRef]

- Muruganathan, M.; Sun, J.; Imamura, T.; Mizuta, H. Electrically Tunable van der Waals Interaction in Graphene–Molecule Complex. Nano Lett. 2015, 15, 8176–8180. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Muruganathan, M.; Mizuta, H. Room temperature detection of individual molecular physisorption using suspended bilayer graphene. Sci. Adv. 2016, 2, e1501518. [Google Scholar] [CrossRef] [PubMed]

- Muruganathan, M.; Miyashita, H.; Kulothungan, J.; Schmidt, M.E.; Mizuta, H. Zeptogram Level Mass Sensing of Light Weight Gas Molecules Using Graphene Nanomechanical (GNEM) Resonator. In Proceedings of the 2018 IEEE SENSORS, New Delhi, India, 28–31 October 2018; pp. 1–4. [Google Scholar]

- Liu, F.; Wang, Z.; Nakanao, S.; Ogawa, S.; Morita, Y.; Schmidt, M.; Haque, M.; Muruganathan, M.; Mizuta, H. Conductance Tunable Suspended Graphene Nanomesh by Helium Ion Beam Milling. Micromachines 2020, 11, 387. [Google Scholar] [CrossRef] [PubMed]

- Iwasaki, T.; Sun, J.; Kanetake, N.; Chikuba, T.; Akabori, M.; Muruganathan, M.; Mizuta, H. Hydrogen intercalation: An approach to eliminate silicon dioxide substrate doping to graphene. Appl. Phys. Express 2015, 8, 015101. [Google Scholar] [CrossRef]

- Iwasaki, T.; Muruganathan, M.; Schmidt, M.E.; Mizuta, H. Partial hydrogenation induced interaction in a graphene–SiO2 interface: Irreversible modulation of device characteristics. Nanoscale 2017, 9, 1662–1669. [Google Scholar] [CrossRef]

- Hammam, A.M.M.; Schmidt, M.E.; Muruganathan, M.; Mizuta, H. Sharp switching behaviour in graphene nanoribbon p-n junction. Carbon 2017, 121, 399–407. [Google Scholar] [CrossRef]

- Hamam, A.M.M.; Schmidt, M.E.; Muruganathan, M.; Suzuki, S.; Mizuta, H. Sub-10 nm graphene nano-ribbon tunnel field-effect transistor. Carbon 2018, 126, 588–593. [Google Scholar] [CrossRef]

- Kareekunnan, A.; Muruganathan, M.; Mizuta, H. Manipulating Berry curvature in hBN/bilayer graphene commensurate heterostructures. Phys. Rev. B 2020, 101, 195406. [Google Scholar] [CrossRef]

- Kareekunnan, A.; Muruganathan, M.; Mizuta, H. Electrically controlled valley states in bilayer graphene. Nanoscale 2019, 11, 14707–14711. [Google Scholar] [CrossRef]

- Schmidt, M.E.; Iwasaki, T.; Muruganathan, M.; Haque, M.; Van Ngoc, H.; Ogawa, S.; Mizuta, H. Structurally Controlled Large-Area 10 nm Pitch Graphene Nanomesh by Focused Helium Ion Beam Milling. ACS Appl. Mater. Interfaces 2018, 10, 10362–10368. [Google Scholar] [CrossRef]

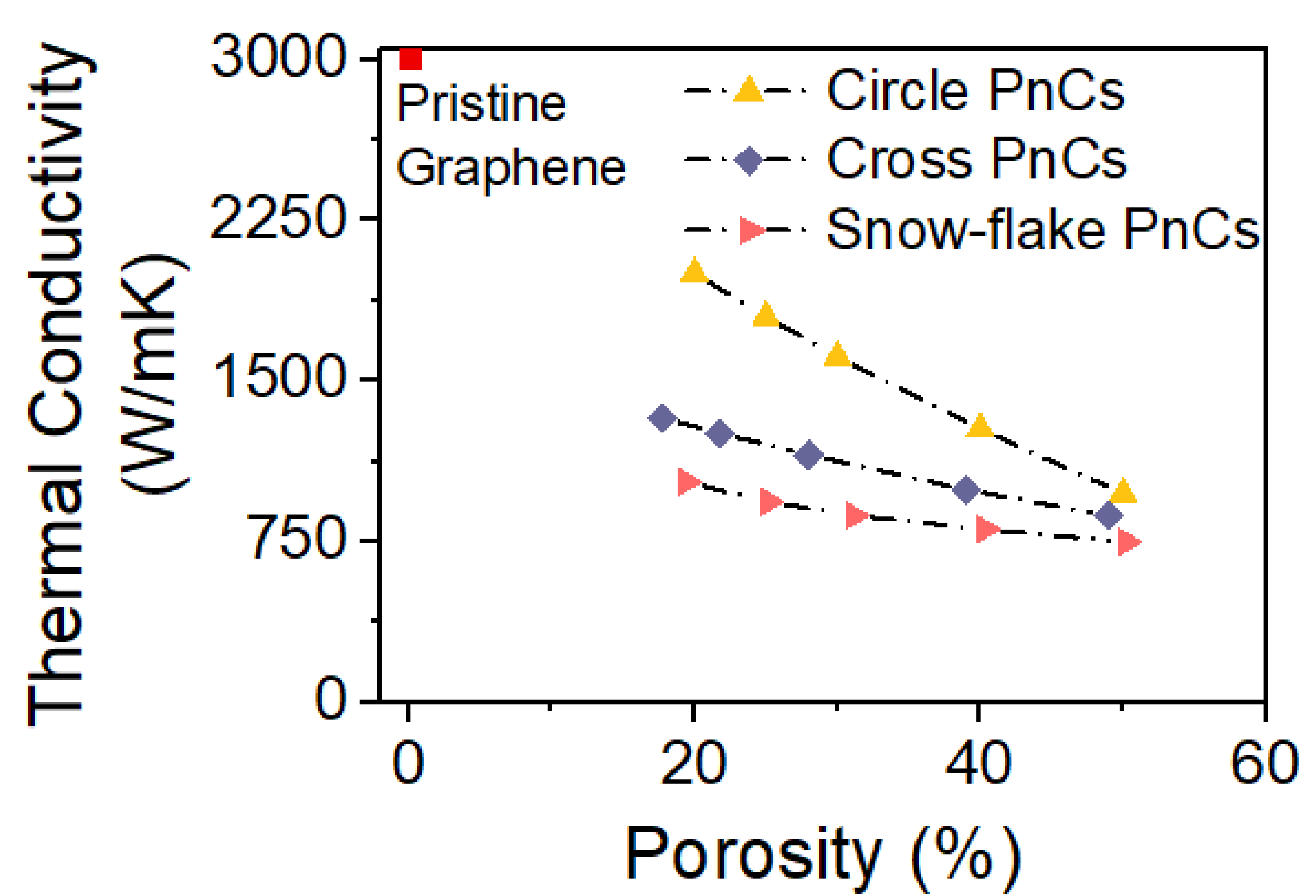

- Yang, L.; Chen, J.; Yang, N.; Li, B. Significant Reduction of Graphene Thermal Conductivity by Phononic Crystal Structure. Int. J. Heat Mass Transf. 2015, 91, 428–432. [Google Scholar] [CrossRef]

- COMSOL MULTIPHYSICS version 5.5. Available online: https://www.comsol.jp/ (accessed on 30 June 2020).

- Gómez García, P.; Fernández-Álvarez, J.-P. Floquet-Bloch Theory and Its Application to the Dispersion Curves of Nonperiodic Layered Systems. Math. Probl. Eng. 2015, 2015, 475362. [Google Scholar] [CrossRef]

- Collet, M.; Ouisse, M.; Ruzzene, M.; Ichchou, M.N. Floquet–Bloch decomposition for the computation of dispersion of two-dimensional periodic, damped mechanical systems. Int. J. Solids Struct. 2011, 48, 2837–2848. [Google Scholar] [CrossRef]

- Elford, D.P.; Chalmers, L.; Kusmartsev, F.V.; Swallowe, G.M. Matryoshka locally resonant sonic crystal. J. Acoust. Soc. Am. 2011, 130, 2746–2755. [Google Scholar] [CrossRef] [PubMed]

- Equivalent Properties of Periodic Microstructures. Available online: https://www.comsol.jp/model/equivalent-properties-of-periodic-microstructures-23621 (accessed on 2 June 2020).

- Ghosh, S.; Calizo, I.; Teweldebrhan, D.; Pokatilov, E.P.; Nika, D.L.; Balandin, A.A.; Bao, W.; Miao, F.; Lau, C.N. Extremely high thermal conductivity of graphene: Prospects for thermal management applications in nanoelectronic circuits. Appl. Phys. Lett. 2008, 92, 151911. [Google Scholar] [CrossRef]

| L | Phononic Bandgap Range | Phononic Bandgap Width |

|---|---|---|

| (nm) | (THz) | (GHz) |

| 6.6 | 1.465–1.479 | 14 |

| 7.6 | 1.698–1.711 | 13 |

| 8 | 1.951–1.980 | 29 |

| 9.2 | 1.948–1.971 | 23 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Masrura, H.M.; Kareekunnan, A.; Liu, F.; Ramaraj, S.G.; Ellrott, G.; Hammam, A.M.M.; Muruganathan, M.; Mizuta, H. Design of Graphene Phononic Crystals for Heat Phonon Engineering. Micromachines 2020, 11, 655. https://doi.org/10.3390/mi11070655

Masrura HM, Kareekunnan A, Liu F, Ramaraj SG, Ellrott G, Hammam AMM, Muruganathan M, Mizuta H. Design of Graphene Phononic Crystals for Heat Phonon Engineering. Micromachines. 2020; 11(7):655. https://doi.org/10.3390/mi11070655

Chicago/Turabian StyleMasrura, Haque Mayeesha, Afsal Kareekunnan, Fayong Liu, Sankar Ganesh Ramaraj, Günter Ellrott, Ahmmed M. M. Hammam, Manoharan Muruganathan, and Hiroshi Mizuta. 2020. "Design of Graphene Phononic Crystals for Heat Phonon Engineering" Micromachines 11, no. 7: 655. https://doi.org/10.3390/mi11070655

APA StyleMasrura, H. M., Kareekunnan, A., Liu, F., Ramaraj, S. G., Ellrott, G., Hammam, A. M. M., Muruganathan, M., & Mizuta, H. (2020). Design of Graphene Phononic Crystals for Heat Phonon Engineering. Micromachines, 11(7), 655. https://doi.org/10.3390/mi11070655