Path Planning Strategies to Optimize Accuracy, Quality, Build Time and Material Use in Additive Manufacturing: A Review

Abstract

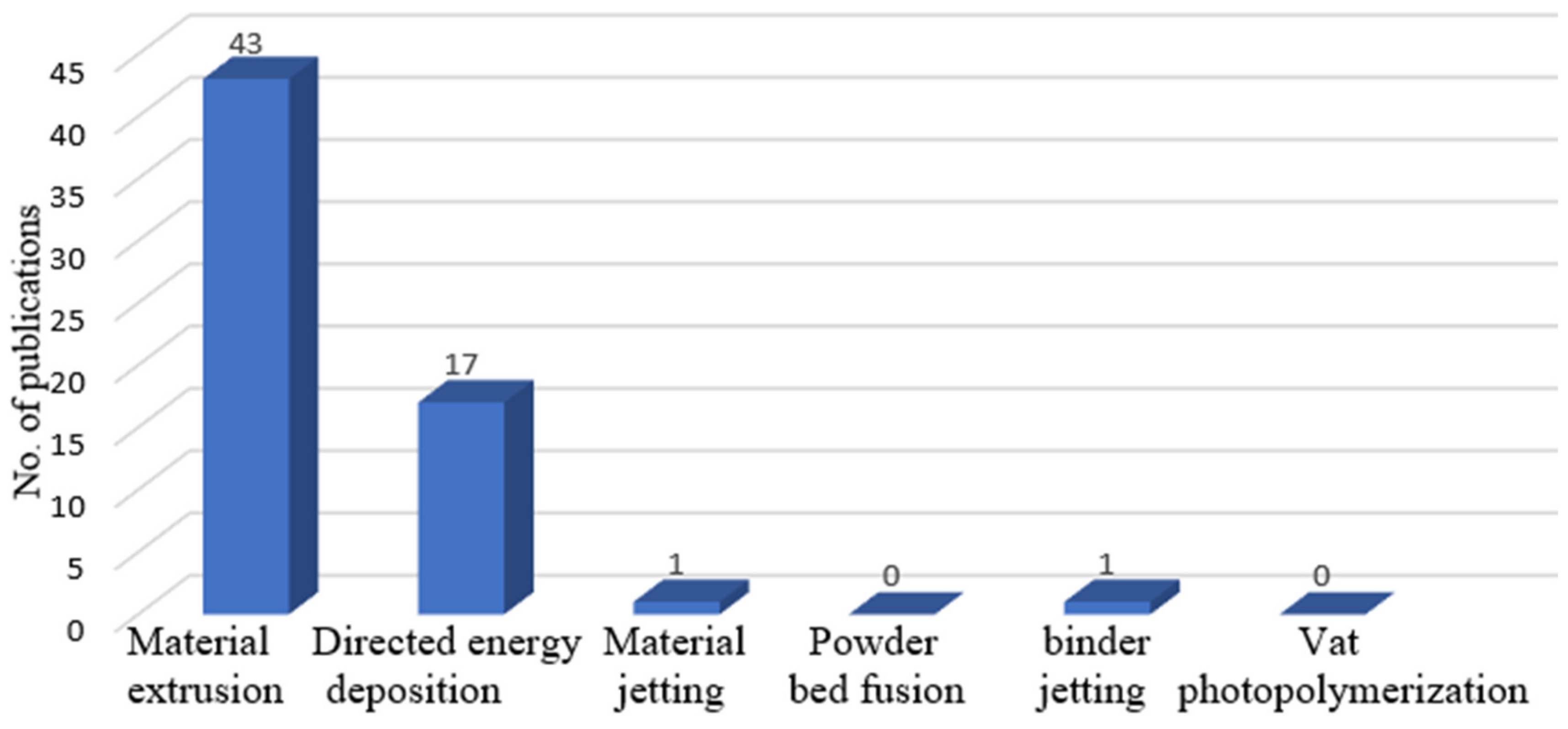

1. Introduction

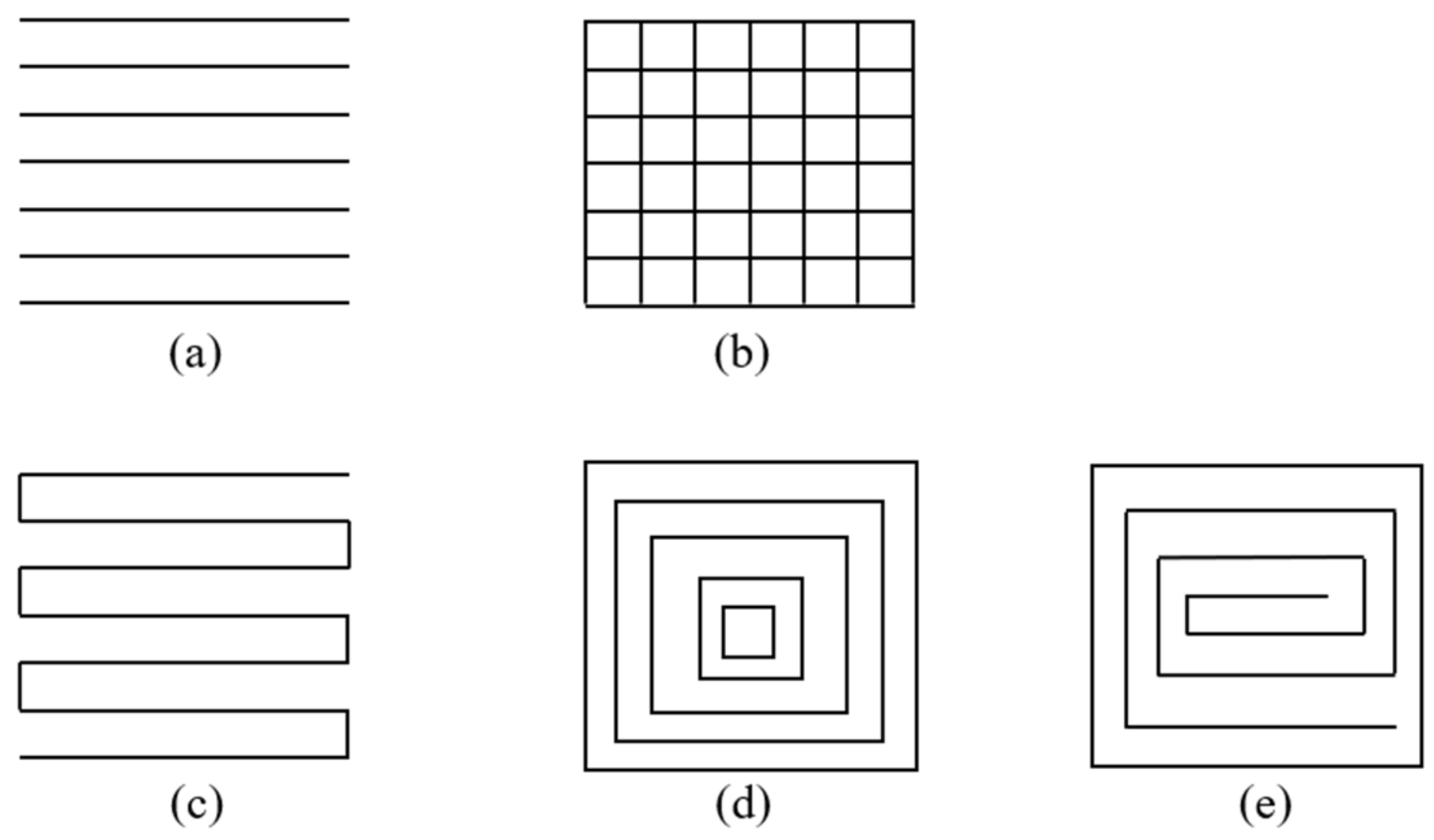

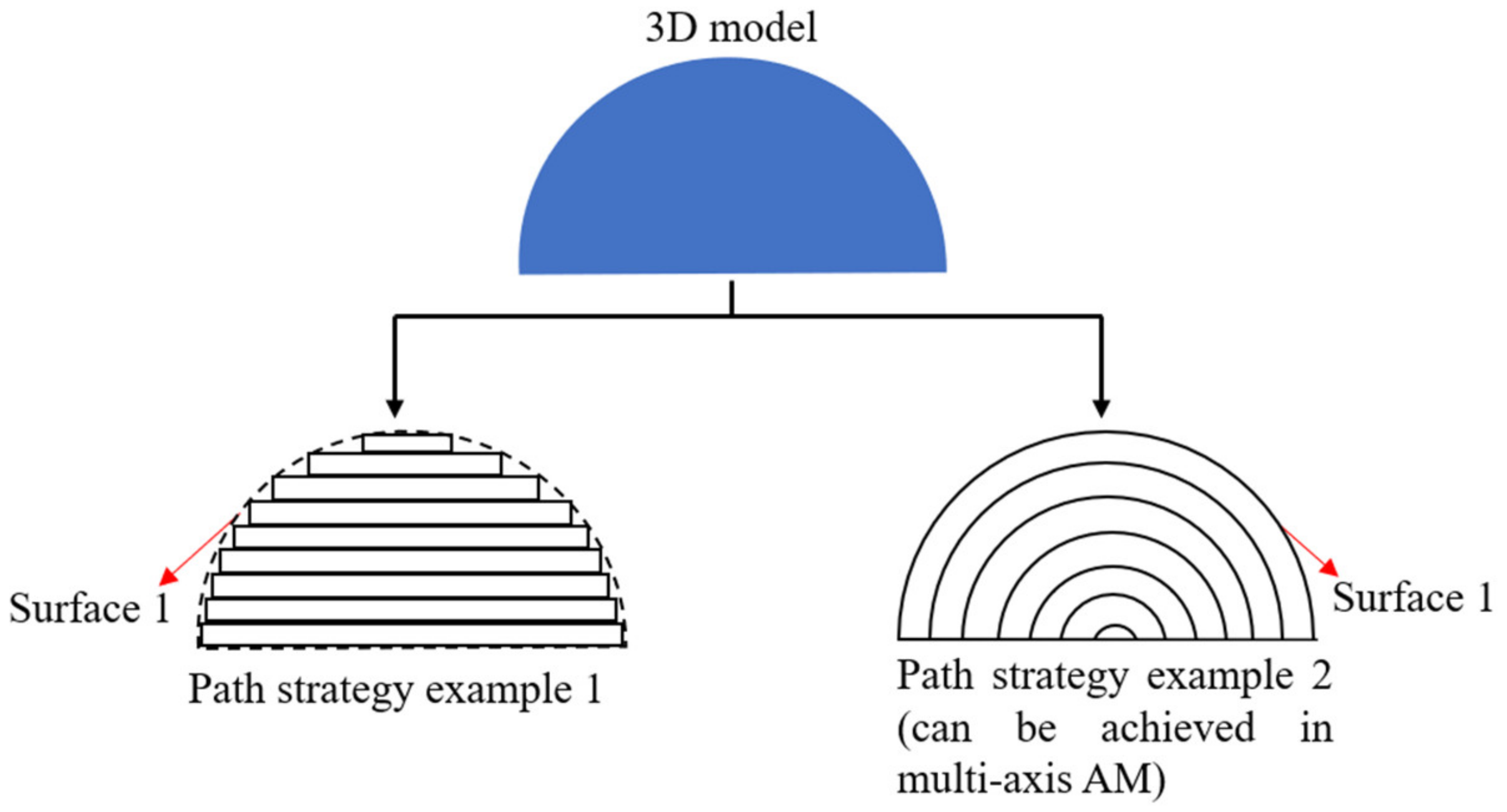

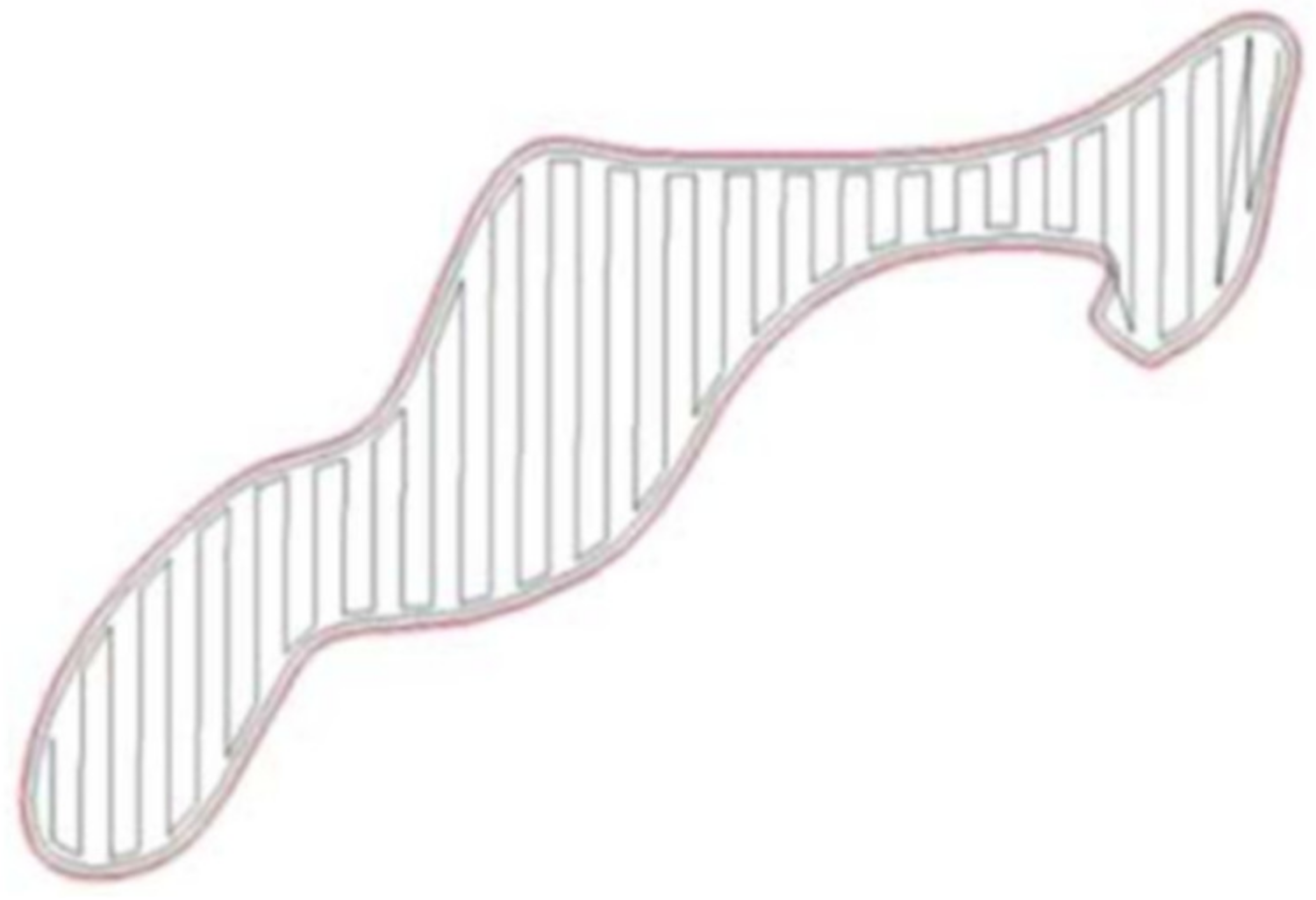

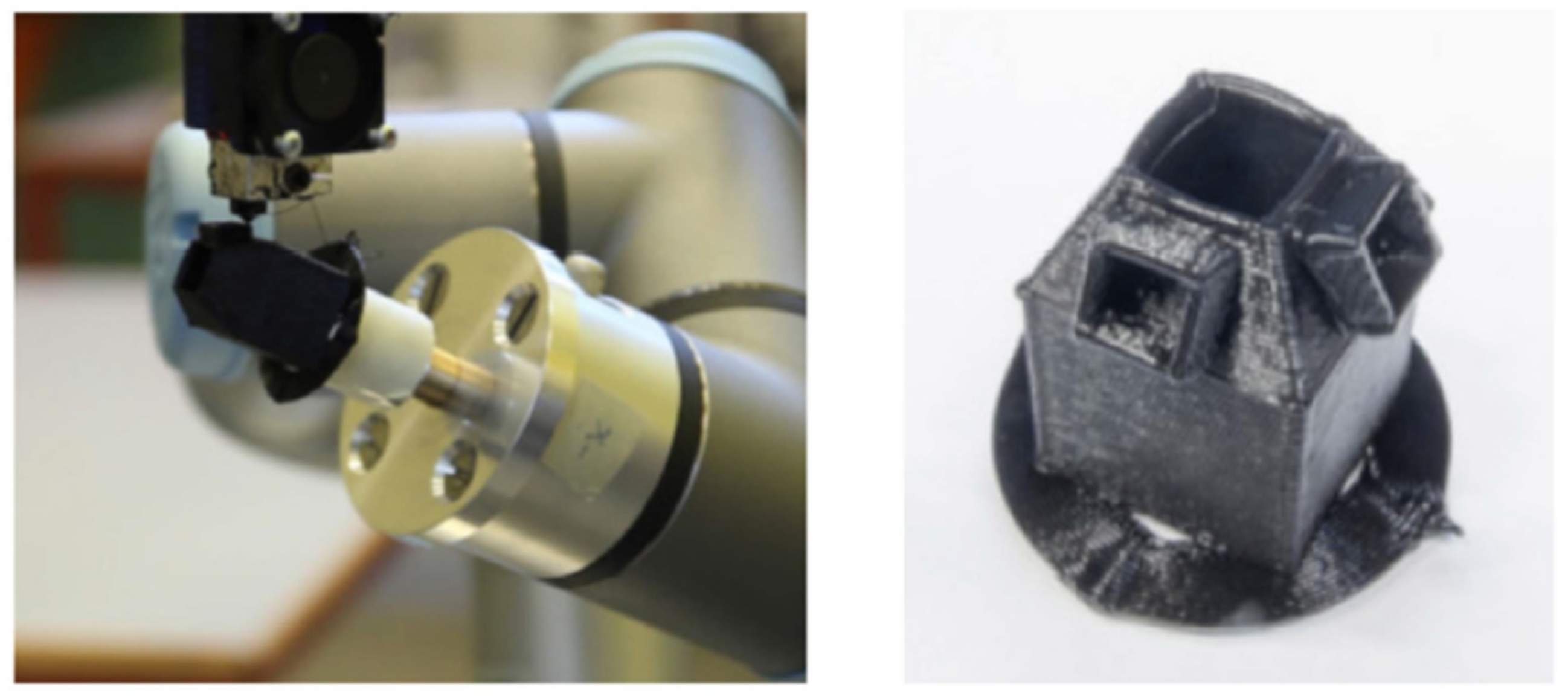

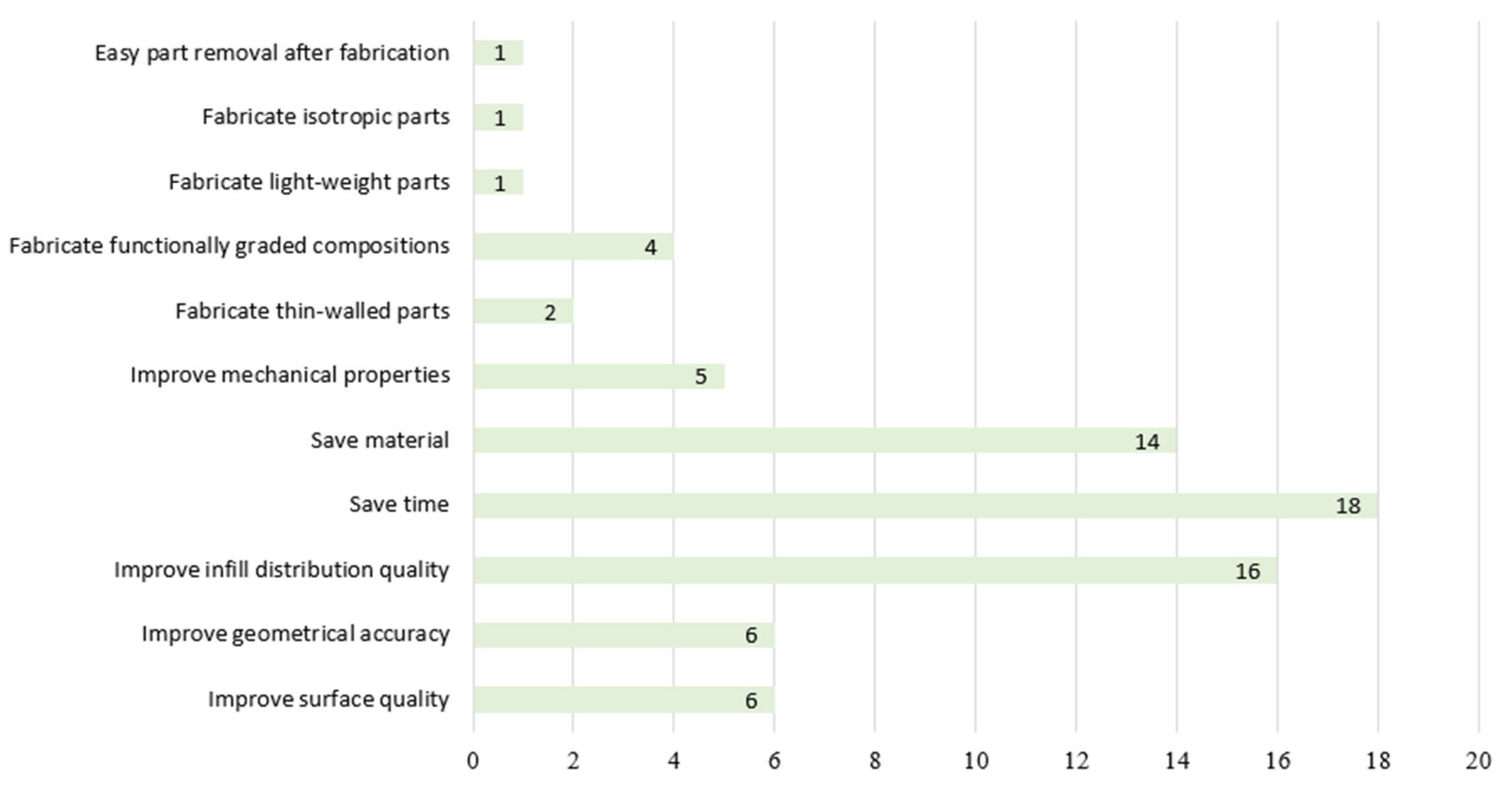

2. Path Planning Strategies

2.1. Improve Printed Qualities

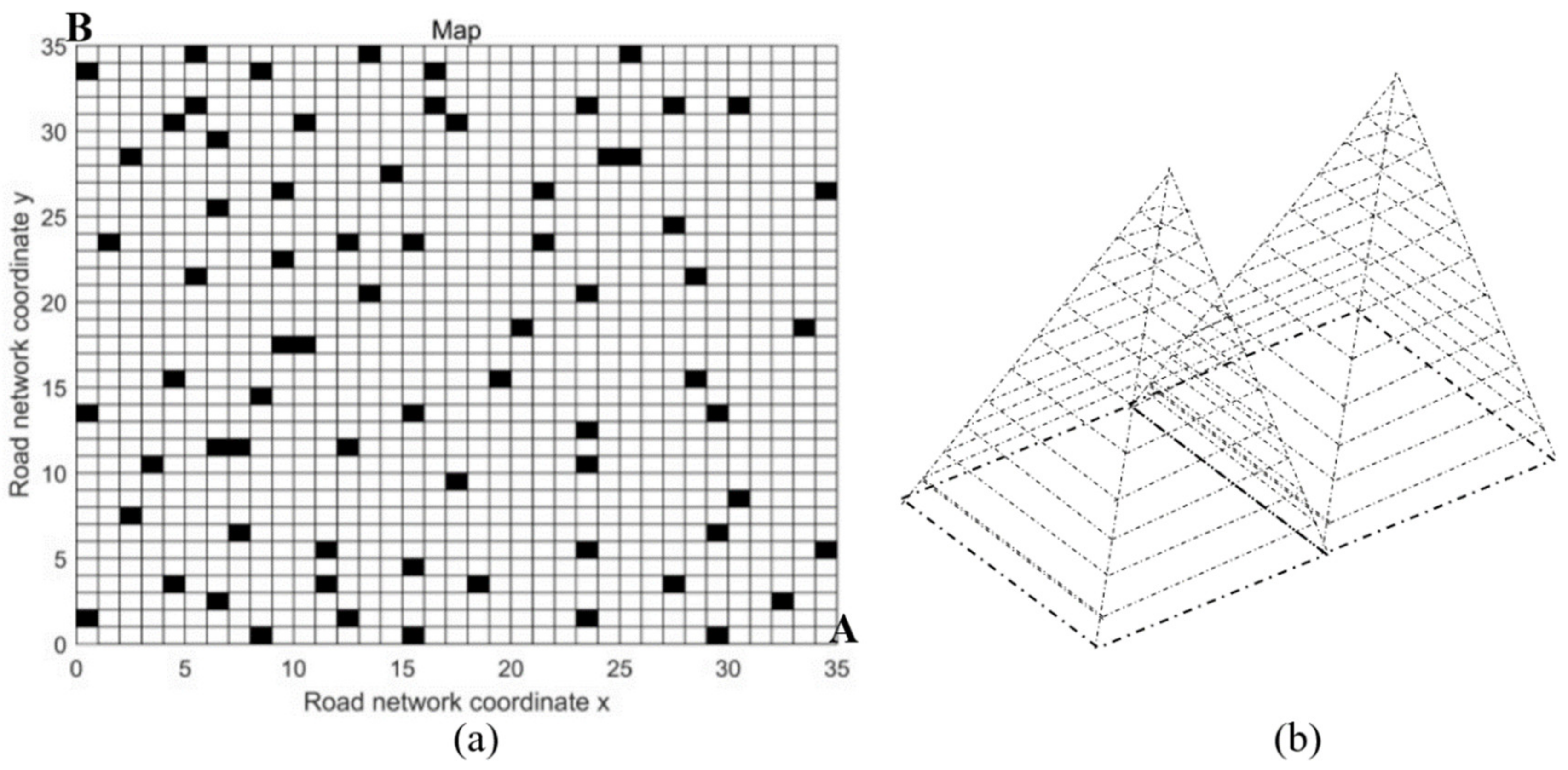

2.2. Save Materials/Time

2.3. Achieve Objective Printed Properties

3. Discussion

4. Future Perspectives

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Jiang, J.; Lou, J.; Hu, G. Effect of support on printed properties in fused deposition modelling processes. Virtual Phys. Prototyp. 2019, 14, 308–315. [Google Scholar] [CrossRef]

- Fu, Y.-F.; Rolfe, B.; Chiu, L.N.S.; Wang, Y.; Huang, X.; Ghabraie, K. Parametric studies and manufacturability experiments on smooth self-supporting topologies. Virtual Phys. Prototyp. 2019, 15, 22–34. [Google Scholar] [CrossRef]

- Jiang, J.; Yu, C.; Xu, X.; Ma, Y.; Liu, J. Achieving better connections between deposited lines in additive manufacturing via machine learning. Math. Biosci. Eng. 2020, 17, 3382–3394. [Google Scholar] [CrossRef]

- Jiang, J.; Stringer, J.; Xu, X.; Zhong, R.Y. Investigation of printable threshold overhang angle in extrusion-based additive manufacturing for reducing support waste. Int. J. Comput. Integr. Manuf. 2018, 31, 1–9. [Google Scholar] [CrossRef]

- Fu, Y.-F.; Rolfe, B.; Chiu, L.N.S.; Wang, Y.; Huang, X.; Ghabraie, K. Design and experimental validation of self-supporting topologies for additive manufacturing. Virtual Phys. Prototyp. 2019, 14, 382–394. [Google Scholar] [CrossRef]

- Bikas, H.; Stavropoulos, P.; Chryssolouris, G. Additive manufacturing methods and modelling approaches: A critical review. Int. J. Adv. Manuf. Technol. 2015, 83, 389–405. [Google Scholar] [CrossRef]

- Haleem, A.; Javaid, M. 3D printed medical parts with different materials using additive manufacturing. Clin. Epidemiol. Glob. Health 2020, 8, 215–223. [Google Scholar] [CrossRef]

- Yusuf, S.M.; Cutler, S.; Gao, N. Review: The Impact of Metal Additive Manufacturing on the Aerospace Industry. Metals 2019, 9, 1286. [Google Scholar] [CrossRef]

- Galati, M.; Minetola, P.; Marchiandi, G.; Atzeni, E.; Calignano, F.; Salmi, A.; Iuliano, L. A methodology for evaluating the aesthetic quality of 3D printed parts. Procedia CIRP 2019, 79, 95–100. [Google Scholar] [CrossRef]

- Jiang, J.; Xu, X.; Stringer, J. Optimisation of multi-part production in additive manufacturing for reducing support waste. Virtual Phys. Prototyp. 2019, 14, 219–228. [Google Scholar] [CrossRef]

- Liu, J.; Gaynor, A.T.; Chen, S.; Kang, Z.; Suresh, K.; Takezawa, A.; Li, L.; Kato, J.; Tang, J.; Wang, C.C.L.; et al. Current and future trends in topology optimization for additive manufacturing. Struct. Multidiscip. Optim. 2018, 57, 2457–2483. [Google Scholar] [CrossRef]

- Jiang, J.; Xu, X.; Stringer, J. Effect of Extrusion Temperature on Printable Threshold Overhang in Additive Manufacturing. Procedia CIRP 2019, 81, 1376–1381. [Google Scholar] [CrossRef]

- Jiang, J.; Hu, G.; Li, X.; Xu, X.; Zheng, P.; Stringer, J. Analysis and prediction of printable bridge length in fused deposition modelling based on back propagation neural network. Virtual Phys. Prototyp. 2019, 14, 253–266. [Google Scholar] [CrossRef]

- Weng, F.; Gao, S.; Jiang, J.; Wang, J.; Guo, P. A novel strategy to fabricate thin 316L stainless steel rods by continuous directed energy deposition in Z direction. Addit. Manuf. 2019, 27, 474–481. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.L.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The status, challenges, and future of additive manufacturing in engineering. Comput. Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- ISO. Additive manufacturing—General principles—Terminology. Iso/Astm 2015, 52900, 1–26. [Google Scholar] [CrossRef]

- Jiang, J.; Xu, X.; Stringer, J. Support Structures for Additive Manufacturing: A Review. J. Manuf. Mater. Process. 2018, 2, 64. [Google Scholar] [CrossRef]

- Jin, G.; Li, W.; Tsai, C.; Wang, L. Adaptive tool-path generation of rapid prototyping for complex product models. J. Manuf. Syst. 2011, 30, 154–164. [Google Scholar] [CrossRef]

- Jin, G.; Li, W.; Gao, L. An adaptive process planning approach of rapid prototyping and manufacturing. Robot. Comput. Manuf. 2013, 29, 23–38. [Google Scholar] [CrossRef]

- Jin, Y.; Du, J.; He, Y.; Fu, G. Modeling and process planning for curved layer fused deposition. Int. J. Adv. Manuf. Technol. 2016, 91, 273–285. [Google Scholar] [CrossRef]

- Ezair, B.; Fuhrmann, S.; Elber, G. Volumetric covering print-paths for additive manufacturing of 3D models. Comput. Des. 2018, 100, 1–13. [Google Scholar] [CrossRef]

- Jensen, M.L.; Mahshid, R.; D’Angelo, G.; Walther, J.U.; Kiewning, M.K.; Spangenberg, J.; Hansen, H.N.; Pedersen, D.B. Toolpath Strategies for 5DOF and 6DOF Extrusion-Based Additive Manufacturing. Appl. Sci. 2019, 9, 4168. [Google Scholar] [CrossRef]

- Routhu, S.; Kanakanala, D.; Ruan, J.; Liu, X.F.; Liou, F. 2-D Path Planning for Direct Laser Deposition Process. In Proceedings of the Volume 1: 36th Design Automation Conference, Parts A and B; ASME International: New York, NY, USA, 2010; pp. 415–423. [Google Scholar]

- Jin, Y.; He, Y.; Fu, J.; Gan, W.-F.; Lin, Z.-W. Optimization of tool-path generation for material extrusion-based additive manufacturing technology. Addit. Manuf. 2014, 1, 32–47. [Google Scholar] [CrossRef]

- Comminal, R.; Serdeczny, M.P.; Pedersen, D.B.; Spangenberg, J. Motion planning and numerical simulation of material deposition at corners in extrusion additive manufacturing. Addit. Manuf. 2019, 29, 100753. [Google Scholar] [CrossRef]

- Liu, H.H.; Zhao, T.; Li, L.Y.; Liu, W.J.; Wang, T.Q.; Yue, J.F. A path planning and sharp corner correction strategy for wire and arc additive manufacturing of solid components with polygonal cross-sections. Int. J. Adv. Manuf. Technol. 2020, 106, 4879–4889. [Google Scholar] [CrossRef]

- Giberti, H.; Sbaglia, L.; Urgo, M. A path planning algorithm for industrial processes under velocity constraints with an application to additive manufacturing. J. Manuf. Syst. 2017, 43, 160–167. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. A tool-path generation strategy for wire and arc additive manufacturing. Int. J. Adv. Manuf. Technol. 2014, 73, 173–183. [Google Scholar] [CrossRef]

- Eiliat, H.; Urbanic, J. Minimizing Voids with Using an Optimal Raster Orientation and Bead Width for a Material Extrusion Based Process. In ASME International Mechanical Engineering Congress and Exposition; American Society of Mechanical Engineers: New York, NY, USA, 2016. [Google Scholar] [CrossRef]

- Eiliat, H. Development of Optimal Material Extrusion Additive Manufacturing Tool Path Parameters for Minimizing Void Regions Using Contemporary Tool Path Solutions; University of Windso: Windsor, ON, Canada, 2016. [Google Scholar]

- Eiliat, H.; Urbanic, J. Visualizing, analyzing, and managing voids in the material extrusion process. Int. J. Adv. Manuf. Technol. 2018, 96, 4095–4109. [Google Scholar] [CrossRef]

- Xiong, Y.; Park, S.-I.; Padmanathan, S.; Dharmawan, A.G.; Foong, S.; Rosen, D.W.; Soh, G.S. Process planning for adaptive contour parallel toolpath in additive manufacturing with variable bead width. Int. J. Adv. Manuf. Technol. 2019, 105, 4159–4170. [Google Scholar] [CrossRef]

- Kumar, A.; Maji, K. Bead Modelling and Deposition Path Planning in Wire Arc Additive Manufacturing of Three Dimensional Parts. Mater. Sci. Forum 2019, 969, 582–588. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, H.; Gui-Lan, W.; Zhao, X. Cylindrical slicing and path planning of propeller in wire and arc additive manufacturing. Rapid Prototyp. J. 2020, 26, 49–58. [Google Scholar] [CrossRef]

- Wang, X.; Wang, A.; Li, Y. A sequential path-planning methodology for wire and arc additive manufacturing based on a water-pouring rule. Int. J. Adv. Manuf. Technol. 2019, 103, 3813–3830. [Google Scholar] [CrossRef]

- Michel, F.; Lockett, H.; Ding, J.; Martina, F.; Marinelli, G.; Williams, S. A modular path planning solution for Wire + Arc Additive Manufacturing. Robot. Comput. Manuf. 2019, 60, 1–11. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. Process planning for robotic wire and arc additive manufacturing. In Proceedings of the 2015 IEEE 10th Conference on Industrial Electronics and Applications (ICIEA), Auckland, New Zealand, 15–17 June 2015; pp. 2000–2003. [Google Scholar]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H.; Larkin, N. Adaptive path planning for wire-feed additive manufacturing using medial axis transformation. J. Clean. Prod. 2016, 133, 942–952. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H.; Van Duin, S.; Larkin, N. Bead modelling and implementation of adaptive MAT path in wire and arc additive manufacturing. Robot. Comput. Manuf. 2016, 39, 32–42. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. A practical path planning methodology for wire and arc additive manufacturing of thin-walled structures. Robot. Comput. Manuf. 2015, 34, 8–19. [Google Scholar] [CrossRef]

- Ren, L.; Ruan, J.; Eiamsa-ard, K.; Liou, F. Adaptive deposition coverage toolpath planning for metal depositon process. In Proceedings of the 2007 ASME International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, DETC2007, Las Vegas, NV, USA, 4–7 September 2007; pp. 413–419. [Google Scholar]

- Han, W.; Jafari, M.A.; Danforth, S.C.; Safari, A. Tool Path-Based Deposition Planning in Fused Deposition Processes. J. Manuf. Sci. Eng. 2002, 124, 462–472. [Google Scholar] [CrossRef]

- Jin, Y.-A.; He, Y.; Xue, G.-H.; Fu, J.-Z. A parallel-based path generation method for fused deposition modeling. Int. J. Adv. Manuf. Technol. 2014, 77, 927–937. [Google Scholar] [CrossRef]

- Jin, Y.; Du, J.; Ma, Z.; Liu, A.; He, Y. An optimization approach for path planning of high-quality and uniform additive manufacturing. Int. J. Adv. Manuf. Technol. 2017, 92, 651–662. [Google Scholar] [CrossRef]

- Zhao, G.; Ma, G.; Feng, J.; Xiao, W. Nonplanar slicing and path generation methods for robotic additive manufacturing. Int. J. Adv. Manuf. Technol. 2018, 96, 3149–3159. [Google Scholar] [CrossRef]

- Tarabanis, K. Path planning in the Proteus rapid prototyping system. Rapid Prototyp. J. 2001, 7, 241–252. [Google Scholar] [CrossRef]

- Jiang, J.; Xu, X.; Stringer, J. Optimization of process planning for reducing material waste in extrusion based additive manufacturing. Robot. Comput. Manuf. 2019, 59, 317–325. [Google Scholar] [CrossRef]

- Jiang, J.; Xu, X.; Stringer, J. A new support strategy for reducing waste in additive manufacturing. In Proceedings of the 48th International Conference on Computers and Industrial Engineering (CIE 48), Auckland, New Zealand, 2–5 December 2018; pp. 1–7. [Google Scholar]

- Jiang, J.; Stringer, J.; Xu, X. Support Optimization for Flat Features via Path Planning in Additive Manufacturing. 3D Print. Addit. Manuf. 2019, 6, 171–179. [Google Scholar] [CrossRef]

- Jiang, J.; Stringer, J.; Xu, X.; Zheng, P. A benchmarking part for evaluating and comparing support structures of additive manufacturing. In Proceedings of the 3rd International Conference on Progress in Additive Manufacturing (Pro-AM 2018), Singapore, 14–17 May 2018. pp. 196–202.

- Nguyen, L.; Buhl, J.; Bambach, M. Decomposition algorithm for tool path planning for wire-arc additive manufacturing. J. Mach. Eng. 2018, 18, 96–107. [Google Scholar] [CrossRef]

- Thompson, B.; Yoon, H.-S. Efficient Path Planning Algorithm for Additive Manufacturing Systems. IEEE Trans. Components, Packag. Manuf. Technol. 2014, 4, 1555–1563. [Google Scholar] [CrossRef]

- Ding, Y.; Dwivedi, R.; Kovacevic, R. Process planning for 8-axis robotized laser-based direct metal deposition system: A case on building revolved part. Robot. Comput. Manuf. 2017, 44, 67–76. [Google Scholar] [CrossRef]

- Zhang, J.; Liou, F. Adaptive Slicing for a Multi-Axis Laser Aided Manufacturing Process. J. Mech. Des. 2004, 126, 254–261. [Google Scholar] [CrossRef]

- Bui, H.; Pierson, H.A.; Nurre, S.G.; Sullivan, K.M. Tool Path Planning Optimization for Multi-Tool Additive Manufacturing. Procedia Manuf. 2019, 39, 457–464. [Google Scholar] [CrossRef]

- Choi, S.; Zhu, W. A dynamic priority-based approach to concurrent toolpath planning for multi-material layered manufacturing. Comput. Des. 2010, 42, 1095–1107. [Google Scholar] [CrossRef]

- Volpato, N.; Galvão, L.C.; Nunes, L.F.; Souza, R.I.; Oguido, K. Combining heuristics for tool-path optimisation in material extrusion additive manufacturing. J. Oper. Res. Soc. 2019, 71, 867–877. [Google Scholar] [CrossRef]

- Ganganath, N.; Cheng, C.-T.; Fok, K.-Y.; Tse, C.K. Trajectory planning for 3D printing: A revisit to traveling salesman problem. In Proceedings of the 2016 2nd International Conference on Control, Automation and Robotics (ICCAR), Hong Kong, China, 28–30 April 2016; pp. 287–290. [Google Scholar]

- Fleming, C.; Walker, S.; Branyan, C.; Nicolai, A.; Hollinger, G.; Mengüç, Y. Toolpath Planning for Continuous Extrusion Additive Manufacturing; Oregon State University: Corvallis, OR, USA, 2017. [Google Scholar]

- Fok, K.-Y.; Ganganath, N.; Cheng, C.-T.; Tse, C.K. A 3D printing path optimizer based on Christofides algorithm. In Proceedings of the 2016 IEEE International Conference on Consumer Electronics-Taiwan (ICCE-TW), Nantou County, Taiwan, 27–29 May 2016; pp. 1–2. [Google Scholar]

- Jin, Y.; He, Y.; Fu, G.; Zhang, A.; Du, J. A non-retraction path planning approach for extrusion-based additive manufacturing. Robot. Comput. Manuf. 2017, 48, 132–144. [Google Scholar] [CrossRef]

- Papacharalampopoulos, A.; Bikas, H.; Stavropoulos, P. Path planning for the infill of 3D printed parts utilizing Hilbert curves. Procedia Manuf. 2018, 21, 757–764. [Google Scholar] [CrossRef]

- Luo, R.C.; Tseng, P.-K. Trajectory generation and planning for simultaneous 3D printing of multiple objects. In Proceedings of the 2017 IEEE 26th International Symposium on Industrial Electronics (ISIE), Edinburgh, UK, 19–21 June 2017; pp. 1147–1152. [Google Scholar] [CrossRef]

- Jiang, J. A novel fabrication strategy for additive manufacturing processes. J. Clean Prod. 2020, in press. [Google Scholar]

- Zhai, X.; Chen, F. Path Planning of a Type of Porous Structures for Additive Manufacturing. Comput. Des. 2019, 115, 218–230. [Google Scholar] [CrossRef]

- Dreifus, G.; Goodrick, K.; Giles, S.; Patel, M.; Foster, R.M.; Williams, C.; Lindahl, J.; Post, B.; Roschli, A.; Love, L.; et al. Path Optimization Along Lattices in Additive Manufacturing Using the Chinese Postman Problem. 3D Print. Addit. Manuf. 2017, 4, 98–104. [Google Scholar] [CrossRef]

- Coupek, D.; Friedrich, J.; Battran, D.; Riedel, O. Reduction of Support Structures and Building Time by Optimized Path Planning Algorithms in Multi-axis Additive Manufacturing. Procedia CIRP 2018, 67, 221–226. [Google Scholar] [CrossRef]

- McQueen, K.; Darensbourg, S.; Moore, C.; Dickens, T.; Allen, C. Efficient Path Planning of Secondary Additive Manufacturing Operations. In Proceedings of the MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2018; Volume 249, p. 03011. [Google Scholar]

- Shembekar, A.V.; Yoon, Y.J.; Kanyuck, A.; Gupta, S.K. Trajectory Planning for Conformal 3D Printing Using Non-Planar Layers. In Proceedings of the Volume 1A: 38th Computers and Information in Engineering Conference; ASME International: New York, NY, USA, 2018. [Google Scholar]

- Cai, Y.; Choi, S. Deposition Group-based Toolpath Planning for Additive Manufacturing with Multiple Robotic Actuators. Procedia Manuf. 2019, 34, 584–593. [Google Scholar] [CrossRef]

- Fügenschuh, A.; Bambach, M.; Buhl, J. Trajectory Optimization for Wire-Arc Additive Manufacturing. Oper. Res. Proc. 2019, 331–337. [Google Scholar] [CrossRef]

- Li, N.; Link, G.; Wang, T.; Ramopoulos, V.; Neumaier, D.; Hofele, J.; Walter, M.; Jelonnek, J. Path-designed 3D printing for topological optimized continuous carbon fibre reinforced composite structures. Compos. Part B Eng. 2020, 182, 107612. [Google Scholar] [CrossRef]

- Asif, S. Modelling and Path Planning for Additive Manufacturing of Continuous Fiber Composites; Sabanci University: Istanbul, Turkey, 2018. [Google Scholar]

- Kraljic, D.; Kamnik, R. Trajectory Planning for Additive Manufacturing with a 6-DOF Industrial Robot. In Proceedings of the Modeling and Control of a Tracked Mobile Robot for Pipeline Inspection; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2018; pp. 456–465. [Google Scholar]

- Liu, J.; Ma, Y.; Qureshi, A.J.; Ahmad, R. Light-weight shape and topology optimization with hybrid deposition path planning for FDM parts. Int. J. Adv. Manuf. Technol. 2018, 97, 1123–1135. [Google Scholar] [CrossRef]

- Liu, J.; Yu, H. Concurrent deposition path planning and structural topology optimization for additive manufacturing. Rapid Prototyp. J. 2017, 23, 930–942. [Google Scholar] [CrossRef]

- Jin, Y.; He, Y.; Shih, A. Process Planning for the Fuse Deposition Modeling of Ankle-Foot-Othoses. Procedia CIRP 2016, 42, 760–765. [Google Scholar] [CrossRef]

- Lin, S.; Xia, L.; Ma, G.; Zhou, S.; Xie, Y.M. A maze-like path generation scheme for fused deposition modeling. Int. J. Adv. Manuf. Technol. 2019, 104, 1509–1519. [Google Scholar] [CrossRef]

- Jin, Y.; He, Y.; Du, J. A novel path planning methodology for extrusion-based additive manufacturing of thin-walled parts. Int. J. Comput. Integr. Manuf. 2017, 30, 1301–1315. [Google Scholar] [CrossRef]

- Ma, G.; Zhao, G.; Li, Z.; Xiao, W. A Path Planning Method for Robotic Wire and Arc Additive Manufacturing of Thin-Walled Structures with Varying Thickness. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 470, p. 012018. [Google Scholar]

- Eliseeva, O.; Kirk, T.; Samimi, P.; Malak, R.; Arróyave, R.; Elwany, A.; Karaman, I. Functionally Graded Materials through robotics-inspired path planning. Mater. Des. 2019, 182, 107975. [Google Scholar] [CrossRef]

- Deuser, B.; Tang, L.; Geldmeier, J.; Landers, R.G.; Leu, M.C. Process planning and control for functionally graded material fabrication using freeze-form extrusion fabrication. In Solid Freeform Fabrication Symposium; Department of Mechanical and Aerospace Engineering Missouri University of Science and Technology: Rolla, MO, USA, 2011. [Google Scholar]

- Ozbolat, I.T.; Khoda, A.K.M.B. Design of a New Parametric Path Plan for Additive Manufacturing of Hollow Porous Structures with Functionally Graded Materials. J. Comput. Inf. Sci. Eng. 2014, 14, 041005. [Google Scholar] [CrossRef]

- Zhu, W.; Yu, K.M. Tool path generation of multi-material assembly for rapid manufacture. Rapid Prototyp. J. 2002, 8, 277–283. [Google Scholar] [CrossRef]

- Jiang, J.; Weng, F.; Gao, S.; Stringer, J.; Xu, X.; Guo, P. A support interface method for easy part removal in directed energy deposition. Manuf. Lett. 2019, 20, 30–33. [Google Scholar] [CrossRef]

- Aoyagi, K.; Wang, H.; Chiba, A.; Sudo, H. Simple method to construct process maps for additive manufacturing using a support vector machine. Addit. Manuf. 2019, 27, 353–362. [Google Scholar] [CrossRef]

- Menon, A.; Póczos, B.; Feinberg, A.W.; Washburn, N.R. Optimization of Silicone 3D Printing with Hierarchical Machine Learning. 3D Print. Addit. Manuf. 2019, 6, 181–189. [Google Scholar] [CrossRef]

- He, H.; Yang, Y.; Pan, Y. Machine learning for continuous liquid interface production: Printing speed modelling. J. Manuf. Syst. 2019, 50, 236–246. [Google Scholar] [CrossRef]

- Stavroulakis, P.; Chen, S.; Delorme, C.; Bointon, P.; Tzimiropoulos, G.; Leach, R. Rapid tracking of extrinsic projector parameters in fringe projection using machine learning. Opt. Lasers Eng. 2019, 114, 7–14. [Google Scholar] [CrossRef]

- Baturynska, I.; Semeniuta, O.; Martinsen, K. Optimization of Process Parameters for Powder Bed Fusion Additive Manufacturing by Combination of Machine Learning and Finite Element Method: A Conceptual Framework. Procedia CIRP 2018, 67, 227–232. [Google Scholar] [CrossRef]

- Yu, C.; Jiang, J. A perspective on Using Machine Learning in 3D Bioprinting. Int. J. Bioprint. 2020, 6, 4–11. [Google Scholar] [CrossRef]

- Francis, J.; Bian, L. Deep Learning for Distortion Prediction in Laser-Based Additive Manufacturing using Big Data. Manuf. Lett. 2019, 20, 10–14. [Google Scholar] [CrossRef]

- Khanzadeh, M.; Rao, P.; Jafari-Marandi, R.; Smith, B.K.; Tschopp, M.A.; Bian, L.; Rao, P.K. Quantifying Geometric Accuracy with Unsupervised Machine Learning: Using Self-Organizing Map on Fused Filament Fabrication Additive Manufacturing Parts. J. Manuf. Sci. Eng. 2017, 140, 031011. [Google Scholar] [CrossRef]

- Zhu, Z.; Anwer, N.; Huang, Q.; Mathieu, L. Machine learning in tolerancing for additive manufacturing. CIRP Ann. 2018, 67, 157–160. [Google Scholar] [CrossRef]

- Tootooni, M.S.; Dsouza, A.; Donovan, R.; Rao, P.K.; Kong, Z.J.; Borgesen, P. Classifying the Dimensional Variation in Additive Manufactured Parts from Laser-Scanned Three-Dimensional Point Cloud Data Using Machine Learning Approaches. J. Manuf. Sci. Eng. 2017, 139, 091005. [Google Scholar] [CrossRef]

- Scime, L.; Beuth, J. Using machine learning to identify in-situ melt pool signatures indicative of flaw formation in a laser powder bed fusion additive manufacturing process. Addit. Manuf. 2019, 25, 151–165. [Google Scholar] [CrossRef]

- Caggiano, A.; Zhang, J.; Alfieri, V.; Caiazzo, F.; Gao, R.X.; Teti, R. Machine learning-based image processing for on-line defect recognition in additive manufacturing. CIRP Ann. 2019, 68, 451–454. [Google Scholar] [CrossRef]

- Zhang, B.; Liu, S.; Shin, Y.C. In-Process monitoring of porosity during laser additive manufacturing process. Addit. Manuf. 2019, 28, 497–505. [Google Scholar] [CrossRef]

- Gu, G.X.; Chen, C.-T.; Richmond, D.J.; Buehler, M.J. Bioinspired hierarchical composite design using machine learning: Simulation, additive manufacturing, and experiment. Mater. Horizons 2018, 5, 939–945. [Google Scholar] [CrossRef]

- Hamel, C.M.; Roach, D.J.; Long, K.N.; Demoly, F.; Dunn, M.L.; Qi, H.J.; Qi, J. Machine-learning based design of active composite structures for 4D printing. Smart Mater. Struct. 2019, 28, 065005. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, Z.; Shi, J.; Wu, D. Prediction of surface roughness in extrusion-based additive manufacturing with machine learning. Robot. Comput. Manuf. 2019, 57, 488–495. [Google Scholar] [CrossRef]

- Liu, X.-H.; Zhang, D.-G.; Yan, H.-R.; Cui, Y.-Y.; Chen, L. A New Algorithm of the Best Path Selection Based on Machine Learning. IEEE Access 2019, 7, 126913–126928. [Google Scholar] [CrossRef]

| Objective | Path Planning Strategy | Suitable AM Technique |

|---|---|---|

| Improve surface quality | NURBS-based strategy [18,19] | Material extrusion |

| Curved layer strategy [20] | FDM (material extrusion) | |

| Curved layer strategy [21] | Material extrusion | |

| Path projection strategy [22] | 5DOF material extrusion | |

| Parent–child approach strategy [22] | 6DOF material extrusion | |

| Improve shape accuracy | Improved zigzag/offset strategy [23] | Laser powder-based metal deposition process (directed energy deposition) |

| Combination of zigzag and contour pattern strategy [28] | Wire and arc AM (directed energy deposition) | |

| Three-step strategy [24] | FDM (material extrusion) | |

| Improve shape accuracy for corners | Corner strategy [25] | Material extrusion |

| Composite strategy [26] | Wire and arc AM (directed energy deposition) | |

| Improve shape accuracy under velocity constraints | Bézier curve strategy [27] | Binder jetting |

| Improve infill distribution quality | Contemporary strategy [29,30,31] | Material extrusion |

| Variable width strategy [32], optimized width and overlapping strategy [33], water-pouring strategy [35], modular strategy [36], MAT strategy [37,38,39] | Wire and arc AM (directed energy deposition) | |

| Cylindrical strategy specifically for cylindrical parts [34] | ||

| MAT strategy specifically for thin-walled structures [40] | ||

| Grouping and mapping strategy [42], sharp corner strategy [43,44] | FDM (material extrusion) | |

| Adaptive contour/zigzag strategy [41] | Metal-directed energy deposition | |

| Save time | Dynamic priority-based strategy [56] | Multi-material extrusion with multiple nozzles (material extrusion) |

| Multi-head strategy [55] | Multi-head material extrusion | |

| Two-robot strategy [68] | Material extrusion with two robotic arms | |

| Combined heuristic strategy [57], salesman strategy [58], continuous strategy [59], NURBS-based strategy [18,19], Christofides strategy [60], Hilbert curve strategy [62], non-retraction strategy [61] | Material extrusion | |

| Porous strategy specifically for porous structures [65] | Material extrusion | |

| Lattice strategy specifically for lattice structures [66] | Material extrusion | |

| Multi-part strategy specifically for multi-part production [63] | FDM (material extrusion) | |

| Partition strategy [71] | Wire and arc AM (directed energy deposition) | |

| Collision-free strategy [69] | 6DOF material extrusion | |

| Coupek strategy [67] | 7DOF material extrusion | |

| Group-based strategy [70] | Multi-robot material extrusion | |

| Save material | Heuristic strategy [51], MAT strategy [37,38] | Wire and arc AM (directed energy deposition) |

| Aerosol strategy [52] | Material jetting | |

| Nonplanar strategy [45] | 5DOF material extrusion | |

| Support optimization strategy [47,48,49], shelving- and bridging-based strategy [46] | FDM (material extrusion) | |

| Path projection strategy [22] | 5DOF material extrusion | |

| Five-axis adaptive slicing strategy [54] | 5DOF directed energy deposition | |

| Parent–child approach strategy [22], Collision-free strategy [69] | 6DOF material extrusion | |

| Revolved strategy [53] | 8DOF directed energy deposition | |

| Improve mechanical properties | Ingenious strategy for fiber-reinforced fabrication [72], Asif strategy for fiberreinforced fabrication [73], stress direction strategy [76] | Material extrusion |

| Kraljić strategy [74] | 6DOF material extrusion | |

| Wavy strategy [77] | FDM (material extrusion) | |

| Fabricate thin-walled parts | Varying thickness strategy [80] | Wire and arc AM (directed energy deposition) |

| Wavy strategy [79] | FDM (material extrusion) | |

| Fabricate functionally graded compositions | Functional strategy [81] | Directed energy deposition |

| Simulation-based strategy [83] | AM | |

| Spatio-temporal strategy [84] | FDM with multiple nozzles (material extrusion) | |

| Deuser strategy [82] | Material extrusion with three nozzles | |

| Fabricate lightweight parts | Topology strategy [75] | FDM (material extrusion) |

| Fabricate isotropic parts | Maze-like strategy [78] | FDM (material extrusion) |

| Easy part removal after fabrication | Support interface strategy [85] | Directed energy deposition |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, J.; Ma, Y. Path Planning Strategies to Optimize Accuracy, Quality, Build Time and Material Use in Additive Manufacturing: A Review. Micromachines 2020, 11, 633. https://doi.org/10.3390/mi11070633

Jiang J, Ma Y. Path Planning Strategies to Optimize Accuracy, Quality, Build Time and Material Use in Additive Manufacturing: A Review. Micromachines. 2020; 11(7):633. https://doi.org/10.3390/mi11070633

Chicago/Turabian StyleJiang, Jingchao, and Yongsheng Ma. 2020. "Path Planning Strategies to Optimize Accuracy, Quality, Build Time and Material Use in Additive Manufacturing: A Review" Micromachines 11, no. 7: 633. https://doi.org/10.3390/mi11070633

APA StyleJiang, J., & Ma, Y. (2020). Path Planning Strategies to Optimize Accuracy, Quality, Build Time and Material Use in Additive Manufacturing: A Review. Micromachines, 11(7), 633. https://doi.org/10.3390/mi11070633