On the Effects of Package on the PMUTs Performances—Multiphysics Model and Frequency Analyses

Abstract

1. Introduction

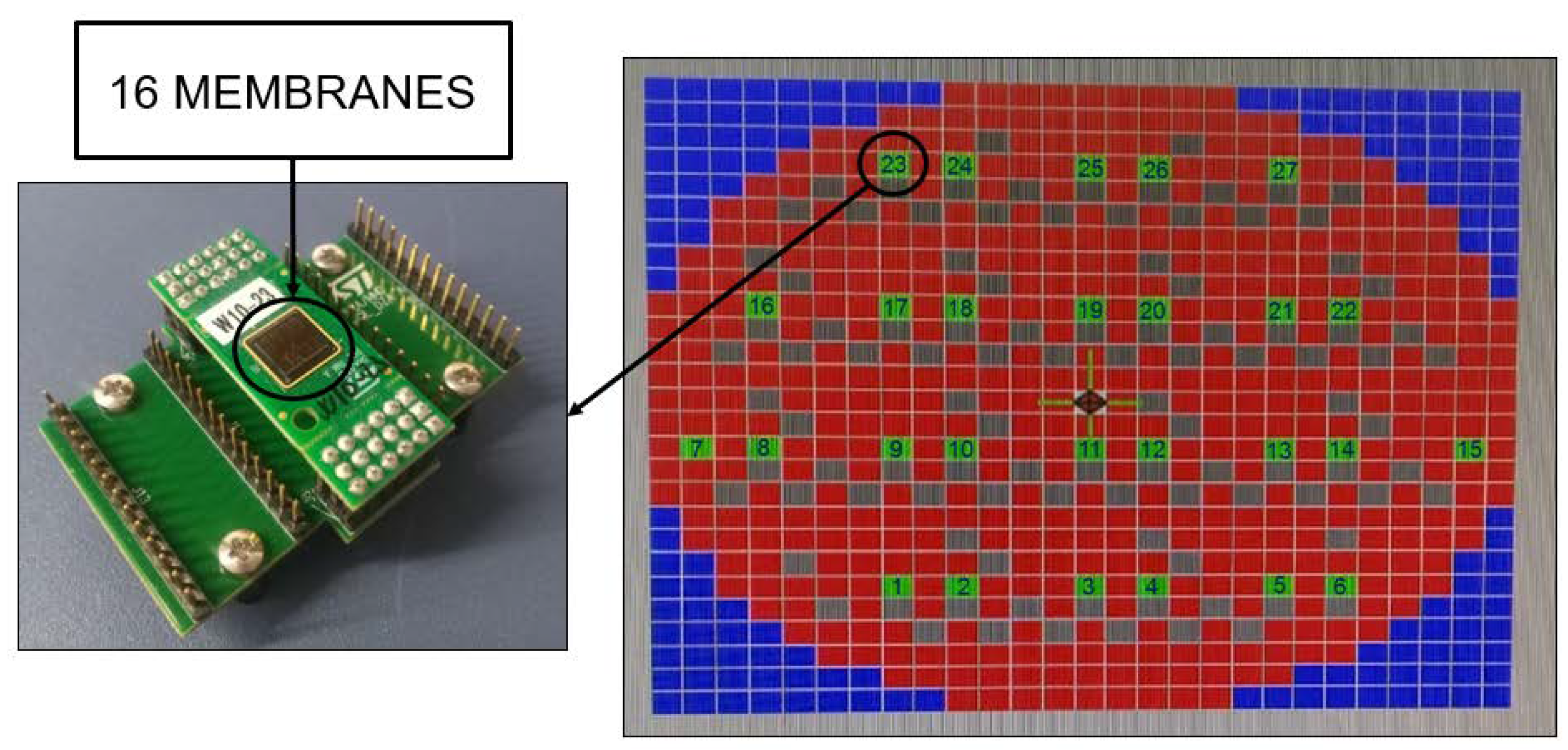

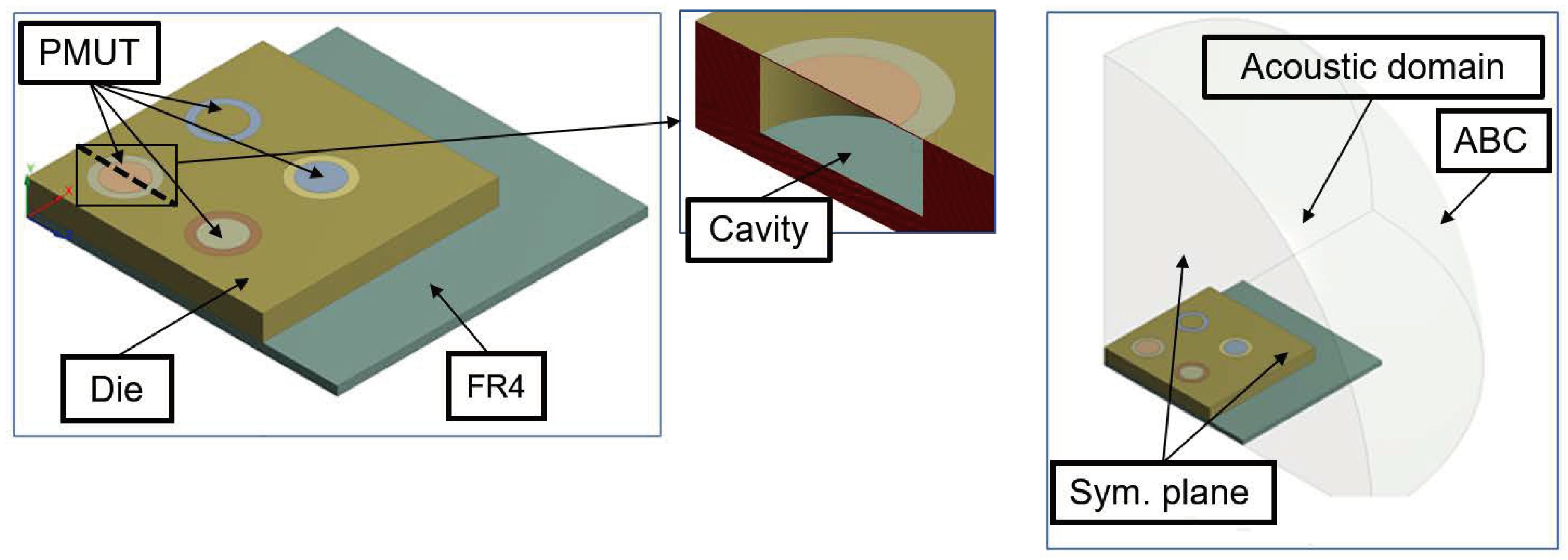

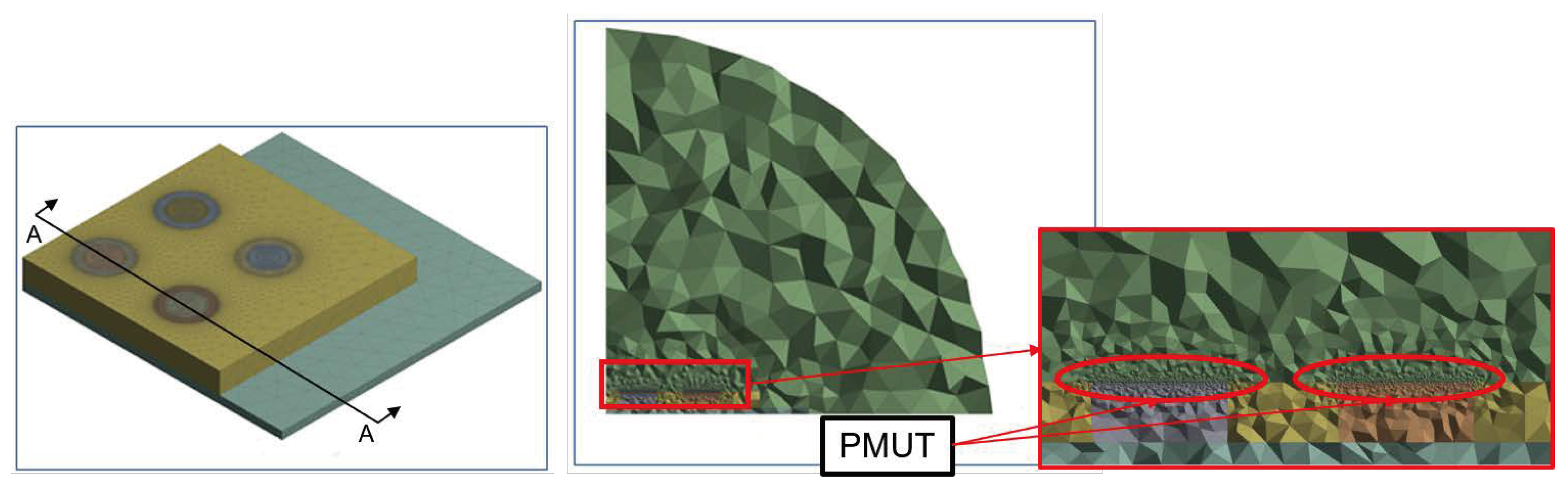

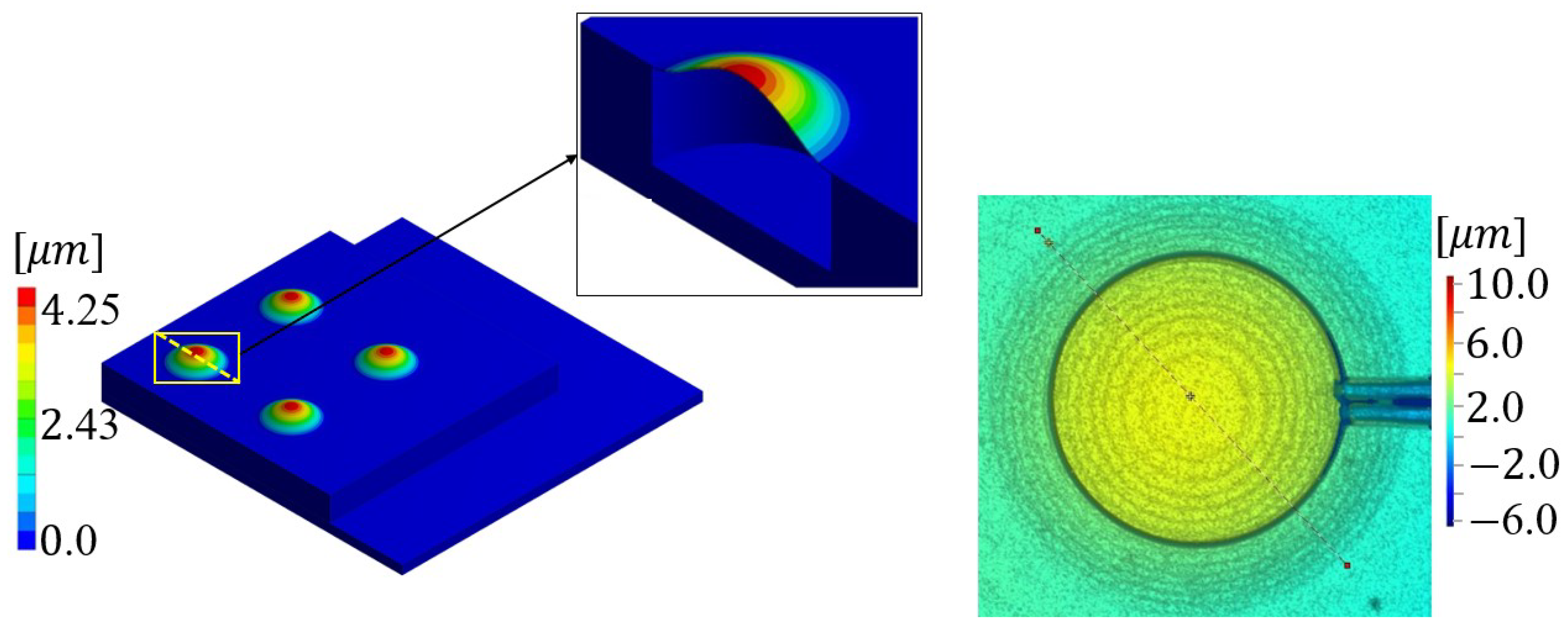

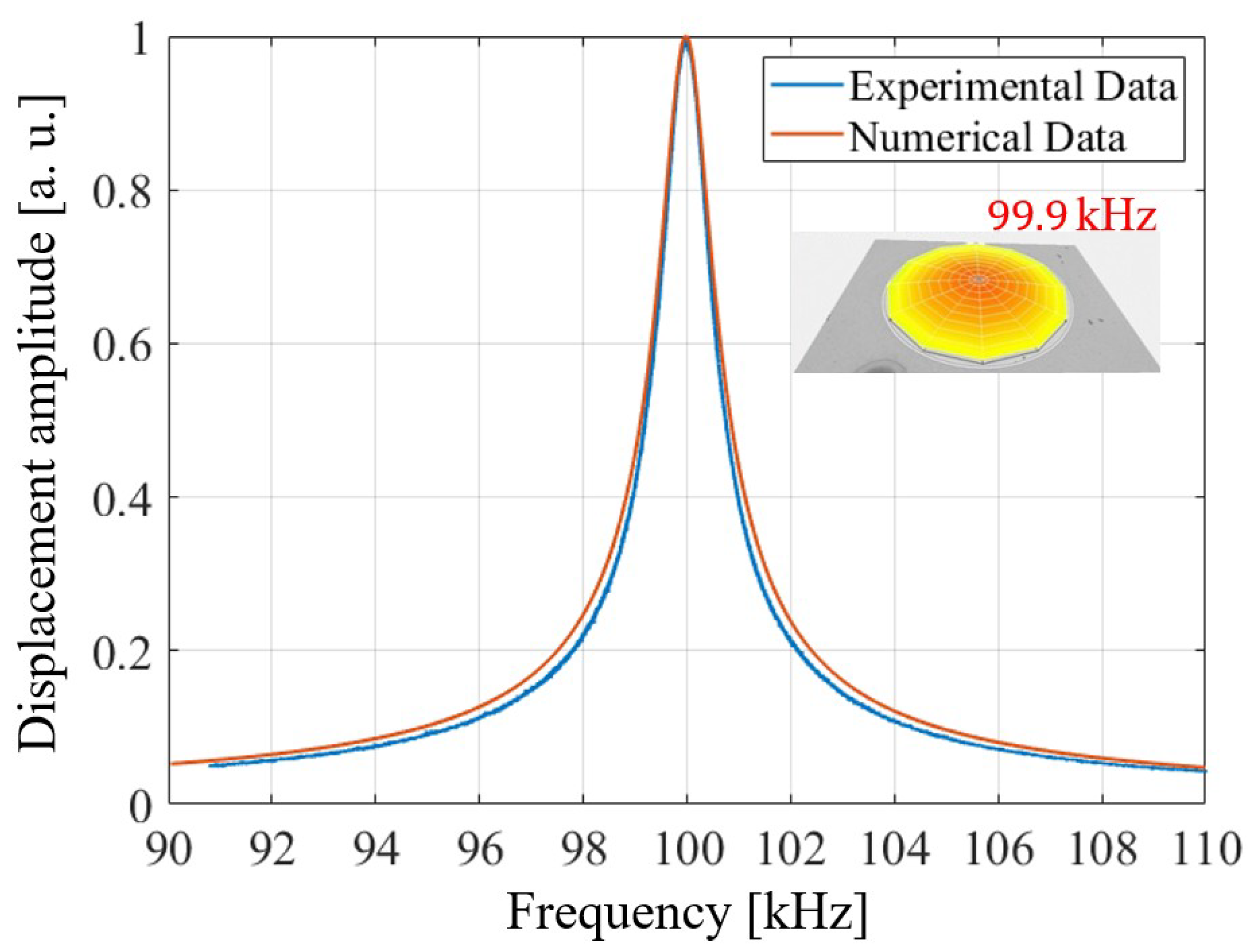

2. Numerical Modelling for the Single Transducer

3. Numerical Results and Experimental Validation

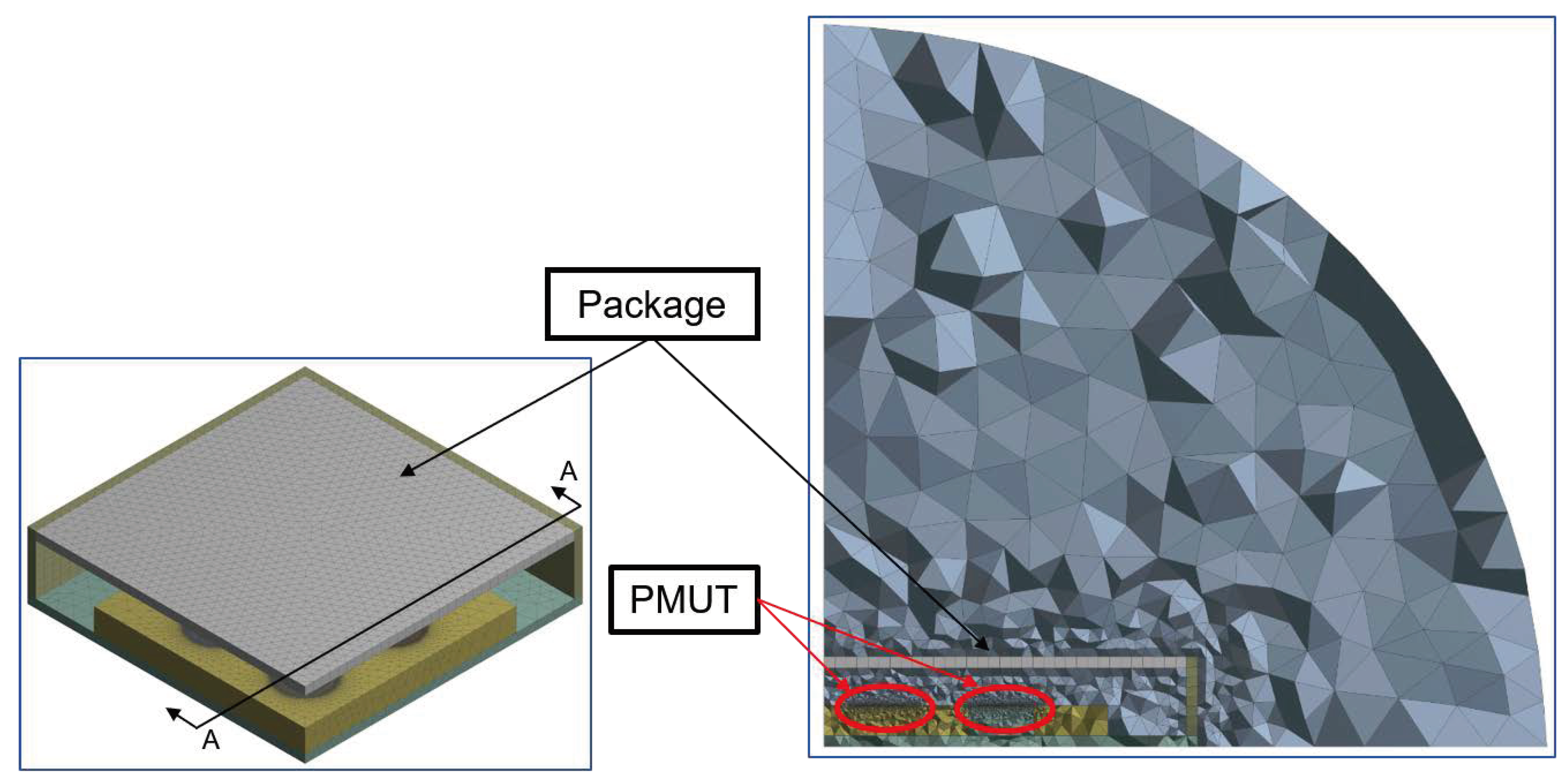

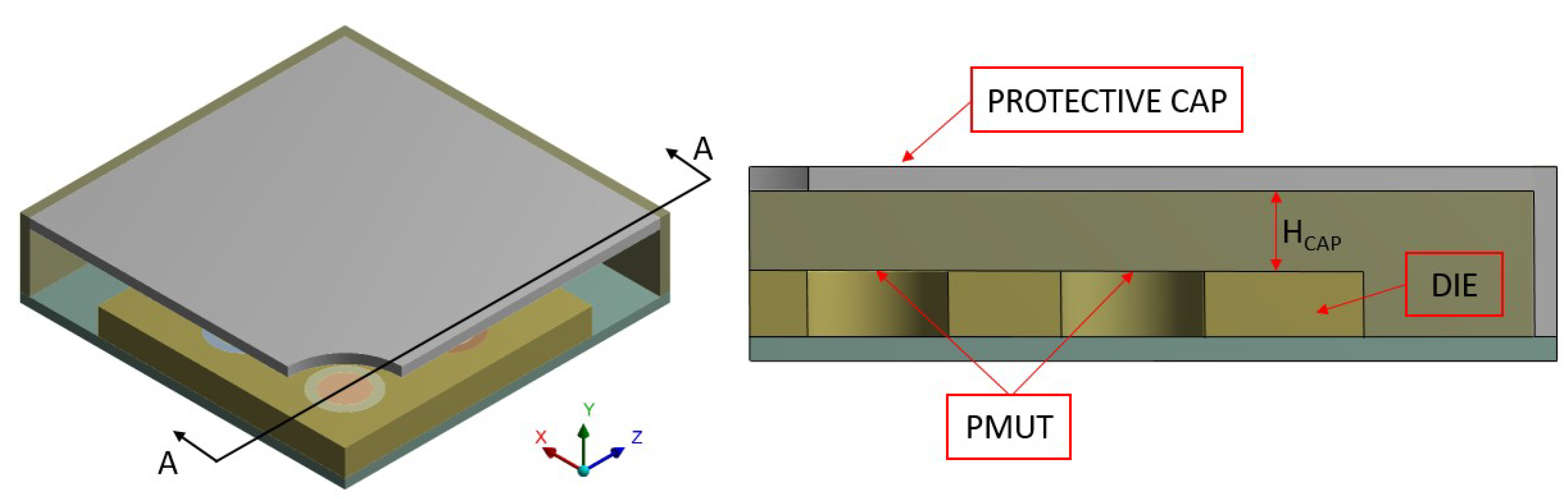

4. Analyses in Presence of Package

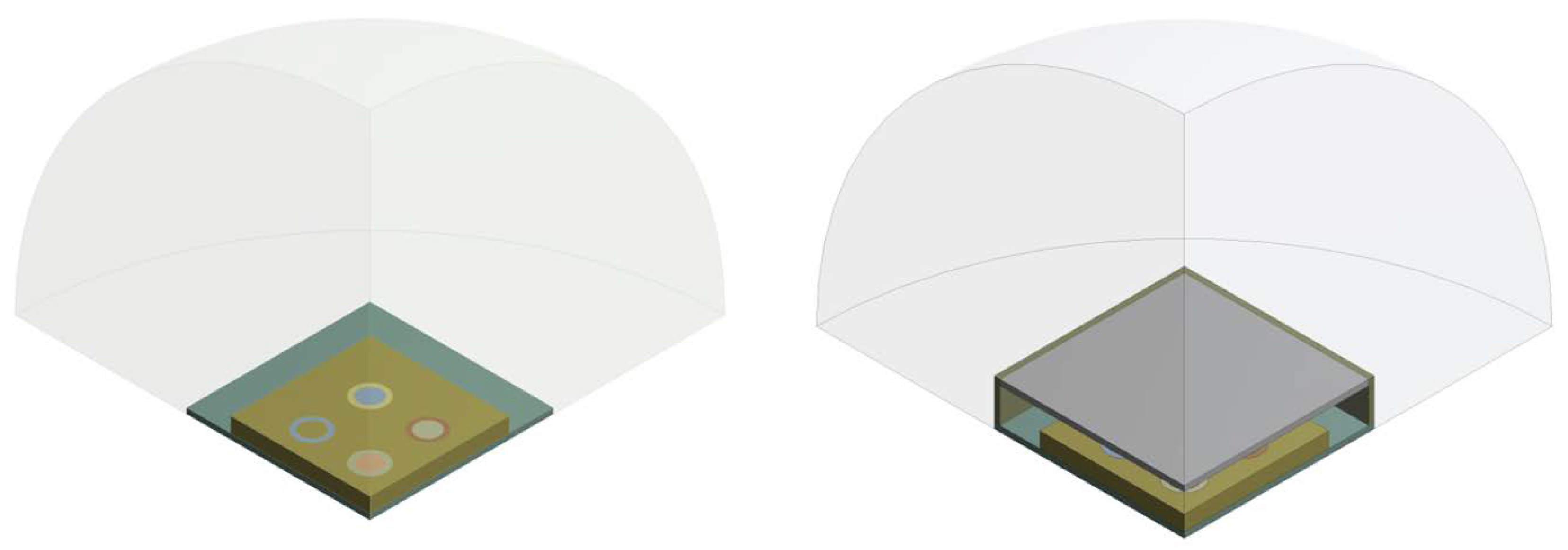

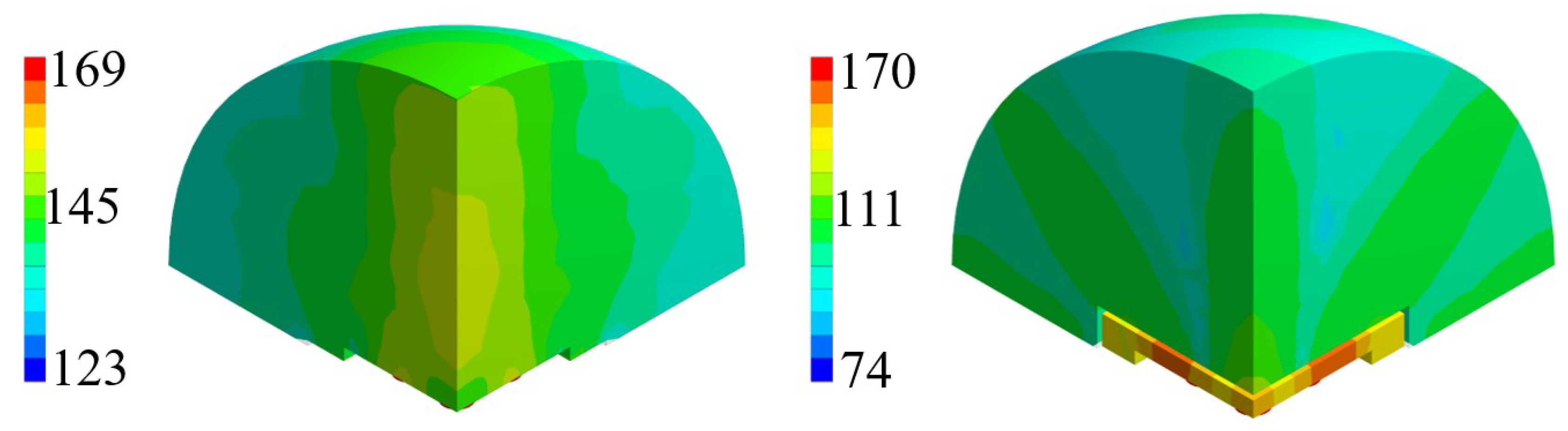

4.1. Stand-Alone Device vs. Packaged Device

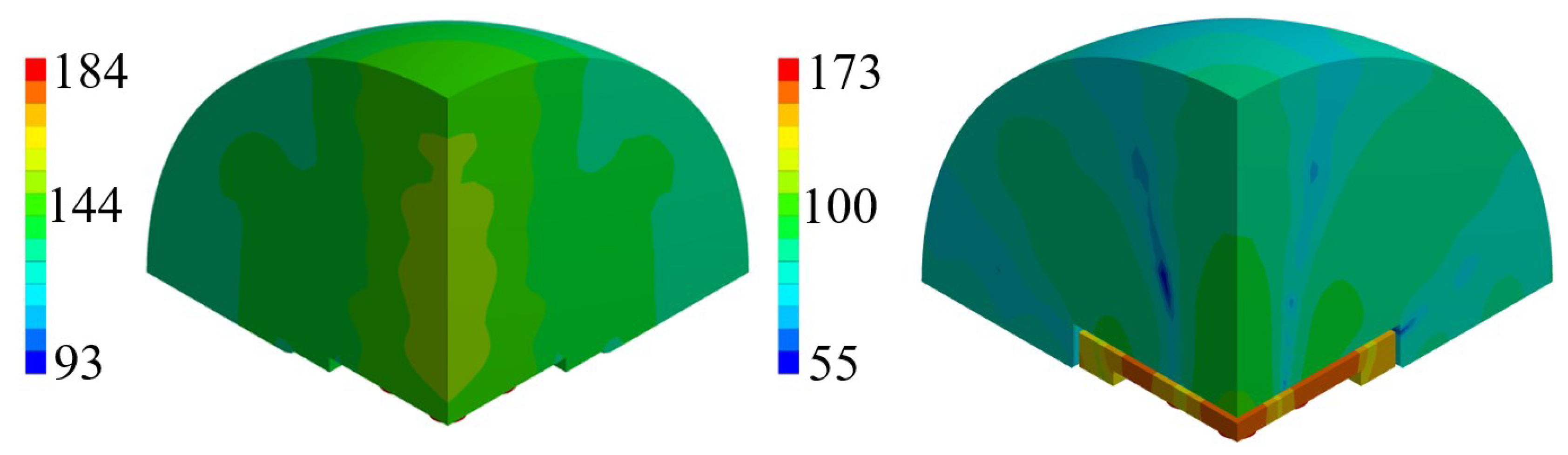

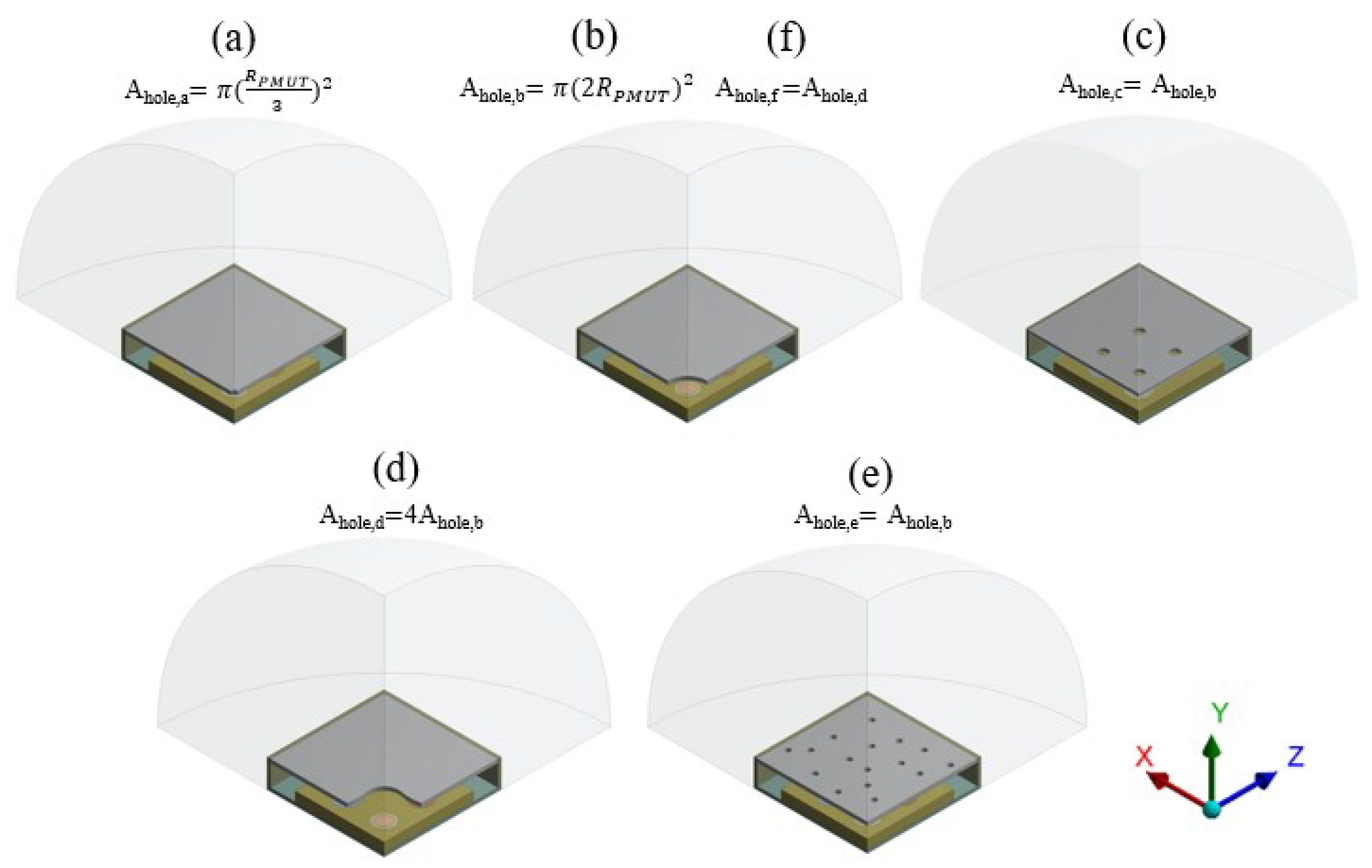

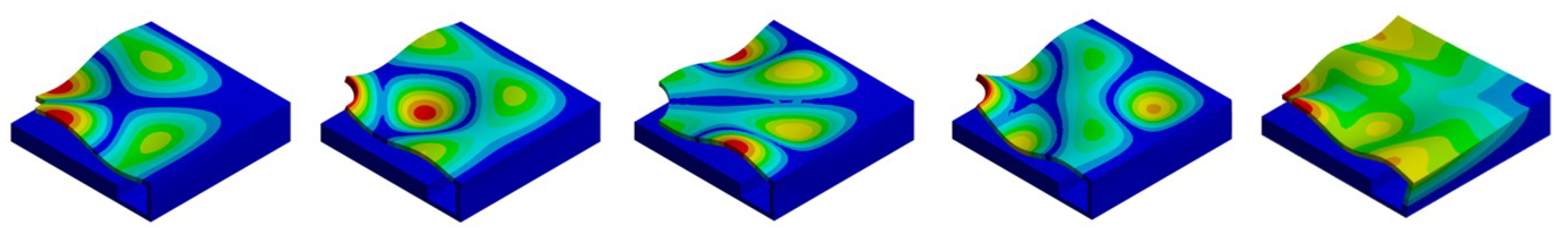

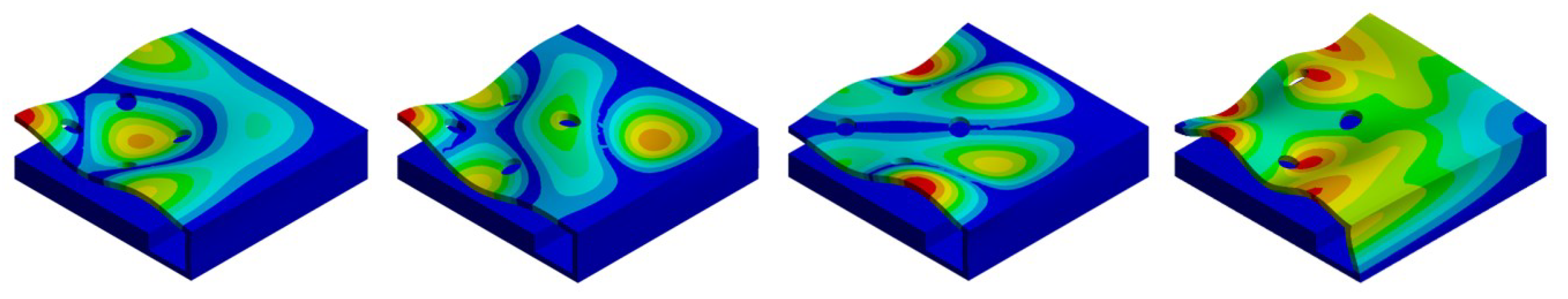

4.2. Simulations for Different Package Geometries

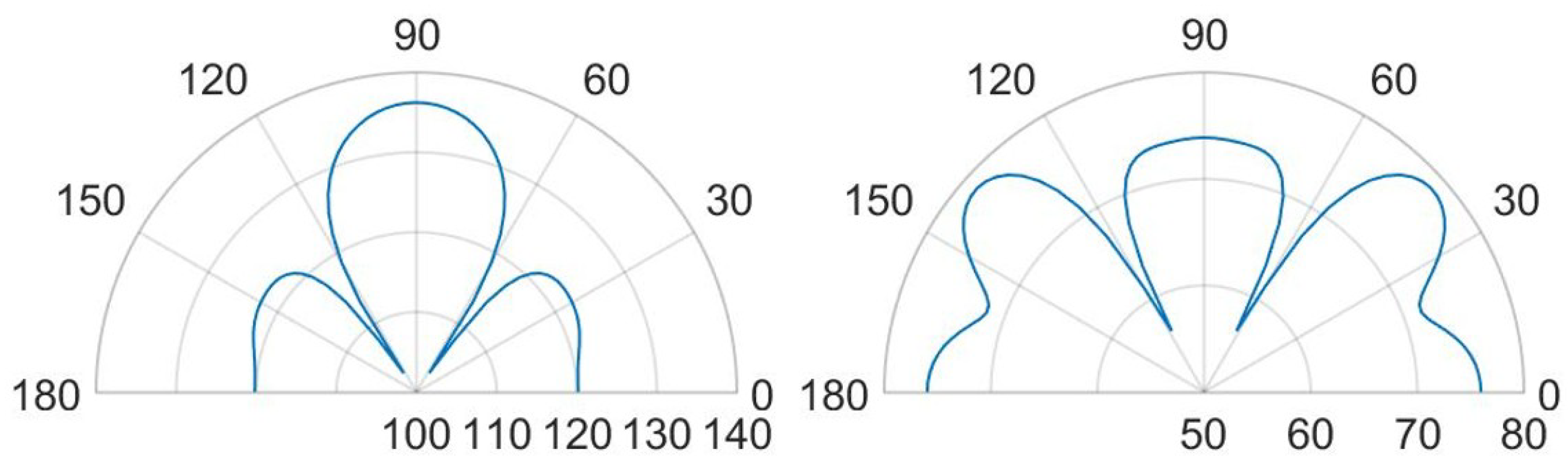

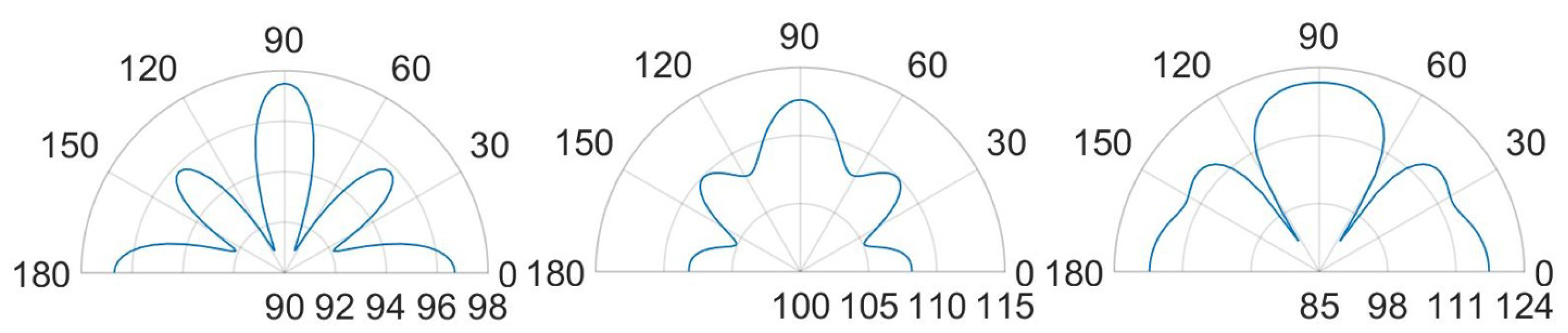

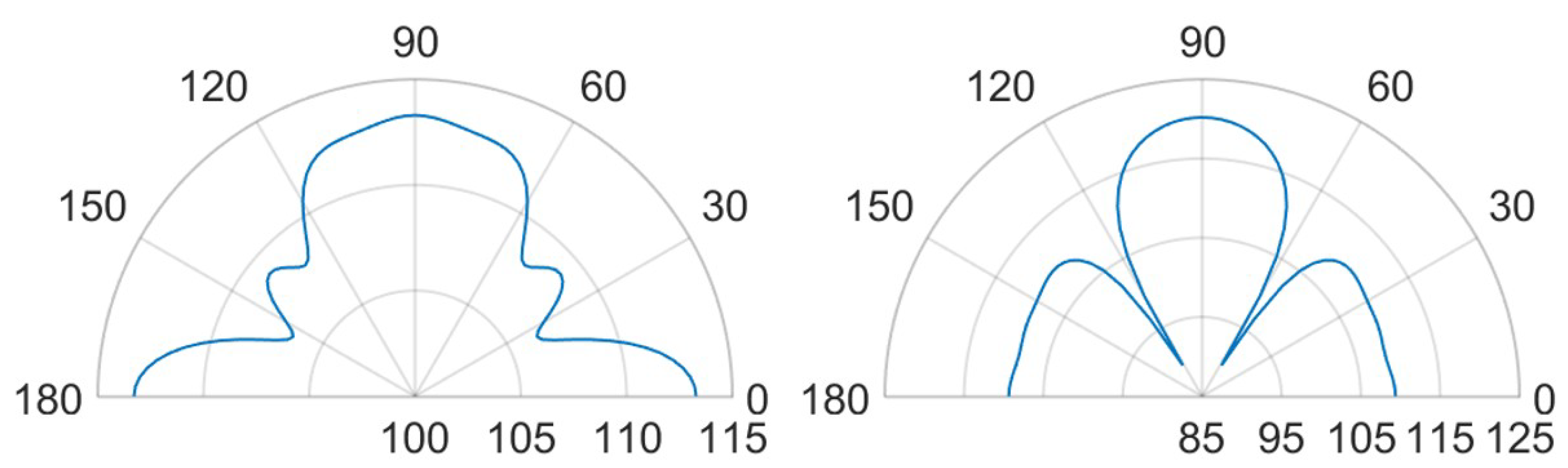

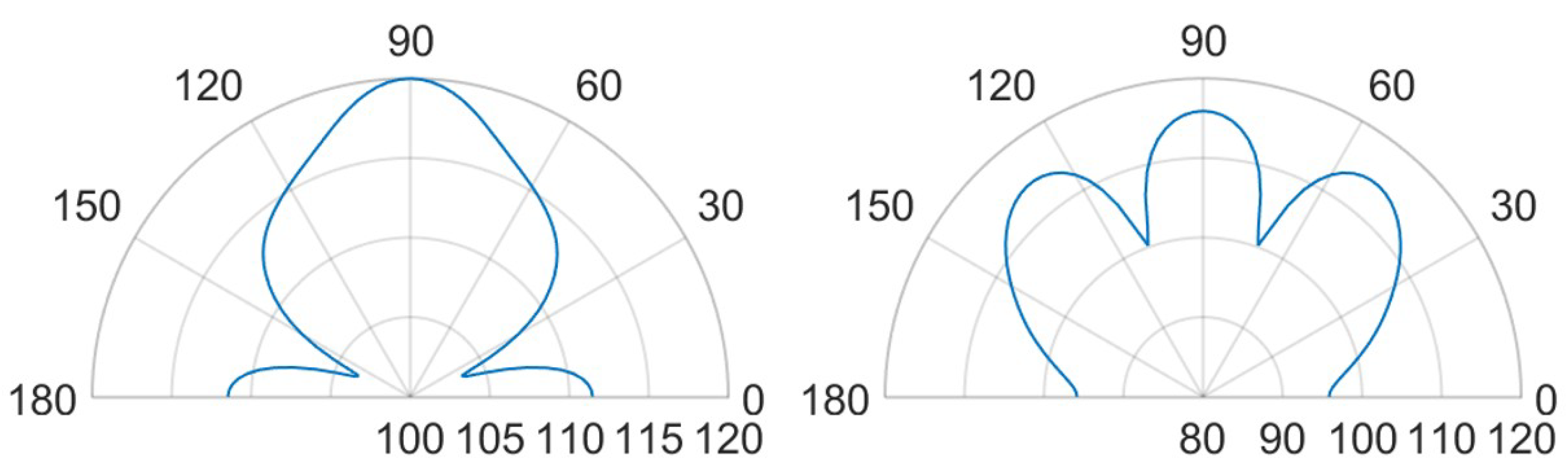

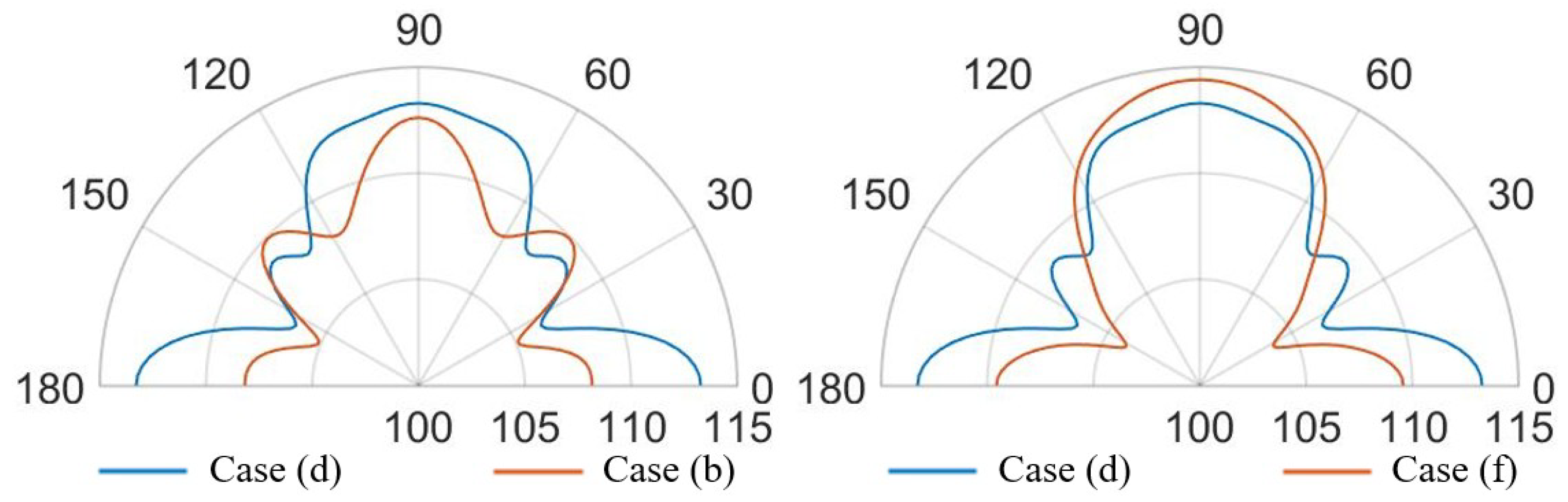

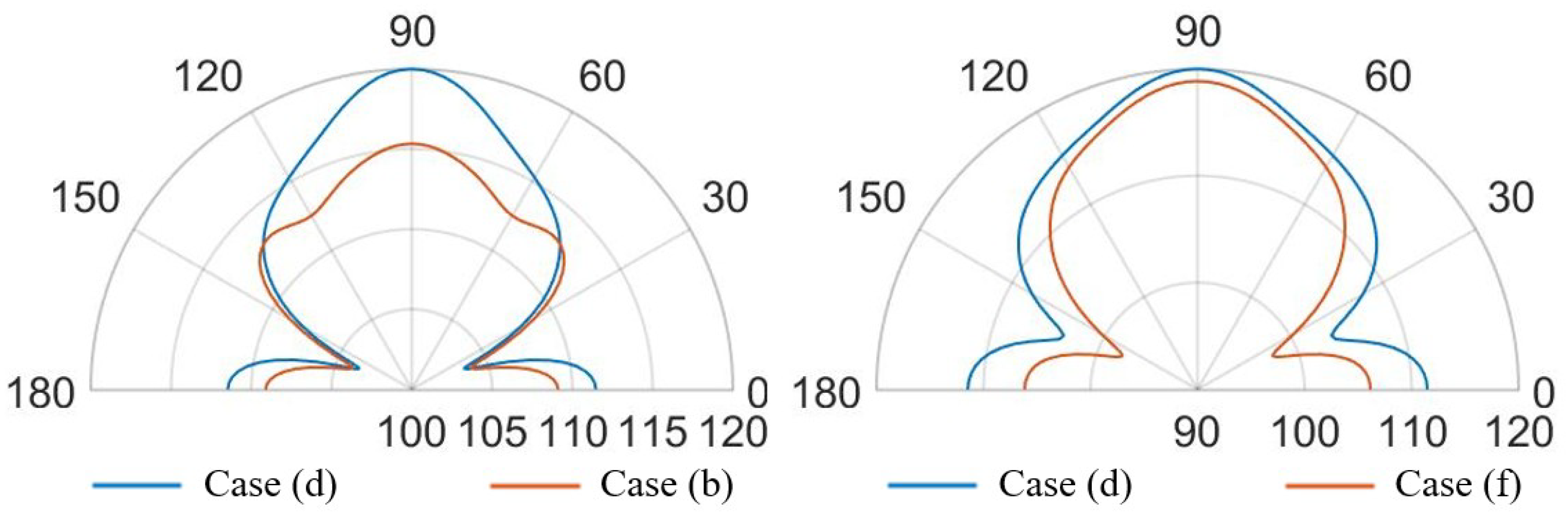

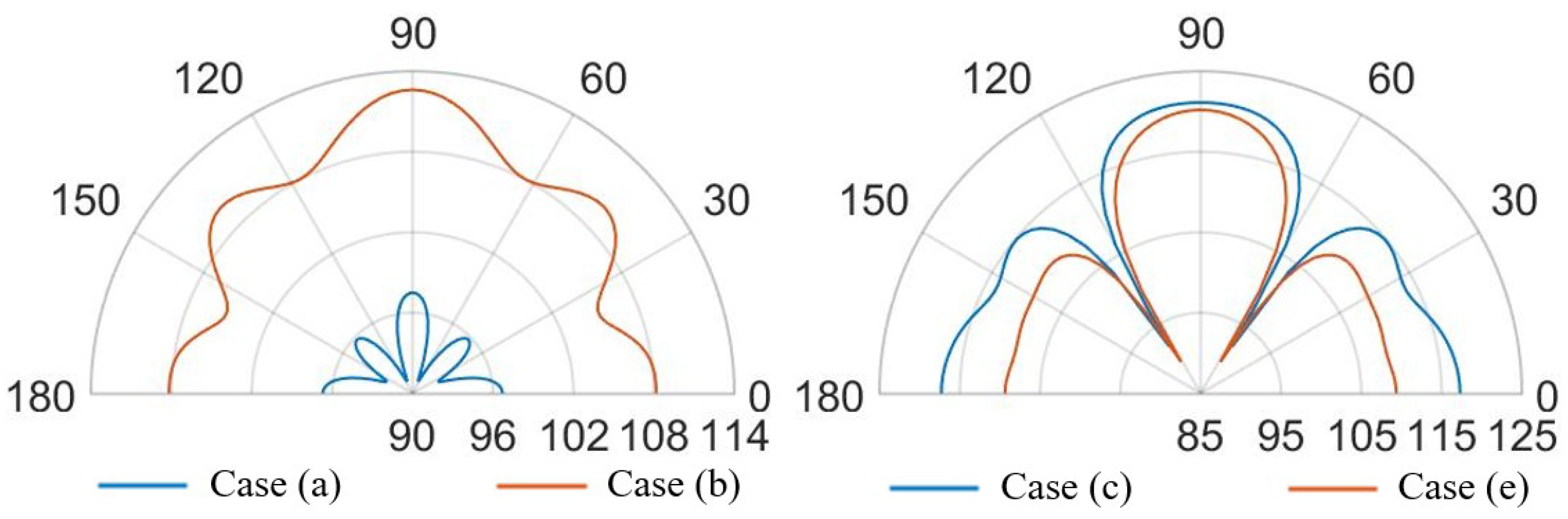

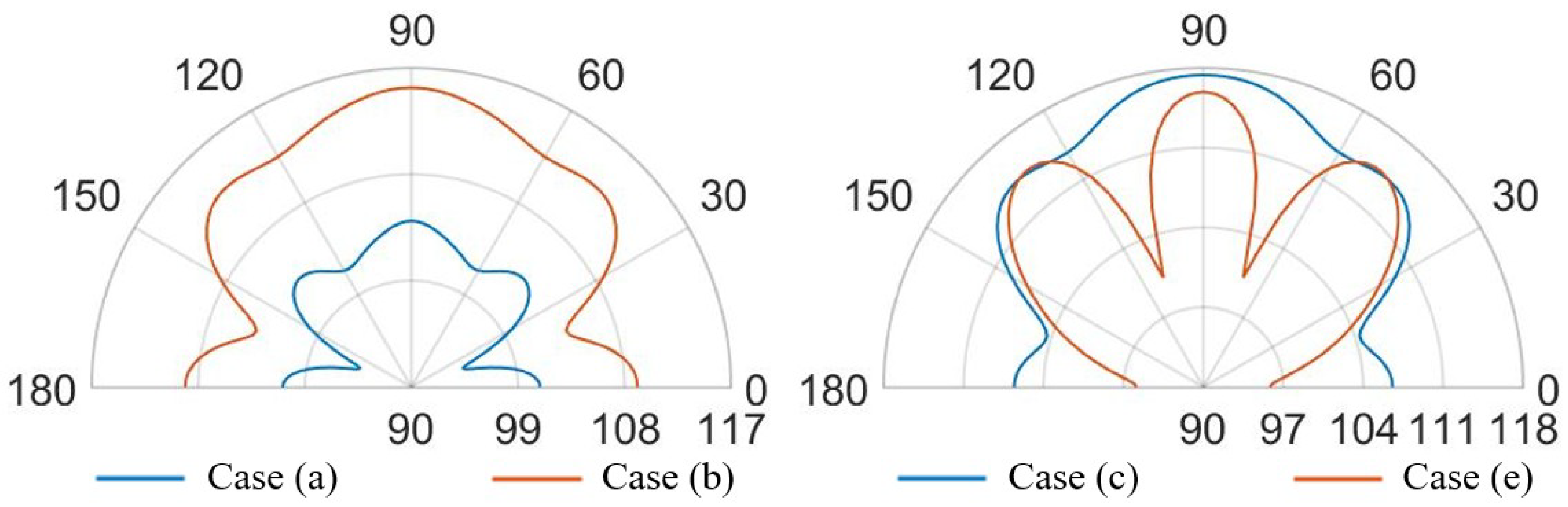

4.3. SPL Polar Comparison among Different Package Configurations

5. Closing Remarks on the Package Effects

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| ABC | Absorbing Boundary Condition |

| ASI | Acoustic-Structure Interaction |

| EMA | Electro-Mechanical-Acoustic |

| FSI | Fluid-Structure Interaction |

| PMUT | Piezoelectric micromachined ultrasonic transducer |

| SPL | Sound pressure level |

References

- Corigliano, A.; Ardito, R.; Comi, C.; Frangi, A.; Ghisi, A.; Mariani, S. Mechanics of Microsystems; John Wiley & Sons: New York, NY, USA, 2018. [Google Scholar]

- Trolier-McKinstry, S.; Muralt, P. Thin film piezoelectrics for MEMS. J. Electroceram. 2004, 12, 7–17. [Google Scholar] [CrossRef]

- Ardito, R.; Bertarelli, E.; Corigliano, A.; Gafforelli, G. On the application of piezolaminated composites to diaphragm micropumps. Compos. Struct. 2013, 99, 231–240. [Google Scholar] [CrossRef]

- Farshchi Yazdi, S.A.F.; Corigliano, A.; Ardito, R. 3-D Design and Simulation of a Piezoelectric Micropump. Micromachines 2019, 10, 259. [Google Scholar] [CrossRef] [PubMed]

- Cazorla, P.H.; Fuchs, O.; Cochet, M.; Maubert, S.; Le Rhun, G.; Fouillet, Y.; Defay, E. A low voltage silicon micro-pump based on piezoelectric thin films. Sens. Actuators A Phys. 2016, 250, 35–39. [Google Scholar] [CrossRef]

- Ardito, R.; Corigliano, A.; Gafforelli, G.; Valzasina, C.; Procopio, F.; Zafalon, R. Advanced Model for Fast Assessment of Piezoelectric Micro Energy Harvesters. Front. Mater. 2016, 3, 17.1–17.9. [Google Scholar] [CrossRef][Green Version]

- Kuwano, H. Highly efficient piezoelectric micro-energy harvesters with AlN thin films grown directly on flexible Ti foils. In Proceedings of the 2017 IEEE 30th International Conference on Micro Electro Mechanical Systems (MEMS), Las Vegas, NV, USA, 22–26 January 2017; pp. 833–836. [Google Scholar]

- Massimino, G.; Colombo, A.; D’Alessandro, L.; Procopio, F.; Ardito, R.; Ferrera, M.; Corigliano, A. Multiphysics modelling and experimental validation of an air-coupled array of PMUTs with residual stresses. J. Micromech. Microeng. 2018, 28, 054005. [Google Scholar] [CrossRef]

- Massimino, G.; Colombo, A.; Ardito, R.; Quaglia, F.; Foncellino, F.; Corigliano, A. Air-Coupled Array of Pmuts at 100 kHz with PZT Active Layer: Multiphysics Model and Experiments. In Proceedings of the 2019 20th International Conference on Thermal, Mechanical and Multi-Physics Simulation and Experiments in Microelectronics and Microsystems (EuroSimE), Hannover, Germany, 24–27 March 2019; pp. 1–5. [Google Scholar]

- Lu, Y.; Horsley, D. Modeling, Fabrication, and Characterization of Piezoelectric Micromachined Ultrasonic Transducer Arrays Based on Cavity SOI Wafers. J. Microelectromech. Syst. 2015, 24, 1142–1149. [Google Scholar] [CrossRef]

- Rozen, O.; Block, S.; Mo, X.; Bland, W.; Hurst, P.; Tsai, J.; Daneman, M.; Amirtharajah, R.; Horsley, D. Monolithic MEMS-CMOS ultrasonic rangefinder based on dual-electrode PMUTs. In Proceedings of the IEEE International Conference on Micro Electro Mechanical Systems (MEMS), Shanghai, China, 24–28 January 2016; pp. 115–118. [Google Scholar] [CrossRef]

- Jiang, X.; Lu, Y.; Tang, H.Y.; Tsai, J.M.; Ng, E.J.; Daneman, M.J.; Boser, B.E.; Horsley, D.A. Monolithic ultrasound fingerprint sensor. Microsyst. Nanoeng. 2017, 3, 17059. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Xu, J.; Chen, H.; Ding, H.; Xie, J. High-Accuracy Ultrasonic Rangefinders via pMUTs Arrays Using Multi-Frequency Continuous Waves. J. Microelectromech. Syst. 2019, 28, 634–642. [Google Scholar] [CrossRef]

- Gijsenbergh, P.; Halbach, A.; Jeong, Y.; Torri, G.B.; Billen, M.; Demi, L.; Huang, C.H.; Cheyns, D.; Rottenberg, X.; Rochus, V. Characterization of polymer-based piezoelectric micromachined ultrasound transducers for short-range gesture recognition applications. J. Micromech. Microeng. 2019, 29, 074001. [Google Scholar] [CrossRef]

- Lu, Y.; Tang, H.; Fung, S.; Wang, Q.; Tsai, J.; Daneman, M.; Boser, B.; Horsley, D. Ultrasonic fingerprint sensor using a piezoelectric micromachined ultrasonic transducer array integrated with complementary metal oxide semiconductor electronics. Appl. Phys. Lett. 2015, 106, 263503. [Google Scholar] [CrossRef]

- Alasatri, S.; Rufer, L.; Lee, J.E.Y. AlN-on-Si Square Diaphragm Piezoelectric Micromachined Ultrasonic Transducer with Extended Range of Detection. Proceedings 2018, 2, 913. [Google Scholar] [CrossRef]

- Ling, J.; Wei, Y.H.; Jiang, G.Y.; Chen, Y.Q.; Tian, H.; Yang, Y.; Ren, T.L. Piezoelectric Micromachined Ultrasonic Transducers for Ultrasound Imaging. In Proceedings of the 2018 IEEE International Conference on Electron Devices and Solid State Circuits (EDSSC), Hong Kong, China, 3–5 June 2018; pp. 1–2. [Google Scholar]

- Smyth, K.; Sodini, C.; Kim, S.G. High electromechanical coupling piezoelectric micro-machined ultrasonic transducer (PMUT) elements for medical imaging. In Proceedings of the 2017 19th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Kaohsiung, Taiwan, 18–22 June 2017; pp. 966–969. [Google Scholar]

- Lu, Y.; Tang, H.Y.; Fung, S.; Boser, B.E.; Horsley, D.A. Pulse-echo ultrasound imaging using an AlN piezoelectric micromachined ultrasonic transducer array with transmit beam-forming. J. Microelectromech. Syst. 2015, 25, 179–187. [Google Scholar] [CrossRef]

- Eovino, B.E.; Liang, Y.; Lin, L. Concentric PMUT Arrays for Focused Ultrasound and High Intensity Applications. In Proceedings of the 2019 IEEE 32nd International Conference on Micro Electro Mechanical Systems (MEMS), Seoul, Korea, 27–31 January 2019; pp. 771–774. [Google Scholar]

- Ardito, R.; D’Alessandro, L.; Massimino, G.; Procopio, F.; Corigliano, A. Multiphysics analyses of the effect of package on the performances of PMUT transducers. In Proceedings of the VII International Conference on Coupled Problems in Science and Engineering, Rhodes Island, Greece, 12–14 June 2017. [Google Scholar]

- Sadeghpour, S.; Lips, B.; Kraft, M.; Puers, R. Flexible Soi-Based Piezoelectric Micromachined Ultrasound Transducer (PMUT) Arrays. In Proceedings of the 2019 20th International Conference on Solid-State Sensors, Actuators and Microsystems & Eurosensors XXXIII (TRANSDUCERS & EUROSENSORS XXXIII), Berlin, Germany, 23–27 June 2019; pp. 250–253. [Google Scholar]

- Massimino, G.; D’Alessandro, L.; Procopio, F.; Ardito, R.; Ferrera, M.; Corigliano, A. Air-coupled PMUT at 100 kHz with PZT active layer and residual stresses: Multiphysics model and experimental validation. In Proceedings of the 18th International Conference on Thermal, Mechanical and Multi-Physics Simulation and Experiments in Microelectronics and Microsystems (EuroSimE), Dresden, Germany, 3–5 April 2017; p. 7926253. [Google Scholar] [CrossRef]

- Sarkar, L.; Joseph, J.; Singh, S.G.; Vanjari, S.R.K. Modeling and Fabrication Aspects of PVDF as a Membrane Material for Air Borne PMUT Applications. In Proceedings of the 2018 IEEE SENSORS, New Delhi, India, 28–31 October 2018; pp. 1–4. [Google Scholar]

- Massimino, G.; D’Alessandro, L.; Procopio, F.; Ardito, R.; Ferrera, M.; Corigliano, A. Multiphysics Analysis and Experimental Validation of an air Coupled Piezoelectric Micromachined Ultrasonic Transducer with Residual Stresses. Procedia Eng. 2016, 168, 852–855. [Google Scholar] [CrossRef]

- Fedeli, P.; Kamlah, M.; Frangi, A. Phase-field modeling of domain evolution in ferroelectric materials in the presence of defects. Smart Mater. Struct. 2019, 28. [Google Scholar] [CrossRef]

- Ohayon, R.; Soize, C. Structural Acoustics and VIBRATION: Mechanical Models, Variational Formulations and Discretization; Elsevier: Amsterdam, The Netherlands, 1997. [Google Scholar]

- Kinsler, L.; Frey, A.; Coppens, A.; Sanders, J. Fundamentals of Acoustics; John Wiley & Sons: New York, NY, USA, 2000. [Google Scholar]

- Been, K.; Lee, J.; Moon, W. Helmholtz-Kirchhoff integral formula for predicting the acoustic pressure from a radiator including irregular surface. J. Acoust. Soc. Am. 2019, 146, 3074. [Google Scholar] [CrossRef]

- Wang, Q.; Horsley, D.A. Using a mutual acoustic impedance model to improve the time domain response of pmut arrays. In Proceedings of the 2017 IEEE International Ultrasonics Symposium (IUS), Washington, DC, USA, 6–9 September 2017; pp. 1–4. [Google Scholar]

- Xu, Q.; Lai, D. Piezoelectric micromachined ultrasonic transducers: Modeling and simulation of structural parameters on transmitting performance. In Proceedings of the 2015 IEEE Advanced Information Technology, Electronic and Automation Control Conference (IAEAC), Chongqing, China, 19–20 December 2015; pp. 648–652. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Massimino, G.; Colombo, A.; Ardito, R.; Quaglia, F.; Corigliano, A. On the Effects of Package on the PMUTs Performances—Multiphysics Model and Frequency Analyses. Micromachines 2020, 11, 307. https://doi.org/10.3390/mi11030307

Massimino G, Colombo A, Ardito R, Quaglia F, Corigliano A. On the Effects of Package on the PMUTs Performances—Multiphysics Model and Frequency Analyses. Micromachines. 2020; 11(3):307. https://doi.org/10.3390/mi11030307

Chicago/Turabian StyleMassimino, Gianluca, Alessandro Colombo, Raffaele Ardito, Fabio Quaglia, and Alberto Corigliano. 2020. "On the Effects of Package on the PMUTs Performances—Multiphysics Model and Frequency Analyses" Micromachines 11, no. 3: 307. https://doi.org/10.3390/mi11030307

APA StyleMassimino, G., Colombo, A., Ardito, R., Quaglia, F., & Corigliano, A. (2020). On the Effects of Package on the PMUTs Performances—Multiphysics Model and Frequency Analyses. Micromachines, 11(3), 307. https://doi.org/10.3390/mi11030307