A Biomimetic Fish Fin-Like Robot Based on Textile Reinforced Silicone

Abstract

1. Introduction

2. Materials and Methods

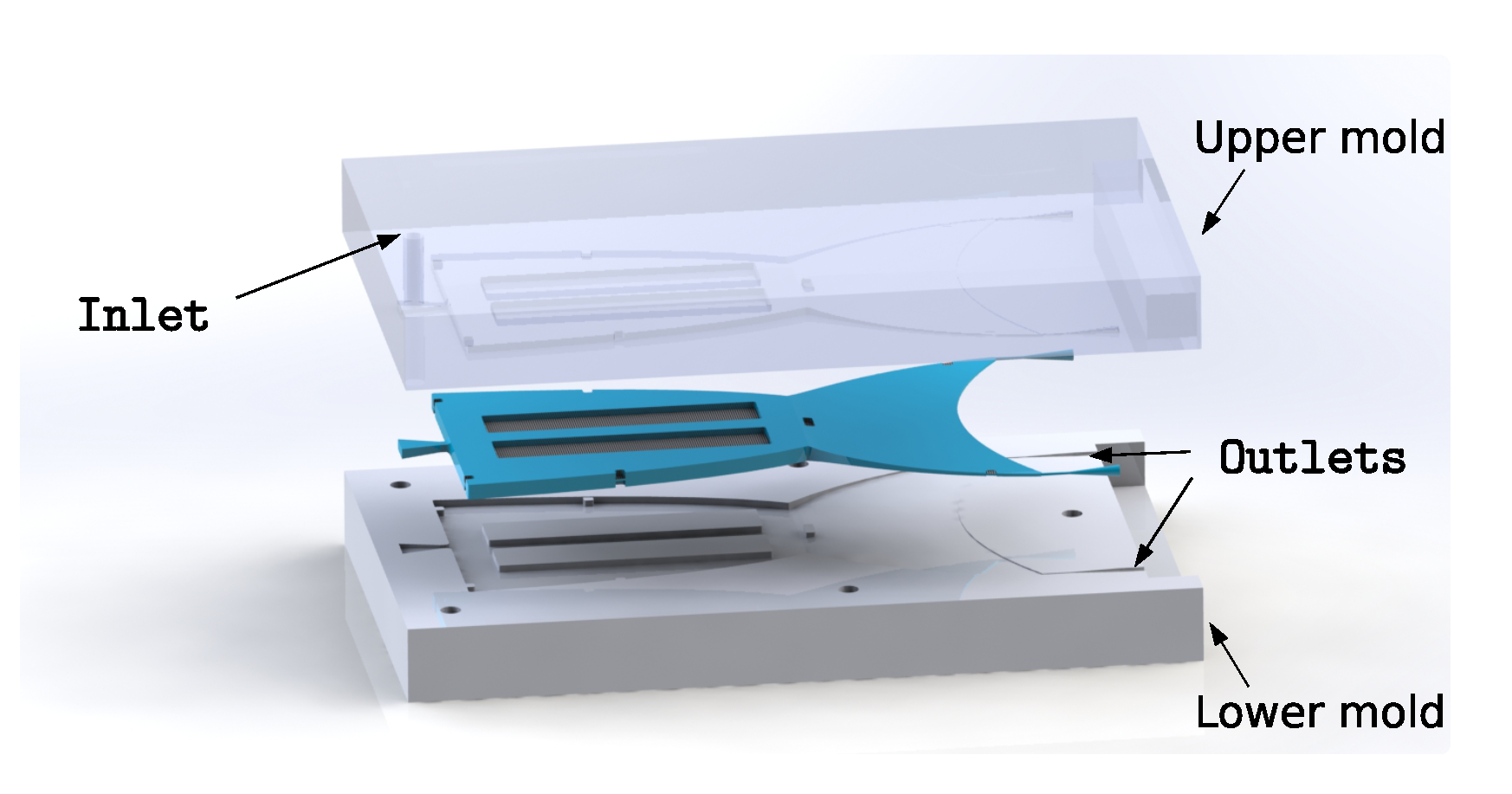

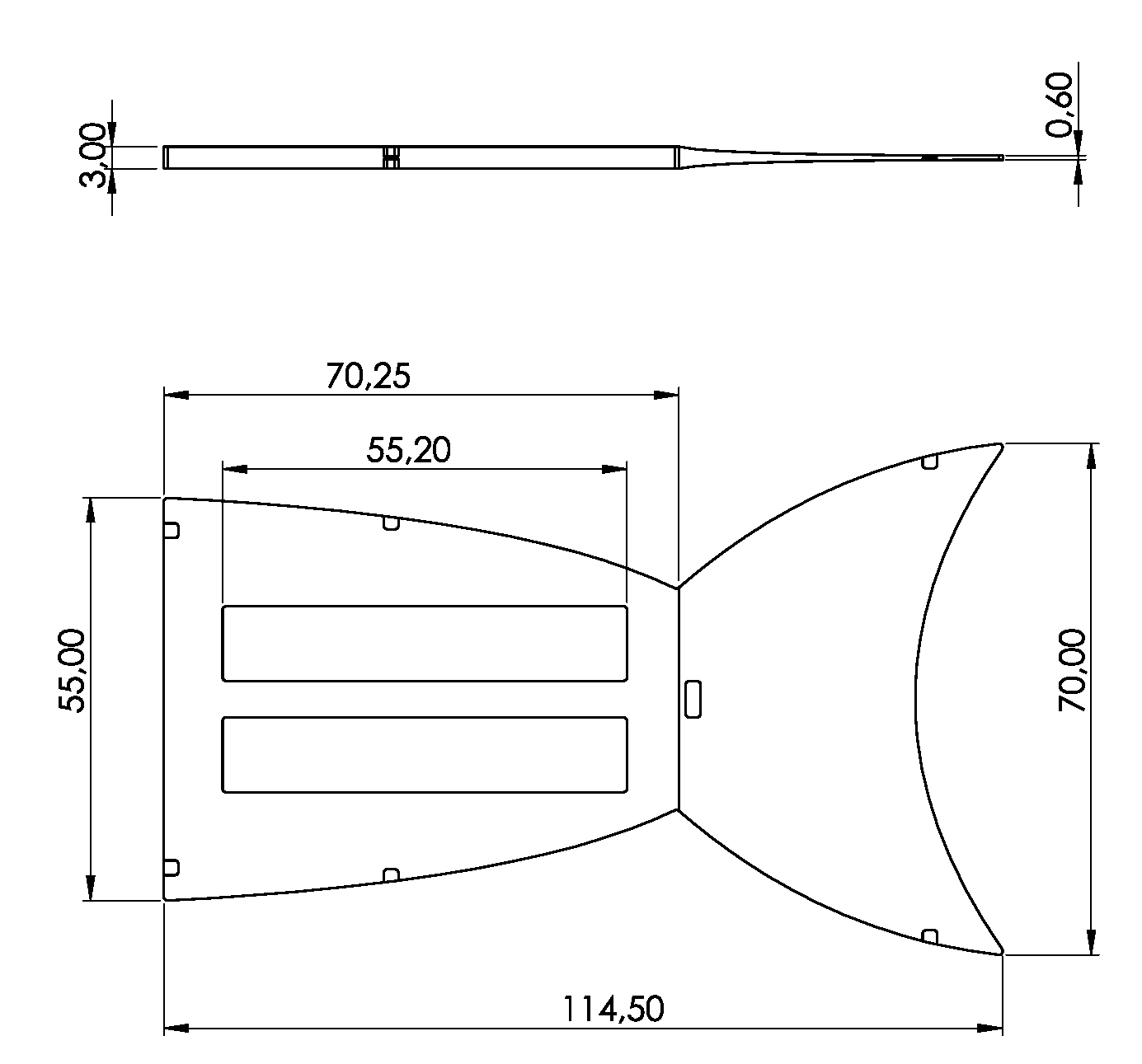

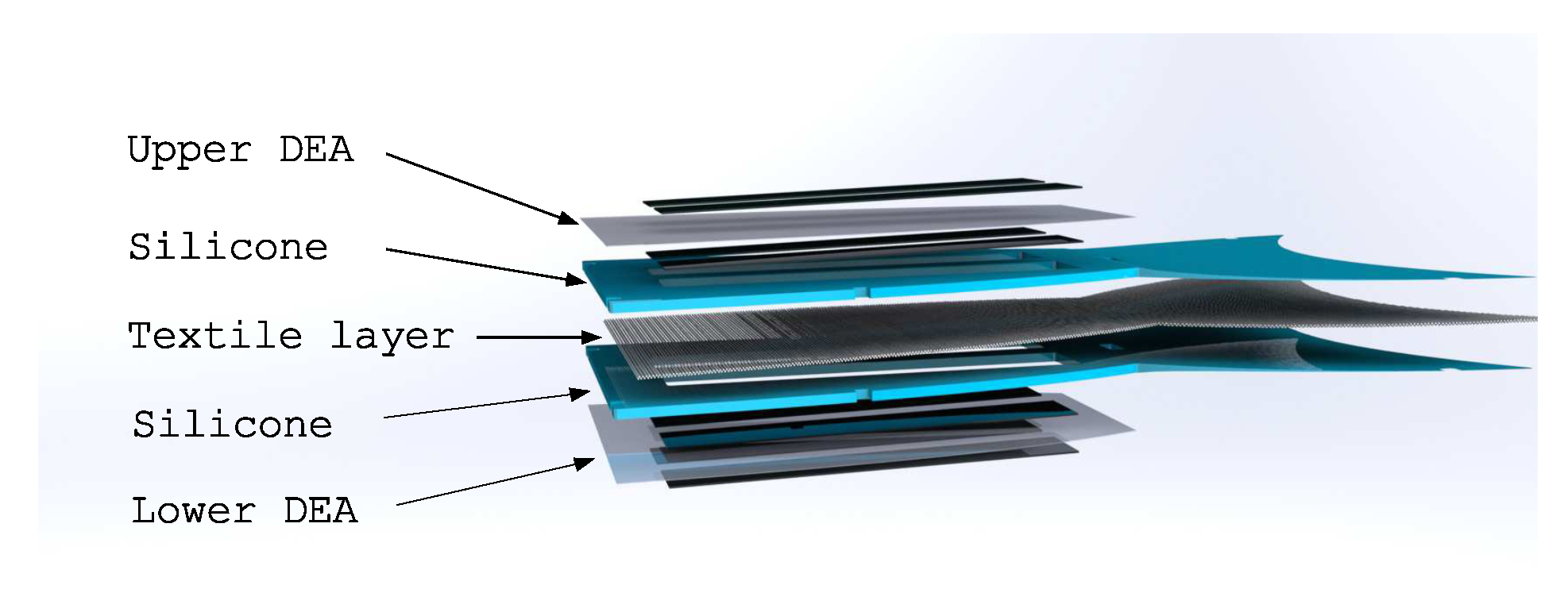

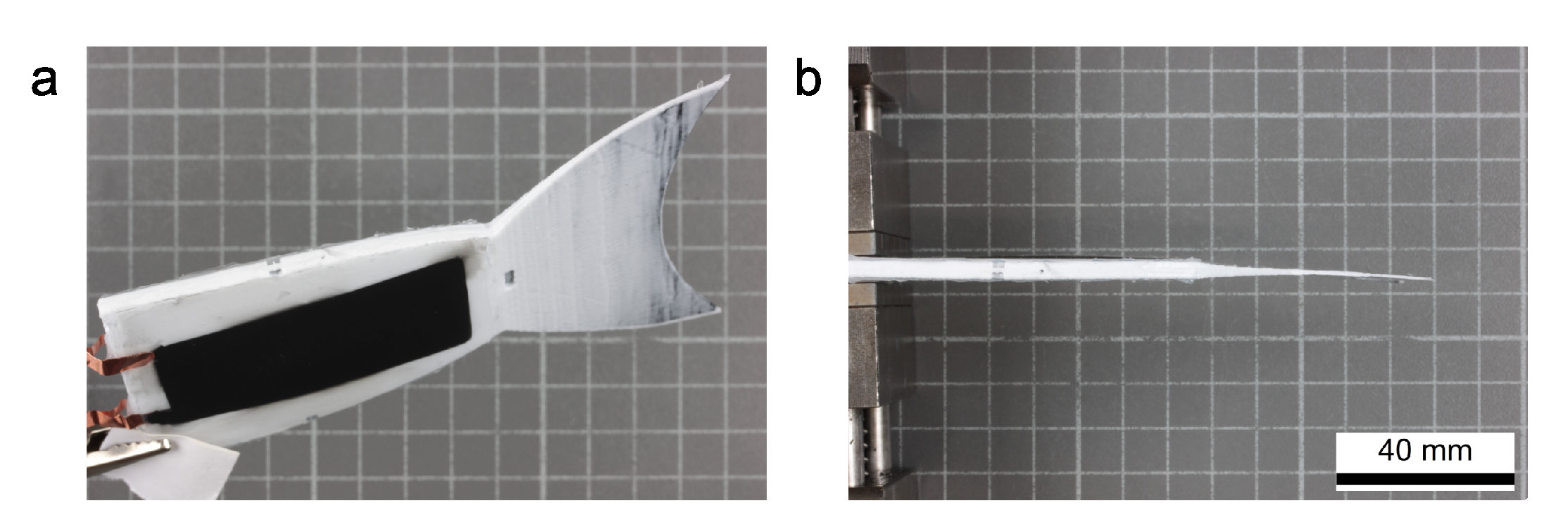

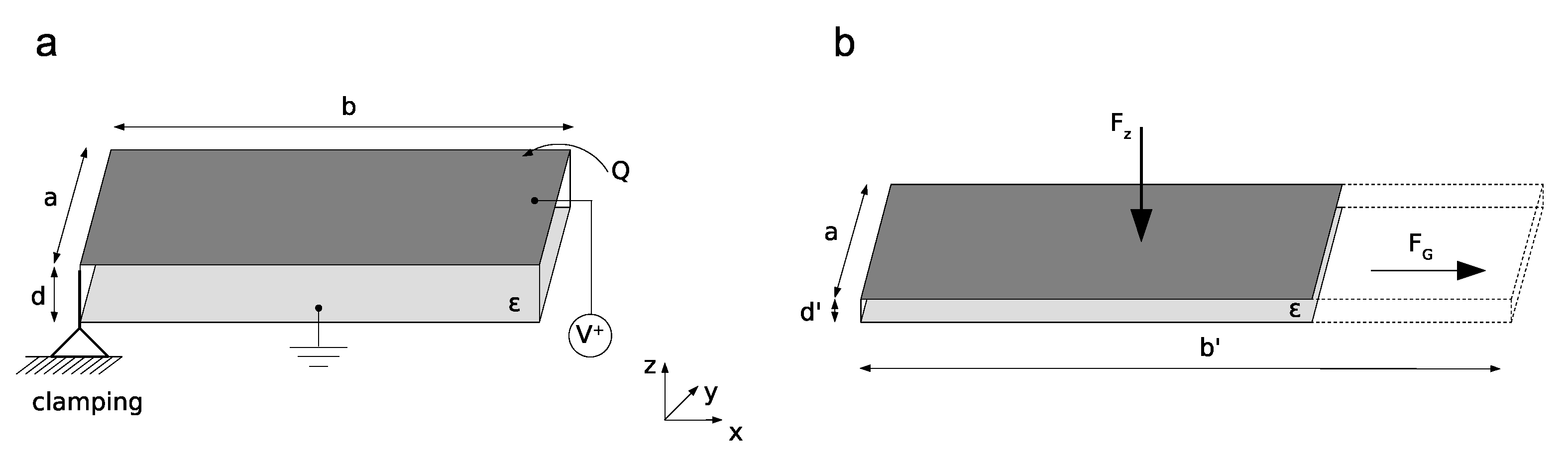

2.1. Robotic Concept

- It increased the electrical breakdown-strength of the material.

- The pull-in instability was suppressed.

- The silicone membrane was kept flat and defined in area, leading to a defined actuation.

- The operating point for the actuation was set in a beneficial region of the hyperelastic stress-strain curve of the dielectric material.

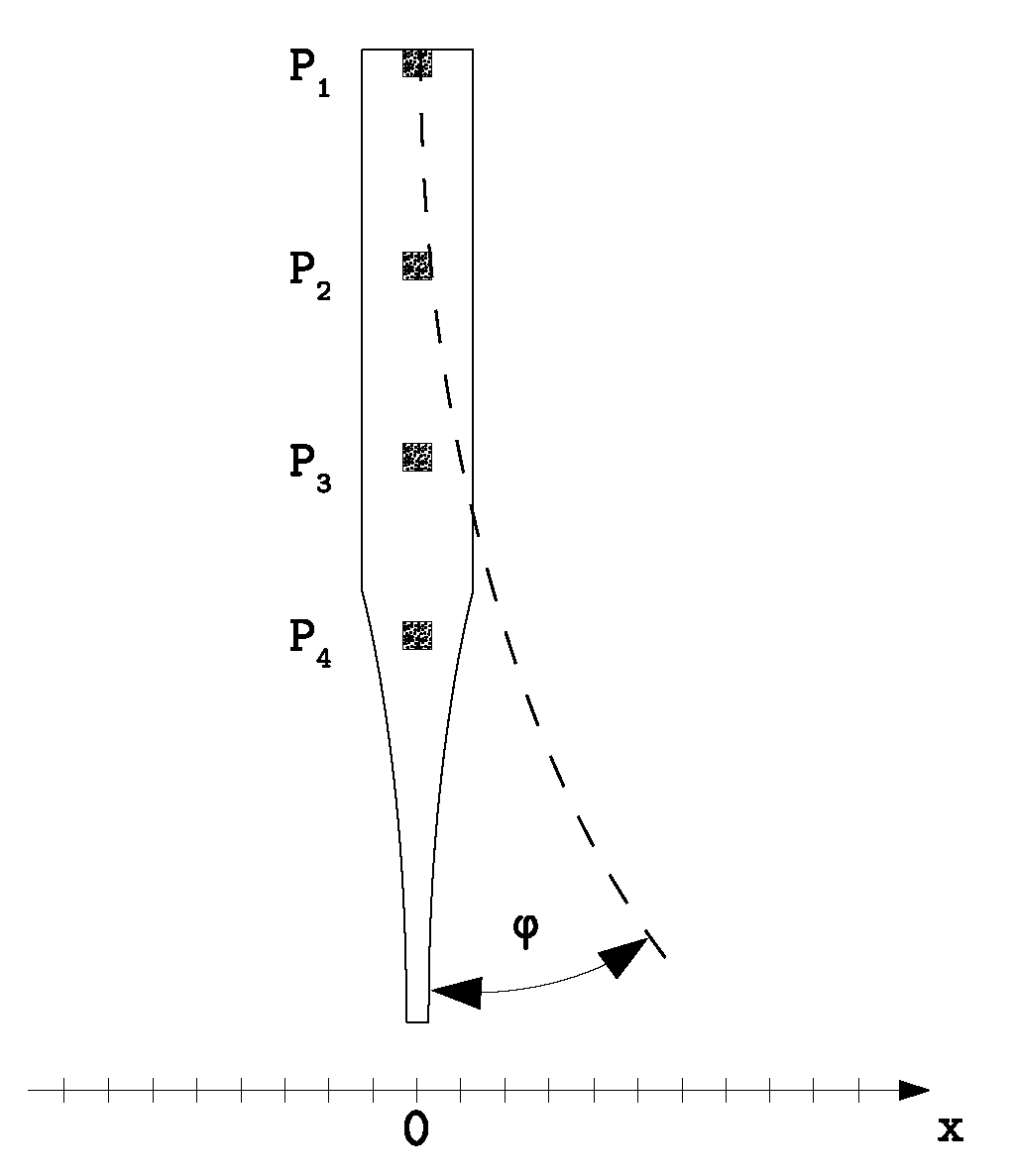

2.2. Bending Movement and Force Generation

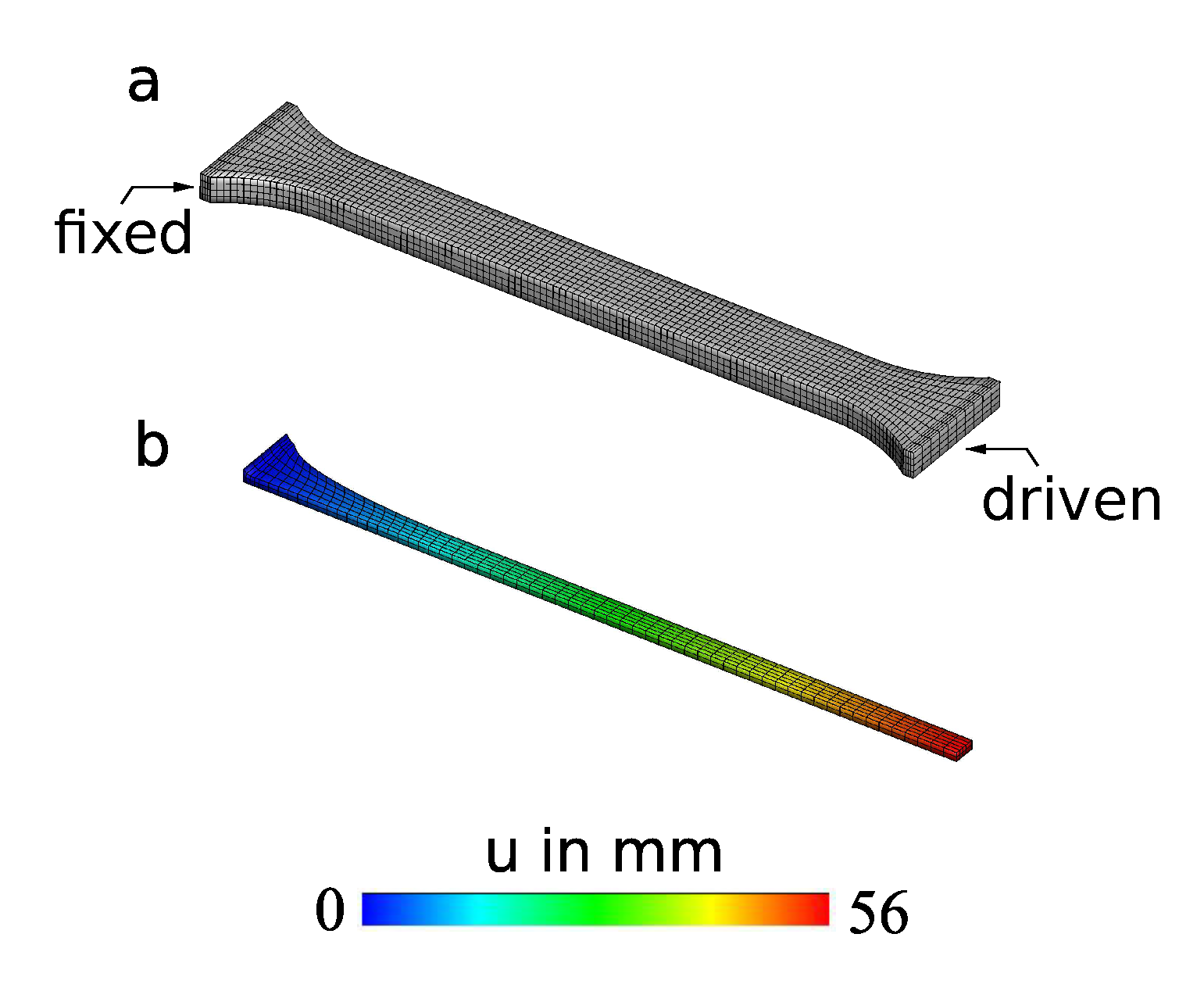

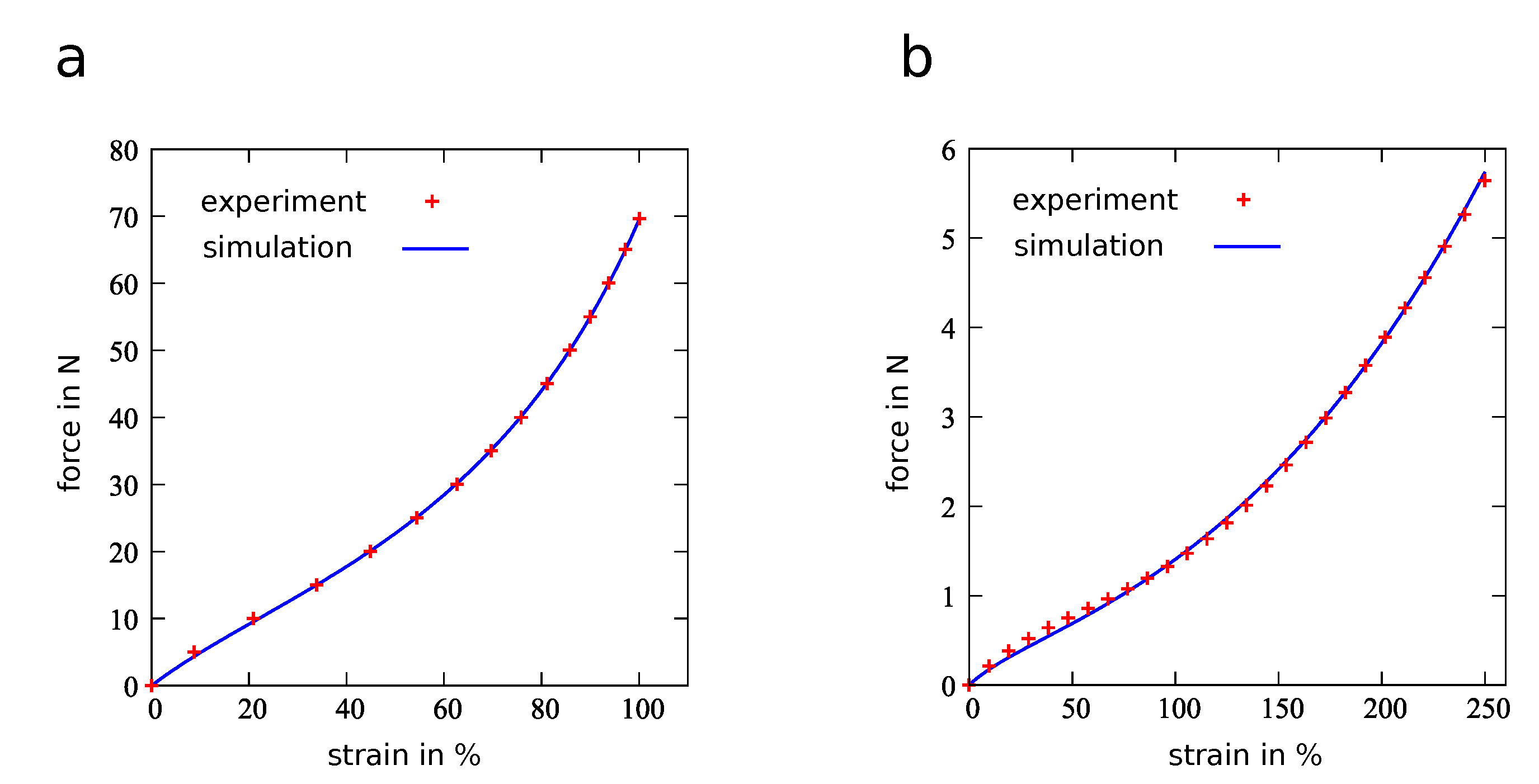

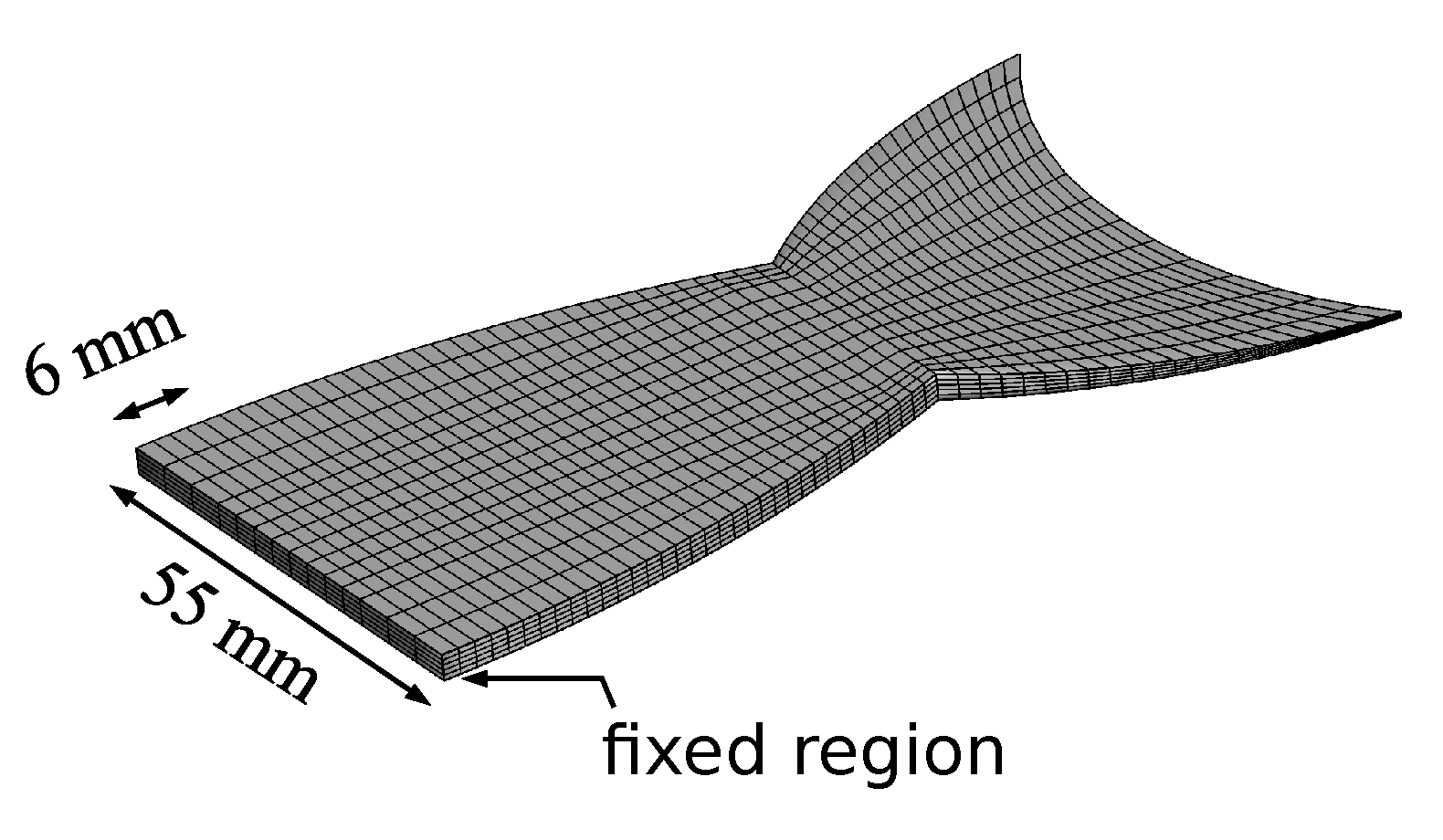

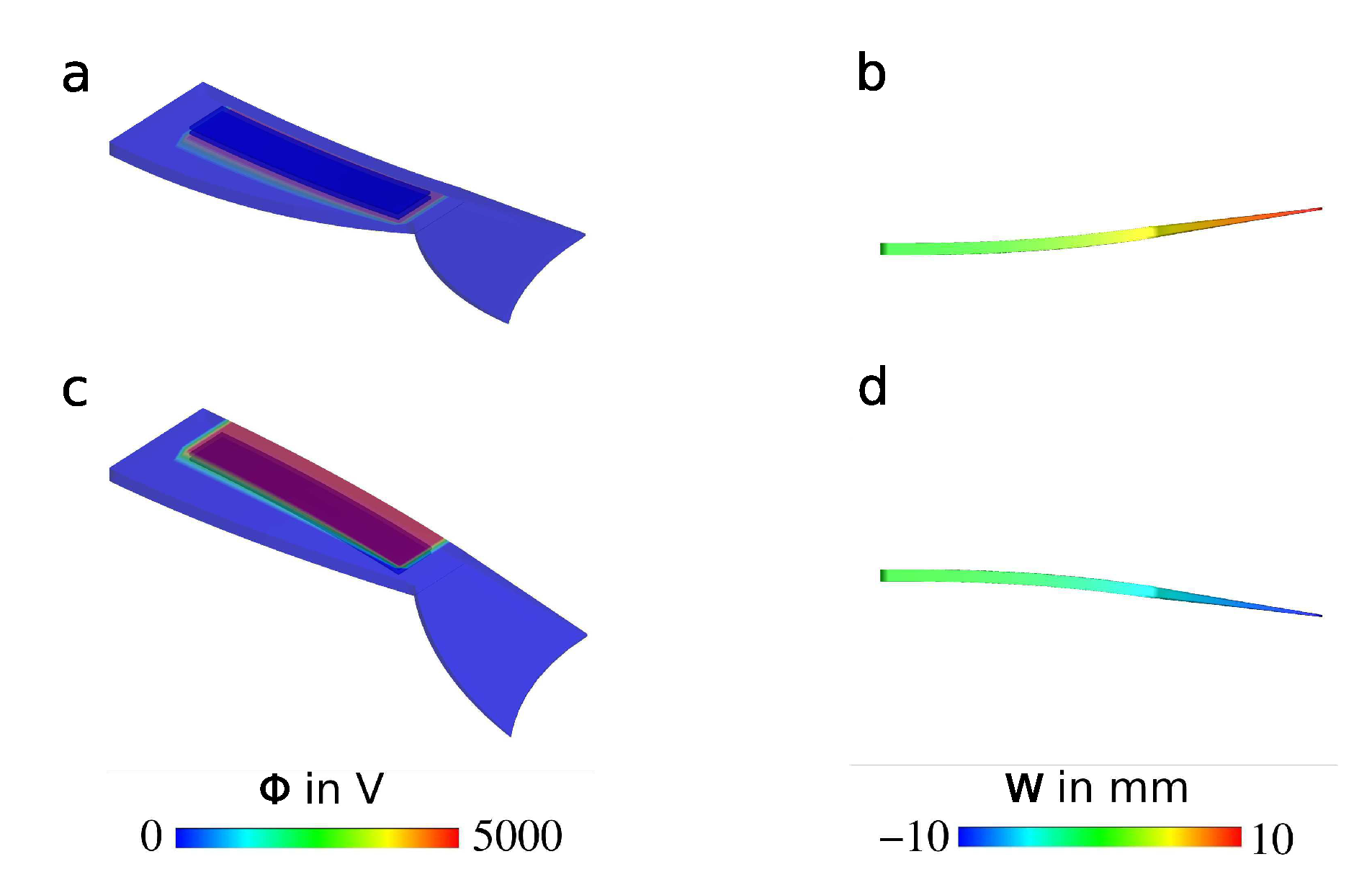

2.3. Simulation of the Bending Structure

- The structure was composed of a fiber-reinforced passive material with internal cavities and active DEAs.

- It had a nonlinear geometry, and its bending deformation was based on a coupled electromechanical response.

- Therefore, a nonlinear material model suitable for the simulation of large deformations was used along with an electromechanical finite element.

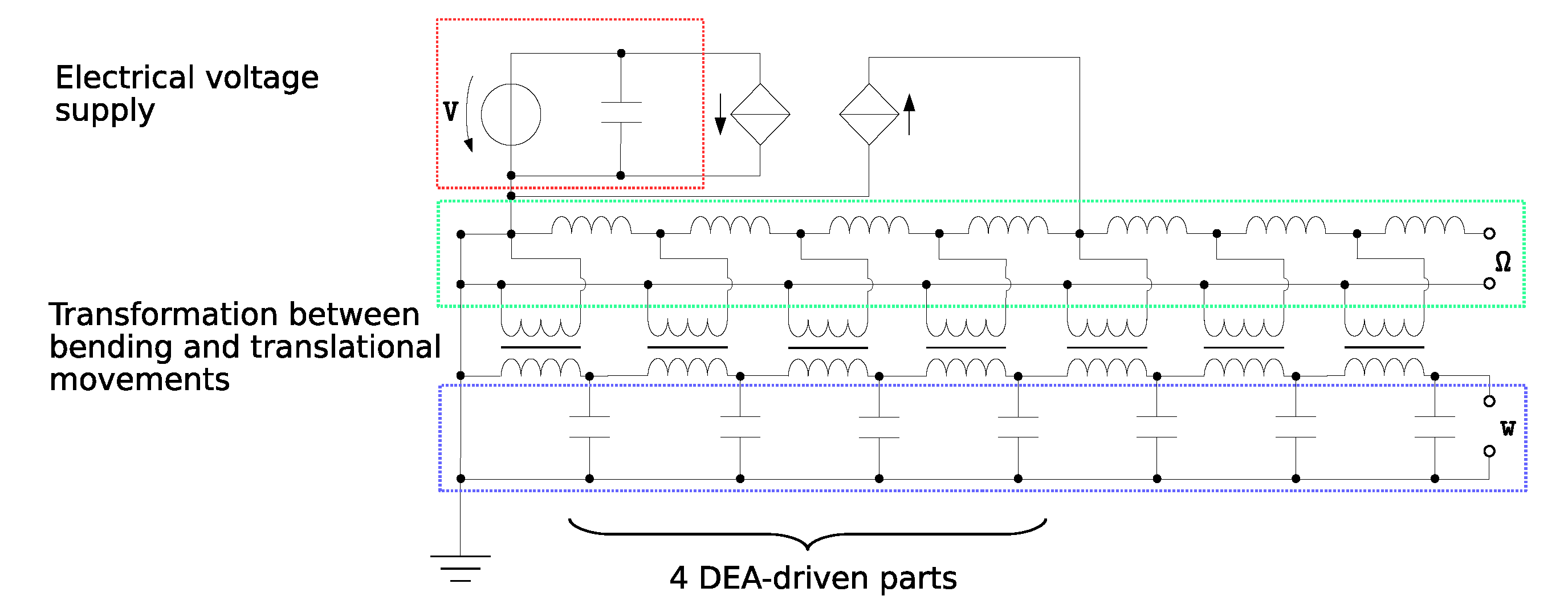

2.4. Electromechanical Network Model

2.5. Image Correlated Measurement

3. Results and Discussion

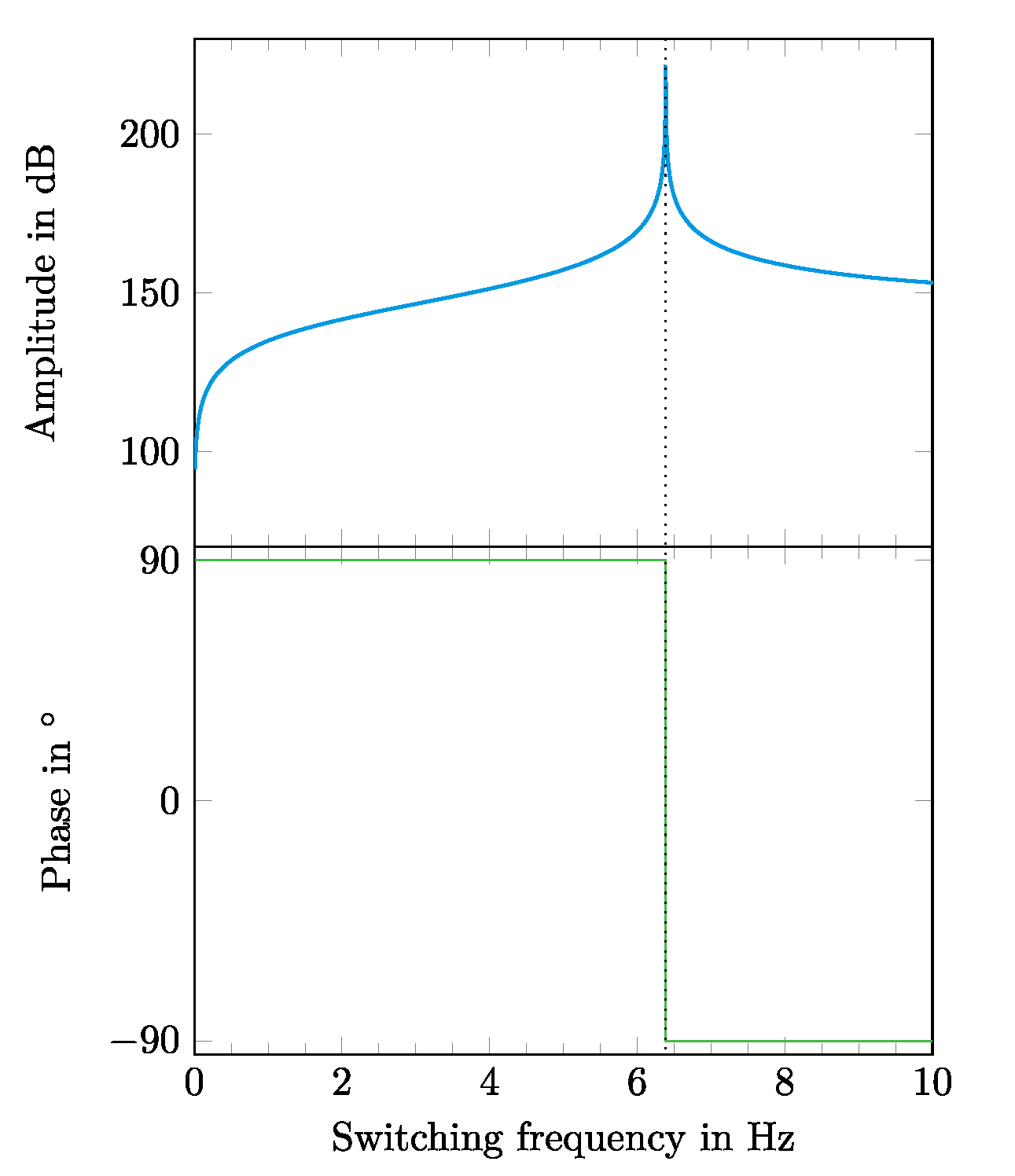

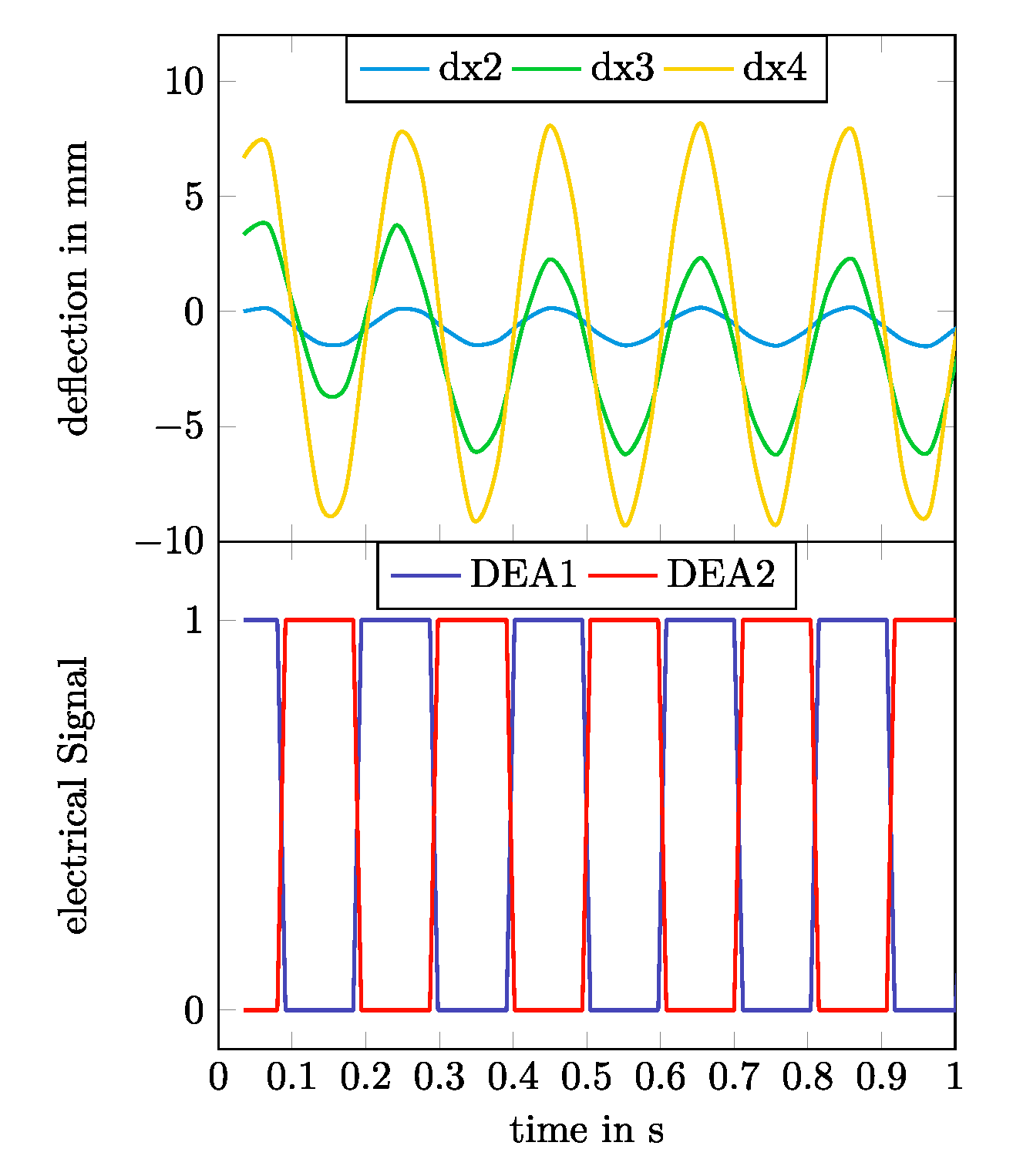

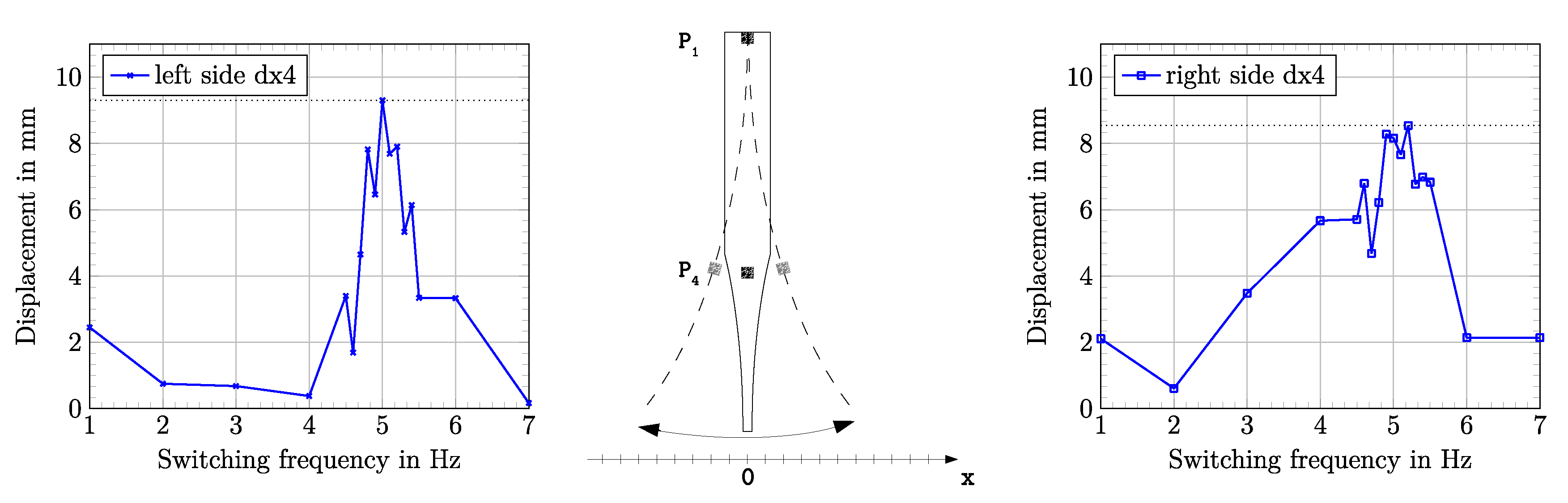

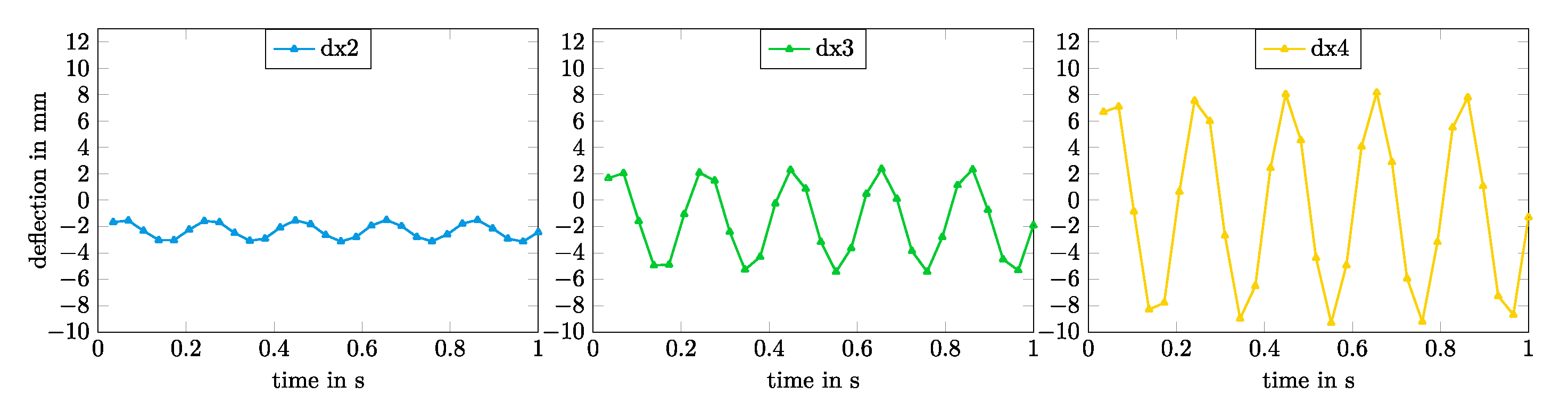

3.1. Displacement Measurement and Mechanical Resonance

3.2. Movement in Water

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| ABS | Acrylonitrile butadiene styrene |

| CF-UD | Carbon fiber unidirectional tape |

| DE | Dielectric elastomer |

| DEA | Dielectric elastomer actuator |

| DIC | Digital image correlation |

| EAP | Electroactive polymer |

| SBR | Styrene butadiene rubber |

References

- Whitesides, G.M. Soft robotics. Angew. Chem. Int. Ed. 2018, 57, 4258–4273. [Google Scholar] [CrossRef] [PubMed]

- Pelrine, R.; Kornbluh, R.; Kofod, G. High-strain actuator materials based on dielectric elastomers. Adv. Mater. 2000, 12, 1223–1225. [Google Scholar] [CrossRef]

- Pelrine, R.; Kornbluh, R.; Joseph, J. Electrostriction of polymer dielectrics with compliant electrodes as a means of actuation. Sens. Actuators A Phys. 1998, 64, 77–85. [Google Scholar] [CrossRef]

- Bar-Cohen, Y. Electroactive Polymer (EAP) Actuators as Artificial Muscles: Reality, Potential, and Challenges; SPIE Press: Bellingham, WA, USA, 2004; Volume 136. [Google Scholar]

- Gisby, T.A.; O’Brien, B.M.; Anderson, I.A. Self sensing feedback for dielectric elastomer actuators. Appl. Phys. Lett. 2013, 102, 193703. [Google Scholar] [CrossRef]

- Jung, K.; Kim, K.J.; Choi, H.R. A self-sensing dielectric elastomer actuator. Sens. Actuators A Phys. 2008, 143, 343–351. [Google Scholar] [CrossRef]

- O’Brien, B.; Thode, J.; Anderson, I.; Calius, E.; Haemmerle, E.; Xie, S. Integrated extension sensor based on resistance and voltage measurement for a dielectric elastomer. In Electroactive Polymer Actuators and Devices (EAPAD); International Society for Optics and Photonics: San Diego, CA, USA, 2007; Volume 6524, p. 652415. [Google Scholar]

- Rosset, S.; O’Brien, B.; Gisby, T.; Xu, D.; Shea, H.; Anderson, I. Self-sensing dielectric elastomer actuators in closed-loop operation. Smart Mater. Struct. 2013, 22, 104018. [Google Scholar] [CrossRef]

- McKay, T.; O’Brien, B.; Calius, E.; Anderson, I. An integrated, self-priming dielectric elastomer generator. Appl. Phys. Lett. 2010, 97, 062911. [Google Scholar] [CrossRef]

- O’Brien, B.; Calius, E.; Inamura, T.; Xie, S.; Anderson, I. Dielectric elastomer switches for smart artificial muscles. Appl. Phys. A 2010, 100, 385–389. [Google Scholar] [CrossRef]

- Henke, M.; Schlatter, S.; Anderson, I. Soft dielectric elastomer oscillators driving bioinspired robots. Soft Robot. 2017, 4, 353–366. [Google Scholar] [CrossRef]

- Marchese, A.; Onal, C.; Rus, D. Autonomous soft robotic fish capable of escape maneuvers using fluidic elastomer actuators. Soft Robot. 2014, 1, 75–87. [Google Scholar] [CrossRef]

- Wehner, M.; Truby, R.; Fitzgerald, D.; Mosadegh, B.; Whitesides, G.; Lewis, J.; Wood, R.J. An integrated design and fabrication strategy for entirely soft, autonomous robots. Nature 2016, 536, 451–455. [Google Scholar] [CrossRef] [PubMed]

- Vincent, J.; Bogatyreva, O.; Bogatyrev, N.; Bowyer, A.; Pahl, A. Biomimetics: Its practice and theory. J. R. Soc. Interface 2006, 3, 471–482. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Laschi, C.; Trimmer, B. Soft robotics: A bioinspired evolution in robotics. Trends Biotechnol. 2013, 31, 287–294. [Google Scholar] [CrossRef] [PubMed]

- Song, J.; Lee, S.; Cha, G.; Jung, S.; Choi, S.; Kim, K.; Mun, M. Surface modification of silicone rubber by ion beam assisted deposition (IBAD) for improved biocompatibility. J. Appl. Polym. Sci. 2006, 96, 1095–1101. [Google Scholar] [CrossRef]

- Joey, Z.; Calderón, A.; Chang, L.; Pérez-Arancibia, N. An earthworm-inspired friction-controlled soft robot capable of bidirectional locomotion. Bioinspir. Biomim. 2019, 14, 036004. [Google Scholar]

- Shepherd, R.; Ilievski, F.; Choi, W.; Morin, S.; Stokes, A.; Mazzeo, A.; Whitesides, G. Multigait soft robot. Proc. Natl. Acad. Sci. USA 2011, 108, 20400–20403. [Google Scholar] [CrossRef]

- Shian, S.; Bertoldi, K.; Clarke, D. Dielectric elastomer based “grippers” for soft robotics. Adv. Mater. 2015, 27, 6814–6819. [Google Scholar] [CrossRef]

- Esposito, C.; Tangorra, J.; Flammang, B.; Lauder, G. A robotic fish caudal fin: Effects of stiffness and motor program on locomotor performance. J. Exp. Biol. 2012, 215, 56–67. [Google Scholar] [CrossRef]

- Milwich, M.; Selvarayan, S.; Gresser, G. Fibrous materials and textiles for soft robotics. In Soft Robotics; Springer: Berlin/Heidelberg, Germany, 2015; pp. 157–172. [Google Scholar]

- Jusufi, A.; Vogt, D.; Wood, R.; Lauder, G. Undulatory swimming performance and body stiffness modulation in a soft robotic fish-inspired physical model. Soft Robot. 2017, 4, 202–210. [Google Scholar] [CrossRef]

- Low, K.; Chong, C. Parametric study of the swimming performance of a fish robot propelled by a flexible caudal fin. Bioinspir. Biomim. 2010, 5, 046002. [Google Scholar] [CrossRef]

- Shintake, J.; Cacucciolo, V.; Shea, H.; Floreano, D. Soft biomimetic fish robot made of dielectric elastomer actuators. Soft Robot. 2018, 5, 466–474. [Google Scholar] [CrossRef] [PubMed]

- Sfakiotakis, M.; Lane, D.; Davies, B. Review of fish swimming modes for aquatic locomotion. IEEE J. Ocean. Eng. 1999, 24, 237–252. [Google Scholar] [CrossRef]

- Datasheet SGL C T50-4.4/255-E100, SGL Carbon SE. Available online: https://www.sglcarbon.com/en/markets-solutions/material/sigrafil-continuous-carbon-fiber-tows/ (accessed on 10 March 2020).

- Shintake, J. Functional Soft Robotic Actuators Based on Dielectric Elastomers. Ph.D. Thesis, EPFL, Lausanne, Switzerland, 2016. [Google Scholar]

- Brochu, P.; Pei, Q. Advances in dielectric elastomers for actuators and artificial muscles. Macromol. Rap. Commun. 2010, 31, 10–36. [Google Scholar] [CrossRef] [PubMed]

- Süße, R. Theoretische Grundlagen der Elektrotechnik 2; Teubner: Wiesbaden, Germany, 2006. [Google Scholar]

- Eringen, A.; Maugin, G. Electrodynamics of Continua I: Foundations and Solid Media; Springer Science & Business Media: Berlin, Germany, 2012. [Google Scholar]

- Behnke, R.; Dal, H.; Kaliske, M. An extended tube model for thermoviscoelasticity of rubberlike materials: Theory and numerical implementation. Const. Models Rubber 2011, VII, 87–92. [Google Scholar]

- Kaliske, M.; Heinrich, G. An extended tube-model for rubber elasticity: Statistical-mechanical theory and finite element implementation. Rubber Chem. Technol. 1999, 72, 602–632. [Google Scholar] [CrossRef]

- Kaliske, M. A formulation of elasticity and viscoelasticity for fibre reinforced material at small and finite strains. Comput. Methods Appl. Mech. Eng. 2000, 185, 225–243. [Google Scholar] [CrossRef]

- Dorfmann, A.; Ogden, R.W. Nonlinear electroelasticity: Material properties, continuum theory and applications. R. Soc. Publ. 2017, 56, 1–34. [Google Scholar] [CrossRef]

- Simo, J.C.; Taylor, R.L. Quasi-incompressible finite elasticity in principal stretches. continuum basis and numerical algorithms. Comput. Methods Appl. Mech. Eng. 1991, 85, 273–310. [Google Scholar] [CrossRef]

- Vu, D.K.; Steinmann, P.; Possart, G. Numerical modeling of non-linear electroelasticity. Int. J. Numer. Methods Eng. 2007, 70, 685–704. [Google Scholar] [CrossRef]

- Firestone, F. A new analogy between mechanical and electrical systems. J. Acoust. Soc. Am. 1933, 4, 249–267. [Google Scholar] [CrossRef]

- Marschner, U.; Gerlach, G.; Starke, E.; Lenk, A. Equivalent circuit models of two-layer flexure beams with excitation by temperature, humidity, pressure, piezoelectric or piezomagnetic interactions. J. Sens. Sens. Syst. 2014, 3, 187–211. [Google Scholar] [CrossRef][Green Version]

- Analog Devices Inc. LTspice XVII [Computer Software]. Available online: https://www.analog.com/en/design-center/design-tools-and-calculators/ltspice-simulator.html (accessed on 10 March 2020).

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pfeil, S.; Katzer, K.; Kanan, A.; Mersch, J.; Zimmermann, M.; Kaliske, M.; Gerlach, G. A Biomimetic Fish Fin-Like Robot Based on Textile Reinforced Silicone. Micromachines 2020, 11, 298. https://doi.org/10.3390/mi11030298

Pfeil S, Katzer K, Kanan A, Mersch J, Zimmermann M, Kaliske M, Gerlach G. A Biomimetic Fish Fin-Like Robot Based on Textile Reinforced Silicone. Micromachines. 2020; 11(3):298. https://doi.org/10.3390/mi11030298

Chicago/Turabian StylePfeil, Sascha, Konrad Katzer, Anas Kanan, Johannes Mersch, Martina Zimmermann, Michael Kaliske, and Gerald Gerlach. 2020. "A Biomimetic Fish Fin-Like Robot Based on Textile Reinforced Silicone" Micromachines 11, no. 3: 298. https://doi.org/10.3390/mi11030298

APA StylePfeil, S., Katzer, K., Kanan, A., Mersch, J., Zimmermann, M., Kaliske, M., & Gerlach, G. (2020). A Biomimetic Fish Fin-Like Robot Based on Textile Reinforced Silicone. Micromachines, 11(3), 298. https://doi.org/10.3390/mi11030298