Wire Electrochemical Micromachining of Aluminum Rings for the Fabrication of Short-Millimeter Corrugated Horns

Abstract

1. Introduction

2. Methods

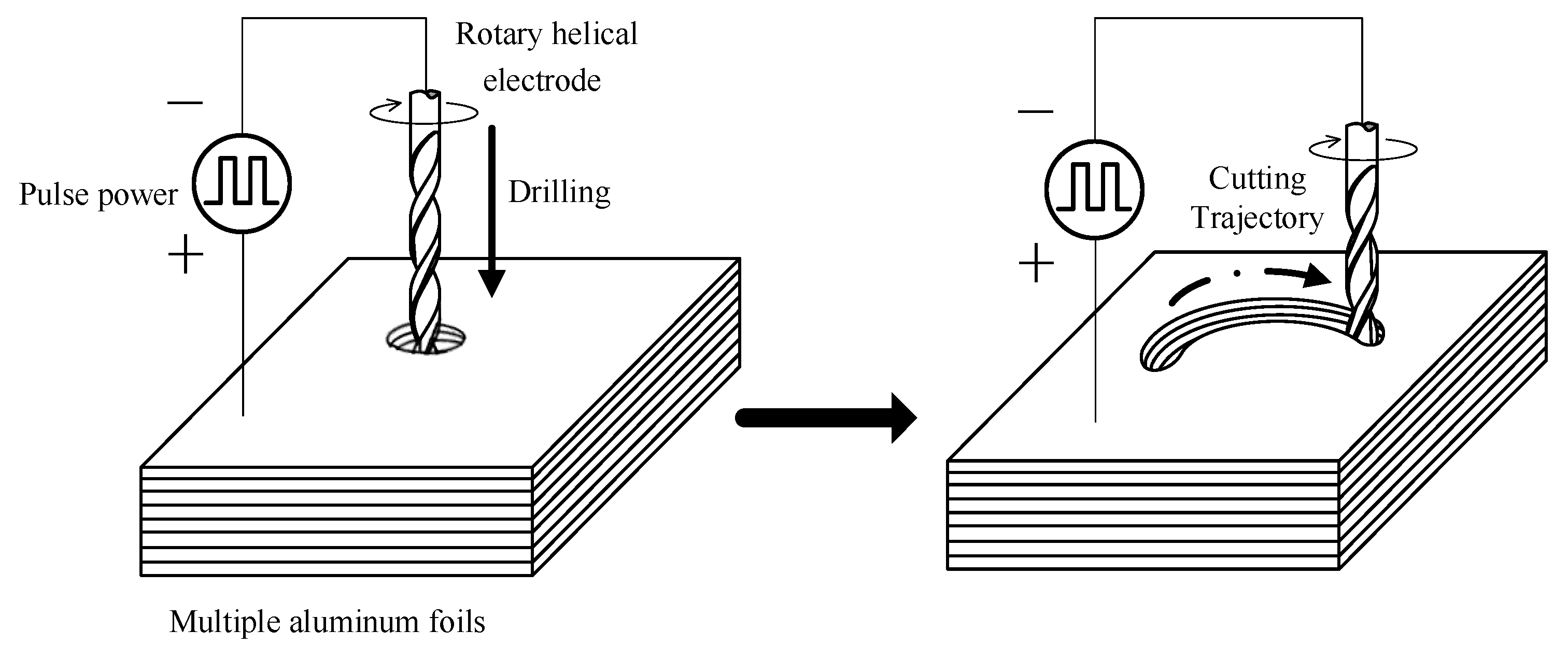

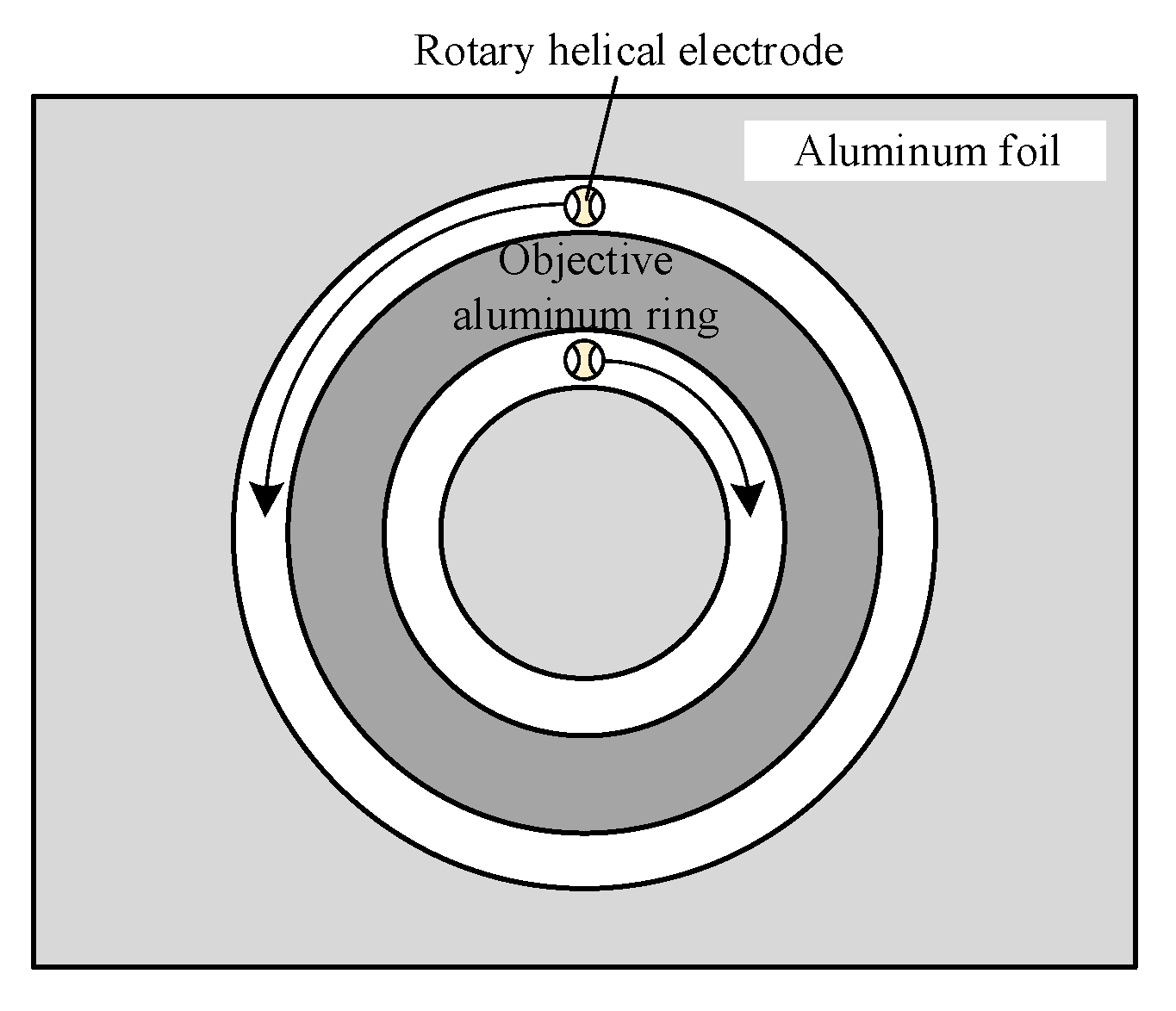

2.1. WECMM Aluminum Ring Utilizing A Rotary Helical Electrode

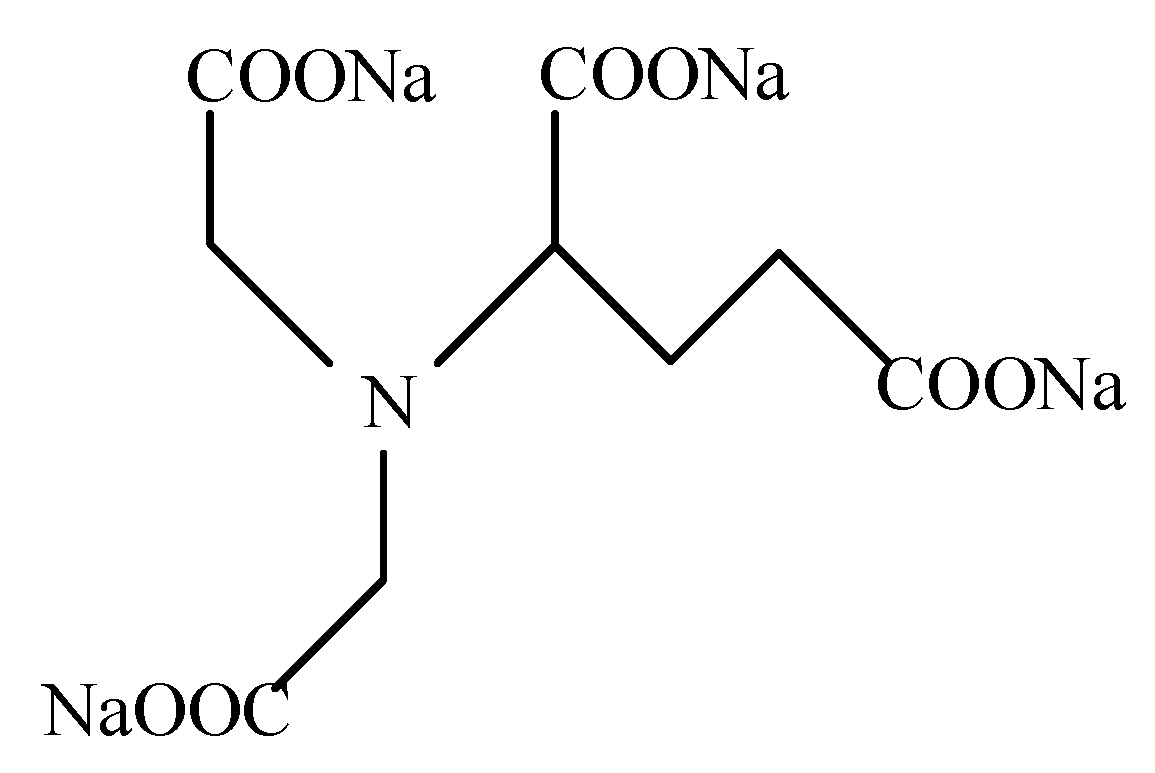

2.2. Effect of Complexing Agents in Electrochemical Reactions

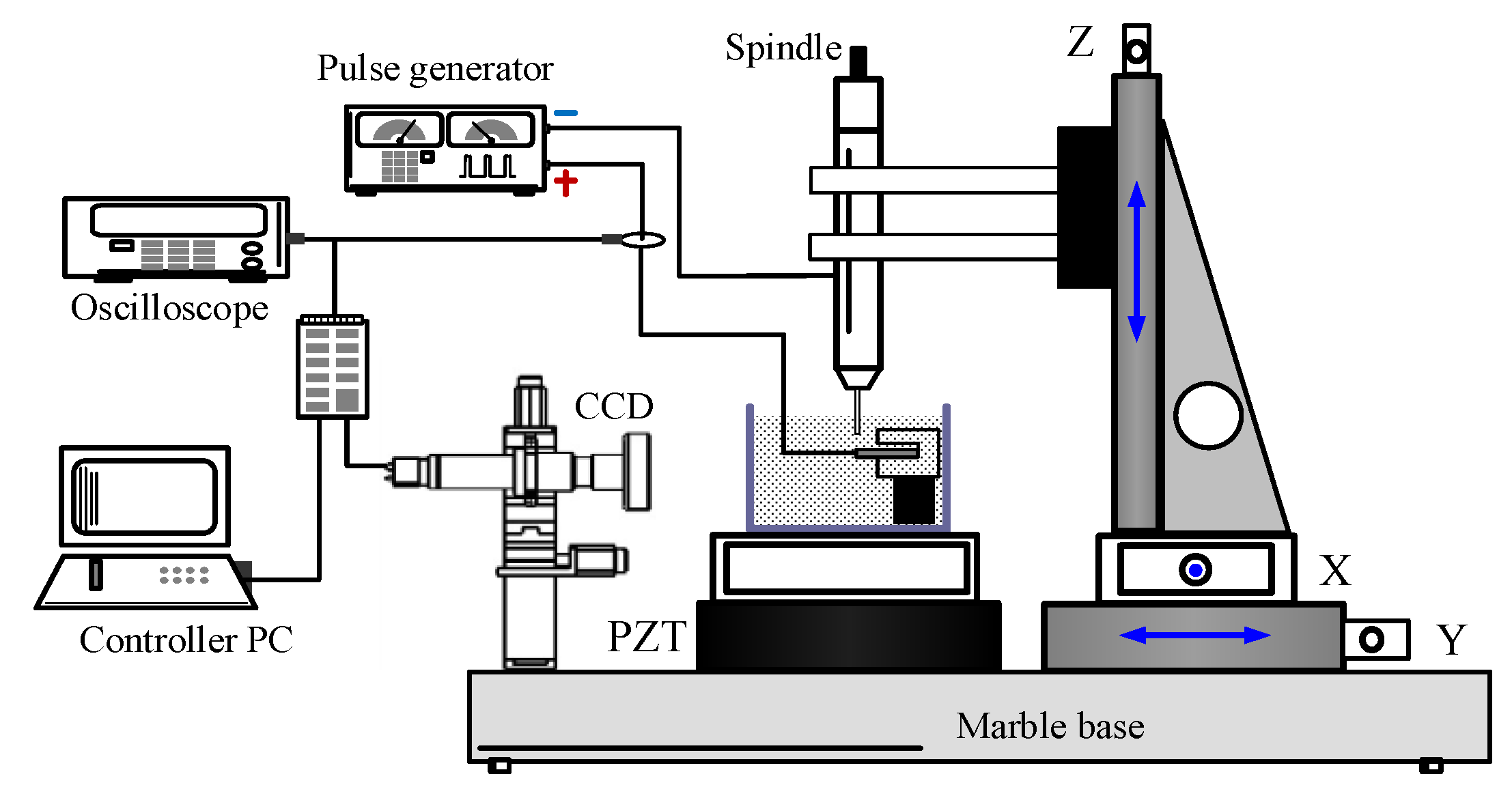

3. Experimental

4. Results and Discussion

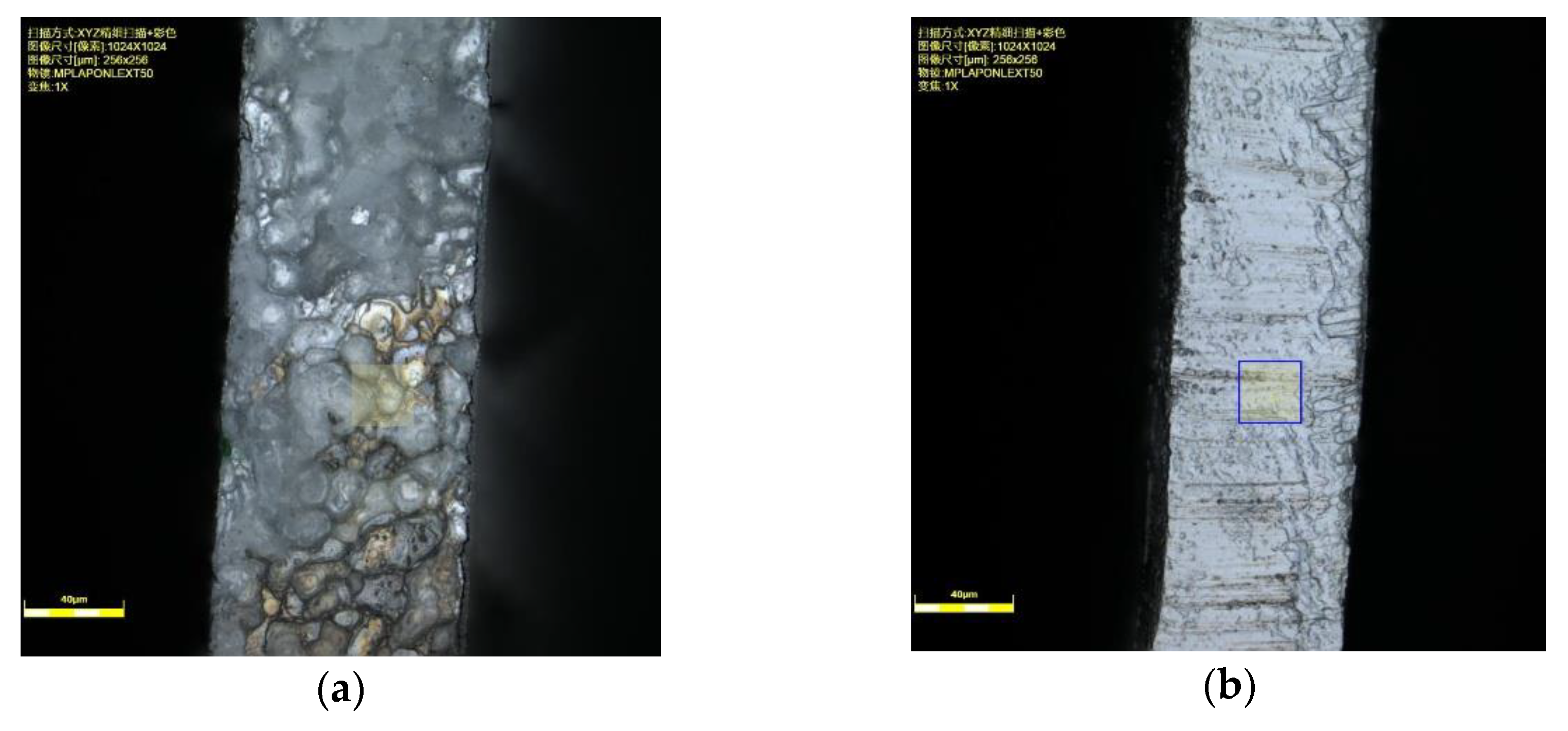

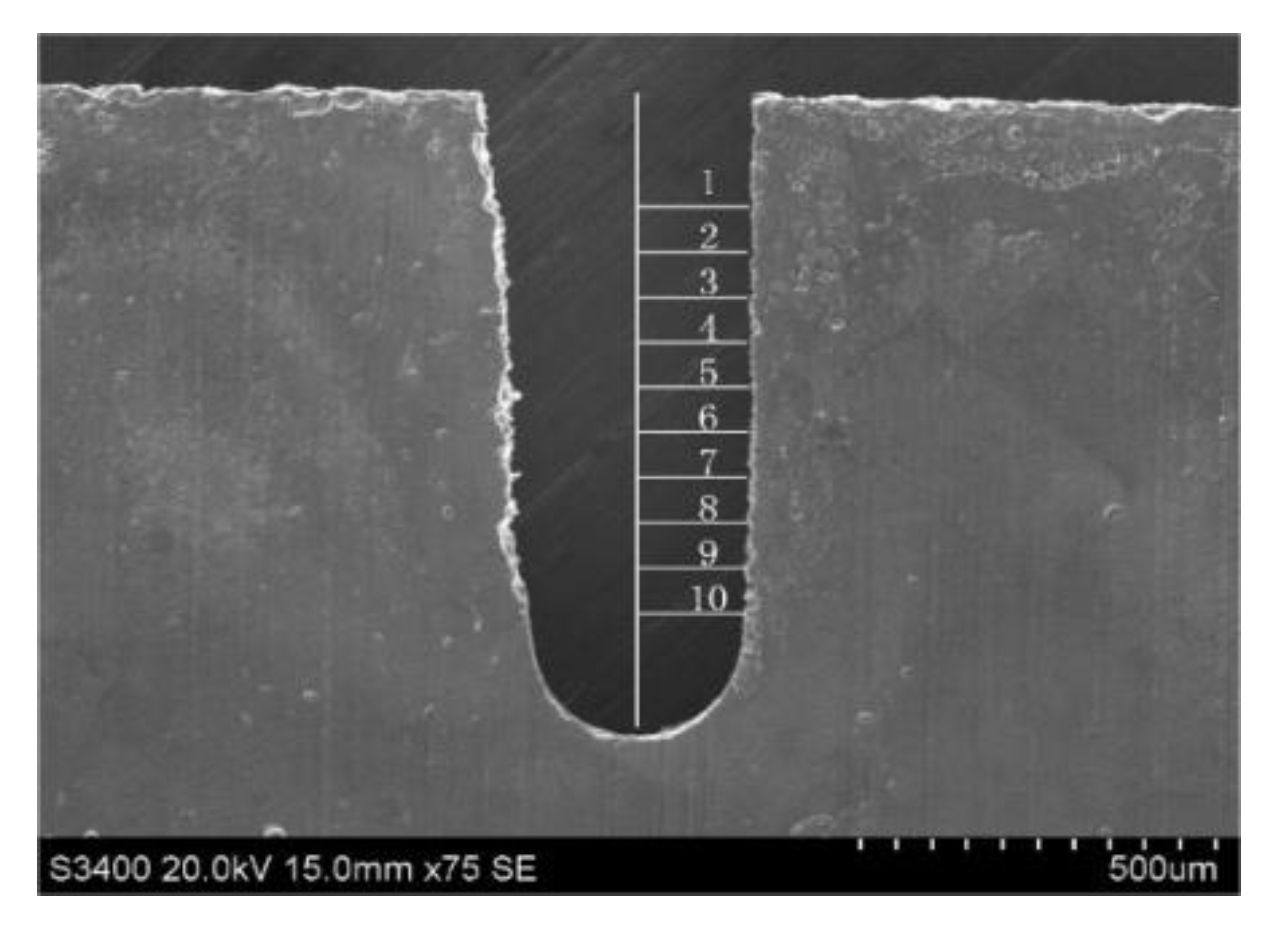

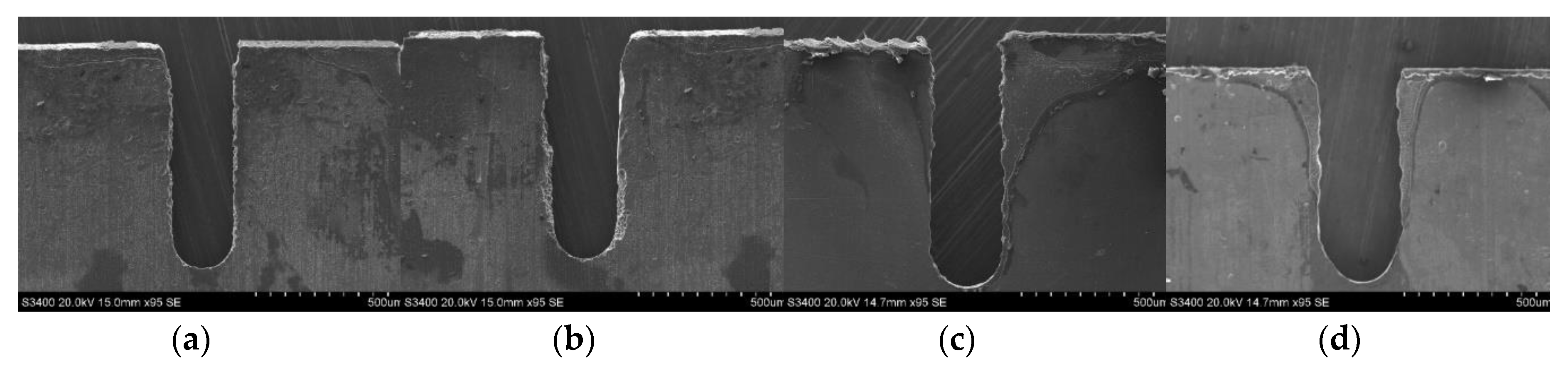

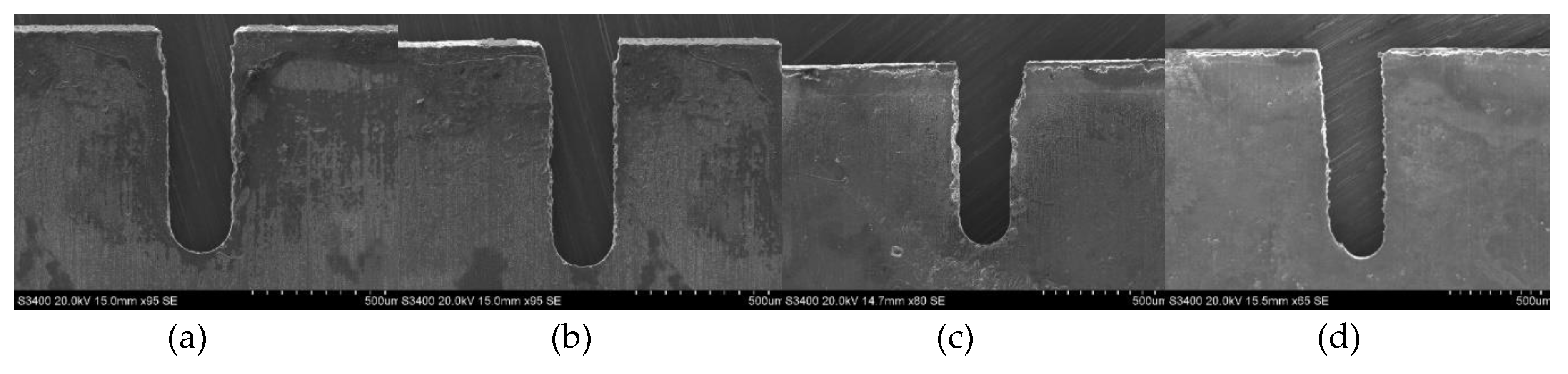

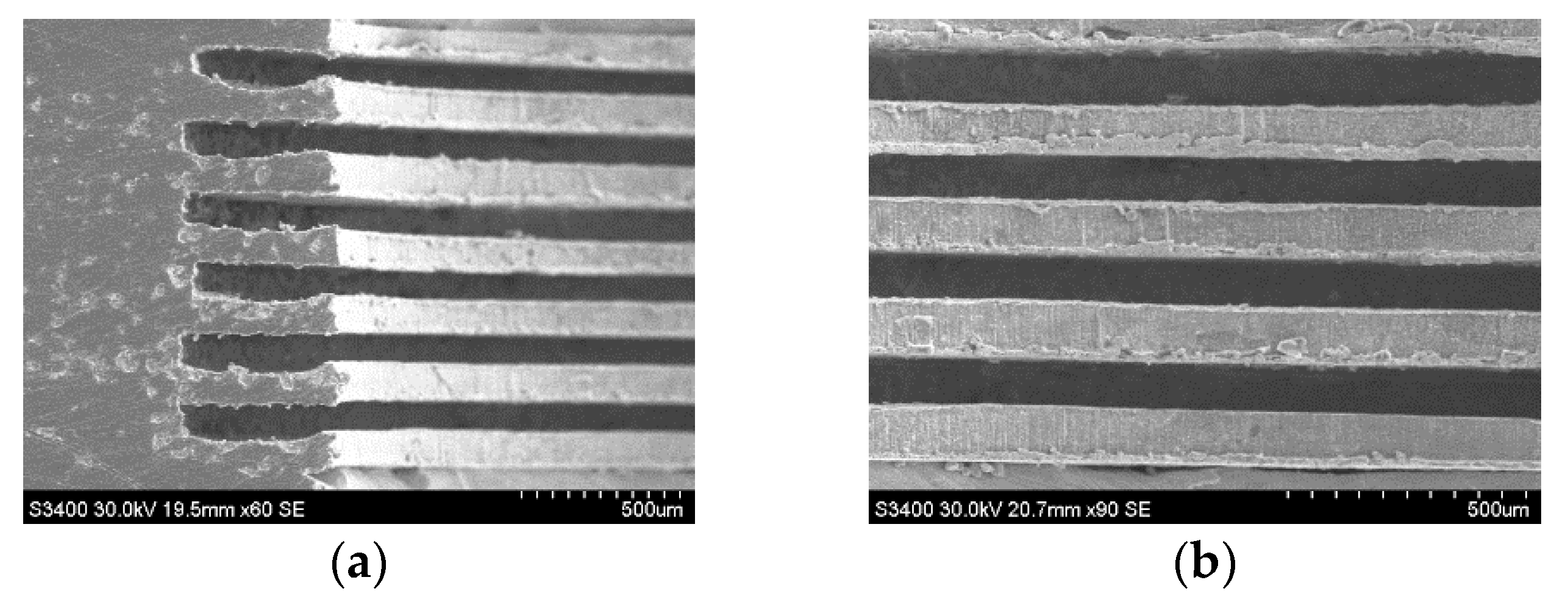

4.1. Surface Difference of Two Sides of Machined Slits

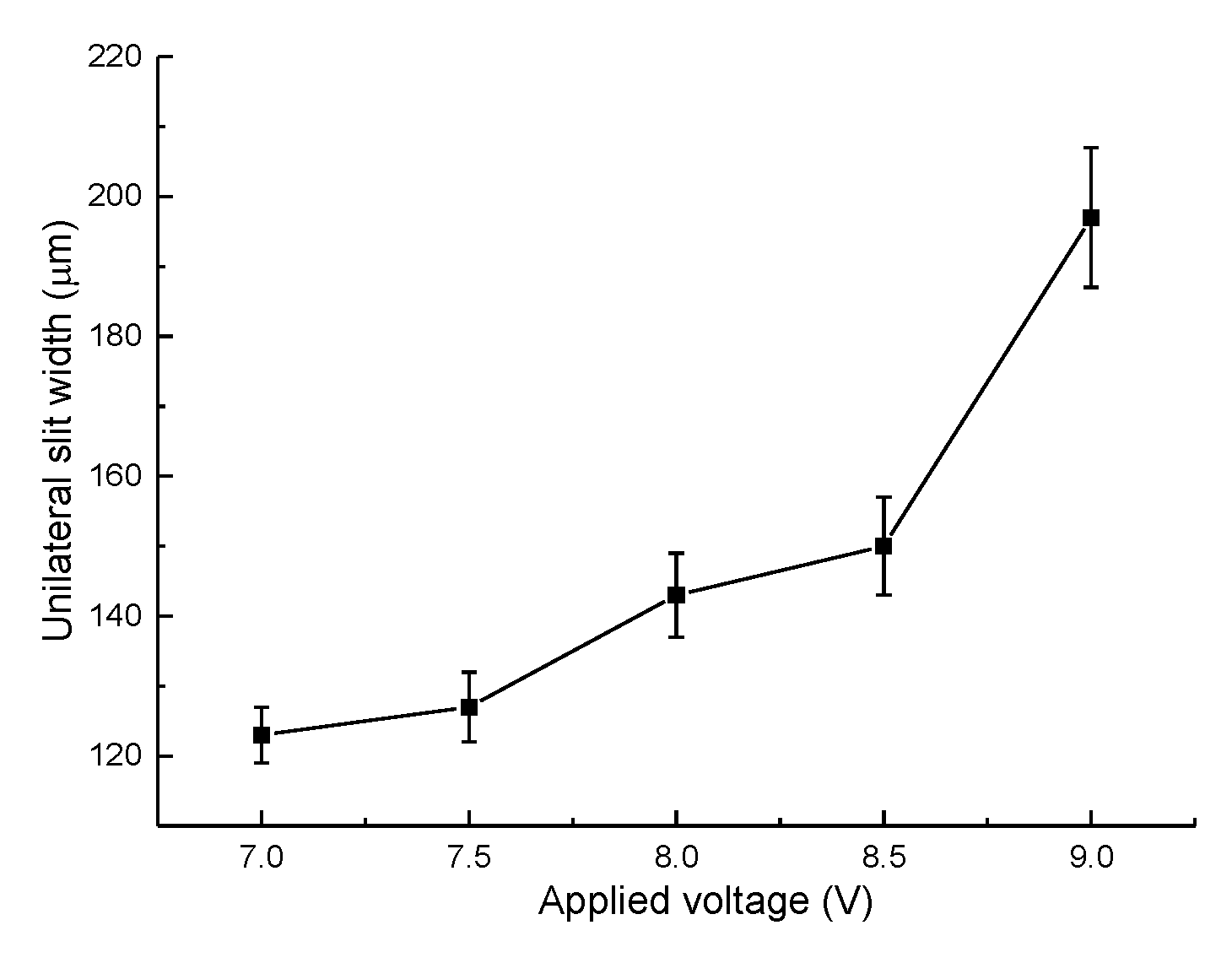

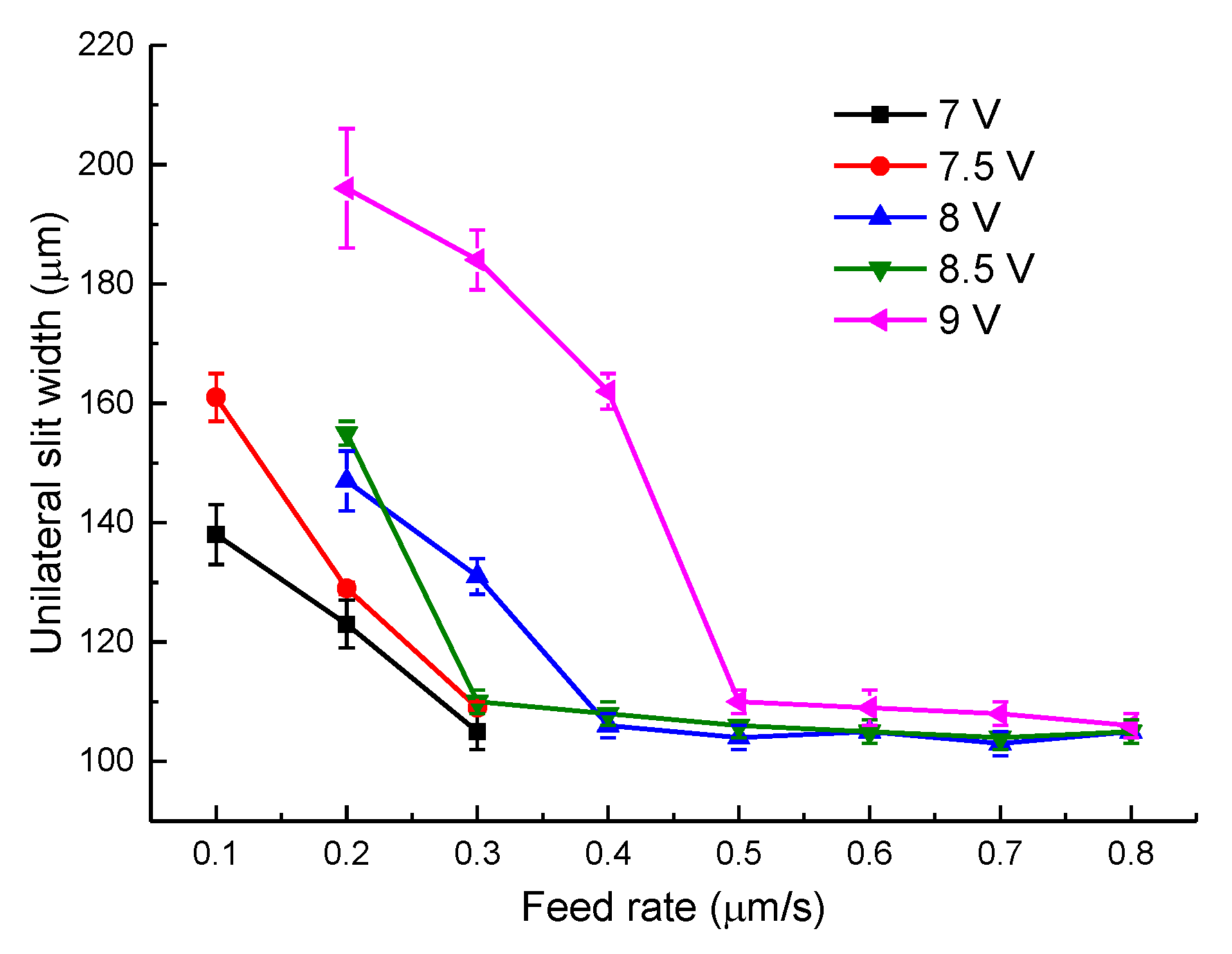

4.2. Effect of Applied Voltage

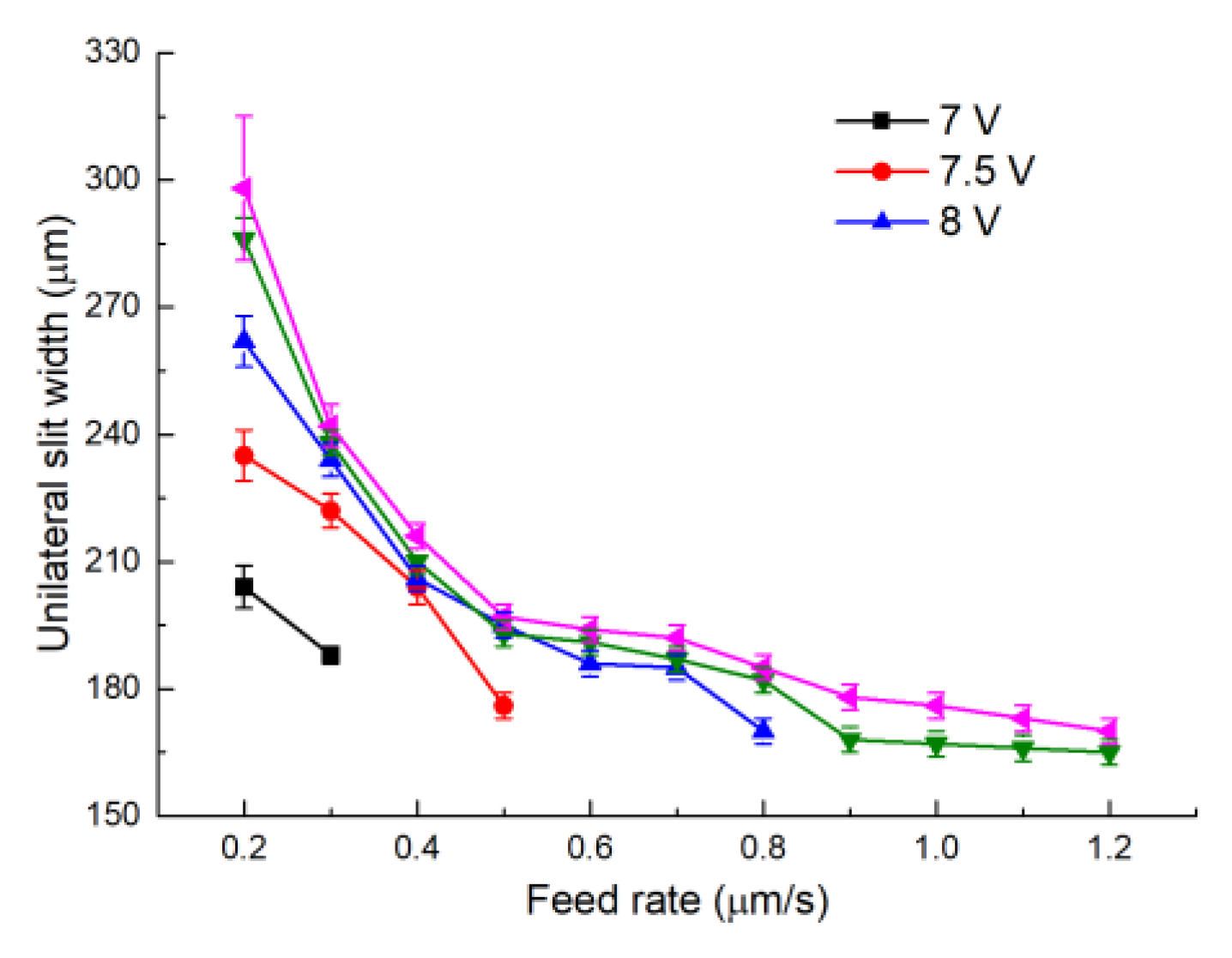

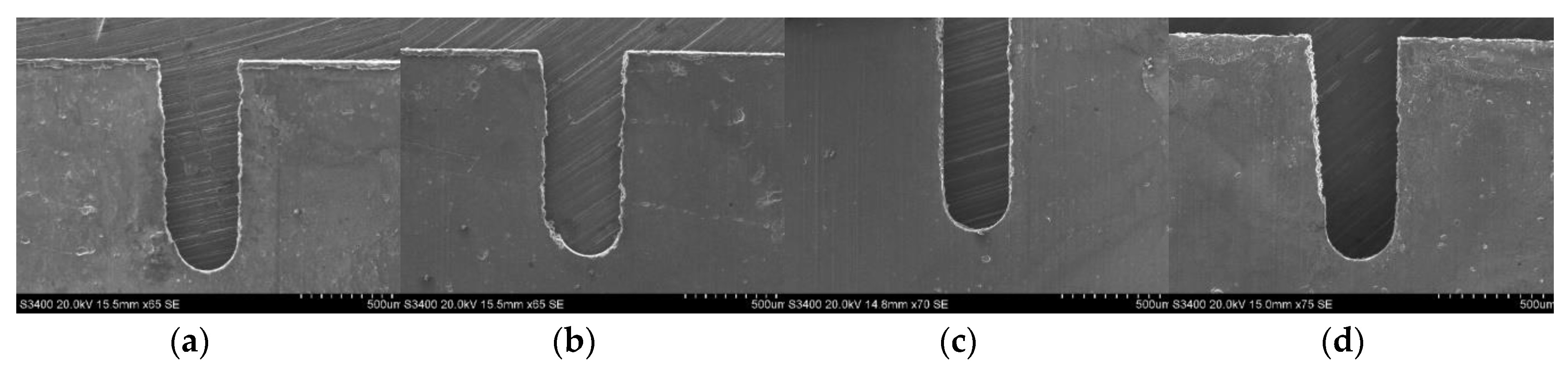

4.3. Effect of Electrode Diameter

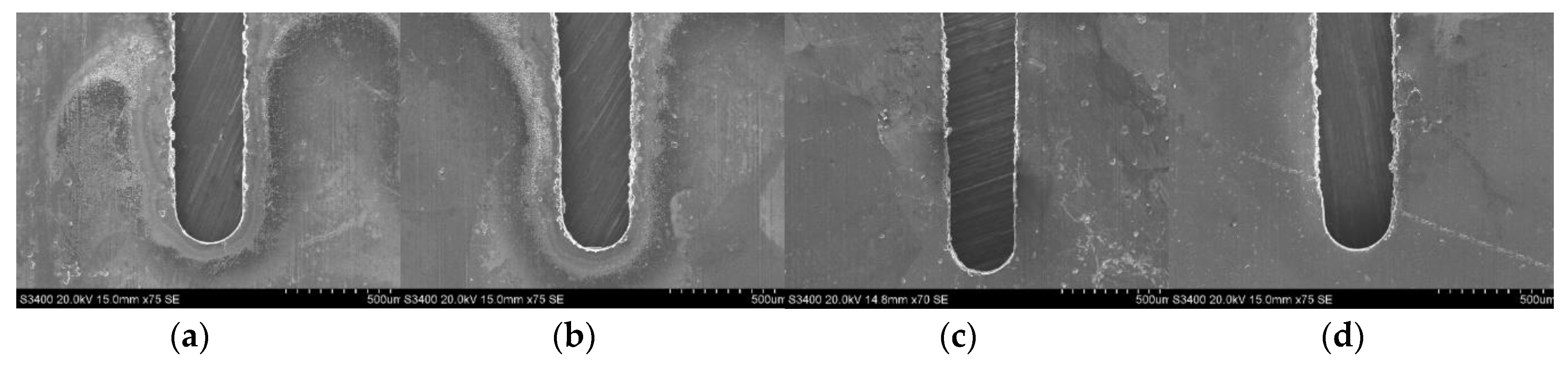

4.4. Effect of GLDA Concentration

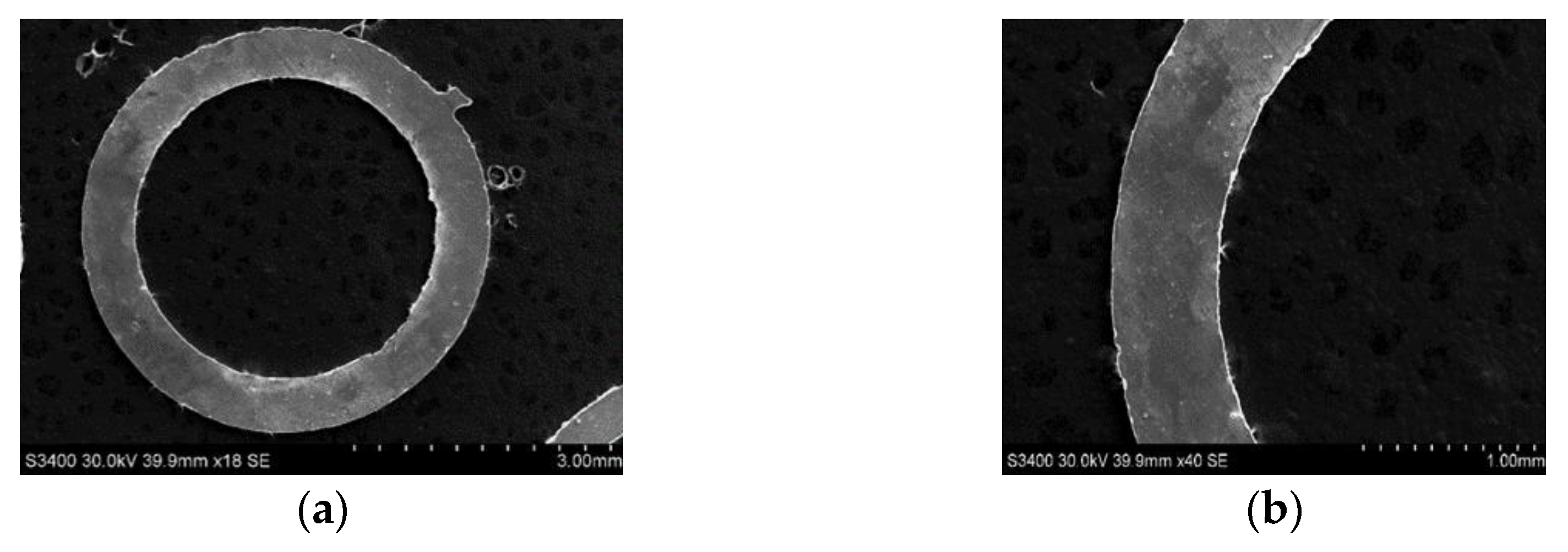

4.5. Fabrication of Aluminum Ring

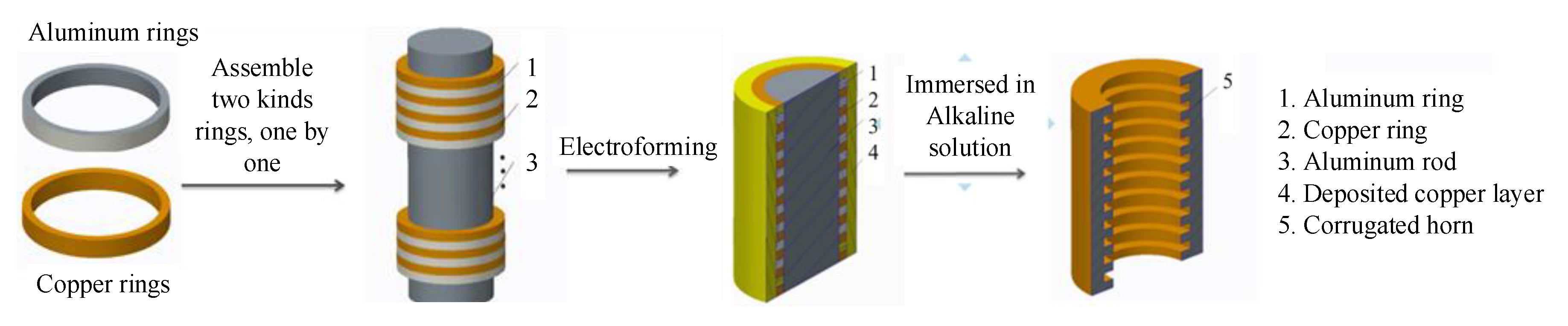

5. Electroformed Corrugated Horn with An Assembled Mandrel

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bhattacharyya, A.K.; Goyette, G. A novel horn radiator with high aperture efficiency and low cross-polarization and applications in arrays and multibeam reflector antennas. IEEE Trans. Antennas Propag. 2004, 52, 2850–2859. [Google Scholar] [CrossRef]

- Beniguel, Y.; Berthon, A.; Klooster, C.V.; Costes, L. Design realization and measurements of a high performance wide-band corrugated horn. IEEE Trans. Antennas Propag. 2005, 53, 3540–3546. [Google Scholar] [CrossRef]

- Kimura, K.; Iwashita, H.; Asayama, S.; Sugimoto, M.; Kikuchi, G.; Ogawa, H. Antenna performance of a directly dug corrugated feedhorn for the 150-GHz band. Int. J. Infrared Millim. Waves 2008, 29, 713–723. [Google Scholar] [CrossRef]

- Lucci, L.; Nesti, R.; Pelosi, G.; Selleri, S. A stackable constant width corrugated horn design for high-performance and low-cost feed arrays at millimeter wavelengths. IEEE Antennas Wirel. Propag. Lett. 2012, 11, 1162–1165. [Google Scholar] [CrossRef]

- Chieh, J.; Dick, B.; Loui, S.; Rockway, J.D. Development of a Ku-band corrugated conical horn using 3-D print technology. IEEE Antennas Wirel. Propag. Lett. 2014, 13, 201–204. [Google Scholar] [CrossRef]

- Sekiguchi, S.; Sugimoto, M.; Shu, S.; Sekimoto, Y.; Mitsui, K.; Nishino, T.; Okada, N.; Kubo, K.; Takahashi, T.; Nitta, T. Broadband corrugated horn array with direct-machined fabrication. IEEE Trans. Terahertz Sci. Technol. 2017, 7, 36–41. [Google Scholar] [CrossRef]

- Bai, B.; Miao, J.G.; Cui, Y.J. Novel technique to manufacture short millimeter wave band corrugated horn antenna. J. Beijing Univ. Aeronaut. Astronaut. 2008, 34, 1109–1112. [Google Scholar]

- Adams, D.P.; Vasile, M.J.; Krishnan, A. Microgrooving and microthreading tools for fabricating curvilinear features. Precis. Eng. 2000, 24, 347–356. [Google Scholar] [CrossRef]

- Wang, Y.K.; Chen, X.; Wang, Z.L. Fabrication of micro-rotating structure by micro reciprocated wire-EDM. J. Micromechanics Microengineering 2016, 26, 115014. [Google Scholar] [CrossRef]

- Rajurkar, K.P.; Levy, G.; Malshe, A.; Sundaram, M.M.; McGeough, J.; Hu, X.; Resnick, R.; DeSilva, A. Micro and nano machining by electro-physical and chemical processes. CIRP Ann. Manuf. Technol. 2006, 55, 643–666. [Google Scholar] [CrossRef]

- Spieser, A.; Ivanov, A. Recent developments and research challenges in electrochemical micromachining (µECM). Int. J. Adv. Manuf. Technol. 2013, 69, 563–581. [Google Scholar] [CrossRef]

- Kim, B.H.; Na, C.W.; Lee, Y.S.; Choi, D.K.; Chu, C.N. Micro electrochemical machining of 3D micro structure using dilute sulfuric acid. CIRP Ann. Manuf. Technol. 2005, 54, 191–194. [Google Scholar] [CrossRef]

- Zhu, D.; Wang, K.; Qu, N.S. Micro wire electrochemical cutting by using in situ fabricated wire electrode. CIRP Ann. Manuf. Technol. 2007, 56, 241–244. [Google Scholar] [CrossRef]

- Shin, H.S.; Kim, B.H.; Chu, C.N. Analysis of the side gap resulting from micro electrochemical machining with a tungsten wire and ultrashort voltage pulses. J. Micromechanics Microengineering 2008, 18, 1–6. [Google Scholar] [CrossRef]

- Ma, X.Y.; Li, Y.; Lv, S.J. Influence of electrolytic products in machining gap on micro ECM. Adv. Mater. Res. 2009, 60–61, 388–393. [Google Scholar] [CrossRef]

- Zeng, Y.B.; Yu, Q.; Wang, S.H.; Zhu, D. Enhancement of mass transport in micro wire electrochemical machining. CIRP Ann. Manuf. Technol. 2012, 61, 195–198. [Google Scholar] [CrossRef]

- Xu, K.; Zeng, Y.B.; Li, P.; Zhu, D. Vibration assisted wire electrochemical micro machining of array micro tools. Precis. Eng. 2016, 47, 487–497. [Google Scholar] [CrossRef]

- Meng, L.C.; Zeng, Y.B.; Fang, X.L.; Zhu, D. Micro-shaping of metallic glass by wire electrochemical micro-machining with a reciprocating traveling workpiece. J. Alloys Compd. 2018, 739, 235–248. [Google Scholar] [CrossRef]

- Shi, H.R. Micro fabrication by electrochemical process in citric acid electrolyte. J. Mater. Process. Technol. 2009, 209, 2831–2837. [Google Scholar]

- Chen, H.; Wang, Y.K.; Wang, Z.L.; Zhao, W.S. Effects of complexing agent on electrochemical micro machining of stainless steel. Am. J. Nanotechnol. 2010, 1, 7–12. [Google Scholar]

- Liu, G.D.; Li, Y.; Kong, Q.C.; Tong, H. Selection and optimization of electrolyte for micro electrochemical machining on stainless steel 304. Procedia CIRP 2016, 42, 412–417. [Google Scholar]

- Milošev, I. Effect of complexing agents on the electrochemical behavior of orthopedic stainless steel in physiological solution. J. Appl. Electrochem. 2002, 32, 311–320. [Google Scholar] [CrossRef]

- Fang, X.L.; Zhang, P.F.; Zeng, Y.B.; Qu, N.S.; Zhu, D. Enhancement of performance of wire electrochemical micromachining using a rotary helical electrode. J. Mater. Process. Technol. 2016, 227, 129–137. [Google Scholar]

- Klocke, F.; Herrig, T.; Zeis, M.; Klink, A. Experimental investigations of cutting rates and surface integrity in wire electrochemical machining with rotating electrode. Procedia CIRP 2018, 68, 725–730. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Electrolyte | 15 g/L NaNO3 |

| Glutamate diacetic acid (GLDA) (g/L) | 0, 7.5, 15, 30, 45 |

| Applied voltage (V) | 7, 7.5, 8, 8.5, 9 |

| Electrode diameter (mm) | 0.2, 0.3 |

| Duty ratio (%) | 10 |

| Electrode rotation speed (rpm) | 2000 |

| Electrode feed rate (μm/s) | 0.1~1.2 |

| Parameter | Value |

|---|---|

| CuSO4 (g/L) | 80 |

| H2SO4 (g/L) | 150 |

| Temperature (°C) | 45 |

| Current density (A/dm2) | 2 |

| Mandrel rotation speed (rpm) | 30 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, X.; Wang, X.; Zhu, J.; Zeng, Y.; Qu, N. Wire Electrochemical Micromachining of Aluminum Rings for the Fabrication of Short-Millimeter Corrugated Horns. Micromachines 2020, 11, 122. https://doi.org/10.3390/mi11020122

Fang X, Wang X, Zhu J, Zeng Y, Qu N. Wire Electrochemical Micromachining of Aluminum Rings for the Fabrication of Short-Millimeter Corrugated Horns. Micromachines. 2020; 11(2):122. https://doi.org/10.3390/mi11020122

Chicago/Turabian StyleFang, Xiaolong, Xiangyang Wang, Jiacheng Zhu, Yongbin Zeng, and Ningsong Qu. 2020. "Wire Electrochemical Micromachining of Aluminum Rings for the Fabrication of Short-Millimeter Corrugated Horns" Micromachines 11, no. 2: 122. https://doi.org/10.3390/mi11020122

APA StyleFang, X., Wang, X., Zhu, J., Zeng, Y., & Qu, N. (2020). Wire Electrochemical Micromachining of Aluminum Rings for the Fabrication of Short-Millimeter Corrugated Horns. Micromachines, 11(2), 122. https://doi.org/10.3390/mi11020122