Facile Fabrication of Highly Perforated Hollow Metallic Cylinder with Changeable Micro-Orifices by Electroforming-Extrusion Molding Hybrid Process

Abstract

1. Introduction

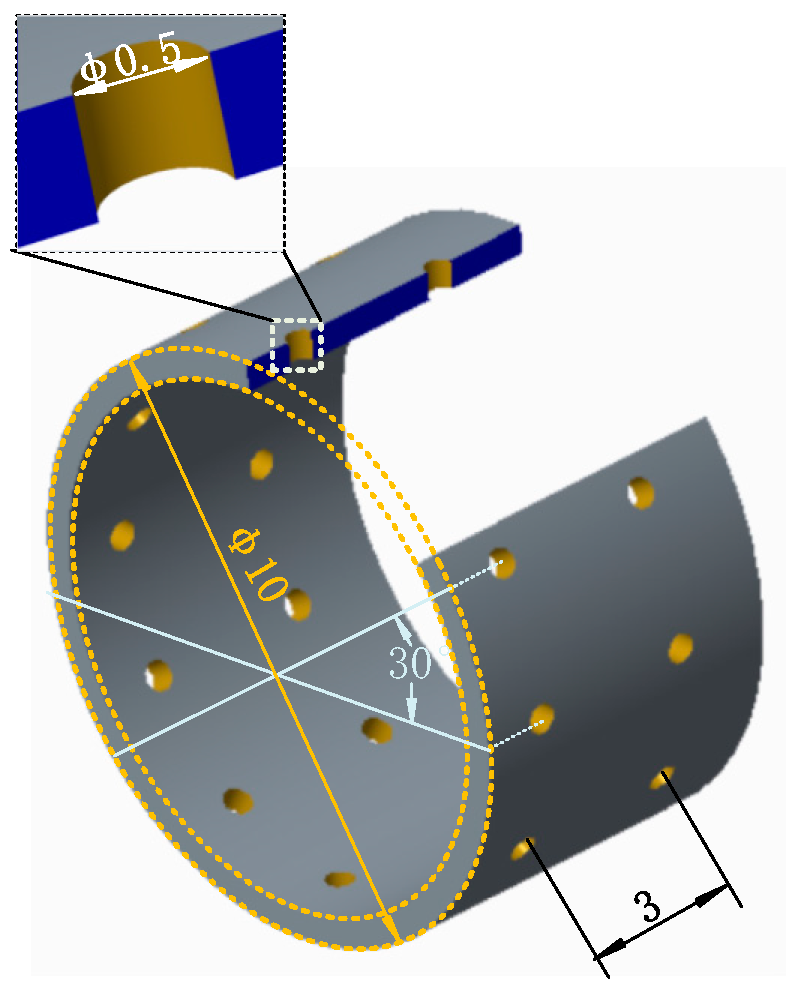

2. Numerical Analysis

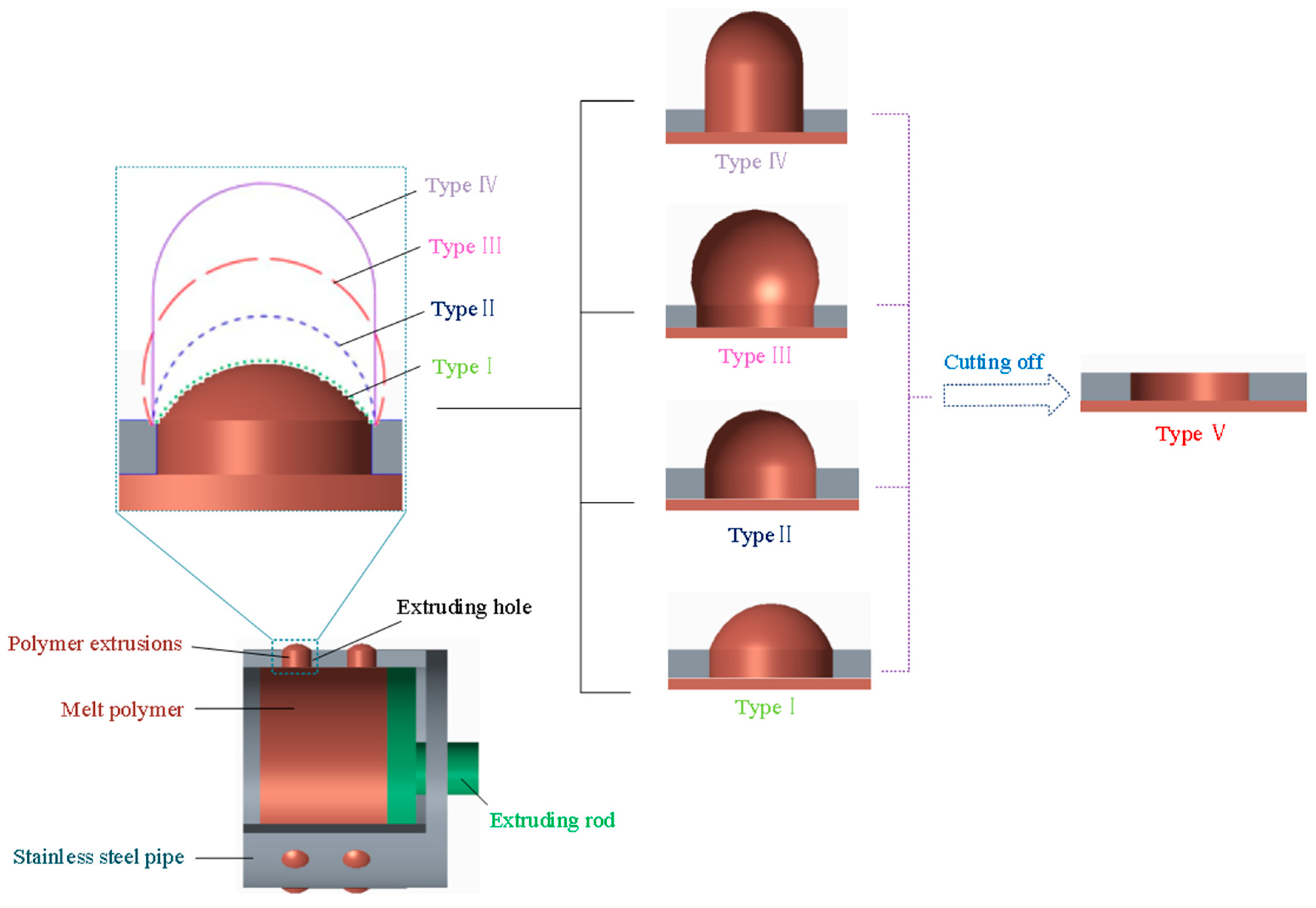

2.1. Over-Growth Electroforming Principle

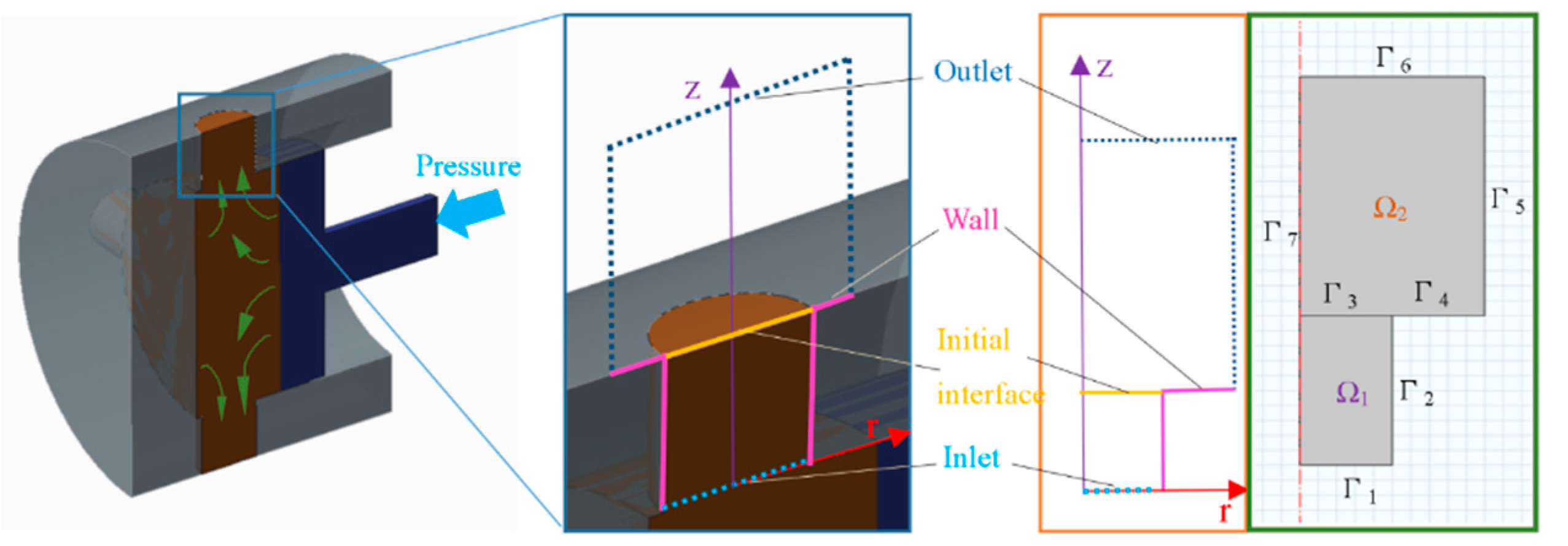

2.2. Model Development and Numerical Solution

- (1)

- the melt polymer is viewed as a kind of viscous fluid and is homogeneous in its material properties;

- (2)

- temperature of the melt polymer keeps constant and is the same everywhere;

- (3)

- neglecting the influence of gravity during polymer extruding-out;

- (4)

- outlet pressure of the melt polymer is set to be zero;

- (5)

- feeding rate of the extruding rod keeps constant;

- (6)

- melt polymer is considered as an incompressible liquid.

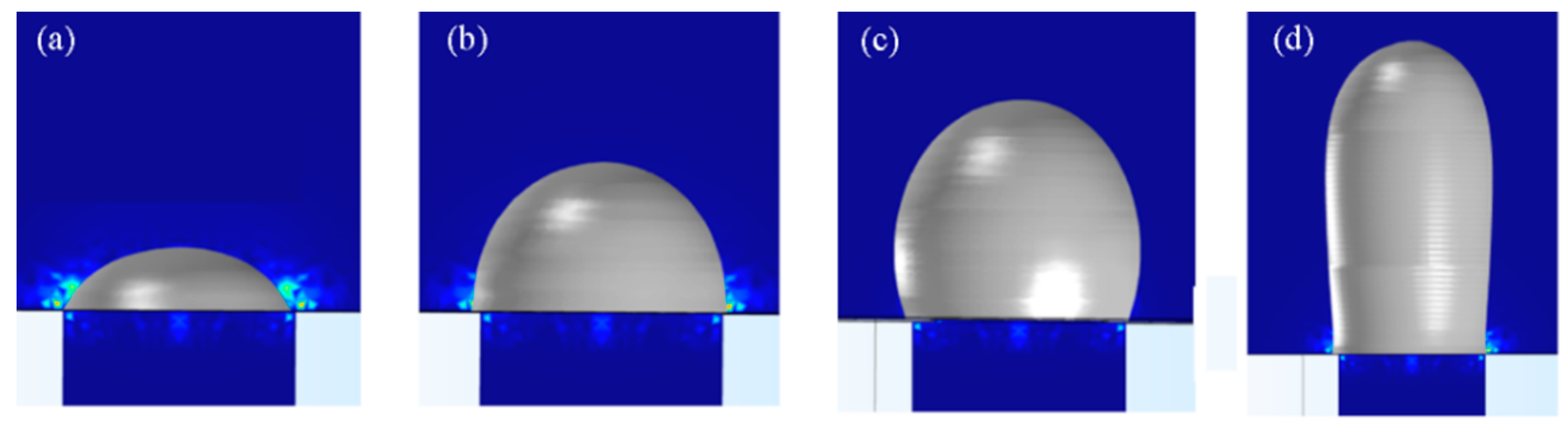

2.3. Analysis of Simulation Results

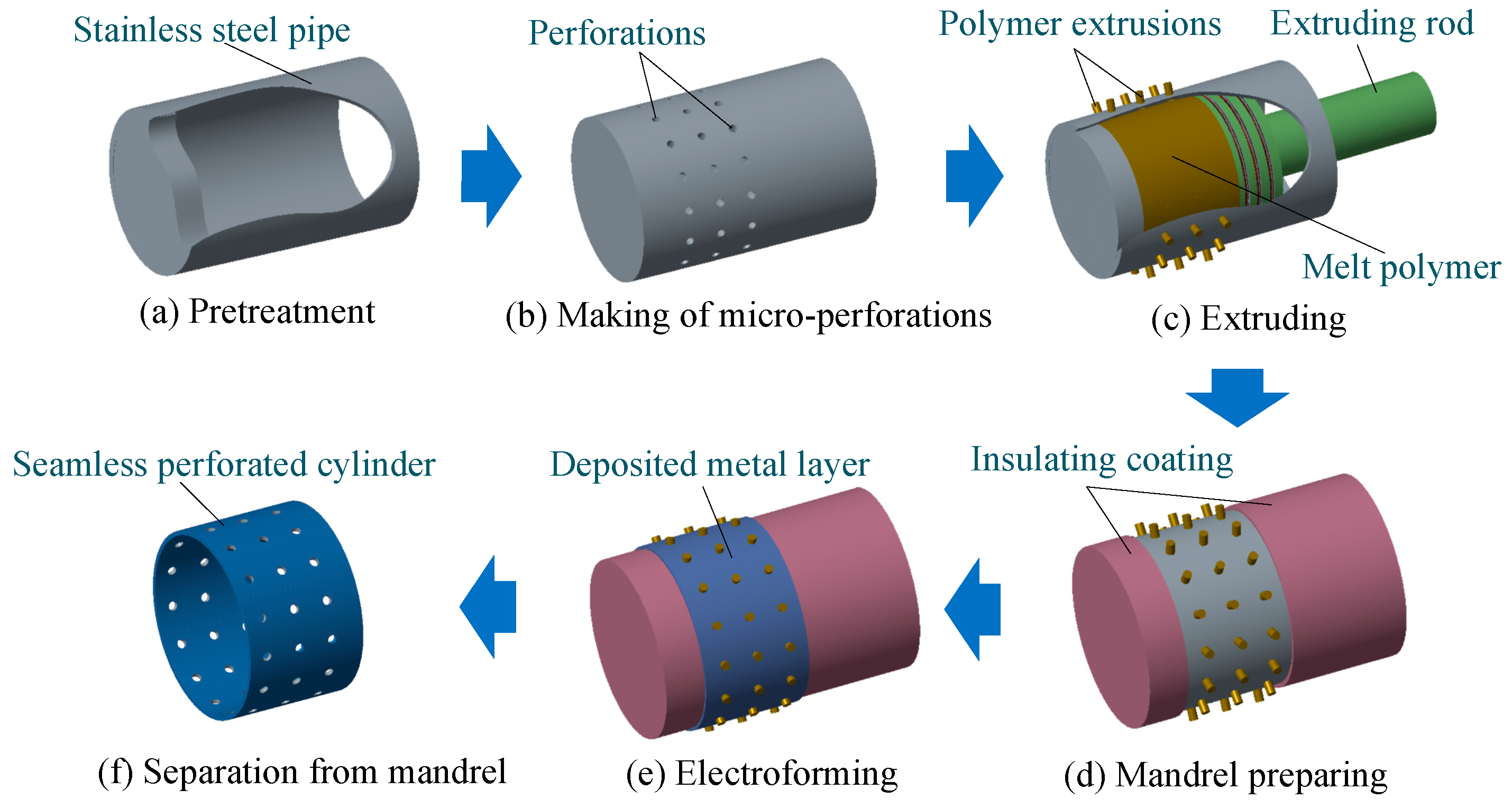

3. Experimentation

4. Results and Discussion

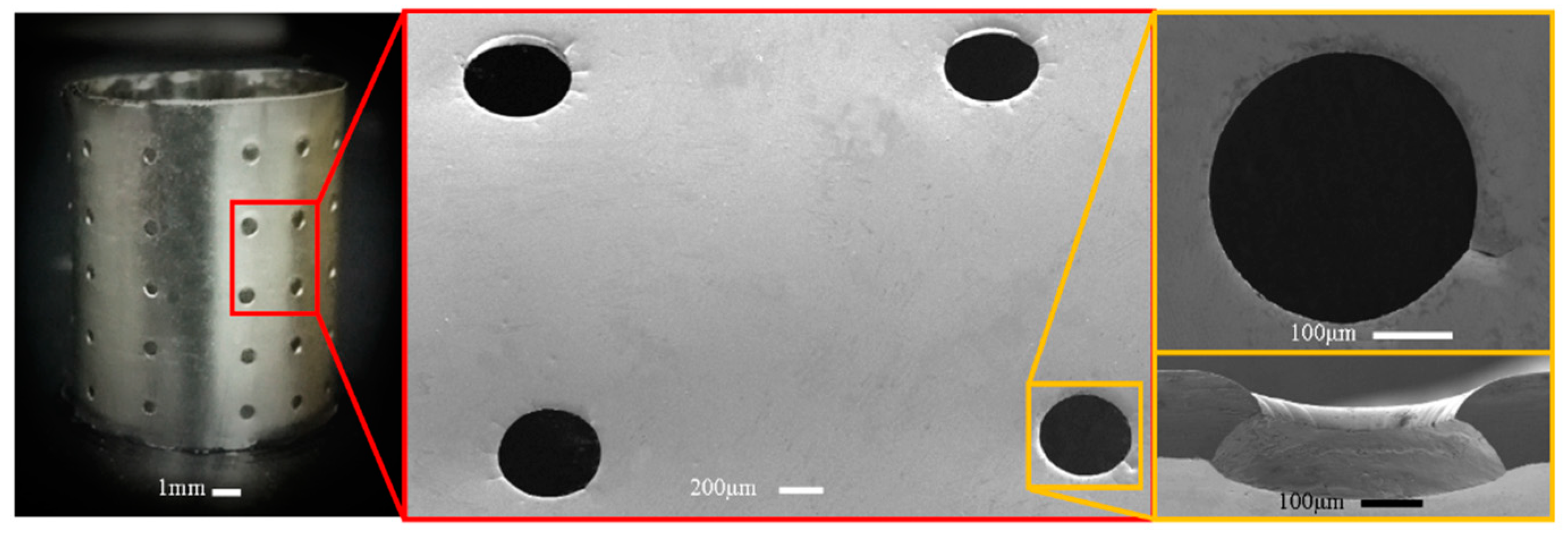

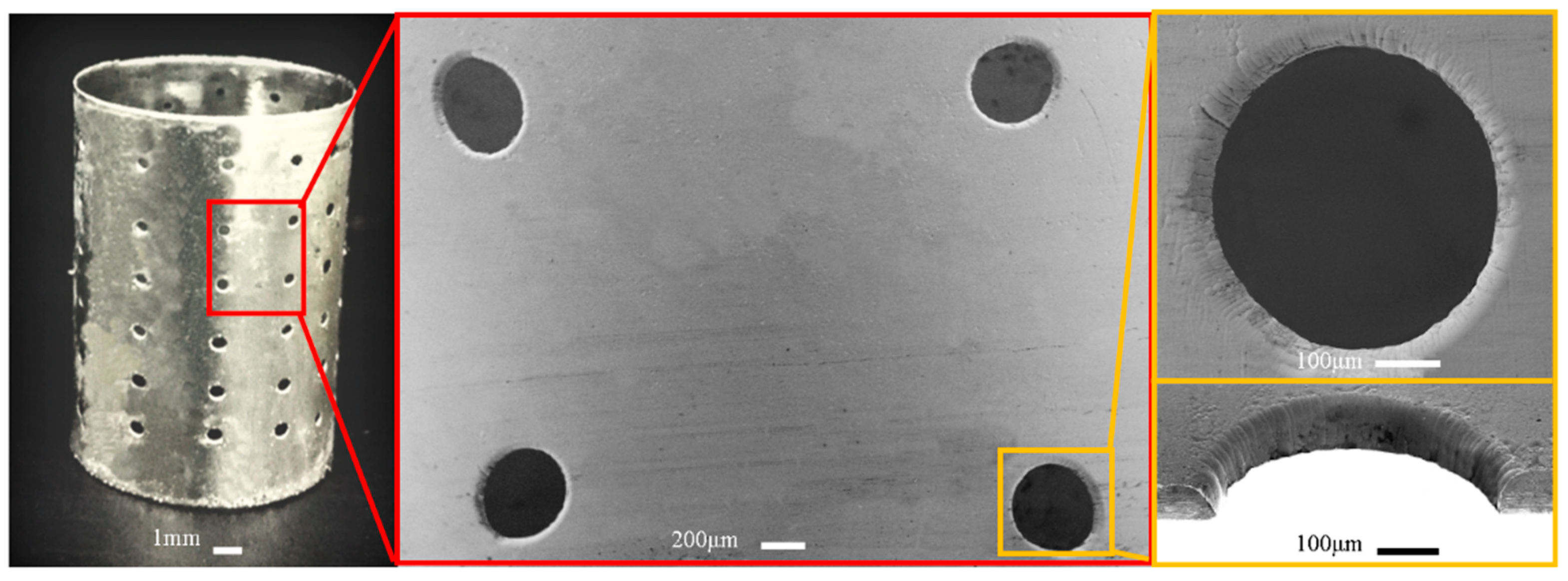

4.1. Achievement of the Seamless Hollow Cylinder with Double Conic-Tapered Perforations

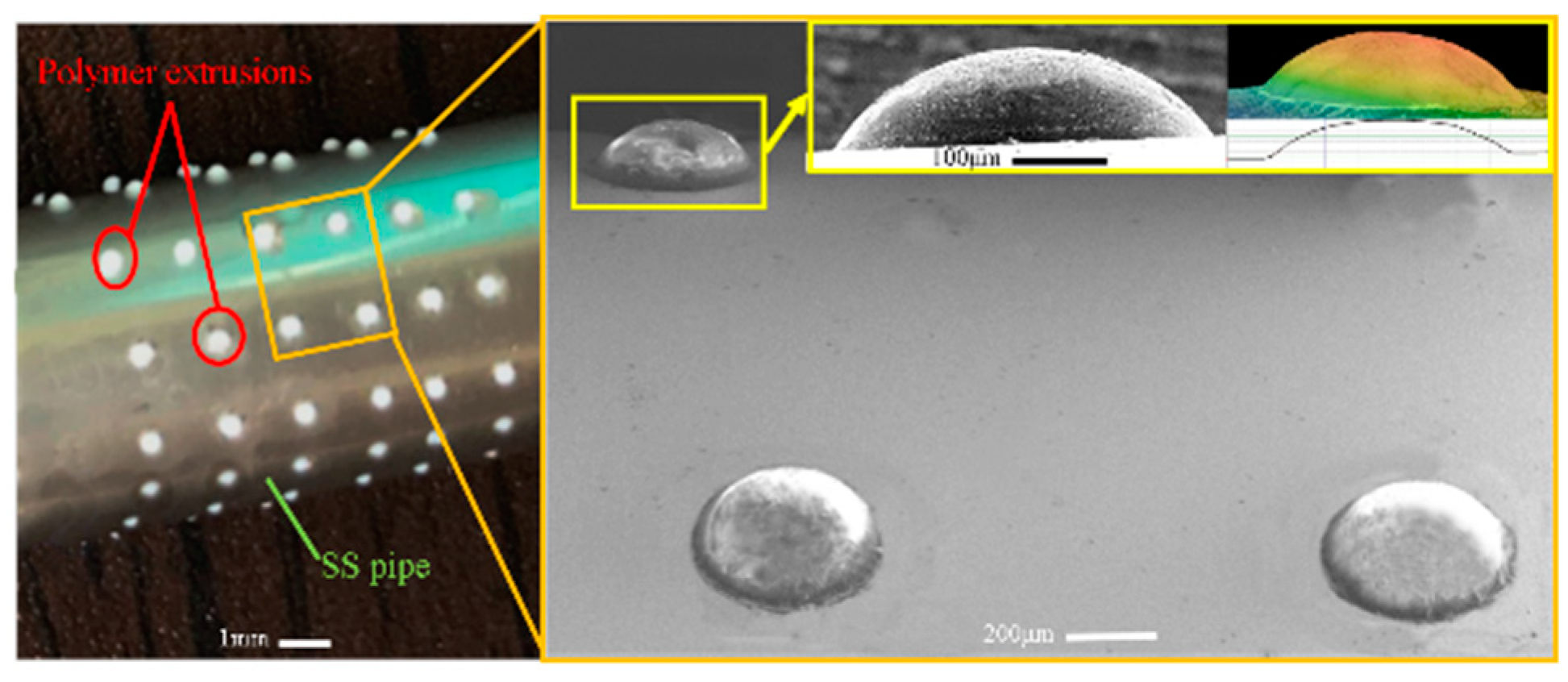

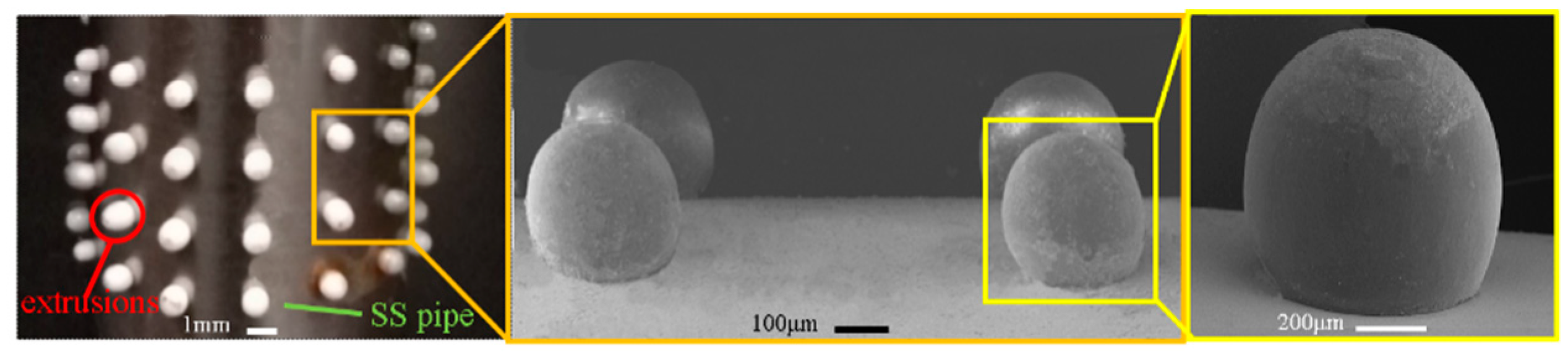

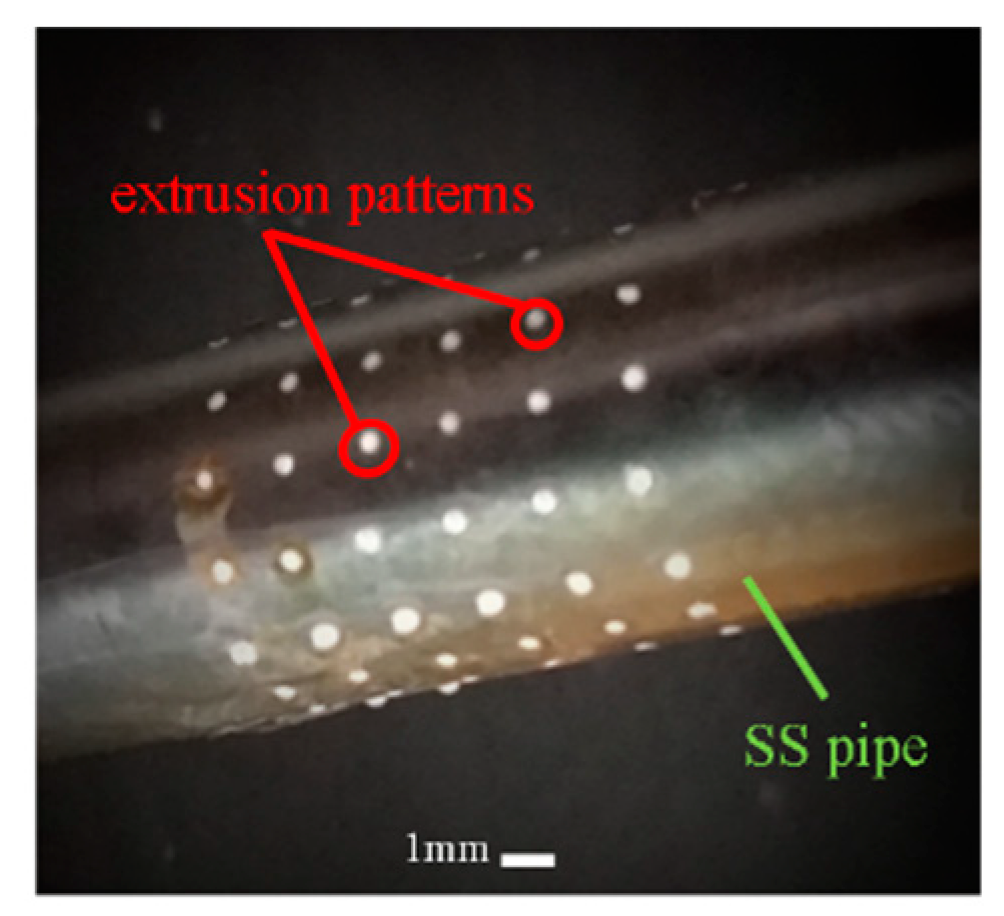

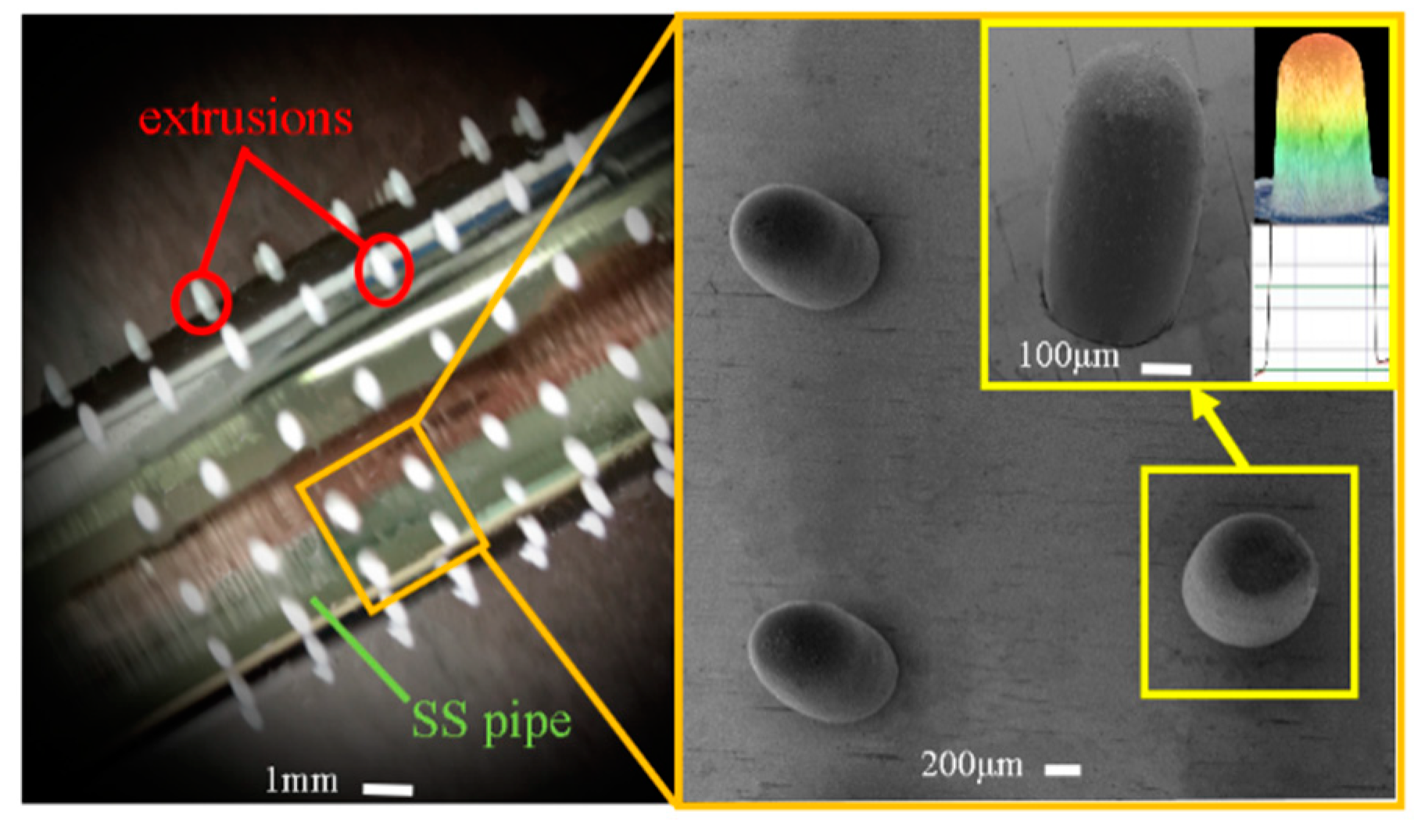

4.2. Achievement of the Seamless Hollow Cylinder with Perforations Having Hemisphere-Cone Double-Tapered Orifices

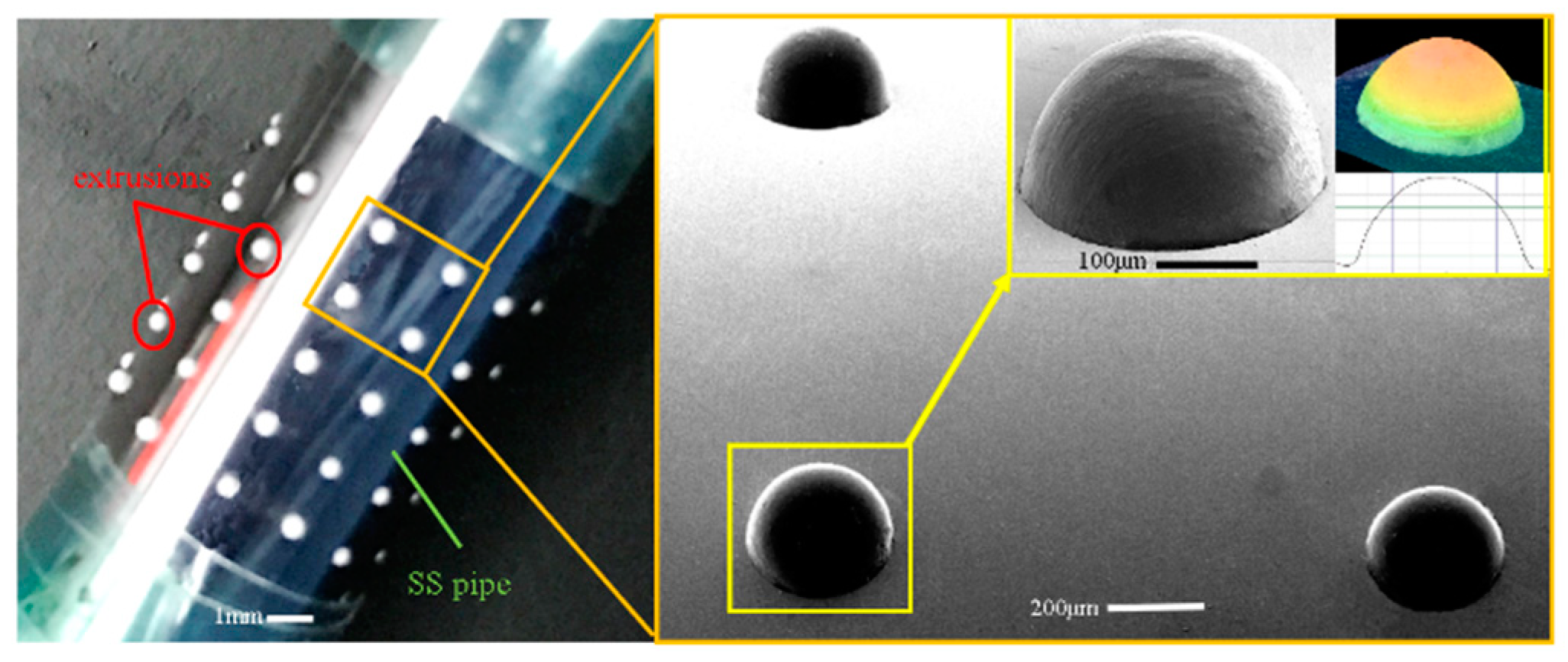

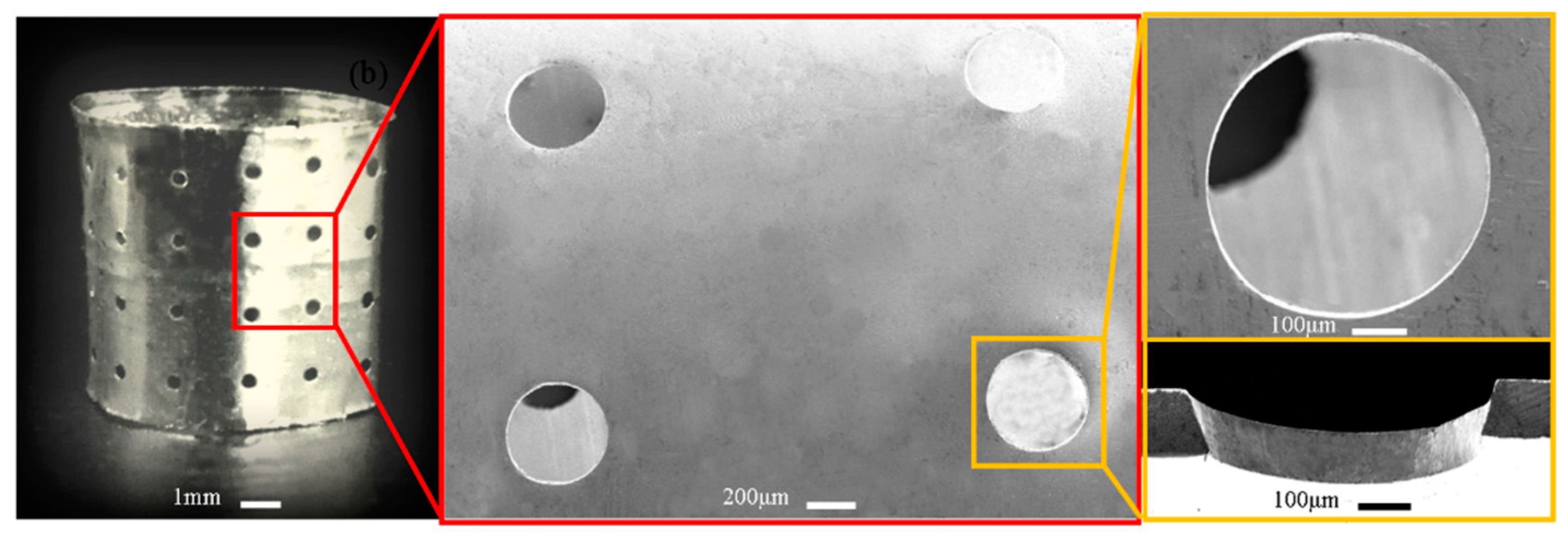

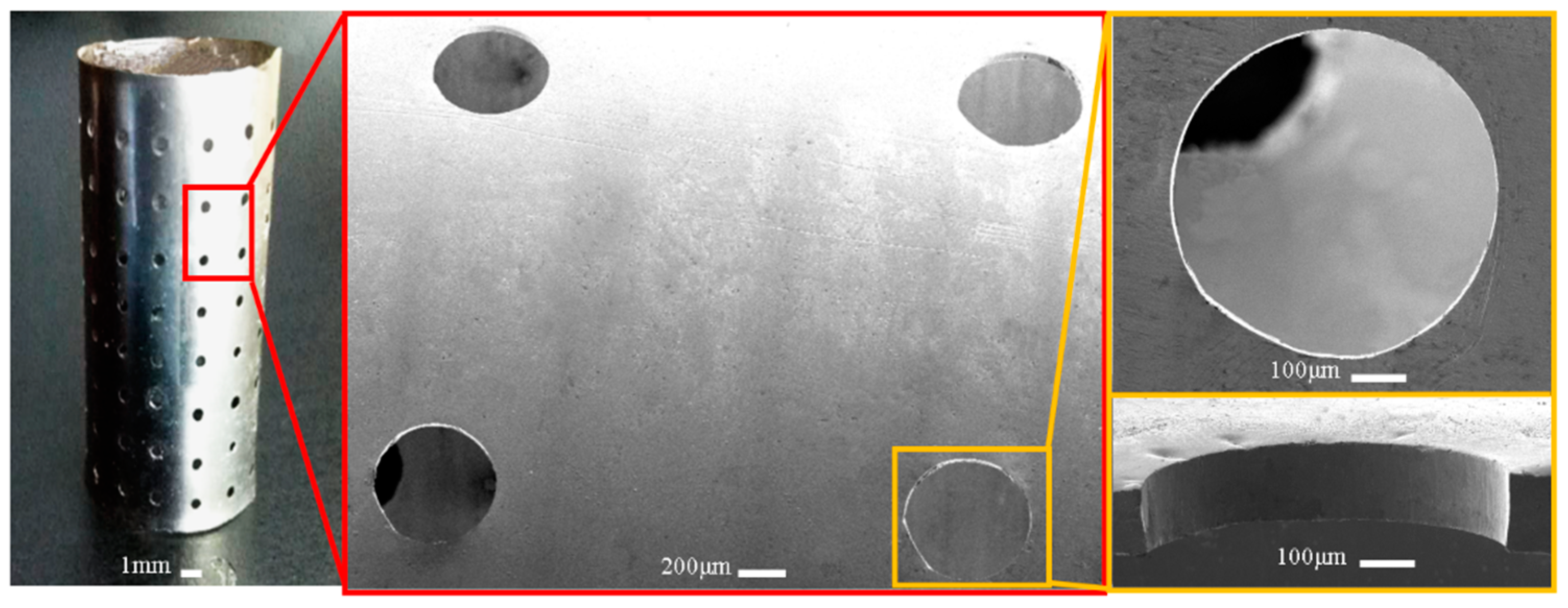

4.3. Achievement of the Seamless Hollow Cylinder with Unidirectionally Tapered Perforations

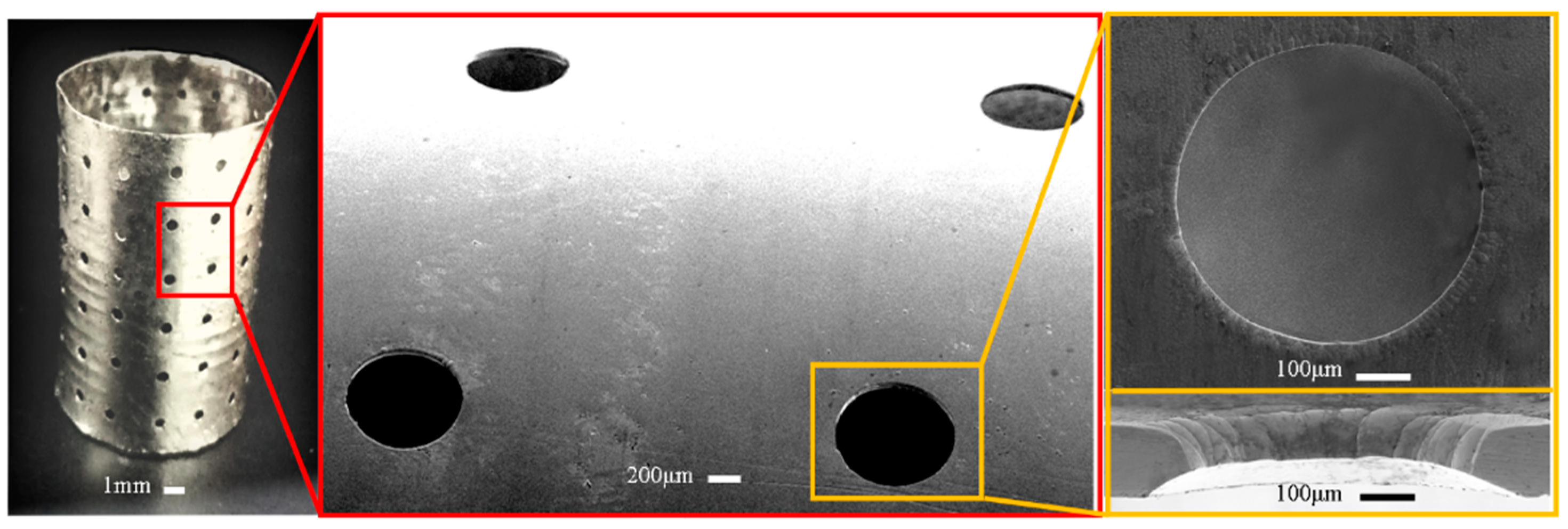

4.4. Achievement of the Seamless Hollow Cylinder with Straight-Walled Perforations

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- DiBari, G.A. Nickel electroplating applications & trends. Plat. Surf. Finish. 1996, 83, 10–14. [Google Scholar]

- Tang, P.T.; Benzon, M.E.; Rasmussen, J.P.; de Fontenay, F.L. Important Parameters and Applications for Nickel Electroforming. In Proceedings of the SUR/FIN Manufacturing and Technology Conference 1996, Cleveland, OH, USA, 5 November 1996; AESF: Hong Kong, China, 1996; pp. 627–635. [Google Scholar]

- Watson, F. Developments in Electroforming of Nickel for Engineering Applications. Metall. Mater. Technol. 1981, 13, 310–314. [Google Scholar]

- McGeough, J.A.; Leu, M.C.; Rajurkar, K.P.; de Silva, A.K.M.; Liu, Q. Electroforming process and application to micro/macro manufacturing. CIRP Ann. Manuf. Technol. 2001, 50, 499–514. [Google Scholar] [CrossRef]

- Nagayama, T.; Yamamoto, T.; Nakamura, T.; Mizutani, Y. Fabrication of Low CTE Metal Masks by the Invar Fe-Ni Alloy Electroforming Process for Large and Fine Pitch OLED Displays. ECS Trans. 2013, 50, 117–122. [Google Scholar] [CrossRef]

- Hart, T.; Watson, A. Electroforming. Met. Finish. 2000, 98, 388–399. [Google Scholar] [CrossRef]

- Datta, M.; Landolt, D. Fundamental Aspects and Applications of Electrochemical Microfabrication. Electrochim. Acta 2000, 45, 2535–2558. [Google Scholar] [CrossRef]

- Wang, W.; Zhu, D.; Allen, D.M.; Almondb, H.J.A. Non-traditional Machining Techniques for Fabricating Metal Aerospace Filters. Chin. J. Aeronaut. 2008, 21, 441–447. [Google Scholar]

- Bhattacharyya, B.; Munda, J.; Malapati, M. Advancement in electrochemical micro-machining. Int. J. Mach. Tools Manuf. 2004, 44, 1577–1589. [Google Scholar] [CrossRef]

- Sen, M.; Shan, H.S. A review of electrochemical macro- to micro-hole drilling processes. Int. J. Mach. Tools Manuf. 2005, 45, 137–152. [Google Scholar] [CrossRef]

- Kern, P.; Veh, J.; Michler, J. New developments in through-mask electrochemical micromachining of titanium. J. Micromech. Microeng. 2007, 17, 1168. [Google Scholar] [CrossRef]

- Zhu, D.; Qu, N.S.; Li, H.S.; Zeng, Y.B.; Li, D.L.; Qian, S.Q. Electrochemical micromachining of microstructures of micro hole and dimple array. CIRP Ann. Manuf. Technol. 2009, 58, 177–180. [Google Scholar] [CrossRef]

- Ehrfeld, W. Electrochemistry and microsystems. Electrochimica Acta 2003, 48, 2857–2868. [Google Scholar] [CrossRef]

- Ming, P.; Bao, X.; Hao, Q.; Wang, J. Fabrication of through-hole with biconically shaped cross sections by using electroforming and inert metal mask electrochemical machining. Int. J. Adv. Manuf. Technol. 2015, 76, 501–512. [Google Scholar] [CrossRef]

- Heidborn, E. Process for Manufacturing Screens for Centrifugals, Particularly Working Screens for Continuously Operating Sugar Centrifugals: USA. U.S. Patent 4341603, 27 July 1982. [Google Scholar]

- Wang, L.X.; You, Y.F. Research progress in nickel screen. Print Dye 2003, 29, 47–48. (In Chinese) [Google Scholar]

- Osher, S.; Sethian, J.A. Fronts propagating with curvature-dependent speed: Algorithms based on Hamilton-Jacobi formulations. J. Comput. Phys. 1988, 79, 12–49. [Google Scholar] [CrossRef]

- Lan, W.; Li, S.; Wang, Y.; Luo, G. CFD Simulation of Droplet Formation in Microchannels by a Modified Level Set Method. Ind. Eng. Chem. Res. 2014, 53, 4913–4921. [Google Scholar] [CrossRef]

- Koutelieris, A.; Kioupi, K.; Haralampous, O.; Kitsakis, K.; Vaxevanidis, N.; Kechagias, J. Simulation of extrusion of high density polyethylene tubes. In Proceedings of the MATEC Web of Conferences; EDP Sciences, Julius, France, 3 July 2017; Volume 112, p. 04004. [Google Scholar]

- Rong, J.H.; Liang, Q.Q. A level set method for topology optimization of continuum structures with bounded design domains. Comput. Methods Appl. Mech. Eng. 2008, 197, 1447–1465. [Google Scholar] [CrossRef]

- Sussman, M.; Smereka, P.; Osher, S. A Level Set Approach for Computing Solutions to Incompressible Two-Phase Flow. J. Comput. Phys. 1994, 114, 146–159. [Google Scholar] [CrossRef]

- Vivacqua, V.; Ghadiri, M.; Abdullah, A.M.; Hassanpour, A.; Al-Marri, M.J.; Azzopardi, B.; Hewakandamby, B.; Kermanie, B. Analysis of partial electrocoalescence by Level-Set and finite element methods. Chem. Eng. Res. Des. 2016, 114, 180–189. [Google Scholar] [CrossRef]

| Domain Conditions | Domain | Property and Values |

| Fluid property | Ω1 | Melt polymer |

| Density of melt polymer | -- | 0.85 g/cm3 |

| Viscosity of melt polymer | -- | 8 N·s/m2 |

| Surface tension of polymer(initial) | -- | 0.086 N/m |

| Fluid property | Ω2 | Air |

| Density of air | -- | 1.225 kg/m3 |

| Viscosity of air | -- | 1.789 × 10−5N·s/m2 |

| Boundary Conditions | Boundary | Property |

| Initial interface | 3 | -- |

| Inlet electrolyte | 1 | Laminar inflow, Φ = 1, u = u(Inlet) |

| Outlet | 5, 6 | P = 0 Pa |

| Constant(k) | -- | 2 |

| wall | 2, 4 | u = 0 |

| Diameter of inlet | 1 | 0.5 mm |

| Diameter of outlet | 5, 6 | 1 mm,1 mm |

| Compositions of Electrolyte and Parameters (Unit) | Value |

|---|---|

| Ni(NH2SO3)2·4H2O (g·L−1) | 360 |

| C12H25SO4Na (g·L−1) | 0.05 |

| NiCl2·7H2O (g·L−1) | 10 |

| H3BO3 (g·L−1) | 40 |

| pH | 4.5 |

| Temperature (°C) | 55 |

| Voltage (V) | 3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Ming, P.; Zhang, X.; Qin, G.; Yan, L.; Zhao, X.; Zheng, X. Facile Fabrication of Highly Perforated Hollow Metallic Cylinder with Changeable Micro-Orifices by Electroforming-Extrusion Molding Hybrid Process. Micromachines 2020, 11, 70. https://doi.org/10.3390/mi11010070

Zhang J, Ming P, Zhang X, Qin G, Yan L, Zhao X, Zheng X. Facile Fabrication of Highly Perforated Hollow Metallic Cylinder with Changeable Micro-Orifices by Electroforming-Extrusion Molding Hybrid Process. Micromachines. 2020; 11(1):70. https://doi.org/10.3390/mi11010070

Chicago/Turabian StyleZhang, Junzhong, Pingmei Ming, Xinmin Zhang, Ge Qin, Liang Yan, Xiaokang Zhao, and Xingshuai Zheng. 2020. "Facile Fabrication of Highly Perforated Hollow Metallic Cylinder with Changeable Micro-Orifices by Electroforming-Extrusion Molding Hybrid Process" Micromachines 11, no. 1: 70. https://doi.org/10.3390/mi11010070

APA StyleZhang, J., Ming, P., Zhang, X., Qin, G., Yan, L., Zhao, X., & Zheng, X. (2020). Facile Fabrication of Highly Perforated Hollow Metallic Cylinder with Changeable Micro-Orifices by Electroforming-Extrusion Molding Hybrid Process. Micromachines, 11(1), 70. https://doi.org/10.3390/mi11010070