Resistive Switching Memory Devices Based on Body Fluid of Bombyx mori L.

Abstract

:1. Introduction

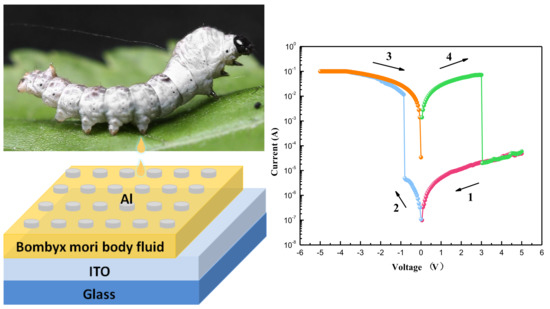

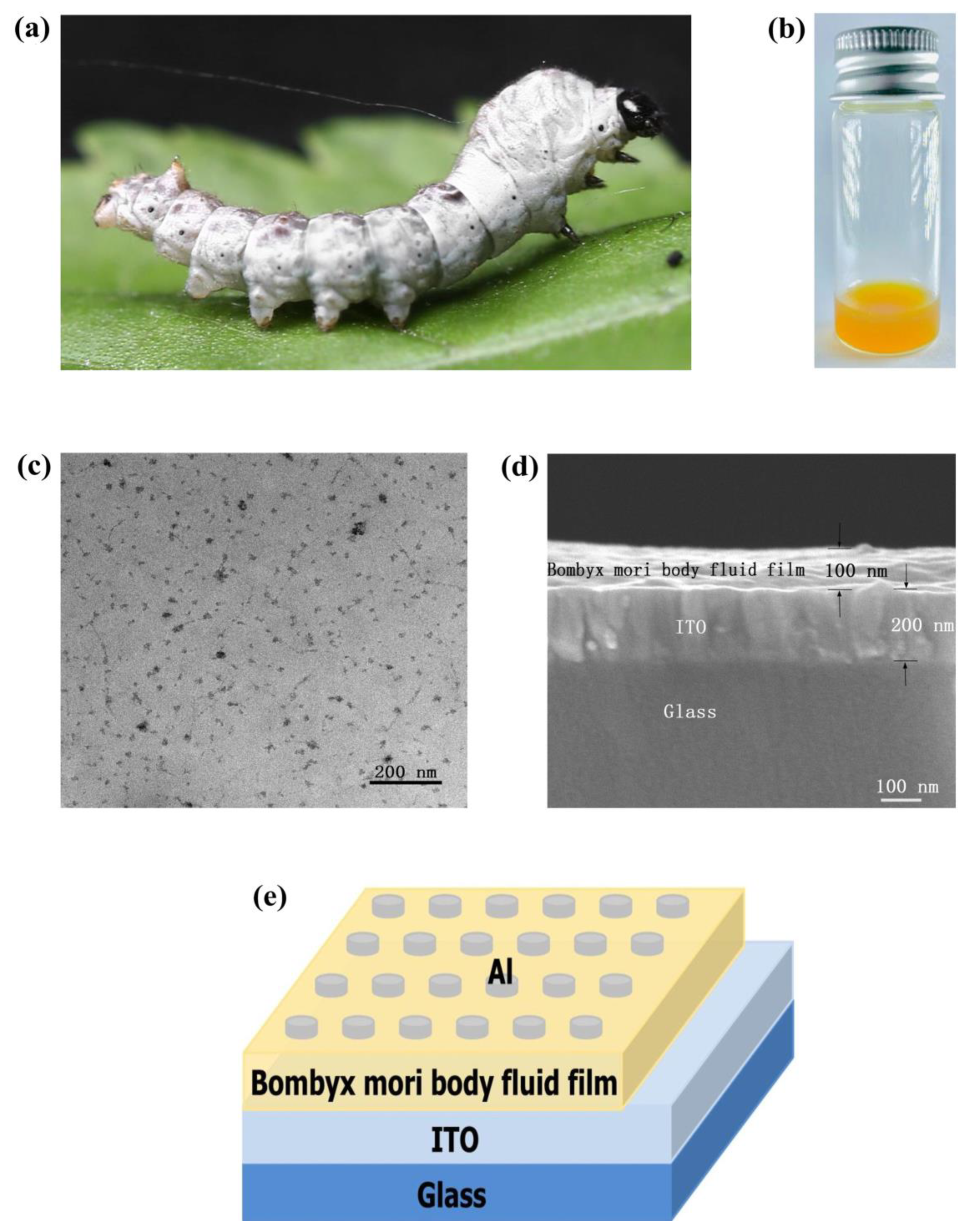

2. Materials and Methods

2.1. Materials and Service Fabrication

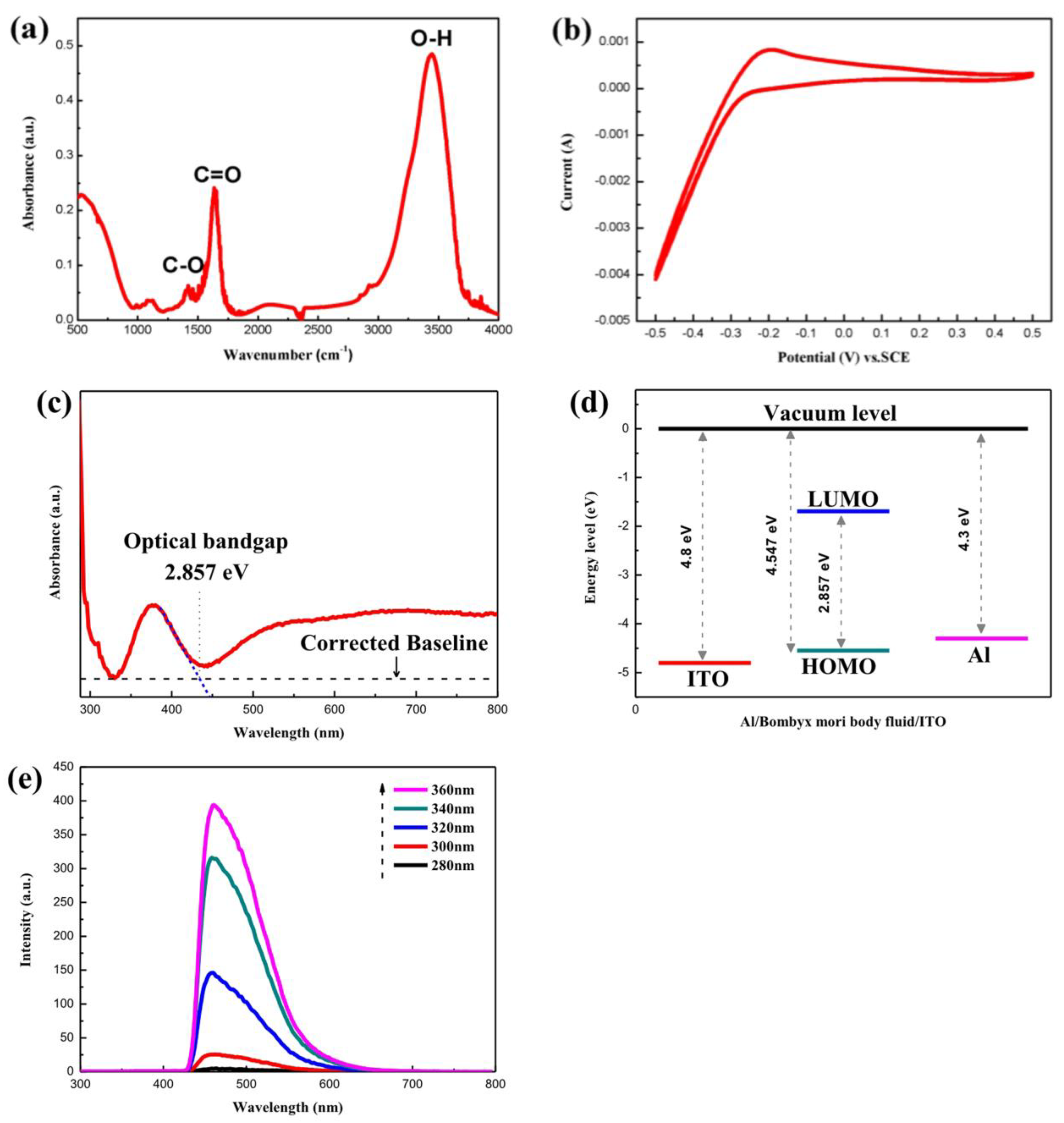

2.2. Characterization

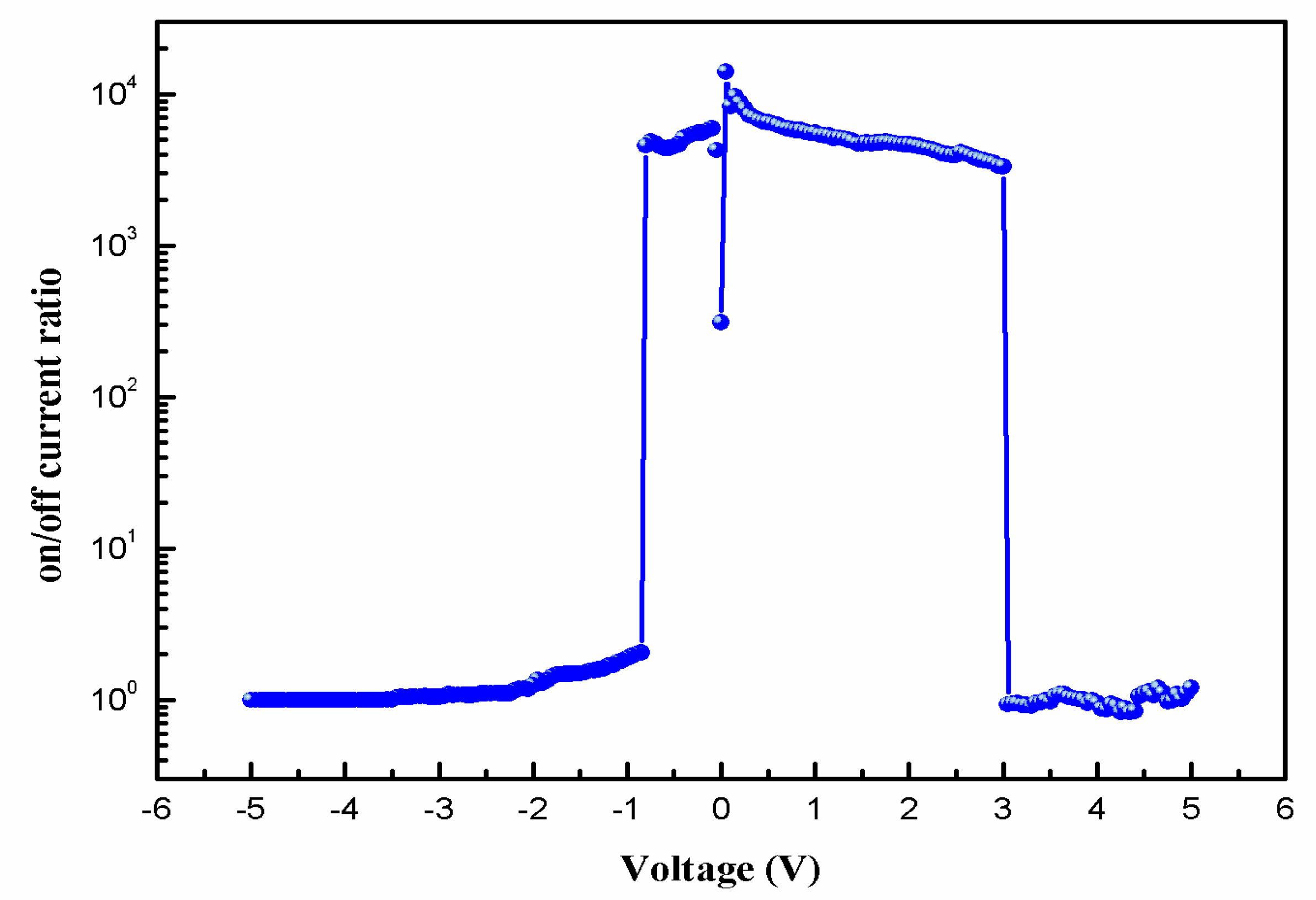

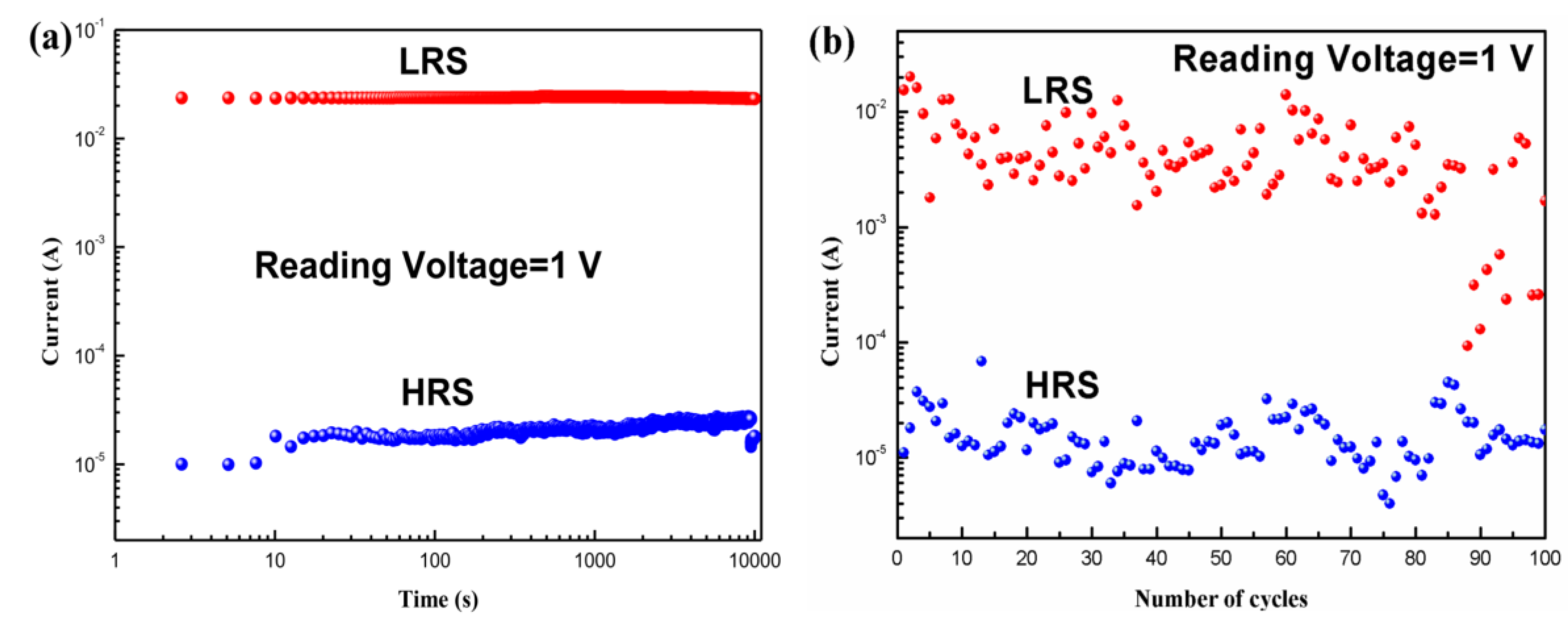

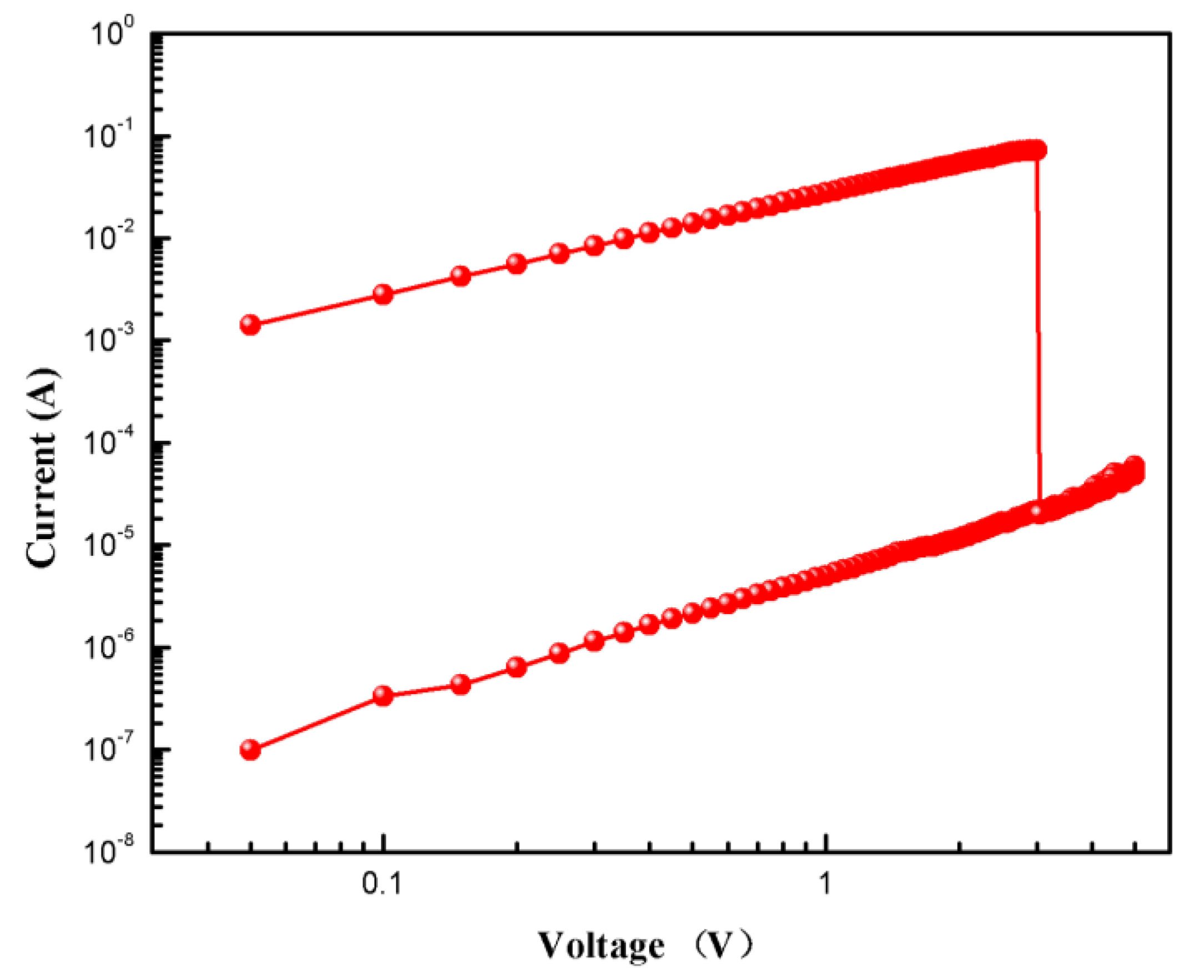

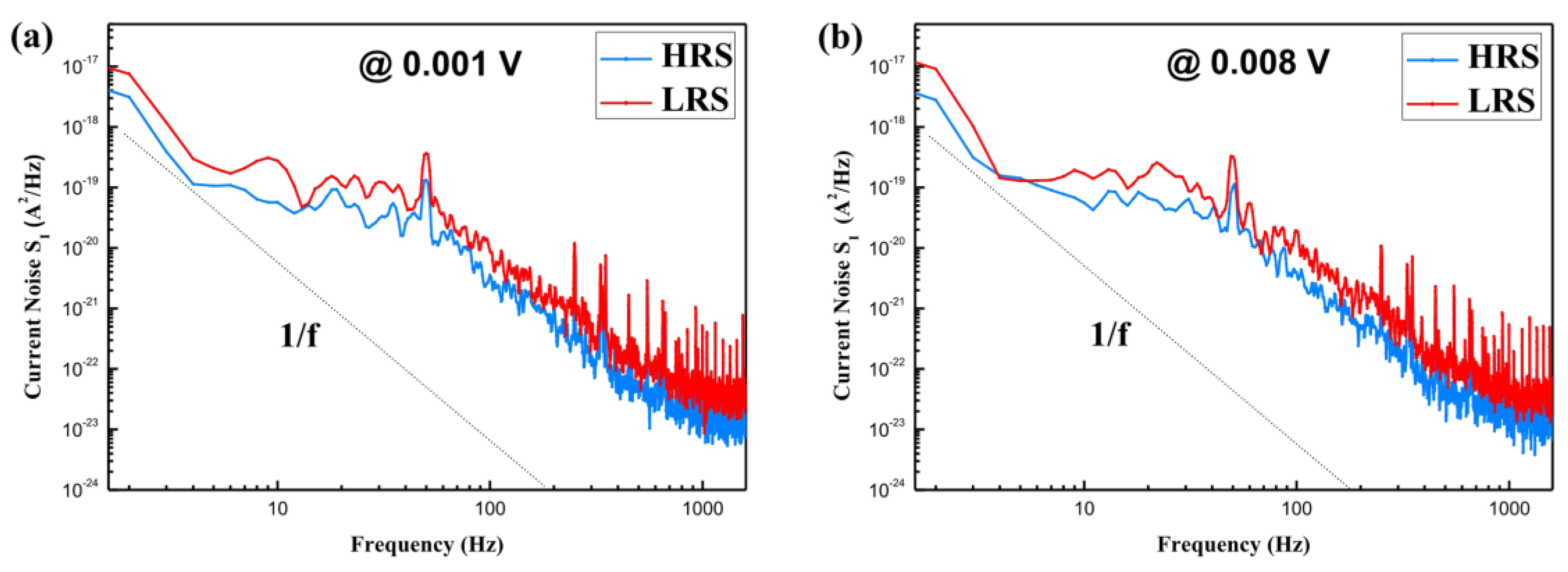

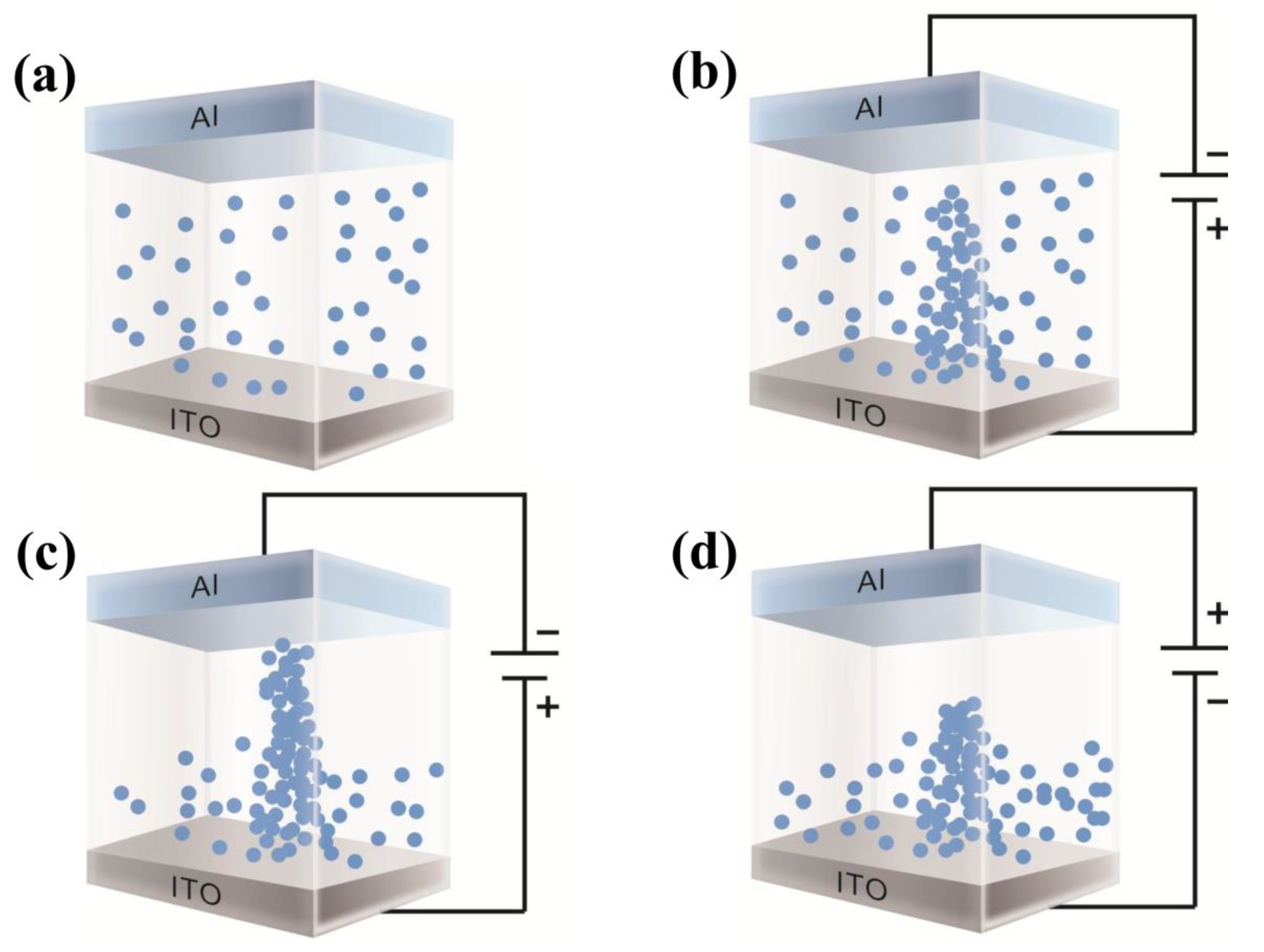

3. Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hosseini, N.R.; Lee, J.-S. Resistive switching memory based on bioinspired natural solid polymer electrolytes. ACS Nano 2014, 9, 419–426. [Google Scholar] [CrossRef] [PubMed]

- Hosseini, N.R.; Lee, J.-S. Biocompatible and flexible chitosan-based resistive switching memory with magnesium electrodes. Adv. Funct. Mater. 2015, 25, 5586–5592. [Google Scholar] [CrossRef]

- Hosseini, N.R.; Lee, J.-S. Controlling the resistive switching behavior in starch-based flexible biomemristors. ACS Appl. Mater. Interfaces 2016, 8, 7326–7332. [Google Scholar] [CrossRef] [PubMed]

- Dutta, M.; Maikap, S.; Qiu, J.T. Controlling conductive filament and tributyrin sensing using an optimized porous iridium interfacial layer in Cu/Ir/TiNxOy/TiN. Adv. Electron. Mater. 2019, 5, 1800288. [Google Scholar]

- Qiu, J.T.; Samanta, S.; Dutta, M.; Ginnaram, S.; Maikap, S. Controlling resistive switching by using an optimized MoS2 interfacial layer and the role of top electrodes on ascorbic acid sensing in TaOx-based RRAM. Langmuir 2019, 35, 3897–3906. [Google Scholar] [CrossRef] [PubMed]

- Jo, S.; Sun, W.; Kim, B.; Kim, S.; Park, J.; Shin, H. Memristor neural network training with clock synchronous neuromorphic system. Micromachines 2019, 10, 384. [Google Scholar] [CrossRef] [PubMed]

- Pham, K.V.; Nguyen, T.V.; Min, K.-S. Partial-gated memristor crossbar for fast and power-efficient defect-tolerant training. Micromachines 2019, 10, 245. [Google Scholar] [CrossRef]

- Goswami, S.; Matula, A.J.; Rath, S.P.; Hedström, S.; Saha, S.; Annamalai, M.; Sengupta, D.; Patra, A.; Ghosh, S.; Jani, H. Robust resistive memory devices using solution-processable metal-coordinated azo aromatics. Nat. Mater. 2017, 16, 1216. [Google Scholar] [CrossRef]

- Zhang, X.; Li, J.; Yang, W.; Leng, B.; Niu, P.; Jiang, X.; Liu, B. High-performance flexible UV photodetectors based on AZO/ZnO/PVK/PEDOT: PSS heterostructures integrated on human hair. ACS Appl. Mater. Interfaces 2019, 11, 24459–24467. [Google Scholar] [CrossRef]

- Kumar, D.; Aluguri, R.; Chand, U.; Tseng, T. Metal oxide resistive switching memory: Materials, properties and switching mechanisms. Ceram. Int. 2017, 43, S547–S556. [Google Scholar] [CrossRef]

- Wang, H.; Meng, F.; Zhu, B.; Leow, W.R.; Liu, Y.; Chen, X. Resistive switching memory devices based on proteins. Adv. Mater. 2015, 27, 7670–7676. [Google Scholar] [CrossRef] [PubMed]

- Yoon, J.H.; Zhang, J.; Ren, X.; Wang, Z.; Wu, H.; Li, Z.; Barnell, M.; Wu, Q.; Lauhon, L.J.; Xia, Q. Truly electroforming-free and low-energy memristors with preconditioned conductive tunneling paths. Adv. Funct. Mater. 2017, 27, 1702010. [Google Scholar] [CrossRef]

- Banerjee, W.; Liu, Q.; Lv, H.; Long, S.; Liu, M. Electronic imitation of behavioral and psychological synaptic activities using TiOx/Al2O3-based memristor devices. Nanoscale 2017, 9, 14442–14450. [Google Scholar] [CrossRef] [PubMed]

- Srivastava, S.; Thomas, J.P.; Heinig, N.F.; Leung, K. High-performance single-active-layer memristor based on an ultrananocrystalline oxygen-deficient TiOx film. ACS Appl. Mater. Interfaces 2017, 9, 36989–36996. [Google Scholar] [CrossRef] [PubMed]

- Yu, Y.; Wang, C.; Jiang, C.; Abrahams, I.; Du, Z.; Zhang, Q.; Sun, J.; Huang, X. Resistive switching behavior in memristors with TiO2 nanorod arrays of different dimensions. Appl. Surf. Sci. 2019, 485, 222–229. [Google Scholar] [CrossRef]

- He, C.; Li, J.; Wu, X.; Chen, P.; Zhao, J.; Yin, K.; Cheng, M.; Yang, W.; Xie, G.; Wang, D. Tunable electroluminescence in planar graphene/SiO2 memristors. Adv. Mater. 2013, 25, 5593–5598. [Google Scholar] [CrossRef] [PubMed]

- Mehonic, A.; Shluger, A.L.; Gao, D.; Valov, I.; Miranda, E.; Ielmini, D.; Bricalli, A.; Ambrosi, E.; Li, C.; Yang, J.J. Silicon oxide (SiOx): A promising material for resistance switching? Adv. Mater. 2018, 30, 1801187. [Google Scholar] [CrossRef] [PubMed]

- Pi, S.; Li, C.; Jiang, H.; Xia, W.; Xin, H.; Yang, J.J.; Xia, Q. Memristor crossbar arrays with 6-nm half-pitch and 2-nm critical dimension. Nat. Nanotechnol. 2019, 14, 35. [Google Scholar] [CrossRef]

- Sysoev, V.; Arkhipov, V.; Okotrub, A.; Pershin, Y. Chemical sensors are hybrid-input memristors. Appl. Surf. Sci. 2018, 436, 1018–1021. [Google Scholar] [CrossRef]

- Upadhyay, N.K.; Jiang, H.; Wang, Z.; Asapu, S.; Xia, Q.; Joshua Yang, J. Emerging memory devices for neuromorphic computing. Adv. Mater. Technol. 2019, 4, 1800589. [Google Scholar] [CrossRef]

- Jang, J.T.; Ko, D.; Ahn, G.; Yu, H.R.; Jung, H.; Kim, Y.S.; Yoon, C.; Lee, S.; Park, B.H.; Choi, S.-J. Effect of oxygen content of the LaAlO3 layer on the synaptic behavior of Pt/LaAlO3/Nb-doped SrTiO3 memristors for neuromorphic applications. Solid-State Electron. 2018, 140, 139–143. [Google Scholar] [CrossRef]

- Nili, H.; Walia, S.; Kandjani, A.E.; Ramanathan, R.; Gutruf, P.; Ahmed, T.; Balendhran, S.; Bansal, V.; Strukov, D.B.; Kavehei, O. Donor-induced performance tuning of amorphous SrTiO3 memristive nanodevices: Multistate resistive switching and mechanical tunability. Adv. Funct. Mater. 2015, 25, 3172–3182. [Google Scholar] [CrossRef]

- Huang, W.; Fang, Y.-W.; Yin, Y.; Tian, B.; Zhao, W.; Hou, C.; Ma, C.; Li, Q.; Tsymbal, E.Y.; Duan, C.-G. Solid-state synapse based on magnetoelectrically coupled memristor. ACS Appl. Mater. Interfaces 2018, 10, 5649–5656. [Google Scholar] [CrossRef]

- Wei, L.; Yuan, Y.; Wang, J.; Tu, H.; Gao, Y.; You, B.; Du, J. Bipolar resistive switching with negative differential resistance effect in a Cu/BaTiO3/Ag device. Phys. Chem. Chem. Phys. 2017, 19, 11864–11868. [Google Scholar] [CrossRef]

- Xu, Z.T.; Jin, K.J.; Gu, L.; Jin, Y.L.; Ge, C.; Wang, C.; Guo, H.Z.; Lu, H.B.; Zhao, R.Q.; Yang, G.Z. Evidence for a crucial role played by oxygen vacancies in LaMnO3 resistive switching memories. Small 2012, 8, 1279–1284. [Google Scholar] [CrossRef] [PubMed]

- Yan, X.; Li, X.; Zhou, Z.; Zhao, J.; Wang, H.; Wang, J.; Zhang, L.; Ren, D.; Zhang, X.; Chen, J. A flexible transparent organic artificial synapse based on tungsten/egg albumen/indium tin oxide/polyethylene terephthalate memristor. ACS Appl. Mater. Interfaces 2019, 11, 18654–18661. [Google Scholar] [CrossRef] [PubMed]

- He, X.; Zhang, J.; Wang, W.; Xuan, W.; Wang, X.; Zhang, Q.; Smith, C.G.; Luo, J. Transient resistive switching devices made from egg albumen dielectrics and dissolvable electrodes. ACS Appl. Mater. Interfaces 2016, 8, 10954–10960. [Google Scholar] [CrossRef] [PubMed]

- Meng, F.; Sana, B.; Li, Y.; Liu, Y.; Lim, S.; Chen, X. Bioengineered tunable memristor based on protein nanocage. Small 2014, 10, 277–283. [Google Scholar] [CrossRef]

- Kim, M.-K.; Lee, J.-S. Ultralow power consumption flexible biomemristors. ACS Appl. Mater. Interfaces 2018, 10, 10280–10286. [Google Scholar] [CrossRef]

- Murgunde, B.K.; Rabinal, M.K.; Kalasad, M.N. Biologically active nanocomposite of DNA-PbS nanoparticles: A new material for non-volatile memory devices. Appl. Surf. Sci. 2018, 427, 344–353. [Google Scholar] [CrossRef]

- Sun, B.; Zhu, S.; Mao, S.; Zheng, P.; Xia, Y.; Yang, F.; Lei, M.; Zhao, Y. From dead leaves to sustainable organic resistive switching memory. J. Colloid Interface Sci. 2018, 513, 774–778. [Google Scholar] [CrossRef] [PubMed]

- Rananavare, A.P.; Kadam, S.J.; Prabhu, S.V.; Chavan, S.S.; Anbhule, P.V.; Dongale, T.D. Organic non-volatile memory device based on cellulose fibers. Mater. Lett. 2018, 232, 99–102. [Google Scholar] [CrossRef]

- Hota, M.K.; Bera, M.K.; Kundu, B.; Kundu, S.C.; Maiti, C.K. A natural silk fibroin protein-based transparent bio-memristor. Adv. Funct. Mater. 2012, 22, 4493–4499. [Google Scholar] [CrossRef]

- Sheng, G.-P.; Yu, H.-Q.; Yu, Z. Extraction of extracellular polymeric substances from the photosynthetic bacterium rhodopseudomonas acidophila. Appl. Microbiol. Biotechnol. 2005, 67, 125–130. [Google Scholar] [CrossRef] [PubMed]

- Moreno-Castilla, C.; Lopez-Ramon, M.; Carrasco-Marın, F. Changes in surface chemistry of activated carbons by wet oxidation. Carbon 2000, 38, 1995–2001. [Google Scholar] [CrossRef]

- Cheng, F.; He, C.; Ren, M.; Yao, L.; Tang, N. Preparation, photophysical, and electrochemical properties of three trinuclear Ru(II) complexes: Bridging ligands composed of 2,2′-bipyridine and 4,5-diazafluorene fragments. Inorg. Chem. Commun. 2014, 43, 10–14. [Google Scholar] [CrossRef]

- Chen, Y.-C.; Yu, H.-C.; Huang, C.-Y.; Chung, W.-L.; Wu, S.-L.; Su, Y.-K. Nonvolatile bio-memristor fabricated with egg albumen film. Sci. Rep. 2015, 5, 10022. [Google Scholar] [CrossRef] [PubMed]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Wen, D. Resistive Switching Memory Devices Based on Body Fluid of Bombyx mori L. Micromachines 2019, 10, 540. https://doi.org/10.3390/mi10080540

Wang L, Wen D. Resistive Switching Memory Devices Based on Body Fluid of Bombyx mori L. Micromachines. 2019; 10(8):540. https://doi.org/10.3390/mi10080540

Chicago/Turabian StyleWang, Lu, and Dianzhong Wen. 2019. "Resistive Switching Memory Devices Based on Body Fluid of Bombyx mori L." Micromachines 10, no. 8: 540. https://doi.org/10.3390/mi10080540

APA StyleWang, L., & Wen, D. (2019). Resistive Switching Memory Devices Based on Body Fluid of Bombyx mori L. Micromachines, 10(8), 540. https://doi.org/10.3390/mi10080540