Microfluidic Generation of Amino-Functionalized Hydrogel Microbeads Capable of On-Bead Bioassay

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

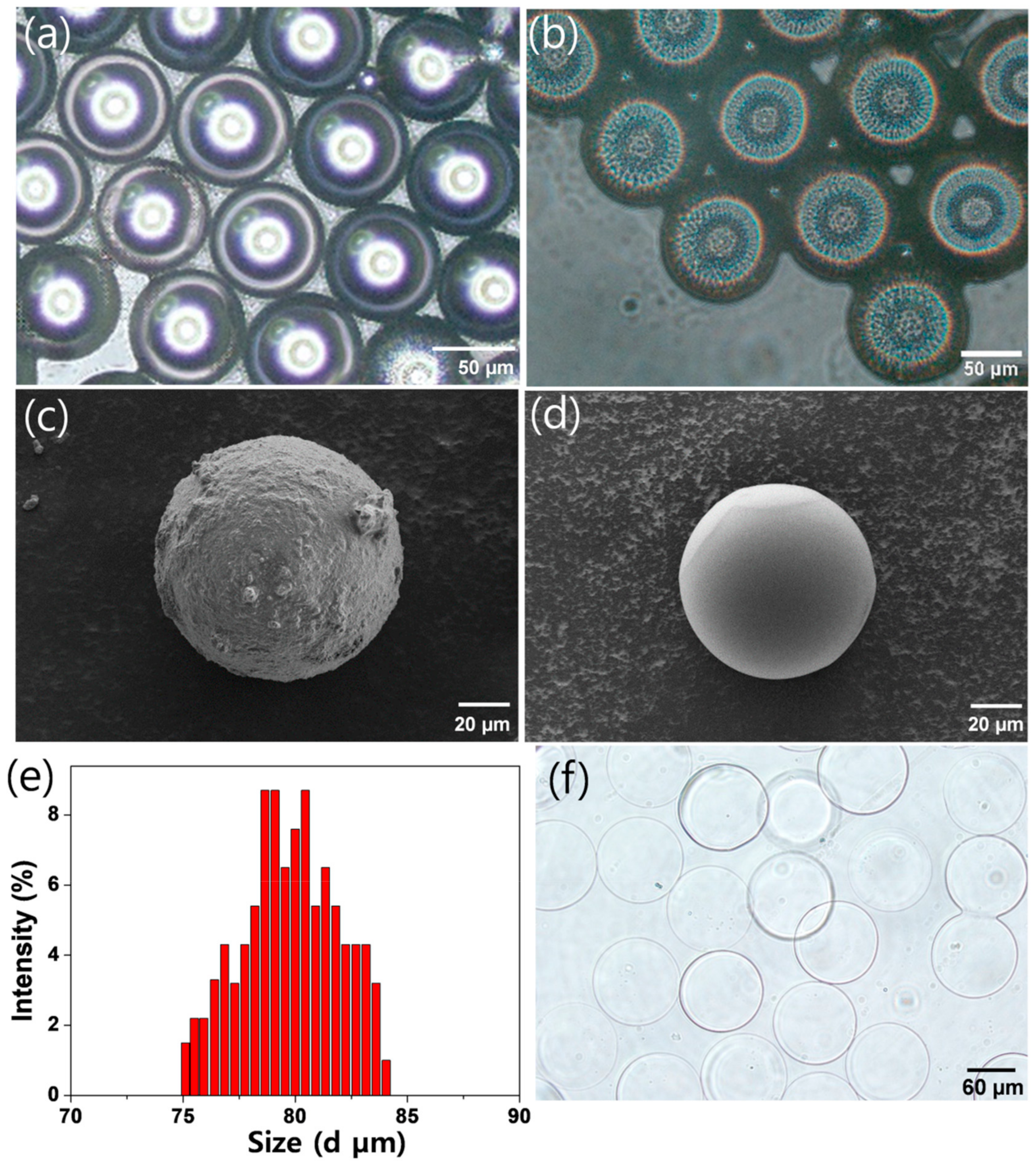

2.2. Generation of PEG-Amine Hydrogel Microbeads

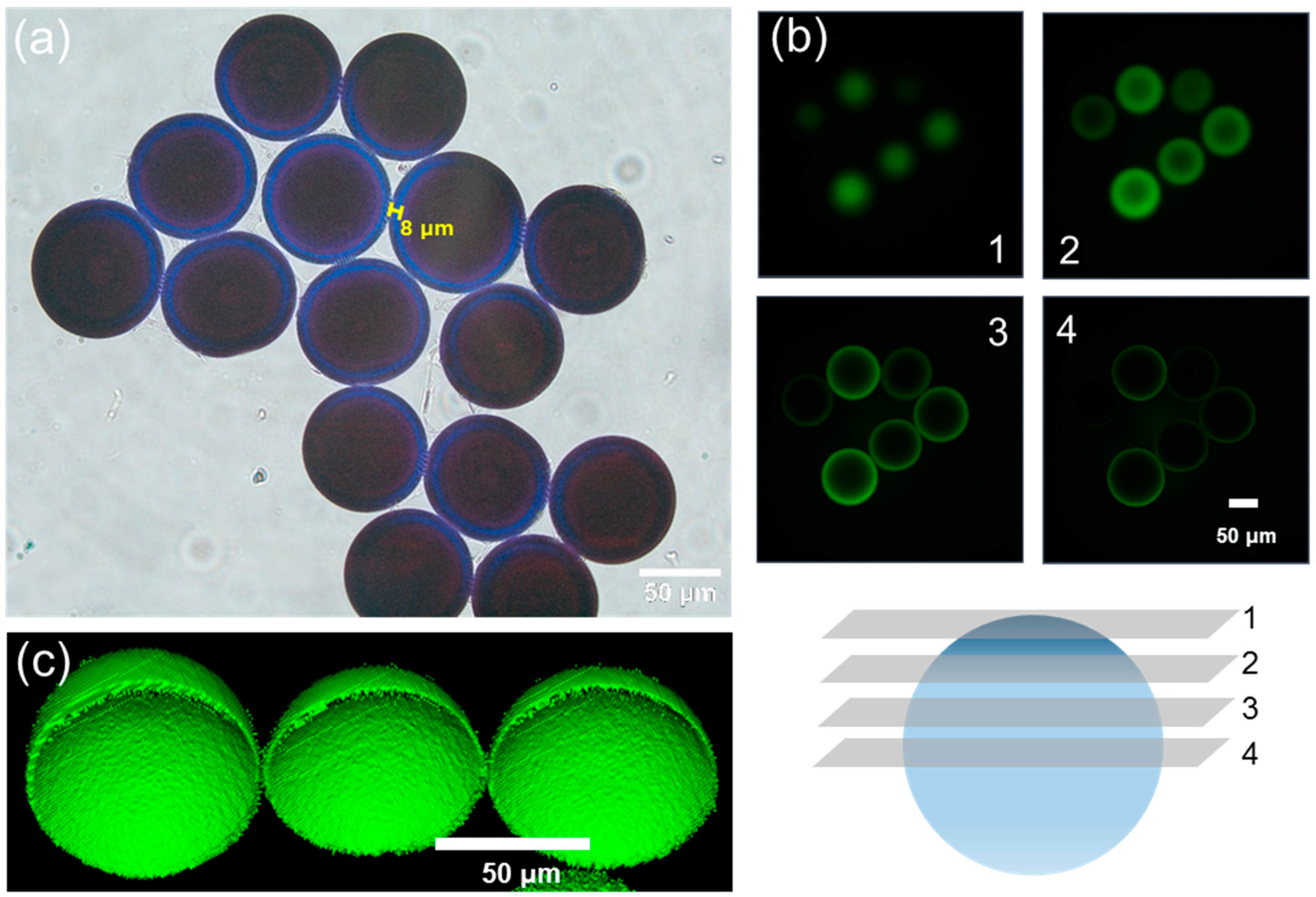

2.3. Coupling of FITC onto PEG-Amine Hydrogel Microbeads

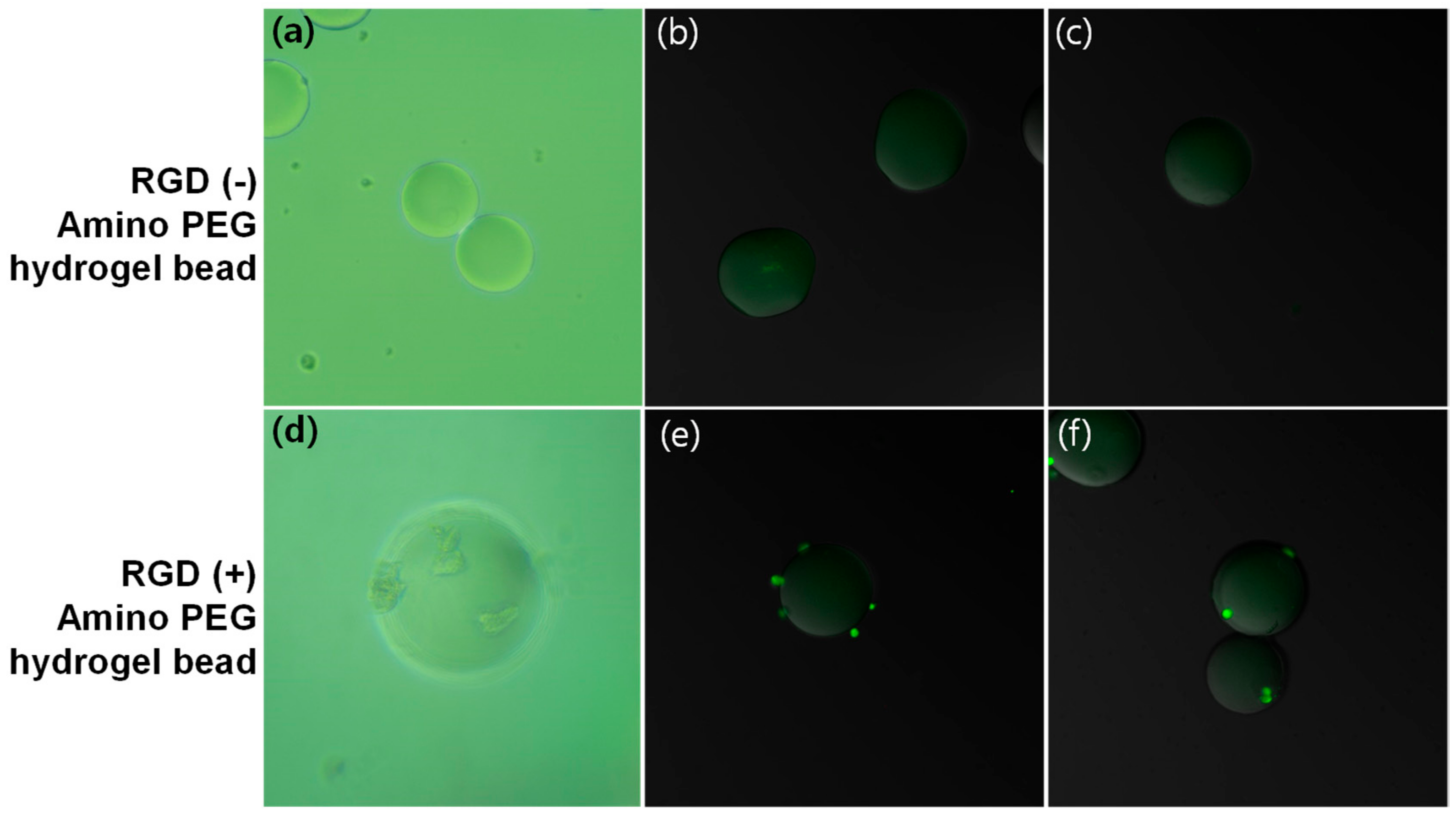

2.4. RGD Peptide Immobilization on Peg Hydrogel Microbeads

2.5. Cell Binding Assay

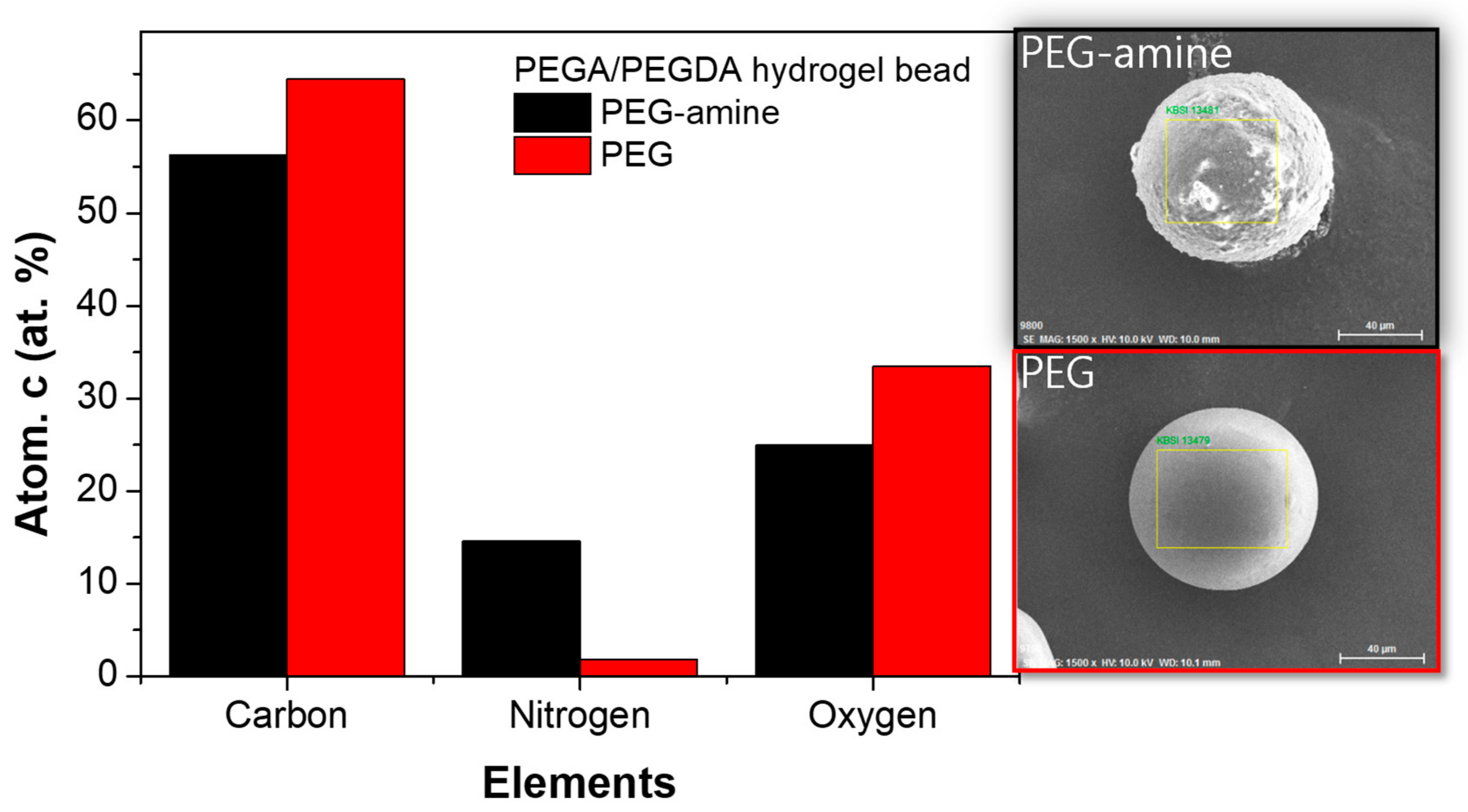

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Gitsov, I.; Zhu, C. Amphiphilic Hydrogels Constructed by Poly(ethylene glycol) and Shape-Persistent Dendritic Fragments. Macromolecules 2002, 35, 8418–8427. [Google Scholar] [CrossRef]

- Mäde, V.; Els-Heindl, S.; Beck-Sickinger, A.G. Automated solid-phase peptide synthesis to obtain therapeutic peptides. Beilstein J. Org. Chem. 2014, 10, 1197–1212. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shin, D.S.; Kim, Y.G.; Kim, E.M.; Kim, M.; Park, H.Y.; Kim, J.H.; Lee, B.S.; Kim, B.G.; Lee, Y.S. Solid-Phase Peptide Library Synthesis on HiCore Resin for Screening Substrate Specificity of Brk Protein Tyrosine Kinase. J. Comb. Chem. 2008, 10, 20–23. [Google Scholar] [CrossRef] [PubMed]

- Acosta, G.A.; Del Fresno, M.; Paradis-Bas, M.; Rigau-DeLlobet, M.; Côté, S.; Royo, M.; Albericio, F. Solid-phase peptide synthesis using acetonitrile as a solvent in combination with PEG-based resins. J. Pept. Sci. 2009, 15, 629–633. [Google Scholar] [CrossRef] [PubMed]

- Palomo, J.M. Solid-phase peptide synthesis: An overview focused on the preparation of biologically relevant peptides. RSC Adv. 2014, 4, 32658–32672. [Google Scholar] [CrossRef]

- Thormann, E.; Simonsen, A.C.; Hansen, P.L.; Mouritsen, O.G. Interactions between a Polystyrene Particle and Hydrophilic and Hydrophobic Surfaces in Aqueous Solutions. Langmuir 2008, 24, 7278–7284. [Google Scholar] [CrossRef] [PubMed]

- Settanni, G.; Zhou, J.; Suo, T.; Schöttler, S.; Landfester, K.; Schmid, F.; Mailänder, V. Protein corona composition of poly(ethylene glycol)- and poly(phosphoester)-coated nanoparticles correlates strongly with the amino acid composition of the protein surface. Nanoscale 2017, 9, 2138–2144. [Google Scholar] [CrossRef] [Green Version]

- Danaei, M.; Dehghankhold, M.; Ataei, S.; Davarani, F.H.; Javanmard, R.; Dokhani, A.; Khorasani, S.; Mozafari, M.R. Impact of Particle Size and Polydispersity Index on the Clinical Applications of Lipidic Nanocarrier Systems. Pharmaceutics 2018, 10, 57. [Google Scholar] [CrossRef]

- Zhang, C.; Li, X.; Chen, S.; Yang, R. Effects of polymerization conditions on particle size distribution in styrene-graphite suspension polymerization process. J. Appl. Polym. Sci. 2016, 133, 44270. [Google Scholar] [CrossRef]

- Brooks, B. Suspension Polymerization Processes. Chem. Eng. Technol. 2010, 33, 1737–1744. [Google Scholar] [CrossRef] [Green Version]

- Machado, F.; Lima, E.L.; Pinto, J.C. A review on suspension polymerization processes. Polimeros 2007, 17, 166–179. [Google Scholar] [CrossRef]

- Penlidis, A.; Wood, P.E.; Hamielec, A.E.; Vivaldo-Lima, E. Determination of the relative importance of process factors on particle size distribution in suspension polymerization using a Bayesian experimental design technique. J. Appl. Polym. Sci. 2006, 102, 5577–5586. [Google Scholar]

- Seiffert, S.; Weitz, D.A. Microfluidic fabrication of smart microgels from macromolecular precursors. Polymers 2010, 51, 5883–5889. [Google Scholar] [CrossRef] [Green Version]

- Young, E.W.K.; Beebe, D.J. Fundamentals of microfluidic cell culture in controlled microenvironments. Chem. Soc. Rev. 2010, 39, 1036–1048. [Google Scholar] [CrossRef] [PubMed]

- Voicu, D.; Scholl, C.; Nasimova, I.; Li, W.; Jagadeesan, D.; Greener, J.; Kumacheva, E. Kinetics of Multicomponent Polymerization Reaction Studied in a Microfluidic Format. Macromolecules 2012, 45, 4469–4475. [Google Scholar] [CrossRef]

- Kong, T.; Wu, J.; To, M.; Yeung, K.W.K.; Shum, H.C.; Wang, L. Droplet based microfluidic fabrication of designer microparticles for encapsulation applications. Biomicrofluidics 2012, 6, 034104. [Google Scholar] [CrossRef] [Green Version]

- Beneyton, T.; Coldren, F.; Griffiths, A.D.; Baret, J.-C.; Taly, V. CotA laccase: High-throughput manipulation and analysis of recombinant enzyme libraries expressed in E. coli using droplet-based microfluidics. Analyst 2014, 139, 3314–3323. [Google Scholar] [CrossRef]

- Kang, D.K.; Ali, M.M.; Zhang, K.; Pone, E.J.; Zhao, W. Droplet microfluidics for single-molecule and single-cell analysis in cancer research, diagnosis and therapy. TrAC Trends Anal. Chem. 2014, 58, 145–153. [Google Scholar] [CrossRef]

- Streets, A.M.; Huang, Y. Microfluidics for biological measurements with single-molecule resolution. Curr. Opin. Biotechnol. 2014, 25, 69–77. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.X.; Utech, S.; Gopez, J.D.; Mabesoone, M.F.J.; Hawker, C.J.; Klinger, D. Non-Covalent Microgel Particles Containing Functional Payloads: Coacervation of PEG-Based Triblocks via Microfluidics. ACS Appl. Mater. Interfaces 2016, 8, 16914–16921. [Google Scholar] [CrossRef]

- Kim, H.; Cho, J.K.; Chung, W.-J.; Lee, Y.-S. Core−Shell-Type Resins for Solid-Phase Peptide Synthesis: Comparison with Gel-Type Resins in Solid-Phase Photolytic Cleavage Reaction. Org. Lett. 2004, 6, 3273–3276. [Google Scholar] [CrossRef] [PubMed]

- Nichols, M.D.; Scott, E.A.; Elbert, D.L. Factors affecting size and swelling of poly(ethylene glycol) microspheres formed in aqueous sodium sulfate solutions without surfactants. Biomaterials 2009, 30, 5283–5291. [Google Scholar] [CrossRef] [Green Version]

- Auzanneau, F.I.; Meldal, M.; Bock, K. Synthesis, characterization and biocompatibility of PEGA resins. J. Pept. Sci. 1995, 1, 31–44. [Google Scholar] [CrossRef]

- Renil, M.; Ferreras, M.; Delaisse, J.M.; Foged, N.T.; Meldal, M. PEGA supports for combinatorial peptide synthesis and solid-phase enzymatic library assays. J. Pept. Sci. 1998, 4, 195–210. [Google Scholar] [CrossRef]

- Caporale, A.; Bolzati, C.; Incisivo, G.M.; Salvarese, N.; Grieco, P.; Ruvo, M. Improved synthesis on solid phase of dithiocarbamic cRGD-derivative and 99mTc-radiolabelling. J. Pept. Sci. 2019, 25, e3140. [Google Scholar] [CrossRef] [PubMed]

- Jafari, S.; Thillier, Y.; Ajena, Y.H.; Shorty, D.; Li, J.; Huynh, J.S.; Pan, B.M.C.; Pan, T.; Lam, K.S.; Liu, R. Rapid Discovery of Illuminating Peptides for Instant Detection of Opioids in Blood and Body Fluids. Molecules 2019, 24, 1813. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Martin, F.; Quintanar-Audelo, M.; Garcia-Ramos, Y.; Cruz, L.J.; Gravel, C.; Furic, R.; Côté, S.; Tulla-Puche, J.; Albericio, F. ChemMatrix, a Poly(ethylene glycol)-Based Support for the Solid-Phase Synthesis of Complex Peptides. J. Comb. Chem. 2006, 8, 213–220. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Ramos, Y.; Paradis-Bas, M.; Tulla-Puche, J.; Albericio, F. ChemMatrix for complex peptides and combinatorial chemistry. J. Pept. Sci. 2010, 16, 675–678. [Google Scholar] [CrossRef]

- Kim, J.; Kim, S.; Shin, D.S.; Lee, Y.S. Preparation of tri(ethylene glycol) grafted core-shell type polymer support for solid-phase peptide synthesis. J. Pept. Sci. 2018, 24, e3061. [Google Scholar] [CrossRef]

- Lee, T.K.; Lee, S.M.; Ryoo, S.J.; Byun, J.W.; Lee, Y.S. Application of AM SURE™ resin to solid-phase peptide synthesis. Tetrahedron Lett. 2005, 46, 7135–7138. [Google Scholar] [CrossRef]

- Cho, H.J.; Lee, T.K.; Kim, J.W.; Lee, S.M.; Lee, Y.S. Controllable Core–Shell-Type Resin for Solid-Phase Peptide Synthesis. J. Org. Chem. 2012, 77, 9156–9162. [Google Scholar] [CrossRef] [PubMed]

- Siltanen, C.; Sutcliffe, J.; Revzin, A.; Shin, D.S.; Shin, D. Micropatterned Photodegradable Hydrogels for the Sorting of Microbeads and Cells. Angew. Chem. 2013, 125, 9394–9398. [Google Scholar] [CrossRef] [Green Version]

- Roh, Y.H.; Lee, H.J.; Bong, K.W. Microfluidic Fabrication of Encoded Hydrogel Microparticles for Application in Multiplex Immunoassay. BioChip J. 2019, 13, 64–81. [Google Scholar] [CrossRef]

| Swelling Volume (mL/g) | Toluene | ACN | DCM | DMF | MeOH | Water |

|---|---|---|---|---|---|---|

| PEG-amine microbead | 1.8 | 3.3 | 3.3 | 2.5 | 2.4 | 2.2 |

| Non-functionalized PEG microbead | 3.4 | 4.2 | 4.6 | 4.0 | 3.1 | 2.5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.; Lee, S.-M.; Lee, S.S.; Shin, D.-S. Microfluidic Generation of Amino-Functionalized Hydrogel Microbeads Capable of On-Bead Bioassay. Micromachines 2019, 10, 527. https://doi.org/10.3390/mi10080527

Kim S, Lee S-M, Lee SS, Shin D-S. Microfluidic Generation of Amino-Functionalized Hydrogel Microbeads Capable of On-Bead Bioassay. Micromachines. 2019; 10(8):527. https://doi.org/10.3390/mi10080527

Chicago/Turabian StyleKim, Seongsoo, Sang-Myung Lee, Sung Sik Lee, and Dong-Sik Shin. 2019. "Microfluidic Generation of Amino-Functionalized Hydrogel Microbeads Capable of On-Bead Bioassay" Micromachines 10, no. 8: 527. https://doi.org/10.3390/mi10080527

APA StyleKim, S., Lee, S.-M., Lee, S. S., & Shin, D.-S. (2019). Microfluidic Generation of Amino-Functionalized Hydrogel Microbeads Capable of On-Bead Bioassay. Micromachines, 10(8), 527. https://doi.org/10.3390/mi10080527