KLu(WO4)2/SiO2 Tapered Waveguide Platform for Sensing Applications

Abstract

1. Introduction

2. Materials and Methods

3. Results

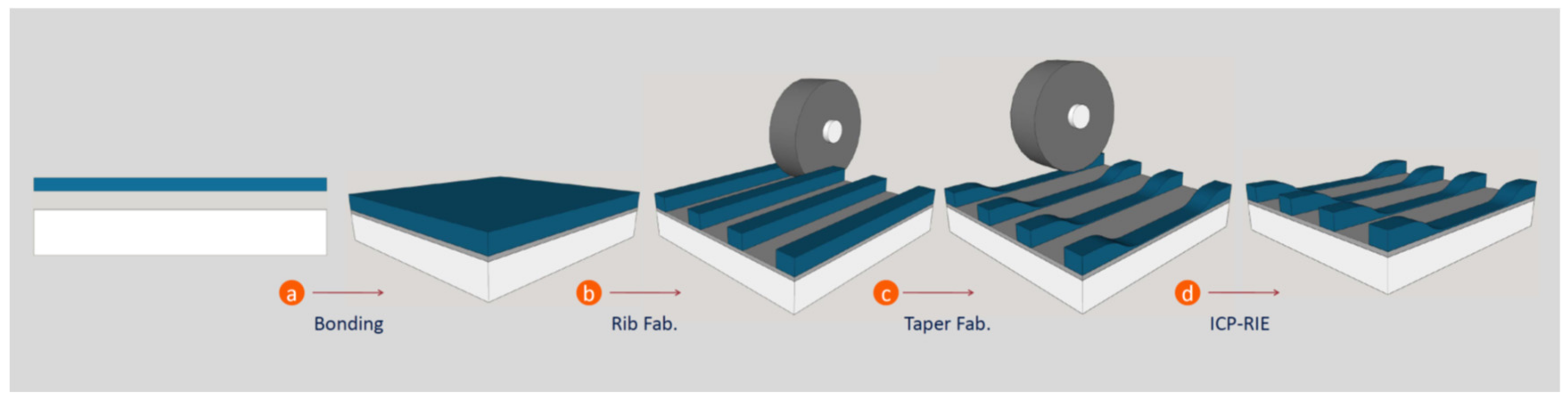

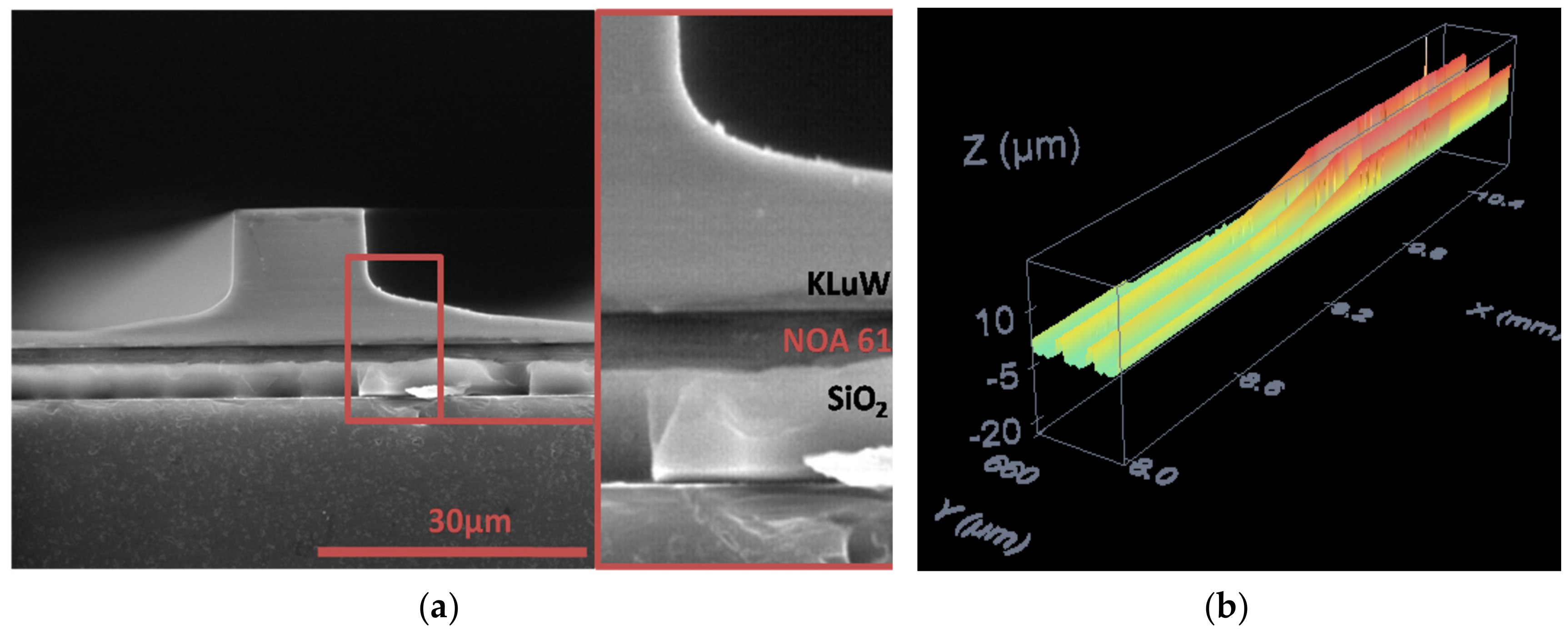

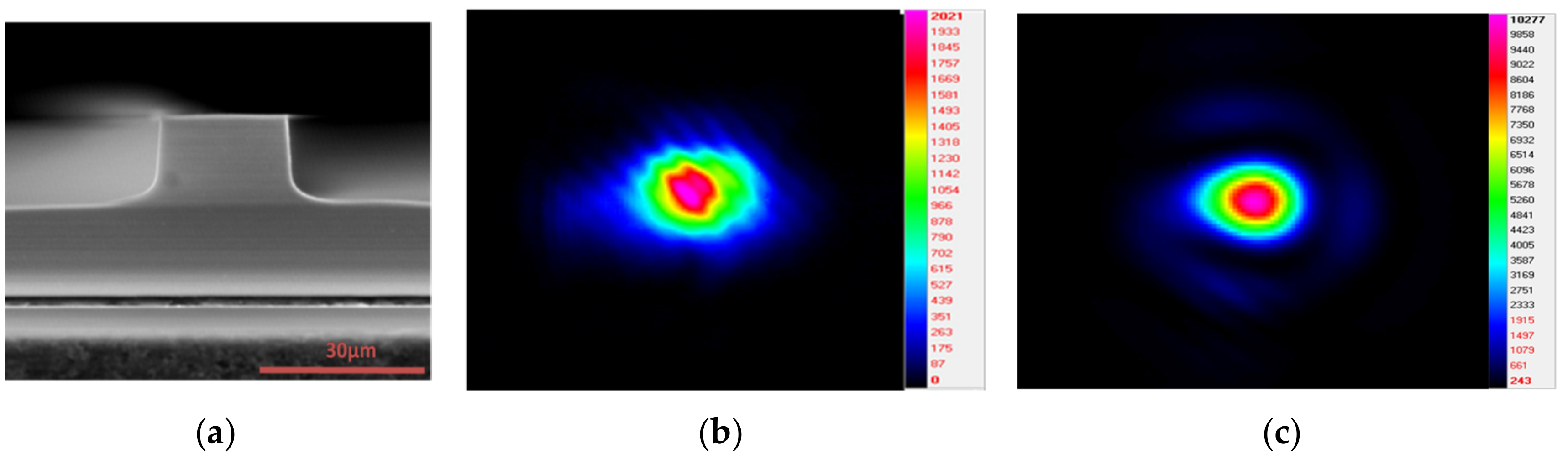

3.1. Sensor Fabrication and Characterization (Top-Down Approach)

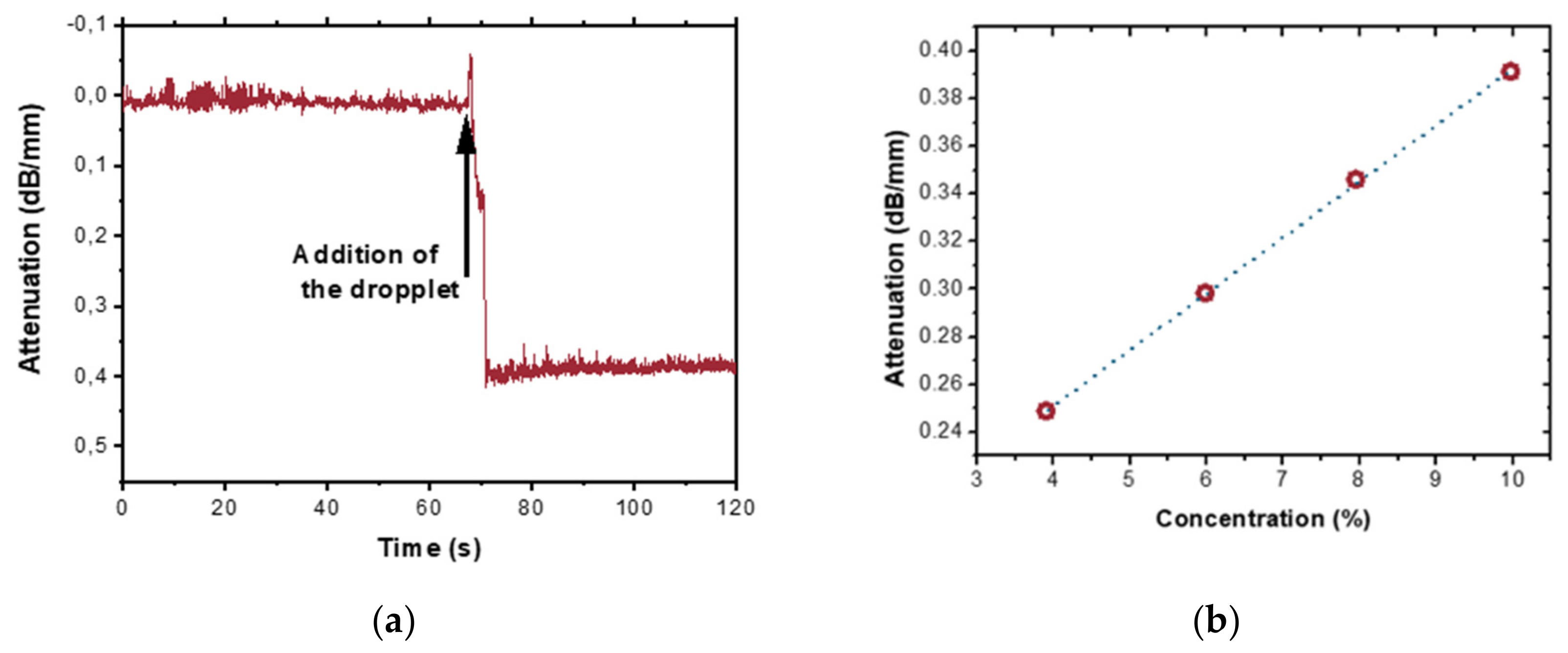

3.2. Sensor Proof of Concept

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Luchansky, M.S.; Bailey, R.C. High-Q Optical sensors for chemical and biological analysis. Anal. Chem. 2011, 84, 793–821. [Google Scholar] [CrossRef] [PubMed]

- Estevez, M.C.; Alvarez, M.; Lechuga, L.M. Integrated optical devices for lab-on-chip biosensing applications. Laser Photonics Rev. 2012, 6, 463–487. [Google Scholar] [CrossRef]

- Fan, X.; White, I.M.; Shopova, S.I.; Zhu, H.; Suter, J.D.; Sun, Y. Sensitive optical biosensors for unlabeled targets: A review. Anal. Chim. Acta 2008, 620, 8–26. [Google Scholar] [CrossRef] [PubMed]

- Fenzl, C.; Hirsch, T.; Wolfbeis, O.S. Photonic crystals for chemical sensing and biosensing. Angew. Chem. Int. Ed. 2014, 53, 3318–3335. [Google Scholar] [CrossRef] [PubMed]

- Monat, C.; Domachuk, P.; Eggleton, B.J. Integrated optofluidics: A new river of light. Nat. Photonics 2007, 1, 106–114. [Google Scholar] [CrossRef]

- Fan, X.; White, I.M. Optofluidic microsystems for chemical and biological analysis. Nat. Photonics 2011, 5, 591–597. [Google Scholar] [CrossRef]

- Zhi, Y.; Yu, X.; Gong, Q.; Yang, L.; Xiao, Y. Single nanoparticle detection using optical microcavities. Adv. Mater. 2017, 29, 1604920. [Google Scholar] [CrossRef]

- Prieto, F.; Sepúlveda, B.; Calle, A.; Llobera, A.; Domínguez, C.; Lechuga, L. Integrated Mach–Zehnder interferometer based on ARROW structures for biosensor applications. Sensor Actuators B-Chem. 2003, 92, 151–158. [Google Scholar] [CrossRef]

- Yin, D.; Deamer, D.W.; Schmidt, H.; Barber, J.P.; Hawkins, A.R. Single-molecule detection sensitivity using planar integrated optics on a chip. Opt. Lett. 2006, 31, 2136–2138. [Google Scholar] [CrossRef]

- Nitkowski, A.; Chen, L.; Lipson, M. Cavity-enhanced on-chip absorption spectroscopy using microring resonators. Opt. Express 2008, 16, 11930–11936. [Google Scholar] [CrossRef]

- Yebo, N.A.; Lommens, P.; Hens, Z.; Baets, R. An integrated optic ethanol vapor sensor based on a Silicon-on-Insulator microring resonator coated with a porous ZnO film. Opt. Express 2010, 18, 11859–11866. [Google Scholar] [CrossRef] [PubMed]

- Luchansky, M.S.; Washburn, A.L.; Qavi, A.J.; Kindt, J.T.; Mcclellan, M.S.; Bailey, R.C. Silicon photonic microring resonator arrays for scalable and multiplexable bioanalysis. In Proceedings of the Frontiers in Biological Detection: From Nanosensors to Systems III, San Francisco, CA, USA, 22–23 January 2011. [Google Scholar]

- Mandal, S.; Goddard, J.M.; Erickson, D. A multiplexed optofluidic biomolecular sensor for low mass detection. Lab Chip 2009, 9, 2924–2932. [Google Scholar] [CrossRef] [PubMed]

- Arnold, S.; Keng, D.; Shopova, S.I.; Holler, S.; Zurawsky, W.; Vollmer, F. Whispering gallery mode carousel—A photonic mechanism for enhanced nanoparticle detection in biosensing. Opt. Express 2009, 17, 6230–6238. [Google Scholar] [CrossRef] [PubMed]

- Lin, P.T.; Lin, H.G.; Han, Z.; Jin, T.; Millender, R.; Kimerling, L.C.; Agarwal, A. Label-free glucose sensing using chip-scale Mid-Infrared integrated photonics. Adv. Opt. Mater. 2016, 4, 1755–1759. [Google Scholar] [CrossRef]

- Lin, P.T. Integrated Mid-Infrared Photonic Circuits for label-free biochemical sensing. Proc. SPIE 2016, 9824. [Google Scholar] [CrossRef]

- Reddy, K.; Guo, Y.; Liu, J.; Lee, W.; Oo, M.K.; Fan, X. Rapid, sensitive, and multiplexed on-chip optical sensors for micro-gas chromatography. Lab Chip 2012, 12, 901–905. [Google Scholar] [CrossRef]

- Ranacher, C.; Consani, C.; Maier, F.J.; Hedenig, U.; Jannesari, R.; Lavchiev, V.; Tortschanoff, A.; Grille, T.; Jakoby, B. Spectroscopic gas sensing using a silicon slab waveguide. Procedia Eng. 2016, 168, 1265–1269. [Google Scholar] [CrossRef]

- Jin, T.; Li, L.; Zhang, B.; Lin, H.G.; Wang, H.; Lin, P.T. Real-time and label-free chemical sensor-on-a-chip using monolithic Si-on-BaTiO3 Mid-Infrared waveguides. Sci. Rep. 2017, 7, 5836. [Google Scholar] [CrossRef]

- Singh, V.; Lin, P.T.; Patel, N.; Lin, H.; Li, L.; Zou, Y.; Deng, F.; Ni, C.; Hu, J.; Giammarco, J.; et al. Mid-infrared materials and devices on a Si platform for optical sensing. Sci. Technol. Adv. Mater. 2014, 15, 014603. [Google Scholar] [CrossRef]

- Korposh, S.; James, S.W.; Lee, S.W.; Tatam, R.P. Tapered optical fibre sensors: Current trends and future perspectives. Sensors 2019, 19, 2294. [Google Scholar] [CrossRef]

- Polynkin, P.; Polynkin, A.; Peyghambarian, N.; Mansuripur, M. Evanescent field-based optical fiber sensing device for measuring the refractive index of liquids in microfluidic channels. Opt. Lett. 2005, 30, 1273–1275. [Google Scholar] [CrossRef] [PubMed]

- Lu, P.; Men, L.; Sooley, K.; Chen, Q. Tapered Fiber Mach–Zehnder interferometer for simultaneous measurement of refractive index and temperature. Appl. Phys. Lett. 2009, 94, 131110. [Google Scholar] [CrossRef]

- Qi, Z.M.; Yimit, A.; Itoh, K.; Murabayashi, M.; Matsuda, N.; Takatsu, A.; Kato, K. Composite optical waveguide composed of a tapered film of Bromothymol Blue evaporated onto a potassium ion–exchanged waveguide and its application as a guided wave absorption–based ammonia-gas sensor. Opt. Lett. 2001, 26, 629–631. [Google Scholar] [CrossRef] [PubMed]

- Xin, Y.; Pandraud, G.; Langen-Suurling, A.V.; French, P. Tapered SU8 waveguide for evanescent sensing by single-step fabrication. In Proceedings of the 2017 IEEE Sensors, Glasgow, UK, 29 October–1 November 2017. [Google Scholar]

- Kasberger, J.; Saeed, A.; Jakoby, B.; Hingerl, K. Improvement of an evanescent field IR-absorption sensor by utilizing a photonic taper structure. Procedia Eng. 2010, 5, 1013–1016. [Google Scholar] [CrossRef][Green Version]

- Peled, A.; Chiasera, A.; Nathan, M.; Ferrari, M.; Ruschin, S. Monolithic Rare-Earth Doped Sol-Gel Tapered Rib Waveguide Laser. Appl. Phys. Lett. 2008, 92, 221104. [Google Scholar] [CrossRef]

- Petrov, V.; Pujol, M.C.; Mateos, X.; Silvestre, O.; Rivier, S.; Aguiló, M.; Solé, R.M.; Liu, J.; Griebner, U.; Díaz, F. Growth and properties of KLu(WO4)2, and novel ytterbium and thulium lasers based on this monoclinic crystalline host. Laser Photonics Rev. 2007, 1, 179–212. [Google Scholar] [CrossRef]

- García-Blanco, S.M.; Pollnau, M.; Bozhevolnyi, S.I. Loss compensation in long-range dielectric-loaded surface plasmon-polarisation waveguides. Opt. Express 2011, 19, 25298. [Google Scholar] [CrossRef]

- Dubbink, T.; Sefunc, M.A.; Pollnau, M.A.; García-Blanco, S.M. Study of Sharp Bends in Anisotropic Potassium Double Tungstate Waveguides. In Proceedings of the 15th International Conference on Transparent Optical Networks (ICTON 2013), Cartagena, Spain, 23–27 June 2013. [Google Scholar]

- Sefunc, M.A.; Segerink, F.; Garcia-Blanco, S.M. High index contrast potassium double tungstate waveguides towards efficient rare-earth ion amplification on-chip. In Proceedings of the Integrated Optics: Devices, Materials, and Technologies XIX, International Society for Optics and Photonics 2015, San Diego, CA, USA, 17–21 August 2015. [Google Scholar]

- Chen, C.; Rüter, C.E.; Volk, M.F.; Chen, C.; Shang, Z.; Lu, Q.; Akhmadaliev, S.; Zhou, S.; Chen, F.; Kip, D. Second harmonic generation of diamond-blade diced KTiOPO4 ridge waveguides. Opt. Express 2016, 24, 16434–16439. [Google Scholar] [CrossRef]

- Brüske, D.; Suntsov, S.; Rüter, C.E.; Kip, D. Efficient ridge waveguide amplifiers and lasers in Er-doped lithium niobate by optical grade dicing and three-side Er and Ti in-diffusion. Opt. Express 2017, 25, 29374–29379. [Google Scholar] [CrossRef]

- Volk, M.F.; Rüter, C.E.; Santandrea, M.; Eigner, C.; Padberg, L.; Herrmann, H.; Silberhorn, C.; Kip, D. Fabrication of low-loss Rb-exchanged ridge waveguides in z-cut KTiOPO4. Opt. Mater. Express 2018, 8, 82–87. [Google Scholar] [CrossRef]

- Suntsov, S.; Rüter, C.E.; Kip, D. Efficient Nd:Ti:LiNbO3 ridge waveguide lasers emitting around 1085 nm. Appl. Phys. B 2017, 123, 8884–8889. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Medina, M.; Rüter, C.E.; Pujol, M.C.; Kip, D.; Masons, J.; Ródenas, A.; Aguiló, M.; Díaz, F. KLu(WO4)2/SiO2 Tapered Waveguide Platform for Sensing Applications. Micromachines 2019, 10, 454. https://doi.org/10.3390/mi10070454

Medina M, Rüter CE, Pujol MC, Kip D, Masons J, Ródenas A, Aguiló M, Díaz F. KLu(WO4)2/SiO2 Tapered Waveguide Platform for Sensing Applications. Micromachines. 2019; 10(7):454. https://doi.org/10.3390/mi10070454

Chicago/Turabian StyleMedina, Marc, Christian E. Rüter, Maria Cinta Pujol, Detlef Kip, Jaume Masons, Airán Ródenas, Magdalena Aguiló, and Francisco Díaz. 2019. "KLu(WO4)2/SiO2 Tapered Waveguide Platform for Sensing Applications" Micromachines 10, no. 7: 454. https://doi.org/10.3390/mi10070454

APA StyleMedina, M., Rüter, C. E., Pujol, M. C., Kip, D., Masons, J., Ródenas, A., Aguiló, M., & Díaz, F. (2019). KLu(WO4)2/SiO2 Tapered Waveguide Platform for Sensing Applications. Micromachines, 10(7), 454. https://doi.org/10.3390/mi10070454