Development of Piezo-Actuated Two-Degree-of-Freedom Fast Tool Servo System

Abstract

1. Introduction

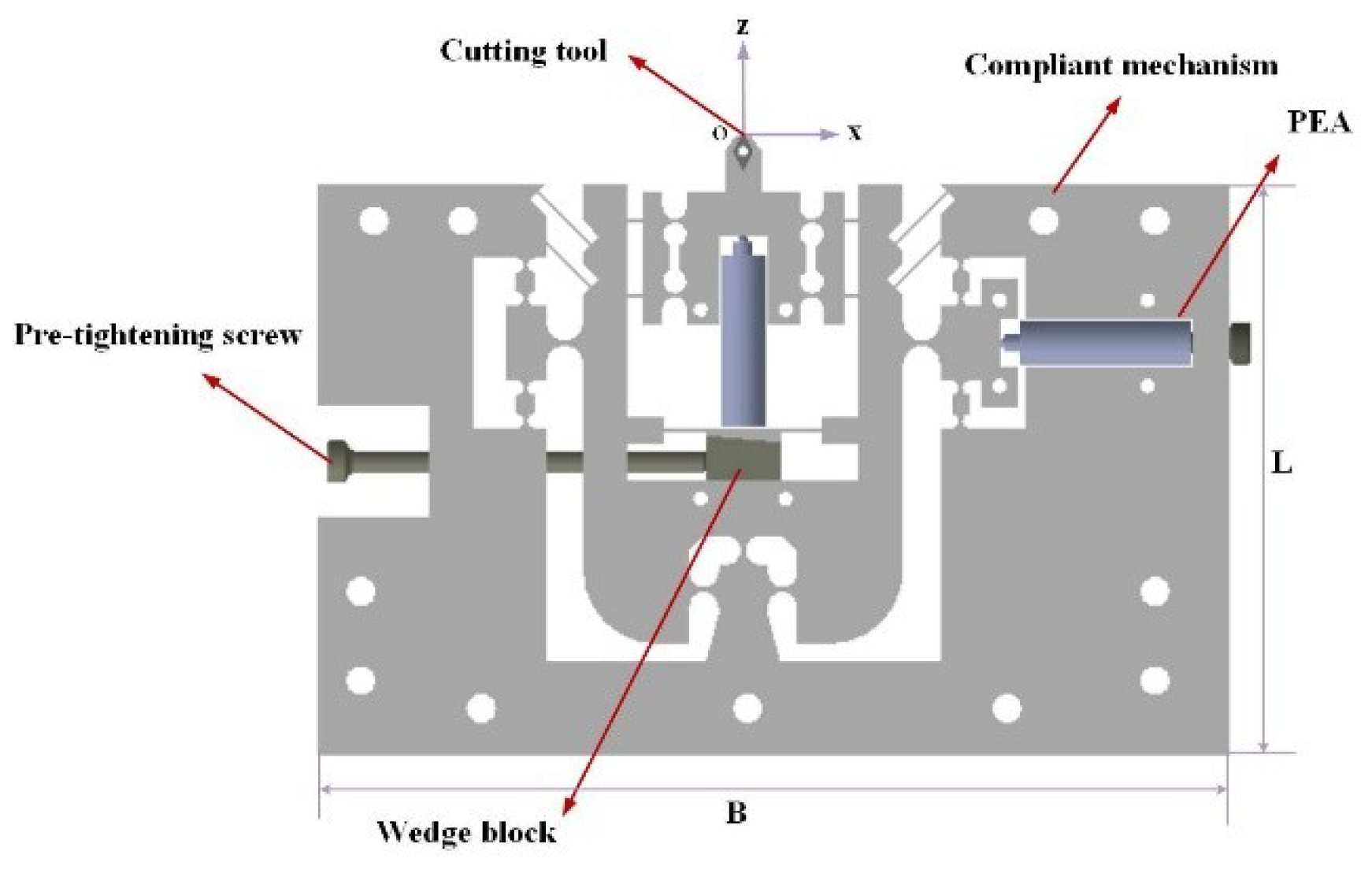

2. Mechanical Design of Two Degrees of Freedom Fast Tool Servo (2-DOF FTS)

3. Compliance Modeling of 2-DOF FTS

3.1. Compliance Modeling Based on Matrix Method

3.2. Output Compliance Modelling

3.2.1. Output Compliance of the Module I

3.2.2. Output Compliance of the Module II

3.2.3. Output Compliance of the Module V

3.2.4. Output Compliance of Module VI

3.3. Input Compliance Modelling

3.4. Finite Element Analysis of Mechanism

3.4.1. Static Analysis

3.4.2. Dynamic Analysis

4. Performance Test of the 2-DOF FTS

4.1. Experimental Setup

4.2. Experimental Results

4.2.1. Stroke and Decoupling Tests

4.2.2. Dynamic Performance Tests

4.2.3. Resolution Tests

4.2.4. Step Responses Tests

4.2.5. Hysteresis Analysis

5. Processing Performance Verification of the Developed 2-DOF FTS

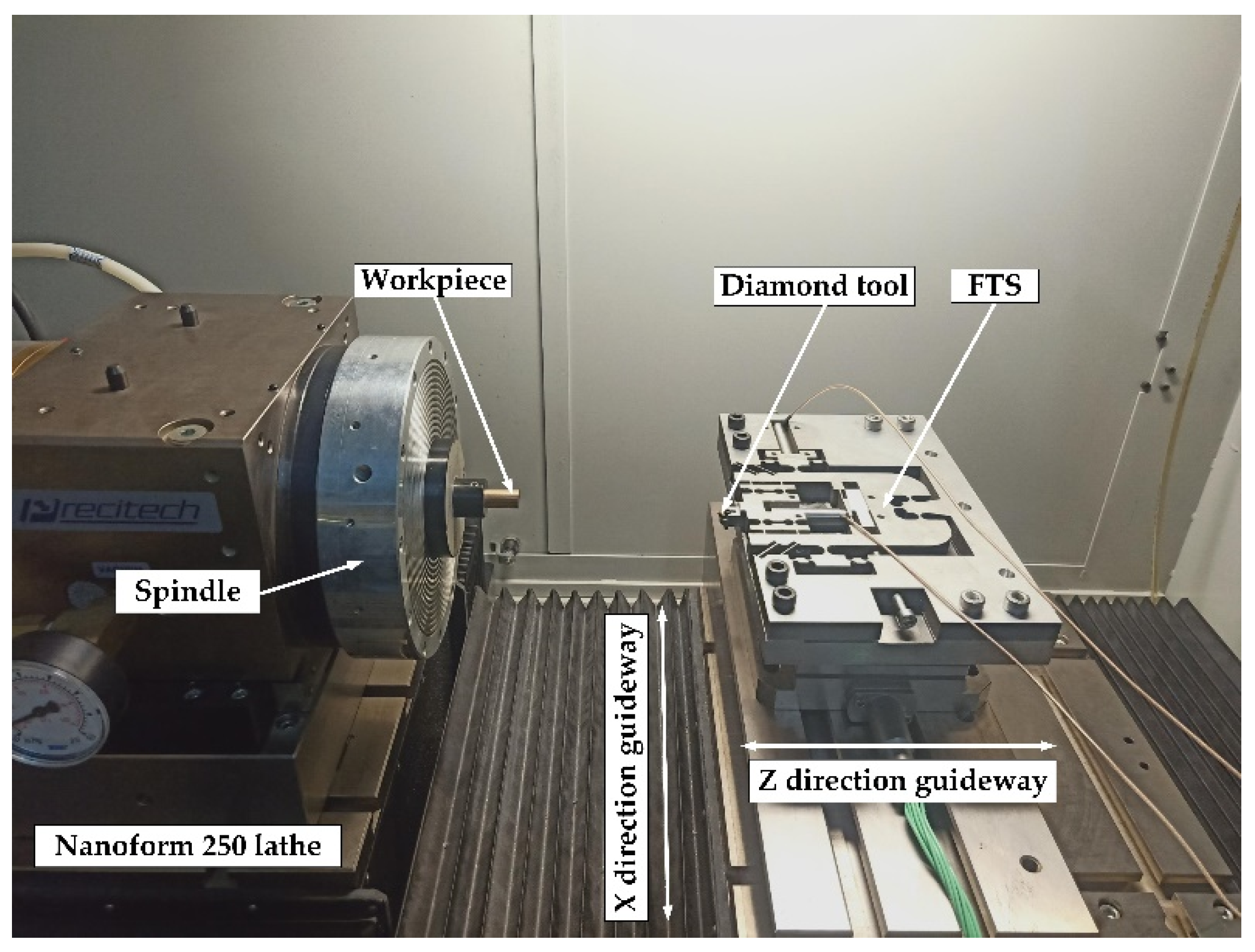

5.1. Experimental Setup

5.2. Results and Discussions

6. Conclusions

- (1)

- The input and output compliances of the developed device are analyzed and calculated using the matrix-based modeling method. In addition, the theoretical results are verified by FEA analysis. The results show that there is good agreement between theoretical analysis and FEA analysis, which proves the effectiveness of the design process.

- (2)

- Experimental tests show that the stroke along the z-axis direction and the x-axis direction can reach 17 μm and 22.5 μm, respectively, and the resolution can reach 45 nm and 50 nm, respectively. The coupling motions in both directions are measured to be approximately 1.47% and 2.22%, respectively. It is also capable to achieve high first natural frequencies. Using the swept excitation test, the natural frequencies of the FTS along the z-axis direction and the x-axis direction can reach 1201 Hz and 1220 Hz, respectively.

- (3)

- Finally, the sinusoidal wavy surface processing experiment validates the effectiveness of the developed device for ultra-precision machining.

Author Contributions

Funding

Conflicts of Interest

References

- Fang, F.Z.; Zhang, X.D.; Weckenmann, A. Manufacturing and measurement of freeform optics. CIRP Ann. 2013, 62, 823–846. [Google Scholar] [CrossRef]

- Forbes, G.W. Characterizing the shape of freeform optics. Opt. Express 2012, 20, 2483–2499. [Google Scholar] [CrossRef]

- Zhu, L.; Li, Z.; Fang, F. Review on fast tool servo machining of optical freeform surfaces. Int. J. Adv. Manuf. Technol. 2018, 95, 2071–2092. [Google Scholar] [CrossRef]

- Gao, W.; Araki, T.; Kiyono, S. Precision nano-fabrication and evaluation of a large area sinusoidal grid surface for a surface encoder. Precis. Eng. 2003, 27, 289–298. [Google Scholar] [CrossRef]

- Yu, D.P.; Hong, G.S.; San, W.Y. Profile error compensation in fast tool servo diamond turning of micro-structured surfaces. Int. J. Mach. Tools Manuf. 2012, 52, 13–23. [Google Scholar] [CrossRef]

- Tian, F.; Yin, Z.; Li, S. A novel long range fast tool servo for diamond turning. Int. J. Adv. Manuf. Technol. 2016, 86, 1227–1234. [Google Scholar] [CrossRef]

- Liu, Q.; Zhou, X.; Xu, P. A flexure-based long-stroke fast tool servo for diamond turning. Int. J. Adv. Manuf. Technol. 2012, 59, 859–867. [Google Scholar] [CrossRef]

- Trumper, D.L.; Lu, X. Fast tool servos: advances in precision, acceleration, and bandwidth. In Towards Synthesis of Micro-/Nano-Systems; Springer: London, UK, 2007; pp. 11–19. [Google Scholar]

- Brecher, C.; Lange, S.; Merz, M. NURBS based ultra-precision free-form machining. CIRP Ann. Manuf. Technol. 2006, 55, 547–550. [Google Scholar] [CrossRef]

- Brinksmeier, E.; Riemer, O.; Gläbe, R. Submicron functional surfaces generated by diamond machining. CIRP Ann. 2010, 59, 535–538. [Google Scholar] [CrossRef]

- Lu, H.; Lee, D.; Kim, J. Modeling and machining evaluation of microstructure fabrication by fast tool servo-based diamond machining. Precis. Eng. 2014, 38, 212–216. [Google Scholar] [CrossRef]

- Bono, M.J.; Hibbard, R.L. Fabrication and Metrology of Micro-Scale Sinusoidal Surfaces in Polymer Workpiece Materials; Lawrence Livermore National Lab (LLNL): Livermore, CA, USA, 2004.

- Chen, Y.L.; Cai, Y.; Tohyama, K. Auto-tracking single point diamond cutting on non-planar brittle material substrates by a high-rigidity force controlled fast tool servo. Precis. Eng. 2017, 49, 253–261. [Google Scholar] [CrossRef]

- Zhu, Z.; Zhou, X.; Liu, Q. Fabrication of micro-structured surfaces on bulk metallic glasses based on fast tool servo assisted diamond turning. Sci. Adv. Mater. 2012, 4, 906–911. [Google Scholar] [CrossRef]

- Tang, H.; Li, H.; To, S. Design and control of a new 3-PUU fast tool servo for complex microstructure machining. Int. J. Adv. Manuf. Technol. 2018, 94, 3503–3517. [Google Scholar] [CrossRef]

- Scheiding, S.; Allen, Y.; Gebhardt, A. Freeform manufacturing of a microoptical lens array on a steep curved substrate by use of a voice coil fast tool servo. Opt. Express 2011, 19, 23938–23951. [Google Scholar] [CrossRef]

- Zhu, Z.; To, S.; Ehmann, K.F. Design, Analysis, and Realization of a Novel Piezoelectrically Actuated Rotary Spatial Vibration System for Micro-/Nanomachining. IEEE/ASME Trans. Mech. 2017, 22, 1227–1237. [Google Scholar] [CrossRef]

- Guo, P.; Ehmann, K.F. Development of a tertiary motion generator for elliptical vibration texturing. Precis. Eng. 2013, 37, 364–371. [Google Scholar] [CrossRef]

- Zhang, J.; Cui, T.; Ge, C. Review of micro/nano machining by utilizing elliptical vibration cutting. Int. J. Mach. Tools Manuf. 2016, 106, 109–126. [Google Scholar] [CrossRef]

- Zhu, Z.; To, S.; Ehmann, K.F. A novel diamond micro-/nano-machining process for the generation of hierarchical micro-/nano-structures. J. Micromech. Microeng. 2016, 26, 31–50. [Google Scholar] [CrossRef]

- Zhou, X.; Zuo, C.; Liu, Q. Surface generation of freeform surfaces in diamond turning by applying double-frequency elliptical vibration cutting. Int. J. Mach. Tools Manuf. 2016, 104, 45–57. [Google Scholar] [CrossRef]

- Wada, T.; Takahashi, M.; Moriwaki, T. Development of a Three Axis controlled Fast Tool Servo for Ultra Precision Machining (1 st Report)-Development of 3-axis FTS Unit and evaluation of its characteristics. Int. J. Jpn. Soc. Precis. Eng. 2007, 73, 1345–1349. [Google Scholar] [CrossRef]

- Zhu, Z.; Zhou, X.; Liu, Z. Development of a piezoelectrically actuated two-degree-of-freedom fast tool servo with decoupled motions for micro-/nanomachining. Precis. Eng. 2014, 38, 809–820. [Google Scholar] [CrossRef]

- Lu, X.D.; Trumper, D.L. Ultrafast tool servos for diamond turning. CIRP Ann. Manuf. Technol. 2005, 54, 383–388. [Google Scholar] [CrossRef]

- Zhu, Z. Multi-objective optimum design of fast tool servo based on improved differential evolution algorithm. J. Mech. Sci. Technol. 2011, 25, 3141–3149. [Google Scholar] [CrossRef]

- Zhu, Z. Optimum Design of a Piezo-Actuated Triaxial Compliant Mechanism for Nanocutting. IEEE. Trans. Ind. Electron. 2018, 65, 6362–6371. [Google Scholar] [CrossRef]

- Henein, S.; Kjelberg, I.; Zelenika, S. Flexible bearings for high-precision mechanisms in accelerator facilities. In Proceedings of the 26th Advanced ICFA Beam Dynamics Workshop on Nanometre-Size Colliding Beams (Nanobeam 2002), Lausanne, Switzerland, 2–6 September 2002; CERN: Geneva, Switzerland, 2002. [Google Scholar]

- Tian, Y.; Zhang, D.; Shirinzadeh, B. Dynamic modelling of a flexure-based mechanism for ultra-precision grinding operation. Precis. Eng. 2011, 35, 554–565. [Google Scholar] [CrossRef]

- Selig, J.M.; Ding, X.A. screw theory of timoshenko beams. J. Appl. Mech. 2009, 76, 031003. [Google Scholar] [CrossRef]

- Koseki, Y.; Tanikawa, T.; Koyachi, N. Kinematic analysis of a translational 3-dof micro-parallel mechanism using the matrix method. Adv. Robot. 2002, 16, 251–264. [Google Scholar] [CrossRef]

- Paros, J.M.; Weisbord, L. How to design flexure hinges. Mach. Des. 1965, 37, 151–156. [Google Scholar]

| L/mm | B/mm | W/mm | E/GPa | σ/MPa | μ | ρ/(kg·m−3) |

|---|---|---|---|---|---|---|

| 154 | 246 | 12 | 71.7 | 503 | 0.33 | 2810 |

| la/mm | lb/mm | l1/mm | w1/mm | R1/mm | t1/mm | b/mm |

|---|---|---|---|---|---|---|

| 7.5 | 6.7 | 4 | 1 | 3.25 | 0.8 | 12 |

| lc/mm | l2/mm | w2/mm | R2/mm | t2/mm | R3/mm | t3/mm | R4/mm | t4/mm |

|---|---|---|---|---|---|---|---|---|

| 7.3 | 17.5 | 0.8 | 2 | 1 | 4 | 1.2 | 5 | 1.2 |

| Performance | Input Stiffness (x) (N/μm) | Input Stiffness (z) (N/μm) | Output Compliance (N/μm) |

|---|---|---|---|

| Matrix model | 20.85 | 28.44 | 12.25 |

| FEA | 18.12 | 31.33 | 15.32 |

| Deviation (%) | 13.09 | 10.16 | 25.06 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Zheng, Y.; Gu, Y.; Lin, J.; Lu, M.; Xu, Z.; Fu, B. Development of Piezo-Actuated Two-Degree-of-Freedom Fast Tool Servo System. Micromachines 2019, 10, 337. https://doi.org/10.3390/mi10050337

Liu Y, Zheng Y, Gu Y, Lin J, Lu M, Xu Z, Fu B. Development of Piezo-Actuated Two-Degree-of-Freedom Fast Tool Servo System. Micromachines. 2019; 10(5):337. https://doi.org/10.3390/mi10050337

Chicago/Turabian StyleLiu, Yamei, Yanping Zheng, Yan Gu, Jieqiong Lin, Mingming Lu, Zisu Xu, and Bin Fu. 2019. "Development of Piezo-Actuated Two-Degree-of-Freedom Fast Tool Servo System" Micromachines 10, no. 5: 337. https://doi.org/10.3390/mi10050337

APA StyleLiu, Y., Zheng, Y., Gu, Y., Lin, J., Lu, M., Xu, Z., & Fu, B. (2019). Development of Piezo-Actuated Two-Degree-of-Freedom Fast Tool Servo System. Micromachines, 10(5), 337. https://doi.org/10.3390/mi10050337