Phototactic Algae-Driven Unidirectional Transport of Submillimeter-Sized Cargo in a Microchannel

Abstract

1. Introduction

2. Materials and Methods

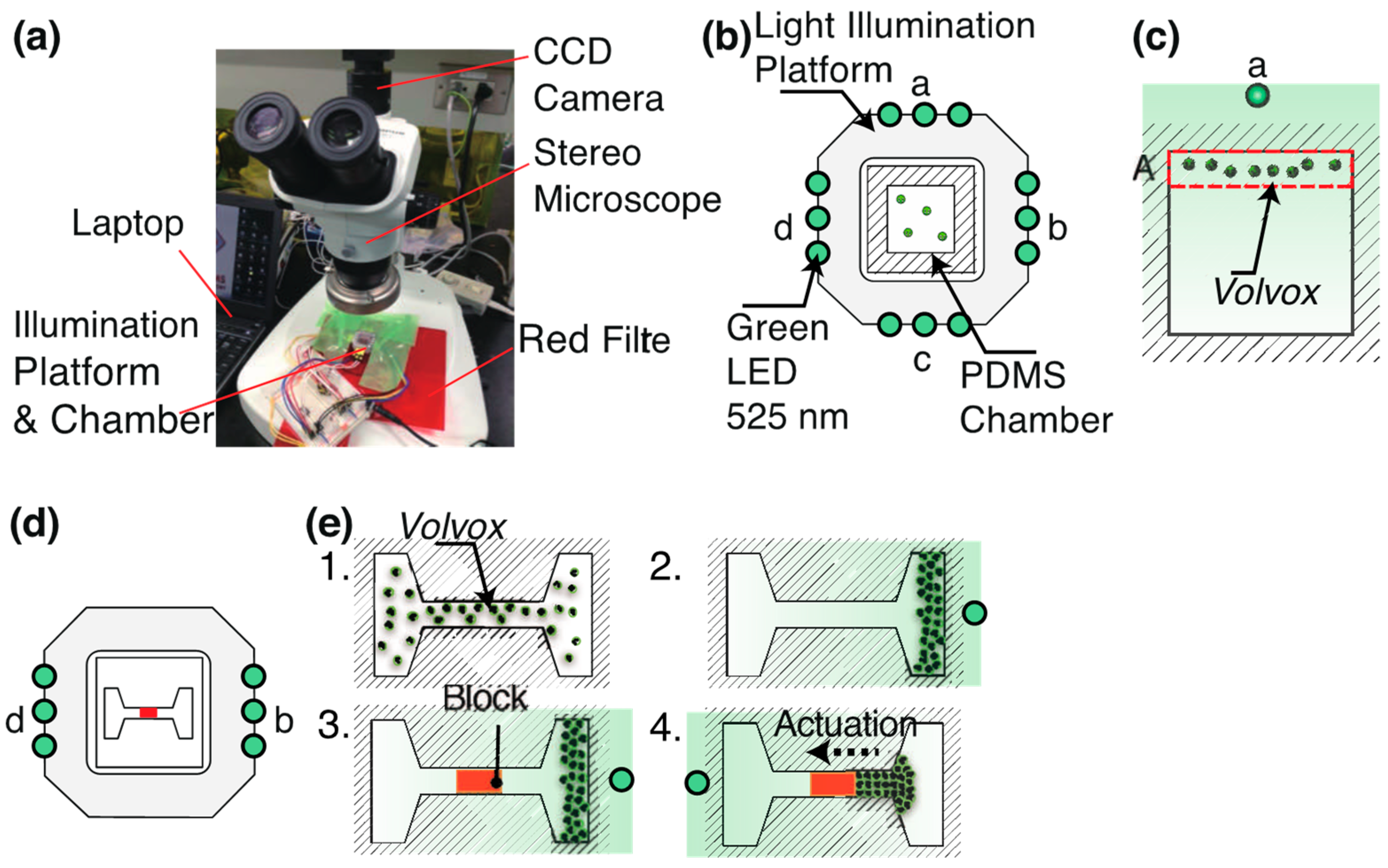

2.1. Overview of Experimental Setup

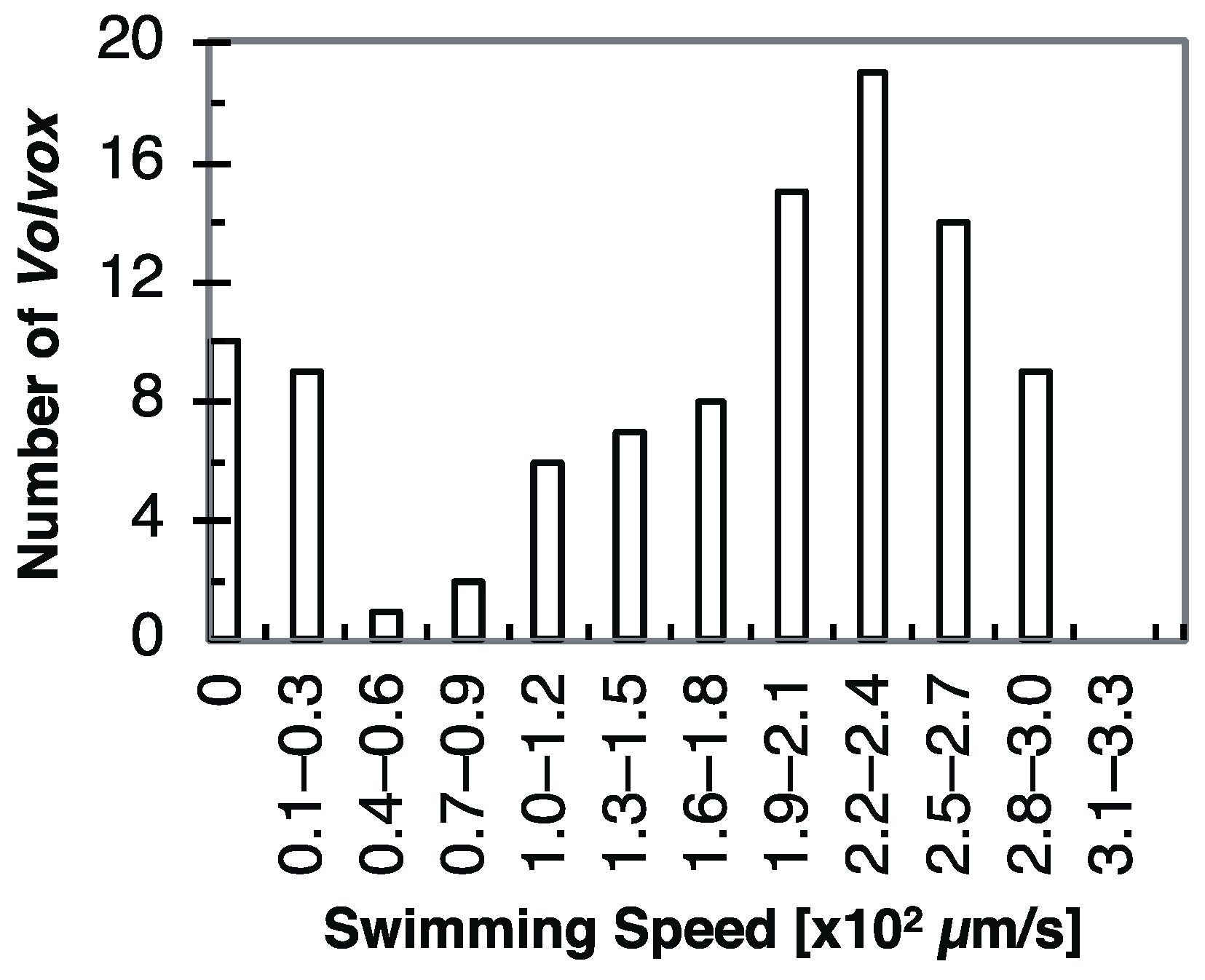

2.2. Phototaxis and Swimming Speed Evaluation of Volvox carteri in Square Microchamber

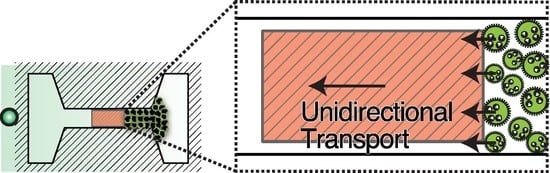

2.3. Unidirectional Transport of the Block by Volvox

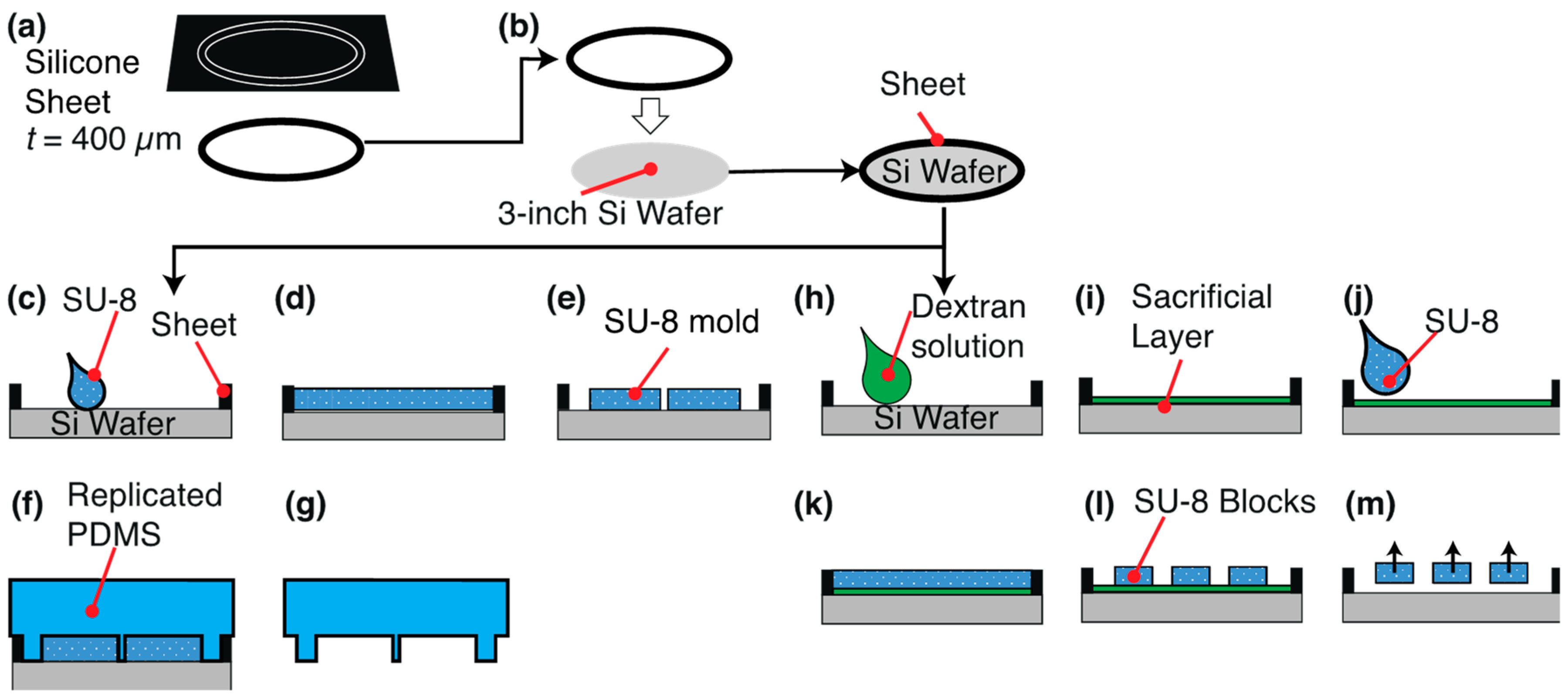

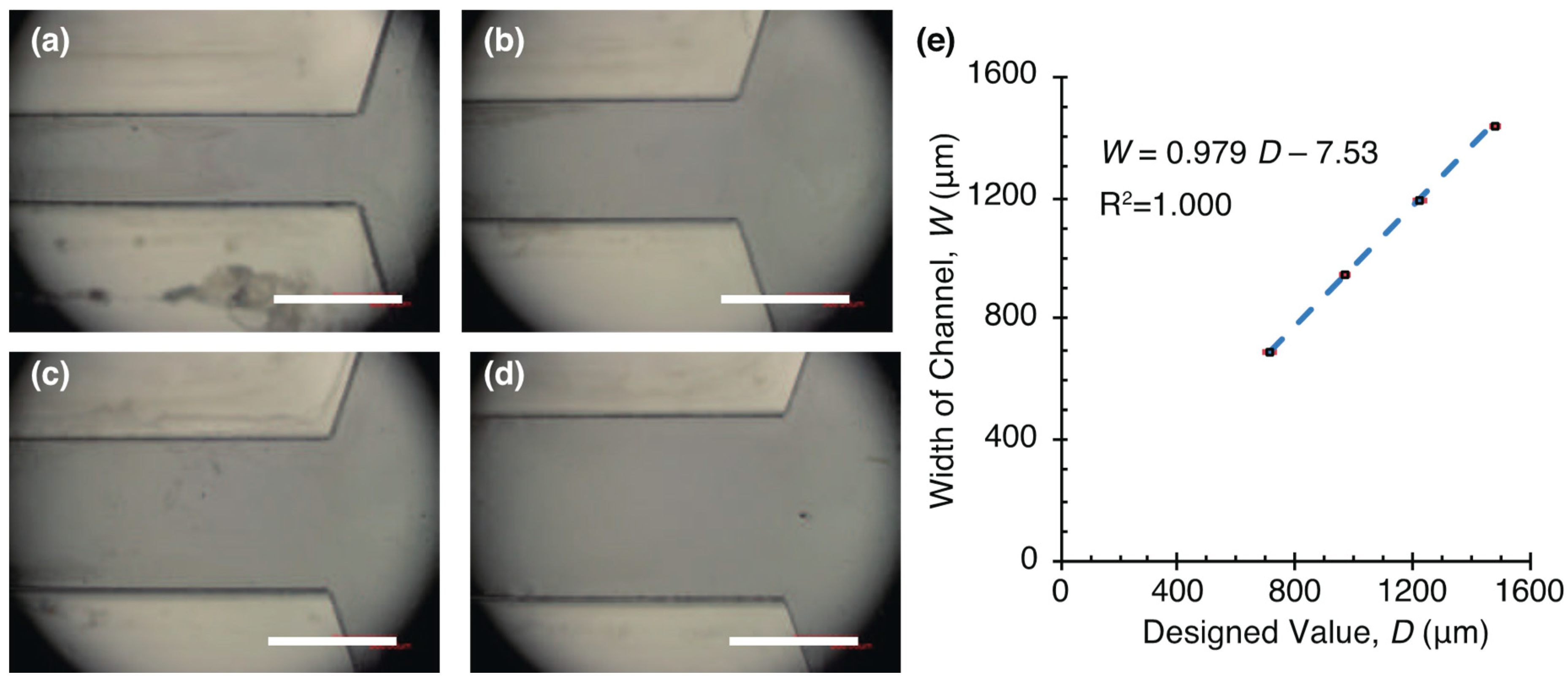

2.4. Fabrication of Thick SU-8 Structure with a Rubber Ring

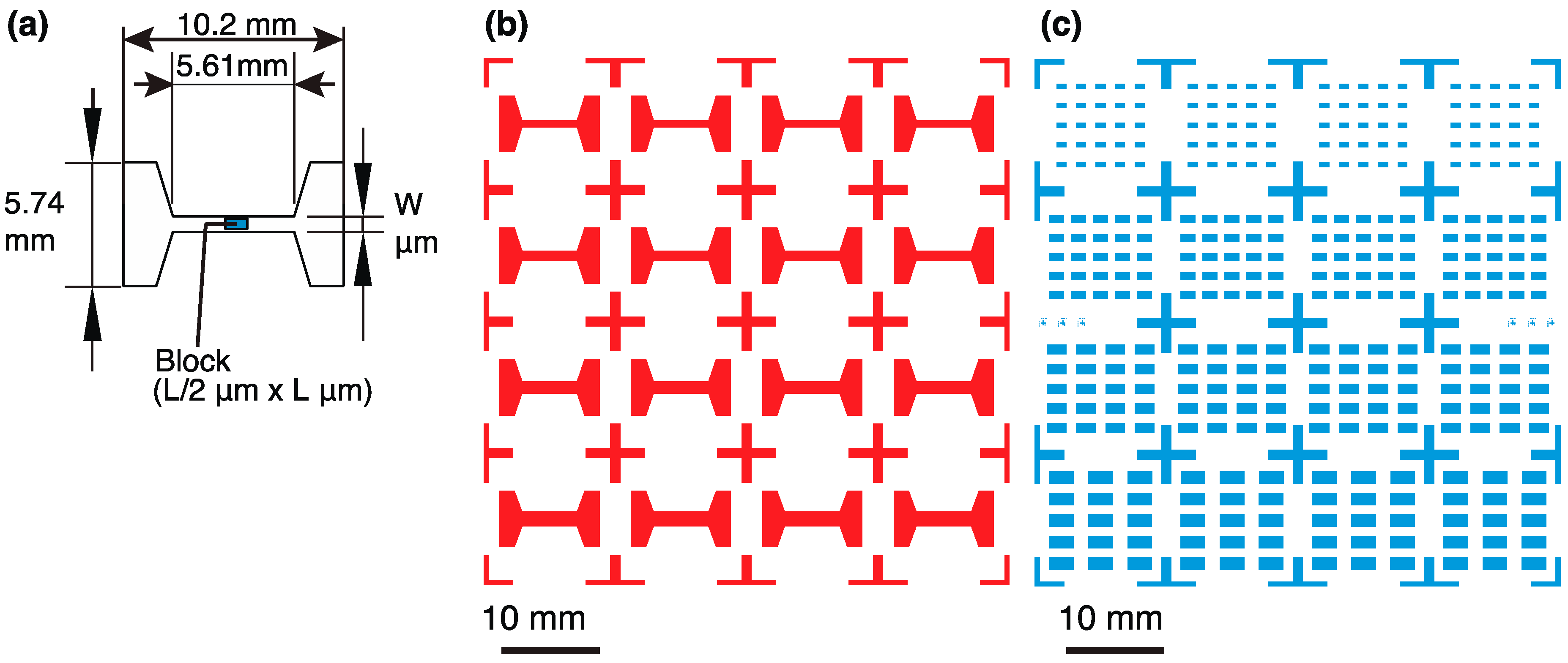

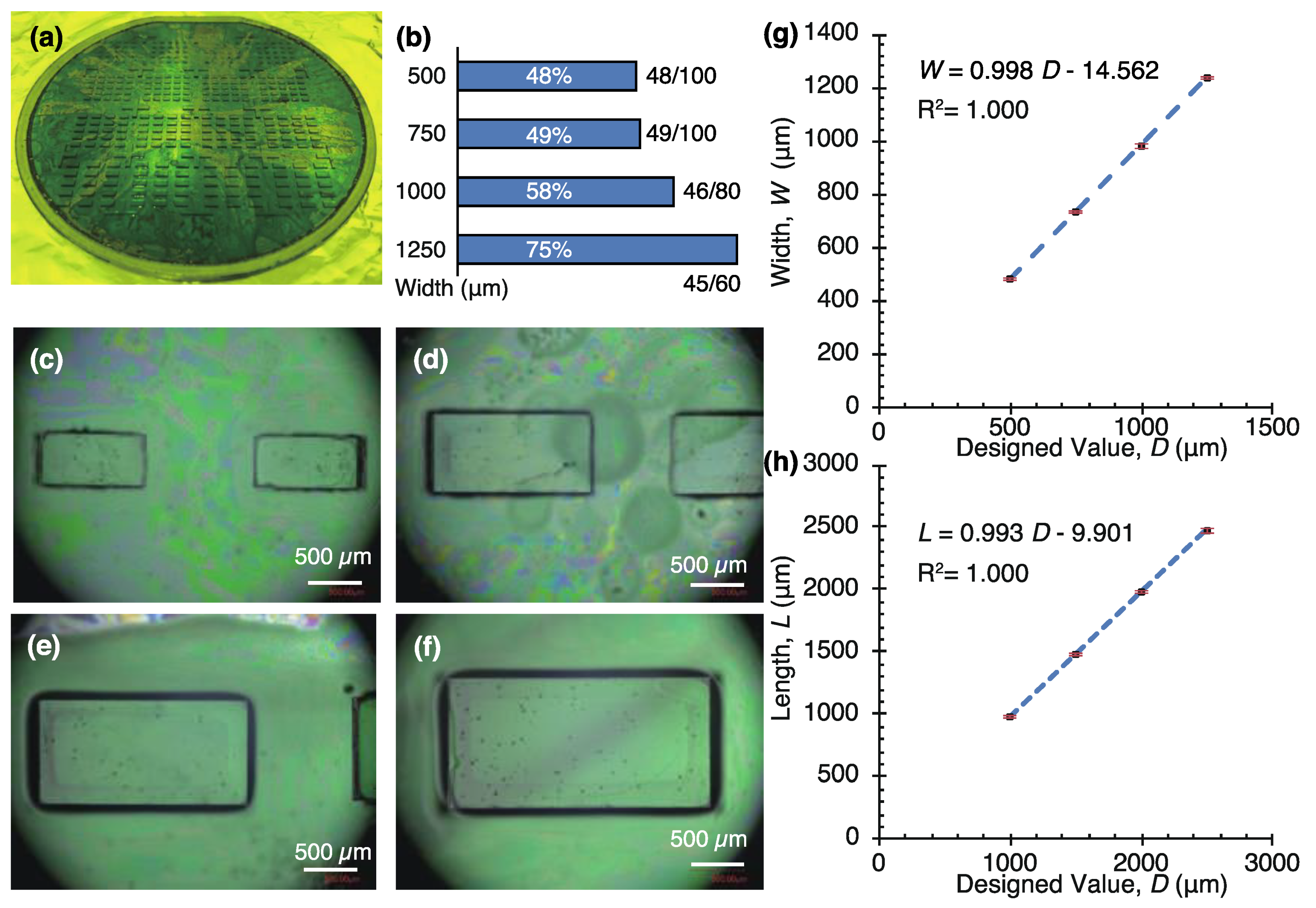

2.5. Fabrication of Open-Top PDMS Chamber and SU-8 Blocks

3. Results and Discussion

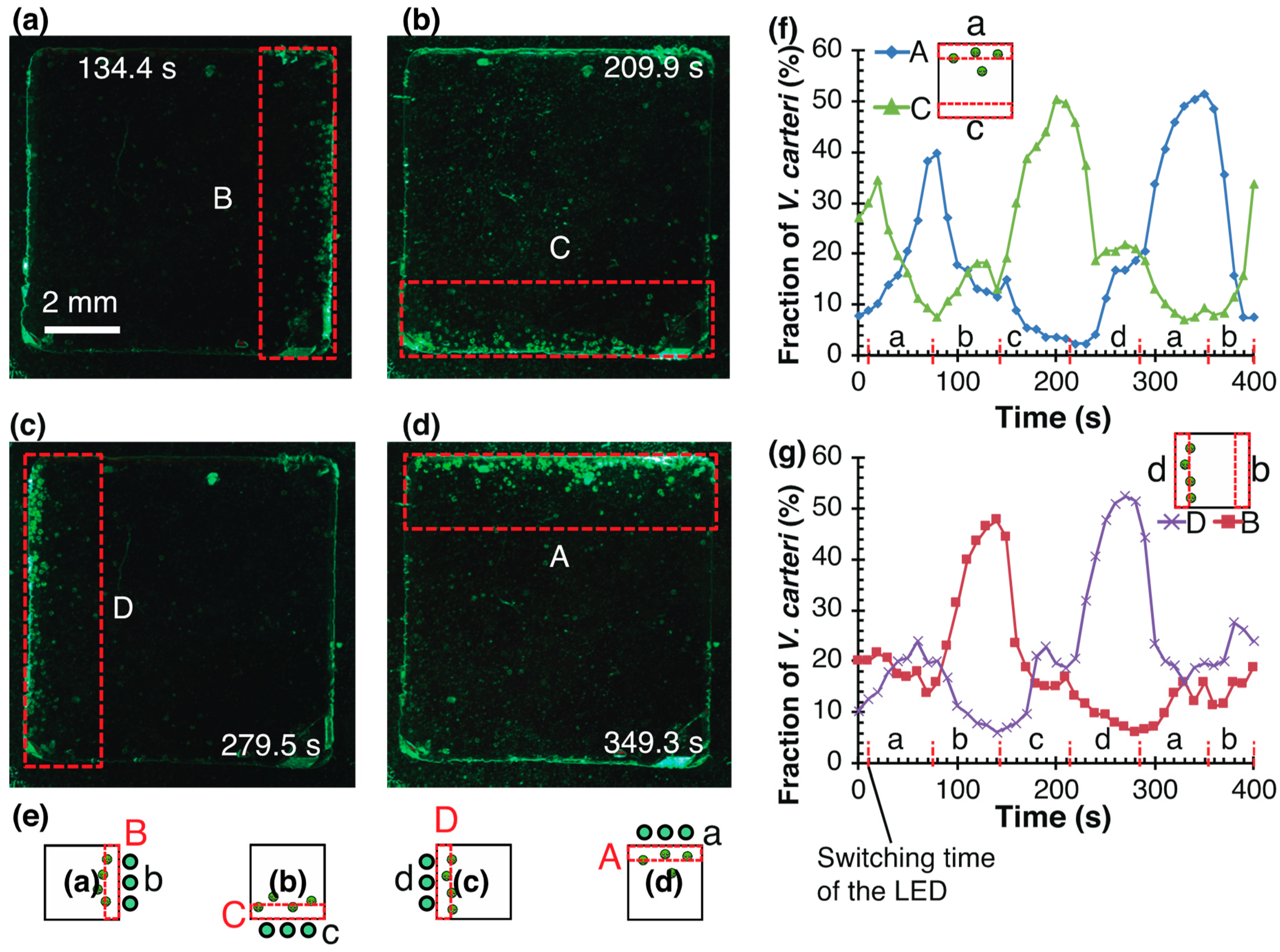

3.1. Phototactic Steering of V. carteri in a Square Chamber

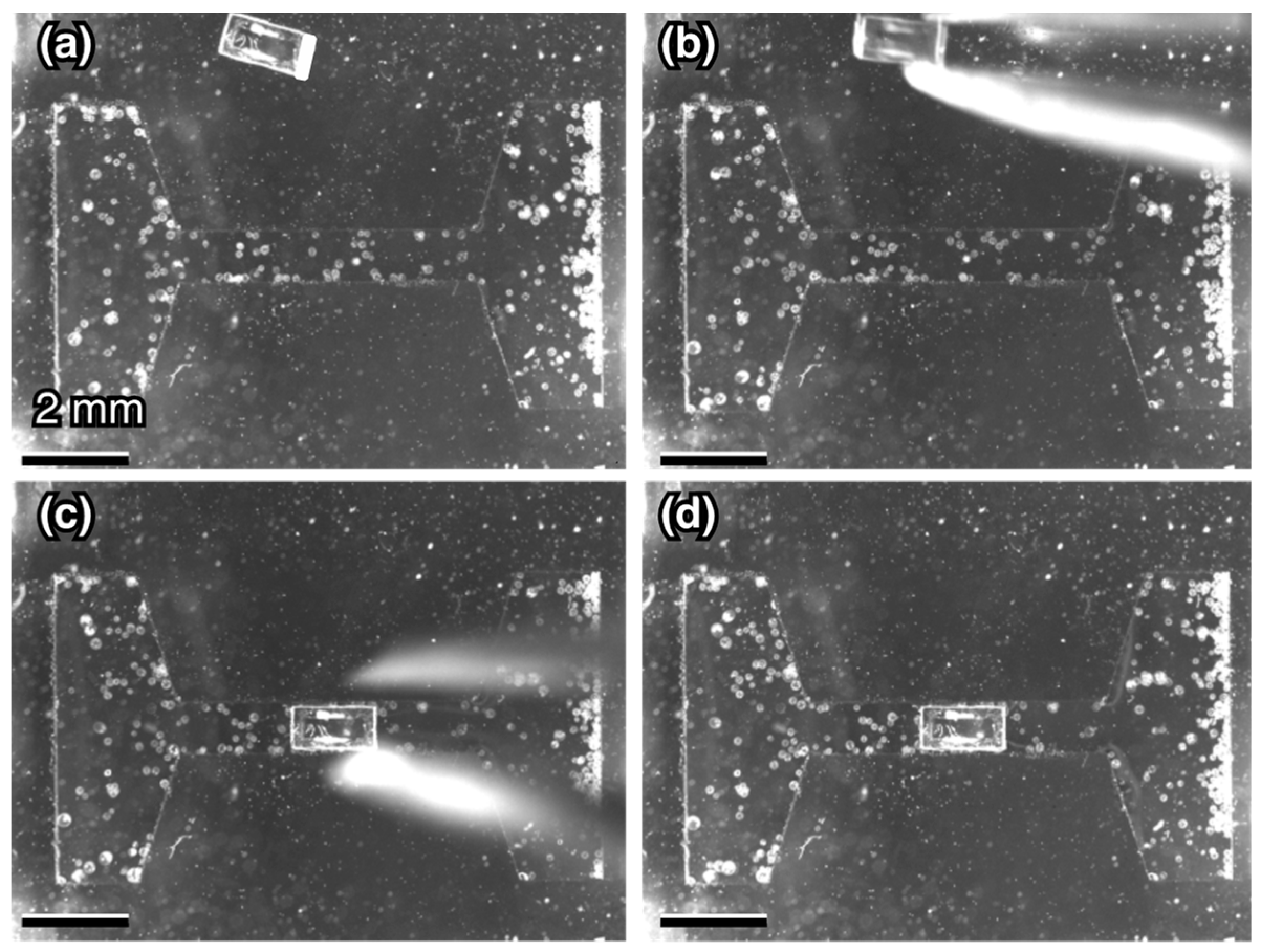

3.2. Fabrication of Thick Open-Top Chambers and SU-8 Blocks

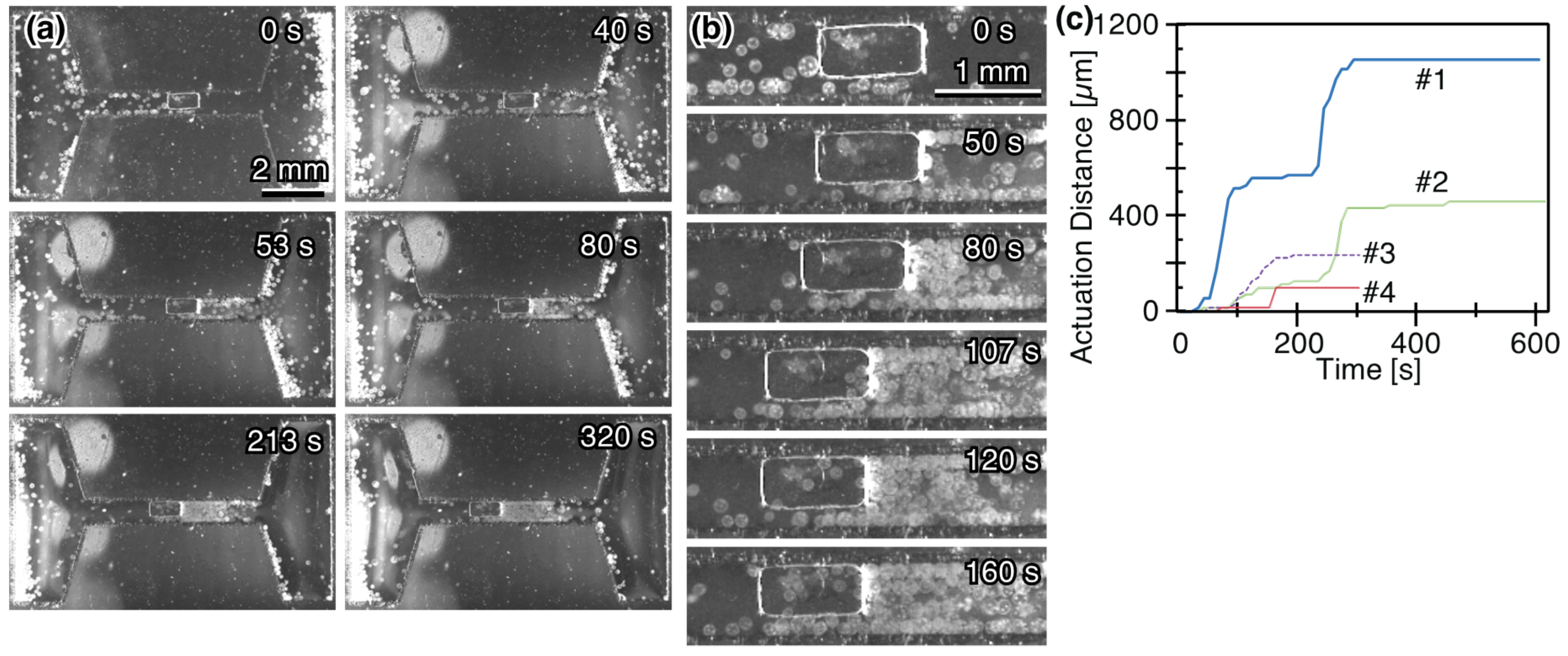

3.3. Unidirectional Transport of a Block by V. carteri

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Franssila, S. Introduction to Microfabrication, 2nd ed.; John Wiley Sons: Chichester, UK, 2010; 518p. [Google Scholar]

- Madou, M.J. Fundamentals of Microfabrication and Nanotechnology, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Wang, J.; Xiong, Z.; Zheng, J.; Zhan, X.; Tang, J. Light-Driven Micro/Nanomotor for Promising Biomedical Tools: Principle, Challenge, and Prospect. Acc. Chem. Res. 2018, 51, 1957–1965. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Mou, F.; Xu, L.; Wang, S.; Guan, J.; Feng, Z.; Wang, Q.; Kong, L.; Li, W.; Wang, J.; et al. Light-Steered Isotropic Semiconductor Micromotors. Adv. Mater. 2017, 29, 1603374. [Google Scholar] [CrossRef] [PubMed]

- Xu, L.; Mou, F.; Gong, H.; Luo, M.; Guan, J. Light-driven micro/nanomotors: From fundamentals to applications. Chem. Soc. Rev. 2017, 46, 6905–6926. [Google Scholar] [CrossRef] [PubMed]

- You, M.; Chen, C.; Xu, L.; Mou, F.; Guan, J. Intelligent Micro/nanomotors with Taxis. Acc. Chem. Res. 2018, 51, 3006–3014. [Google Scholar] [CrossRef] [PubMed]

- Liebchen, B.; Löwen, H. Synthetic Chemotaxis and Collective Behavior in Active Matter. Acc. Chem. Res. 2018, 51, 2982–2990. [Google Scholar] [CrossRef] [PubMed]

- Alberts, B.; Wilson, J.H.; Hunt, T. Molecular Biology of the Cell, 5th ed.; Garland Science: New York, NY, USA, 2008; 1690p. [Google Scholar]

- Akiyama, Y.; Sakuma, T.; Funakoshi, K.; Hoshino, T.; Iwabuchi, K.; Morishima, K. Atmospheric-operable bioactuator powered by insect muscle packaged with medium. Lab Chip 2013, 13, 4870–4880. [Google Scholar] [CrossRef] [PubMed]

- Nagai, M.; Hayasaka, Y.; Kato, K.; Kawashima, T.; Shibata, T. Mixing of solutions by coordinated ciliary motion in Vorticella convallaria and patterning method for microfluidic applications. Sens. Actuators B 2013, 188, 1255–1262. [Google Scholar] [CrossRef]

- Nagai, M.; Hayasaka, Y.; Kawashima, T.; Shibata, T. Active mixing in microchamber using cilia of Vorticella convallaria. IEEJ Trans. Electr. Electron. Eng. 2014, 9, 575–576. [Google Scholar] [CrossRef]

- Vizsnyiczai, G.; Frangipane, G.; Maggi, C.; Saglimbeni, F.; Bianchi, S.; Di Leonardo, R. Light controlled 3d micromotors powered by bacteria. Nat. Commun. 2017, 8, 15974. [Google Scholar] [CrossRef] [PubMed]

- Tanaka, Y.; Morishima, K.; Shimizu, T.; Kikuchi, A.; Yamato, M.; Okano, T.; Kitamori, T. An actuated pump on-chip powered by cultured cardiomyocytes. Lab Chip 2006, 6, 362–368. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.J.; Breuer, K.S. Microfluidic pump powered by self-organizing bacteria. Small 2008, 4, 111–118. [Google Scholar] [CrossRef] [PubMed]

- Martel, S.; Tremblay, C.C.; Ngakeng, S.; Langlois, G. Controlled manipulation and actuation of micro-objects with magnetotactic bacteria. Appl. Phys. Lett. 2006, 89, 233904. [Google Scholar] [CrossRef]

- Kim, D.H.; Cheang, U.K.; Kőhidai, L.; Byun, D.; Kim, M.J. Artificial magnetotactic motion control of tetrahymena pyriformis using ferromagnetic nanoparticles: A tool for fabrication of microbiorobots. Appl. Phys. Lett. 2010, 97, 173702. [Google Scholar] [CrossRef]

- Ma, Q.; Chen, C.; Wei, S.; Chen, C.; Wu, L.-F.; Song, T. Construction and operation of a microrobot based on magnetotactic bacteria in a microfluidic chip. Biomicrofluidics 2012, 6, 024107. [Google Scholar] [CrossRef]

- Felfoul, O.; Mohammadi, M.; Taherkhani, S.; de Lanauze, D.; Xu, Y.Z.; Loghin, D.; Essa, S.; Jancik, S.; Houle, D.; Lafleur, M.; et al. Magneto-aerotactic bacteria deliver drug-containing nanoliposomes to tumour hypoxic regions. Nat. Nanotechnol. 2016, 11, 941. [Google Scholar] [CrossRef]

- Santomauro, G.; Singh, A.V.; Park, B.-W.; Mohammadrahimi, M.; Erkoc, P.; Goering, E.; Schütz, G.; Sitti, M.; Bill, J. Incorporation of terbium into a microalga leads to magnetotactic swimmers. Adv. Biosyst. 2018, 2, 1800039. [Google Scholar] [CrossRef]

- Itoh, A. Motion control of protozoa for bio-mems. IEEE/ASME Trans. Mechatron. 2000, 5, 181–188. [Google Scholar] [CrossRef]

- Kim, D.H.; Casale, D.; Kőhidai, L.; Kim, M.J. Galvanotactic and phototactic control of Tetrahymena pyriformis as a microfluidic workhorse. Appl. Phys. Lett. 2009, 94, 163901. [Google Scholar] [CrossRef]

- Ogawa, N.; Oku, H.; Hashimoto, K.; Ishikawa, M. Microrobotic visual control of motile cells using high-speed tracking system. IEEE Trans. Robot. 2005, 21, 704–712. [Google Scholar] [CrossRef]

- Edward, B.S.; Mahmut Selman, S.; Dal Hyung, K.; Vijay, K.; George, J.P.; Min Jun, K. Electrokinetic and optical control of bacterial microrobots. J. Micromech. Microeng. 2011, 21, 035001. [Google Scholar]

- Nagai, M.; Ryu, S.; Thorsen, T.; Matsudaira, P.; Fujita, H. Chemical control of vorticella bioactuator using microfluidics. Lab Chip 2010, 10, 1574–1578. [Google Scholar] [CrossRef]

- Nagai, M.; Matsumoto, N.; Kawashima, T.; Shibata, T. Reversible motion control of vorticella stalk in microchannel. Microelectron. Eng. 2013, 108, 28–32. [Google Scholar] [CrossRef]

- Kim, M.J.; Breuer, K.S. Controlled mixing in microfluidic systems using bacterial chemotaxis. Anal. Chem. 2007, 79, 955–959. [Google Scholar] [CrossRef]

- Park, B.-W.; Zhuang, J.; Yasa, O.; Sitti, M. Multifunctional bacteria-driven micro-swimmers for targeted active drug delivery. ACS Nano 2017, 11, 8910–8923. [Google Scholar] [CrossRef]

- Kim, J.; Ennis, H.L.; Nguyen, T.H.; Zhuang, X.; Luo, J.; Yao, J.; Kessin, R.H.; Stojanovic, M.; Lin, Q. Light-directed migration of D. discoideum slugs in microfabricated confinements. Sens. Actuators A 2012, 188, 312–319. [Google Scholar] [CrossRef]

- Ozasa, K.; Lee, J.; Song, S.; Hara, M.; Maeda, M. Two-dimensional optical feedback control of euglena confined in closed-type microfluidic channels. Lab Chip 2011, 11, 1933–1940. [Google Scholar] [CrossRef] [PubMed]

- Steager, E.; Kim, C.-B.; Patel, J.; Bith, S.; Naik, C.; Reber, L.; Kim, M.J. Control of microfabricated structures powered by flagellated bacteria using phototaxis. Appl. Phys. Lett. 2007, 90, 263901. [Google Scholar] [CrossRef]

- Weibel, D.B.; Garstecki, P.; Ryan, D.; DiLuzio, W.R.; Mayer, M.; Seto, J.E.; Whitesides, G.M. Microoxen: Microorganisms to move microscale loads. Proc. Natl. Acad. Sci. USA 2005, 102, 11963–11967. [Google Scholar] [CrossRef] [PubMed]

- Hatsuzawa, T.; Ito, D.; Nisisako, T.; Yanagida, Y. Micro-rotary ratchets driven by migratory phytoplankton with phototactic stimulus. Precis. Eng. 2017, 48, 107–113. [Google Scholar] [CrossRef]

- Hatsuzawa, T.; Yamazaki, A.; Nisisako, T.; Yanagida, Y. Design and evaluation of artemia-driven micro ratchet gears. Sens. Actuators A 2015, 235, 182–186. [Google Scholar] [CrossRef]

- Hatsuzawa, T.; Michishita, K.; Yanagida, Y. A reciprocating linear actuator driven by anti-phototaxis of plankton. Sens. Actuators A 2013, 201, 316–320. [Google Scholar] [CrossRef]

- Stanton, M.M.; Park, B.-W.; Miguel-López, A.; Ma, X.; Sitti, M.; Sánchez, S. Biohybrid microtube swimmers driven by single captured bacteria. Small 2017, 13, 1603679. [Google Scholar] [CrossRef]

- Stanton, M.M.; Simmchen, J.; Ma, X.; Miguel-López, A.; Sánchez, S. Biohybrid janus motors driven by Escherichia coli. Adv. Mater. Interfaces 2016, 3, 1500505. [Google Scholar] [CrossRef]

- Di Leonardo, R.; Angelani, L.; Dell’Arciprete, D.; Ruocco, G.; Iebba, V.; Schippa, S.; Conte, M.P.; Mecarini, F.; De Angelis, F.; Di Fabrizio, E. Bacterial ratchet motors. Proc. Natl. Acad. Sci. USA 2010. [Google Scholar] [CrossRef]

- Xu, H.; Medina-Sánchez, M.; Magdanz, V.; Schwarz, L.; Hebenstreit, F.; Schmidt, O.G. Sperm-hybrid micromotor for targeted drug delivery. ACS Nano 2018, 12, 327–337. [Google Scholar] [CrossRef]

- Kirk, D.L. Seeking the ultimate and proximate causes of Volvox multicellularity and cellular differentiation. Integr. Comp. Biol. 2003, 43, 247–253. [Google Scholar] [CrossRef] [PubMed]

- Drescher, K.; Leptos, K.C.; Tuval, I.; Ishikawa, T.; Pedley, T.J.; Goldstein, R.E. Dancing Volvox: Hydrodynamic bound states of swimming algae. Phys. Rev. Lett. 2009, 102, 168101. [Google Scholar] [CrossRef] [PubMed]

- Solari, C.A.; Michod, R.E.; Goldstein, R.E. Volvox barberi, the fastest swimmer of the volvocales (chlorophyceae). J. Phycol. 2008, 44, 1395–1398. [Google Scholar] [CrossRef] [PubMed]

- Eric, L.; Thomas, R.P. The hydrodynamics of swimming microorganisms. Rep. Prog. Phys. 2009, 72, 096601. [Google Scholar]

- Brumley, D.R.; Polin, M.; Pedley, T.J.; Goldstein, R.E. Metachronal waves in the flagellar beating of Volvox and their hydrodynamic origin. J. R. Soc. Interface 2015, 12, 20141358. [Google Scholar] [CrossRef] [PubMed]

- Drescher, K.; Goldstein, R.E.; Michel, N.; Polin, M.; Tuval, I. Direct measurement of the flow field around swimming microorganisms. Phys. Rev. Lett. 2010, 105, 168101. [Google Scholar] [CrossRef] [PubMed]

- Drescher, K.; Goldstein, R.E.; Tuval, I. Fidelity of adaptive phototaxis. Proc. Natl. Acad. Sci. USA 2010, 107, 11171–11176. [Google Scholar] [CrossRef]

- Charles, B.; Yohannes, D.; Kevin, K. Ultra-deep X-ray lithography of densely packed su-8 features: I. An su-8 casting procedure to obtain uniform solvent content with accompanying experimental results. J. Micromech. Microeng. 2005, 15, 1242. [Google Scholar]

- Hernandez, C.J.; Mason, T.G. Colloidal alphabet soup: Monodisperse dispersions of shape-designed lithoparticles. J. Phys. Chem. C 2007, 111, 4477–4480. [Google Scholar] [CrossRef]

- Nagai, M.; Oguri, M.; Shibata, T. Characterization of light-controlled Volvox as movable microvalve element assembled in multilayer microfluidic device. Jpn. J. Appl. Phys. 2015, 54, 067001. [Google Scholar] [CrossRef]

- Dong, L.; Jiang, H. Autonomous microfluidics with stimuli-responsive hydrogels. Soft Matter 2007, 3, 1223–1230. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nagai, M.; Hirano, T.; Shibata, T. Phototactic Algae-Driven Unidirectional Transport of Submillimeter-Sized Cargo in a Microchannel. Micromachines 2019, 10, 130. https://doi.org/10.3390/mi10020130

Nagai M, Hirano T, Shibata T. Phototactic Algae-Driven Unidirectional Transport of Submillimeter-Sized Cargo in a Microchannel. Micromachines. 2019; 10(2):130. https://doi.org/10.3390/mi10020130

Chicago/Turabian StyleNagai, Moeto, Takahiro Hirano, and Takayuki Shibata. 2019. "Phototactic Algae-Driven Unidirectional Transport of Submillimeter-Sized Cargo in a Microchannel" Micromachines 10, no. 2: 130. https://doi.org/10.3390/mi10020130

APA StyleNagai, M., Hirano, T., & Shibata, T. (2019). Phototactic Algae-Driven Unidirectional Transport of Submillimeter-Sized Cargo in a Microchannel. Micromachines, 10(2), 130. https://doi.org/10.3390/mi10020130