Development of A New Type of 2-DOF Piezo-Actuated Pseudo-Decoupled Compliant Mechanism for Elliptical Vibration Machining

Abstract

:1. Introduction

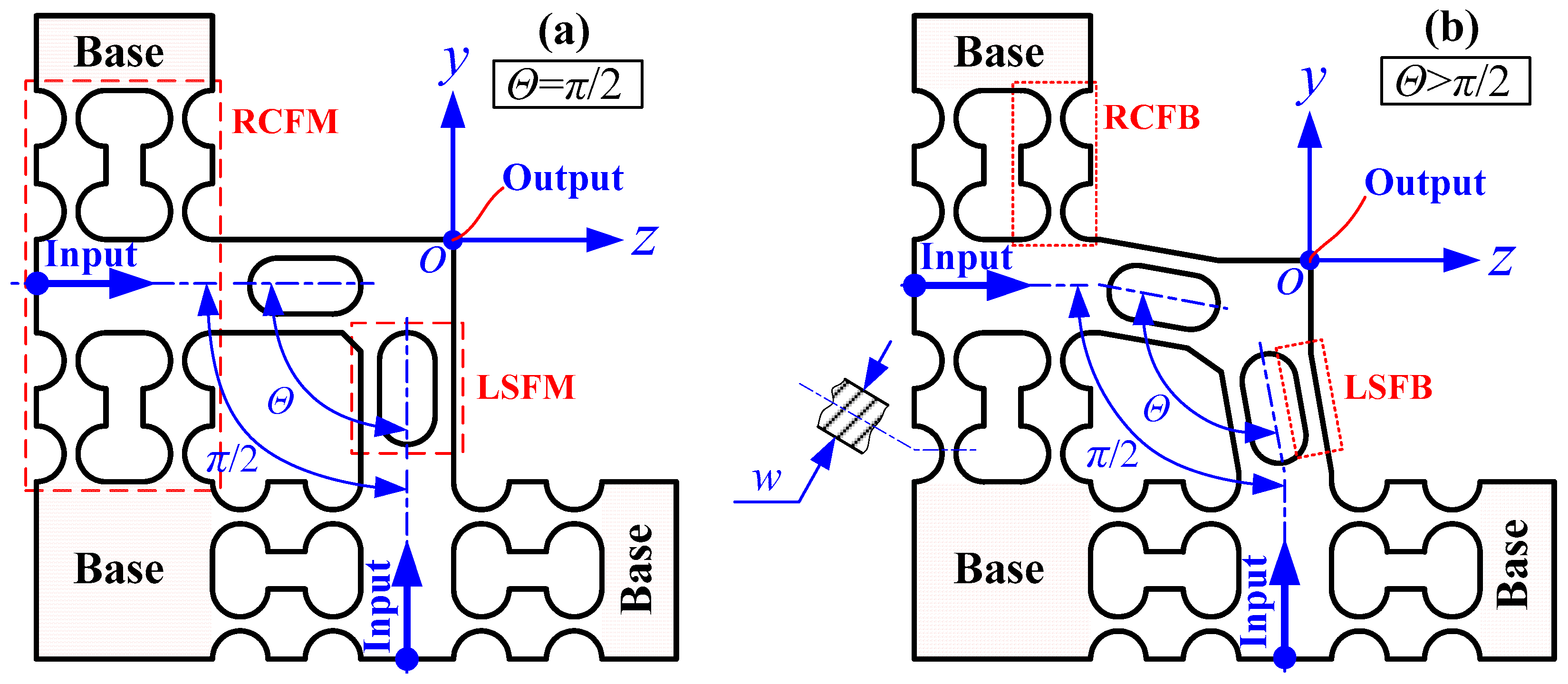

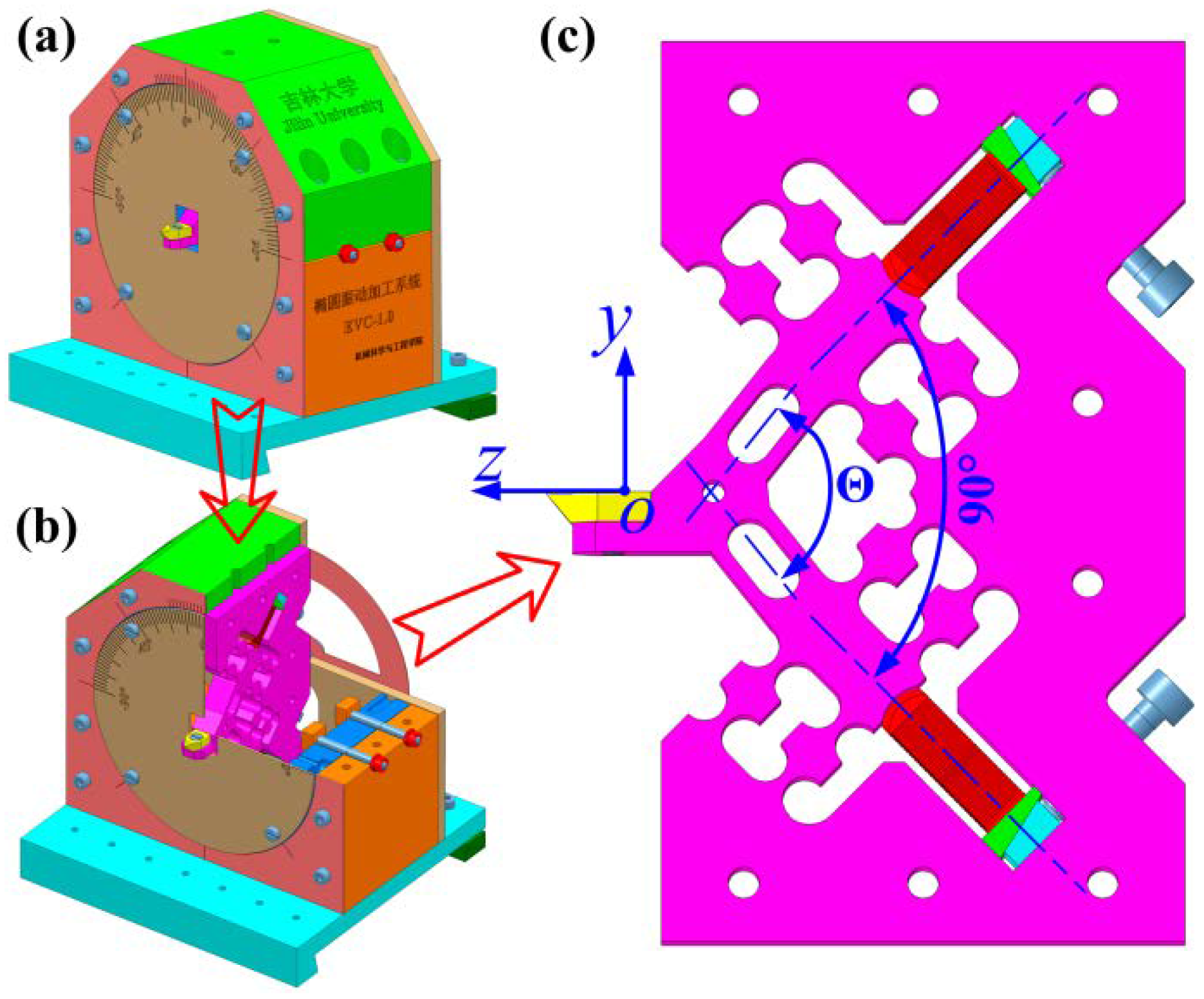

2. Basic Principle and Compliance Model

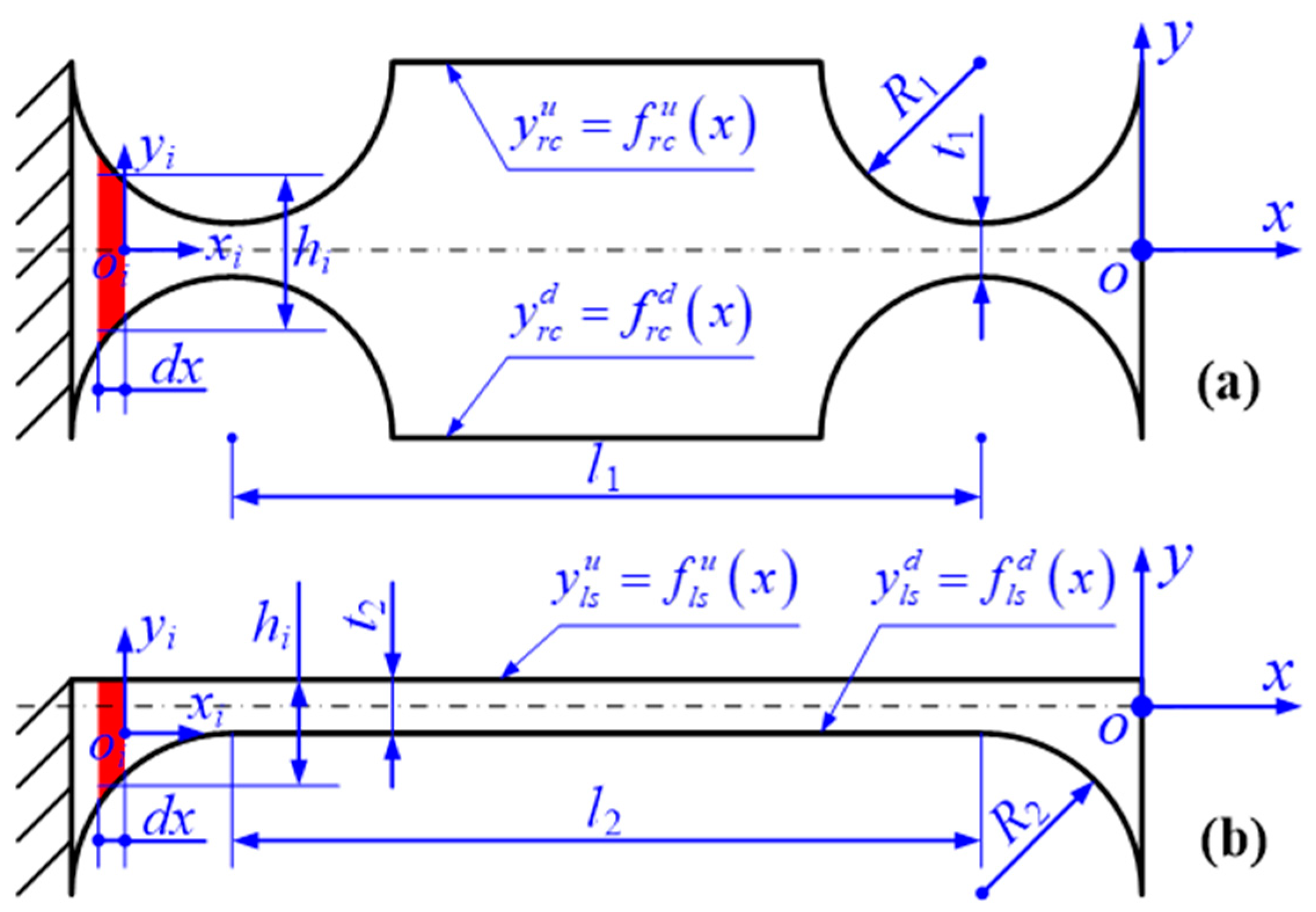

2.1. The Principle of The FBMM Method

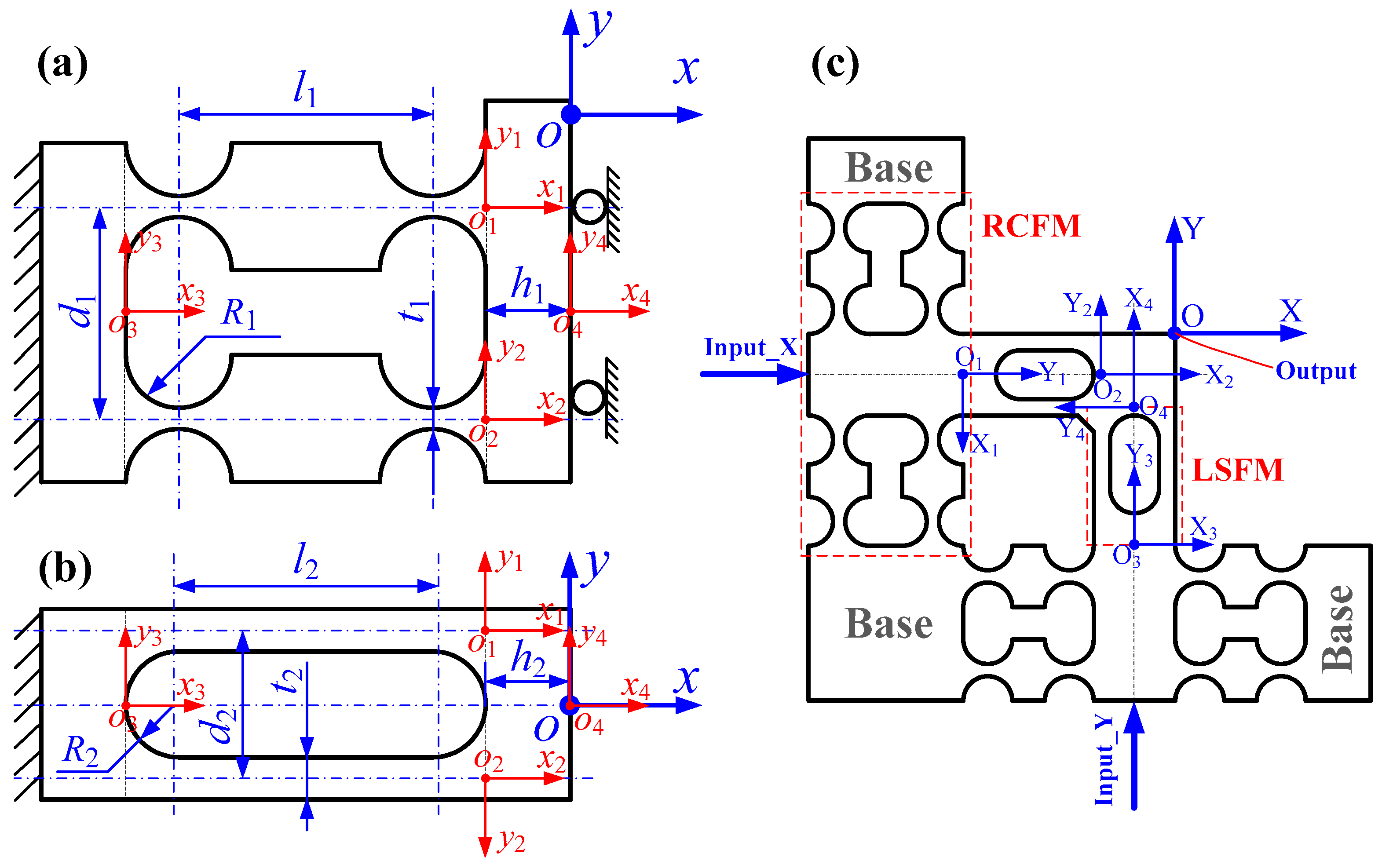

2.2. The Compliance Model of The 2-DOF PDCM

3. Finite Element Analysis of The 2-DOF PDCM

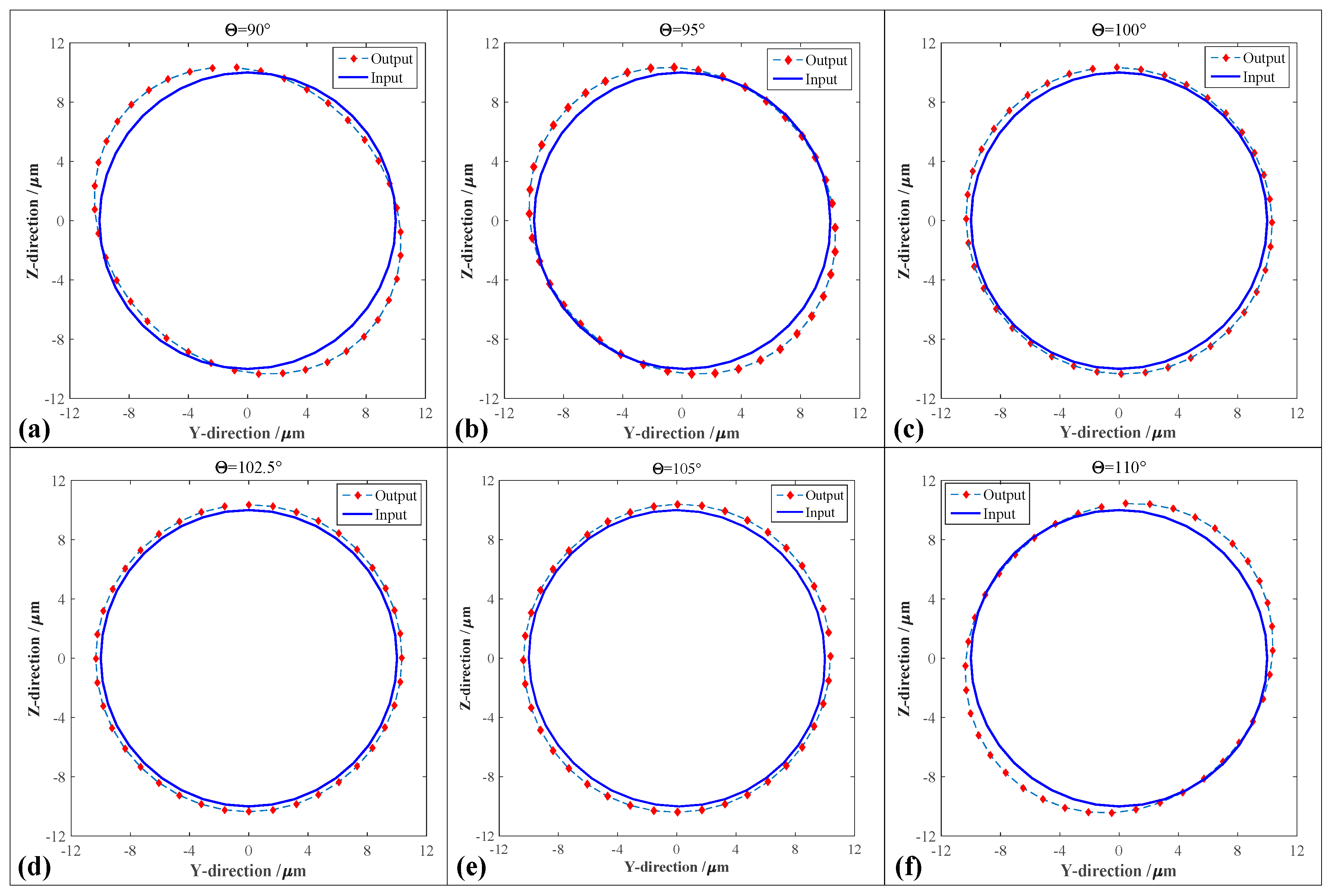

3.1. FEA Verification

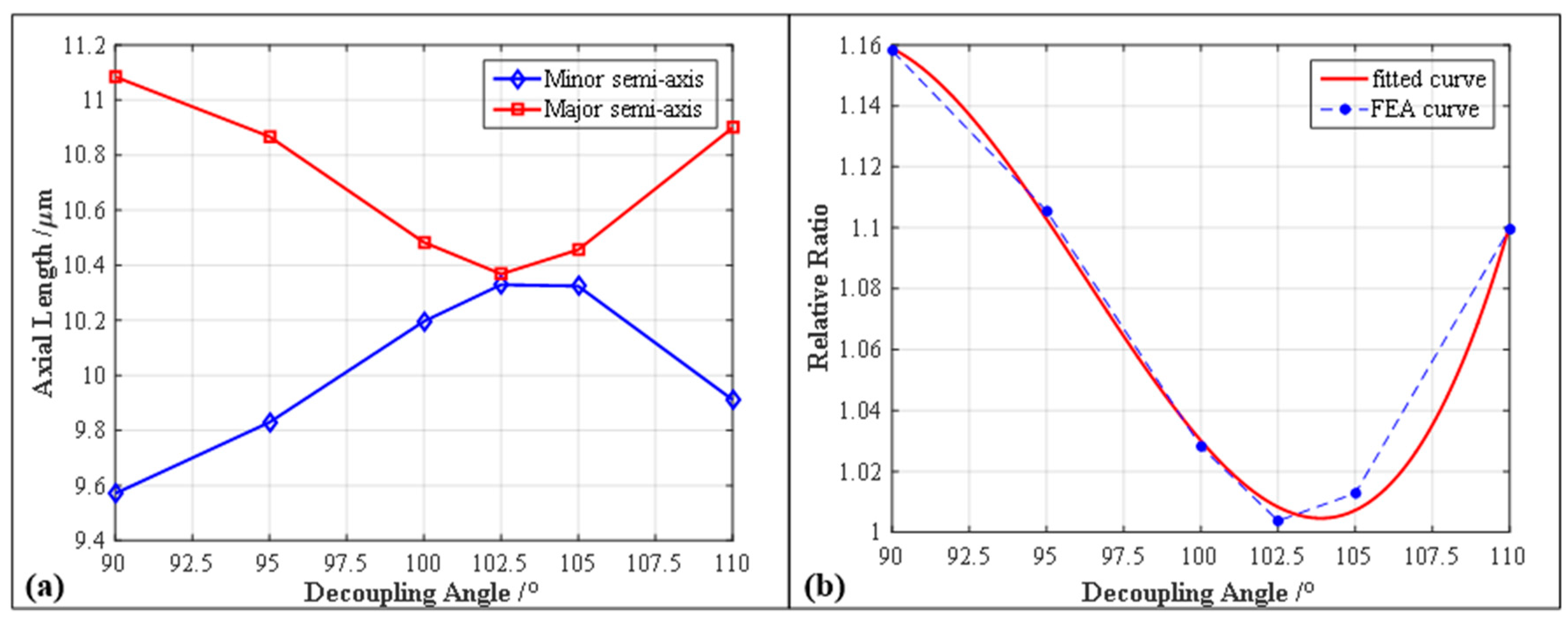

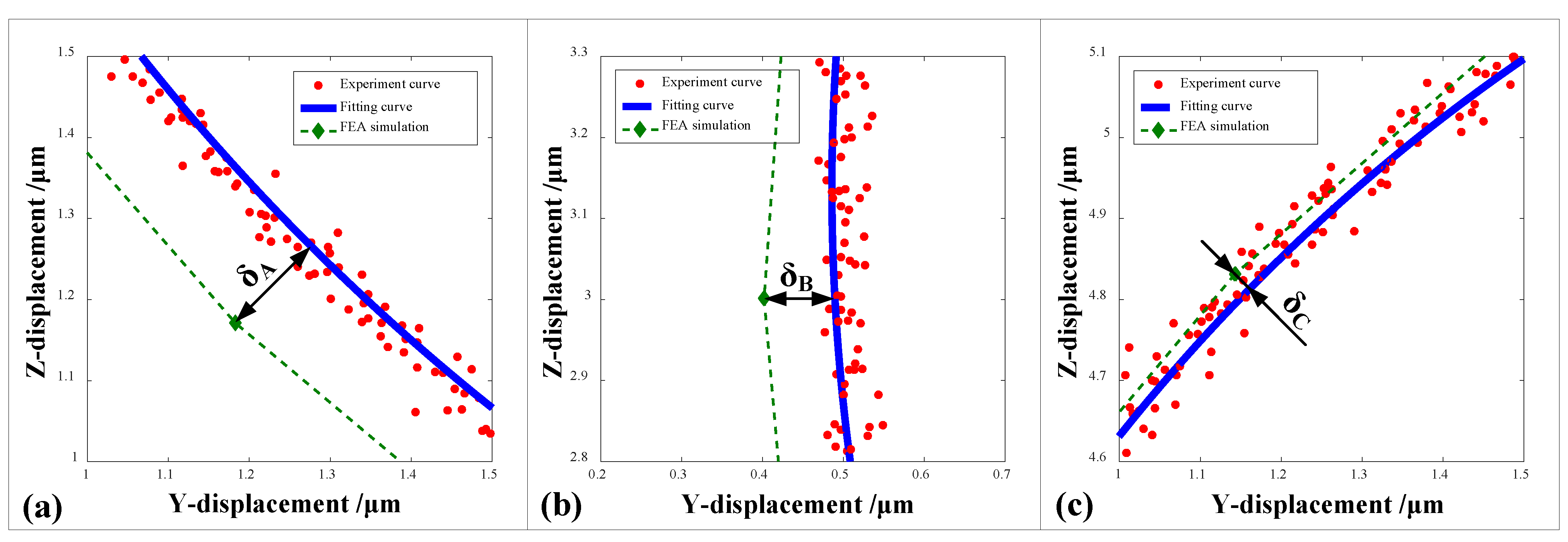

3.2. Decoupling Analysis

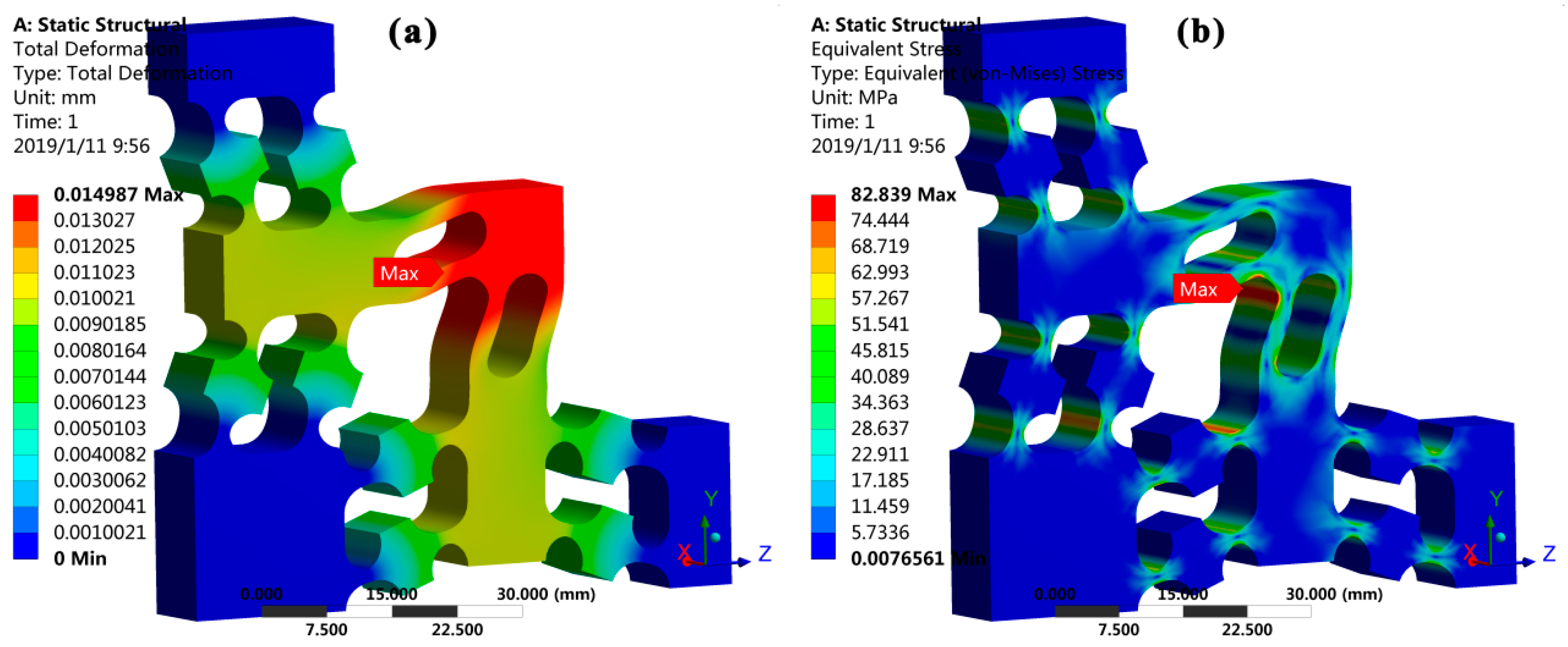

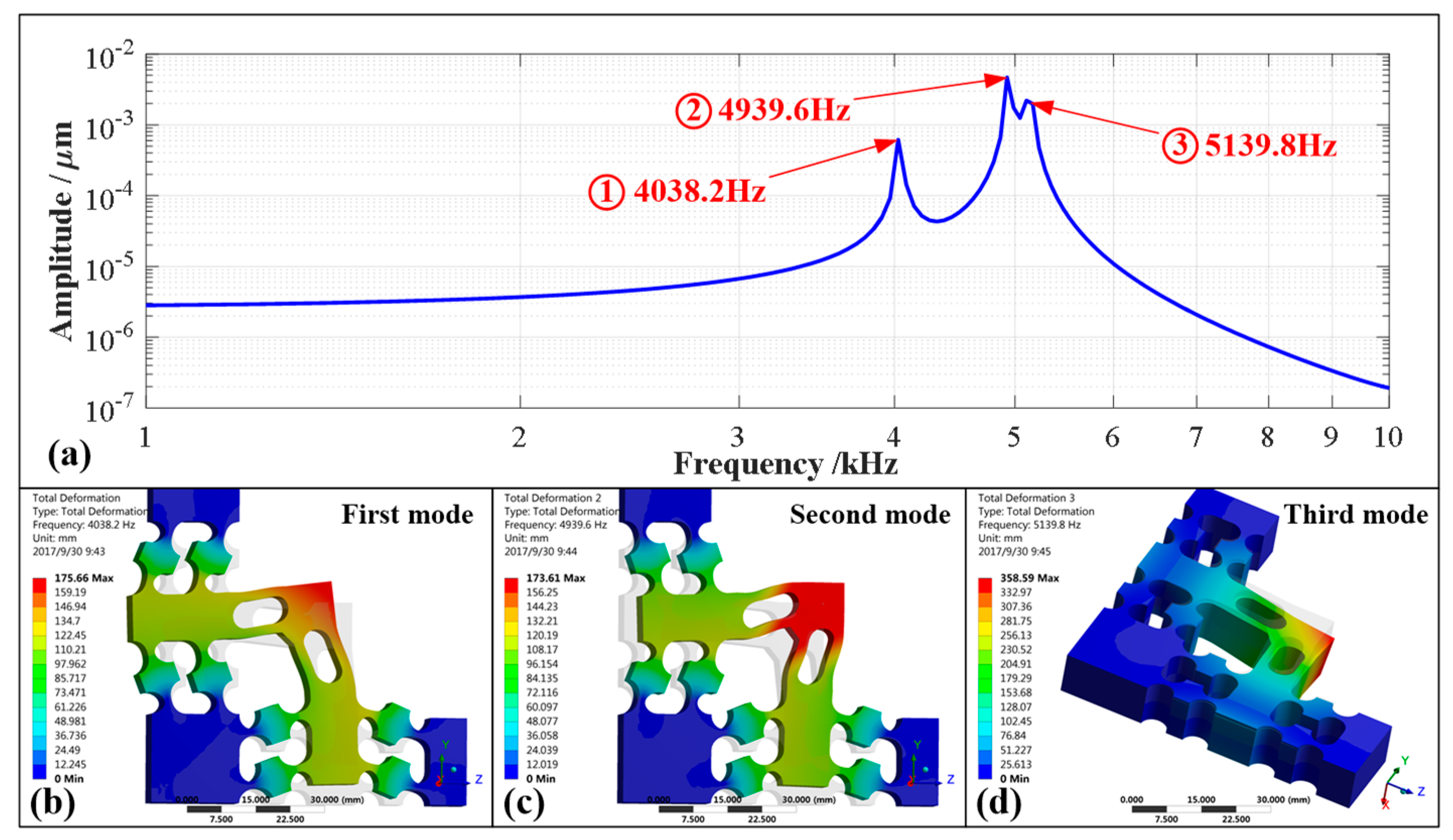

3.3. Static and Dynamic Analysis

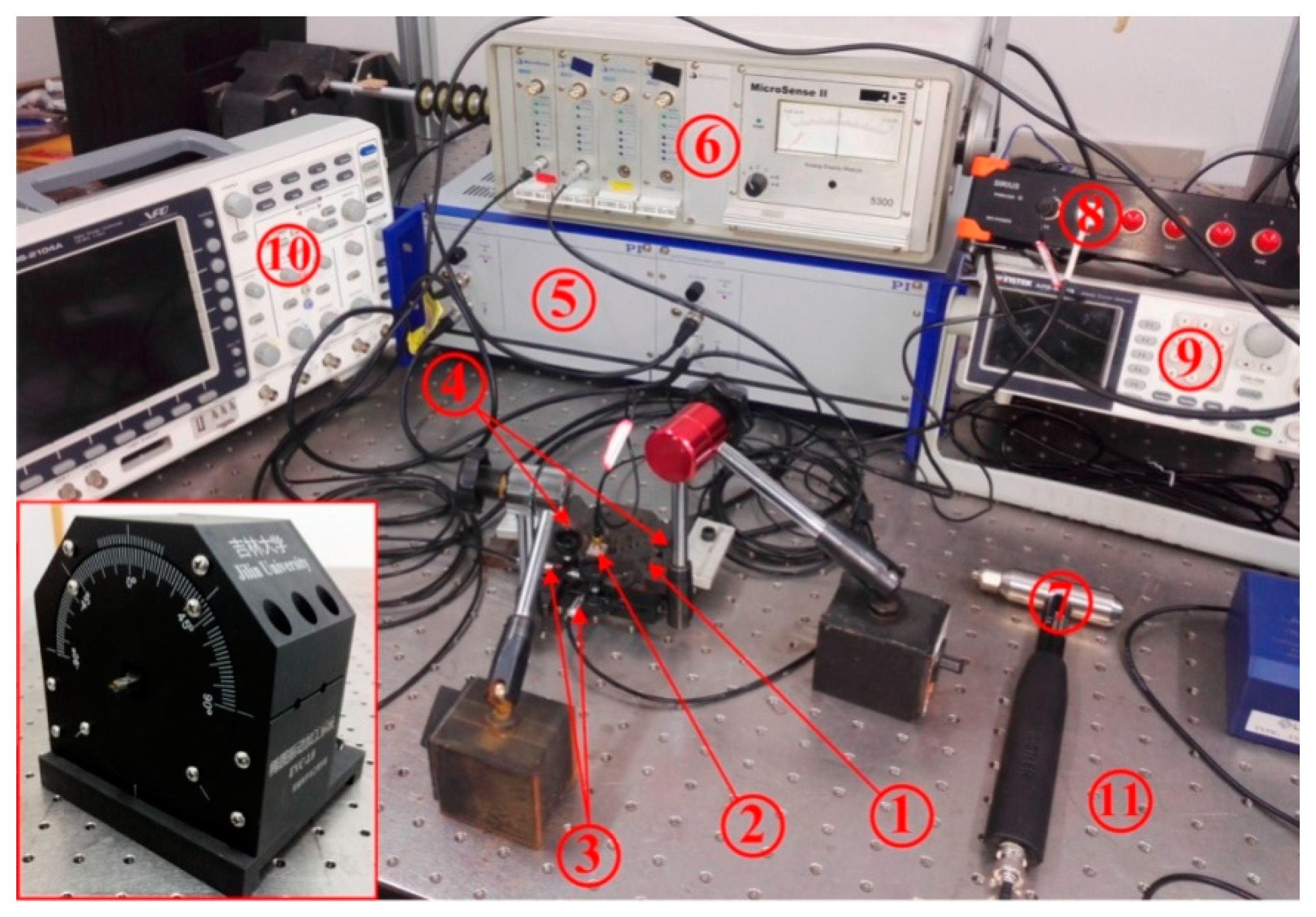

4. Experimental Verification

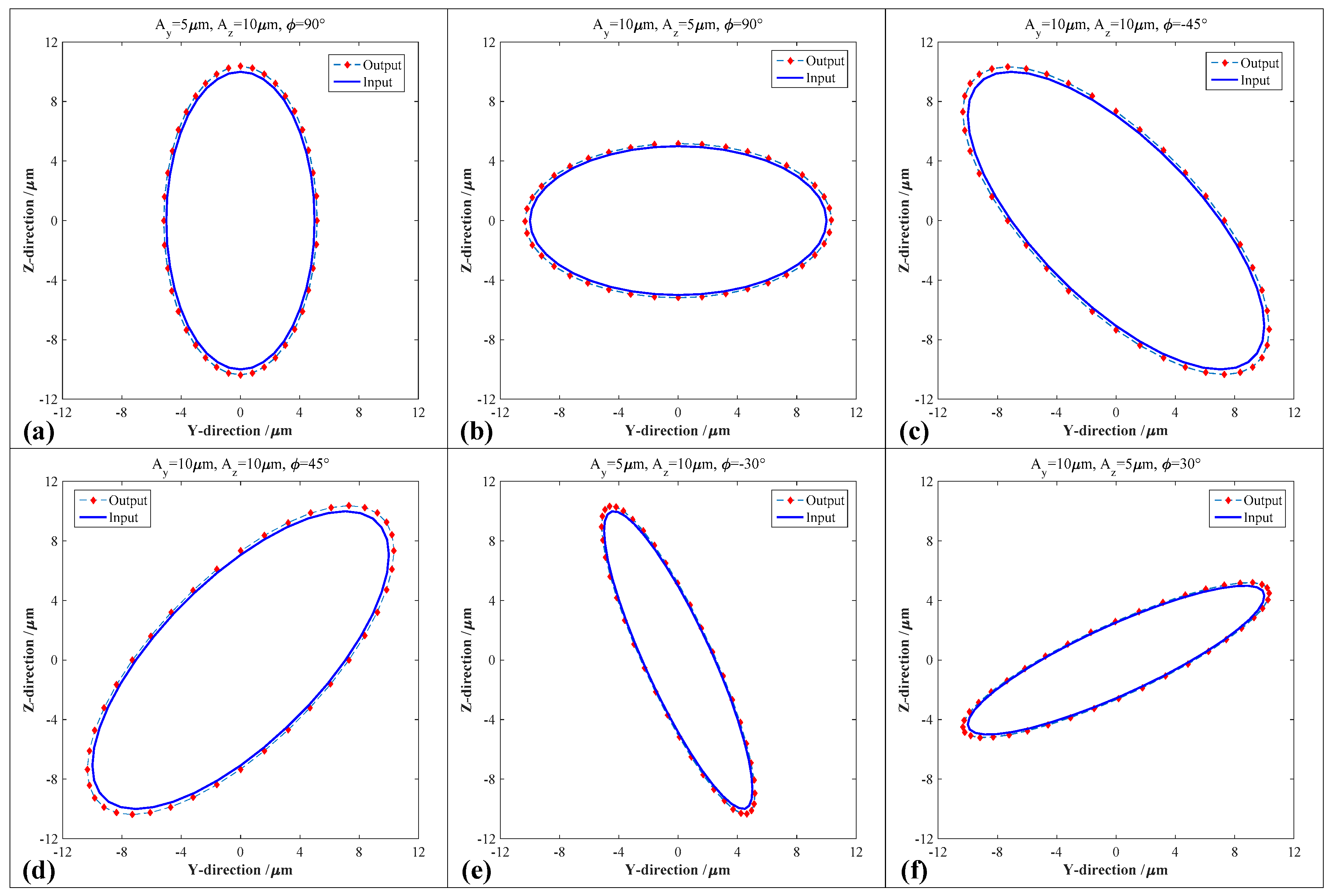

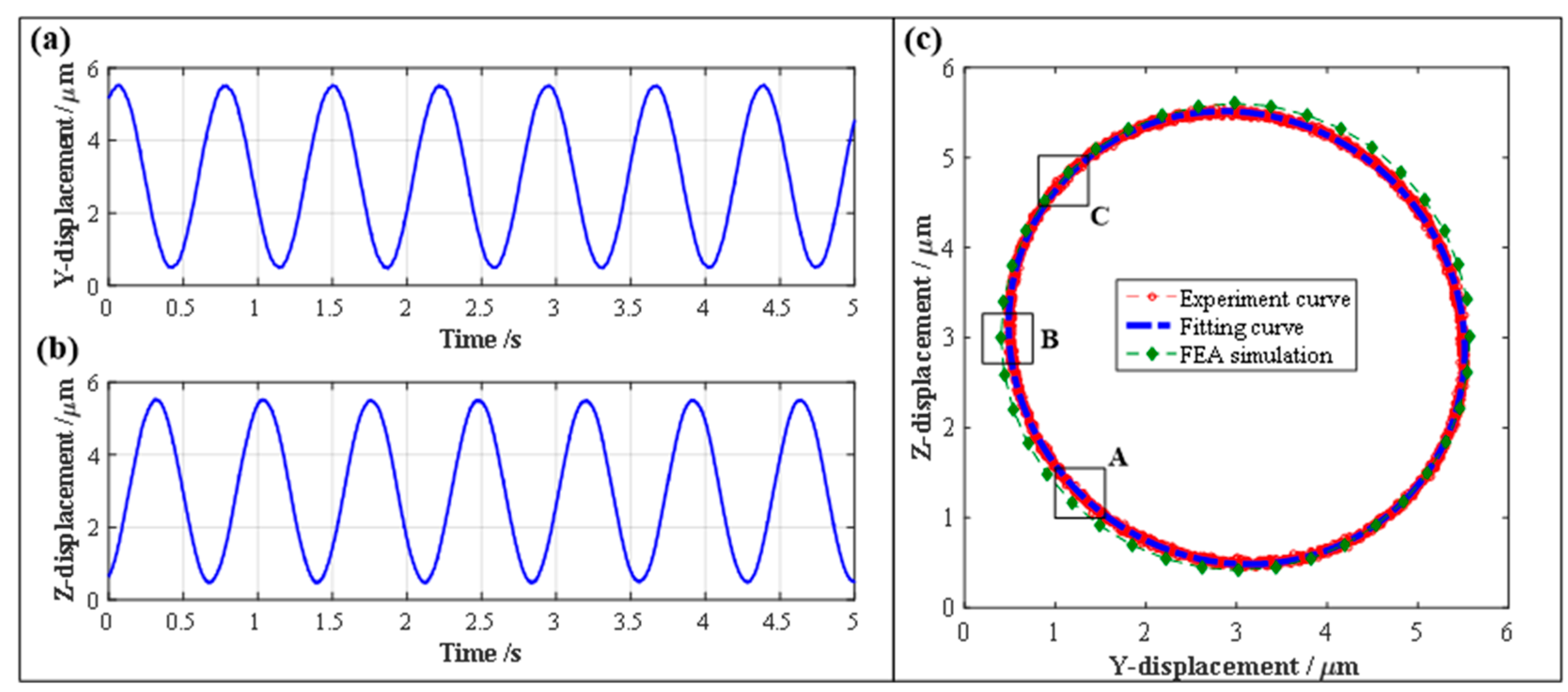

4.1. Kinematic Performance

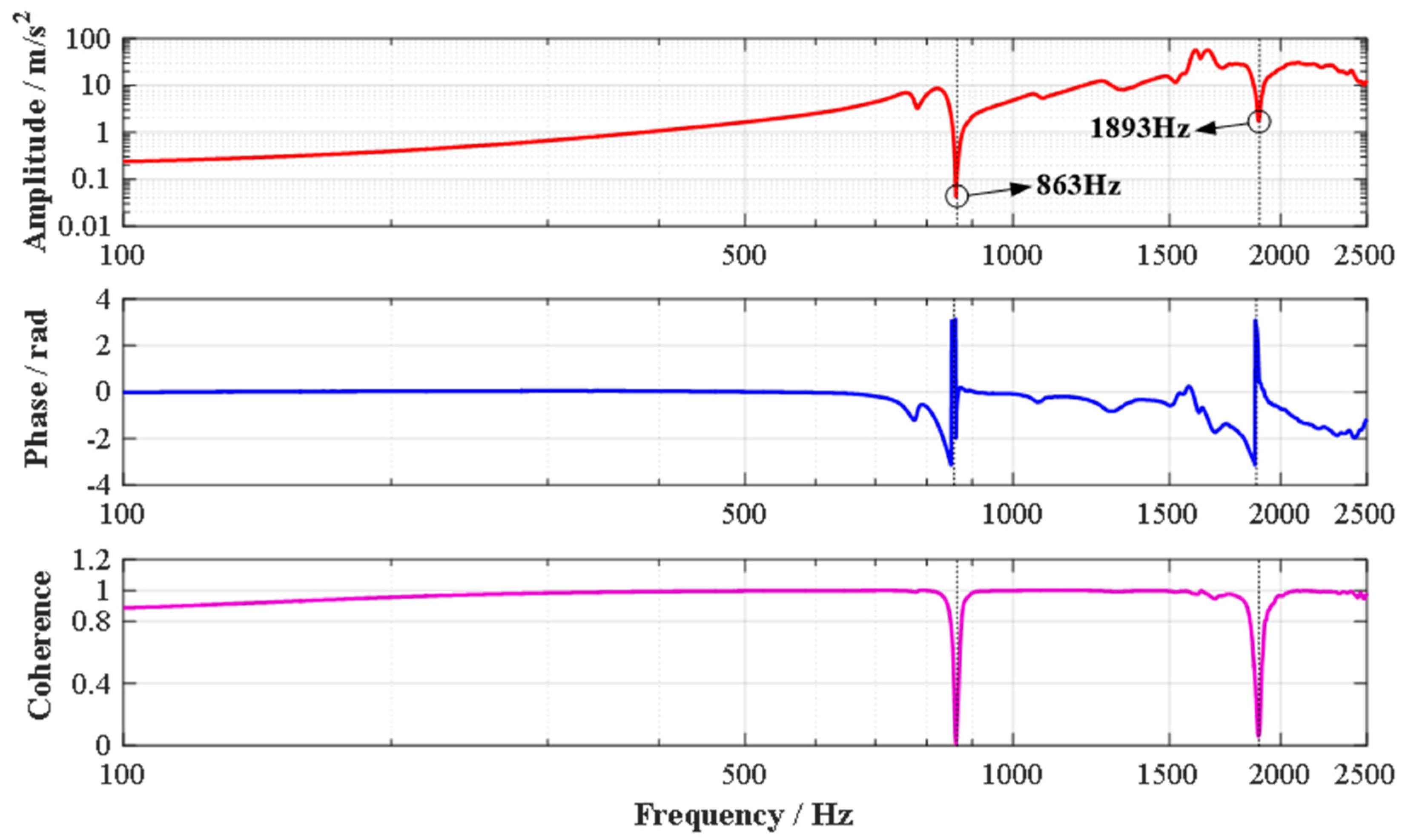

4.2. Dynamic Performance

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Brehl, D.E.; Dow, T.A. Review of vibration-assisted machining. Precis. Eng. 2008, 32, 153–172. [Google Scholar] [CrossRef]

- Dae, K.G.; Gook, L.B. Characteristics of elliptical vibration cutting in micro-V grooving with variations in the elliptical cutting locus and excitation frequency. J. Micromech. Microeng. 2008, 18, 025002. [Google Scholar]

- Wang, R.; Zhou, X.; Meng, G. Development of a new type of elliptical/non-elliptical vibration coining for manufacturing functional microstructure surfaces. J. Micromech. Microeng. 2019, 29, 025012–025027. [Google Scholar] [CrossRef]

- Zhou, X.; Zuo, C.; Liu, Q.; Lin, J. Surface generation of freeform surfaces in diamond turning by applying double-frequency elliptical vibration cutting. Int. J. Mach. Tools Manuf. 2016, 104, 45–57. [Google Scholar] [CrossRef]

- Zhang, J.; Cui, T.; Ge, C.; Sui, Y.; Yang, H. Review of micro/nano machining by utilizing elliptical vibration cutting. Int. J. Mach. Tools Manuf. 2016, 106, 109–126. [Google Scholar] [CrossRef]

- Kurniawan, R.; Kiswanto, G.; Ko, T.J. Surface roughness of two-frequency elliptical vibration texturing (TFEVT) method for micro-dimple pattern process. Int. J. Mach. Tools Manuf. 2017, 116, 77–95. [Google Scholar] [CrossRef]

- Han, J.; Lin, J.; Li, Z.; Lu, M.; Zhang, J. Design and computational optimization of elliptical vibration-assisted cutting system with a novel flexure structure. IEEE Trans. Ind. Electron. 2019, 66, 1151–1161. [Google Scholar] [CrossRef]

- Zhou, X.; Zuo, C.; Liu, Q.; Wang, R.; Lin, J. Development of a double- frequency elliptical vibration cutting apparatus for freeform surface diamond machining. Int. J. Adv. Manuf. Technol. 2016, 87, 2099–2111. [Google Scholar] [CrossRef]

- Zuo, C.; Zhou, X.; Liu, Q.; Wang, R.; Lin, J.; Xu, P.; Zhang, X. Analytical topography simulation of micro/nano textures generated on freeform surfaces in double-frequency elliptical vibration cutting based diamond turning. J. Manuf. Sci. Eng. 2018, 140, 101010. [Google Scholar] [CrossRef]

- Li, Y.; Huang, J.; Tang, H. A compliant parallel XY micromotion stage with complete kinematic decoupling. IEEE Trans. Autom. Sci. Eng. 2012, 9, 538–553. [Google Scholar] [CrossRef]

- Lai, L.J.; Gu, G.Y.; Zhu, L.M. Design and control of a decoupled two degree of freedom translational parallel micro-positioning stage. Rev. Sci. Instrum. 2012, 83, 045105. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Xu, Q. Development and assessment of a novel decoupled XY parallel micropositioning platform. IEEE/ASME Trans. Mechatron. 2010, 15, 125–135. [Google Scholar]

- Li, Y.; Xu, Q. Design and analysis of a totally decoupled flexure-based XY parallel micromanipulator. IEEE Trans. Robot. 2009, 25, 645–657. [Google Scholar]

- Xiao, X.; Li, Y.; Xiao, S. Development of a novel large stroke 2-DOF micromanipulator for micro/nano manipulation. Microsyst. Technol. 2017, 23, 2993–3003. [Google Scholar] [CrossRef]

- Sun, X.; Chen, W.; Tian, Y.; Fatikow, S.; Zhou, R.; Zhang, J.; Mikczinski, M. A novel flexure-based microgripper with double amplification mechanisms for micro/nano manipulation. Rev. Sci. Instrum. 2013, 84, 957–978. [Google Scholar] [CrossRef]

- Zhu, Z.; Zhou, X.; Liu, Z.; Wang, R.; Zhu, L. Development of a piezoelectrically actuated two-degree-of-freedom fast tool servo with decoupled motions for micro-/nanomachining. Precis. Eng. 2014, 38, 809–820. [Google Scholar] [CrossRef]

- Liu, Q.; Pan, S.; Yan, H.; Zhou, X.; Wang, R. In situ measurement and error compensation of optical freeform surfaces based on a two DOF fast tool servo. Int. J. Adv. Manuf. Technol. 2016, 86, 793–798. [Google Scholar] [CrossRef]

- Polit, S.; Dong, J. Development of a high-bandwidth XY nanopositioning stage for high-rate micro-/nanomanufacturing. IEEE/ASME Trans. Mechatron. 2011, 16, 724–733. [Google Scholar] [CrossRef]

- Yong, Y.K.; Aphale, S.S.; Moheimani, S.R. Design, identification, and control of a flexure- based XY stage for fast nanoscale positioning. IEEE Trans. Nanotechnol. 2009, 8, 46. [Google Scholar] [CrossRef]

- Xiao, S.; Li, Y.; Zhao, X. Design and analysis of a novel flexure-based XY micro- positioning stage driven by electromagnetic actuators. In Proceedings of the International Conference on Fluid Power and Mechatronics (FPM), Beijing, China, 17–20 August 2011. [Google Scholar]

- Zhu, Z.; Zhou, X.; Wang, R.; Liu, Q. A simple compliance modeling method for flexure hinges. Sci. China Technol. Sci. 2015, 58, 56–63. [Google Scholar] [CrossRef]

- Wang, R.; Zhou, X.; Zhu, Z. Development of a novel sort of exponent-sine-shaped flexure hinges. Rev. Sci. Instrum. 2013, 84, 289. [Google Scholar] [CrossRef]

- Pham, H.H.; Chen, I.M. Stiffness modeling of flexure parallel mechanism. Precis. Eng. 2005, 29, 467–478. [Google Scholar] [CrossRef]

- Koseki, Y.; Tanikawa, T.; Koyachi, N.; Arai, T. Kinematic analysis of translational 3-DOF micro parallel mechanism using matrix method. In Proceedings of the 2000 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS 2000) (Cat No00CH37113), Takamatsu, Japan, 31 October–5 November 2000. [Google Scholar]

- Kang, D.; Gweon, D. Analysis and design of a cartwheel-type flexure hinge. Precis. Eng. 2013, 37, 33–43. [Google Scholar] [CrossRef]

- Jensen, J.J. On the shear coefficient in Timoshenko’s beam theory. J. Sound Vib. 1983, 87, 621–635. [Google Scholar] [CrossRef]

- Chen, G.; Howell, L.L. Two general solutions of torsional compliance for variable rectangular cross-section hinges in compliant mechanisms. Precis. Eng. 2009, 33, 268–274. [Google Scholar] [CrossRef]

| Dimension parameters | |||||

| LSFM | t1 = 1 mm | R1 = 2.5 mm | l1 = 10 mm | h1 = 4 mm | d1 = 10 mm |

| RCFM | t2 = 1 mm | R2 = 3.0 mm | l2 = 10 mm | h2 = 4 mm | d2 = 7.0 mm |

| Result analysis | |||||

| FBMM | FEA | Deviation | |||

| dx/Fx or dy/Fy | 1.15 × 10-7 m/N | 1.26 × 10-7 m/N | 8.7% | ||

| dy/Fx or dx/Fy | 1.45 × 10-9 m/N | 1.53 × 10-9 m/N | 5.2% | ||

| Motion parameters | Value | Elliptical parameters | Value |

|---|---|---|---|

| Amplitude in Y-axis /Ay | 2.5151 μm | Semi-major axis /a | 2.5841 μm |

| Amplitude in Z-axis /Az | 2.5132 μm | Semi-minor axis /b | 2.4449 μm |

| Offset in Y-axis /By | 3.0000 μm | Center in Y-axis /yo | 3.0012 μm |

| Offset in Z-axis /Bz | 2.9990 μm | Center in Z-axis /zo | 2.9986 μm |

| ------- | ------ | Inclined angle /θ | -44.9850° |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, R.; Zhou, X.; Meng, G. Development of A New Type of 2-DOF Piezo-Actuated Pseudo-Decoupled Compliant Mechanism for Elliptical Vibration Machining. Micromachines 2019, 10, 122. https://doi.org/10.3390/mi10020122

Wang R, Zhou X, Meng G. Development of A New Type of 2-DOF Piezo-Actuated Pseudo-Decoupled Compliant Mechanism for Elliptical Vibration Machining. Micromachines. 2019; 10(2):122. https://doi.org/10.3390/mi10020122

Chicago/Turabian StyleWang, Rongqi, Xiaoqin Zhou, and Guangwei Meng. 2019. "Development of A New Type of 2-DOF Piezo-Actuated Pseudo-Decoupled Compliant Mechanism for Elliptical Vibration Machining" Micromachines 10, no. 2: 122. https://doi.org/10.3390/mi10020122

APA StyleWang, R., Zhou, X., & Meng, G. (2019). Development of A New Type of 2-DOF Piezo-Actuated Pseudo-Decoupled Compliant Mechanism for Elliptical Vibration Machining. Micromachines, 10(2), 122. https://doi.org/10.3390/mi10020122