Development of a Lab-on-a-Disk Platform with Digital Imaging for Identification and Counting of Parasite Eggs in Human and Animal Stool

Abstract

1. Introduction

- Start from a gram-amount of stool to have a representative aliquot;

- Sample-in result-out test principle;

- Fully automated;

- Digital output for test results, either by pictures of the ROI (region of interest), or a table;

- Quality controlled procedure containing a positive control for sample manipulation, egg collection, and reproducibility in counting of parasitic eggs;

- Data upload to a monitoring system; and

- Re-usable assay components or environmentally friendly single-use disposables.

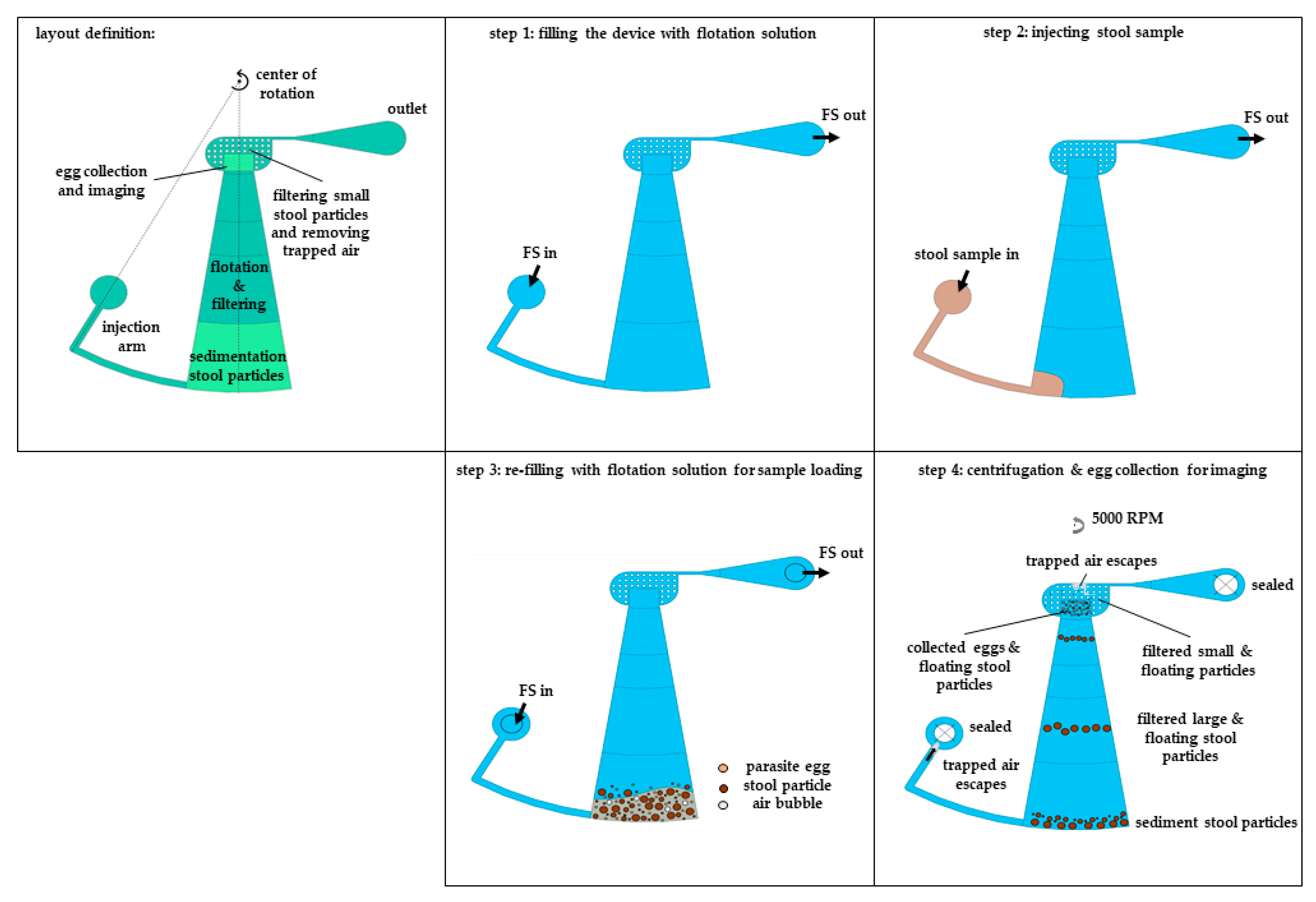

2. Device Design and Operation

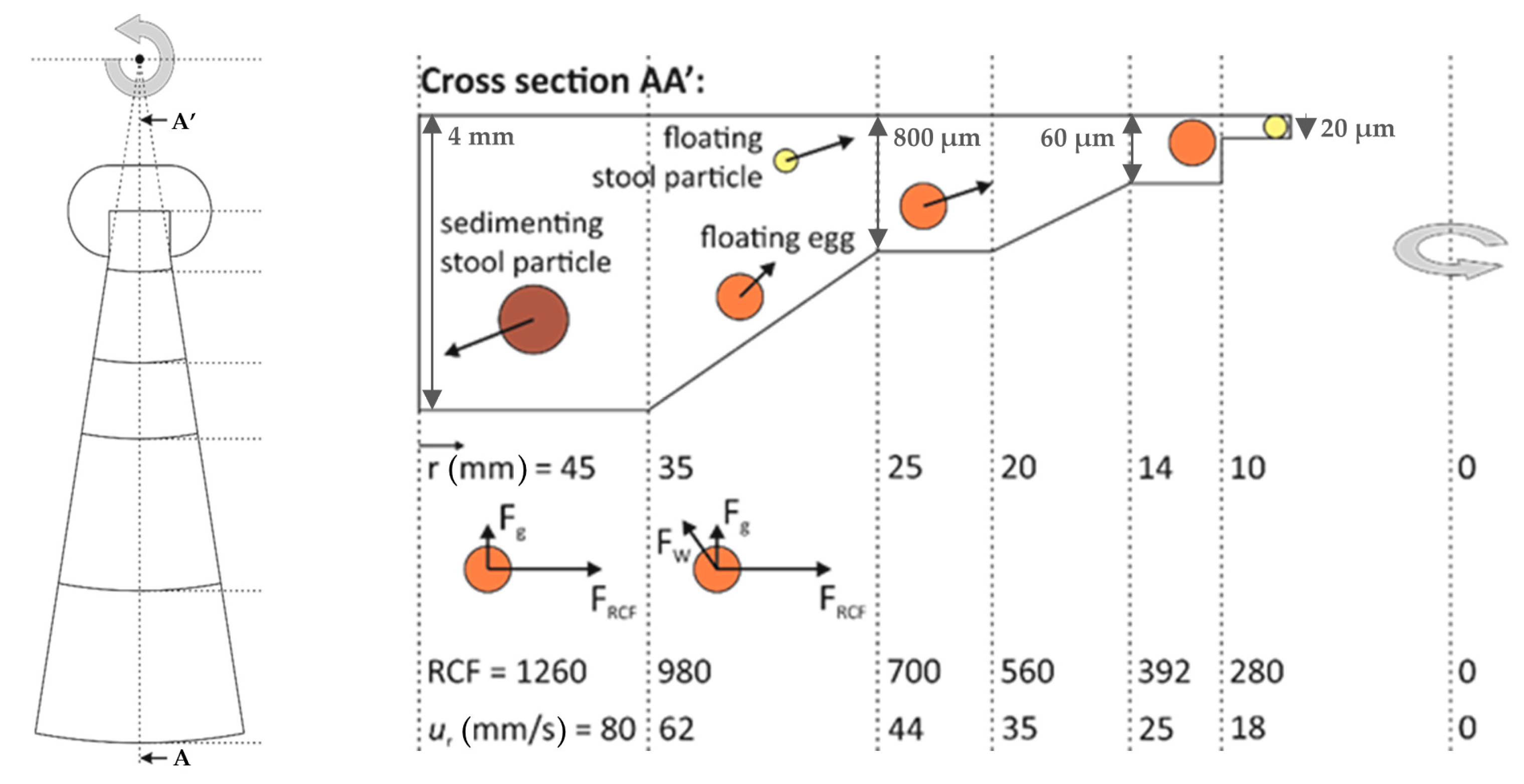

2.1. Guided Two-Dimensional (2D) Flotation

2.2. Converging Chamber

2.3. Continuous Size-Based Filtering

2.4. Single-Shot Imaging

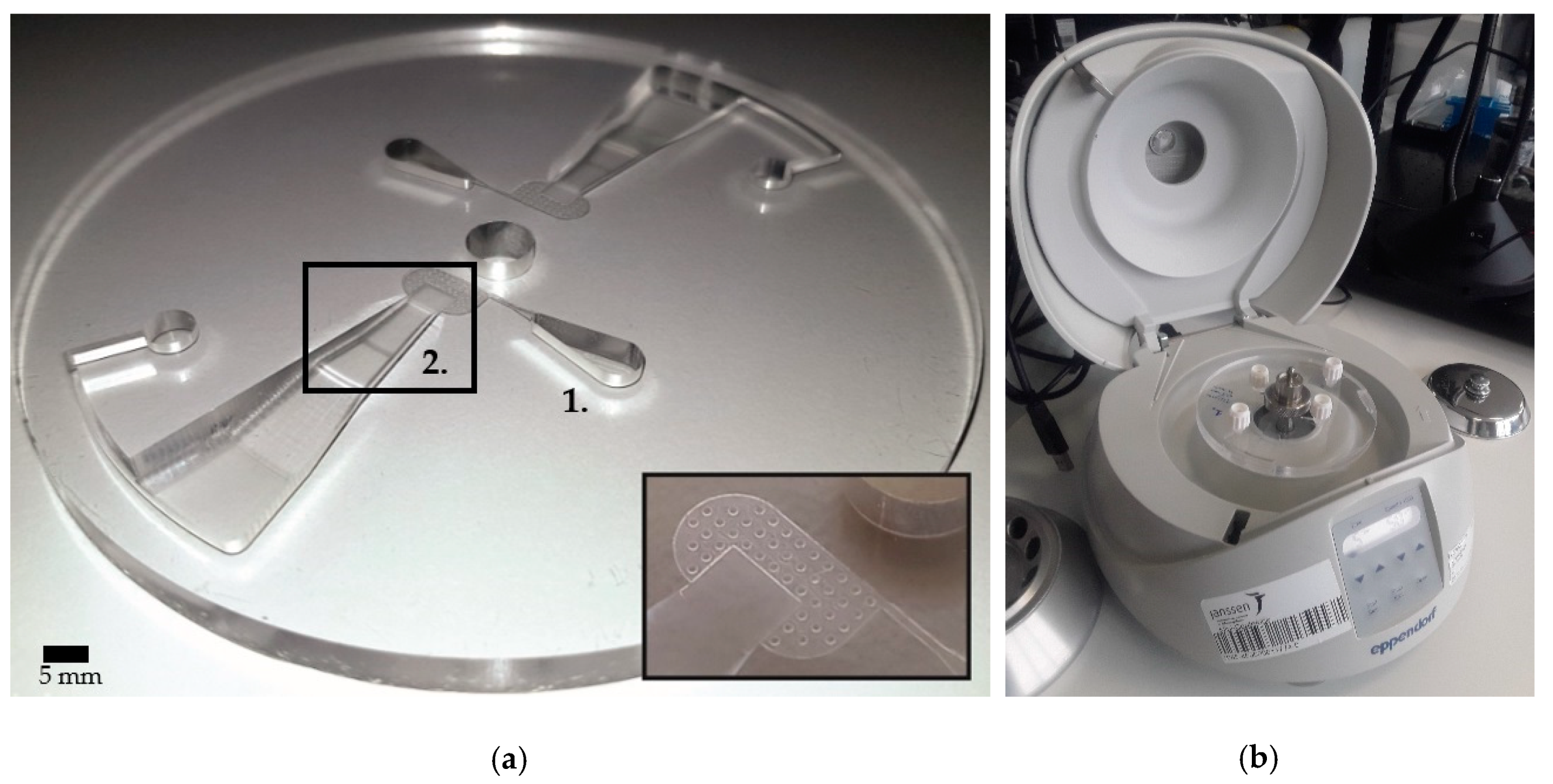

2.5. Design

3. Materials and Methods

3.1. Fabrication

3.2. Imaging Setup

4. Experimental

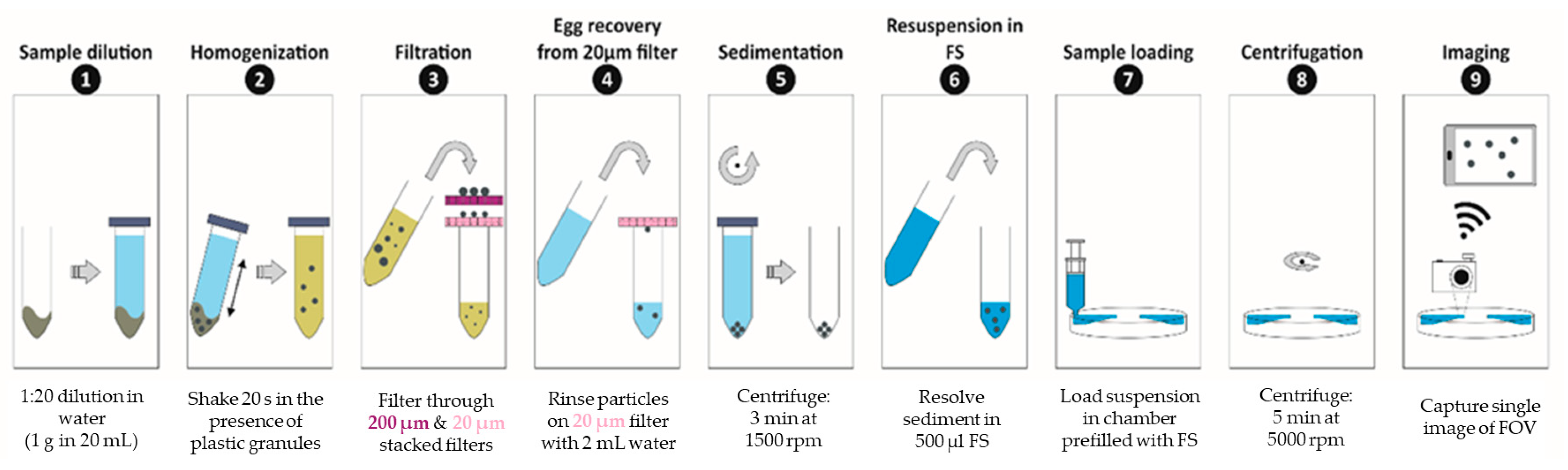

4.1. Sample Preparation

4.2. Centrifugation

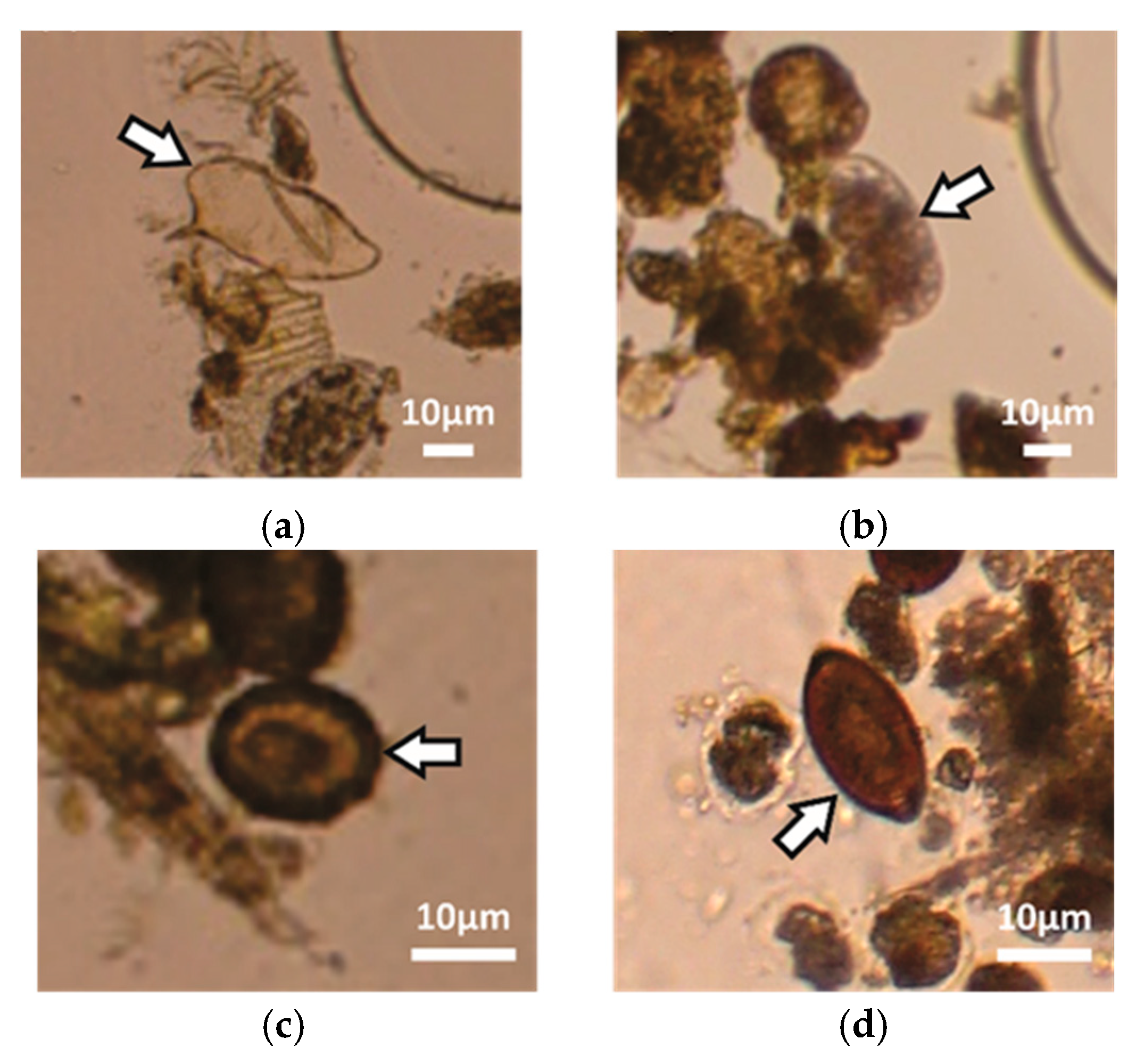

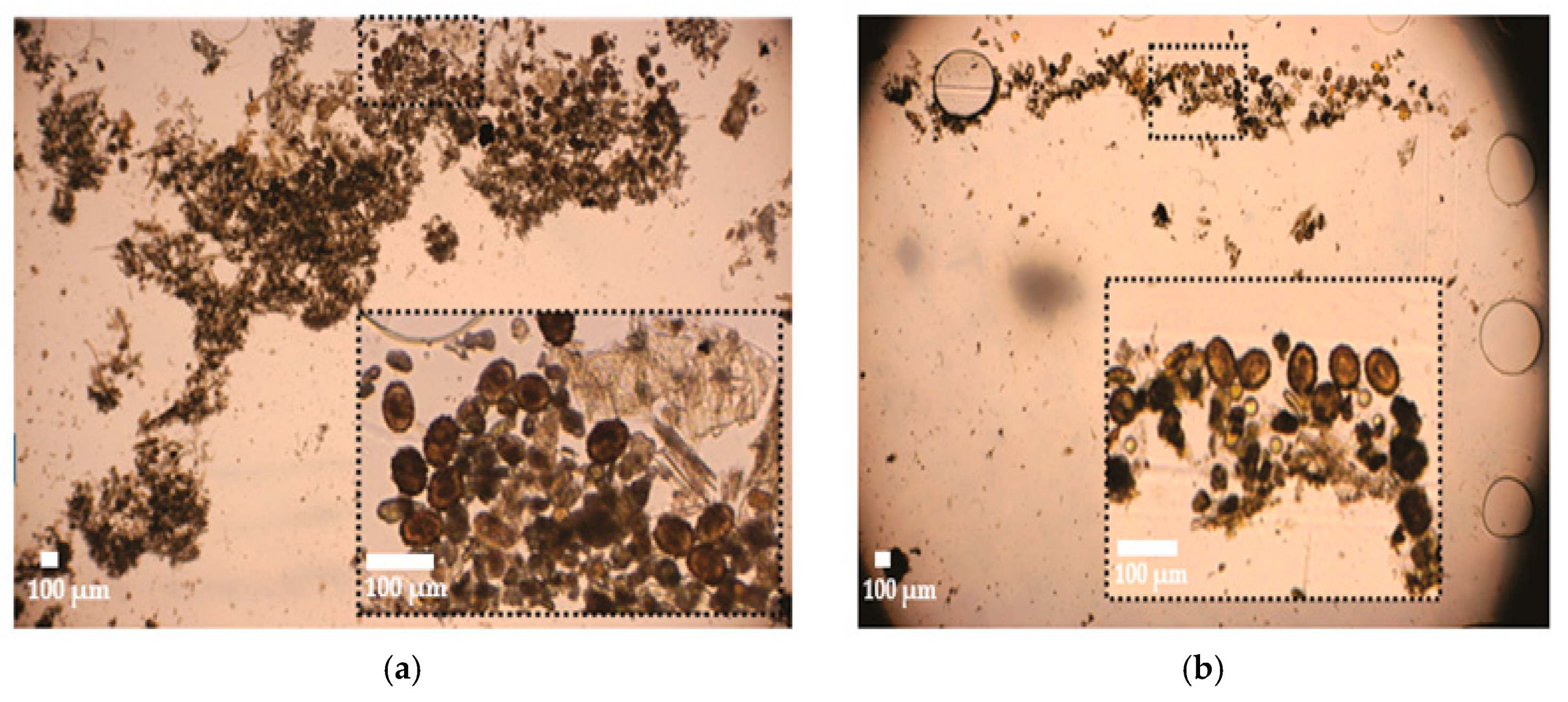

5. Results and Discussion

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- World Health Organization. Soil-transmitted helminth infection: Fact sheet No 366. Available online: https://www.who.int/news-room/fact-sheets/detail/soil-transmitted-helminth-infections (accessed on 14 January 2019).

- World Health Organization. Prevention and control of schistosomiasis and soil-transmitted helminthiasis. Report of a WHO Expert Committee. WHO Tech. Rep. Ser. 2002, 912, 32–34. [Google Scholar]

- Guerrant, R.L. Bench aids for the diagnosis of intestinal parasites. Parasitol. Today 1995, 11, 238. [Google Scholar] [CrossRef]

- Knopp, S.; Mohammed, K.A.; Khamis, I.S.; Mgeni, A.F.; Stothard, J.R.; Rollinson, D.; Marti, H.; Utzinger, J. Spatial distribution of soil-transmitted helminths, including Strongyloides stercoralis, among children in Zanzibar. Geospat. Health 2008, 3, 47–56. [Google Scholar] [CrossRef] [PubMed]

- Knopp, S.; Mgeni, A.F.; Khamis, I.S.; Steinmann, P.; Stothard, J.R.; Rollinson, D.; Marti, H.; Utzinger, J. Diagnosis of soil-transmitted helminths in the era of preventive chemotherapy: effect of multiple stool sampling and use of different diagnostic techniques. PLoS Negl. Trop. Dis. 2008, 2, e331. [Google Scholar] [CrossRef] [PubMed]

- Bergquist, R.; Johansen, M.V.; Utzinger, J. Diagnostic dilemmas in helminthology: what tools to use and when? Trends Parasitol. 2009, 25, 151–156. [Google Scholar] [CrossRef]

- McCarthy, D.P.; Donald, P.F.; Scharlemann, J.P.W.; Buchanan, G.M.; Balmford, A.; Green, J.M.H.; Bennun, L.A.; Burgess, N.D.; Fishpool, L.D.C.; Garnett, S.T.; et al. Financial costs of meeting global biodiversity conservation targets: Current spending and unmet needs. Science 2012, 338, 916. [Google Scholar] [CrossRef]

- Cools, P.; Vlaminck, J.; Albonico, M.; Ame, S.; Ayana, M.; Jose Antonio, B.P.; Cringoli, G.; Dana, D.; Keiser, J.; Maurelli, M.P.; et al. Diagnostic performance of a single and duplicate Kato-Katz, Mini-FLOTAC, FECPAKG2 and qPCR for the detection and quantification of soil-transmitted helminths in three endemic countries. PLoS Negl. Trop. Dis. 2019, 13, e0007446. [Google Scholar] [CrossRef]

- Egwang, T.G.; Slocombe, J.O. Efficiency and sensitivity of techniques for recovering nematode eggs from bovine feces. Canad. J. Comp. Med. 1981, 45, 243–248. [Google Scholar]

- Egwang, T.G.; Slocombe, J.O. Evaluation of the Cornell-Wisconsin centrifugal flotation technique for recovering trichostrongylid eggs from bovine feces. Canad. J. Comp. Med. 1982, 46, 133–137. [Google Scholar]

- Cringoli, G.; Maurelli, M.P.; Levecke, B.; Bosco, A.; Vercruysse, J.; Utzinger, J.; Rinaldi, L. The Mini-FLOTAC technique for the diagnosis of helminth and protozoan infections in humans and animals. Nat. Protoc. 2017, 12, 1723–1732. [Google Scholar] [CrossRef]

- Levecke, B.; Behnke, J.M.; Ajjampur, S.S.R.; Albonico, M.; Ame, S.M.; Charlier, J.; Geiger, S.M.; Hoa, N.T.V.; Ngassam, R.I.K.; Kotze, A.C.; et al. A comparison of the sensitivity and fecal egg counts of the McMaster egg counting and Kato-Katz thick smear methods for soil-transmitted helminths. PLOS Negl. Trop. Dis. 2011, 5, e1201. [Google Scholar] [CrossRef]

- Cringoli, G.; Rinaldi, L.; Maurelli, M.P.; Utzinger, J. FLOTAC: new multivalent techniques for qualitative and quantitative copromicroscopic diagnosis of parasites in animals and humans. Nat. Protoc. 2010, 5, 503–515. [Google Scholar] [CrossRef]

- Barda, B.D.; Rinaldi, L.; Ianniello, D.; Zepherine, H.; Salvo, F.; Sadutshang, T.; Cringoli, G.; Clementi, M.; Albonico, M. Mini-FLOTAC, an Innovative Direct Diagnostic Technique for Intestinal Parasitic Infections: Experience from the Field. PLoS Negl. Tropic. Dis. 2013, 7, e2344. [Google Scholar] [CrossRef]

- Rinaldi, L.; Coles, G.C.; Maurelli, M.P.; Musella, V.; Cringoli, G. Calibration and diagnostic accuracy of simple flotation, McMaster and FLOTAC for parasite egg counts in sheep. Vet Parasitol 2011, 177, 345–352. [Google Scholar] [CrossRef]

- Rashid, M.H.; Stevenson, M.A.; Waenga, S.; Mirams, G.; Campbell, A.J.D.; Vaughan, J.L.; Jabbar, A. Comparison of McMaster and FECPAKG2 methods for counting nematode eggs in the faeces of alpacas. Parasit. Vectors 2018, 11, 10–13. [Google Scholar] [CrossRef]

- Moser, W.; Bärenbold, O.; Mirams, G.J.; Cools, P.; Vlaminck, J.; Ali, S.M.; Ame, S.M.; Hattendorf, J.; Vounatsou, P.; Levecke, B.; et al. Diagnostic comparison between FECPAKG2 and the Kato-Katz method for analyzing soil-transmitted helminth eggs in stool. PLoS Negl. Tropic. Dis. 2018, 12, 1–13. [Google Scholar] [CrossRef]

- Lim, M.D.; Brooker, S.J.; Belizario, V.Y., Jr.; Gay-Andrieu, F.; Gilleard, J.; Levecke, B.; van Lieshout, L.; Medley, G.F.; Mekonnen, Z.; Mirams, G.; et al. Diagnostic tools for soil-transmitted helminths control and elimination programs: A pathway for diagnostic product development. PLoS Negl. Trop. Dis. 2018, 12, e0006213. [Google Scholar] [CrossRef]

- Kellog, G.J.; Arnold, T.E.; Carvalho, L.; Duffy, D.C.; Sheppard, N.F. Centrifugal Microfluidics Applications. In Proceedings of the µTAS 2000 Symposium, Enschede, The Netherlands, 14–18 May 2000; pp. 239–242. [Google Scholar]

- Amasia, M.; Cozzens, M.; Madou, M.J. Centrifugal microfluidic platform for rapid PCR amplification using integrated thermoelectric heating and ice-valving. Sens. Actuat. B-Chem. 2012, 161, 1191–1197. [Google Scholar] [CrossRef]

- Sundberg, S.O.; Wittwer, C.T.; Gao, C.; Gale, B.K. Spinning disk platform for microfluidic digital polymerase chain reaction. Anal. Chem. 2010, 82, 1546–1550. [Google Scholar] [CrossRef]

- Haeberle, S.; Brenner, T.; Zengerle, R.; Ducree, J. Centrifugal extraction of plasma from whole blood on a rotating disk. Lab Chip 2006, 6, 776–781. [Google Scholar] [CrossRef]

- Amasia, M.; Madou, M. Large-volume centrifugal microfluidic device for blood plasma separation. Bioanalysis 2010, 2, 1701–1710. [Google Scholar] [CrossRef]

- Morais, S.; Cararascosa, J.; Mira, D.; Puchades, R.; Maquieira, A.; Utzinger, J.; Rinaldi, L. Microimmunoanalysis on Standard Compact Discs to Determine Low Abundant Compounds. Anal. Chem. 2007, 79, 7628–7635. [Google Scholar] [CrossRef]

- Nagai, H.; Narita, Y.; Ohtaki, M.; Saito, K.; Wakida, S.I. A Single-Bead Analysis on a Disk-shaped Microfluidic Device Using an Antigen-immobilized Bead. Anal. Sci. 2007, 23, 975–979. [Google Scholar] [CrossRef] [PubMed]

- Lee, B.S.; Lee, J.N.; Park, J.M.; Lee, J.G.; Kim, S.; Cho, Y.K.; Ko, C. A fully automated immunoassay from whole blood on a disc. Lab Chip 2009, 9, 1548–1555. [Google Scholar] [CrossRef] [PubMed]

- Steigert, J.; Grumann, M.; Brenner, T.; Riegger, L.; Harter, J.; Zengerle, R.; Ducree, J. Fully integrated whole blood testing by real-time absorption measurement on a centrifugal platform. Lab Chip 2006, 6, 1040–1044. [Google Scholar] [CrossRef]

- Schembri, C.T.; Ostoich, V.; Lingane, P.J.; Burd, T.L.; Buhl, S.N. Portable simultaneous multiple analyte whole-blood analyzer for point-of-care testing. Clin. Chem. 1992, 38, 1665–1670. [Google Scholar]

- Kim, N.; Dempsey, C.M.; Kuan, C.J.; Zoval, J.V.; O’Rourke, E.; Ruvkun, G.; Madou, M.J.; Sze, J.Y. Gravity force transduced by the MEC-4/MEC-10 DEG/ENaC channel modulates DAF-16/FoxO activity in Caenorhabditis elegans. Genetics 2007, 177, 835–845. [Google Scholar] [CrossRef][Green Version]

- Kim, N.; Dempsey, C.M.; Zoval, J.V.; Sze, J.Y.; Madou, M.J. Automated microfluidic compact disc (CD) cultivation system of Caenorhabditis elegans. Sens. Actuat. B-Chem. 2007, 122, 511–518. [Google Scholar] [CrossRef]

- LaCroix-Fralish, A.; Clare, J.; Skinner, C.D.; Salin, E.D. A centrifugal microanalysis system for the determination of nitrite and hexavalent chromium. Talanta 2009, 80, 670–675. [Google Scholar] [CrossRef]

- Duford, D.A.; Xi, Y.; Salin, E.D. Enzyme Inhibition-Based Determination of Pesticide Residues in Vegetable and Soil in Centrifugal Microfluidic Devices. Anal. Chem. 2013, 85, 7834–7841. [Google Scholar] [CrossRef]

- Czugala, M.; Gorkin III, R.; Phelan, T.; Gaughran, J.; Curto, V.F.; Ducrée, J.; Diamond, D.; Benito-Lopez, F. Optical sensing system based on wireless paired emitter detector diode device and ionogels for lab-on-a-disc water quality analysis. Lab Chip 2012, 12, 5069. [Google Scholar] [CrossRef] [PubMed]

- Kinahan, D.J.; Kearney, S.M.; Kilcawley, N.A.; Early, P.L.; Glynn, M.T.; Ducrée, J. Density-Gradient Mediated Band Extraction of Leukocytes from Whole Blood Using Centrifugo-Pneumatic Siphon Valving on Centrifugal Microfluidic Discs. PLoS ONE 2016, 11, e0155545. [Google Scholar] [CrossRef] [PubMed]

- Moen, S.T.; Hatcher, C.L.; Singh, A.K. A Centrifugal Microfluidic Platform That Separates Whole Blood Samples into Multiple Removable Fractions Due to Several Discrete but Continuous Density Gradient Sections. PLoS ONE 2016, 11, e0153137. [Google Scholar] [CrossRef] [PubMed]

- Gorkin, R.; Park, J.; Siegrist, J.; Amasia, M.; Lee, B.S.; Park, J.M.; Kim, J.; Kim, H.; Madou, M.; Cho, Y.K. Centrifugal microfluidics for biomedical applications. Lab Chip 2010, 10, 1758. [Google Scholar] [CrossRef]

- Strohmeier, O.; Keller, M.; Schwemmer, F.; Zehnle, S.; Mark, D.; von Stetten, F.; Zengerle, R.; Paust, N. Centrifugal microfluidic platforms: advanced unit operations and applications. Chem. Soc. Rev. 2015, 44, 6187–6229. [Google Scholar] [CrossRef]

- Berthier, J.; Silberzan, P. Microfluidics for Biotechnology, 2nd ed.; Artech House: Norwood, MA, USA, 2010. [Google Scholar]

| Method | Principle | Advantage | Disadvantage | Sensitivity | Time | Sample Amount |

|---|---|---|---|---|---|---|

| Kato–Katz | Feces are pressed through a mesh screen to remove large particles. A portion of sieved sample is then transferred to the hole of a template on a slide. After filling the hole, the template is removed, and the remaining sample is covered with a piece of cellophane soaked in glycerol. The glycerol clears the fecal material from around the eggs. | Easy sample preparation Cheap | Reduced sensitivity in individuals with low parasite loads | Medium | 30–60 min | 41.7 mg |

| McMaster | Sample is added to a flotation solution and placed under a slide with two gridded chambers. Eggs float towards the surface and the ones within the gridded area of the chamber are counted using a microscope. | Easy procedure Fast results | Lacks sensitivity at low eggs counts | Medium | 5–10 min | 2 g |

| FECPAK | A tube with a central pillar is filled with a stool sample dissolved in flotation solution, allowing the parasite eggs to accumulate into a single viewing area within a fluid meniscus. An image of the fecal sample is then captured. | Digitalized images Doesn’t require technical skills | Limited sensitivity of the test | Medium | 24 min | 3 g |

| FLOTAC | Technique based on centrifugal flotation of a fecal sample suspension and subsequent translation of the apical portion of the floating suspension. | Very precise and sensitive | Complexity of the application Requirement for large swinging bucket centrifuge | Very high | 12–15 min | 1 g |

| Mini-FLOTAC | Method based on flotation of the eggs. Miniaturized version of FLOTAC. Two chambers (1 mL each) are filled with fecal sample diluted in flotation solution. | Permits work with fresh and fixed fecal samples No centrifugation steps | Detection of some parasites (e.g., trematoda) requires centrifugation | High | 12 min | 2 g |

| Cornell Wisconsin | Flotation of eggs in salt solutions is enabled by centrifugation. After centrifugation in a swinging bucket rotor, the eggs are collected on the top of the centrifugal tube meniscus, and subsequently transferred onto a cover slip and counted by light microscopy. | No expensive tools needed Cheap and easy procedure | Lack of precision, owing to the absence of a grid on the coverslip Low sensitivity | Low | 20 min | 5 g |

| Lab-on-a-disk | Separation is based on a combined gravitational and centrifugal flotation, with the eggs guided to a packed monolayer, enabling quantitation and identification of subtypes of the eggs present in a single field of view | Single and high quality digitalized image Fast results | Not commercially available Cost unclear | High | 15 min | 1 g |

| Sample | Reference Method * Total # of Eggs in the Sample (EPG) | Reference Method ** Total # of Eggs after Sample Preparation Steps (EPG) | # of Eggs in the FOV of Lab-on-a-Disk Device (EPG) | Total # of Eggs Inserted in the Lab-on-a-Disk Device (EPG) | Detection (%) | ||

|---|---|---|---|---|---|---|---|

| Loss Within the Chip | Total Eggs # Inserted in Chip vs. * | Total Eggs # Inserted in Chip vs. ** | |||||

| Ascaris infected pigs | 120 | 250 | 70 | 140 | 50 | 116.67 | 56 |

| Ascaris infected pigs | 30 | 100 | 20 | 100 | 80 | 333.33 | 100 |

| Ascaris infected pigs | 30 | 10 | 0 | 10 | 100 | 33.33 | 100 |

| Trichuris infected pigs | 220 | 310 | 50 | 250 | 80 | 113.64 | 80.65 |

| Human | 50 | 115 | 5 | 30 | 83.33 | 60 | 26.09 |

| Human | 60 | 130 | 30 | 90 | 66.67 | 150 | 69.23 |

| Human | 50 | 65 | 5 | 40 | 87.50 | 66.67 | 61.54 |

| Average ± standard deviation (%) | 78 ± 16 | 125 ± 100 | 71 ± 26 | ||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sukas, S.; Van Dorst, B.; Kryj, A.; Lagatie, O.; De Malsche, W.; Stuyver, L.J. Development of a Lab-on-a-Disk Platform with Digital Imaging for Identification and Counting of Parasite Eggs in Human and Animal Stool. Micromachines 2019, 10, 852. https://doi.org/10.3390/mi10120852

Sukas S, Van Dorst B, Kryj A, Lagatie O, De Malsche W, Stuyver LJ. Development of a Lab-on-a-Disk Platform with Digital Imaging for Identification and Counting of Parasite Eggs in Human and Animal Stool. Micromachines. 2019; 10(12):852. https://doi.org/10.3390/mi10120852

Chicago/Turabian StyleSukas, Sertan, Bieke Van Dorst, Agata Kryj, Ole Lagatie, Wim De Malsche, and Lieven J. Stuyver. 2019. "Development of a Lab-on-a-Disk Platform with Digital Imaging for Identification and Counting of Parasite Eggs in Human and Animal Stool" Micromachines 10, no. 12: 852. https://doi.org/10.3390/mi10120852

APA StyleSukas, S., Van Dorst, B., Kryj, A., Lagatie, O., De Malsche, W., & Stuyver, L. J. (2019). Development of a Lab-on-a-Disk Platform with Digital Imaging for Identification and Counting of Parasite Eggs in Human and Animal Stool. Micromachines, 10(12), 852. https://doi.org/10.3390/mi10120852