High Cell Density Cultivation Process for the Expression of Botulinum Neurotoxin a Receptor Binding Domain

Abstract

1. Introduction

2. Results

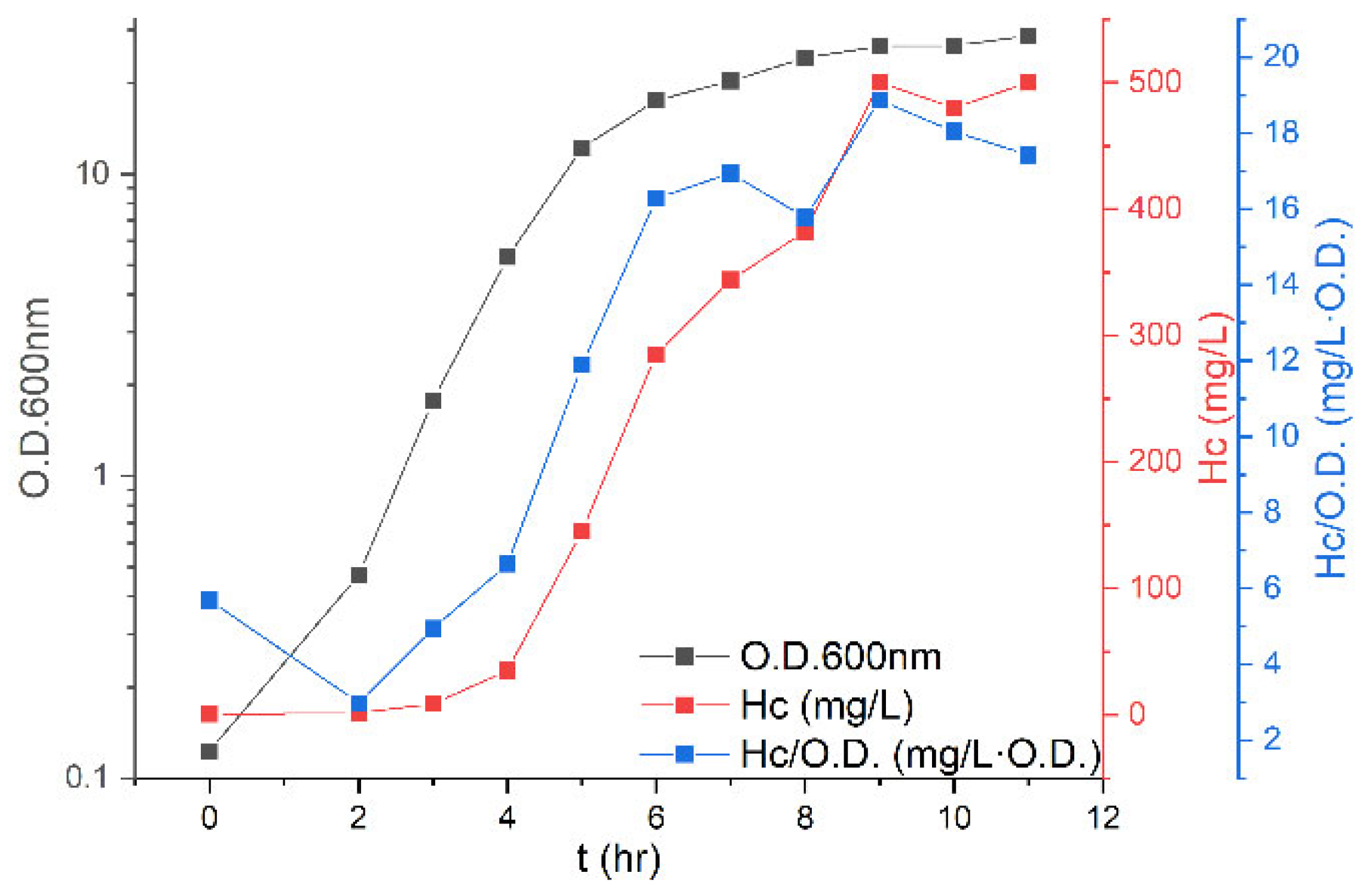

2.1. Characterization of HC Fragment Expression in Shake Flasks

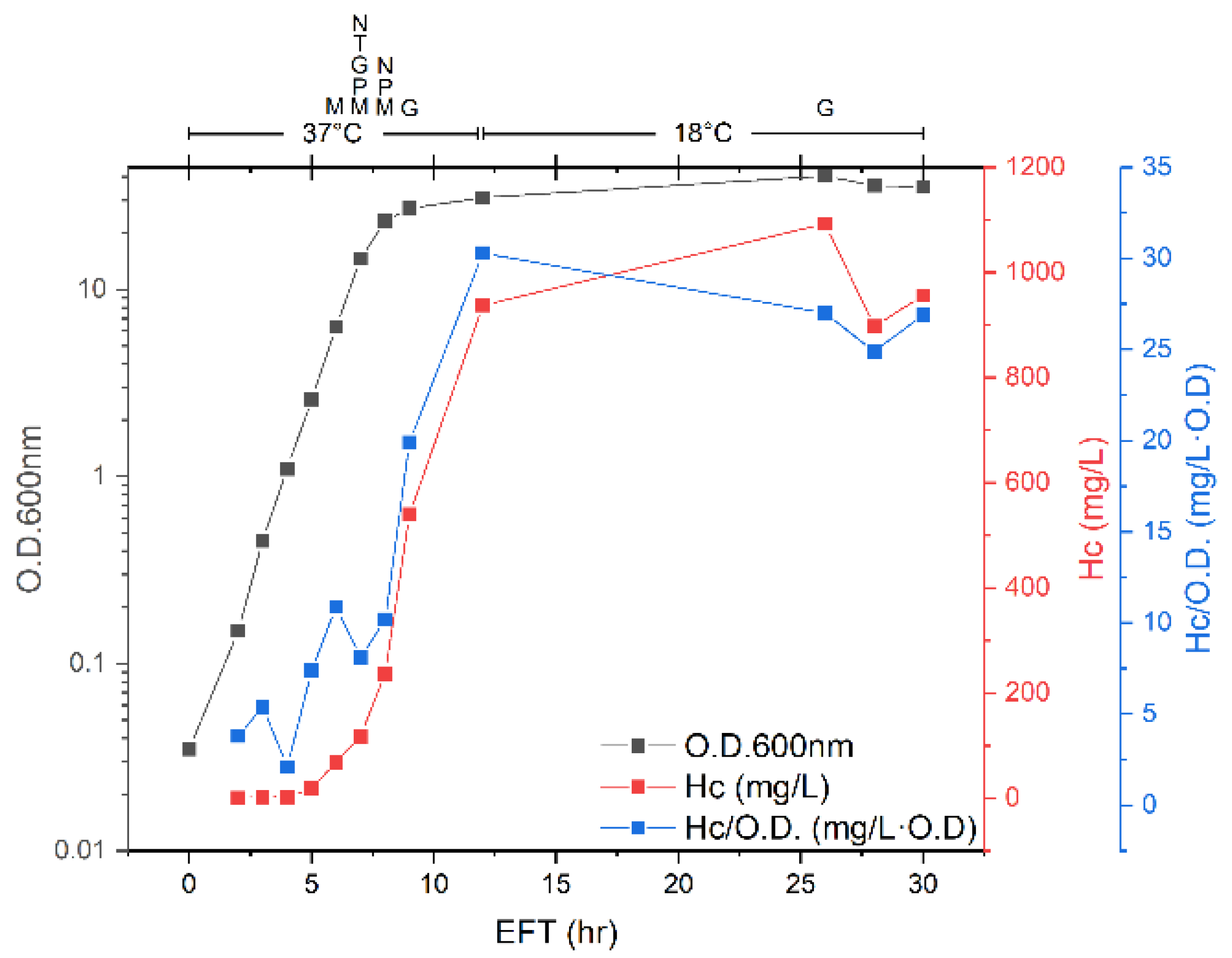

2.2. Upscaling HC Fragment Expression to a 4-L Fermenter

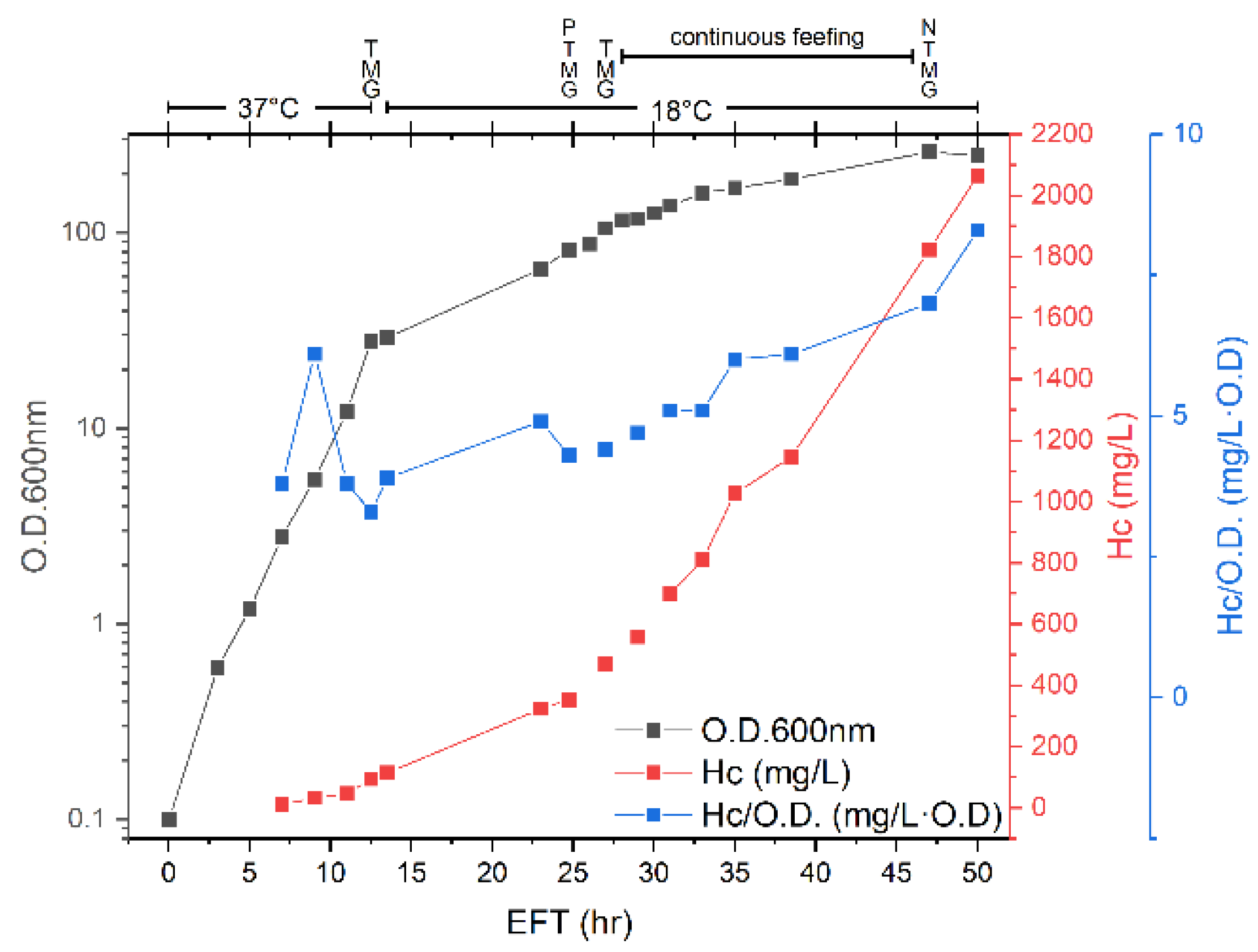

2.3. Fed-Batch Fermentation for HC Fragment Expression

2.4. High Cell Density Cultivation for HC Fragment Expression

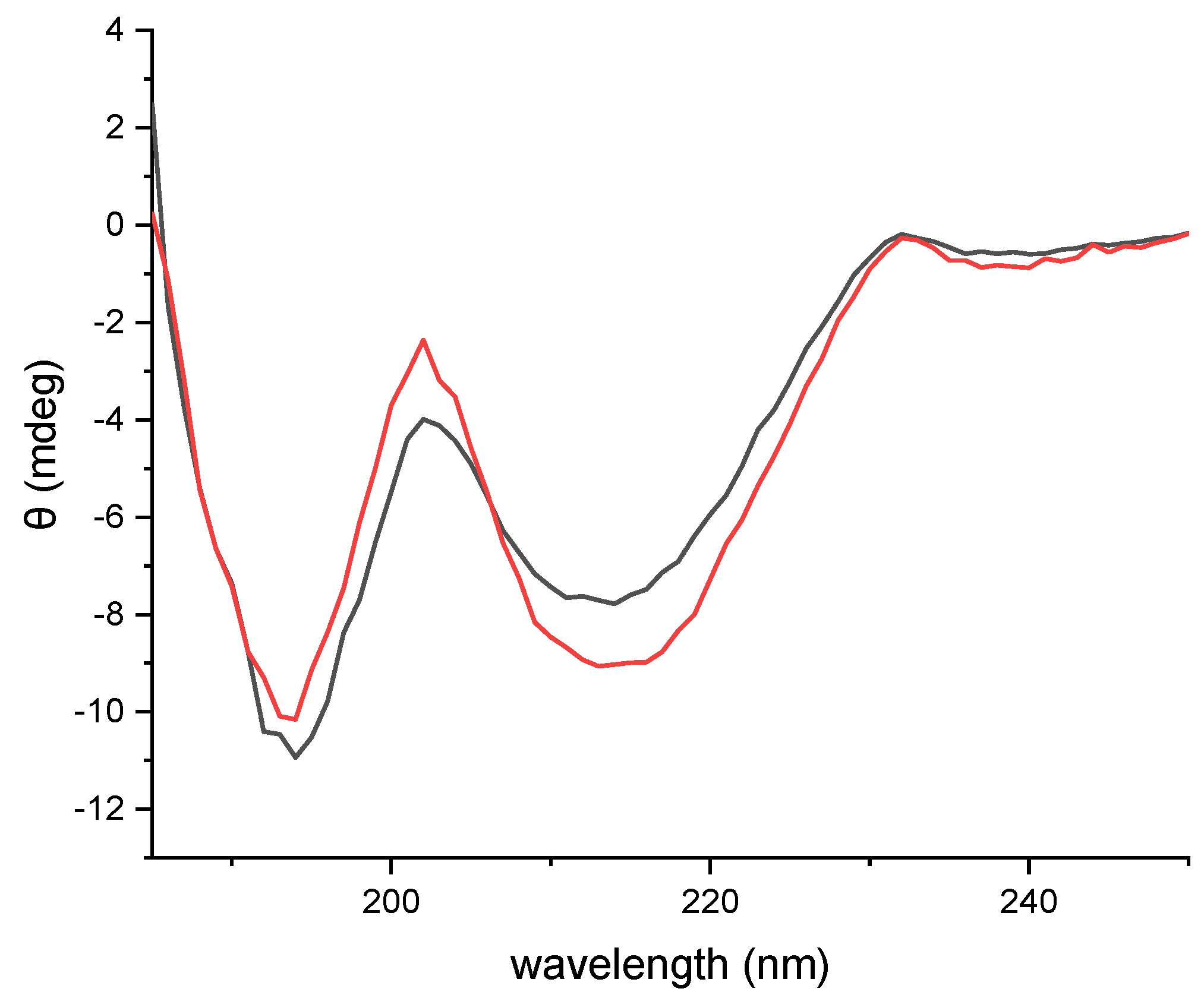

2.5. Purification and Characterization of HC Fragment Expressed in A HCDC Process

3. Discussion

4. Conclusions

5. Materials and Methods

5.1. Ethics Statement

5.2. Materials

5.3. Bacteria and Toxin

5.4. Expression of the HC Fragment Using Shake Flasks

5.5. Fermentation Processes

5.5.1. Batch-Mode Fermentation

5.5.2. Fed-Batch Fermentation

5.5.3. High Cell Density Cultivation

5.6. Purification of HC Fragment

5.7. Circular Dichroism Analysis

5.8. Mouse Vaccination and Toxin Challenge

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gill, D.M. Bacterial toxins: A table of lethal amounts. Microbiol. Rev. 1982, 46, 86–94. [Google Scholar] [CrossRef]

- Smith, L.A.; Rusnak, J.M. Botulinum neurotoxin vaccines: Past, present, and future. Crit. Rev. Immunol. 2007, 27, 303–318. [Google Scholar] [CrossRef]

- Montal, M. Botulinum neurotoxin a marvell of protein design. Annu. Rev. Biochem. 2010, 79, 591–617. [Google Scholar] [CrossRef]

- Rusnak, J.M.; Smith, L.A. Botulinum neurotoxin vaccines: Past history and recent developments. Hum. Vaccines 2009, 5, 794–805. [Google Scholar] [CrossRef]

- Arnon, S.S.; Schechter, R.; Inglesby, T.V.; Henderson, D.A.; Bartlett, J.G.; Ascher, M.S.; Eitzen, E.; Fine, A.D.; Hauer, J.; Layton, M.; et al. Botulinum toxin as a biological weapon: Medical and public health managment. J. Am. Med Assoc. 2001, 285, 1059–1070. [Google Scholar] [CrossRef]

- Smith, L.A. Development of recombinant vaccines for botulinum neurotoxin. Toxicon 1998, 36, 1539–1548. [Google Scholar] [CrossRef]

- Smith, L.A. Botulism and vaccines for its prevention. Vaccine 2009, 27, D33–D39. [Google Scholar] [CrossRef]

- Rasetti-Escargueil, C.; Popoff, M.R. Engineering Botulinum Neurotoxins for Enhanced Therapeutic Applications and Vaccine Development. Toxins 2020, 13, 1. [Google Scholar] [CrossRef]

- Shone, C.; Agostini, H.; Clancy, J.; Gu, M.; Yang, H.H.; Chu, Y.; Johnson, V.; Taal, M.; McGlashan, J.; Brehm, J.; et al. Bivalent recombinant vaccine for botulinum neurotoxin types A and B based on a polypeptide comprising their effector and translocation domains that is protective against the predominant A and B subtypes. Infect. Immun. 2009, 77, 2795–2801. [Google Scholar] [CrossRef]

- Webb, R.P.; Smith, T.J.; Smith, L.A.; Wright, P.M.; Guernieri, R.L.; Brown, J.L.; Skerry, J.C. Recombinant Botulinum Neurotoxin Hc Subunit (BoNT Hc) and Catalytically Inactive Clostridium botulinum Holoproteins (ciBoNT HPs) as Vaccine Candidates for the Prevention of Botulism. Toxins 2017, 9, 269. [Google Scholar] [CrossRef]

- Zichel, R.; Mimran, A.; Keren, A.; Barnea, A.; Steinberger-Levy, I.; Marcus, D.; Turgeman, A.; Reuveny, S. Efficacy of a potential trivalent vaccine based on Hc fragments of botulinum toxins A, B, and E produced in a cell-free expression system. Clin. Vaccine Immunol. 2010, 17, 784–792. [Google Scholar] [CrossRef] [PubMed]

- Kiyatkin, N.; Maksymowych, A.B.; Simpson, L.L. Induction of an immune response by oral administration of recombinant botulinum toxin. Infect. Immun. 1997, 65, 4586–4591. [Google Scholar] [CrossRef] [PubMed]

- Shearer, J.D.; Vassar, M.L.; Swiderski, W.; Metcalfe, K.; Niemuth, N.; Henderson, I. Botulinum neurotoxin neutralizing activity of immune globulin (IG) purified from clinical volunteers vaccinated with recombinant botulinum vaccine (rBV A/B). Vaccine 2010, 28, 7313–7318. [Google Scholar] [CrossRef] [PubMed]

- Khouri, J.M.; Motter, R.N.; Arnon, S.S. Safety and immunogenicity of investigational recombinant botulinum vaccine, rBV A/B, in volunteers with pre-existing botulinum toxoid immunity. Vaccine 2018, 36, 2041–2048. [Google Scholar] [CrossRef]

- Baldwin, M.R.; Tepp, W.H.; Przedpelski, A.; Pier, C.L.; Bradshaw, M.; Johnson, E.A.; Barbieri, J.T. Subunit vaccine against the seven serotypes of botulism. Infect. Immun. 2008, 76, 1314–1318. [Google Scholar] [CrossRef]

- Clayton, M.A.; Clayton, J.M.; Brown, D.R.; Middlebrook, J.L. Protective vaccination with a recombinant fragment of Clostridium botulinum neurotoxin serotype A expressed from a synthetic gene in Escherichia coli. Infect. Immun. 1995, 63, 2738–2742. [Google Scholar] [CrossRef]

- LaPenotiere, H.F.; Clayton, M.A.; Middlebrook, J.L. Expression of a large, nontoxic fragment of botulinum neurotoxin serotype A and its use as an immunogen. Toxicon 1995, 33, 1383–1386. [Google Scholar] [CrossRef]

- Boles, J.; West, M.; Montgomery, V.; Tammariello, R.; Pitt, M.L.M.; Gibbs, P.; Smith, L.; LeClaire, R.D. Recombinant C fragment of botulinum neurotoxin B serotype (rBoNTB (HC)) immune response and protection in the rhesus monkey. Toxicon 2006, 47, 877–884. [Google Scholar] [CrossRef]

- Byrne, M.P.; Smith, T.J.; Montgomery, V.A.; Smith, L.A. Purification, potency, and efficacy of the botulinum neurotoxin type A binding domain from Pichia pastoris as a recombinant vaccine candidate. Infect. Immun. 1998, 66, 4817–4822. [Google Scholar] [CrossRef]

- Byrne, M.P.; Titball, R.W.; Holley, J.; Smith, L.A. Fermentation, purification, and efficacy of a recombinant vaccine candidate against botulinum neurotoxin type F from Pichia pastoris. Protein Expr. Purif. 2000, 18, 327–337. [Google Scholar] [CrossRef]

- Dux, M.P.; Barent, R.; Sinha, J.; Gouthro, M.; Swanson, T.; Barthuli, A.; Inan, M.; Ross, J.T.; Smith, L.A.; Smith, T.J.; et al. Purification and scale-up of a recombinant heavy chain fragment C of botulinum neurotoxin serotype E in Pichia pastoris GS115. Protein Expr. Purif. 2006, 45, 359–367. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Dux, M.P.; Huang, J.; Barent, R.; Inan, M.; Swanson, S.T.; Sinha, J.; Ross, J.T.; Smith, L.A.; Smith, T.J.; Henderson, I.; et al. Purification of a recombinant heavy chain fragment C vaccine candidate against botulinum serotype C neurotoxin [rBoNTC(Hc)] expressed in Pichia pastoris. Protein Expr. Purif. 2011, 75, 177–185. [Google Scholar] [CrossRef] [PubMed]

- Potter, K.J.; Zhang, W.; Smith, L.A.; Meagher, M.M. Production and purification of the heavy chain fragment C of botulinum neurotoxin, serotype A, expressed in the methylotrophic yeast Pichia pastoris. Protein Expr. Purif. 2000, 19, 393–402. [Google Scholar] [CrossRef]

- Ben David, A.; Diamant, E.; Barnea, A.; Rosen, O.; Torgeman, A.; Zichel, R. The receptor binding domain of botulinum neurotoxin serotype A (BoNT/A) inhibits BoNT/A and BoNT/E intoxications in vivo. Clin. Vaccine Immunol. 2013, 20, 1266–1273. [Google Scholar] [CrossRef] [PubMed]

- Shiloach, J.; Fass, R. Growing E. coli to high cell density—A historical perspective on method development. Biotechnol. Adv. 2005, 23, 345–357. [Google Scholar] [CrossRef]

- Zha, D.; Linden, T.; Potgieter, T. Production of monoclonal antibodies in glycoengineered Pchia pastoris. In Antibody Expression and Production; Al-Rubeai, Ed.; Springer: Dordrecht, The Netherlands; Heidelberg, Germany; London, UK; New York, NY, USA, 2011; pp. 77–98. [Google Scholar]

- Wang, D.L.C.; Cooney, C.L.; Demain, A.L.; Dunnill, P.; Humphrey, A.E.; Lilley, M.D. Fermentation and Enzyme Technology; John Wiley & Sons Ltd.: New York, NY, USA, 1979. [Google Scholar]

- Ko, Y.F.; Bentley, W.E.; Weigand, W.A. The effect of cellular energetics on foreign protein production. Appl. Biochem. Biotechnol. 1995, 50, 145–159. [Google Scholar] [CrossRef] [PubMed]

- Han, K.; Lim, H.C.; Hong, J. Acetic acid formation in Escherichia coli fermentation. Biotechnol. Bioeng. 1992, 39, 663–671. [Google Scholar] [CrossRef]

- Kleman, G.L.; Strohl, W.R. Acetate metabolism by Escherichia coli in high-cell-density fermentation. Appl. Environ. Microbiol. 1994, 60, 3952–3958. [Google Scholar] [CrossRef]

- Doelle, H.W.; Ewings, K.N.; Hollywood, N.W. Regulation of glucose metabolism in bacterial systems. In Microbial Reactions; Springer: Berlin/Heidelberg, Germany, 1982; pp. 1–35. [Google Scholar]

- Korz, D.J.; Rinas, U.; Hellmuth, K.; Sanders, E.A.; Deckwer, W.D. Simple fed-batch technique for high cell density cultivation of Escherichhia coli. J. Biotechnol. 1995, 39, 59–65. [Google Scholar] [CrossRef]

- Meyer, H.-P.; Leist, C.; Fiechter, A. Acetate formation in continuous culture of Escherichia coli K12 D1 on defined and complex media. J. Biotechnol. 1984, 1, 355–358. [Google Scholar] [CrossRef]

- Grossman, T.H.; Kawasaki, E.S.; Sandhya, R.P.; Osburne, M.S. Spontaneous cAMP-dependent derepression of gene expression in stationary phase plays a role in recombinant expression instability. Gene 1998, 209, 95–103. [Google Scholar] [CrossRef]

- Tavallaei, M.; Chenal, A.; Gillet, D.; Pereira, Y.; Manich, M.; Gibert, M.; Raffestin, S.; Popoff, M.; Marvaud, J.C. Interaction between the two subdomains of the C-terminal part of the botulinum neurotoxin A is essential for the generation of protective antivodies. FEBS Letters 2004, 572, 299–306. [Google Scholar] [CrossRef]

- Baldwin, M.R.; Tepp, W.H.; Pier, C.L.; Bradshaw, M.; Ho, M.; Wilson, B.A.; Fritz, R.B.; Johnson, E.A.; Barbieri, J.T. Characterization of the antibody response to the receptor binding domain of botulinum neurotoxin serotypes A and E. Infect. Immun. 2005, 73, 6998–7005. [Google Scholar] [CrossRef][Green Version]

- Choi, J.H.; Keum, K.C.; Lee, S.Y. Production of recombinant proteins by high cell density culture of Escherichia coli. Chem. Eng. Sci. 2006, 61, 876–885. [Google Scholar] [CrossRef]

- Jeong, K.J.; Lee, S.Y. High-level production of human leptin by fed-batch cultivation of recombinant Escherichia coli and its purification. Appl. Environ. Microbiol. 1999, 65, 3027–3032. [Google Scholar] [CrossRef]

- Glazyrina, J.; Materne, E.M.; Dreher, T.; Storm, D.; Junne, S.; Adams, T.; Greller, G.; Neubauer, P. High cell density cultivation and recombinant protein production with Escherichia coli in a rocking-motion-type bioreactor. Microb. Cell Fact 2010, 9, 42. [Google Scholar] [CrossRef]

- Roos, N.; Breiner, B.; Preuss, L.; Lilie, H.; Hipp, K.; Herrmann, H.; Horn, T.; Biener, R.; Iftner, T.; Simon, C. Optimized production strategy of the major capsid protein HPV 16L1 non-assembly variant in E. coli. Protein Expr. Purif. 2020, 175, 105690. [Google Scholar] [CrossRef]

- Diamant, E.; Lachmi, B.E.; Keren, A.; Barnea, A.; Marcus, H.; Cohen, S.; Ben David, A.; Zichel, R. Evaluating the synergistic neutralizing effect of anti-botulinum oligoclonal antibody preparations. PLoS ONE 2014, 9, e87089. [Google Scholar] [CrossRef]

| Shake Flask | Batch Fermentation | Fed-Batch Fermentation | HCDC | |

|---|---|---|---|---|

| OD * | 28.7 | 11 | 40.5 | 250 |

| the volumetric yield of HC fragment (mg/L) * | 500 | 123.1 | 1093 | 2065 |

| specific yield of HC fragment (mg/L·OD) * | 17.4 | 11.2 | 27 | 8.3 |

| process duration (h) * | 11 | 11 | 26 | 50 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ben David, A.; Papir, Y.; Hazan, O.; Redelman, M.; Diamant, E.; Barnea, A.; Torgeman, A.; Zichel, R. High Cell Density Cultivation Process for the Expression of Botulinum Neurotoxin a Receptor Binding Domain. Toxins 2022, 14, 281. https://doi.org/10.3390/toxins14040281

Ben David A, Papir Y, Hazan O, Redelman M, Diamant E, Barnea A, Torgeman A, Zichel R. High Cell Density Cultivation Process for the Expression of Botulinum Neurotoxin a Receptor Binding Domain. Toxins. 2022; 14(4):281. https://doi.org/10.3390/toxins14040281

Chicago/Turabian StyleBen David, Alon, Yoel Papir, Ophir Hazan, Moses Redelman, Eran Diamant, Ada Barnea, Amram Torgeman, and Ran Zichel. 2022. "High Cell Density Cultivation Process for the Expression of Botulinum Neurotoxin a Receptor Binding Domain" Toxins 14, no. 4: 281. https://doi.org/10.3390/toxins14040281

APA StyleBen David, A., Papir, Y., Hazan, O., Redelman, M., Diamant, E., Barnea, A., Torgeman, A., & Zichel, R. (2022). High Cell Density Cultivation Process for the Expression of Botulinum Neurotoxin a Receptor Binding Domain. Toxins, 14(4), 281. https://doi.org/10.3390/toxins14040281