Effect of Atmospheric Cold Plasma Treatments on Reduction of Alternaria Toxins Content in Wheat Flour

Abstract

:1. Introduction

2. Results and Discussion

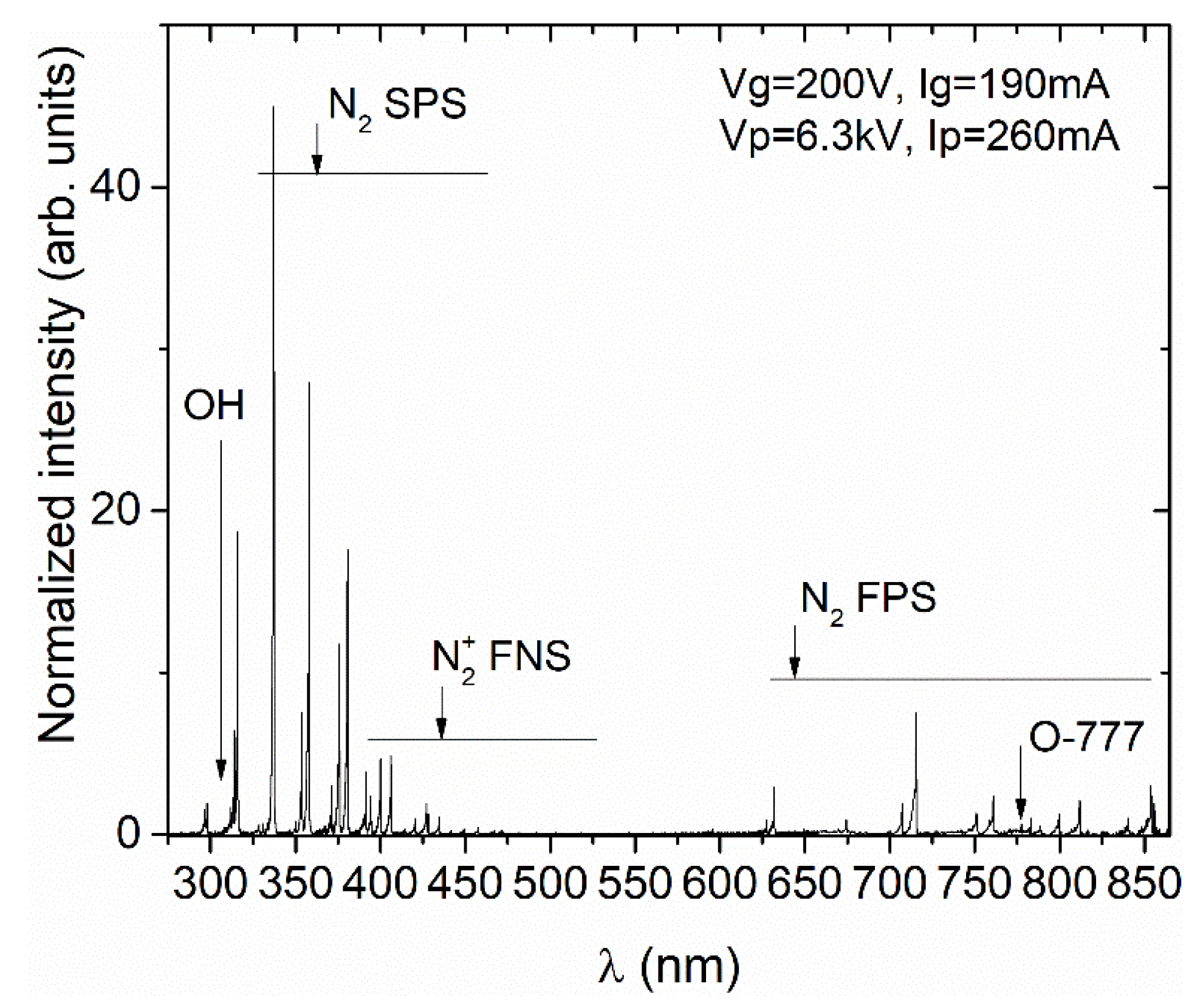

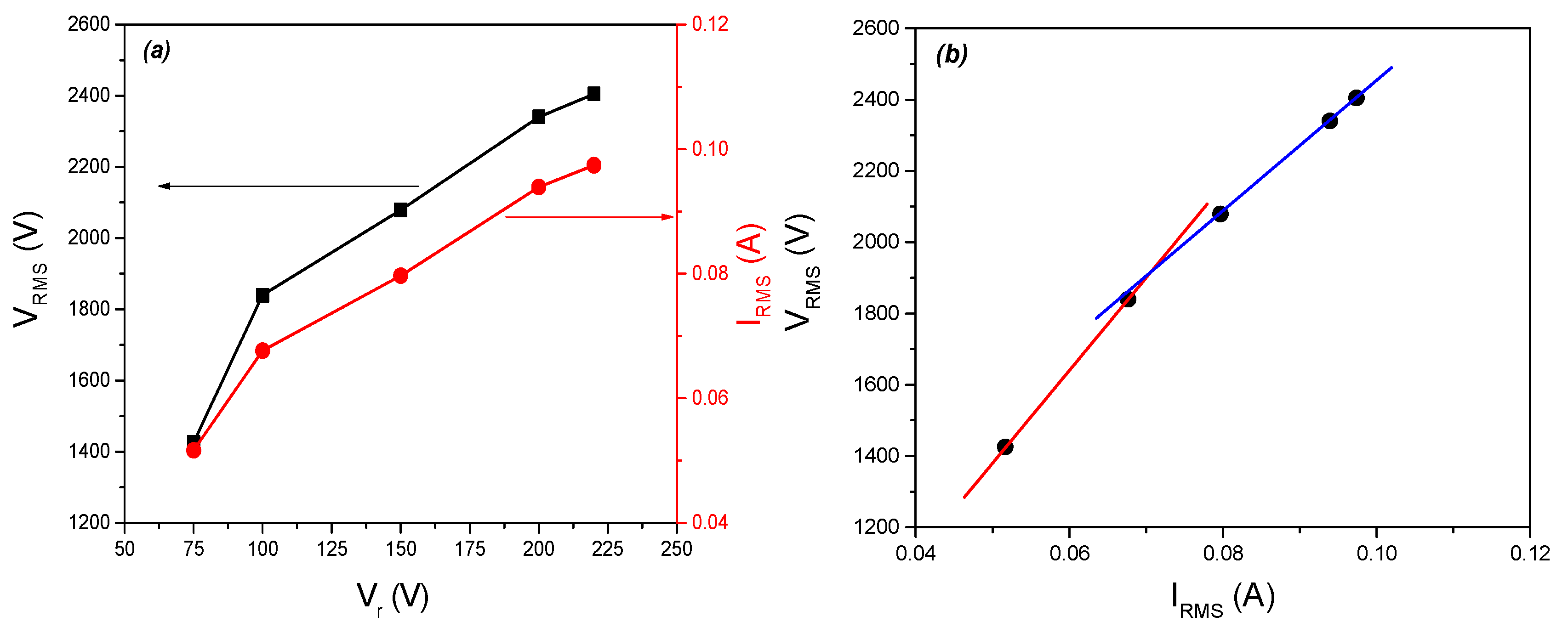

2.1. Optical Emission Spectroscopy and Electrical Characterization of Plasma Source

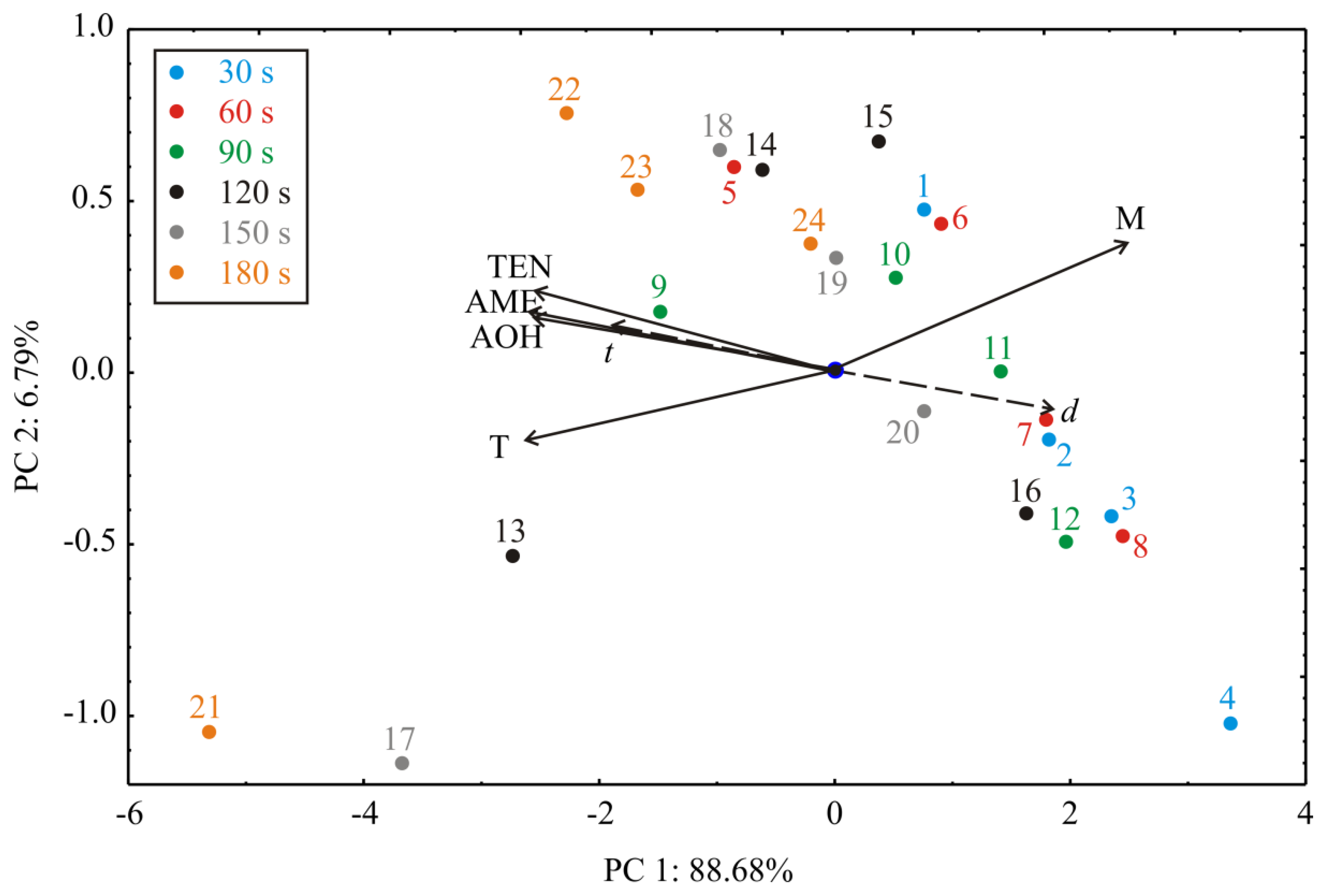

2.2. Reduction of Alternaria Toxins by Atmospheric Cold Plasma Treatments

2.3. Experimental Verification of the Mathematical Models

3. Conclusions

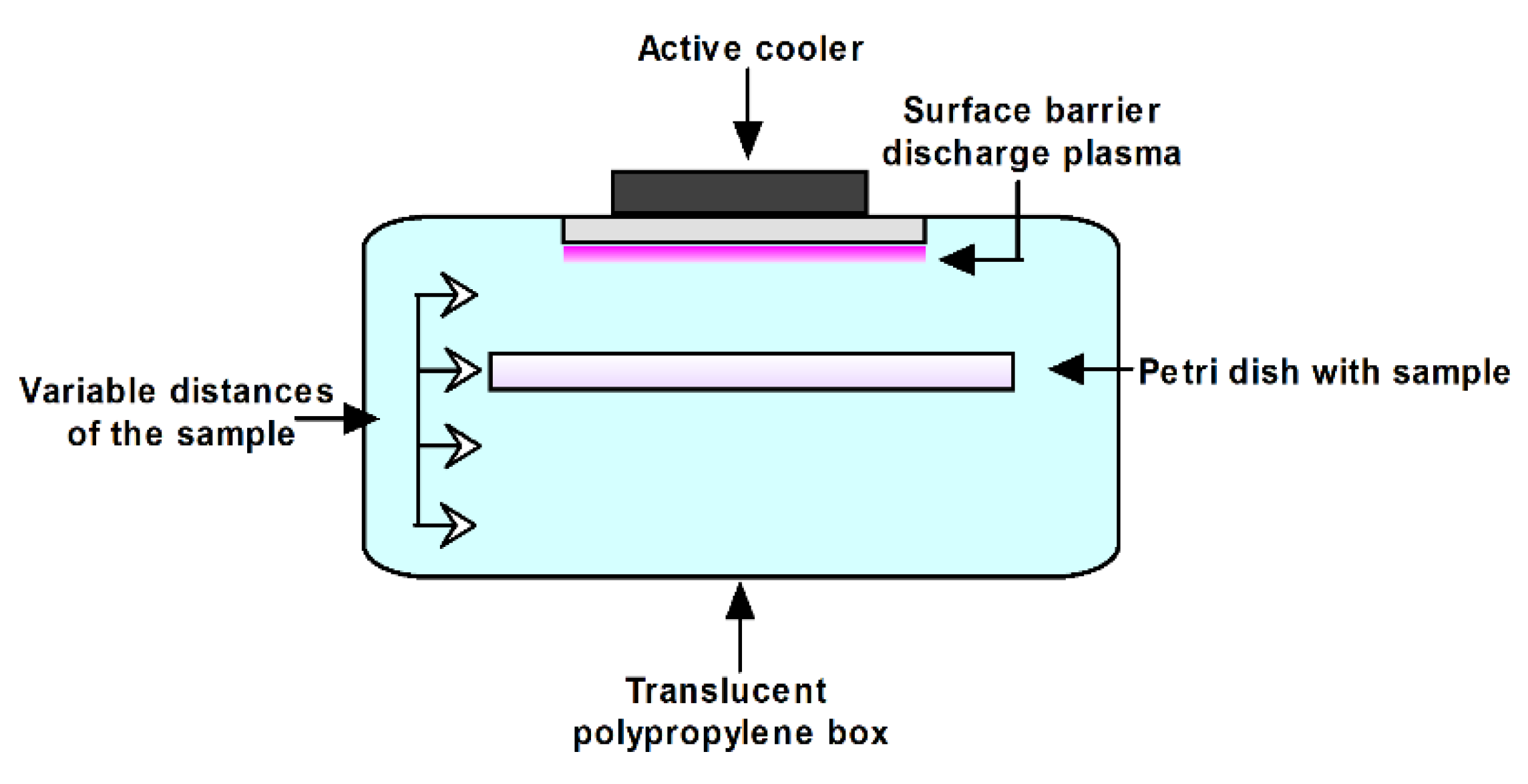

4. Materials and Methods

4.1. Material

4.2. Treating Spiked Samples with SDBD

4.3. Optical Emission Spectroscopy

4.4. Electrical Measurements

4.5. Moisture Content

4.6. Sample Preparation

4.7. Instrumental Conditions

4.8. Method Validation

4.9. Alternaria Toxins Determination

4.10. Statistical Analysis

4.10.1. SOP Models

4.10.2. The Accuracy of the Models

4.10.3. Standard Score Calculation

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- FAOSTAT. Available online: http://fenix.fao.org/faostat/internal/en/#data/QC/ (accessed on 19 June 2019).

- Grain Production Worldwide by Type, 2018/19|Statistic. Available online: https://www.statista.com/statistics/263977/world-grain-production-by-type/ (accessed on 19 June 2019).

- Doolotkeldieva, T.D. Microbiological Control of Flour-Manufacture: Dissemination of Mycotoxins Producing Fungi in Cereal Products. Microbiol. Insights 2010, 3, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Pinto, E.V.F.; Patriarca, A. Mycotoxigenic Fungi. Mycotoxigenic Fungi: Methods and Protocols 2017, 13–32. [Google Scholar]

- EFSA Panel on Contaminants in the Food Chain (CONTAM). Scientific opinion on the risks for animal and public health related to the presence of Alternaria toxins in feed and food. EFSA J. 2011, 9, 2407–2504. [Google Scholar]

- EFSA (European Food Safety Authority); Arcella, D.; Eskola, M.; Gómez Ruiz, J.A. Scientific report on the dietary exposure assessment to Alternaria toxins in the European population. EFSA J. 2016, 14, 4654. [Google Scholar]

- Walravens, J.; Mikula, H.; Rychlik, M.; Asam, S.; Ediage, E.N.; Di Mavungu, J.D.; Van Landschoot, A.; Vanhaecke, L.; De Saeger, S. Development and validation of an ultra-high-performance liquid chromatography tandem mass spectrometric method for the simultaneous determination of free and conjugated Alternaria toxins in cereal-based foodstuffs. J. Chromatogr. A 2014, 1372, 91–101. [Google Scholar] [CrossRef]

- Janić Hajnal, E.; Orčić, D.; Torbica, A.; Kos, J.; Mastilović, J.; Škrinjar, M. Alternaria toxins in wheat from the Autonomous Province of Vojvodina, Serbia: A preliminary survey. Food Addit. Contam. A 2015, 32, 361–370. [Google Scholar]

- Müller, M.E.H.; Korn, U. Alternaria mycotoxins in wheat—A 10 years survey in the Northeast of Germany. Food Control 2013, 34, 191–197. [Google Scholar] [CrossRef]

- Xu, W.; Han, X.; Li, F.; Zhang, L. Natural Occurrence of Alternaria Toxins in the 2015 Wheat from Anhui Province, China. Toxins 2016, 8, 308. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Juan, C.; Covarelli, L.; Beccari, G.; Colasante, V.; Mañes, J. Simultaneous analysis of twenty-six mycotoxins in durum wheat grain from Italy. Food Control 2016, 62, 322–329. [Google Scholar] [CrossRef]

- Egbontan, A.O.; Afolabi, C.G.; Kehinde, I.A.; Enikuomehin, O.A.; Ezekiel, C.N.; Sulyok, M.; Warth, B.; Krska, R. A mini-survey of moulds and mycotoxins in locally grown and imported wheat grains in Nigeria. Mycotoxin Res. 2017, 33, 59–64. [Google Scholar] [CrossRef]

- Scott, P.M.; Zhao, W.; Feng, S.; Lau, B.P.-Y. Alternaria toxins alternariol and alternariol monomethyl ether in grain foods in Canada. Mycotoxin Res. 2012, 28, 261–266. [Google Scholar] [CrossRef] [Green Version]

- Janić Hajnal, E.; Mastilović, J.; Bagi, F.; Orčić, D.; Budakov, D.; Kos, J.; Savić, Z. Effect of Wheat Milling Process on the Distribution of Alternaria Toxins. Toxins 2019, 11, 139. [Google Scholar] [CrossRef] [Green Version]

- Janić Hajnal, E.; Kos, J.; Orčić, D. Stability of Alternaria toxins during bread-making process. Food Feed Res. 2019, 46, 73–81. [Google Scholar] [CrossRef]

- Janić Hajnal, E.; Čolović, R.; Pezo, L.; Orčić, D.; Vukmirović, Đ.; Mastilović, J. Possibility of Alternaria toxins reduction by extrusion processing of whole wheat flour. Food Chem. 2016, 213, 784–790. [Google Scholar] [CrossRef]

- Misra, N.N. The contribution of non-thermal and advanced oxidation technologies towards dissipation of pesticide residues. Trends Food Sci. Technol. 2015, 45, 229–244. [Google Scholar] [CrossRef] [Green Version]

- Vukić, M.; Vujadinović, D.; Ivanović, M.; Gojković, V.; Grujić, R. Color change of orange and carrot juice blend treated by non-thermal atmospheric plasma. J. Food Process. Preserv. 2018, 42, e13525. [Google Scholar] [CrossRef]

- Puač, N.; Gherardi, M.; Shiratani, M. Plasma agriculture: A rapidly emerging field. Plasma Process. Polym. 2018, 15, 1700174. [Google Scholar] [CrossRef]

- Misra, N.N.; Tiwari, B.K.; Raghavarao, K.S.M.S.; Cullen, P.J. Nonthermal Plasma Inactivation of Food-Borne Pathogens. Food Eng. Rev. 2011, 3, 159–170. [Google Scholar] [CrossRef] [Green Version]

- Niemira, B.A. Cold Plasma Decontamination of Foods. Annu. Rev. Food Sci. Technol. 2012, 3, 125–142. [Google Scholar] [CrossRef]

- Kayes, M.M.; Critzer, F.J.; Kelly-Wintenberg, K.; Roth, J.R.; Montie, T.C.; Golden, D.A. Inactivation of Foodborne Pathogens Using A One Atmosphere Uniform Glow Discharge Plasma. Foodborne Pathog. Dis. 2007, 4, 50–59. [Google Scholar] [CrossRef]

- Sarangapani, C.; O’Toole, G.; Cullen, P.J.; Bourke, P. Atmospheric cold plasma dissipation efficiency of agrochemicals on blueberries. Innov. Food Sci. Emerg. 2017, 44, 235–241. [Google Scholar] [CrossRef] [Green Version]

- Sarangapani, C.; Ziuzina, D.; Behan, P.; Boehm, D.; Gilmore, B.F.; Cullen, P.J.; Bourke, P. Degradation kinetics of cold plasma-treated antibiotics and their antimicrobial activity. Sci. Rep. 2019, 9, 3955. [Google Scholar] [CrossRef] [Green Version]

- Misra, N.N.; Kaur, S.; Tiwari, B.K.; Kaur, A.; Singh, N.; Cullen, P.J. Atmospheric pressure cold plasma (ACP) treatment of wheat flour. Food Hydrocolloids 2015, 44, 115–121. [Google Scholar] [CrossRef]

- Misra, N.N.; Yadav, B.; Roopesh, M.S.; Jo, C. Cold Plasma for Effective Fungal and Mycotoxin Control in Foods: Mechanisms, Inactivation Effects, and Applications. Compr. Rev. Food Sci. Food Saf. 2019, 18, 106–120. [Google Scholar] [CrossRef] [Green Version]

- Ten Bosch, L.; Pfohl, K.; Avramidis, G.; Wieneke, S.; Viöl, W.; Karlovsky, P. Plasma-Based Degradation of Mycotoxins Produced by Fusarium, Aspergillus and Alternaria Species. Toxins 2017, 9, 97. [Google Scholar] [CrossRef] [Green Version]

- Siciliano, I.; Spadaro, D.; Prelle, A.; Vallauri, D.; Cavallero, M.; Garibaldi, A.; Gullino, M. Use of Cold Atmospheric Plasma to Detoxify Hazelnuts from Aflatoxins. Toxins 2016, 8, 125. [Google Scholar] [CrossRef]

- Hojnik, N.; Modic, M.; Tavčar-Kalcher, G.; Babič, J.; Walsh, J.L.; Cvelbar, U. Mycotoxin Decontamination Efficacy of Atmospheric Pressure Air Plasma. Toxins 2019, 11, 219. [Google Scholar] [CrossRef] [Green Version]

- Turner, M. Physics of Cold Plasma. In Cold Plasma in Food and Agriculture; Misra, N.N., Schlüter, O., Cullen, P.J., Eds.; Academic Press: San Diego, CA, USA, 2016; pp. 17–51. [Google Scholar]

- Robert, E.; Barbosa, E.; Dozias, S.; Vandamme, M.; Cachoncinlle, C.; Viladrosa, R.; Pouvesle, J.M. Experimental study of a compact nanosecond plasma gun. Plasma Process. Polym. 2009, 6, 795–802. [Google Scholar] [CrossRef]

- Maletić, D.; Puač, N.; Malović, G.; Đorđević, A.; Petrović, Z.L. The influence of electrode configuration on light emission profiles and electrical characteristics of an atmospheric-pressure plasma jet. J. Phys. D Appl. Phys. 2017, 50, 145202. [Google Scholar] [CrossRef]

- Hasan, M.I.; Walsh, J.L. Numerical investigation of the spatiotemporal distribution of chemical species in an atmospheric surface barrier-discharge. J. Appl. Phys. 2016, 119, 203302. [Google Scholar] [CrossRef] [Green Version]

- Yonemori, S.; Ono, R. Flux of OH and O radicals onto a surface by an atmospheric-pressure helium plasma jet measured by laser-induced fluorescence. J. Phys. D Appl. Phys. 2014, 47, 125401. [Google Scholar] [CrossRef]

- Graves, D.B. The emerging role of reactive oxygen and nitrogen species in redox biology and some implications for plasma applications to medicine and biology. J. Phys. D Appl. Phys. 2012, 45, 263001. [Google Scholar] [CrossRef]

- Pârvulescu, V.I.; Magureanu, M.; Lukes, P. Plasma Chemistry and Catalysis in Gases and Liquids; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2012; pp. 1–401. [Google Scholar]

- Wang, L.; Shao, H.; Luo, X.; Wang, R.; Li, Y.; Li, Y.; Luo, Y.; Chen, Z. Effect of Ozone Treatment on Deoxynivalenol and Wheat Quality. PLoS ONE 2016, 11, e0147613. [Google Scholar] [CrossRef]

- Olszewski, P.; Li, J.F.; Liu, D.X.; Walsh, J.L. Optimizing the electrical excitation of an atmospheric pressure plasma advanced oxidation process. J. Hazard. Mater. 2014, 279, 60–66. [Google Scholar] [CrossRef] [Green Version]

- Misra, N.N.; Moiseev, T.; Patil, S.; Pankaj, S.K.; Bourke, P.; Mosnier, J.P.; Keener, K.M.; Cullen, P.J. Cold Plasma in Modified Atmospheres for Post-harvest Treatment of Strawberries. Food Bioprocess Technol. 2014, 7, 3045–3054. [Google Scholar] [CrossRef]

- Park, B.J.; Takatori, K.; Sugita-Konishi, Y.; Kim, I.-H.; Lee, M.-H.; Han, D.-W.; Chung, K.-H.; Hyun, S.O.; Park, J.-C. Degradation of mycotoxins using microwave-induced argon plasma at atmospheric pressure. Surf. Coat. Technol. 2007, 201, 5733–5737. [Google Scholar] [CrossRef]

- Shi, H.; Ileleji, K.; Stroshine, R.L.; Keener, K.; Jensen, J.L. Reduction of Aflatoxin in Corn by High Voltage Atmospheric Cold Plasma. Food Bioprocess Technol. 2017, 10, 1042–1052. [Google Scholar] [CrossRef]

- Walsh, J.L.; Liu, D.X.; Iza, F.; Rong, M.Z.; Kong, M.G. Contrasting characteristics of sub-microsecond pulsed atmospheric air and atmospheric pressure helium–oxygen glow discharges. J. Phys. D Appl. Phys. 2010, 43, 032001. [Google Scholar] [CrossRef]

- Watson, D.H. Natural Toxicants in Food; Sheffield Academic Press: Sheffield, UK, 1998; p. 322. [Google Scholar]

- Moiseev, T.; Misra, N.N.; Patil, S.; Cullen, P.J.; Bourke, P.; Keener, K.M.; Mosnier, J.P. Post-discharge gas composition of a large-gap DBD in humid air by UV–Vis absorption spectroscopy. Plasma Sources Sci. Technol. 2014, 23, 065033. [Google Scholar] [CrossRef]

- Zorlugenç, B.; Zorlugenç, F.K.; Öztekin, S.; Evliya, I.B. The influence of gaseous ozone and ozonated water on microbial flora and degradation of aflatoxin B1 in dried figs. Food Chem. Toxicol. 2008, 46, 3593–3597. [Google Scholar] [CrossRef]

- De Alencar, E.R.; Faroni, L.R.; Soares Nde, F.; da Silva, W.A.; Carvalho, M.C. Efficacy of ozone as a fungicidal and detoxifying agent of aflatoxins in peanuts. J. Sci. Food Agric. 2012, 92, 899–905. [Google Scholar] [CrossRef]

- Arsenović, M.; Pezo, L.; Stanković, S.; Radojević, Z. Factor space differentiation of brick clays according to mineral content: Prediction of final brick product quality. Appl. Clay Sci. 2015, 115, 108–114. [Google Scholar] [CrossRef]

- Siegel, D.; Feist, M.; Proske, M.; Koch, M.; Nehls, I. Degradation of the Alternaria mycotoxins alternariol, alternariol monomethyl ether, and altenuene upon bread baking. J. Agric. Food Chem. 2010, 58, 9622–9630. [Google Scholar] [CrossRef]

- European Commission. Commission Regulation 2002/657/EC of 12 August 2002 implementing council directive 96/23/EC concerning the performance of analytical methods and the interpretation of results. OJEC 2002, 221, 8–36. [Google Scholar]

- STATISTICA (Data Analysis Software System), V13.3; StatSoft, Inc.: Tulsa, OK, USA, 2018.

- Box, G.E.P.; Behnken, D.W. Some New Three Level Designs for the Study of Quantitative Variables. Technometrics 1960, 2, 455–475. [Google Scholar] [CrossRef]

- Khuri, A.I.; Mukhopadhyay, S. Response surface methodology. Wiley Interdiscip. Rev. Comput. Stat. 2010, 2, 128–149. [Google Scholar] [CrossRef]

- Brlek, T.; Pezo, L.; Voća, N.; Krička, T.; Vukmirović, Đ.; Čolović, R.; Bodroža-Solarov, M. Chemometric approach for assessing the quality of olive cake pellets. Fuel Process. Technol. 2013, 116, 250–256. [Google Scholar] [CrossRef]

| Trial | Input d [mm] | t [s] | Responses AOH (%)* | AME (%) * | TEN (%) * | T (°C) | M (%) | SS |

|---|---|---|---|---|---|---|---|---|

| 1 | 6 | 30 | 21.5 | 44.6 | 30.6 | 29.0 | 14.1 | 0.420 |

| 2 | 21 | 30 | 17.0 | 37.0 | 14.4 | 27.0 | 14.1 | 0.327 |

| 3 | 36 | 30 | 8.9 | 32.2 | 13.7 | 25.7 | 14.1 | 0.287 |

| 4 | 51 | 30 | 2.4 | 22.3 | 3.6 | 24.0 | 14.1 | 0.200 |

| 5 | 6 | 60 | 29.1 | 61.3 | 37.6 | 33.2 | 13.8 | 0.539 |

| 6 | 21 | 60 | 21.8 | 49.7 | 22.7 | 27.9 | 14.1 | 0.418 |

| 7 | 36 | 60 | 12.3 | 40.5 | 16.2 | 26.9 | 14.1 | 0.332 |

| 8 | 51 | 60 | 3.0 | 32.9 | 15.4 | 25.9 | 14.1 | 0.275 |

| 9 | 6 | 90 | 32.9 | 61.5 | 38.5 | 37.4 | 13.6 | 0.546 |

| 10 | 21 | 90 | 24.2 | 51.4 | 23.2 | 30.0 | 14.0 | 0.430 |

| 11 | 36 | 90 | 12.6 | 41.8 | 22.7 | 28.7 | 14.1 | 0.350 |

| 12 | 51 | 90 | 6.3 | 35.2 | 18.5 | 27.5 | 14.0 | 0.306 |

| 13 | 6 | 120 | 33.0 | 65.0 | 48.1 | 41.6 | 13.0 | 0.632 |

| 14 | 21 | 120 | 27.5 | 55.9 | 40.7 | 32.0 | 13.8 | 0.534 |

| 15 | 36 | 120 | 16.4 | 48.8 | 39.7 | 30.5 | 14.1 | 0.443 |

| 16 | 51 | 120 | 7.7 | 38.2 | 20.7 | 29.1 | 14.0 | 0.319 |

| 17 | 6 | 150 | 35.0 | 69.2 | 50.2 | 45.9 | 12.6 | 0.675 |

| 18 | 21 | 150 | 30.5 | 56.4 | 44.1 | 34.1 | 13.8 | 0.544 |

| 19 | 36 | 150 | 16.9 | 49.7 | 40 | 32.2 | 13.9 | 0.458 |

| 20 | 51 | 150 | 9.4 | 47.4 | 29.6 | 30.8 | 13.9 | 0.394 |

| 21 | 6 | 180 | 60.7 | 73.8 | 54.5 | 50.0 | 12.3 | 0.800 |

| 22 | 21 | 180 | 47.9 | 62.7 | 48.6 | 36.0 | 13.5 | 0.664 |

| 23 | 36 | 180 | 41.1 | 57.3 | 46.4 | 34.0 | 13.5 | 0.627 |

| 24 | 51 | 180 | 28.6 | 52.7 | 31.8 | 32.5 | 13.9 | 0.476 |

| Polarity | + | + | + | − | − |

| Responses | AME | TEN | T | M |

|---|---|---|---|---|

| AOH | 0.902 | 0.848 | 0.844 | −0.784 |

| AME | 0.933 | 0.901 | −0.792 | |

| TEN | 0.861 | −0.751 | ||

| T | −0.963 |

| Term | df | AOH | AME | TEN | T | M |

|---|---|---|---|---|---|---|

| d | 1 | 2296.355 * | 1942.272 * | 1573.696 * | 370.657 * | 1.704 * |

| d2 | 1 | 2.385 | 17.783 | 1.845 | 73.150 * | 0.570 * |

| t | 1 | 1892.277 * | 1675.572 * | 2626.082 * | 391.053 * | 1.808 * |

| t2 | 1 | 344.607 * | 21.607 | 6.396 | 0.142 | 0.066 |

| d × t | 1 | 26.331 | 4.890 | 2.185 | 52.807 * | 0.890 * |

| Error | 18 | 356.801 | 148.727 | 321.540 | 41.188 | 0.451 |

| r2 | 0.927 | 0.961 | 0.929 | 0.956 | 0.918 |

| Responses | χ2 | RMSE | MBE | MPE | r2 | Skew | Kurt | Mean | StDev | Var |

|---|---|---|---|---|---|---|---|---|---|---|

| AOH | 18.779 | 3.856 | 0.000 | 19.474 | 0.927 | −0.756 | −0.179 | 0.000 | 3.939 | 15.513 |

| AME | 7.828 | 2.489 | 0.000 | 4.427 | 0.961 | 0.025 | −0.072 | 0.000 | 2.543 | 6.466 |

| TEN | 16.923 | 3.660 | 0.000 | 11.794 | 0.929 | −0.038 | 0.681 | 0.000 | 3.739 | 13.980 |

| T | 2.168 | 1.310 | 0.000 | 3.427 | 0.956 | −0.579 | −0.210 | 0.000 | 1.338 | 1.791 |

| M | 0.024 | 0.137 | 0.000 | 0.816 | 0.918 | 0.515 | −0.177 | 0.000 | 0.140 | 0.020 |

| Verification Trial | d (mm) | t (s) | AOH (%) * | AME (%) * | TEN (%) * | T (°C) | M (%) |

|---|---|---|---|---|---|---|---|

| Model | 40 | 45 | 8.370 | 32.179 | 12.858 | 24.809 | 14.200 |

| Exp. | 40 | 45 | 8.498 | 31.980 | 12.754 | 24.767 | 14.249 |

| Model | 15 | 165 | 43.825 | 65.288 | 49.448 | 40.717 | 13.098 |

| Exp. | 15 | 165 | 44.408 | 64.022 | 50.256 | 40.852 | 13.027 |

| Optimal | 6 | 180 | 55.708 | 72.484 | 56.482 | 48.106 | 12.409 |

| Parameter * | Value |

|---|---|

| Variac voltage/frequency | 200 V/50 Hz |

| Applied RMS voltage/current | 2340 V/0.094 A |

| Sample weight | 10 g |

| Compartment box size (L × W × H) | 195 mm × 125 mm × 65 mm |

| Gas temperature | ≈40 °C |

| Analytes | Concentration Range (µg kg−1) | Overall Method Recovery RA (%) * | Sample Preparation Recovery RE (%) ** | Matrix Effect SSE (%) *** | LOD/LOQ (µg kg−1) |

|---|---|---|---|---|---|

| AOH | 2.5–100 | 90.4 | 80.4 | 112.5 | 0.75/2.5 |

| AME | 2.5–100 | 68.5 | 83.0 | 82.5 | 0.3/0.9 |

| TEN | 2.5–100 | 90.4 | 74.1 | 122.0 | 0.5/1.5 |

| Analytes | Spiking Level (µg kg−1) | Repeatability (n = 6) RSD (%) | Within-Laboratory Reproducibility (n = 3 × 6) RSDs (%) |

|---|---|---|---|

| AOH | 25 | 11.2 | 11.8 |

| 50 | 7.4 | 8.8 | |

| 100 | 6.0 | 7.7 | |

| AME | 25 | 11.0 | 11.5 |

| 50 | 7.0 | 7.2 | |

| 100 | 3.1 | 6.1 | |

| TEN | 25 | 10.1 | 11.9 |

| 50 | 5.3 | 9.8 | |

| 100 | 3.4 | 6.2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Janić Hajnal, E.; Vukić, M.; Pezo, L.; Orčić, D.; Puač, N.; Škoro, N.; Milidrag, A.; Šoronja Simović, D. Effect of Atmospheric Cold Plasma Treatments on Reduction of Alternaria Toxins Content in Wheat Flour. Toxins 2019, 11, 704. https://doi.org/10.3390/toxins11120704

Janić Hajnal E, Vukić M, Pezo L, Orčić D, Puač N, Škoro N, Milidrag A, Šoronja Simović D. Effect of Atmospheric Cold Plasma Treatments on Reduction of Alternaria Toxins Content in Wheat Flour. Toxins. 2019; 11(12):704. https://doi.org/10.3390/toxins11120704

Chicago/Turabian StyleJanić Hajnal, Elizabet, Milan Vukić, Lato Pezo, Dejan Orčić, Nevena Puač, Nikola Škoro, Ardea Milidrag, and Dragana Šoronja Simović. 2019. "Effect of Atmospheric Cold Plasma Treatments on Reduction of Alternaria Toxins Content in Wheat Flour" Toxins 11, no. 12: 704. https://doi.org/10.3390/toxins11120704

APA StyleJanić Hajnal, E., Vukić, M., Pezo, L., Orčić, D., Puač, N., Škoro, N., Milidrag, A., & Šoronja Simović, D. (2019). Effect of Atmospheric Cold Plasma Treatments on Reduction of Alternaria Toxins Content in Wheat Flour. Toxins, 11(12), 704. https://doi.org/10.3390/toxins11120704