Examining Heterogeneity of Food Fortification and Biofortification Business Models: Emerging Evidence for a Typology

Abstract

1. Introduction

2. Materials and Methods

Limitations

3. Results

3.1. Fortification Type, Business Model and Country Groupings

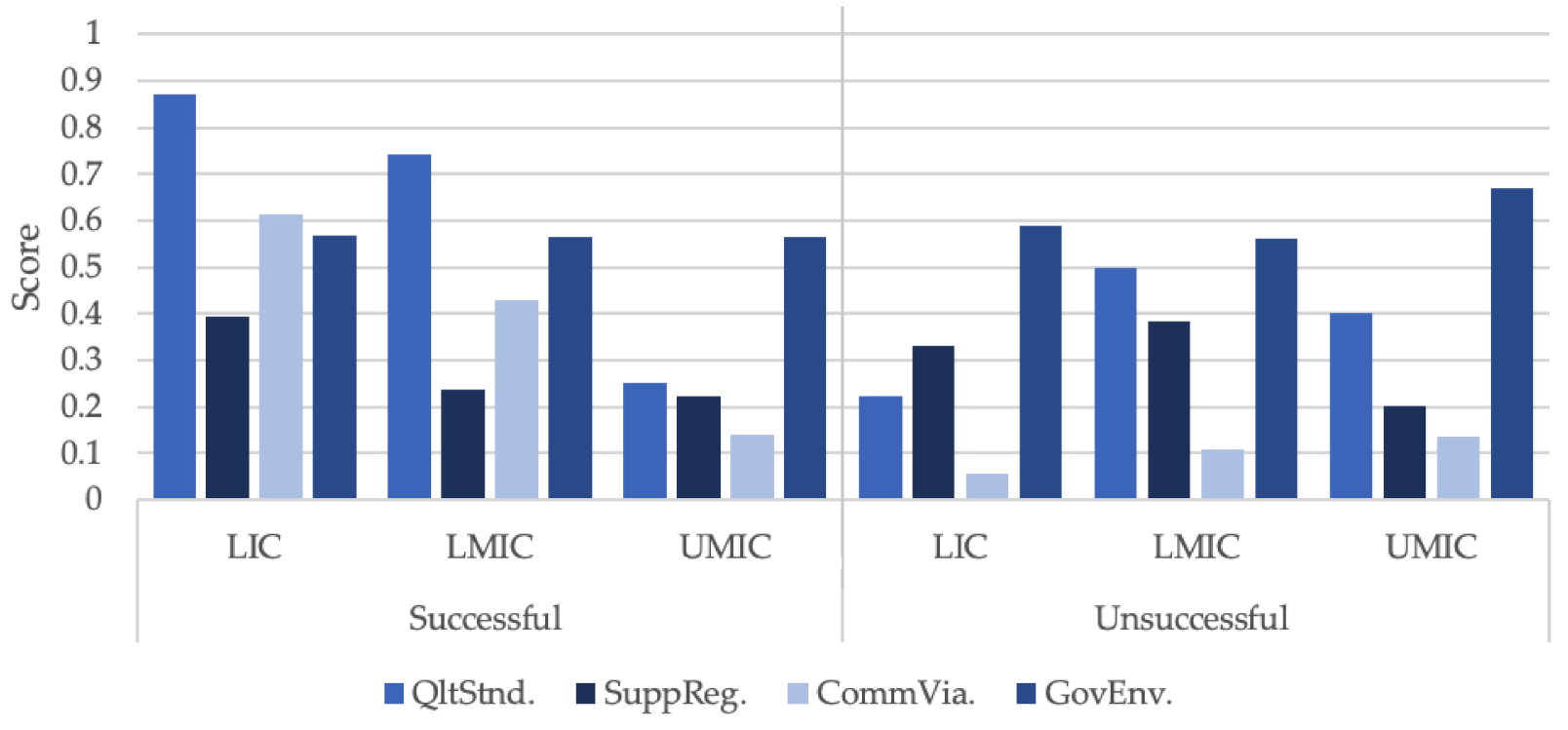

3.2. Scoring Criteria

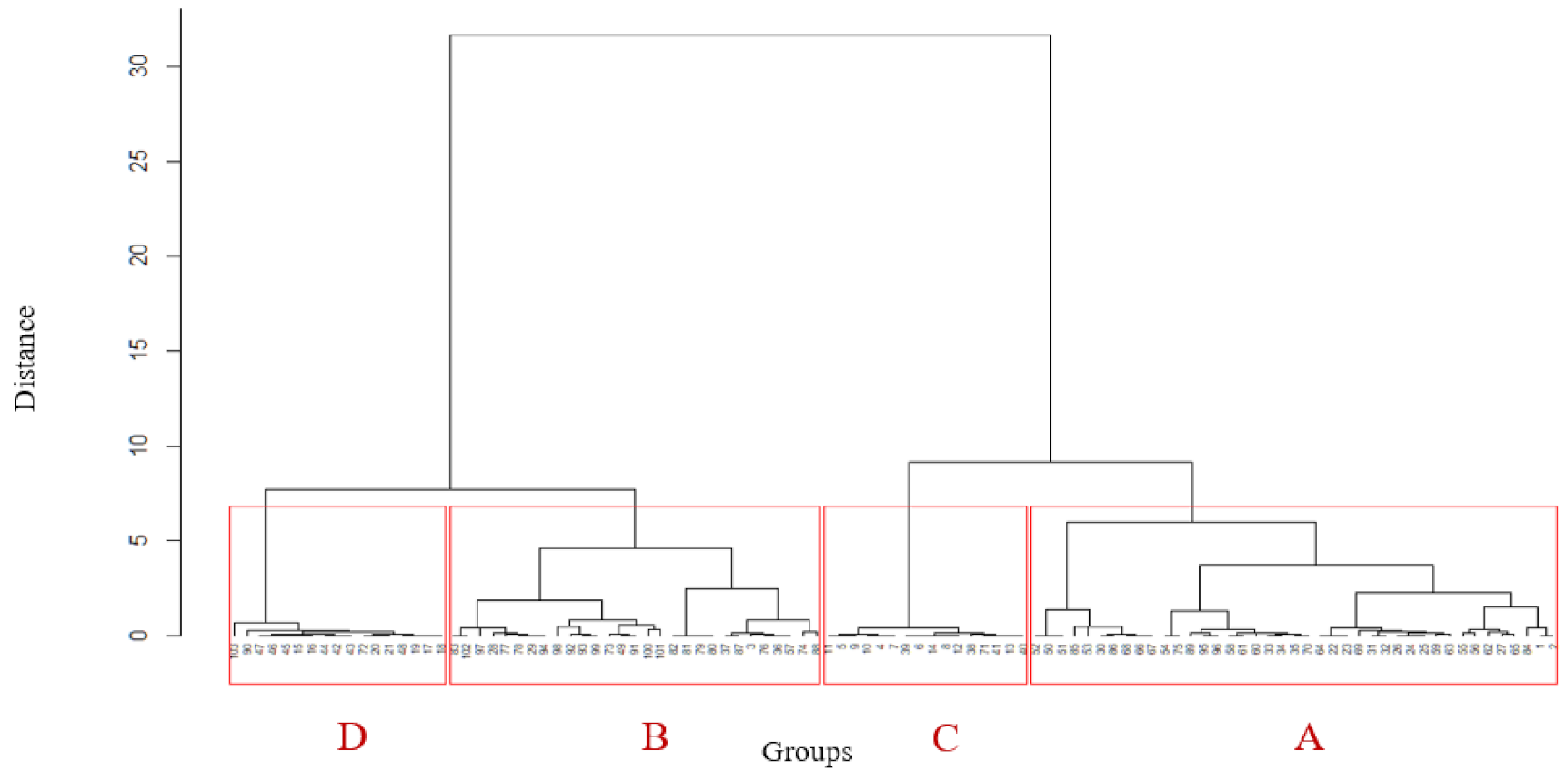

3.3. Developing the Typology

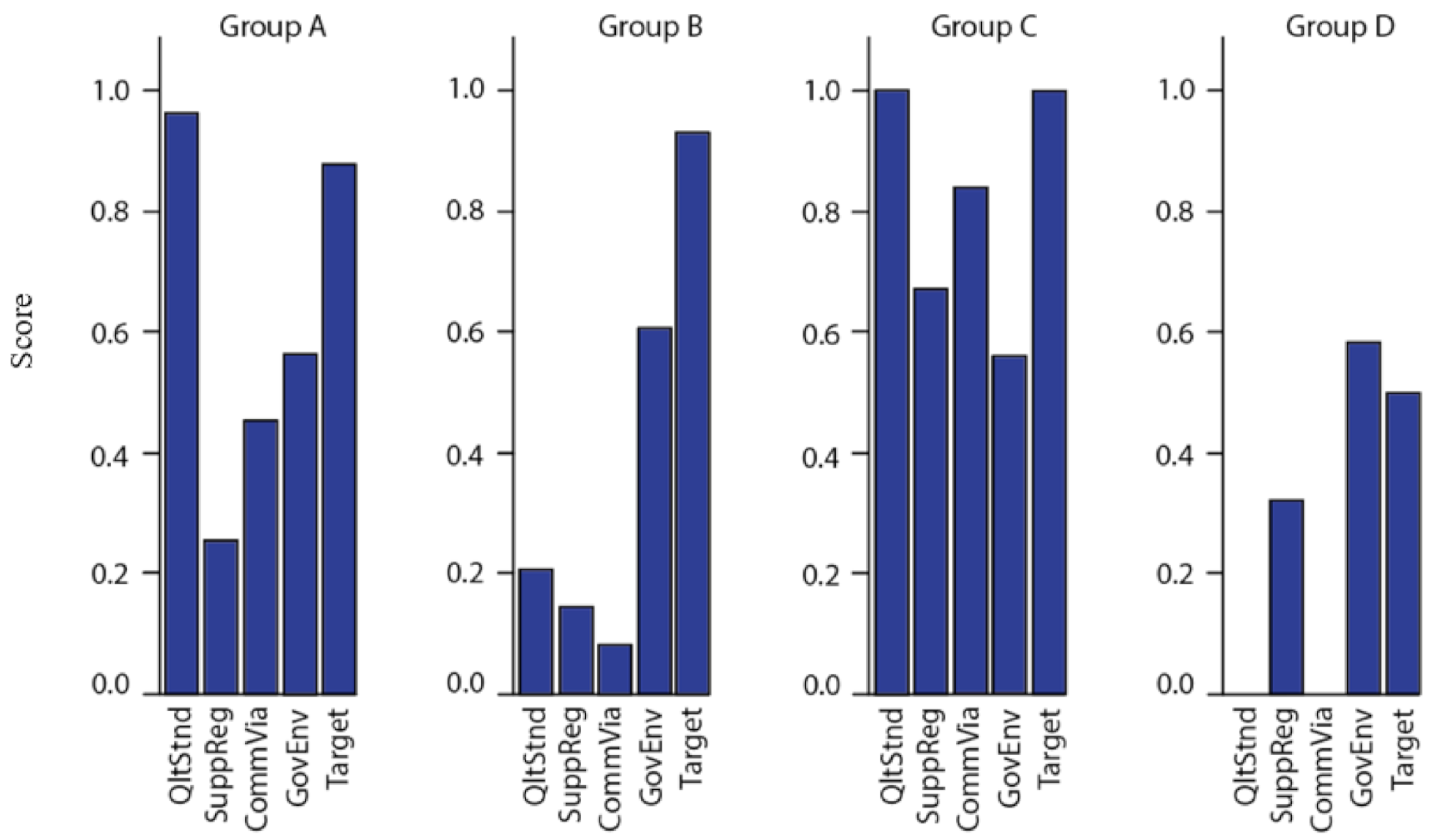

3.4. Typology

4. Discussion

5. Conclusions

- Mandatory regulation without quality infrastructure, leads to disappointing results (e.g., Group A—high quality standards identified with a good commercial environment but unregulated);

- Public-private partnership seems more successful in less structured low-income economies where value chains are highly dispersed and have many actors/actions but the vehicles were processed in a more centralized way, such as vegetable oil and sugar (e.g., Group C—high quality standards identified with good supportive regulations and commercial environment.);

- More coherent value chains find it easier to self-regulate in higher income economies and are not as impacted by scale as complex or dispersed value chains (Group B—Low quality standards identified with some supportive regulations but predominantly unregulated); and,

- Scale is not a success factor where other policies undermine fortification initiatives (particularly domestic regulation, market intervention by government and absence of quality infrastructure). i.e., Group D—(low supportive regulations with a high rate of unsuccessful programmes).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| No. | Reference | Used in Stage 3 | Referenced in the Typology |

|---|---|---|---|

| 1 | Aaron, G.J., et al., Assessing Program Coverage of Two Approaches to Distributing a Complementary Feeding Supplement to Infants and Young Children in Ghana. PLoS One, 2016. 11(10): p. e0162462. | ✓ | ✓ |

| 2 | Aaron, G.J., et al., Coverage of Large-Scale Food Fortification of Edible Oil, Wheat Flour, and Maize Flour Varies Greatly by Vehicle and Country but Is Consistently Lower among the Most Vulnerable: Results from Coverage Surveys in 8 Countries. The Journal of Nutrition, 2017. 147(5): p. 984S-994S. | ✓ | ✓ |

| 3 | Assey, V.D., et al., Improved salt iodation methods for small-scale salt producers in low-resource settings in Tanzania. 2009. 9(1): p. 187. | ✓ | ✓ |

| 4 | Baltussen, R., C. Knai, and M. Sharan, Iron fortification and iron supplementation are cost-effective interventions to reduce iron deficiency in four subregions of the world. The Journal of nutrition, 2004. 134(10): p. 2678–2684. | ✓ | X |

| 5 | Beinner, M.A., et al., Iron-Fortified Rice Is As Efficacious As Supplemental Iron Drops in Infants and Young Children. The Journal of Nutrition, 2010. 140(1): p. 49–53. | ✓ | ✓ |

| 6 | Bouis, H.E. and A. Saltzman, Improving nutrition through biofortification: A review of evidence from HarvestPlus, 2003 through 2016. Global Food Security, 2017. 12: p. 49–58. | ✓ | ✓ |

| 7 | Chilimba, A.D.C., et al., Agronomic biofortification of maize with selenium (Se) in Malawi. Field Crops Research, 2012. 125: p. 118–128. | ✓ | ✓ |

| 8 | Darnton-Hill, I. and R. Nalubola, Fortification strategies to meet micronutrient needs: successes and failures. Proceedings of the Nutrition Society, 2002. 61(02): p. 231–241. | ✓ | ✓ |

| 9 | De Groote, H., et al., The effectiveness of extension strategies for increasing the adoption of biofortified crops: the case of quality protein maize in East Africa. Food Security, 2016. 8(6): p. 1101–1121. | ✓ | ✓ |

| 10 | Elhakim, N., et al., Fortifying baladi Bread in Egypt: Reaching More than 50 Million People through the Subsidy Program. 2012. 33(4 suppl3): p. S260-S271. | ✓ | ✓ |

| 11 | Fiedler, J.L. and B. Macdonald, A Strategic Approach to the Unfinished Fortification Agenda: Feasibility, Costs, and Cost-Effectiveness Analysis of Fortification Programs in 48 Countries. 2009. 30(4): p. 283–316. | ✓ | X |

| 12 | Fiedler, J.L. and C. Puett, Micronutrient program costs: Sources of variations and noncomparabilities. Food and Nutrition Bulletin, 2015. 36(1): p. 43–56. | ✓ | X |

| 13 | Fiedler, J.L., et al., Maize flour fortification in Africa: markets, feasibility, coverage, and costs. Annals of the New York Academy of Sciences, 2014. 1312(1): p. 26–39. | ✓ | X |

| 14 | Forsman, C., et al., Rice fortification: A comparative analysis in mandated settings. Annals of the New York Academy of Sciences 2014. 1324(1): p. 67–81. | ✓ | X |

| 15 | Garrett, G.S., C. Manus, and A. Bleuthner, Chapter 11—The Importance of Public–Private Collaboration in Food Fortification Programs, in Food Fortification in a Globalized World, M.G.V. Mannar and R.F. Hurrell, Editors. 2018, Academic Press. p. 113–120. | ✓ | ✓ |

| 16 | González, C., N. Johnson, and M. Qaim, Consumer acceptance of second-generation GM Foods: The case of biofortified cassava in the North-east of Brazil. Journal of Agricultural economics, 2009. 60(3): p. 604–624. | ✓ | ✓ |

| 17 | Greiner, T., Fortification of processed cereals should be mandatory. Lancet, 2007. 369: p. 1766–1768. | ✓ | ✓ |

| 18 | Gómez-Galera, S., et al., Critical evaluation of strategies for mineral fortification of staple food crops. Transgenic Research, 2010. 19(2): p. 165–180. | ✓ | ✓ |

| 19 | Horton, S., The Economics of Food Fortification. The Journal of Nutrition, 2006. 136(4): p. 1068–1071. | ✓ | X |

| 20 | Hotz, C., et al., Efficacy of Iron-Fortified Ultra Rice in Improving the Iron Status of Women in Mexico. 2008. 29(2): p. 140–149. | ✓ | ✓ |

| 21 | Humphrey, J. and E. Robinson, Markets for Nutrition: What Role for Business? IDS Bulletin, 2015. 46(3): p. 59–69. | ✓ | ✓ |

| 22 | Jenkins, M., et al., Factors affecting farmers’ willingness and ability to adopt and retain vitamin A-rich varieties of orange-fleshed sweet potato in Mozambique. Food Security, 2018. 10(6): p. 1501–1519. | ✓ | ✓ |

| 23 | Kaput, J., et al., Enabling nutrient security and sustainability through systems research. Genes & nutrition, 2015. 10(3): p. 12. | ✓ | X |

| 24 | Meenakshi, J., Biofortification. Best practice paper: new advice from CC08. 2009: Copenhagen Consensus Center. | ✓ | ✓ |

| 25 | Muange, E.N. and A. Oparinde, Social Network Effects on Consumer Willingness to Pay for Biofortified Crops. 2018. | ✓ | X |

| 26 | Nguyen, M., et al., A Delivery Model for Home Fortification of Complementary Foods with Micronutrient Powders: Innovation in the Context of Vietnamese Health System Strengthening. Nutrients, 2016. 8(5): p. 259. | ✓ | ✓ |

| 27 | Hunter, D., et al., Enabled or Disabled: is the environment right for Using Biodiversity to improve Nutrition? Frontiers in nutrition, 2016. 3: p. 14. | ✓ | X |

| 28 | Ogunmoyela, O.A., et al., A Critical Evaluation of Survey Results of Vitamin A and Fe Levels in the Mandatory Fortified Food Vehicles and Some Selected Processed Foods in Nigeria. 2013. 31(2): p. 52–62. | ✓ | ✓ |

| 29 | Osendarp, S.J.M., et al., Large-Scale Food Fortification and Biofortification in Low- and Middle-Income Countries: A Review of Programs, Trends, Challenges, and Evidence Gaps. Food and Nutrition Bulletin, 2018. 39(2): p. 315–331. | ✓ | ✓ |

| 30 | Smale, M., et al., The Changing Structure of the Maize Seed Industry in Zambia: Prospects for Orange Maize. 2015. 31(1): p. 132–146. | ✓ | X |

| 31 | Stein, A.J., et al., Plant breeding to control zinc deficiency in India: how cost-effective is biofortification? Public health nutrition, 2007. 10(5): p. 492–501. | ✓ | ✓ |

| 32 | Tsang, B.L., et al., Public and Private Sector Dynamics in Scaling Up Rice Fortification. Food and Nutrition Bulletin, 2016. 37(3): p. 317–328. | ✓ | ✓ |

| 33 | Vaiknoras, K., et al., Promoting rapid and sustained adoption of biofortified crops: What we learned from iron-biofortified bean delivery approaches in Rwanda. Food Policy, 2019. 83: p. 271–284. | ✓ | ✓ |

| 34 | Zimmerman, S., et al., Mandatory policy: Most successful way to maximize fortification’s effect on vitamin and mineral deficiency. Indian Journal of Community Health, 2014. 26(Supp 2): p. 369–374. | ✓ | X |

| Group | Food vehicle (Figures Represent the Total Average per Vehicle in the Group) | Fortification Type | Scale | Business Model | Country | Legislation |

|---|---|---|---|---|---|---|

| Group A | Beans 12% (n = 5) | All biofortification | All large-scale | Multi-sector 80% (n = 4) Public-led 20% (n = 1) | LIC 80% (n = 4) LMIC 20% (n = 1) | All not stated |

| Cassava 7% (n = 3) | All biofortification | Small-scale 33% (n = 1) Large-scale 67% (n = 2) | Multi sector 33% (n = 1) Not stated 33% (n = 1) Public-led 33% (n = 1) | All LMIC | All not stated | |

| Maize (All maize products including maize flour) 22% (n = 9) | Biofortification 67% (n = 6) Fortification 33% (n = 3) | All large-scale | Multi sector 67% (n = 6) Not stated 33% (n = 3) | LIC 56% (n = 5) LMIC 44% (n = 4) | Mandatory 11% (n = 1) Not stated 67% (n = 6) Voluntary 22% (n = 2) | |

| Not stated (Cases where no vehicles were referenced) 2% (n = 1) | All complementary food | All large-scale | All public-led | All LIC | All voluntary | |

| Oil 7% (n = 3) | All fortification | All large-scale | Multi sector 33% (n = 1) Not stated 33% (n = 1) Public-led 33% (n = 1) | All LMIC | Mandatory 67% (n = 2) Voluntary 33% (n = 1) | |

| Other flour including cereal 5% (n = 2) | All fortification | All large-scale | Not stated 50% (n = 1) Public-led 50% (n = 1) | All LMIC | All mandatory | |

| Pear Millet 2% (n = 1) | All biofortification | All large-scale | All multi sector | All LMIC | All not stated | |

| Powder 5% (n = 2) | All complementary food | All medium-Scale | Multi sector 50% (n = 1) Public-led 50% (n = 1) | All LMIC | All voluntary legislation | |

| Rice 7% (n = 3) | Biofortification 67% (n = 2) Fortification 33% (n = 1) | Not stated 33% (n = 1) Large-scale 67% (n = 2) | Multi sector 33% (n = 1) Not stated 67% (n = 2) | LMIC 67% (n = 2) UMIC 33% (n = 1) | Not stated 67% (n = 2) Voluntary 33% (n = 1) | |

| Salt 1% (n = 1) | All fortification | All small-scale | All multi sector partnerships | All LIC | All mandatory | |

| Sugar 5% (n = 2) | All fortification | All large-scale | Not stated 50% (n = 1) Public-led 50% (n = 1) | All LMIC | All mandatory | |

| Sweet potato 10% (n = 4) | All biofortification | All large-scale | Multi sector 50% (n = 2) Not stated 25% (n = 1) Public-Led 25% (n = 1) | All LIC | All not stated | |

| Wheat (All wheat products including wheat flour and grain) 12% (n = 5) | Biofortification 80% (n = 4) Fortification 20% (n = 1) | Not stated 20% (n = 1) Large-scale 80% (n = 4) | Multi sector 40% (n = 2) Not stated 20% (n = 1) Private 40% (n = 2) | LIC 20% (n = 1) LMIC 80% (n = 4) | Mandatory (partial) 20% (n = 1) Not stated 80% (n = 4) | |

| Group B | Beans 3% (n = 1) | All biofortification | All large-scale | All not stated | All LIC | All not stated |

| Cassava 3% (n = 1) | All biofortification | All not stated | All multi-sector | All UMIC | All not stated | |

| Maize 14% (n = 4) | Biofortification 50% (n = 2) Fortification 50% (n = 2) | Small-scale 25% (n = 1) Medium-scale 25% (n = 1) Large-scale 50% (n = 2) | All not stated | LMIC 50% (n = 2) UMIC 50% (n = 2) | Mandatory 25% (n = 1) Not stated 75% (n = 3) | |

| Margarine 3% (n = 1) | All fortification | All large scale | All not stated | All HIC | All not stated | |

| Milk 3% (n = 1) | All fortification | All not stated | All public-led | All UMIC | All mandatory | |

| Oil 3% (n = 1) | All fortification | All large scale | All not stated | All LMIC | All mandatory | |

| Rice 38% (n = 11) | Biofortification 36% (n = 4) Fortification 64% (n = 7) | Small-scale 9% (n = 1) Not stated 18% (n = 2) Large-scale 73% (n = 8) | Not stated 55% (n = 6) Private-led 46% (n = 5) | HIC 9% (n = 1) LMIC 36% (n = 4) UMIC 55% (n = 6) | Not stated 55% (n = 6) Voluntary 45% (n = 5) | |

| Sugar 17% (n = 5) | All fortification | Not stated 80% (n = 4) Large-scale 20% (n = 1) | Multi-sector 60% (n = 3) Not stated 40% (n = 2) | LMIC 60% (n = 3) UMIC 40% (n-2) | Mandatory 80% (n = 4) Voluntary 20% (n = 5) | |

| Sweet potato 10% (n = 3) | All biofortification | All large scale | All not stated | LIC 67% (n = 67%) UMIC 33% (n = 1) | All not stated | |

| Wheat 3% (n = 1) | All fortification | All not stated | All not stated | All UMIC | All mandatory | |

| Group C | Oil 81% (n = 13) | All fortification | All large-scale | All multi-sector | LIC 85% (n = 11) LMIC 15% (n = 15%) | All mandatory |

| Sugar 19% (n = 3) | All fortification | All large-scale | All multi-sector | LMIC 67% (n = 2) UMIC 33% (n = 1) | All mandatory | |

| Group D | Bread 6% (n = 1) | All fortification | All not stated | Not stated | All HIC | All not stated |

| Maize 18% (n = 3) | All fortification | All large-scale | Not stated | LIC 67% (n = 2) LMIC 33% (n = 33) | All mandatory | |

| Oil 24% (n = 4) | All fortification | All large-scale | Not stated | LIC 50% (n = 1) LMIC 50% (n = 1) | All mandatory | |

| Salt 6% (n = 1) | All fortification | All not stated | Not stated | All LMIC | All voluntary | |

| Wheat 47% (n = 8) | All fortification | All large-scale | Not stated | LIC 38% (n = 3) LMIC 50% (n = 4) UMIC 13% (n = 1) | All mandatory |

References

- Moench-Pfanner, R.; Van Ameringen, M. The Global Alliance for Improved Nutrition (GAIN): A Decade of Partnerships to Increase Access to and Affordability of Nutritious Foods for the Poor. Food Nutr. Bull. 2012, 33, S373–S380. [Google Scholar] [CrossRef] [PubMed]

- European Commission. Food Fortification Global Mapping Study 2016. Available online: https://www.gainhealth.org/sites/default/files/publications/documents/food-fortification-global-mapping-study-2016.pdf (accessed on 6 November 2020).

- Bouis, H.E.; Saltzman, A. Improving nutrition through biofortification: A review of evidence from HarvestPlus, 2003 through 2016. Glob. Food Secur. 2017, 12, 49–58. [Google Scholar] [CrossRef] [PubMed]

- Lalani, B.; Bechoff, A.; Bennett, B. Which Choice of Delivery Model(s) Works Best to Deliver Fortified Foods? Nutrients 2019, 11, 1594. [Google Scholar] [CrossRef] [PubMed]

- Lalani, B.; Ndegwa, M.; Bennett, B. Unpacking the ‘Business Model’ for Fortification Initiatives in Low- and Middle-Income Countries: Stakeholder Identified Drivers of Success and Constraints to Progress. Int. J. Environ. Res. Public Heal. 2020, 17, 8862. [Google Scholar] [CrossRef] [PubMed]

- Osendarp, S.J.M.; Martinez, H.; Garrett, G.S.; Neufeld, L.M.; De-Regil, L.M.; Vossenaar, M.; Darnton-Hill, I. Large-Scale Food Fortification and Biofortification in Low- and Middle-Income Countries: A Review of Programs, Trends, Challenges, and Evidence Gaps. Food Nutr. Bull. 2018, 39, 315–331. [Google Scholar] [CrossRef] [PubMed]

- Global Alliance for Improved Nutrition. Large-Scale Food Fortification. Available online: https://www.gainhealth.org/impact/programmes/large-scale-food-fortification (accessed on 6 November 2020).

- World Health Organization. Guidelines on Food Fortification with Micronutrients. Available online: https://www.who.int/publications/i/item/9241594012 (accessed on 6 November 2020).

- Nelson, J.; Business and Sustainable Development Commission. Partnerships for Sustainable Development: Collective Action by Business, Governments and Civil Society to Achieve Scale and Transform Markets. Available online: http://s3.amazonaws.com/aws-bsdc/PartnershipsforSD.pdf (accessed on 6 November 2020).

- Weber, M. The methodology of social sciences; Free Press: New York, NY, USA, 1949. [Google Scholar]

- Glaser, B.G.; Strauss, A. The Discovery of Grounded Theory: Strategies for Qualitative Research; Aldine Publishing: Chicago, IL, USA, 1967. [Google Scholar]

- Kluge, S. Empirically Grounded Construction Types and Typologies in Qualitative Social Research. Qual. Soc. Res. 2007, 1, 14. [Google Scholar] [CrossRef]

- Hutchison, A.J.; Johnston, L.H.; Breckon, J.D. Using QSR-NVivo to facilitate the development of a grounded theory project: An account of a worked example. Int. J. Soc. Res. Methodol. 2010, 13, 283–302. [Google Scholar] [CrossRef]

- Foundation, T.H. Index of Economic Freedom. Available online: https://www.heritage.org/index/explore (accessed on 6 November 2020).

- Bamberger, C.; Rossmeier, A.; Lechner, K.; Wu, L.; Waldmann, E.; Fischer, S.; Stark, R.G.; Altenhofer, J.; Henze, K.; Parhofer, K.G. A Walnut-Enriched Diet Affects Gut Microbiome in Healthy Caucasian Subjects: A Randomized, Controlled Trial. Nutrients 2018, 10, 244. [Google Scholar] [CrossRef]

- Domínguez-Yescas, R.; Vázquez-García, J.A.; Muñiz-Castro, M.Á.; Hernández-Vera, G.; Salcedo-Pérez, E.; Rodríguez-Pérez, C.; Gallardo-Yobal, S.I. Small-Scale Environmental Drivers of Plant Community Structure and Diversity in Neotropical Montane Cloud Forests Harboring Threatened Magnolia dealbata in Southern Mexico. Diversity 2020, 12, 444. [Google Scholar] [CrossRef]

- Legendre, P.; Legendre, L. Numerical Ecology; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Ng’Endo, M.; Bhagwat, S.; Keding, G.B. Contribution of Nutrient Diversity and Food Perceptions to Food and Nutrition Security Among Smallholder Farming Households in Western Kenya: A Case Study. Food Nutr. Bull. 2018, 39, 86–106. [Google Scholar] [CrossRef]

- Plaza-Díaz, J.; Molina-Montes, E.; Soto-Méndez, M.J.; Madrigal, C.; Hernández-Ruiz, Á.; Valero, T.; Lara Villoslada, F.; Leis, R.; Martínez de Victoria, E.; Moreno, J.M.; et al. Clustering of Dietary Patterns and Lifestyles Among Spanish Children in the EsNuPI Study†. Nutrients 2020, 12, 2536. [Google Scholar] [CrossRef]

- Minchin, P.R. An evaluation of the relative robustness of techniques for ecological ordination. Adv. Veg. Sci. 1987, 69, 89–107. [Google Scholar] [CrossRef]

- Zhu, C.; Yu, J. Nonmetric Multidimensional Scaling Corrects for Population Structure in Association Mapping With Different Sample Types. Genetics 2009, 182, 875–888. [Google Scholar] [CrossRef]

- Nelson, A.G.; Quideau, S.A.; Frick, B.; Hucl, P.J.; Thavarajah, D.; Clapperton, M.J.; Spaner, D.M. The Soil Microbial Community and Grain Micronutrient Concentration of Historical and Modern Hard Red Spring Wheat Cultivars Grown Organically and Conventionally in the Black Soil Zone of the Canadian Prairies. Sustainability 2011, 3, 500–517. [Google Scholar] [CrossRef]

- Carrothers, J.M.; York, A.M.; Brooker, S.L.; Lackey, A.K.; Williams, E.J.; Shafii, B.; Price, W.J.; Settles, M.L.; McGuire, A.M.; McGuire, M.K. Fecal Microbial Community Structure Is Stable over Time and Related to Variation in Macronutrient and Micronutrient Intakes in Lactating Women. J. Nutr. 2015, 145, 2379–2388. [Google Scholar] [CrossRef]

- Elhakim, N.; Laillou, A.; El Nakeeb, A.; Yacoub, R.; Shehata, M. Fortifying baladi Bread in Egypt: Reaching More than 50 Million People through the Subsidy Program. Food Nutr. Bull. 2012, 33, S260–S271. [Google Scholar] [CrossRef]

- Assey, V.D.; Tylleskär, T.; Momburi, P.B.; Maganga, M.; Mlingi, N.V.; Reilly, M.; Greiner, T.; Peterson, S. Improved salt iodation methods for small-scale salt producers in low-resource settings in Tanzania. BMC Public Heal. 2009, 9, 187. [Google Scholar] [CrossRef]

- Garrett, G.S.; Manus, C.; Bleuthner, A. The Importance of Public–Private Collaboration in Food Fortification Programs. In Food Fortification in a Globalized World; Mannar, M.G.V., Hurrell, R.F., Eds.; Academic Press: Cambridge, MA, USA, 2018; pp. 113–120. [Google Scholar]

- Tsang, B.L.; Moreno, R.; Dabestani, N.; Pachón, H.; Spohrer, R.; Milani, P. Public and Private Sector Dynamics in Scaling Up Rice Fortification. Food Nutr. Bull. 2016, 37, 317–328. [Google Scholar] [CrossRef]

- Aaron, G.J.; Friesen, V.M.; Jungjohann, S.; Garrett, G.S.; Neufeld, L.M.; Myatt, M. Coverage of Large-Scale Food Fortification of Edible Oil, Wheat Flour, and Maize Flour Varies Greatly by Vehicle and Country but Is Consistently Lower among the Most Vulnerable: Results from Coverage Surveys in 8 Countries. J. Nutr. 2017, 147, 984S–994S. [Google Scholar] [CrossRef]

- Nguyen, M.; Poonawala, A.; Leyvraz, M.; Berger, J.; Schofield, D.; Nga, T.T.; Van, T.K.; Hoa, D.T.B.; Wieringa, F.T. A Delivery Model for Home Fortification of Complementary Foods with Micronutrient Powders: Innovation in the Context of Vietnamese Health System Strengthening. Nutrients 2016, 8, 259. [Google Scholar] [CrossRef]

- Vaiknoras, K.; Larochelle, C.; Birol, E.; Asare-Marfo, D.; Herrington, C. Promoting rapid and sustained adoption of biofortified crops: What we learned from iron-biofortified bean delivery approaches in Rwanda. Food Policy 2019, 83, 271–284. [Google Scholar] [CrossRef]

- Bouis, H.E.; Hotz, C.; McClafferty, B.; Meenakshi, J.V.; Pfeiffer, W.H. Biofortification: A new tool to reduce micronutrient malnutrition. Food Nutr. Bull. 2011, 32, S31–S40. [Google Scholar] [CrossRef]

- Mkambula, P.; Mbuya, M.N.N.; Rowe, L.A.; Sablah, M.; Friesen, V.M.; Chadha, M.; Osei, A.K.; Ringholz, C.; Vasta, F.C.; Gorstein, J. The Unfinished Agenda for Food Fortification in Low- and Middle-Income Countries: Quantifying Progress, Gaps and Potential Opportunities. Nutrients 2020, 12, 354. [Google Scholar] [CrossRef]

- Humphrey, J.; Robinson, E. Markets for Nutrition: What Role for Business? IDS Bull. 2015, 46, 59–69. [Google Scholar] [CrossRef]

- Jenkins, M.; Shanks, C.B.; Brouwer, R.; Houghtaling, B. Factors affecting farmers’ willingness and ability to adopt and retain vitamin A-rich varieties of orange-fleshed sweet potato in Mozambique. Food Secur. 2018, 10, 1501–1519. [Google Scholar] [CrossRef]

- Timmer, A. Iodine nutrition and universal salt iodization: A landscape analysis in 2012. IDD Newsletter 2012, 40, 5–9. [Google Scholar]

- Meenakshi, J. Biofortification. Best Practice Paper: New Advice From CC08. Available online: https://www.copenhagenconsensus.com/sites/default/files/biofortification.pdf (accessed on 6 November 2020).

- Mildon, A.; Klaas, N.; O’Leary, M.; Yiannakis, M. Can fortification be implemented in rural African communities where micronutrient deficiencies are greatest? Lessons from projects in Malawi, Tanzania, and Senegal. Food Nutr. Bull. 2015, 36, 3–13. [Google Scholar] [CrossRef]

- Darnton-Hill, I.; Nalubola, R. Fortification strategies to meet micronutrient needs: Sucesses and failures. Proc. Nutr. Soc. 2002, 61, 231–241. [Google Scholar] [CrossRef] [PubMed]

| Steps | Data | Thematic/Statistical Analysis | Results |

|---|---|---|---|

| Step 1. Literature search | Key word search found 106 articles, of which 34 were relevant for this study | ScienceDirect, Scopus, Google Scholar and Web of Science | 34 articles. (Full list can be found in Table A1) |

| Step 2. Identifying cases | The articles were loaded onto NVivo to be analysed. | Information from each article were grouped into 17 different notes with each note representing a particular set of information. See Table 2 for details | 17 nodes. See Table 2. |

| Stage 3. Building the database | Information from NVivo were used to develop a master spreadsheet. Each case logged represented one fortificant type (e.g., Iron, Zinc, Vitamin A etc.) and one method of fortification (e.g., spraying, coating etc.). | Both VLOOKUP/and Pivot Tables were used to summaries the data | 955 cases were identified from 79 countries, of which 36 types of food vehicles were used, with minerals accounting for 34% and vitamins for 28%. |

| Stage 4. Statistical analysis | List of cases reduced from 955 to 263. This included only cases that have shown either successful or unsuccessful results. Cases that were associated with the same product were then grouped to be presented as one case. Cases with no country association were also removed from the final list. This helped narrowed the list from 263 to 103 | 103 cases from 41 countries, of which 16 types of food vehicles were used, with minerals accounting for 25% and vitamins for 60%. | |

| Stage 5. developing the typology and further analysis | A set of four scoring criteria were developed using the data from Excel: CommVia, SuppReg, QltStnd and Target. A fifth criteria, GovEnv, was developed using data from The Heritage Foundation Index, Governance environment (ref) | Cluster analysis based on the scoring criteria was used to produce a dendrogram to define the groups. A non-metric multidimensional scaling (NMDS) was used to illustrate the distance between cases. A correlation test found significant correlation between CommVia and Target and between QltStnd to and Target. No correlation found between SuppReg and Target, also between GovReg and Target. | Four business model groupings identified: 1. Large-scale private, unregulated. 2. Mixed-Scale, private, unregulated. 3. Large-scale, public-private, regulated. 4. Large-scale, private, regulated. |

| Initial Dimension of Food Fortification Business (Lalani et al., 2019) | Characteristic of Dimension |

|---|---|

| (1) Fortification | Mode of fortification (fortification, biofortification or supplementation foods?) |

| (2) Fortificant | The type of fortificant used for each food vehicle e.g., vitamins or mineral. |

| (3) Food vehicle | Choice of food(s) used to for the fortification type. For instance, commodity, food product (weaning, sprinkles, bar, yoghurt etc), crop |

| (4) Technology | The type of technology (or special methods) used for the fortification process e.g., processing, spraying, coating, pre-mix etc. |

| (5) Regulation | The type of legislations found i.e., mandatory or voluntary inclusion |

| (6) Standards | Types of control mechanisms used to enforce regulations. It covers monitoring tools, quality checks and also covers issues of commitment, compliance and willingness to ensure the fortification process/output is delivered. |

| (1) Programme success | Based on the authors definition of success and/or whether the programme reached target. |

| (2) Geographical coverage | Supra-national, national, regional, district, group/cooperative |

| (3) Countries/Region | The country of operation. |

| (4) Country type | Economic status of target country e.g., high-income country (HIC), upper-middle income country (UMIC) etc. |

| (5) Firm type and size | Information on firm size, for instance, small and medium sized firm (SME) or large firm. * If this is not stated but a firm name is provided, we estimated the size based on the volume of operation, capacity and market reach. |

| (6) Business model | Types of business model e.g., public led, private led and multi-sector partnerships |

| (7) Target group | Target customers/consumers and their characteristics e.g., whole population, specific vulnerable groups, age, gender, health status etc. |

| (8) Resources | Type of recourses used/needed to deliver the fortification programme e.g., financial support for small scale firms, data/information for biofortification programmes. Other resources include distribution networks such as national healthcare systems. Technology, machinery and material can also be considered as a resource which includes milling equipment, hammermills, blending mechanism |

| (9) Economics/costs | This includes any discussion on the cost of running the programme including margins, initial capital, cost of consumption (price) and production. |

| (10) Competition | Level/type competition between firms |

| (11) Marketing efforts | Branding and communicating the value of fortification programme |

| Categories | Description |

|---|---|

| Fortificant type | Minerals: Calcium, Copper, Iodine, Iron, Selenium, Zinc Vitamins: Provitamin A, Vitamin A, Vitamin B, Vitamin C, Vitamin D, Vitamin E, Vitamin K1. |

| Food vehicle used for fortification (n = 36) | Banana, Beans, Biscuits, Bread, Cakes, Canola, Capsule, Cassava, Chickpea, Corn, Cowpea, Edible oil, Flour (Cereal, Maize, Wheat), Lentil, Maize (and other related products such Orange Maize and Maize meal), Margarine, Milk, Monosodium glutamate, Noodles, Oil, Pasta, Pastries, Pearl Millet, Potato (and Sweet potato, Powder, Pumpkin, Rice (Regular, Golden and Ultra), Salt, Sorghum, Soybeans, Sprinkles, Sugar, Tomato, Vanaspati, Wheat (and other related products such as Wheat buns and Wheat grain), Yogurt. |

| Countries (n = 79) | Afghanistan, Angola, Argentina, Australia, Bangladesh, Benin, Bolivia, Brazil, Burkina Faso, Burundi, Cambodia, Cameroon, Canada, Chad, Chile, China, Colombia, Costa Rica, Cote d’Ivoire, Democratic Republic of Congo, Denmark, Dominican Republic, Ecuador, Egypt, El Salvador, Eritrea, Ethiopia, Gambia, Ghana, Guatemala, Guinea, Guinea-Bissau, Haiti, Honduras, India, Indonesia, Ireland, Kenya, Liberia, Madagascar, Maharashtra, Malawi, Malaysia, Mali, Mexico, Morocco, Mozambique, Myanmar, Nepal, Nicaragua, Niger, Nigeria, Oman, Pakistan, Panama, Papua New Guinea, Paraguay, Peru, Philippines, Rwanda, Senegal, Sierra Leone, South Africa, Sri Lanka, Sudan, Sweden, Switzerland, Tanzania, Thailand, Togo, Turkey, Uganda, United States, Uzbekistan, Venezuela, Vietnam, Yemen, Zambia, Zimbabwe. |

| Final Index/Indicator | Scoring Objective | Categories Used from Table 2 to form Final Index/Indicators | Final Scoring Used for PCA/Scoring Explained |

|---|---|---|---|

| (1) Quality and standards (QltStnd) | To identify whether national micronutrient guidelines were stated and/or the quality of the fortified vehicle is in line with consumer expectation (based on taste and habit). | Standards identified | Score 0.5 |

| Quality identified | Score 0.5 | ||

| (2) Supportive regulations/legislations/policies (SuppReg) | To identify the types of supportive regulations found in each case. Different scores were given to mandatory and voluntary fortification cases | Regulation of business space | 0.25 if voluntary |

| 0.5 if mandatory | |||

| Government support | 0.5 if government support (e.g., subsides) provided | ||

| 0.5 if other government support provided | |||

| (3) Commercial viability (CommVia) | To identify the structure of the programme from ownership (collaboration between different sectors and firm size) and supply chain integration (i.e., vertical or horizontal integration) | Business/programme model | 0.25 if led by multiple sectors |

| 0.17 if led by either the privet or public sector | |||

| Collaboration (between different sized firms?) | 0.25 if collaborated with different size firms | ||

| Vertical integration | 0. 17 if vertical integrated | ||

| Horizontal integration | 0. 17 if horizontally integration | ||

| Integration with public systems | 0.17 if integrated with public distribution systems | ||

| (4) Target reached (Target) | Identify if the programme showed positive results e.g., high uptake in fortification products, reduce the Disability-Adjusted Life Year (DALY) fatalities, successful distribution etc. | Programme success | 1 if successful |

| 0.5 if not successful | |||

| (5) Governing Environment (GovEnv) | Information was obtained from the Index of Economic Freedom to represent case country profiles [14]. | Scores range from 0 (low) to 1 (high) | |

| Country type | n | Results |

|---|---|---|

| LIC | 36 | Biofortification (n = 16), all successful. Fortification (n = 20), 11 successful and 9 unsuccessful. |

| LMIC | 47 | Biofortification (n = 17), all successful. Complementary food (n = 3), 2 successful, and 1 unsuccessful. Fortification (n = 27), 12 successful 15 unsuccessful. |

| UMIC | 17 | Biofortification (n = 2), all successful. Fortification (n = 15), 10 successful 5 unsuccessful. |

| HIC | 3 | Biofortification (n = 1), all successful. Fortification (n = 2), 1 successful 1 unsuccessful. |

| Scale | n | Results |

|---|---|---|

| Large-scale | 83 | Biofortification (n = 29), all successful. Complementary food (n = 1), successful. Fortification (n = 53), 26 successful 27 unsuccessful. |

| Medium-scale | 2 | All Complementary food, 1 successfully and 1 unsuccessful. |

| Small-scale | 4 | Biofortification (n = 3), all successful. Fortification (n = 1), unsuccessful. |

| Not stated | 14 | Biofortification (n = 4), all successful. Fortification (n = 10), 8 successful 2 unsuccessful. |

| Ownership | n | Results for Each Programme Type |

|---|---|---|

| Multi-sector | 40 | Biofortification (n = 17), all successful. Complementary food (n = 1), all unsuccessful. Fortification (n = 22), 21 successful 1 unsuccessful. |

| Private sector | 7 | Biofortification (n = 2), all successful. Fortification (n = 5), 1 successful 4 unsuccessful. |

| Public-sector | 9 | Biofortification (n = 3), all successful. Complementary food (n = 2), all successful. Fortification (n = 4), 1 successful 3 unsuccessful. |

| Not stated | 47 | Biofortification (n = 14), all successful. Fortification (n = 33), 11 successful 22 unsuccessful. |

| Ownership | n | Results for Each Programme Type |

|---|---|---|

| Multi-sector | 40 | LIC (n = 23), 22 successful, 1 unsuccessful. LMIC (n = 14), 13 successful, 1 unsuccessful. UMIC (n = 3), all successful. |

| Private sector | 7 | LMIC (n = 2), all successful. UMIC (n = 5), 1 successful, 4 unsuccessful |

| Public-sector | 9 | LIC (n = 1), all successful. LMIC (n = 7), 4 successful, 3 unsuccessful. UMIC (n = 1), all successful. |

| Not stated | 47 | LIC (n = 12), 4 successful, 8 unsuccessful. LMIC (n = 24), 12 successful, 12 unsuccessful. UMIC (n = 8), 7 successful, 1 unsuccessful. HIC (n = 3), 2 successful, 1 unsuccessful. |

| Regulations | n | Results |

|---|---|---|

| Mandatory | 47 | ◦ All Fortification, 24 successful 23 unsuccessful. |

| Mandatory (partial) | 1 | ◦ Fortification and successful. |

| Voluntary | 13 | ◦ Complementary food (n = 3), 2 successful 1 unsuccessful. ◦ Fortification (n = 10), 4 successful 6 unsuccessful. |

| Not stated | 42 | ◦ Biofortification (n = 36), all successful. ◦ Fortification (n = 6), 5 successful, 1 unsuccessful. |

| Criteria | Mean Score | Standard Error |

|---|---|---|

| Quality and Standards (QltStnd) | 0.59 | 0.04 |

| Supportive Regulations (SuppReg) | 0.30 | 0.02 |

| Commercial Viability (CommVia) | 0.33 | 0.30 |

| Government Environment (GovEnv) | 0.58 | 0.01 |

| Target | 0.85 | 0.02 |

| Intervention Type | Example Challenge | Explaination |

|---|---|---|

| Continuous intervnetion | Egypt, bread fortification (Group A) | In [24] identified the need for continuous support (in subsidy) under the national Food Subsidy programme to ensure quality products are continually distributed to the wider population. |

| Tanzania, salt fortification (Group A) | In [25] identified the need for further support in improving testing and training necessary to achieve a homogeneous concentration of iodine in salt. | |

| Senegal and Mali oil fortification (Group C) | In [26] Identified the need for continued public-private collaboration in areas linked to budgeting and capacity building. | |

| Direct intervnetion | Columbia, Rice fortification (Group B) | In [27] identified two challenges that require direct intervention from the government (1) legislation which makes rice fortification mandatory, and (2) the need for price controls to ensure products are affordable and accessible to the wider population |

| Nigeria, Uganda and Tanzania wheat fortification (Group D) | In [28] Identified the need for direct intervention to improve the choice of fortified vehicles and programme design. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lalani, B.; Hassan, R.; Bennett, B. Examining Heterogeneity of Food Fortification and Biofortification Business Models: Emerging Evidence for a Typology. Nutrients 2021, 13, 1233. https://doi.org/10.3390/nu13041233

Lalani B, Hassan R, Bennett B. Examining Heterogeneity of Food Fortification and Biofortification Business Models: Emerging Evidence for a Typology. Nutrients. 2021; 13(4):1233. https://doi.org/10.3390/nu13041233

Chicago/Turabian StyleLalani, Baqir, Rania Hassan, and Ben Bennett. 2021. "Examining Heterogeneity of Food Fortification and Biofortification Business Models: Emerging Evidence for a Typology" Nutrients 13, no. 4: 1233. https://doi.org/10.3390/nu13041233

APA StyleLalani, B., Hassan, R., & Bennett, B. (2021). Examining Heterogeneity of Food Fortification and Biofortification Business Models: Emerging Evidence for a Typology. Nutrients, 13(4), 1233. https://doi.org/10.3390/nu13041233