Research Progress of SHM System for Super High-Rise Buildings Based on Wireless Sensor Network and Cloud Platform

Abstract

1. Introduction

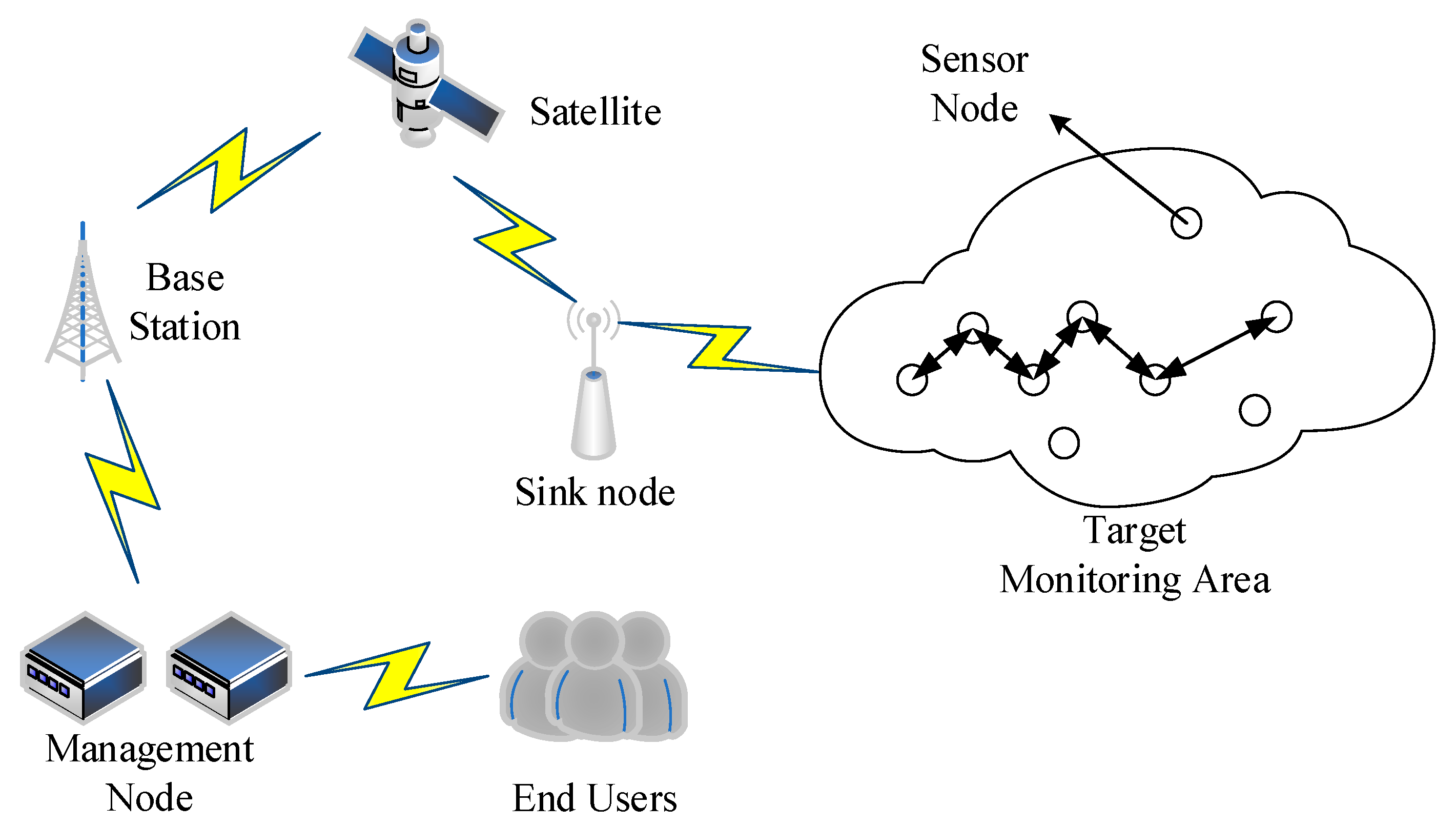

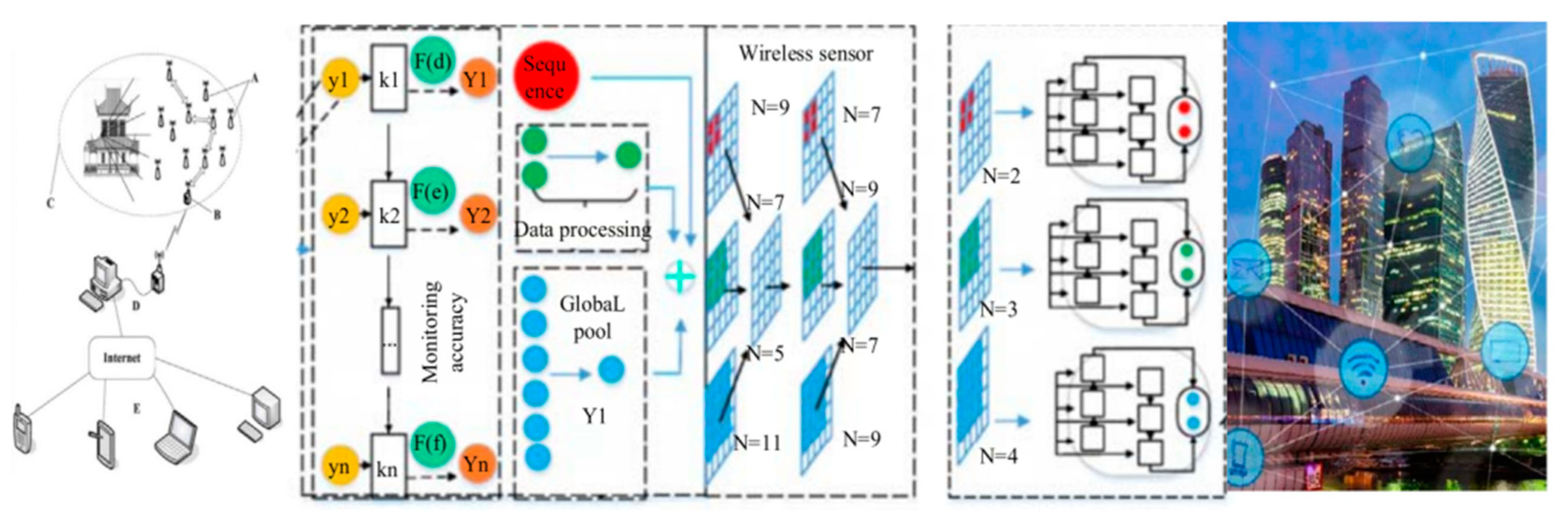

2. Wireless Sensor Network

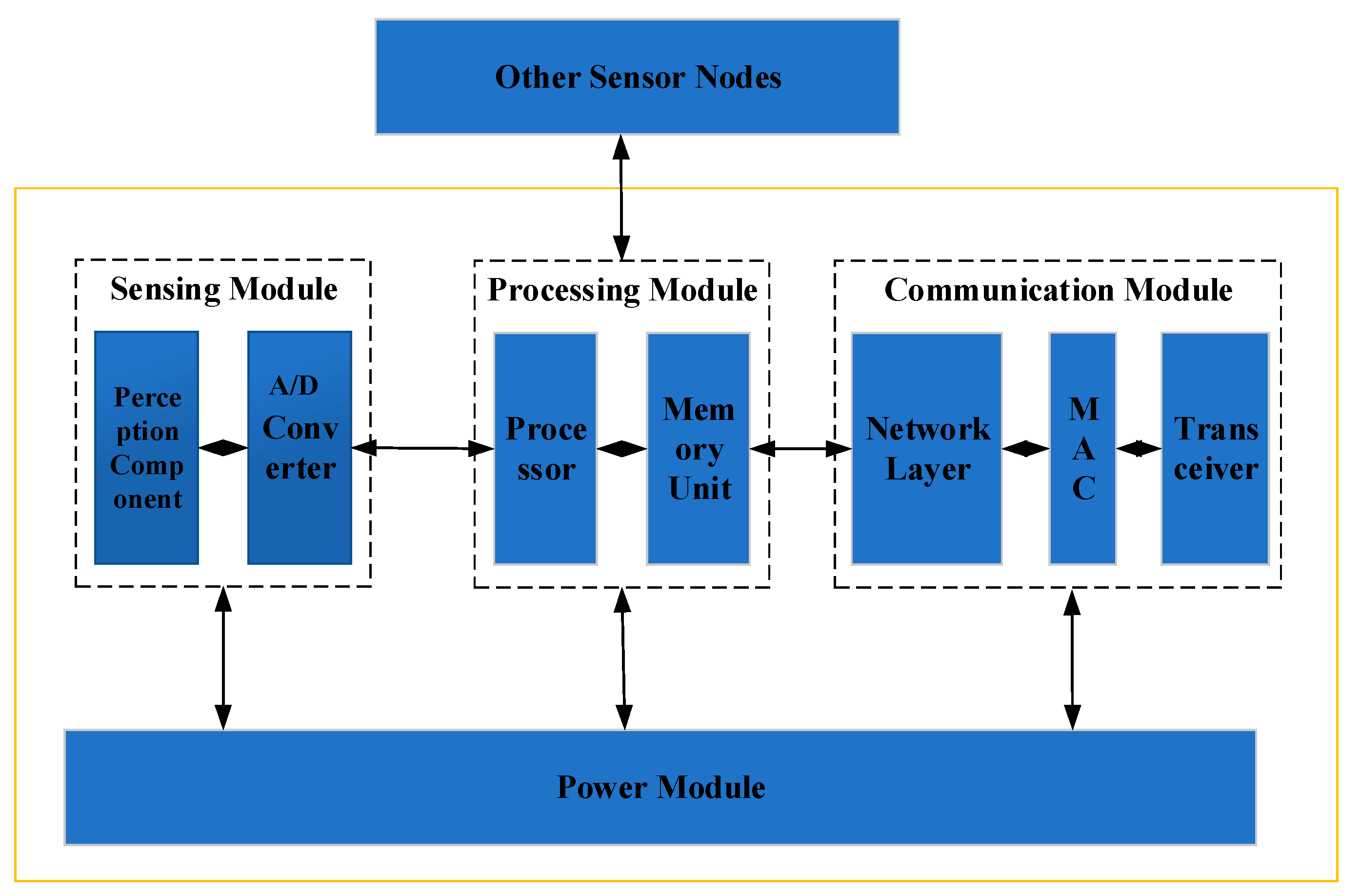

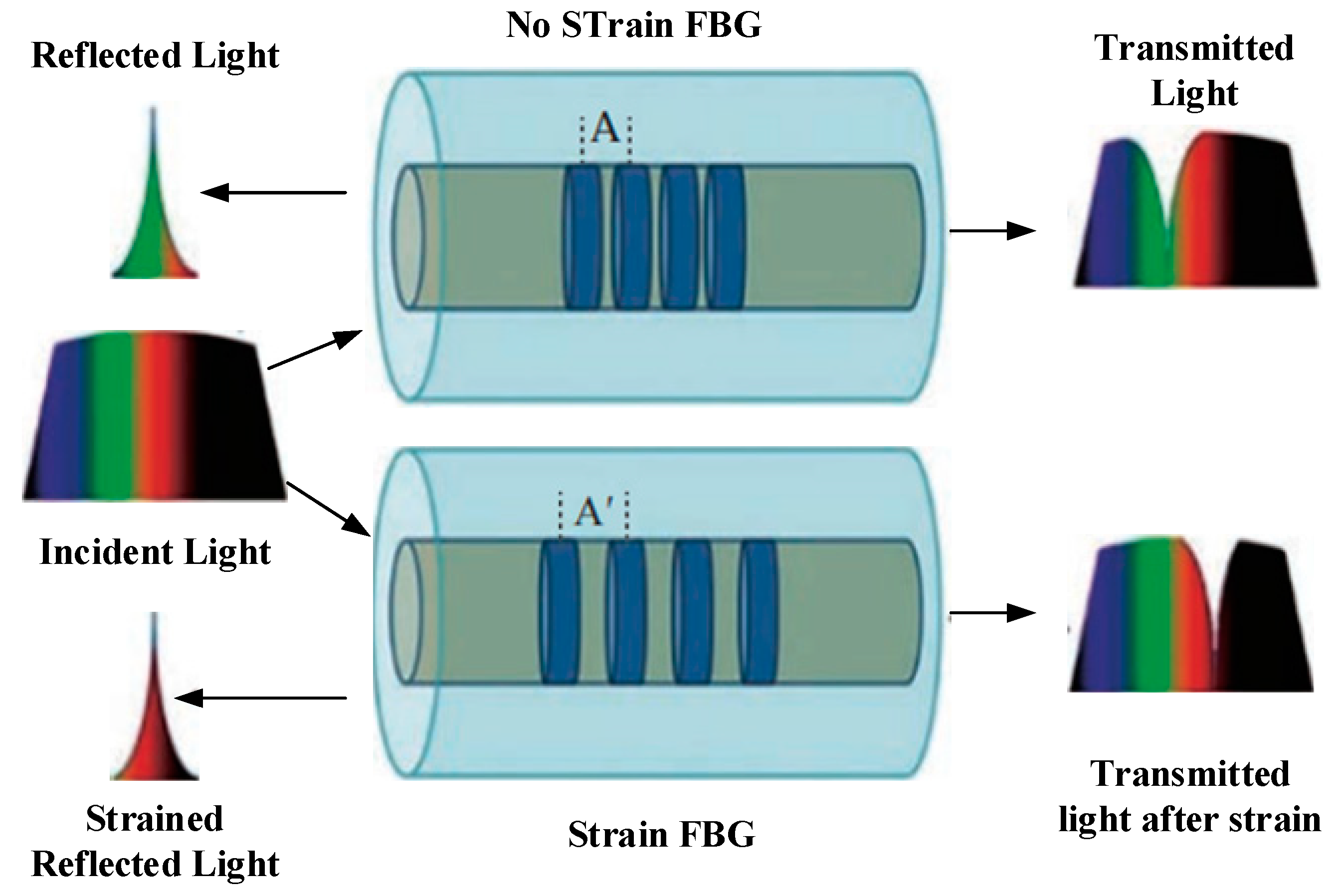

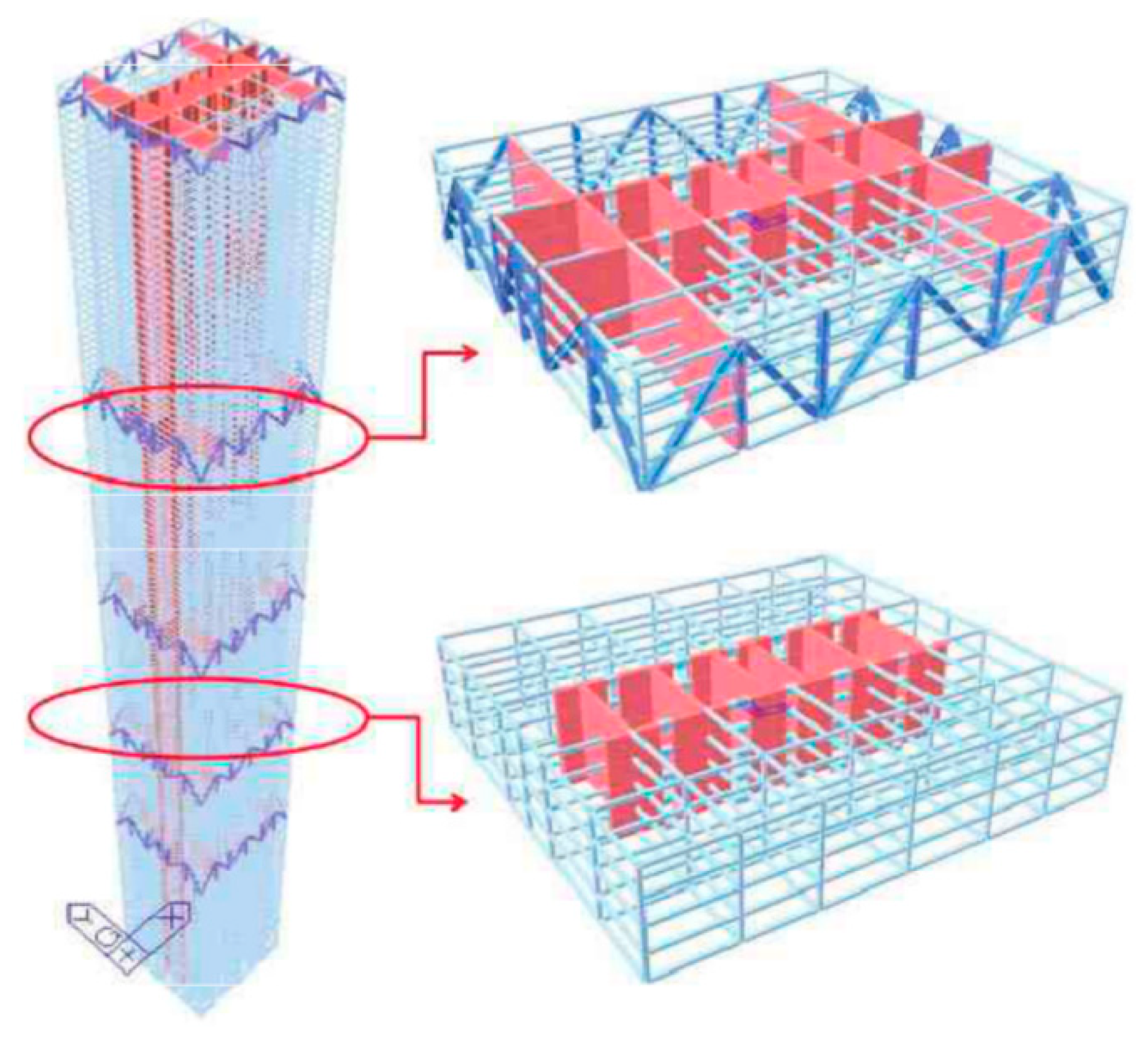

2.1. Sensing Subsystem

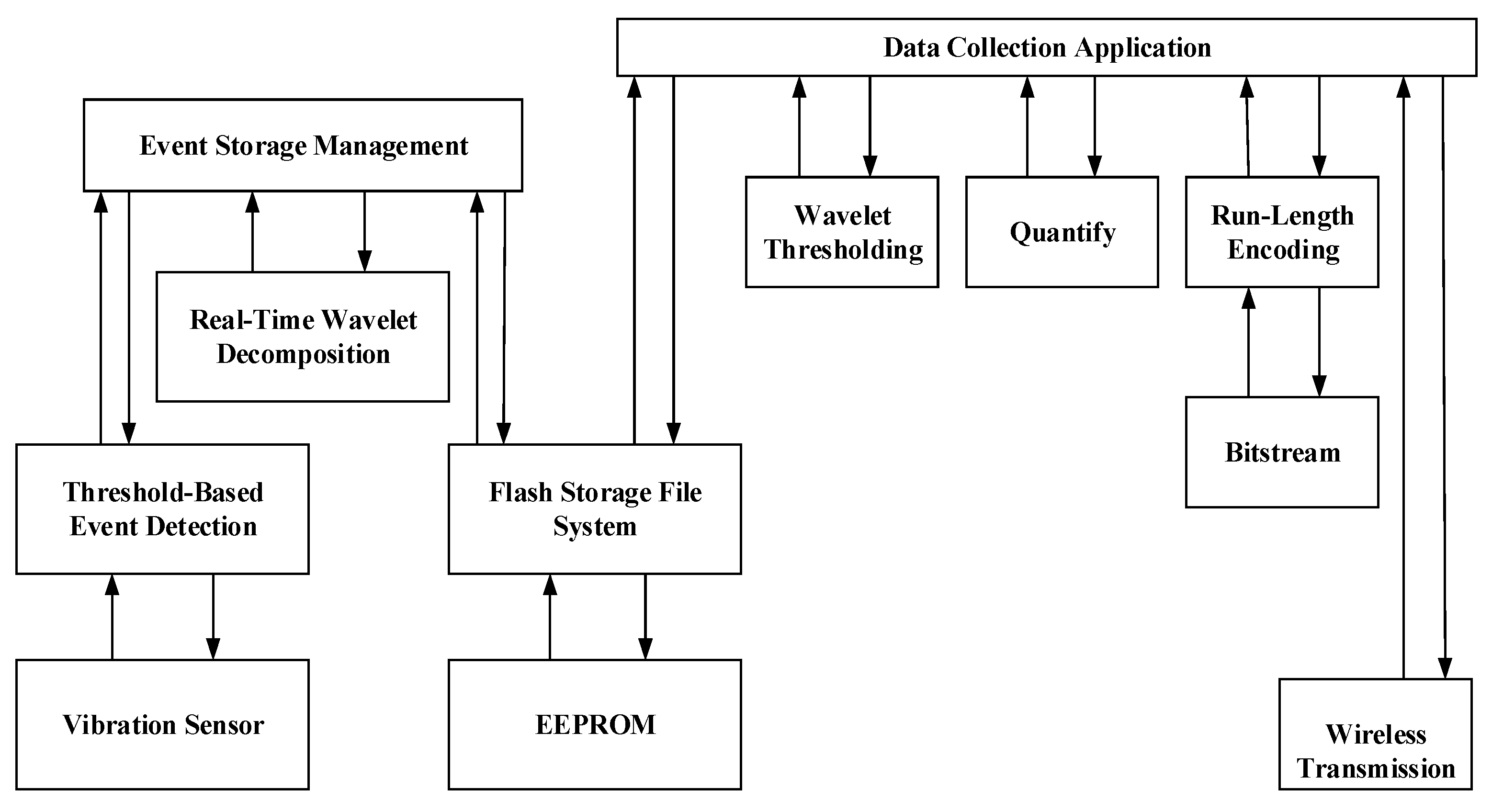

2.2. Data Acquisition Subsystem

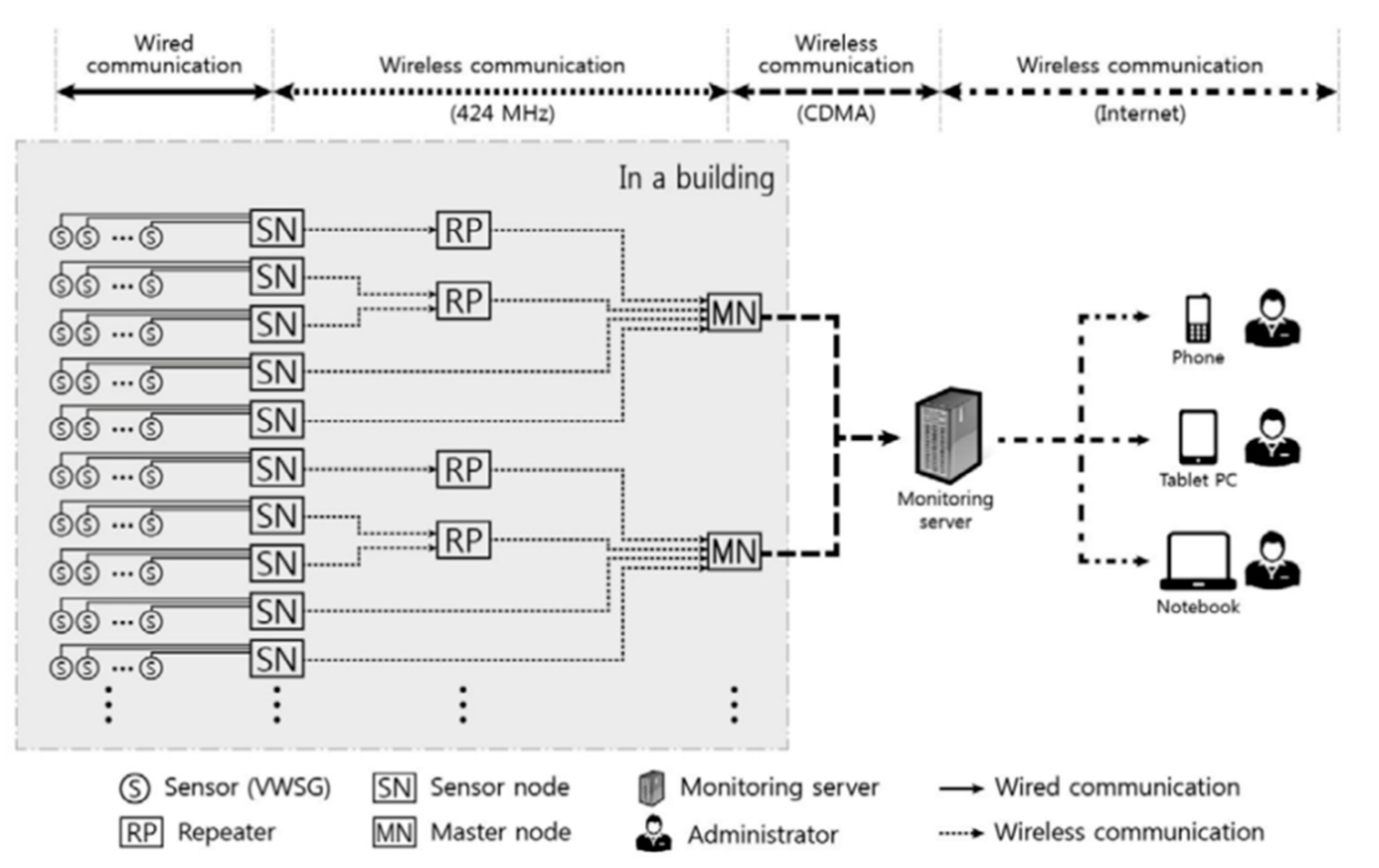

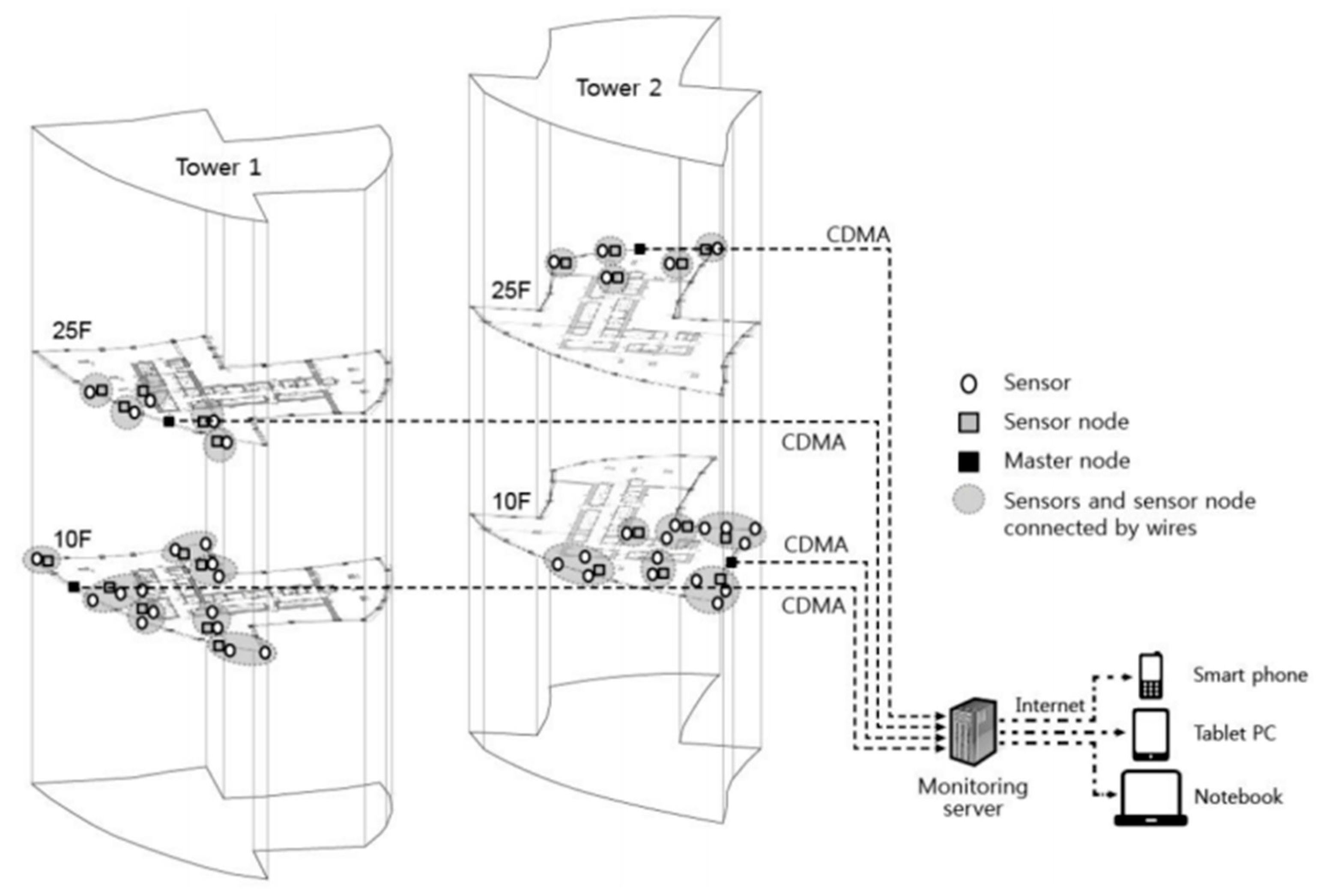

2.3. Data Transmission Subsystem

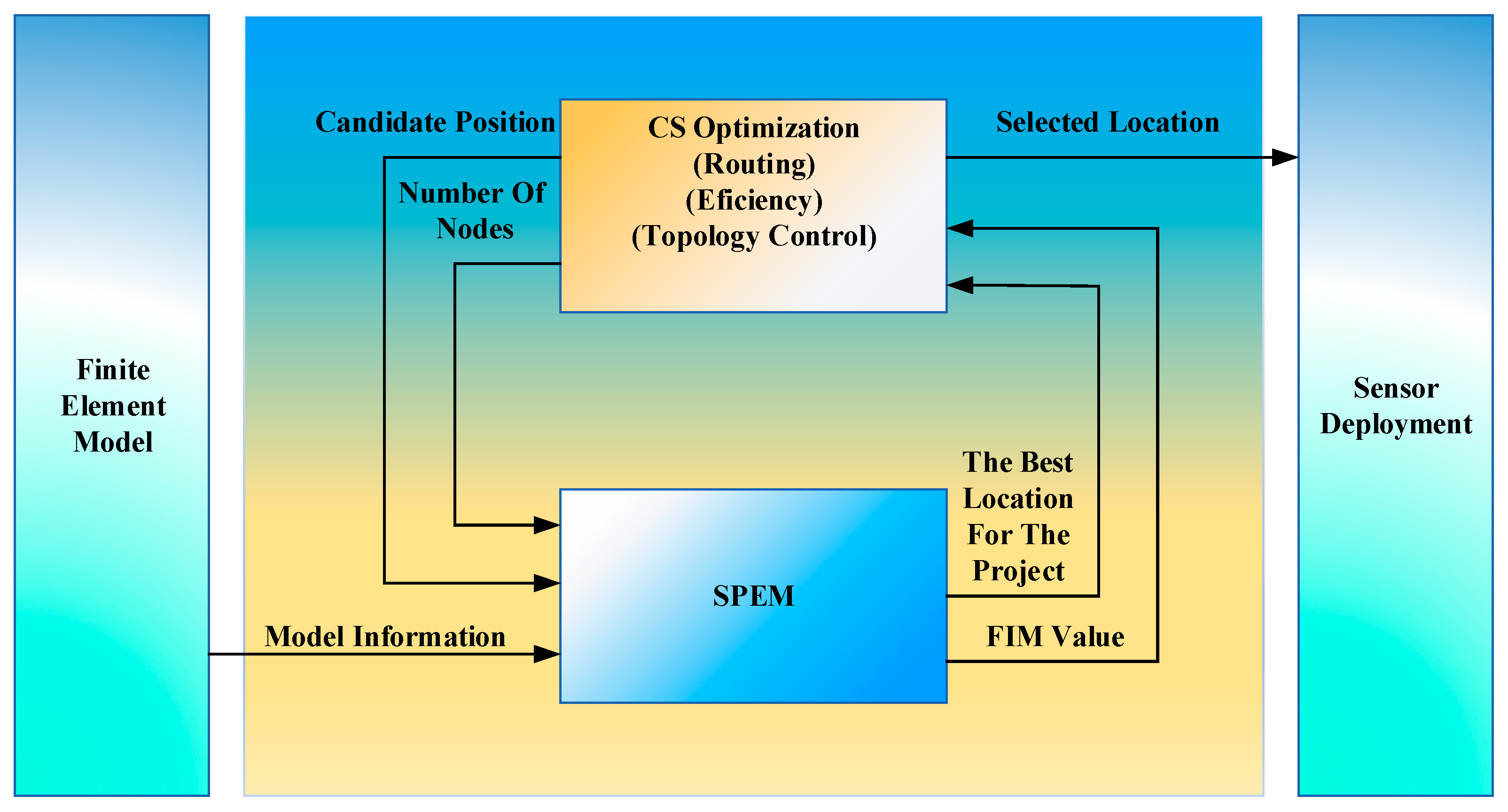

2.4. Node Deployment Control and Perception Optimization

2.5. Energy Management Technology

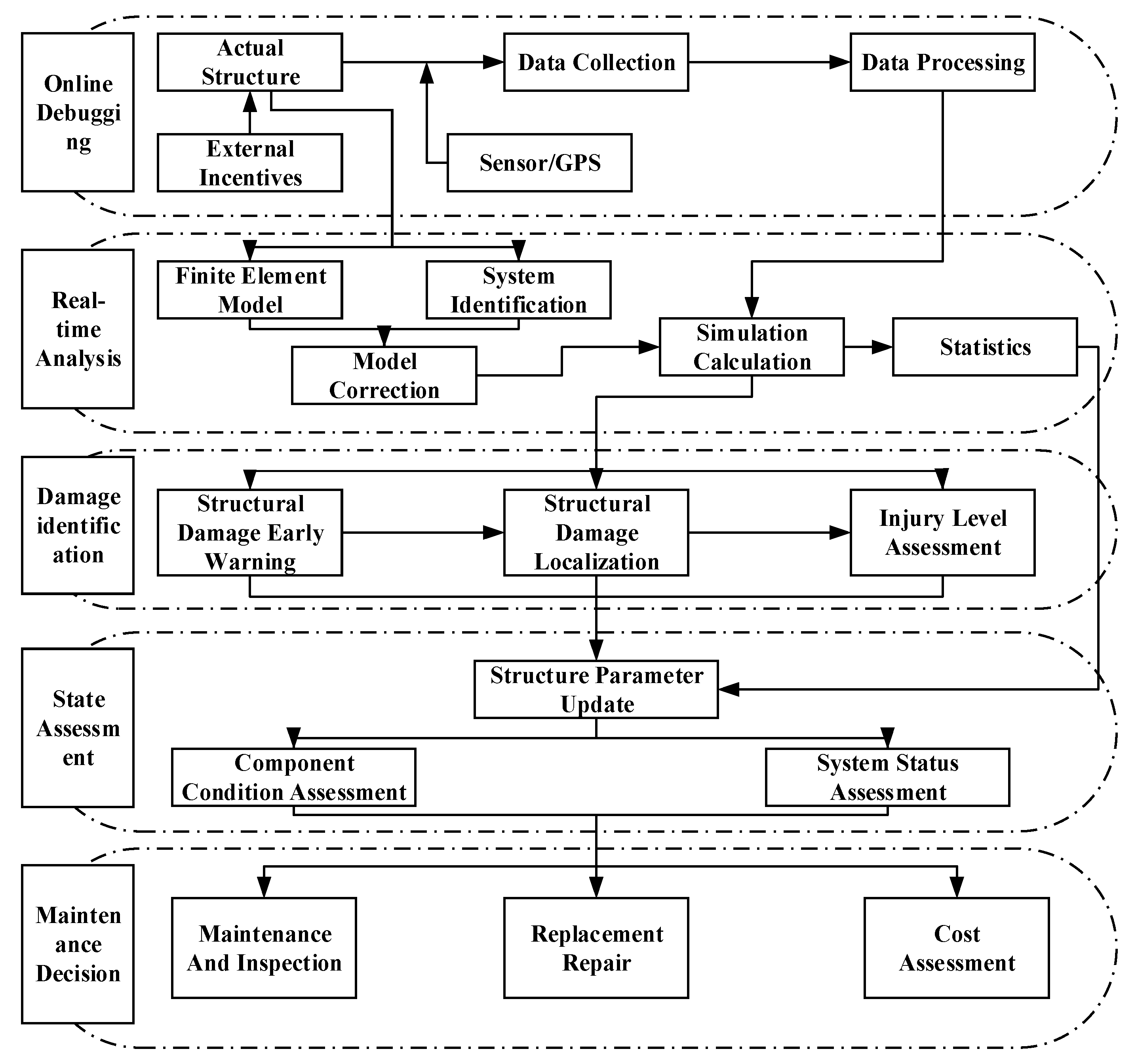

3. Damage Processing and Cloud Platform Technology

3.1. Damage Identification and Prediction Technology

3.1.1. Damage Identification Method

3.1.2. Damage Prediction Method

3.2. Data Interaction, Monitoring, and Early Warning of Cloud Platform

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, Q.S.; He, Y.H.; Wang, H.; Zhou, K.; Yan, B.W. Monitoring and time-dependent analysis of vertical deformations of the tallest building in China. Struct. Control Health Monit. 2017, 24, e1936. [Google Scholar] [CrossRef]

- Ye, X.W.; Ni, Y.Q.; Xia, Y.X. Distributed Strain Sensor Networks for In Construction Monitoring and Safety Evaluation of a High Rise Building. Int. J. Distrib. Sens. Netw. 2012, 8, 34–63. [Google Scholar] [CrossRef]

- Li, Q.; Yi, J. Monitoring of dynamic behavior of super-tall buildings during typhoons. Struct. Infrastruct. Eng. 2016, 12, 289–311. [Google Scholar] [CrossRef]

- Li, Q.S.; Zhi, L.H.; To, A.; Jeary, A.J. Field Measurements of Typhoon Effects on the Tallest Building in Hong Kong. In Proceedings of the Seventh Asia-Pacific Conference on Wind Engineering (APCWE-7), Taipei, Taiwan, 8–12 November 2009; pp. 109–116. [Google Scholar]

- Li, Q.S.; Wu, J.R. Time-frequency analysis of typhoon effects on a 79-storey tall building. J. Wind Eng. Ind. Aerodyn. 2007, 95, 1648–1666. [Google Scholar] [CrossRef]

- Li, Q.S.; Yang, K.; Wong, C.K.; Jeary, A.J. The effect of amplitude-dependent damping on wind induced vibrations of a super tall building. J. Wind Eng. Ind. Aerodyn. 2003, 91, 1175–1198. [Google Scholar] [CrossRef]

- Haque, M.E.; Zain, M.; Jamil, M. Performance Assessment of tree topology sensor network based on scheduling algorithm for overseeing high-rise building structural health information. Optik 2015, 126, 1676–1682. [Google Scholar] [CrossRef]

- Wang, F.; Wang, D.; Liu, J. High-rise structure monitoring with elevator-assisted wireless sensor networking: Design, optimization, and case study. Wirel. Netw 2019, 25, 29–47. [Google Scholar] [CrossRef]

- Soeharwinto, E.; Sinulingga, B.; Siregar, B. Remote monitoring of post-eruption volcano environment based-on wireless sensor network (WSN): The mount sinabung case. J. Phys. Conf 2017, 801, 12084–12098. [Google Scholar] [CrossRef]

- Mohammed, M.S. Building vitality productive correspondence protocol to remote micro-sensor networks. Int. J. Appl. Eng. Res 2018, 13, 6358–6360. [Google Scholar]

- Guo, W.; Zhai, Z.; Wang, H. Shaking table test and numerical analysis of an asymmetrical twin-tower super high-rise building connected with long-span steel truss. Struct Des. Tall Spec Build 2019, 28, e1630.1–e1630.27. [Google Scholar] [CrossRef]

- Chen, Z.P.; Wu, G.; Feng, D.C. Numerical study of the static and dynamic characteristics of reinforced concrete cassette structures for high-rise buildings. Struct Des. Tall Spec Build 2019, 28, e1574.1–e1574.24. [Google Scholar] [CrossRef]

- Bornemann, S.; Lang, W. Experimental Study on Stress Impact during FML Manufacturing on the Functional Conformity of an Embeddable SHM-Sensor-Node. Eng. Proc. 2021, 10, 72. [Google Scholar]

- Harms, T.; Sedigh, S.; Bastianini, F. Structural health monitoring of bridges using wireless sensor networks. IEEE Instrum. Meas. Mag. 2010, 13, 14–18. [Google Scholar] [CrossRef]

- Wang, P.; Yan, Y.; Tianm, G.Y.; Bouzid, O.; Ding, Z.G. Investigation of wireless sensor networks for structural health monitoring. J. Sens. 2012, 2012, 30–36. [Google Scholar] [CrossRef]

- Han, R. The Exploratory Research on Large-Scale Cloud Monitoring of Civil Engineering Structure Based on Smart Mobile Terminal; Dalian University of Technology: Dalian, China, 2014. [Google Scholar]

- Zhao, X.; Yu, Y.; Li, M.; Ou, J. Research on Cloud-SHM and its applications. In Proceedings of the 7th International Conference on Structural Health Monitoring of Intelligent Infrastructure, Torino, Italy, 1–3 July 2015. [Google Scholar]

- Cheng, Y.; Li, X.; Li, Z.; Jiang, S.; Li, Y.; Jia, J.; Jiang, X. Aircloud: A cloud-based air-quality monitoring system for everyone. In Proceedings of the 12th ACM Conference on Embedded Network Sensor Systems, Memphis, TN, USA, 3–6 November 2014; pp. 1–14. [Google Scholar]

- Zhou, G.D.; Yi, T.H. Recent developments on wireless sensor networks technology for bridge health monitoring. Math. Probl. Eng. 2013, 2013, 1–33. [Google Scholar] [CrossRef]

- Chae, M.J.; Yoo, H.S.; Kim, J.Y.; Cho, M.Y. Development of a wireless sensor network system for suspension bridge health monitoring. Autom. Constr. 2012, 21, 237–252. [Google Scholar] [CrossRef]

- Akyildiz, I.F.; Su, W.; Sankarasubramaniam, Y.; Cayirci, E. A survey on sensor networks. IEEE Commun. Mag. 2002, 40, 102–114. [Google Scholar] [CrossRef]

- Yick, J.; Mukherjee, B.; Ghosal, D. Wireless sensor network survey. Comput. Netw. 2008, 52, 2292–2330. [Google Scholar] [CrossRef]

- Pakzad, S.N.; Fenves, G.L.; Kim, S.; Culler, D.E. Design and implementation of salable wireless sensor network for structural monitoring. J. Infrastruct. Syst. 2008, 14, 89–101. [Google Scholar] [CrossRef]

- Sofi, A.; Regita, J.J.; Rane, B.; Lau, H.H. Structural health monitoring using wireless smart sensor network–An overview. Mech. Syst. Signal Process 2022, 163, 108113. [Google Scholar] [CrossRef]

- Noel, A.B.; Abdaoui, A.; Elfouly, T.; Ahmed, M.H.; Badawy, A.; Shehata, M.S. Structural health monitoring using wireless sensor networks: A Comprehensive Survey. IEEE Commun. Surv. Tutor. 2017, 19, 1403–1423. [Google Scholar] [CrossRef]

- Perera, R.; Pérez, A.; García-Diéguez, M.; Zapico-Valle, J.L. Active Wireless System for Structural Health Monitoring Applications. Sensors 2017, 17, 2880. [Google Scholar] [CrossRef] [PubMed]

- Yan, S.; Ma, H.; Li, P.; Song, G.; Wu, J. Development and application of a structural health monitoring system based on wireless smart aggregates. Sensors 2017, 17, 1641. [Google Scholar] [CrossRef] [PubMed]

- Spencer, B.F.; Park, J.; Mechitov, K.A.; Jo, H.; Agha, G. Next generation wireless smart sensors towards sustainable civil infrastructure. Procedia Eng. 2017, 171, 5–13. [Google Scholar] [CrossRef]

- Yuguang, F.; Hoang, T.; Mechitov, K.; Kim, J.R.; Zhang, D.Z.; Spencer, B.F. Sudden event monitoring of civil infrastructure using demand-based wireless smart sensors. Sensors 2018, 18, 4480. [Google Scholar]

- Bao, Y.; Shi, Z.; Wang, X.; Li, H. Compressive sensing of wireless sensors based on group sparse optimization for structural health monitoring. Struct. Health Monit. 2017, 1, 1–14. [Google Scholar] [CrossRef]

- Ostachowicz, W.; Soman, R.; Malinowski, P. Optimization of sensor placement for structural health monitoring: A review. Struct. Health Monit. 2019, 18, 963–988. [Google Scholar] [CrossRef]

- Abdulkarem, M.; Samsudin, K.; Rokhani, F.Z.; Rasid, M. Wireless sensor network for structural health monitoring: A con-temporary review of technologies, challenges, and future direction. Struct. Health Monit. 2019, 19, 693–735. [Google Scholar] [CrossRef]

- Dai, Z.C.; Wang, S.M.; Yan, Z.H. BSHM-WSN: A wireless sensor network for bridge structure health monitoring. In Proceedings of the 2012 Proceedings of International Conference on Modelling, Identification and Control, Wuhan, China, 24–26 June 2012; pp. 24–26. [Google Scholar]

- Whelan, M.J.; Janoyan, K.D. Design of a robust, high-rate wireless sensor network for static and dynamic structural monitoring. J. Intell. Mater. Syst. Struct. 2009, 20, 849–863. [Google Scholar] [CrossRef]

- Sivasuriyan, A.; Vijayan, D.S.; Leemarose, A. Development of Smart Sensing Technology Approaches in Structural Health Monitoring of Bridge Structures. Adv. Mater. Sci. Eng. 2021, 2021, 2615029. [Google Scholar] [CrossRef]

- Zanelli, F.; Castelli-Dezza, F.; Tarsitano, D.; Diana, G. Design and field validation of a low power wire-less sensor node for structural health monitoring. Sensors 2021, 21, 1050. [Google Scholar] [CrossRef]

- Surya, S.; Ravi, R. Damage Detection and Evaluation in Wireless Sensor Network for Structural Health Monitoring. Lec-Ture Notes Data Eng. Commun. Technol. 2020, 33, 207–211. [Google Scholar]

- Liu, C.; Jiang, Z.; Wang, F.; Chen, H. Energy-efficient heterogeneous wireless sensor deployment with multiple objectives for structural health monitoring. Sensors 2016, 16, 1865. [Google Scholar] [CrossRef]

- Zhao, Z.Z.; Sun, J.B.; Fei, X.T.; Liu, W.; Cheng, X.H.; Wang, Z.G.; Yang, H.Z. Wireless sensor network based cable tension monitoring for cable-stayed bridges. In Proceedings of the 2012 14th International Conference on Advanced Communication Technology (ICACT), Pyeongchang, Republic of Korea, 19–22 February 2012; pp. 527–532. [Google Scholar]

- Brownjohn, J.; Pan, T.; Cheong, H.K. Dynamic response of republic Plaza, Singapore. Struct. Eng. 1998, 76, 221–226. [Google Scholar]

- Brownjohn, J. Structural health monitoring of civil infrastructure. Philos. Trans. Math. Phys. Eng. Sci. 2007, 365, 589–622. [Google Scholar] [CrossRef]

- Torfs, T.; Sterken, T.; Brebels, S.; Santana, J.; van den Hoven, R.; Spiering, V.; Bertsch, N.; Trapani, D.; Zonta, D. Low Power Wireless Sensor Network for Building Monitoring. IEEE Sens. J. 2013, 13, 909–915. [Google Scholar] [CrossRef]

- Shi, B.; Song, G.; Liu, J.; Li, Y.; Gong, Y. Structural Health Monitoring of High-Rise Buildings Using Fiber Bragg Grating Sensors. Sensors 2018, 18, 1906. [Google Scholar]

- Xu, F.; Xu, J.; Zhang, X. Structural Health Monitoring of a High-Rise Building Using Distributed Fiber Optic Sensors. Sensors 2019, 19, 1862. [Google Scholar]

- Zhang, Z.; Song, G.; Shi, B.; Li, Y. Structural health monitoring of a high-rise building using a fiber optic sensing network. Measurement 2020, 155, 107524. [Google Scholar]

- Janting, J.; Pedersen, J.K.M.; Woyessa, G.; Nielsen, K.; Bang, O. Small and robust all-polymer fiber Bragg grating based on sensor. J. Light Wave Technol. 2019, 37, 4480–4486. [Google Scholar] [CrossRef]

- Chitalia, Y.; Deaton, N.J.; Jeong, S.; Rahman, D.; Desai, J.P. Towards FBG based shape sensing for micro-scale and mesoscale continuum robots with large deflection. IEEE Robot. Autom. Lett. 2020, 5, 1712–1719. [Google Scholar] [CrossRef]

- Wang, X.M.; Fang, G.; Wang, K.; Xie, X.C.; Lee, K.H.; Wang, K.; Tang, W.L.; Lam, J.; Kwok, K.W. Eye-in-hand visual servicing enhanced with sparse strain measurement for soft continuum robots. IEEE Robot. Autom. Lett. 2020, 5, 2161–2168. [Google Scholar] [CrossRef]

- Kanellos, G.T.; Papaioannou, G.; Tsiokos, D.; Mitrogiannis, C.; Nianios, G.; Pleros, N. Two dimensional polymer-embedded quasi-distributed FBG pressure sensor for biomedical applications. Opt Express 2010, 18, 179–186. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, D.S.A.; Goncalves, A.F.; Deaf, L.A.; Araujo, F.M.M.; Mendes, P.M.; Correia, J.H. A smart skin PVC foil based on FBG sensors for monitoring strain and temperature. IEEE Trans. Ind. Electron. 2011, 58, 2728–2735. [Google Scholar] [CrossRef]

- Mieloszyk, M.; Ostachowicz, W. An application of structural health monitoring system based on FBG sensors to offshore wind turbine support structure model. Mar. Struct. 2017, 51, 65–86. [Google Scholar] [CrossRef]

- Wang, H.; Jiang, L.; Xiang, P. Improving the durability of the optical fiber sensor based on strain transfer analysis. Opt. Fiber Technol. 2018, 42, 97–104. [Google Scholar] [CrossRef]

- Wang, H.; Jiang, L.; Xiang, P. Priority design parameters of industrialized optical fiber sensors in civil engineering. Opt. Laser Technol. 2018, 100, 119–128. [Google Scholar] [CrossRef]

- Djurhuus, M.S.E.; Werzingers, S.; Schmauss, B.; Clausen, A.T.; Zibar, D. Machine learning assisted fiber Bragg grating-based temperature sensing. IEEE Photonics Technol. Lett. 2019, 31, 939–942. [Google Scholar] [CrossRef]

- Lun, T.L.T.; Wang, K.; Ho, D.L.; Kit-Hang, L.; Sze, K.Y.; Ka-Wai, K. Real time surface shape sensing for soft and flexible structures using fiber Bragg gratings. IEEE Robot. Autom. Lett. 2019, 4, 1454–1461. [Google Scholar] [CrossRef]

- Soman, R.; Ostachowicz, W. Ultrasonic fiber bragg grating sensor placement optimization in structural health monitoring using covariance matrix adaptation evolutionary strategy. Health Monit. Struct. Biol. Syst. XV 2021, 115931A, 327–334. [Google Scholar]

- Liu, F.; Li, S.; Yu, Z.; Ju, X.; Wang, H.; Qi, Q. Adaptive intrusion recognition for ultraweak FBG signals of perimeter monitoring based on convolution neural networks. In Proceedings of the International Conference on Neural Information Processing, Siem Reap, Cambodia, 13–16 December 2018; pp. 359–369. [Google Scholar]

- Chen, X. Condition monitoring system of electromechanical equipment based on fiber Bragg grating sensors and artificial neural network. In Proceedings of the 2018 IEEE 18th International Conference on Communication Technology (ICCT), Chongqing, China, 8–11 October 2018; pp. 548–551. [Google Scholar]

- Ha, N.; Lee, H.-S.; Lee, S. Development of a Wireless Corrosion Detection System for Steel-Framed Structures Using Pulsed Eddy Currents. Sensors 2021, 21, 8199. [Google Scholar] [CrossRef] [PubMed]

- Zamora-Arellano, F.; López-Bonilla, O.R.; García-Guerrero, E.E.; Olguín-Tiznado, J.E.; Inzunza-González, E.; López-Mancilla, D.; Tlelo-Cuautle, E. Development of a Portable, Reliable and Low-Cost Electrical Impedance Tomography System Using an Embedded System. Electronics 2021, 10, 15. [Google Scholar] [CrossRef]

- Whelan, M.J.; Gangone, M.V.; Janoyan, K.D. Highway bridge assessment using an adaptive real-time wireless sensor network. IEEE Sens. J. 2009, 9, 1405–1413. [Google Scholar] [CrossRef]

- Whelan, M.J.; Gangone, M.V.; Janoyan, K.D.; Jha, R. Real-Time wireless vibration monitoring for operational modal analysis of an integral abutment highway bridge. Eng. Struct. 2009, 31, 2224–2235. [Google Scholar] [CrossRef]

- Kim, S.; Pakzad, S.; Culler, D.; Demmel, J. Health monitoring of civil infrastructures using wireless sensor networks. In Proceedings of the 6th International Conference on Information Processing in Sensor Networks (IPSN), Cambridge, MA, USA, 25–27 April 2007; ACM Press: New York, NY, USA, 2007; pp. 254–263. [Google Scholar]

- Lynch, J.P.; Sundararajan, A.; Law, K.H.; Kiremidjian, A.S.; Carryer, E. Embedding damage detection algorithms in a wireless sensing unit for operational power efficiency. Smart Mater. Struct. 2004, 13, 800–810. [Google Scholar] [CrossRef]

- Bhuiyan, M.Z.A.; Cao, J.N.; Wang, G.J. Deploying wireless sensor networks with fault tolerance for structural health monitoring. In Proceedings of the 8th IEEE International Conference on Distributed Computing in Sensor Systems, Hangzhou, China, 16–18 May 2012; pp. 194–202. [Google Scholar]

- Ye, W.; Heidemann, J.; Estrin, D. Medium access control with coordinated adaptive sleeping for wireless sensor networks. IEEE/ACM Trans. Netw. 2004, 12, 493–506. [Google Scholar] [CrossRef]

- Yu, J.; Meng, X.; Shao, X.; Yan, B.; Yang, L. Identification of Dynamic Displacements and Modal Frequencies of a Medium span Suspension Bridge Using Multitude GNSS Processing. Eng. Struct. 2014, 81, 432–443. [Google Scholar] [CrossRef]

- Ogundipe, O.; Roberts, G.W.; Brown, C.J. GPS Monitoring of a Steel Box Girder Viaduct. Struct. Infrastruct. Eng. 2014, 10, 25–40. [Google Scholar] [CrossRef]

- Moschas, F.; Stiros, S. Measurement of the Dynamic Displacements and of the Modal Frequencies of a Short-span Pedestrian Bridge Using GPS and an Accelerometer. Eng. Struct. 2011, 33, 10–17. [Google Scholar] [CrossRef]

- Yi, T.H.; Li, H.N.; Gu, M. Recent Research and Applications of GPS-based Monitoring Technology for High rise Structures. Struct. Control Health Monit. 2013, 20, 649–670. [Google Scholar] [CrossRef]

- Kijewski-correa, T.; Kareem, A.; Kochly, M. Experimental Verification and Full-scale Deployment of Global Positioning Systems to Monitor the Dynamic Response of Tall Building. J. Struct. Eng. 2006, 132, 1242–1253. [Google Scholar] [CrossRef]

- Yu, J.; Meng, X.; Yan, B.; Xu, B.; Fan, Q.; Xie, Y. Global navigation satellite system-based positioning technology for structural health moni-toring: A review. Struct. Control Health Monit. 2020, 27, e2467. [Google Scholar] [CrossRef]

- Xi, R.; Chen, H.; Meng, X.; Chen, Q. Reliable dynamic monitoring of bridges with integrated GPS and BeiDou. J. Surv. Eng. 2018, 144, 04018008. [Google Scholar] [CrossRef]

- Yu, J.; Yan, B.; Meng, X.; Shao, X.; Ye, H. Measurement of bridge dynamic responses using network-based real-time kine-matic GNSS technique. J. Surv. Eng. 2016, 142, 04015013. [Google Scholar] [CrossRef]

- Kaloop, M.; Hu, J. Dynamic performance analysis of tower long-span bridge based on GPS monitoring technique. J. Sens. 2016, 2016, 1–15. [Google Scholar] [CrossRef]

- Ueckert, S.; Mentré, F. A new method for evaluation of the Fisher information matrix for discrete mixed effect models using Monte Carlo sampling and adaptive Gaussian quadrature. Comput. Stat. Data Anal. 2017, 111, 203–219. [Google Scholar] [CrossRef]

- Li, Z.; Dong, Y.; Li, P.; Li, H.; Liew, Y. A New Method for Remote Sensing Satellite Observation Effectiveness Evaluation. Aerospace 2022, 9, 317. [Google Scholar] [CrossRef]

- An, H.; Youn, B.D.; Kim, H.S. A methodology for sensor number and placement optimization for vibration-based damage detection of composite structures under model uncertainty. Compos. Struct. 2022, 279, 63. [Google Scholar] [CrossRef]

- Jung, Y.; Lee, I. Optimal design of experiments for optimization-based model calibration using Fisher information matrix. Reliab. Eng. Syst. Saf. 2021, 216, 107968. [Google Scholar] [CrossRef]

- Bhuiyan, M.Z.A.; Wang, G.J.; Cao, J.N. Sensor placement with multiple objectives for structural health monitoring in WSNs. In Proceedings of the IEEE 14th International Conference on High Performance Computing and Communications (HPCC), Liverpool, UK, 25–27 June 2012; IEEE Press: New York, NY, USA, 2012; pp. 699–706. [Google Scholar]

- Meo, M.; Zumpano, G. On the optimal sensor placement techniques for a bridge structure. Eng. Struct. 2005, 27, 1488–1497. [Google Scholar] [CrossRef]

- Li, B.; Wang, D.; Wang, F.; Ni, Y.Q. High quality sensor placement for SHM systems: Refocusing on application demands. In Proceedings of the 29th IEEE Conference on Information Communications (INFOCOM), San Diego, CA, USA, 14–19 March 2010; IEEE Press: New York, NY, USA, 2010; pp. 650–658. [Google Scholar]

- Liu, X.; Fu, Q.; Ye, N.H.; Yin, L.R. The multi-objective reliability-based design optimization for structure based on probability and ellipsoidal convex hybrid model. Struct. Saf. 2019, 77, 48–56. [Google Scholar] [CrossRef]

- Anastasi, G.; Conti, M.; Francesco, M.D.; Passarella, A. Energy conservation in wireless sensor networks: A survey. Ad Hoc Netw. 2009, 7, 537–568. [Google Scholar] [CrossRef]

- Alippi, C.; Anastasi, G.; Francesco, M.D.; Roveri, M. Energy management in wireless sensor networks with energy-hungry sensors. IEEE Instrum. Meas. Mag. 2009, 12, 16–23. [Google Scholar] [CrossRef]

- Araujo, A.; García-Palacios, J.; Blesa, J.; Tirado, F.; Romero, E.; Samartín, A.; Nieto-Taladriz, O. Wireless measurement system for structural health monitoring with high time-synchronization accuracy. IEEE Trans. Instrum. Meas. 2012, 61, 801–810. [Google Scholar] [CrossRef]

- Ali, R.; Eassa, H.; Aly, H.H.; Abaza, M.; Eisa, S.M. Low Power FPGA Implementation of a Smart Building Free Space Optical Communication System. Photonics 2022, 9, 432. [Google Scholar] [CrossRef]

- Chen, C.S.; Chen, W.C. Research and Development of Automatic Monitoring System for Livestock Farms. Appl. Sci. 2019, 9, 1132. [Google Scholar] [CrossRef]

- Kimura, N.; Latifi, S. A survey on data compression in wireless sensor networks. In Proceedings of the International Conference on Information Technology: Coding and Computing (ITCC), Las Vegas, NV, USA, 4–6 April 2005; pp. 8–13. [Google Scholar]

- Ni, Y.Q.; Xia, Y.; Liao, W.Y.; Ko, J.M. Technology innovation in developing the structural health monitoring system for Guangzhou new TV tower. Struct. Control Health Monit. 2009, 16, 73–98. [Google Scholar] [CrossRef]

- Ou, J.; Li, H. Structural Health Monitoring in Mainland China: Review and Future Trends. Struct. Health Monit. 2010, 9, 219–231. [Google Scholar]

- Xu, N.; Rangwala, S.; Chintalapudi, K.K.; Ganesan, D.; Broad, A.; Govindan, R.; Estrin, D. A wireless sensor network for structural monitoring. In Proceedings of the 2nd ACM Conference on Embedded Networked Sensor Systems (SenSys); Stankovic, J.A., Arora, A., Govindan, R., Eds.; ACM Press: New York, NY, USA, 2004; pp. 13–24. [Google Scholar]

- Kundu, S.; Roy, S.; Pal, A. A power-aware wireless sensor network based bridge monitoring system. In Proceedings of the 2008 16th IEEE International Conference on Networks (ICON), New Delhi, India, 12–14 December 2008; pp. 1–7. [Google Scholar]

- Farrar, C.R.; Lieven, N.A.J. Damage Prognosis: The Future of Structural Health Monitoring. Philos. Trans. R. Soc. A 2007, 365, 623–632. [Google Scholar] [CrossRef]

- Xiao, H.; Li, T.S.; Ogai, H.; Zou, X.H.; Otawa, T.; Umeda, S.; Tsuji, T. The health monitoring system based on distributed data aggregation for WSN used in bridge diagnosis. In Proceedings of the Society of Instrument and Control Engineers (SICE), Taipei, Taiwan, 18–21 August 2010; pp. 2134–2138. [Google Scholar]

- Kothamasu, R.; Huang, S.H.; Verduin, W.H. System Health Monitoring and Prognostics: A Review of Current Paradigms and Practices. Int. J. Adv. Manuf. Technol. 2006, 28, 1012–1024. [Google Scholar] [CrossRef]

- Caminero, M.A.; Pavlopoulou, S.; Lopez-pe-drosa, M.; Nicolaisson, B.G.; Pinna, C.; Soutis, C. Analysis of Adhesively Bonded Re-pairs in Composites: Damage Detection and Prognosis. Compos. Struct. 2013, 95, 500–517. [Google Scholar] [CrossRef]

- Yang, Y.; Lu, H.; Tan, X.; Chai, H.K.; Zhang, Y. Fundamental mode shape estimation and element stiffness evaluation of girder bridges by using passing tractor-trailers. Mech. Syst. Signal Process. 2022, 169, 108746. [Google Scholar] [CrossRef]

- Yang, Y.; Lu, H.; Tan, X.; Wang, R.; Zhang, Y. Mode Shape Identification and Damage Detection of Bridge by Movable Sensory System. In IEEE Transactions on Intelligent Transportation Systems; IEEE: New York, NY, USA, 2022; p. 3151529. [Google Scholar]

- Yang, Y.; Ling, Y.; Tan, X.; Wang, S.; Wang, R. Damage identification of frame structure based on approximate Metropolis–Hastings algorithm and probability density evolution method. Int. J. Struct. Stab. Dynaics 2022, 22, 3–4. [Google Scholar] [CrossRef]

- Gao, Y.; Mosalam, K. Deep transfer learning for image-based structural damage recognition. Comput.-Aided Civ. Infrastruct. Eng. 2018, 33, 748–768. [Google Scholar] [CrossRef]

- Lin, Z.; Zhou, H.; Liu, X.; Chen, Y. Early warning and health monitoring of a high-rise building structure based on fiber optic sensors. J. Sens. 2019, 43, 5735929. [Google Scholar]

- Ye, J.; Wu, W.; Wu, Y.; Liao, W. An innovative health monitoring method for high-rise buildings based on frequency analysis and machine learning. J. Sound Vib. 2020, 473, 115214. [Google Scholar]

- Zhou, L.; Zhao, X.; Zhang, J. A novel strategy for early damage detection of high-rise building structures based on statistical pattern recognition. Struct. Health Monit. 2020, 19, 236–247. [Google Scholar]

- Hashemi, S.M.; Al-Mahaidi, R.M.; Nielsen, S.R.K. Damage identification of high-rise buildings using fuzzy logic. Eng. Struct. 2016, 117, 325–335. [Google Scholar]

- Hashemi, S.M.; Al-Mahaidi, R.M.; Nielsen, S.R.K. Uncertainty quantification in damage identification of high-rise buildings using output-only modal analysis. Struct. Control Health Monit. 2017, 24, e2049. [Google Scholar]

- Liu, Y.; Zhu, J. A hybrid method for damage identification in high-rise buildings based on data fusion of multi-sensor information. Smart Struct. Syst. 2018, 22, 399–413. [Google Scholar]

- Wu, Y.; Li, Y.; Lei, Y. Damage identification of super-tall building structures based on nonlinear dynamics. Nonlinear Dyn. 2015, 81, 2035–2049. [Google Scholar]

- Benaissa, B.; Hocine, N.A.; Khatir, S.; Riahi, M.K.; Mirjalili, S. YUKI Algorithm and POD-RBF for Electrostatic and dynamic crack identification. J. Comput. Sci. 2021, 55, 101451. [Google Scholar] [CrossRef]

- Han, F.; Lei, Y. A damage detection method for high-rise buildings using empirical mode decomposition and random decrement technique. Smart Struct. Syst. 2017, 19, 289–302. [Google Scholar]

- He, Y.; Yan, F.; Li, X. Damage identification of high-rise building structures using time-frequency domain features and neural networks. J. Sound Vib. 2018, 434, 145–161. [Google Scholar]

- Guo, S.X.; Qiang, P. Application of short-time Fourier transform to high-rise frame structural-health monitoring based on change of inherent frequency over time. J. Chongqing Univ. 2017, 16, 1–10. [Google Scholar]

- Ghasemi, M.R.; Nobahari, M.; Shabakhty, N. Enhanced optimization-based structural damage detection method using modal strain energy and modal frequencies. Eng. Comput. 2018, 34, 637–647. [Google Scholar] [CrossRef]

- Gao, H.; Guo, X.; Ouyang, H.; Yang, X. Multi-damage localization in plate structure using frequency response function-based indices. J. Phys. Conf. Ser. 2015, 628, 012004. [Google Scholar] [CrossRef]

- Pandey, A.K.; Biswas, M. Damage detection in structures using changes in flexibility. J. Sound Vib. 1994, 169, 3–17. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, Y.L.; Li, J.; Xia, Y.; Li, J.C. Statistical moment-based structural damage detection method in time domain. Earthq. Eng. Eng. Vib. 2013, 12, 13–23. [Google Scholar] [CrossRef]

- Yang, Z.B.; Radzienski, M.; Kudela, P.; Ostachowicz, W. Two-dimensional chebyshev pseudo spectral modal curvature and its application in damage detection for composite plates. Compos. Struct. 2017, 168, 372–383. [Google Scholar] [CrossRef]

- Jiang, X.; Mahadevan, S. Bayesian wavelet methodology for structural damage detection. Struct. Control Health Monit. 2008, 15, 974–991. [Google Scholar] [CrossRef]

- Sevillano, E.; Sun, R.; Perera, R. Damage evaluation of structures with uncertain parameters via interval analysis and FE model updating methods. Struct. Control Health Monit. 2017, 24, e1901. [Google Scholar] [CrossRef]

- Sohn, H.; Czarnecki, J.A.; Farrar, C.R. Structural health monitoring using statistical process control. J. Struct. Eng. 2000, 126, 1356–1363. [Google Scholar] [CrossRef]

- Tang, L.; DeCastro, J.; Kacprzynski, G.; Goebel, K.; Vachtsevanos, G. Filtering and prediction techniques for model-based prognosis and uncertainty management. In Proceedings of the 2010 Prognostics and System Health Management Conference, Macao, China, 12–14 January 2010. [Google Scholar]

- Engel, S.J.; Gilmartin, B.J.; Bongort, K.; Hess, A. Prognostics, the real issues involved with predicting life remaining. In Proceedings of the 2000 IEEE Aerospace Conference, Big Sky, MT, USA, 25–25 March 2000. [Google Scholar]

- Luchinsky, D.G.; Osipov, V.V.; Smelyanskiy, V.N.; Timucin, D.A.; Uckun, S. Model based IVHM system for the solid rocket booster. In Proceedings of the 2008 IEEE Aerospace Conferenc, Big Sky, MT, USA, 1–8 March 2008; Volume 25, pp. 1–15. [Google Scholar]

- Bessason, B.; Einarsson, B. Structural HealthModeling of the Olfusa Suspension Bridge; University of Iceland: Reykjavik, Iceland, 2012. [Google Scholar]

- Zhang, J.; Zhang, J.; Teng, S.; Chen, G.; Teng, Z. Structural damage detection based on vibration signal fusion and deep learning. J. Vib. Eng. Technol. 2022, 10, 1205–1220. [Google Scholar] [CrossRef]

- Ding, C.; Xu, J.; Xu, L. ISHM-based intelligent fusion prognostics for space avionics. Dialogues Cardiovasc. Med. Dcm 2013, 29, 200–205. [Google Scholar] [CrossRef]

- Catbas, N.; Gokce, H.B.; Frangopol, D.M. Predictive Analysis by Incorporating Uncertainty Through a Family of Models Calibrated with Structural Health Monitoring Data. J. Eng. Mech. 2013, 139, 712–723. [Google Scholar] [CrossRef]

- Guan, X.F.; Jha, R.; Liu, Y.M. Probabilistic Fatigue Damage Prognosis Using Maximum Entropy Approach. J. Intell. Manuf. 2012, 23, 163–171. [Google Scholar] [CrossRef]

- Toh, G.; Park, J. Review of vibration-based structural health monitoring using deep learning. Appl. Sci. 2020, 10, 1680. [Google Scholar] [CrossRef]

- Flah, M.; Nunez, I.; Chaabene, W.B.; Nehdi, M.L. Machine learning algorithms in civil structural health monitoring: A systematic review. Arch. Comput. Methods Eng. 2021, 28, 2621–2643. [Google Scholar] [CrossRef]

- Ghiasi, R.; Torkzadeh, P.; Noori, M. A machine-learning approach for structural damage detection using least square support vector machine based on a new combinational kernel function. Struct. Health Monit. 2016, 15, 302–316. [Google Scholar] [CrossRef]

- Zhou, Q.F.; Ning, Y.P.; Zhou, Q.Q.; Luo, L.K.; Lei, J.Y. Structural damage detection method based on random forests and data fusion. Struct. Health Monit. 2012, 12, 48–58. [Google Scholar] [CrossRef]

- Heng, A.; Zhang, S.; Tan, A.C.C.; Mathew, J. Rotating Machinery Prognostics: State of the Art, Challenges and Opportunities. Mech. Syst. Signal Process 2009, 23, 724–739. [Google Scholar] [CrossRef]

- Biondi, A.M.; Zhou, J.; Guo, X.; Wu, R.; Tang, Q.; Gandhi, H.; Yu, T.; Wang, X. Pipeline structural health monitoring using distributed fiber optic sensing textile. Opt. Fiber Technol. 2022, 70, 102876. [Google Scholar] [CrossRef]

- Goodwin, J.; Woods, J.E.; Hoult, N.A. Assessing the structural behaviour of glued-laminated timber beams using distributed strain sensing. Constr. Build. Mater. 2022, 325, 126844. [Google Scholar] [CrossRef]

- Wu, B.T.; Wu, G.; Yang, C.Q.; He, Y. Damage identification method for continuous girder bridges based on spatially-distributed long-gauge strain sensing under moving loads. Mech. Syst. Signal Process. 2018, 104, 415–435. [Google Scholar] [CrossRef]

- Puppo, L.; Pedroni, N.; Di Maio, F.; Bersano, A.; Bertani, C.; Zio, E. A Framework based on Finite Mixture Models and Adaptive Kriging for Characterizing Non-Smooth and Multimodal Failure Regions in a Nuclear Passive Safety System. Reliab. Eng. Syst. Saf. 2021, 216, 107963. [Google Scholar] [CrossRef]

- Chen, F.B.; Wang, X.L.; Li, X.; Shu, Z.R.; Zhou, K. Prediction of wind pressures on tall buildings using wavelet neural network. J. Build. Eng. 2022, 46, 103674. [Google Scholar] [CrossRef]

- Wei, S.; Yang, H.; Song, J.; Abbaspour, K.; Xu, Z. A wavelet-neural network hybrid modelling approach for estimating and predicting river monthly flows. Hydrol. Sci. J. 2013, 58, 374–389. [Google Scholar] [CrossRef]

- Zhao, E.F.; Wu, C.Q. Long-term safety assessment of large-scale arch dam based on non-probabilistic reliability analysis. Structure 2021, 32, 298–312. [Google Scholar] [CrossRef]

- Heatherington, C.; Grinham, A.; Penesis, I.; Hunter, S.; Cossu, R. Geotechnical Approach to Early-Stage Site Characterisation of Shallow Wave Energy Sites. J. Mar. Sci. Eng. 2021, 9, 605. [Google Scholar] [CrossRef]

- Jang, S.; Jo, H.; Cho, S.; Mechitov, K.; Rice, J.A.; Sim, S.H.; Jung, H.J.; Yun, C.B.; Spencer, B.F.; Agha, G. Structural health monitoring of a cable-stayed bridge using smart sensor technology: Deployment and evaluation. Smart Struct. Syst. 2010, 6, 439–459. [Google Scholar] [CrossRef]

- Li, J.; Tan, L.; Huang, X.; Wang, R.; Zhang, M. The Influence of Substrate Size Changes on the Coil Resistance of the Wireless Power Transfer System. Electronics 2020, 9, 1025. [Google Scholar] [CrossRef]

- Mascareñas, D.; Flynn, E.; Todd, M.; Park, G.; Farrar, C. Wireless sensor technologies for monitoring civil structures. Sound Vib. 2008, 4, 16–20. [Google Scholar]

- Ray, P.P. A survey of IoT cloud platforms. Future Comput. Inform. J. 2017, 1, 35–46. [Google Scholar] [CrossRef]

- Hong, J.; Morris, P.; Seo, J. Interconnected Personal Health Record Ecosystem Using IoT Cloud Platform and HL7 FHIR. In Proceedings of the 5th IEEE International Conference on Healthcare Informatics (ICHI), Park City, UT, USA, 23–26 August 2017. [Google Scholar]

- Kodali, R.K.; Sahu, A. An IoT Based Soil Moisture Monitoring on Losant Platform. In Proceedings of the 2nd International Conference on Contemporary Computing and Informatics (IC3I), Greater Noida, India, 14–17 December 2016. [Google Scholar]

- Praveen, M.; Harini, V. NB-IOT based smart car parking system. In Proceedings of the IEEE 6th International Conference on smart structures and systems (ICSSS), Chennai, India, 14–15 March 2019. [Google Scholar]

- Souza, G.B.D.C.; Vieira, F.H.T.; Lima, C.R.; Deus, G.A.D.J.; Castro, M.S.D.; Araujo, S.G.D.; Vasques, T.L. Developing Smart Grids Based on GPRS and Zig Bee Technologies Using Queueing Modeling–Based Optimization Algorithm. ETRI J. 2016, 38, 41–51. [Google Scholar] [CrossRef]

- Wu, G.; Wu, H.; Shi, H.; Zhang, Y. Cloud-based structural health monitoring system for a super-tall building: A case study of Shanghai Tower. Smart Struct. Syst. 2019, 23, 535–543. [Google Scholar]

- Kim, S.; Kim, J.; Kim, J.H.; Chang, K.C. A cloud-based structural health monitoring system for the Lotte World Tower in Seoul, Korea. Int. J. Distrib. Sens. Netw. 2018, 25, 14. [Google Scholar]

- Huang, K.; Yu, Z.; Li, Z. Cloud-Based Structural Health Monitoring System for a Mega-Braced Frame Super-Tall Building. J. Comput. Civ. Eng. 2017, 35, 31. [Google Scholar]

- Kijewski-Correa, T.; Kwon, D.K.; Kareem, A.; Bentz, A.; Guo, Y.; Bobby, S.; Abdelrazaq, A. SmartSync: An Integrated Real-Time Structural Health Monitoring and Structural Identification System for Tall Buildings. J. Struct. Eng. 2013, 139, 1675–1687. [Google Scholar] [CrossRef]

- Bazant, Z.P.; Wittmann, F.H. Creep and Shrinkage in Concrete Structures; John Wiley & Sons: New York, NY, USA, 1982. [Google Scholar]

- Choi, S.W.; Kim, Y.; Kim, J.M.; Park, H.S. Field Monitoring of Column Shortenings in a High-Rise Building during Construction. Sensors 2013, 13, 14321–14338. [Google Scholar] [CrossRef]

- Yuan, S. High-Rise Building Deformation Monitoring Based on Remote Wireless Sensor Network. IEEE Sens. J. 2021, 21, 25133–25141. [Google Scholar] [CrossRef]

- Kim, H.S.; Shin, S.H. Column shortening analysis with lumped construction sequences. Procedia Eng. 2011, 14, 1791–1798. [Google Scholar] [CrossRef]

| Transmission Strategy | Applicability | Advantage | Shortcoming | Example System |

|---|---|---|---|---|

| Real-time transmission | The sampling frequency is not high; not many nodes | Get real-time effective data | Limited application scenarios; limited real-time transmission bandwidth | Whelan [61] |

| Transmission after sampling raw data | Large local storage of nodes | Eliminate transmission bandwidth restrictions | Continuous monitoring is not possible; transmission time and energy consumption after sampling | Kim [63] |

| Transmission after pre-processing | Strong node processing capacity | Eliminate transmission bandwidth limitation; reduce data transmission energy consumption | Continuous monitoring is not possible; unable to perform global data analysis | Lynch [64] Bhuiyan [65] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Xu, W.; Gao, Z.; Yu, Z.; Zhang, Y. Research Progress of SHM System for Super High-Rise Buildings Based on Wireless Sensor Network and Cloud Platform. Remote Sens. 2023, 15, 1473. https://doi.org/10.3390/rs15061473

Yang Y, Xu W, Gao Z, Yu Z, Zhang Y. Research Progress of SHM System for Super High-Rise Buildings Based on Wireless Sensor Network and Cloud Platform. Remote Sensing. 2023; 15(6):1473. https://doi.org/10.3390/rs15061473

Chicago/Turabian StyleYang, Yang, Wenming Xu, Zhihao Gao, Zhou Yu, and Yao Zhang. 2023. "Research Progress of SHM System for Super High-Rise Buildings Based on Wireless Sensor Network and Cloud Platform" Remote Sensing 15, no. 6: 1473. https://doi.org/10.3390/rs15061473

APA StyleYang, Y., Xu, W., Gao, Z., Yu, Z., & Zhang, Y. (2023). Research Progress of SHM System for Super High-Rise Buildings Based on Wireless Sensor Network and Cloud Platform. Remote Sensing, 15(6), 1473. https://doi.org/10.3390/rs15061473