Construction of “Space-Sky-Ground” Integrated Collaborative Monitoring Framework for Surface Deformation in Mining Area

Abstract

:1. Introduction

2. Methodology

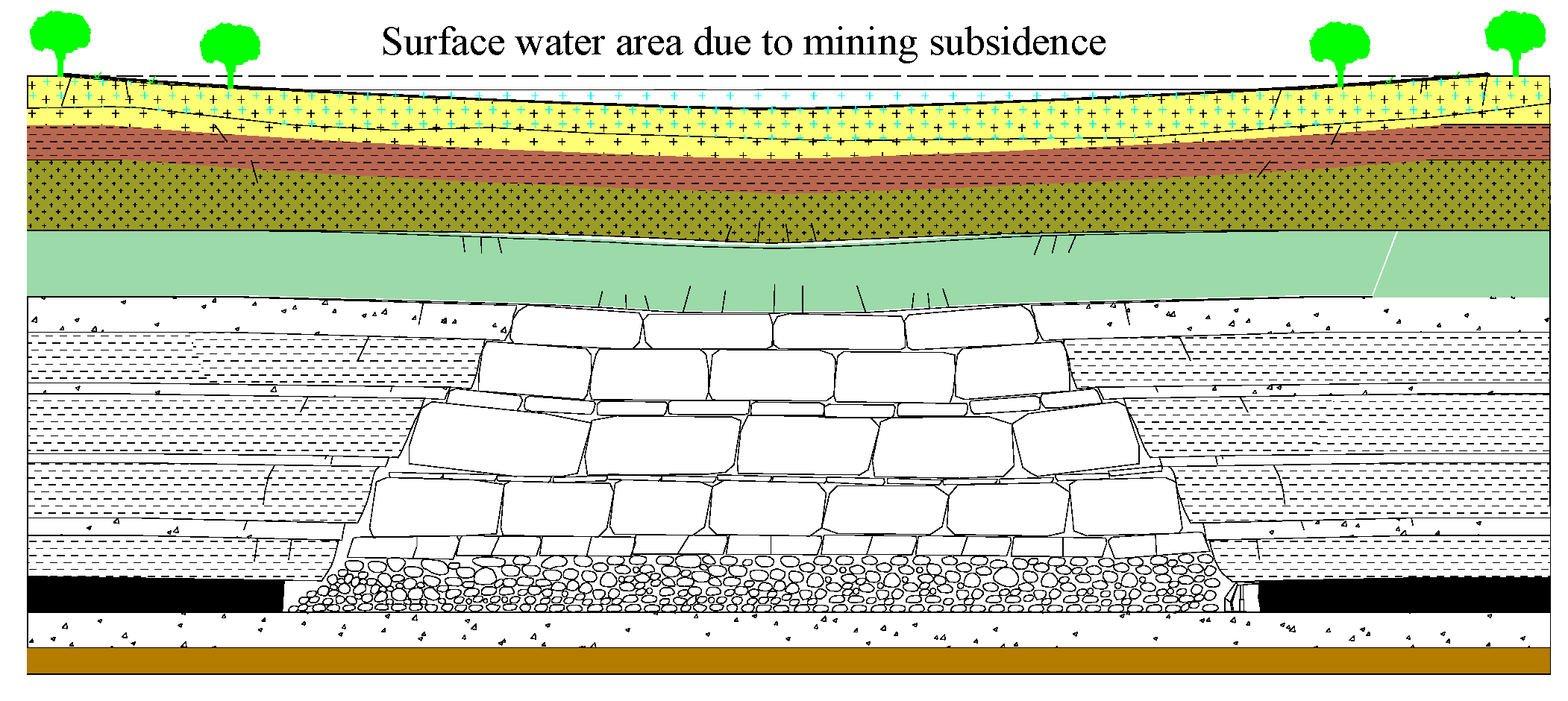

2.1. Surface Deformation in Mining Area

- (1)

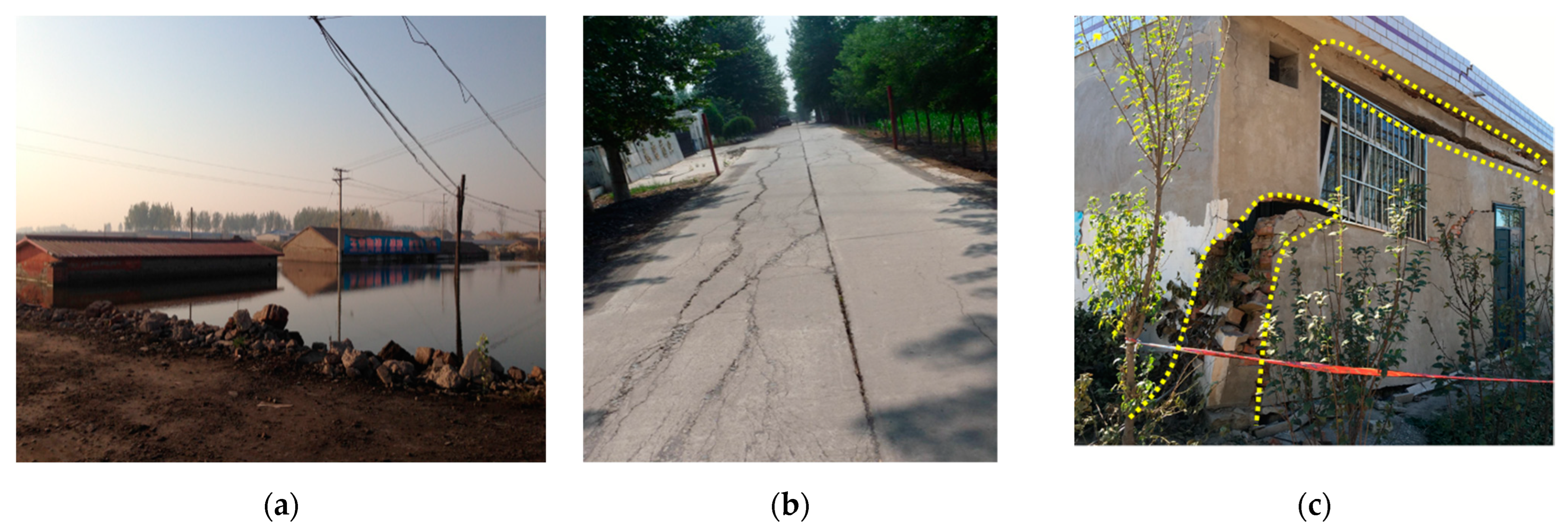

- Continuous deformation: Subsidence is a general description of movement and deformation. According to the different ways, directions and properties of movement and deformation, the subsidence conditions of rock strata and surface are described as subsidence, inclination, curvature, horizontal movement and horizontal deformation. The above-mentioned five basic movement and deformation variables are usually used. Damage of continuous deformation to the surface is shown in Figure 2a–c. The trajectory of the surface point depends on the relationship between the surface point and the relative position of the working face in time-space. In general, the moving vector of each point on the surface above the bending zone points to the center of the moving basin from both its starting and ending relative positions.

- (2)

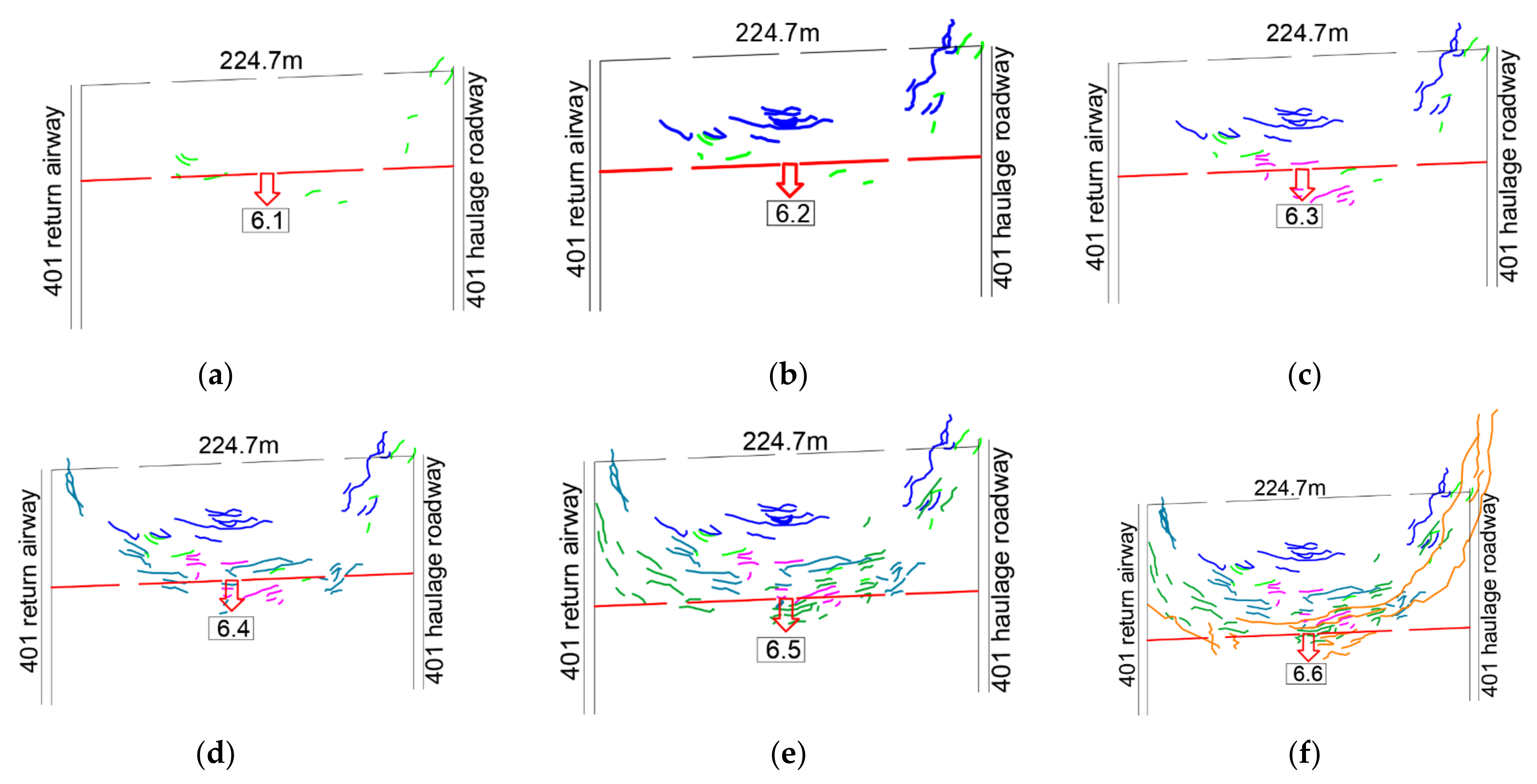

- Discontinuous deformation: Discontinuous deformation refers to the large surface displacement over limited surface area with steps or discontinuities in the surface profile, discontinuous deformation within underground coal mining rock formations contains: (a) crown hole; (b) chimney caving; (c) plug subsidence; (d) solution cavities; (e) block caving; (f) progressive hanging wall caving [44]. In China, it is generally considered that the main manifestations of surface discontinuous deformation are mining cracks, step cracks and collapse pits [45,46]. As a typical manifestation of discontinuous deformation, surface mining cracks are prevalent and worthy of study. The discussion in this paper focuses on surface mining cracks in discontinuous deformation. Discontinuous deformation is generated with certain conditions; the surface mining fracture characteristics are closely related to the location of generation; the fracture zone is generated periodically with the surface advance in the direction of working face advance; the mining cracks are developed in the form of fracture zones; the topsoil properties have a significant influence on the discontinuous development characteristics. The damage of discontinuous deformation on the surface is shown in Figure 2d,e.

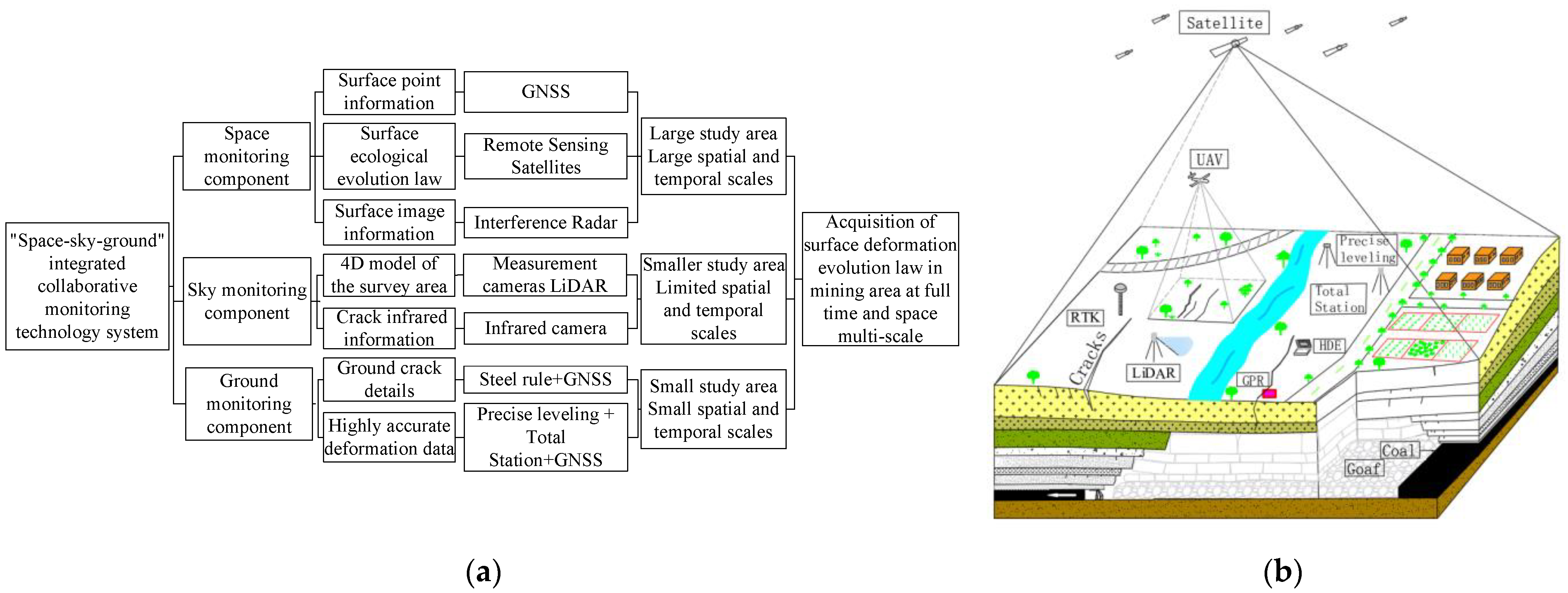

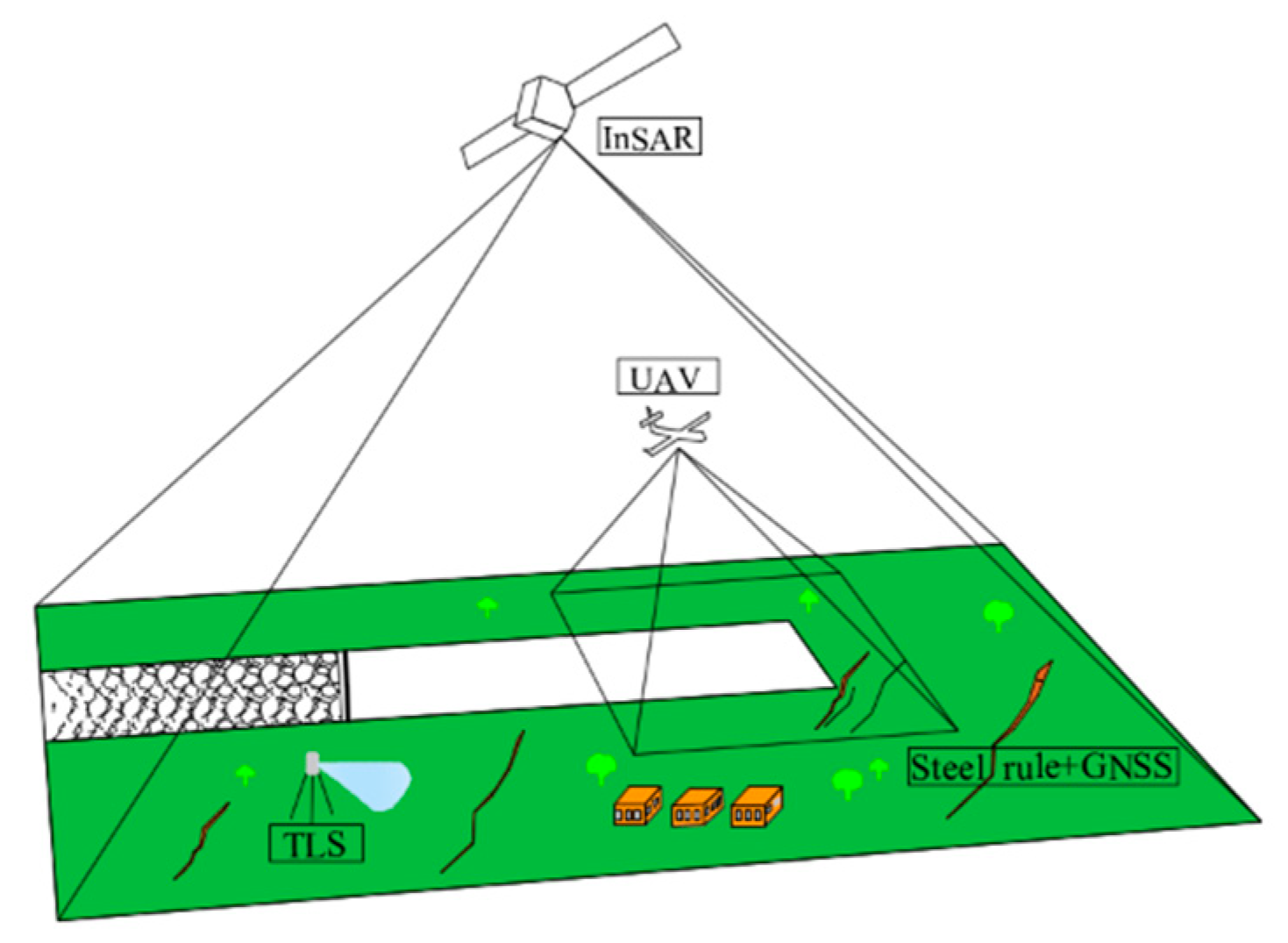

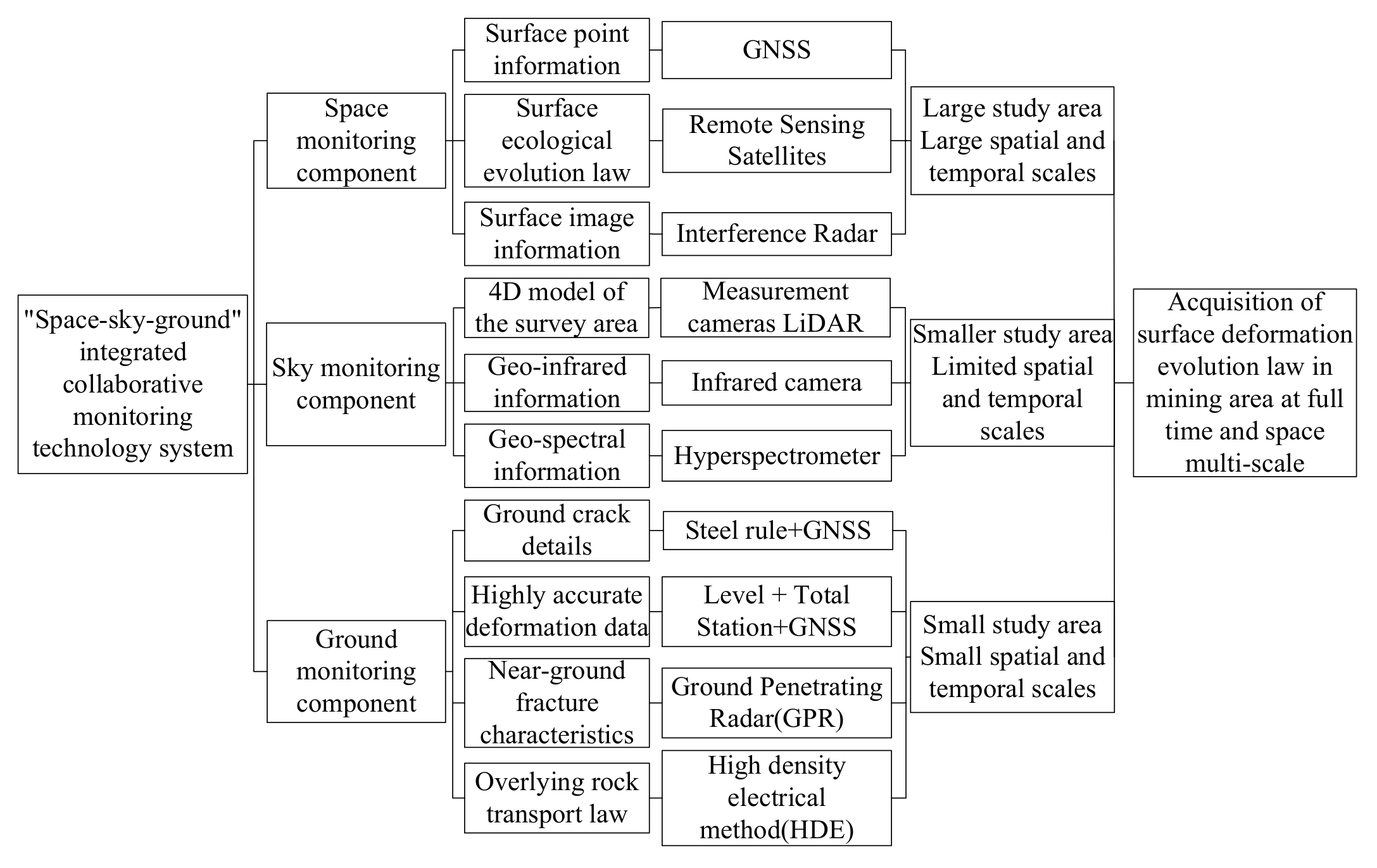

2.2. “Space-Sky-Ground” Collaborative Monitoring Framework of Mining Subsidence

2.3. Preference Model

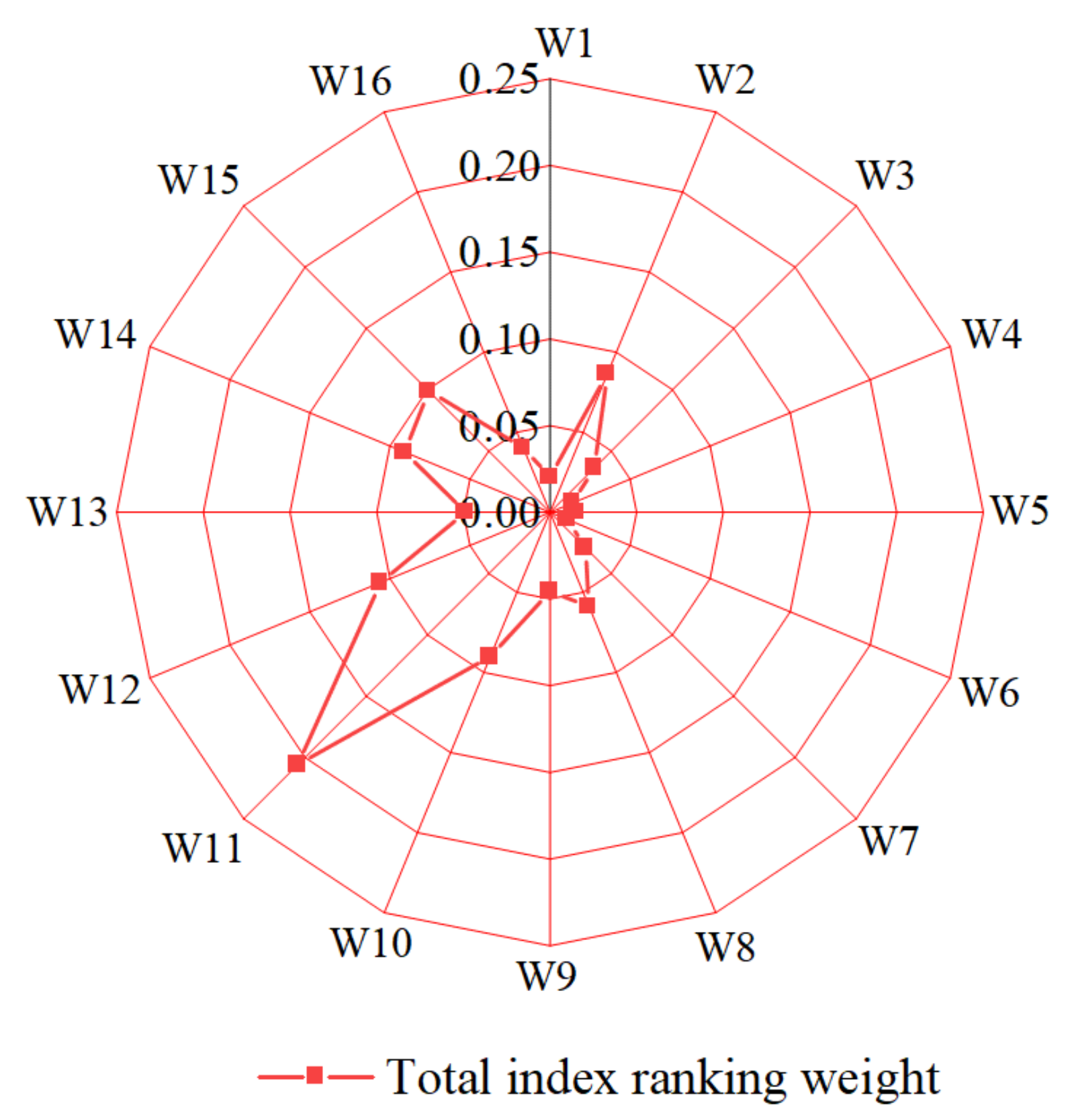

2.3.1. Infactors Determination and Analysis

2.3.2. Comprehensive Preferred Model Based on AHP-TOPSIS

3. Case Study

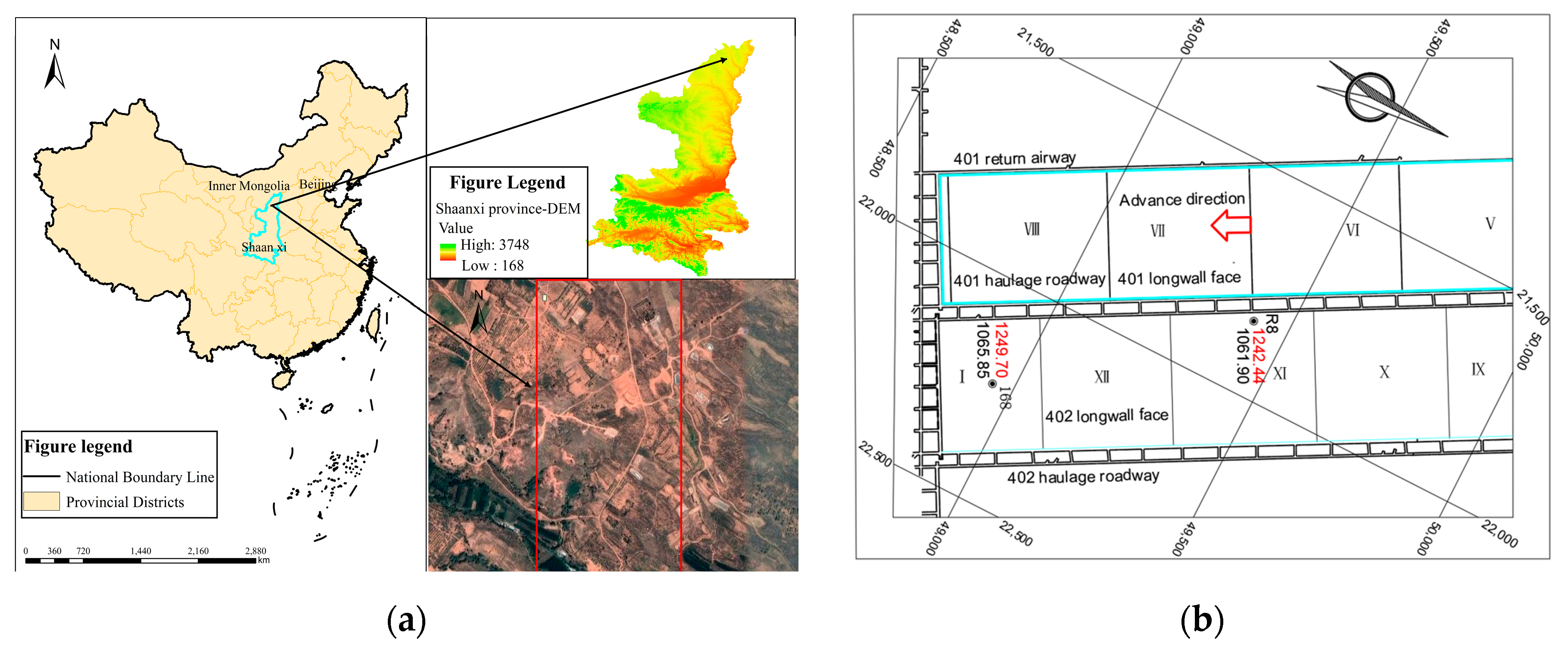

3.1. Study Area

3.2. Preference of Surface Subsidence Monitoring Program

3.3. Surface Subsidence Monitoring

3.3.1. InSAR Subsidence Monitoring

3.3.2. TLS Subsidence Monitoring

3.3.3. UAV Subsidence Monitoring

3.3.4. Steel Ruler and GNSS Subsidence Monitoring

4. Results

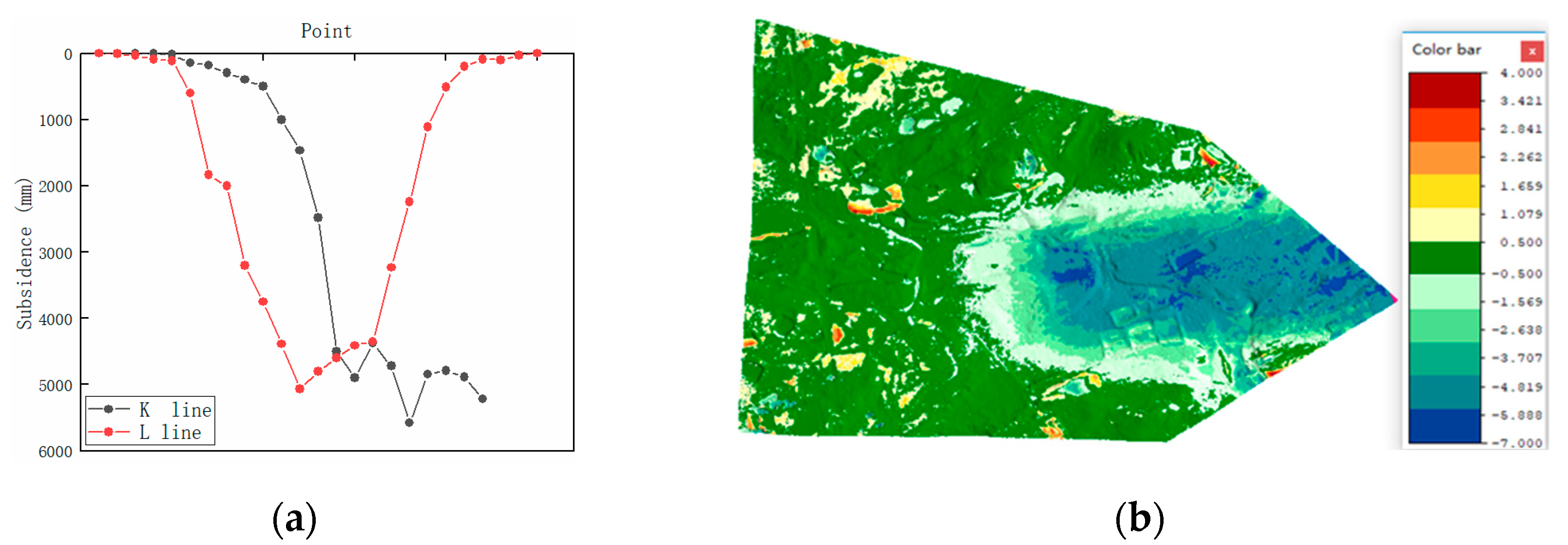

4.1. Surface Subsidence Monitoring from Single Technique

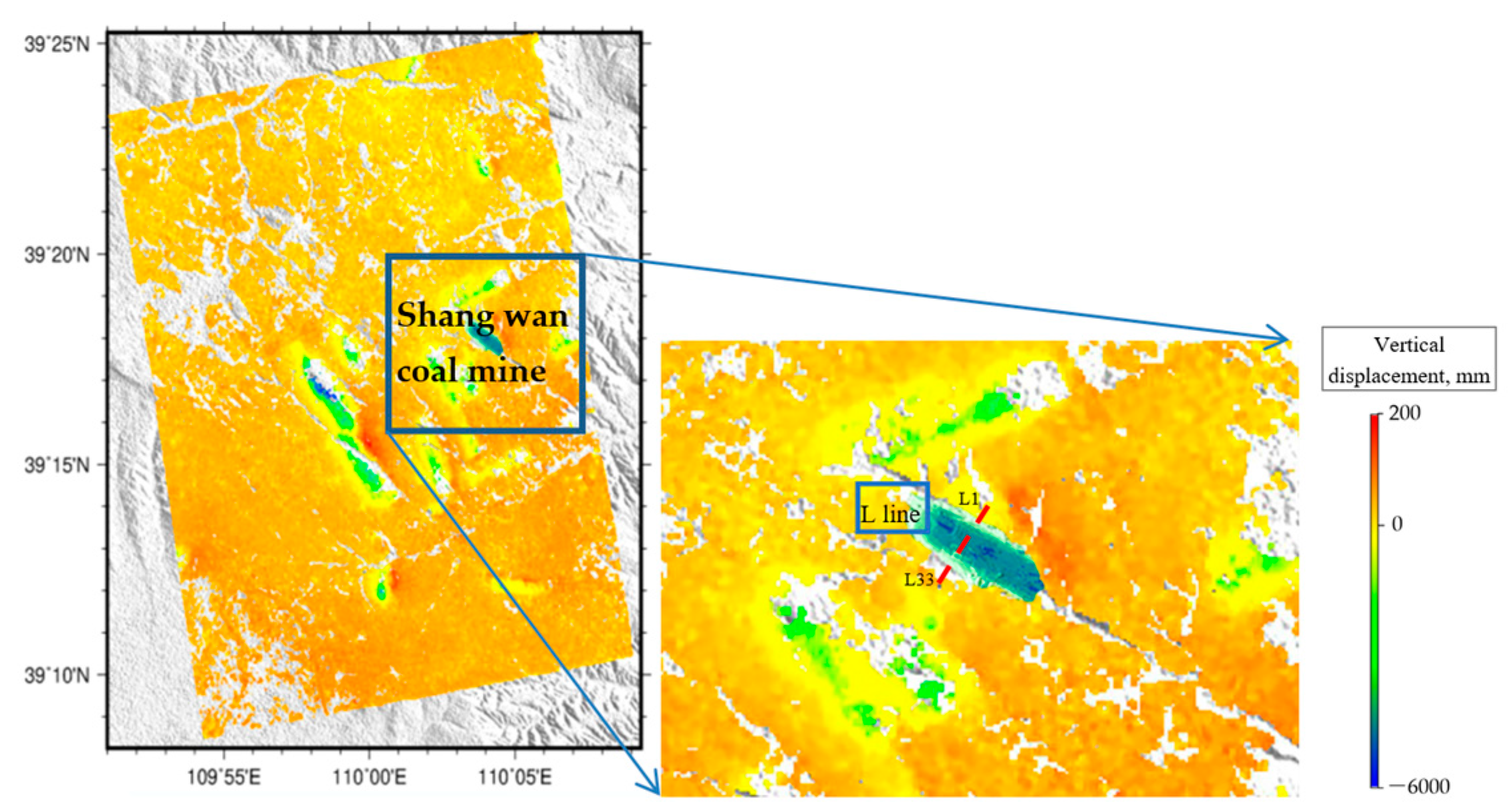

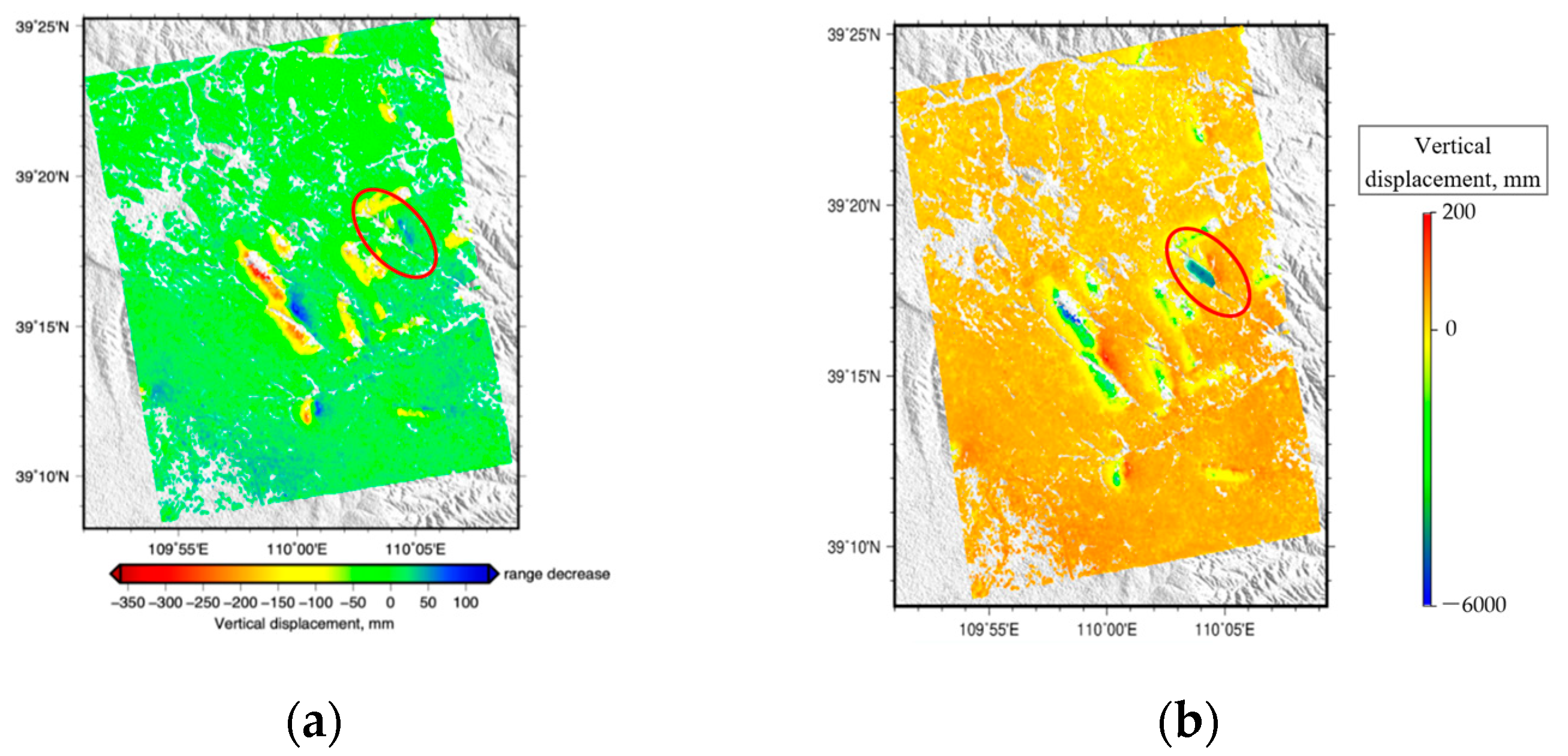

4.1.1. Surface Deformation Monitoring Results of Mining Area Based on InSAR Technology

4.1.2. TLS Deformation Results

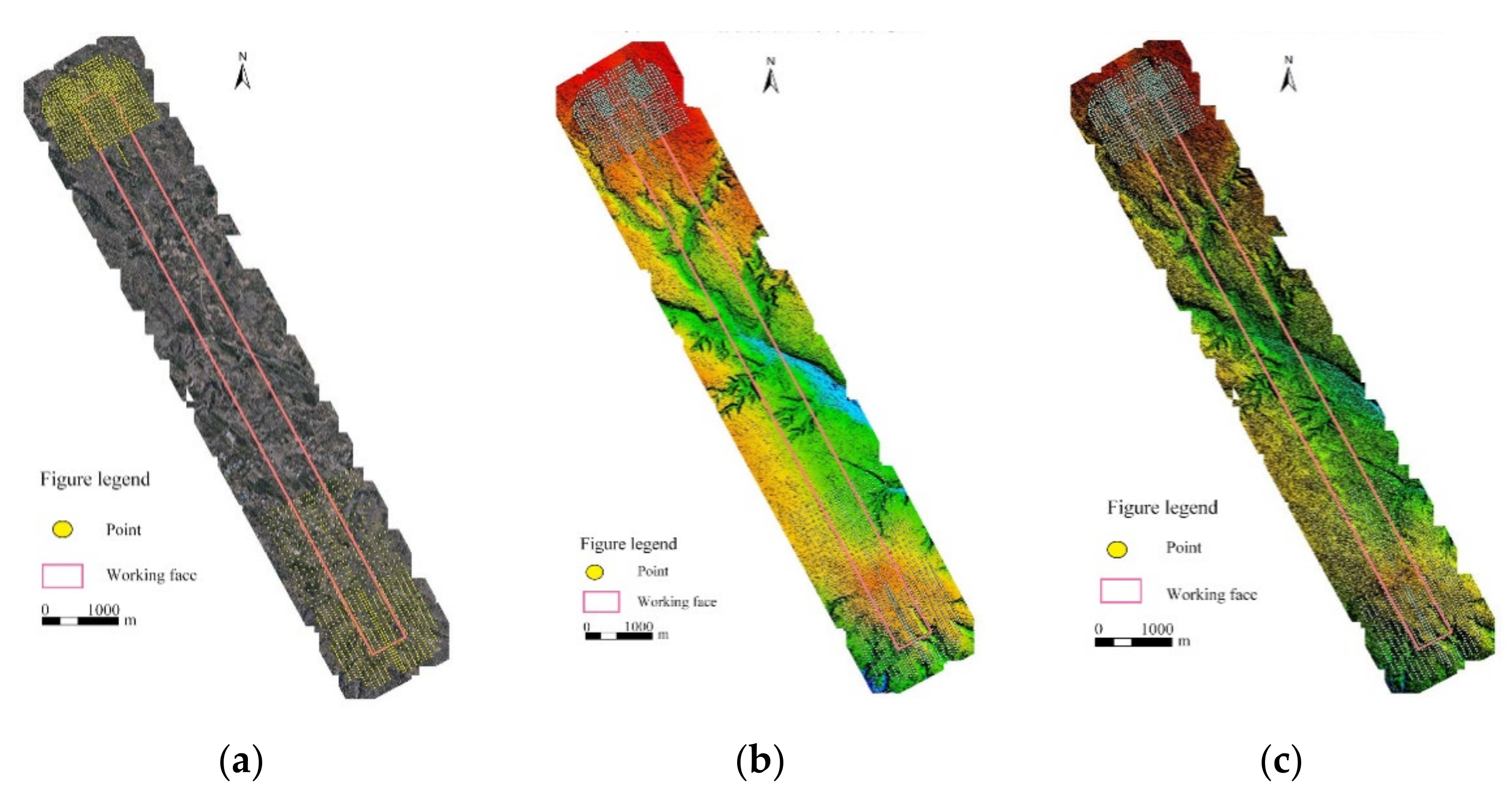

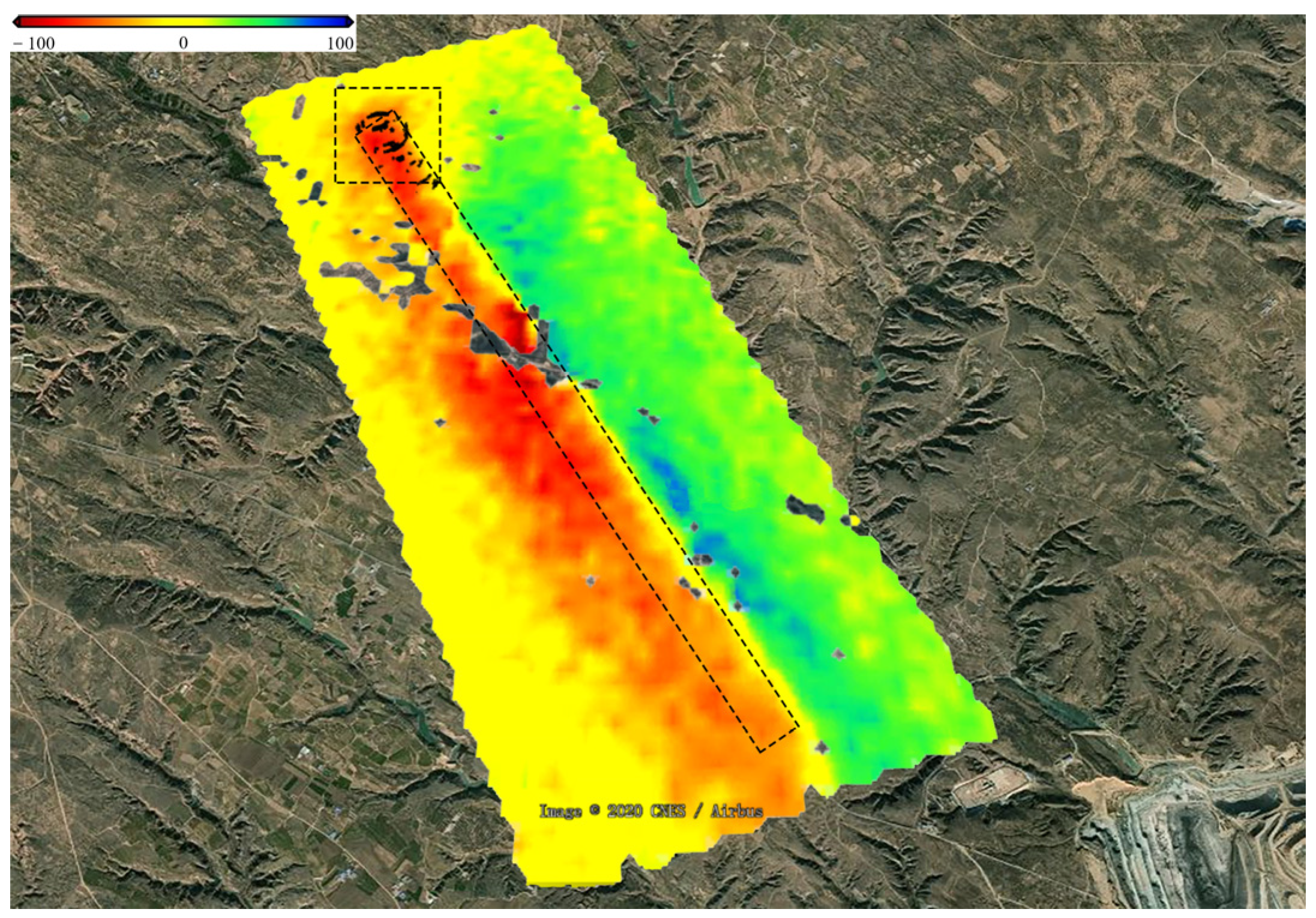

4.1.3. UAV Deformation Results

- (1)

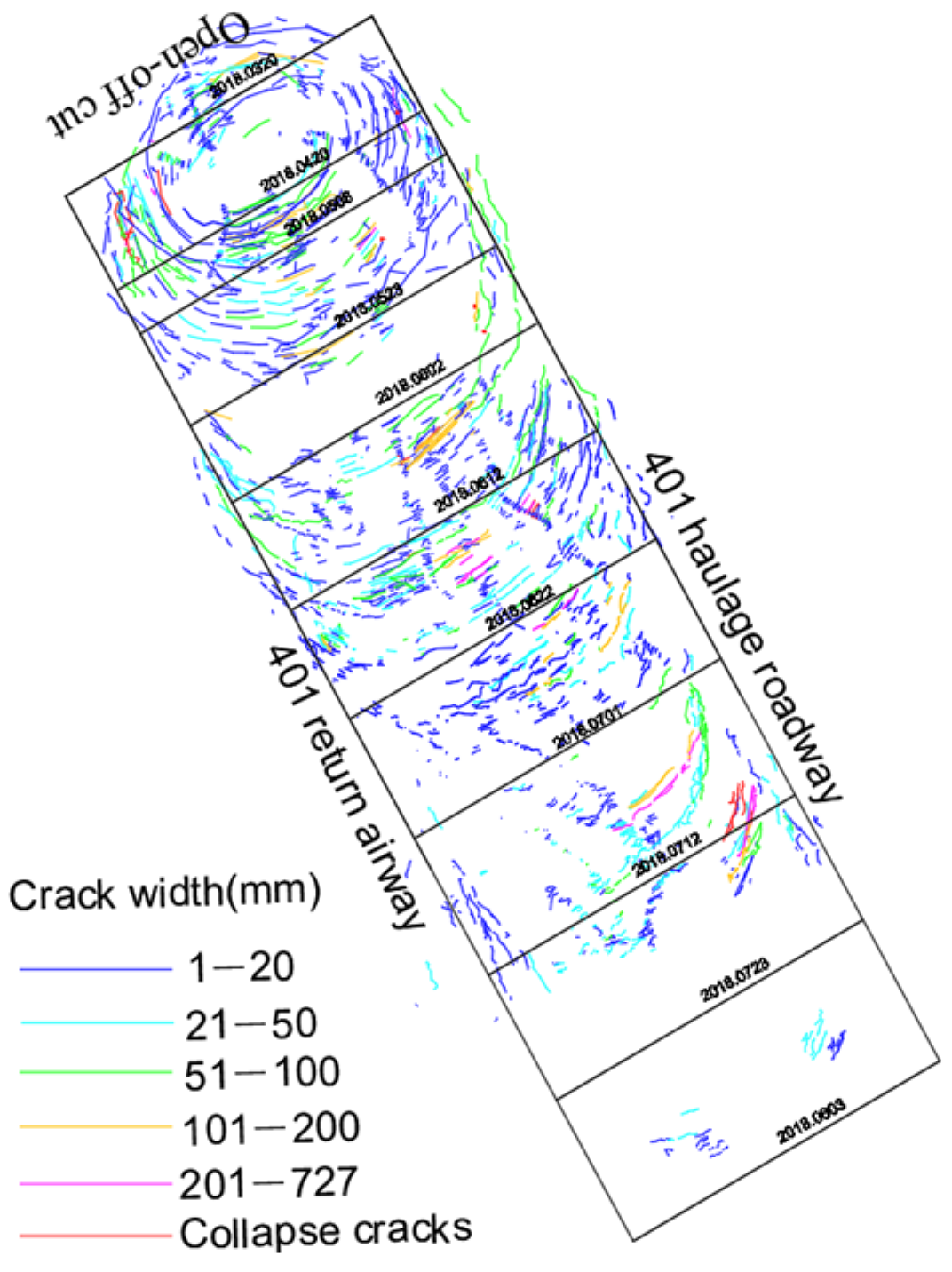

- Surface cracks

- (2)

- Construction of 3d surface model

4.1.4. Deformation from Steel Ruler and GNSS

4.2. Deformation Results from the “Space-Sky-Ground” Collaborative Monitoring Framework

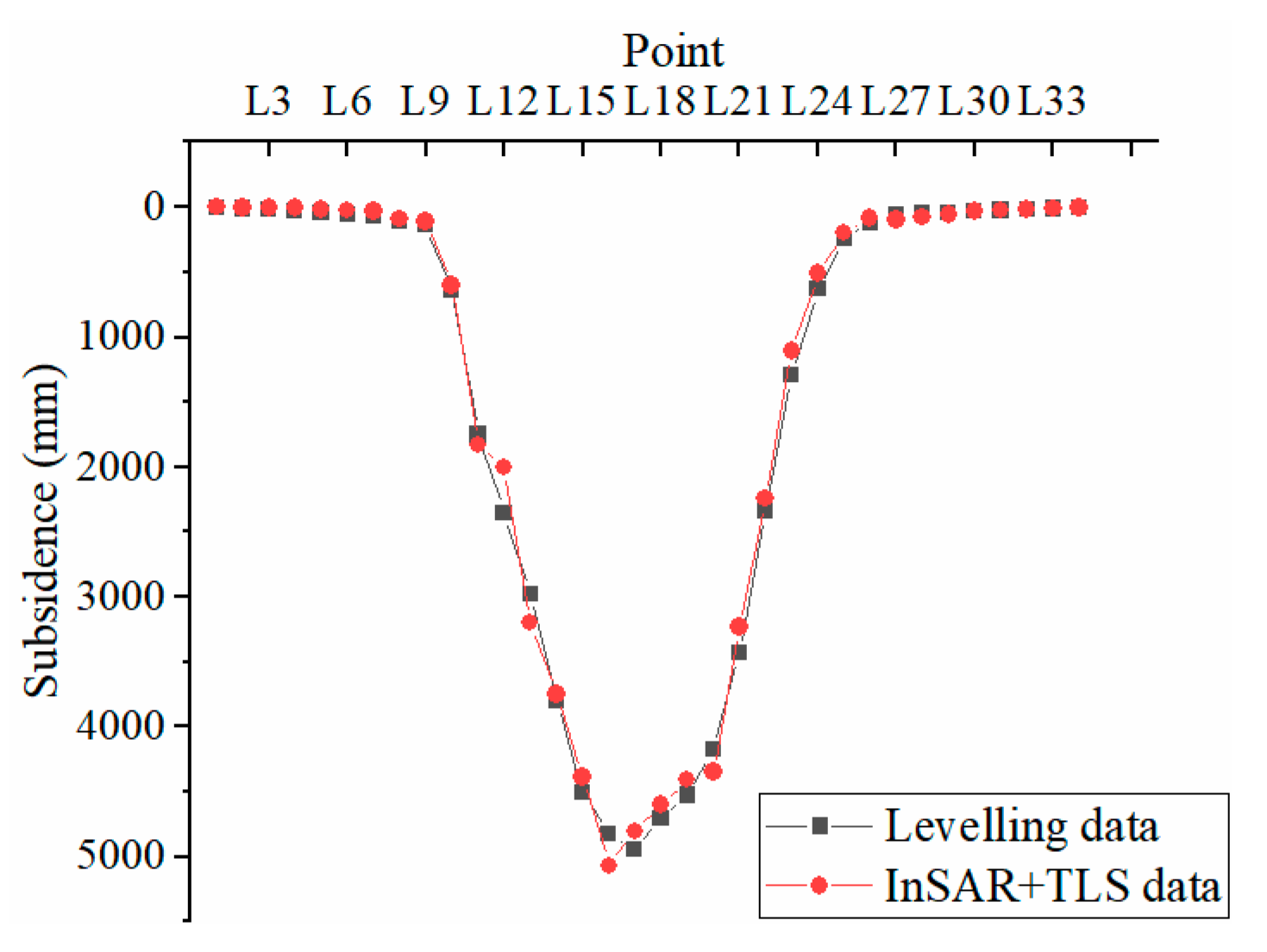

4.2.1. Results of Continuous Surface Deformation

4.2.2. Discontinuous Deformation Identification and Distribution

- (1)

- Surface discontinuous deformation identification

- (2)

- Surface discontinuous deformation distribution

5. Discussion

- (1)

- Based on the characteristics of surface deformation in mining areas and existing surface deformation monitoring technologies, this paper established the “space-sky-ground” collaborative monitoring framework. This framework is an important guideline for the preference model of “space-sky-ground” collaborative monitoring and the integration of various technologies. The determination of the weighting of different programs in the monitoring program selection model needs to be combined with the “space-sky-ground” collaborative monitoring framework, so as to better utilize the advantages of each monitoring technology, for example, in Section 3.2 of this paper, the weighting process of the “spatial scale evolution law” is based on the “space-sky-ground” collaborative monitoring framework, and program 1 (GNSS and CORS, InSAR, TLS, UAV) is less weighted than the other schemes because of the lack of small-scale measurement techniques; the integration of multiple technologies needs to fully consider the time scale and spatial scale of each monitoring method in the “space-sky-ground” cooperative monitoring framework, so as to obtain the best data fusion results and comprehensively obtain the surface subsidence pattern.

- (2)

- The AHP-TOPSIS model has many applications in other areas of program selection. In this paper, the AHP-TOPSIS model is chosen as the preferred model for the “space-sky-ground” collaborative monitoring framework. The purpose of this paper is to apply the AHP-TOPSIS model in the “space-sky-ground” collaborative monitoring framework to prefer a monitoring program. The preferred model directly determines the results of “space-sky-ground” collaborative monitoring framework and should be taken seriously. As the field of artificial intelligence continues to receive attention, artificial intelligence algorithms such as neural networks and support vector machines will significantly improve the rationality and accuracy of monitoring method selection.

- (3)

- InSAR technology has the advantages of easy data acquisition and large monitoring period span, which can monitor long-period surface subsidence and be used to compare the difference of deformation patterns with the adjacent unmined areas, but InSAR is limited by decoherence and cannot monitor continuous large surface deformation in a short period of time (Figure 21a). TLS monitoring has the advantage of acquiring surface subsidence information with high accuracy, and the fusion of the two surface subsidence monitoring results can accurately obtain the large-scale surface subsidence laws (Figure 21b). Combining the fused monitoring results of InSAR and TLS provides a new way of thinking for the later analysis of the surface subsidence laws over a large area of the working face. The results provide a foundation for global planning to protect the ecological environment of the mining area and provide data for overburden damage control and ecological restoration in the area, which cannot be achieved by using a single TLS or InSAR monitoring technique.

- (4)

- Combining InSAR monitoring technology with the advantages of easy data acquisition and large observation time range, InSAR is used to calculate the surface deformation gradient, analyzing the location of surface cracks generated in the mine area. This technique provides a new idea for other working faces to use InSAR technology to identify the location of surface cracks in subsidence areas and provides a reference for the filling of surface cracks and the restoration of surface ecology. Figure 22 shows the process of manual treatment of the cracks identified by InSAR.

- (5)

- By combining traditional ground crack survey methods and UAV crack monitoring technology, the final distribution law of surface cracks can be accurately obtained by applying UAV technology to monitor cracks in the center of the subsidence basin and at the inflection point and applying traditional ground fracture survey methods to cracks at the edge of the subsidence basin, in response to the characteristics of shallow buried thick coal seam mining in western mining areas. The “space-sky-ground” collaborative monitoring framework gives full play to the advantages of the emerging technology, making it possible to comprehensively understand the development law of cracks and laying the foundation for the analysis and management of cracks in large areas of coal mine subsidence areas.

6. Conclusions

- (1)

- Based on the characteristics of surface deformation in mining areas and existing monitoring technologies, this paper established the “space-sky-ground” collaboration monitoring framework in mining areas. The monitoring framework consists of three parts: space monitoring component, sky monitoring component and ground monitoring component, moreover, it basically includes the existing surface monitoring technologies, and new monitoring technologies can be added to the framework in the future according to their own characteristics. The framework of this paper is an important guide to the analysis of the influencing factors of the “space-sky-ground” collaborative monitoring preference program, the establishment of the preference model and the implementation steps of the preference model. At the same time, the proposed framework presents new thinking to recognize the multi-temporal and multi-scale surface subsidence patterns in mining areas.

- (2)

- Determine the influencing factors affecting the surface preference monitoring program, a total of 3 primary indicators and 16 secondary indicators, the primary indicators include: natural factors, target constraints and site needs. The importance of the 16 secondary indicators was analyzed using AHP. Meanwhile, combining the advantages of AHP-TOPSIS preference model, the AHP-TOPSIS preference model was constructed based the “space-sky-ground” collaborative monitoring framework, and four steps of monitoring scheme preference based on AHP-TOPSIS model were proposed. The practical application was carried out in the surface monitoring program preference of 401 working face in Shendong mine.

- (3)

- Based on the preferred monitoring program under the “space-sky-ground” collaborative monitoring framework at the 401 working face of the Shendong mine, the information on the distribution of discontinuous deformation and the results of continuous deformation of large surface area in the whole area of the mine were obtained, and the discontinuous large deformation was identified. The results obtained provide a data support for the crack management in the mine area, and provide an example for the further extension of the “space-sky-ground” collaborative monitoring results proposed in this paper. The “space-sky-ground” collaborative monitoring framework established in this paper helps scholars to understand the surface subsidence pattern in mining areas at multiple scales and provide a technical and data support for surface ecological restoration.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, Y.; Tao, Q.; Liu, G.; Wang, L.; Wang, F.; Wang, K. Detailed mining subsidence monitoring combined with InSAR and probability integral method. Chin. J. Geophys. 2021, 64, 3554–3566. [Google Scholar] [CrossRef]

- Dai, H.; Guo, J.; Yi, S.; Wang, G.; Liu, A.; Kong, B.; Zou, B. The mechanism of strata and surface movements induced by extra-thick steeply inclined coal seam applied horizontal slice mining. J. China Coal Soc. 2013, 38, 1109–1115. [Google Scholar] [CrossRef]

- Dai, H. Mining subsidence variables and their time-space relationship description. J. China Coal Soc. 2018, 43, 450–459. [Google Scholar] [CrossRef]

- Alam, M.S.; Kumar, D.; Chatterjee, R.S. Improving the capability of integrated DInSAR and PSI approach for better detection, monitoring, and analysis of land surface deformation in underground mining environment. Geocarto Int. 2021, 2021, 1864028. [Google Scholar] [CrossRef]

- Minami, M.; Morikawa, H.; Aoyama, T.; Mizumachi, M. An adaptive multipath estimation/elimination technique for GPS signals reception. Electron. Commun. Jpn. 2003, 86, 74–82. [Google Scholar] [CrossRef]

- Patel, P.R.; Kulkarni, M.N. Preliminary Results of GPS Studies for Monitoring Land Subsidence Over the Shallow Gas Reservoir in India. Surv. Rev. 2013, 40, 356–365. [Google Scholar] [CrossRef]

- Zhao, H.; Ma, F.; Zhang, Y.; Gue, J. Monitoring and Assessment of Ming Subsidence in a Metal Mine in China. Environ. Eng. Manag. J. 2014, 13, 3015–3024. [Google Scholar] [CrossRef]

- Hung, W.; Hwang, C.; Chang, C.; Yen, J.; Liu, C.; Yang, W. Monitoring severe aquifer-system compaction and land subsidence in Taiwan using multiple sensors: Yunlin, the southern Choushui River Alluvial Fan. Environ. Earth Sci. 2009, 59, 1535–1548. [Google Scholar] [CrossRef]

- Kim, D.; Lee, H.; Okeowo, M.A.; Basnayake, S.; Jayasinghe, S. Cost-effective monitoring of land subsidence in developing countries using semipermanent GPS stations: A test study over Houston, Texas. J. Appl. Remote Sens. 2017, 11, 026033. [Google Scholar] [CrossRef]

- Ao, J.; Wu, K.; Wang, Y.; Li, L. Subsidence Monitoring Using Lidar and Morton Code Indexing. J. Surv. Eng. 2016, 142, 06015002. [Google Scholar] [CrossRef]

- Chen, S.; Wang, C.; Dai, H.; Zhang, H.; Pan, F.; Xi, X.; Yan, Y.; Wang, P.; Yang, X.; Zhu, X.; et al. Power Pylon Reconstruction Based on Abstract Template Structures Using Airborne LiDAR Data. Remote Sens. 2019, 11, 1579. [Google Scholar] [CrossRef] [Green Version]

- Jones, L.; Hobbs, P. The Application of Terrestrial LiDAR for Geohazard Mapping, Monitoring and Modelling in the British Geological Survey. Remote Sens. 2021, 13, 395. [Google Scholar] [CrossRef]

- Tiwari, A.; Narayan, A.B.; Dwivedi, R.; Dikshit, O.; Nagarajan, B. Monitoring of landslide activity at the Sirobagarh landslide, Uttarakhand, India, using LiDAR, SAR interferometry and geodetic surveys. Geocarto Int. 2018, 35, 535–558. [Google Scholar] [CrossRef]

- Dawei, Z.; Lizhuang, Q.; Demin, Z.; Baohui, Z.; Lianglin, G. Unmanned Aerial Vehicle (UAV) Photogrammetry Technology for Dynamic Mining Subsidence Monitoring and Parameter Inversion: A Case Study in China. IEEE Access 2020, 8, 16372–16386. [Google Scholar] [CrossRef]

- Ignjatović Stupar, D.; Rošer, J.; Vulić, M. Investigation of Unmanned Aerial Vehicles-Based Photogrammetry for Large Mine Subsidence Monitoring. Minerals 2020, 10, 196. [Google Scholar] [CrossRef] [Green Version]

- Mateos, R.M.; Azañón, J.M.; Roldán, F.J.; Notti, D.; Pérez-Peña, V.; Galve, J.P.; Pérez-García, J.L.; Colomo, C.M.; Gómez-López, J.M.; Montserrat, O.; et al. The combined use of PSInSAR and UAV photogrammetry techniques for the analysis of the kinematics of a coastal landslide affecting an urban area (SE Spain). Landslides 2016, 14, 743–754. [Google Scholar] [CrossRef]

- Park, S.; Choi, Y. Applications of Unmanned Aerial Vehicles in Mining from Exploration to Reclamation: A Review. Minerals 2020, 10, 663. [Google Scholar] [CrossRef]

- Rauhala, A.; Tuomela, A.; Davids, C.; Rossi, P. UAV Remote Sensing Surveillance of a Mine Tailings Impoundment in Sub-Arctic Conditions. Remote Sens. 2017, 9, 1318. [Google Scholar] [CrossRef] [Green Version]

- Vlastelica, G.; Matoš, B.; Pikelj, K.; Lužar-Oberiter, B.; Kordić, B. Integration of Terrestrial Laser Scanning and UAS Photogrammetry in Geological Studies: Examples from Croatia. Period. Polytech. Civ. Eng. 2019, 63, 989–1003. [Google Scholar] [CrossRef] [Green Version]

- Yao, H.; Qin, R.; Chen, X. Unmanned Aerial Vehicle for Remote Sensing Applications—A Review. Remote Sens. 2019, 11, 1443. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.; Zhou, Y.; Chen, G.; Hao, M. Decades of Ground Deformation in the Weihe Graben, Shaanxi Province, China, in Response to Various Land Processes, Observed by Radar Interferometry and Levelling. Remote Sens. 2021, 13, 2374. [Google Scholar] [CrossRef]

- Chen, Y.; Tong, Y.; Tan, K. Coal mining deformation monitoring using SBAS-InSAR and offset tracking: A case study of Yu County China. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2020, 13, 10. [Google Scholar] [CrossRef]

- Diao, X.; Wu, K.; Zhou, D.; Li, L. Integrating the probability integral method for subsidence prediction and differential synthetic aperture radar interferometry for monitoring mining subsidence in Fengfeng, China. J. Appl. Remote Sens. 2016, 10, 016028. [Google Scholar] [CrossRef]

- Furst, S.L.; Doucet, S.; Vernant, P.; Champollion, C.; Carme, J.L. Monitoring surface deformation of deep salt mining in Vauvert (France), combining InSAR and leveling data for multi-source inversion. Solid Earth 2021, 12, 15–34. [Google Scholar] [CrossRef]

- He, Q.; Zhang, Y.; Wu, H.; Luo, Y. Mining Subsidence Monitoring with Modified Time-Series SAR Interferometry Method Based on the Multi-Level Processing Strategy. IEEE Access 2021, 9, 106039–106048. [Google Scholar] [CrossRef]

- Liu, X.; Huang, J. An Improved Multi-Platform Stacked D-InSAR Method for Monitoring the Three-Dimensional Deformation of the Mining Area. IEEE Access 2021, 9, 66878–66890. [Google Scholar] [CrossRef]

- Ng, A.H.-M.; Ge, L.; Li, X.-j. Assessments of land subsidence in the Gippsland Basin of Australia using ALOS PALSAR data. Remote Sens. Environ. 2015, 159, 15. [Google Scholar] [CrossRef]

- Yang, Z.; Li, Z.; Zhu, J.; Yi, H.; Hu, J.; Feng, G. Deriving Dynamic Subsidence of Coal Mining Areas Using InSAR and Logistic Model. Remote Sens. 2017, 9, 125. [Google Scholar] [CrossRef] [Green Version]

- Dwornik, M.; Bała, J.; Franczyk, A. Application of a New Semi-Automatic Algorithm for the Detection of Subsidence Areas in SAR Images on the Example of the Upper Silesian Coal Basin. Energies 2021, 14, 3051. [Google Scholar] [CrossRef]

- Fan, H.D.; Cheng, D.; Deng, K.Z.; Chen, B.Q.; Zhu, C.G. Subsidence monitoring using D-InSAR and probability integral prediction modelling in deep mining areas. Surv. Rev. 2015, 47, 438–445. [Google Scholar] [CrossRef]

- Jiang, C.; Wang, L.; Yu, X. Retrieving 3D Large Gradient Deformation Induced to Mining Subsidence Based on Fusion of Boltzmann Prediction Model and Single-Track InSAR Earth Observation Technology. IEEE Access 2021, 9, 87156–87172. [Google Scholar] [CrossRef]

- Li, T.; Zhang, H.; Fan, H.; Zheng, C.; Liu, J. Position Inversion of Goafs in Deep Coal Seams Based on DS-InSAR Data and the Probability Integral Methods. Remote Sens. 2021, 13, 2898. [Google Scholar] [CrossRef]

- Balt, K.; Goosen, R.L. MSAHP: An approach to mining method selection. J. South. Afr. Inst. Min. Metall. 2020, 120, 451–460. [Google Scholar] [CrossRef]

- Reich, J.; Kinra, A.; Kotzab, H.; Brusset, X. Strategic global supply chain network design how decision analysis combining MILP and AHP on a Pareto front can improve decision making. Int. J. Prod. Res. 2021, 59, 1557–1572. [Google Scholar] [CrossRef]

- Satty, T.L. How to make a decision: The analytic hierarchy process. Interfaces 1994, 24, 19–43. [Google Scholar] [CrossRef] [Green Version]

- Chen, C. Extensions of the TOPSIS for group decision-making under fuzzy environment. Fuzzy Set. Syst. 2000, 114, 1–9. [Google Scholar] [CrossRef]

- Gul, M.; Celik, E.; Aydin, N.; Taskin Gumus, A.; Guneri, A.F. A state of the art literature review of VIKOR and its fuzzy extensions on applications. Appl. Soft Comput. 2016, 46, 60–89. [Google Scholar] [CrossRef]

- Onut, S.; Soner, S. Transshipment site selection using the AHP and TOPSIS approaches under fuzzy environment. Waste Manag. 2007, 28, 1552–1559. [Google Scholar] [CrossRef]

- Pazand, K.; Hezarkhani, A. Porphyry Cu potential area selection using the combine AHP-TOPSIS methods: A case study in Siahrud area (NW, Iran). Earth Sci. Inform. 2015, 8, 207–220. [Google Scholar] [CrossRef]

- Hanine, M.; Boutkhoum, O.; Tikniouine, A.; Agouti, T. An Application of OLAP/GIS-Fuzzy AHP-TOPSIS Methodology for Decision Making: Location Selection for Landfill of Industrial Wastes as a Case Study. KSCE J. Civ. Eng. 2016, 21, 2074–2084. [Google Scholar] [CrossRef]

- Mishra, P.K.; Nadda, R.; Kumar, R.; Rana, A.; Sethi, M.; Ekileski, A. Optimization of multiple arcs protrusion obstacle parameters using AHP-TOPSIS approach in an impingement jet solar air passage. Heat Mass Transf. 2018, 54, 3797–3808. [Google Scholar] [CrossRef]

- Yu, J.; Wang, L.; Gong, X. Study on the Status Evaluation of Urban Road Intersections Traffic Congestion Base on AHP-TOPSIS Modal. Procedia Soc. Behav. Sci. 2013, 96, 609–616. [Google Scholar] [CrossRef] [Green Version]

- Zhuang, Z.-Y.; Lin, C.-C.; Chen, C.-Y.; Su, C.-R. Rank-Based Comparative Research Flow Benchmarking the Effectiveness of AHP–GTMA on Aiding Decisions of Shredder Selection by Reference to AHP–TOPSIS. Appl. Sci. 2018, 8, 1974. [Google Scholar] [CrossRef] [Green Version]

- Brady, B.H.G.; Brown, E.T. Rock Mechanics for Underground Mining; George Allen &Unwin: London, UK, 1985. [Google Scholar]

- Yin, D.; Chen, S.; Li, B.; Guo, W. Bed separation backfill to reduce surface cracking due to mining under thick and hard conglomerate: A case study. R. Soc. Open Sci. 2019, 6, 190880. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zuo, J.; Yu, M.; Li, C.; Sun, Y.; Hu, S.; Li, Z. Analysis of Surface Cracking and Fracture Behavior of a Single Thick Main Roof Based on Similar Model Experiments in Western Coal Mine, China. Nat. Resour. Res. 2021, 30, 657–680. [Google Scholar] [CrossRef]

- Wang, G.; Wu, Q.; Li, P.; Cui, X.; Gong, Y.; Zhang, J.; Tang, W. Mining Subsidence Prediction Parameter Inversion by Combining GNSS and DInSAR Deformation Measurements. IEEE Access 2021, 9, 89043–89054. [Google Scholar] [CrossRef]

- Lian, X.; Li, Z.; Yuan, H.; Hu, H.; Cai, Y.; Liu, X. Determination of the Stability of High-Steep Slopes by Global Navigation Satellite System (GNSS) Real-Time Monitoring in Long Wall Mining. Appl. Sci. 2020, 10, 1952. [Google Scholar] [CrossRef] [Green Version]

- Tao, T.; Liu, J.; Qu, X.; Gao, F. Real-time monitoring rapid ground subsidence using GNSS and Vondrak filter. Acta Geophys. 2018, 67, 133–140. [Google Scholar] [CrossRef]

- Yao, J.; Yao, X.; Wu, Z.; Liu, X.; Diraco, G. Research on Surface Deformation of Ordos Coal Mining Area by Integrating Multitemporal D-InSAR and Offset Tracking Technology. J. Sens. 2021, 2021, 660922. [Google Scholar] [CrossRef]

- Pawluszek-Filipiak, K.; Borkowski, A. Integration of DInSAR and SBAS Techniques to Determine Mining-Related Deformations Using Sentinel-1 Data: The Case Study of Rydułtowy Mine in Poland. Remote Sens. 2020, 12, 242. [Google Scholar] [CrossRef] [Green Version]

- Anders, K.; Marx, S.; Boike, J.; Herfort, B.; Wilcox, E.J.; Langer, M.; Marsh, P.; Höfle, B. Multitemporal terrestrial laser scanning point clouds for thaw subsidence observation at Arctic permafrost monitoring sites. Earth Surf. Processes Landf. 2020, 45, 1589–1600. [Google Scholar] [CrossRef]

- Barbarella, M.; Fiani, M.; Lugli, A. Landslide monitoring using multitemporal terrestrial laser scanning for ground displacement analysis. Geomat. Nat. Hazards Risk 2013, 6, 398–418. [Google Scholar] [CrossRef]

- Lian, X.; Hu, H. Terrestrial laser scanning monitoring and spatial analysis of ground disaster in Gaoyang coal mine in Shanxi, China: A technical note. Environ. Earth Sci. 2017, 76, 287. [Google Scholar] [CrossRef]

- Matwij, W.; Gruszczyński, W.; Puniach, E.; Ćwiąkała, P. Determination of underground mining-induced displacement field using multi-temporal TLS point cloud registration. Measurement 2021, 180, 109482. [Google Scholar] [CrossRef]

- Puniach, E.; Gruszczyński, W.; Ćwiąkała, P.; Matwij, W. Application of UAV-based orthomosaics for determination of horizontal displacement caused by underground mining. ISPRS J. Photogramm. Remote Sens. 2021, 174, 282–303. [Google Scholar] [CrossRef]

- Zhou, T.; Hasheminasab, S.M.; Habib, A. Tightly-coupled camera/LiDAR integration for point cloud generation from GNSS/INS-assisted UAV mapping systems. ISPRS J. Photogramm. Remote Sens. 2021, 180, 336–356. [Google Scholar] [CrossRef]

- Jing-xiang, G.; Hong, H. Advanced GNSS technology of mining deformation monitoring. Procedia Earth Planet. Sci. 2009, 1, 1081–1088. [Google Scholar] [CrossRef] [Green Version]

- Dai, H.; Luo, J.; Guo, J.; Yan, Y.; Zhang, W.; Zhu, Y. In site surveying and study on development laws of surface cracks by high—intensity mining in Shangwan Mine. Coal Sci. Technol. 2020, 48, 124–129. [Google Scholar] [CrossRef]

- Aminbakhsh, S.; Gunduz, M.; Sonmez, R. Safety risk assessment using analytic hierarchy process (AHP) during planning and budgeting of construction projects. J. Saf. Res. 2013, 46, 99–105. [Google Scholar] [CrossRef]

- Du, Y.; Chen, W.; Cui, K.; Zhang, K. Study on Damage Assessment of Earthen Sites of the Ming Great Wall in Qinghai Province Based on Fuzzy-AHP and AHP-TOPSIS. Int. J. Archit. Herit. 2019, 14, 903–916. [Google Scholar] [CrossRef]

- Ercanoglu, M.; Kasmer, O.; Temiz, N. Adaptation and comparison of expert opinion to analytical hierarchy process for landslide susceptibility mapping. Bull. Eng. Geol. Environ. 2008, 67, 565–578. [Google Scholar] [CrossRef]

- Tuzkaya, G.; Onut, S.; Tuzkaya, U.R.; Gulsun, B. An analytic network process approach for locating undesirable facilities: An example from Istanbul, Turkey. J. Environ. Manag. 2008, 88, 970–983. [Google Scholar] [CrossRef] [PubMed]

- Vahidnia, M.H.; Alesheikh, A.A.; Alimohammadi, A. Hospital site selection using fuzzy AHP and its derivatives. J. Environ. Manag. 2009, 90, 3048–3056. [Google Scholar] [CrossRef]

- Chen, Y.; Yu, S.; Tao, Q.; Liu, G.; Wang, L.; Wang, F. Accuracy Verification and Correction of D-InSAR and SBAS-InSAR in Monitoring Mining Surface Subsidence. Remote Sens. 2021, 13, 4365. [Google Scholar] [CrossRef]

- Gu, Y.; Zhou, D.; Zhang, D.; Wu, K.; Zhou, B. Study on subsidence monitoring technology using terrestrial 3D laser scanning without a target in a mining area: An example of Wangjiata coal mine, China. Bull. Eng. Geol. Environ. 2020, 79, 3575–3583. [Google Scholar] [CrossRef]

- Ishwar, S.G.; Kumar, D. Application of DInSAR in mine surface subsidence monitoring and prediction. Curr. Sci. 2017, 112, 46–51. [Google Scholar] [CrossRef]

- Zhang, C.; Zhao, Y.; He, X.; Guo, J.; Yan, Y. Space-sky-surface integrated monitoring system for overburden migration regularity in shallow-buried high-intensity mining. Bull. Eng. Geol. Environ. 2020, 80, 1403–1417. [Google Scholar] [CrossRef]

| Monitoring Method | Advantages | Accuracy |

|---|---|---|

| GNSS and CORS | Simple operation; Small workload [47,48,49] | 5 mm |

| D-InSAR | Low cost; Long period; Global surface deformation [26,30,50] | 1–3 cm |

| SBAS-InSAR [51] | Enhancement of SAR data usage; Low cost | <1 cm |

| TLS [52,53,54,55] | Long range; High accuracy | 1 cm |

| UAV [56,57] | High speed and efficiency; Flexibility | 10–15 cm |

| Levelling and Total station | High monitoring accuracy; Accurate reflection of the law of settlement | 1 mm |

| GNSS and RTK | High speed and efficiency [58] | 2 cm |

| Steel rule and GNSS | High accuracy; Law of accurate reflection [59] | 0.1 mm |

| Judgment Matrix | Maximum Eigenvalue | Eigenvector |

|---|---|---|

| A (Preferred monitoring method) | 3.0536 | 0.1571, 0.2493, 0.5936 |

| B1 (Natural factors) | 4.1023 | 0.1306, 0.5492, 0.2302, 0.0900 |

| B2 (Targets constraints) | 6.5616 | 0.0603, 0.0440, 0.1162, 0.2355, 0.1829, 0.3611 |

| B3 (Site needs) | 6.4613 | 0.3466, 0.1784, 0.0821, 0.1528, 0.1607, 0.0676 |

| Index | A | B1 | B2 | B3 |

|---|---|---|---|---|

| IC | 0.0268 | 0.0341 | 0.1123 | 0.0923 |

| IR | 0.0462 | 0.0379 | 0.0906 | 0.0744 |

| Program | GNSS and CORS | InSAR | TLS | UAV | Steel Rule and GNSS |

|---|---|---|---|---|---|

| I | √ | √ | √ | √ | |

| II | √ | √ | √ | √ | |

| III | √ | √ | √ | √ | |

| IV | √ | √ | √ | √ | |

| V | √ | √ | √ | √ |

| Number | Date | Path-Frame | Orbital Direction | Polarization Mode | Model | Incidence Angle |

|---|---|---|---|---|---|---|

| 1 | 14 October 2017 | 11-126 | Ascending | VV | IW | 40-41 |

| 2 | 26 October 2017 | 11-126 | Ascending | VV | IW | 40-41 |

| 3 | 7 November 2017 | 11-126 | Ascending | VV | IW | 40-41 |

| 4 | 19 November 2017 | 11-126 | Ascending | VV | IW | 40-41 |

| 5 | 1 December 2017 | 11-126 | Ascending | VV | IW | 40-41 |

| 6 | 13 December 2017 | 11-126 | Ascending | VV | IW | 40-41 |

| 7 | 25 December 2017 | 11-126 | Ascending | VV | IW | 40-41 |

| 8 | 6 January 2018 | 11-126 | Ascending | VV | IW | 40-41 |

| 9 | 30 January 2018 | 11-126 | Ascending | VV | IW | 40-41 |

| 10 | 11 February 2018 | 11-126 | Ascending | VV | IW | 40-41 |

| 11 | 23 February 2018 | 11-126 | Ascending | VV | IW | 40-41 |

| 12 | 7 March 2018 | 11-126 | Ascending | VV | IW | 40-41 |

| 13 | 19 March 2018 | 11-126 | Ascending | VV | IW | 40-41 |

| 14 | 31 March 2018 | 11-126 | Ascending | VV | IW | 40-41 |

| 15 | 12 April 2018 | 11-126 | Ascending | VV | IW | 40-41 |

| 16 | 24 April 2018 | 11-126 | Ascending | VV | IW | 40-41 |

| 17 | 6 May 2018 | 11-126 | Ascending | VV | IW | 40-41 |

| 18 | 18 May 2018 | 11-126 | Ascending | VV | IW | 40-41 |

| 19 | 30 May 2018 | 11-126 | Ascending | VV | IW | 40-41 |

| 20 | 11 June 2018 | 11-126 | Ascending | VV | IW | 40-41 |

| 21 | 23 June 2018 | 11-126 | Ascending | VV | IW | 40-41 |

| 22 | 5 July 2018 | 11-126 | Ascending | VV | IW | 40-41 |

| 23 | 29 July 2018 | 11-126 | Ascending | VV | IW | 40-41 |

| 24 | 10 August 2018 | 11-126 | Ascending | VV | IW | 40-41 |

| 25 | 22 August 2018 | 11-126 | Ascending | VV | IW | 40-41 |

| 26 | 3 September 2018 | 11-126 | Ascending | VV | IW | 40-41 |

| 27 | 15 September 2018 | 11-126 | Ascending | VV | IW | 40-41 |

| 28 | 27 September 2018 | 11-126 | Ascending | VV | IW | 40-41 |

| 29 | 9 October 2018 | 11-126 | Ascending | VV | IW | 40-41 |

| 30 | 21 October 2018 | 11-126 | Ascending | VV | IW | 40-41 |

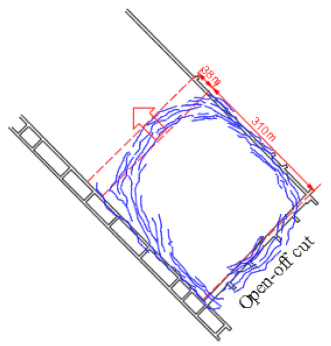

| Advance the Position | 155 m | 310 m |

|---|---|---|

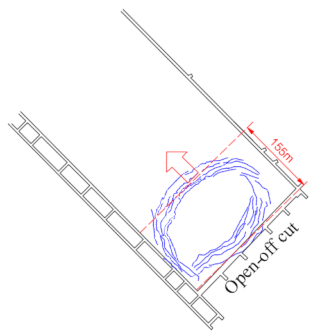

| Crack development law | The working face advances slowly, the old roof is damaged by mining to a relatively large extent, and the overlying rock and surface cracks are fully developed, resulting in the development of cracks ahead of the working face. | All three marginal cracks beyond the working face are developed beyond the mining boundary, and the new ground cracks continue to develop 38 m forward. |

| Schematic diagram |  |  |

| Maximum Subsidence Value | Point Cloud Data (InSAR and TLS) | Levelling Data |

|---|---|---|

| K line | 5579 mm (K36) | 5562 mm (K36) |

| L line | 5067 mm (L22) | 4942 mm (L22) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, Y.; Li, M.; Dai, L.; Guo, J.; Dai, H.; Tang, W. Construction of “Space-Sky-Ground” Integrated Collaborative Monitoring Framework for Surface Deformation in Mining Area. Remote Sens. 2022, 14, 840. https://doi.org/10.3390/rs14040840

Yan Y, Li M, Dai L, Guo J, Dai H, Tang W. Construction of “Space-Sky-Ground” Integrated Collaborative Monitoring Framework for Surface Deformation in Mining Area. Remote Sensing. 2022; 14(4):840. https://doi.org/10.3390/rs14040840

Chicago/Turabian StyleYan, Yueguan, Ming Li, Linda Dai, Junting Guo, Huayang Dai, and Wei Tang. 2022. "Construction of “Space-Sky-Ground” Integrated Collaborative Monitoring Framework for Surface Deformation in Mining Area" Remote Sensing 14, no. 4: 840. https://doi.org/10.3390/rs14040840

APA StyleYan, Y., Li, M., Dai, L., Guo, J., Dai, H., & Tang, W. (2022). Construction of “Space-Sky-Ground” Integrated Collaborative Monitoring Framework for Surface Deformation in Mining Area. Remote Sensing, 14(4), 840. https://doi.org/10.3390/rs14040840