Precise Positioning Method of Moving Laser Point Cloud in Shield Tunnel Based on Bolt Hole Extraction

Abstract

1. Introduction

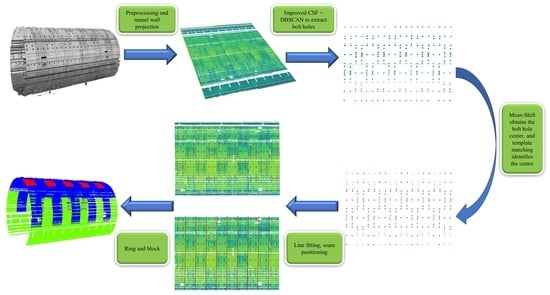

2. Materials and Methods

2.1. Point Cloud Preprocessing

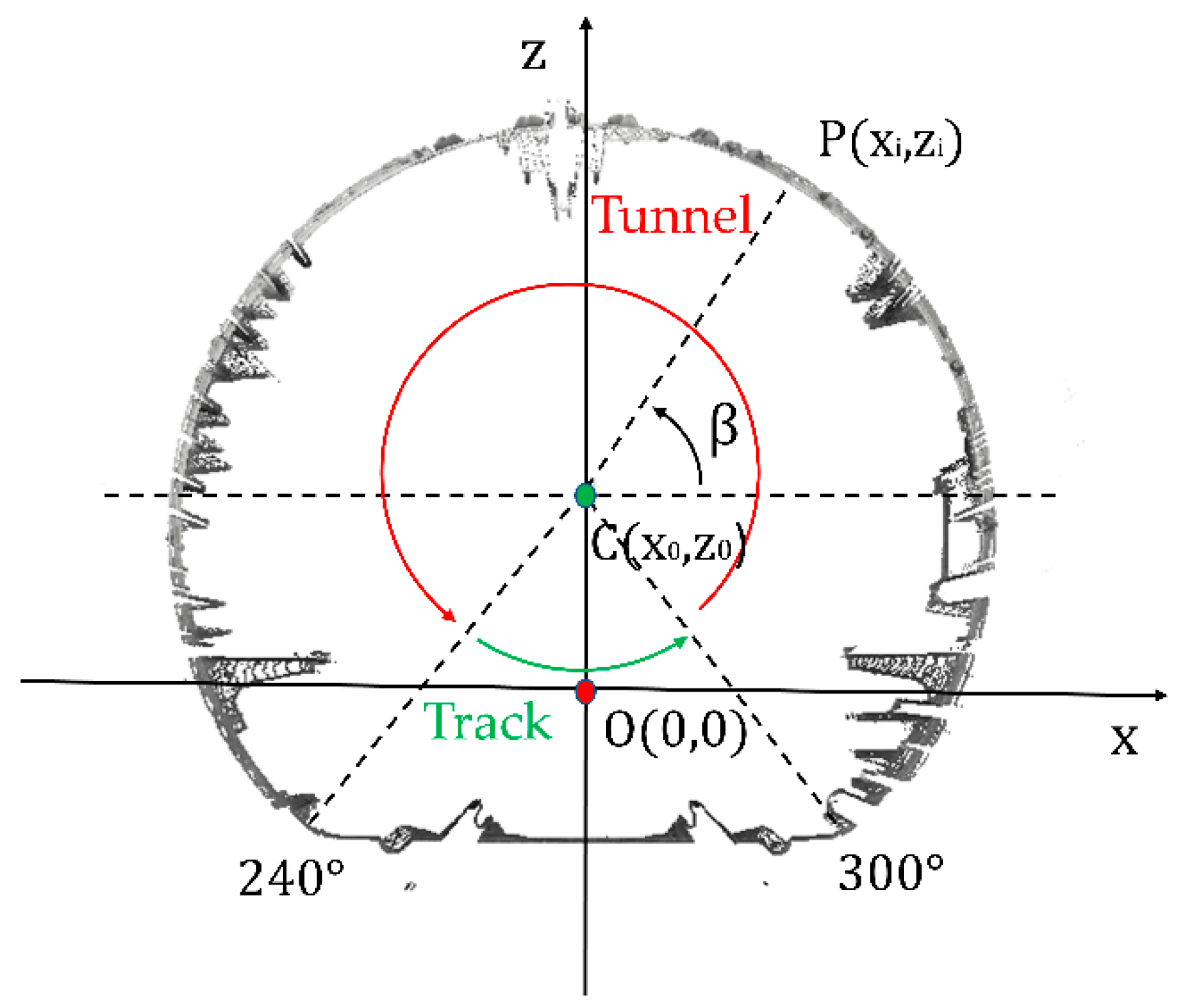

2.1.1. Tunnel Track Separation

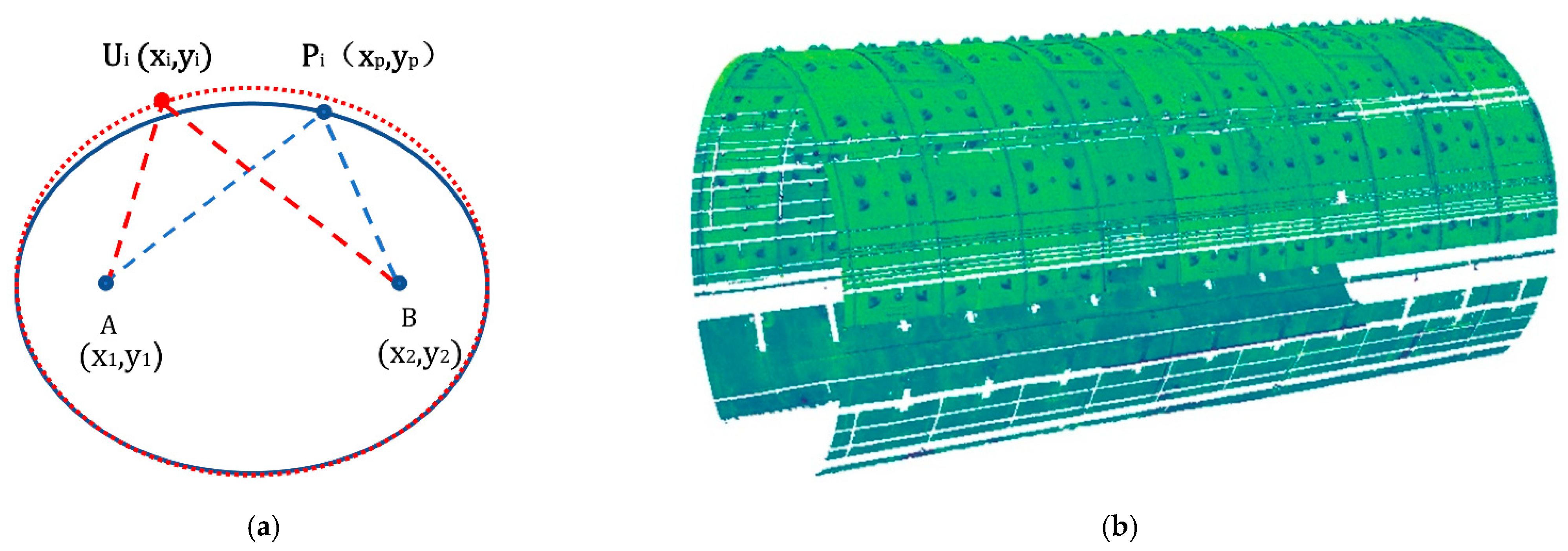

2.1.2. Removal of Appendages inside the Tunnel

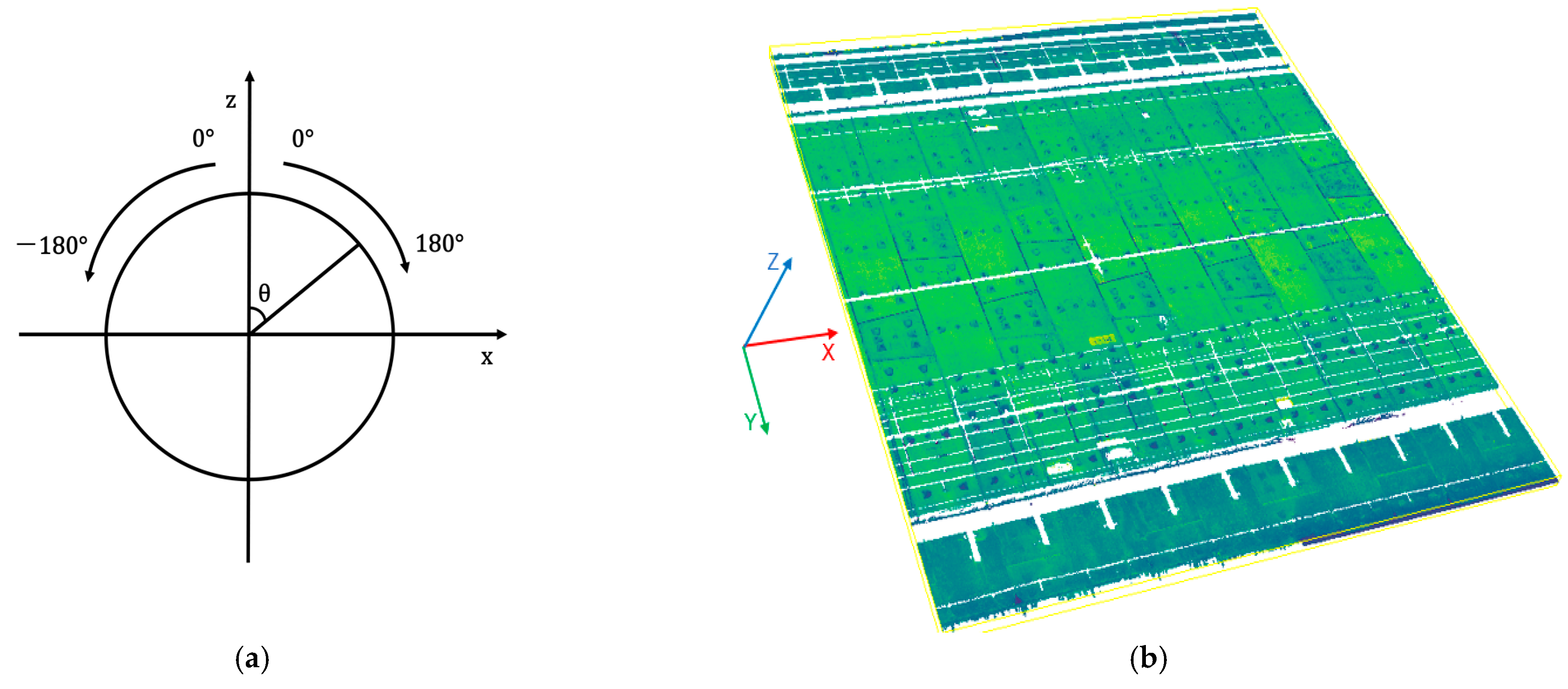

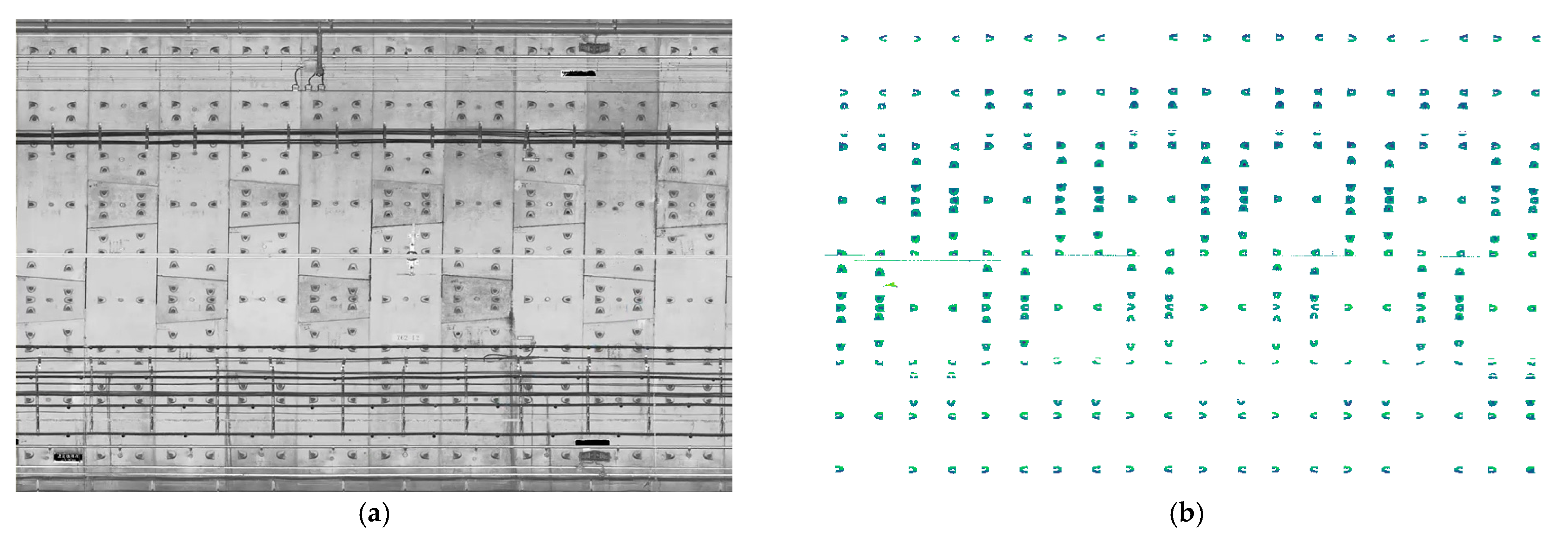

2.1.3. Projection Expansion of the Point Cloud of the Cylindrical Tunnel Wall

2.2. Extraction and Classification of Bolt Hole Center Point

2.2.1. Bolt Hole Point Cloud Extraction

- Modification of Cloth Simulation

- (1)

- Set the “correct position” of the cloth particles to the initial position, which is above the maximum elevation value after the flipped point cloud of the tunnel wall.

- (2)

- Modify the classification threshold to ; where is the highest value of the point cloud elevation, is the difference between the cloth node and highest value, is the average value of the point cloud elevation, and is the compensation parameter used to adjust the effect of the separation between the tunnel wall and bolt hole.

- (3)

- The cloth resolution is set to 3 times the average value of the radial and circumferential point spacing.

- The Process of Extracting Bolt Holes Using the Improved CSF Algorithm with the Self-Adaptive Parameter Adjustment Combined with the DBSCAN Algorithm

- (1)

- Invert the tunnel Light Detection and Ranging (LiDAR) point cloud.

- (2)

- The mesh resolution of the initial cloth mesh is set to 3 times the point spacing, and the cloth position is set above the highest point.

- (3)

- Obtain the classification threshold .

- (4)

- Iterate the loop and calculate the height difference between the LiDAR point cloud and cloth particles.

- (5)

- Distinguish the tunnel wall and bolt hole points. If the distance between the LiDAR point and cloth particle is greater than the threshold , it is considered as a bolt hole point; otherwise, it is considered as a non-bolt hole point.

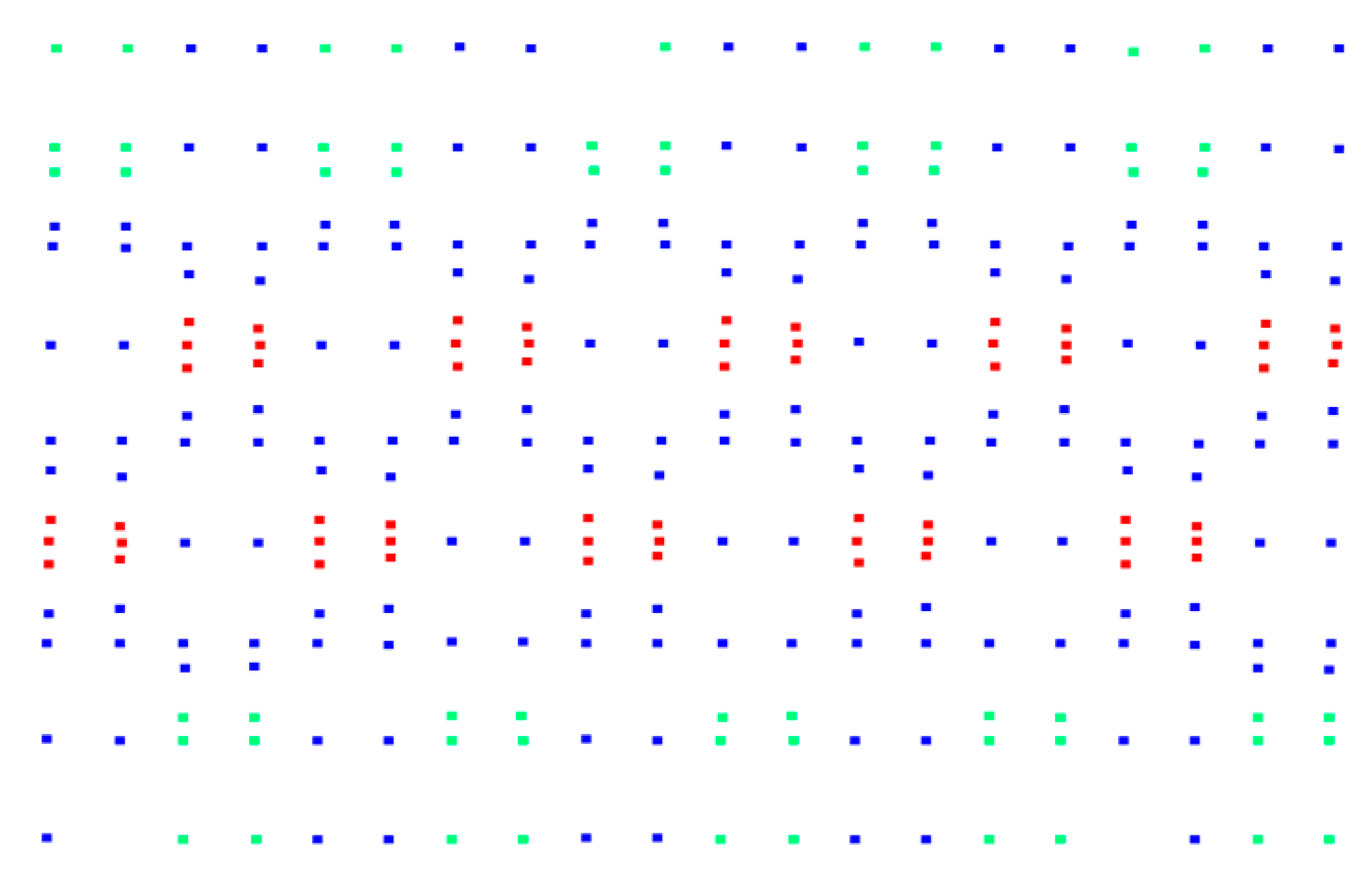

2.2.2. Bolt Hole Clustering to Obtain the Center

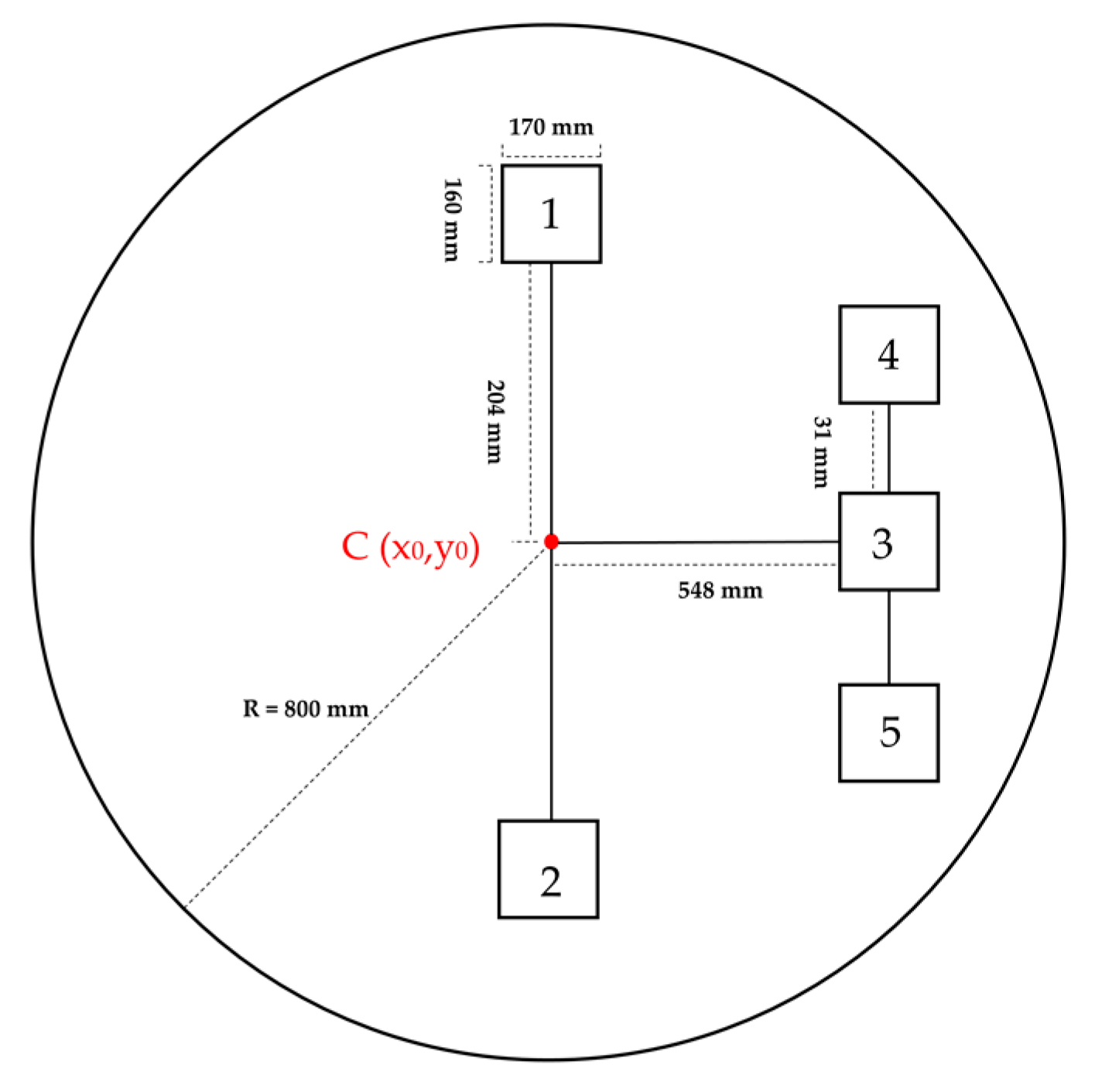

2.2.3. Identifying Bolt Hole Centers Subordinate to Various Blocks

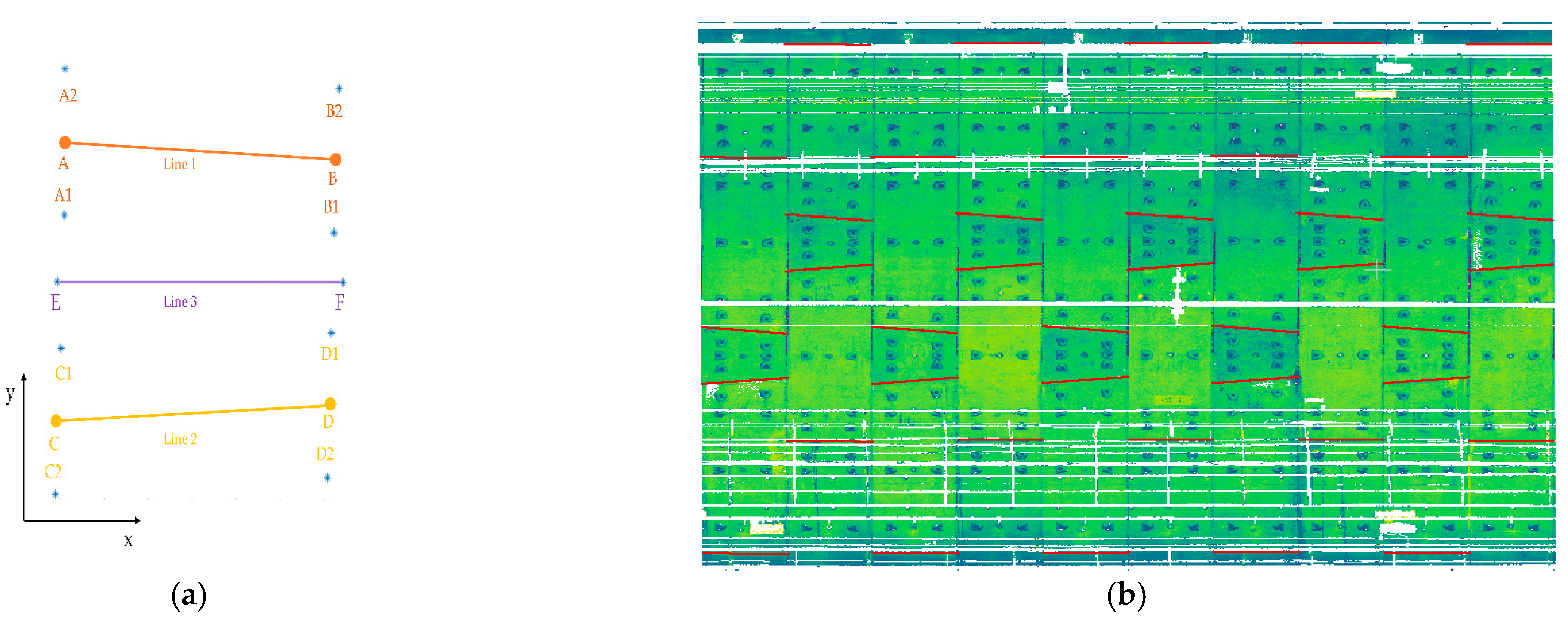

2.3. Seam Positioning and Ring Block Segmentation

3. Results

3.1. Experimental Analysis

3.1.1. Extraction Rate of Bolt Holes

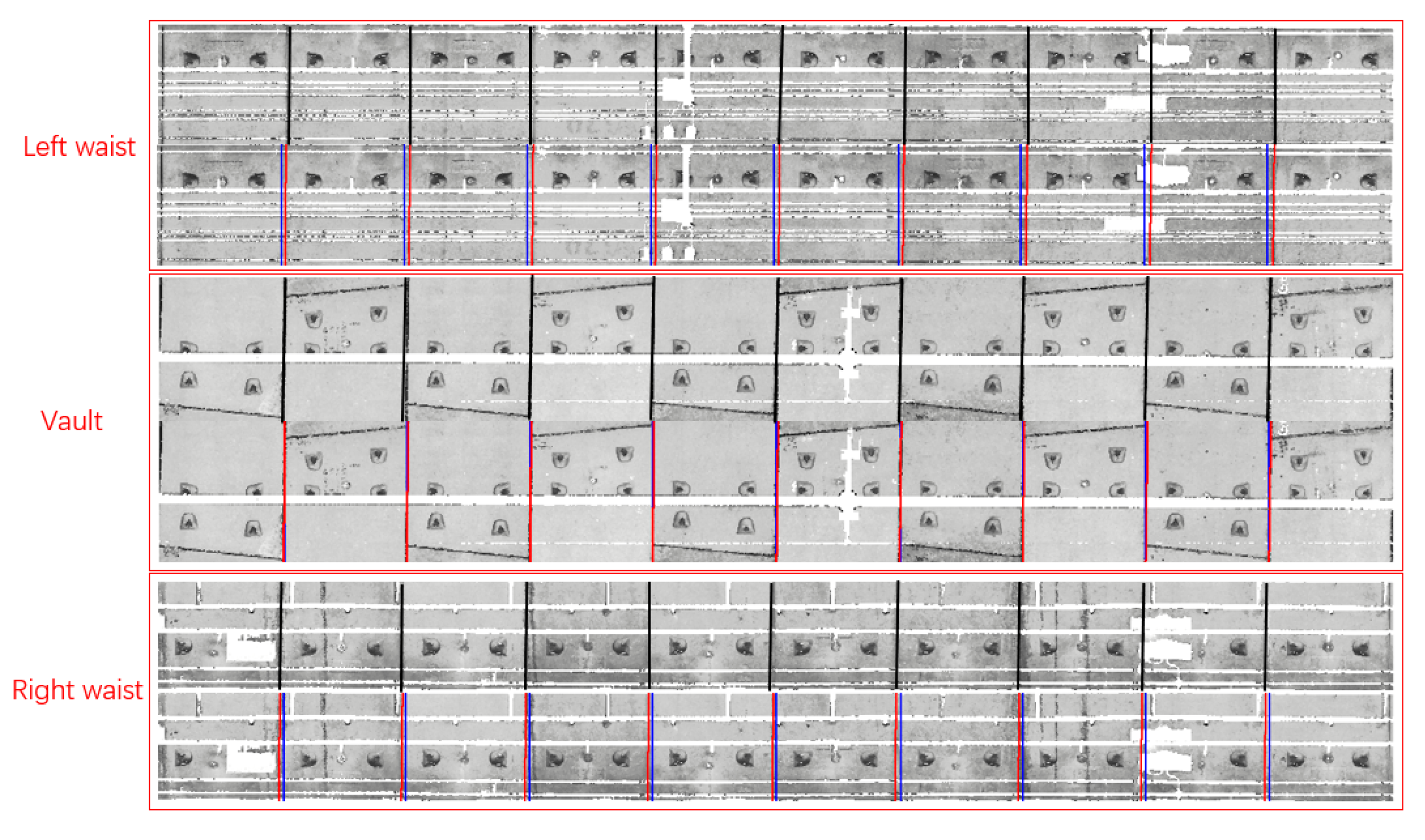

3.1.2. Positioning Accuracy of Longitudinal Seams

3.1.3. Positioning Accuracy of Circumferential Seam

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Statistics and analysis of urban rail transit data in 2021. Mod. Urban Transit. 2022, 5, 117.

- Yang, Y.; Zhang, Y.; Tan, X. Review on Vibration-Based Structural Health Monitoring Techniques and Technical Codes. Symmetry. 2021, 13, 1998. [Google Scholar] [CrossRef]

- Sainoki, A.; Tabata, S.; Mitri, H.S.; Fukuda, D.; Kodama, J.-i. Time-dependent tunnel deformations in homogeneous and heterogeneous weak rock formations. Comput. Geotech. 2017, 92, 186–200. [Google Scholar] [CrossRef]

- Janda, T.; Šejnoha, M.; Šejnoha, J. Applying bayesian approach to predict deformations during tunnel construction. Int. J. Numer. Anal. Met. 2018, 42, 1765–1784. [Google Scholar]

- Paraskevopoulou, C.; Diederichs, M. Analysis of time-dependent deformation in tunnels using the convergence-confinement method. Tunn. Undergr. Sp. Tech. 2018, 71, 62–80. [Google Scholar] [CrossRef]

- Bian, D.Y.; Lu, X.P.; Li, Y.Q.; Zhang, G.S. On survey technique in subway sectional shield construction. Bull. Surv. Mapp. Suppl. 2011, 4, 51–55. [Google Scholar]

- Yue, R.H.; Ge, J.Y.; Duan, W. Study on long term convergence measurement method of metro tunnel. Mod. Surv. Mapp. 2015, 38, 8–10. [Google Scholar]

- Li, Y.B.; Shen, Z.M.; Su, M.; Zhao, Y.S. Data processing and analysis for convergent and settlement monitoring in subway shield tunne. J. Southe. Univ. Nat. Sci. Ed. 2013, 43, 296–301. [Google Scholar]

- Li, G.Y.; Fan, B.X. The development of precise engineering surveying technology. Acta Geod. Cartogr. Sin. 2017, 46, 1742–1751. [Google Scholar]

- Yuan, H.; Liu, C.L.; Lu, J.; Deng, C.; Gong, S. The principle and accuracy analysis of non-contact monitoring for tunnel based on free station of total station. Geotech. Invest. Surv. 2012, 40, 63–67. [Google Scholar]

- Luo, Y.; Chen, J.; Xi, W.; Zhao, P.; Qiao, X.; Deng, X.; Liu, Q. Analysis of tunnel displacement accuracy with total station. Measurement 2016, 83, 29–37. [Google Scholar] [CrossRef]

- Yang, Y.; Lu, H.; Tan, X.; Chai, H.K.; Wang, R.; Zhang, Y. Fundamental mode shape estimation and element stiffness evaluation of girder bridges by using passing tractor-trailers. Mech. Syst. Signal Process 2022, 169, 108746. [Google Scholar] [CrossRef]

- Yang, Y.; Tan, X.; Lu, H.; Xue, S.; Wang, R.; Zhang, Y. Indirect Approach to Identify Girder Bridge Element Stiffness Based on Blind Source Separation. Symmetry 2022, 14, 1963. [Google Scholar] [CrossRef]

- Yang, Y.; Ling, Y.; Tan, X.; Wang, S.; Wang, R. Damage identification of frame structure based on approximate Metropolis–Hastings algorithm and probability density evolution method. Int. J. Struct. Stab. Dy. 2022, 22. [Google Scholar] [CrossRef]

- Han, S.; Cho, H.; Kim, S.; Jung, J.; Heo, J. Automated and efficient method for extraction of tunnel cross sections using terrestrial laser scanned data. J. Comput. Civil. Eng. 2013, 27, 274–281. [Google Scholar] [CrossRef]

- Montero, R.; Victores, J.G.; Martínez, S.; Jardón, A.; Balaguer, C. Past, present and future of Robotic Tunnel Inspection. Automat. Constr. 2015, 59, 99–112. [Google Scholar] [CrossRef]

- Tuo, L.; Kang, Z.Z.; Xie, Y.C.; Wang, B.Q. Continuously vertical section abstraction for deformation monitoring of subway tunnel based on terrestrial point clouds. Geomat. Inf. Sci. Wuhan Univ. 2013, 38, 171–175, 185. [Google Scholar]

- Cui, H.; Ren, X.; Mao, Q.; Hu, Q.; Wang, W. Shield subway tunnel deformation detection based on mobile laser scanning. Automat. Constr. 2019, 106, 102889. [Google Scholar] [CrossRef]

- Cao, Z.; Chen, D.; Shi, Y.; Zhang, Z.; Jin, F.; Yun, T.; Xu, S.; Kang, Z.; Zhang, L. A flexible architecture for extracting Metro Tunnel Cross sections from Terrestrial Laser Scanning Point Clouds. Remote Sens. 2019, 11, 297. [Google Scholar] [CrossRef]

- Sun, H.; Liu, S.; Zhong, R.; Du, L. Cross-section deformation analysis and visualization of shield tunnel based on Mobile Tunnel Monitoring System. Sensors 2020, 20, 1006. [Google Scholar] [CrossRef]

- Yue, Z.; Sun, H.; Zhong, R.; Ma, H.; Xu, Z.; Elliott, F. Measurement of tunnel clearance convergence using mobile laser detection technology. Can. J. Remote Sens. 2021, 47, 1–19. [Google Scholar] [CrossRef]

- Yue, Z.; Sun, H.; Zhong, R.; Du, L. Method for tunnel displacements calculation based on Mobile Tunnel Monitoring System. Sensors 2021, 21, 4407. [Google Scholar] [CrossRef] [PubMed]

- GRP IMS5000 Tunnel Scanning System. 2022. Available online: http://www.brailtec.com/index/products.html?id=%2027 (accessed on 7 July 2022).

- TS3 Three Channels Scanner. 2022. Available online: https://www.spacetec.de/en/products/ts3/ (accessed on 7 July 2022).

- SiTrack One Mobile Track Scanning System. 2022. Available online: http://leica-gd.com/Products/Show_49.html (accessed on 7 July 2022).

- Track Moving 3D Laser Measurement System (rMMS). 2022. Available online: http://www.hirail.cn/product_detail/id/7.html (accessed on 7 July 2022).

- Liu, S.; Sun, H.; Zhang, Z.; Li, Y.; Zhong, R.; Li, J.; Chen, S. A multiscale deep feature for the instance segmentation of water leakages in tunnel using MLS point cloud intensity images. IEEE T. Geosci. Remote 2022, 60, 1–16. [Google Scholar] [CrossRef]

- Wang, R.L.; Jia, J.; Liao, S. Shanghai Metro Guardianship Practice; Tongji University Press: Shanghai, China, 2013. [Google Scholar]

- Yan, J.L. Study on Segment Seam Behavior of Shield Tunnel; Tongji University: Shanghai, China, 2006. [Google Scholar]

- GB 50446-2017; Code for Shield Construction and Acceptance. China Architecture Press: Beijing, China, 2017.

- Chen, L.; Ge, K.L.; Wang, T. Central axis extraction method of shield tunnel based on ring seam point cloud. J. Hohai Univ. Nat. Sci. 2020, 48, 73–78. [Google Scholar]

- Du, L.; Zhong, R.; Sun, H.; Liu, Y.; Wu, Q. Cross-section positioning based on a dynamic MLS Tunnel Monitoring System. Photogrammetric. Rec. 2019, 34, 244–265. [Google Scholar] [CrossRef]

- Liu, X.G.; Chen, Y.Y.; Liu, X.Z. Laser scanning-based rapid detection of deformation of shield tunnel section. J. Traffic Transp. Eng. 2021, 21, 107–116. [Google Scholar]

- Cheng, S.; Sang, Z.L.; Wu, Y.; Zheng, J.J.; Lu, J.J. Tunnel segment dislocation detection based on mobile 3D laser scanning. Geomat. Spat. Inf. Technol. 2022, 45, 5–9. [Google Scholar]

- Sun, H.; Xu, Z.; Yao, L.; Zhong, R.; Du, L.; Wu, H. Tunnel monitoring and measuring system using mobile laser scanning: Design and deployment. Remote Sens. 2020, 12, 730. [Google Scholar] [CrossRef]

- Zhang, W.; Qi, J.; Wan, P.; Wang, H.; Xie, D.; Wang, X.; Yan, G. An easy-to-use airborne lidar data filtering method based on cloth simulation. Remote Sens. 2016, 8, 501. [Google Scholar] [CrossRef]

- Cheng, X.J.; Jia, D.F.; Liu, Y.P.; Cheng, X.L. Tunnel point cloud denoising algorithm based on centerline. J. Tongji Univ. 2015, 43, 1239–1245. [Google Scholar]

- Walton, G.; Delaloye, D.; Diederichs, M.S. Development of an elliptical fitting algorithm to improve change detection capabilities with applications for deformation monitoring in circular tunnels and shafts. Tunn. Undergr. Sp. Tech. 2014, 43, 336–349. [Google Scholar] [CrossRef]

- Lv, Y.L.; Li, Y.Q.; Dong, Y.N.; Yang, Q.K. Tunnel point cloud filtering based on ellipserestriction. Eng. Surv. Mapp. 2019, 28, 44–50. [Google Scholar]

- Kang, Z.; Tuo, L.; Zlatanova, S. Continuously deformation monitoring of subway tunnel based on Terrestrial Point Clouds. In Proceedings of the ISPRS—International Archives of the Photogrammetry, Remote Sensing and Spatial Information Sciences, Nice, France, 6–11 June 2012; Volume XXXIX-B5, pp. 199–203. [Google Scholar]

- Kang, Z.; Zhang, L.; Tuo, L.; Wang, B.; Chen, J. Continuous extraction of subway tunnel cross sections based on Terrestrial Point Clouds. Remote Sens. 2014, 6, 857–879. [Google Scholar] [CrossRef]

- Li, C.; Lu, X.P.; Zhu, N.N.; Lu, Y.; Wu, Y.; Li, G. Continuously Extracting Section and Deformation Analysis for Subway Tunnel Based on LiDAR Points. Acta Geod. Cartogr. Sin. 2015, 44, 1056–1062. [Google Scholar]

- Du, L.M.; Zhong, R.F.; Sun, H.L.; Zhu, Q.; Zhang, Z. Tunnel cross section extraction and deformation analysis based on mobile laser scanning technology. Bull. Surv. Mapp. Suppl. 2018, 6, 61–67. [Google Scholar]

- Gao, Z.M.; Wang, J.X.; Shen, Z.Y. Aerial LiDAR building point-cloud progressive extraction algorithm. Bull. Surv. Mapp. Suppl. 2021, 8, 7–13. [Google Scholar]

- Comaniciu, D.; Meer, P. Mean shift: A robust approach toward feature space analysis. IEEE Trans. Pattern Anal. Mach. Intell. 2002, 24, 603–619. [Google Scholar] [CrossRef]

| Pre-Projection x (m) | Pre-Projection y (m) | Pre-Projection z (m) | Intensity i | X after Projection (m) | Y after Projection (m) | Z after Projection (m) |

|---|---|---|---|---|---|---|

| 1.830 | 19,155.287 | −1.087 | 126 | 19,155.287 | 6.535 | 2.746 |

| 1.835 | 19,155.287 | −1.081 | 118 | 19,155.287 | 6.527 | 2.745 |

| 1.842 | 19,155.287 | −1.076 | 115 | 19,155.287 | 6.518 | 2.746 |

| Laser System | |

|---|---|

| Beam divergence | <0.5 mrad |

| Ranging range | 0.3–119 m |

| Ranging resolution | 0.1 mm |

| Measuring point rate | Maximum 1.016 million points per second |

| Linearity error | ≤1 mm |

| Transmitter Unit | |

| Vertical viewing angle | 360° |

| Angular resolution | 0.0088° (40,960 pixel/360°) |

| Angle accuracy | 0.02° rms |

| Rotating speed | 50–200 Hz (Highest 12,000 rpm) |

| Serial Number | Location | Y-Value of Longitudinal Seam in the Point Cloud (m) | Y-Value of Longitudinal Seam Located by this Method (m) | D-Value (mm) |

|---|---|---|---|---|

| 1 | A | 1.552 | 1.554 | 2 |

| B | 1.449 | 1.443 | 6 | |

| C | 0.497 | 0.495 | 2 | |

| D | 0.606 | 0.599 | 6 | |

| 2 | A | −0.568 | −0.560 | 9 |

| B | −0.675 | −0.677 | 2 | |

| C | −1.624 | −1.617 | 7 | |

| D | −1.507 | −1.512 | 4 | |

| 3 | A | 1.550 | 1.552 | 2 |

| B | 1.433 | 1.429 | 3 | |

| C | 0.482 | 0.482 | 0 | |

| D | 0.590 | 0.588 | 2 | |

| 4 | A | −0.569 | −0.567 | 2 |

| B | −0.689 | −0.691 | 1 | |

| C | −1.630 | −1.635 | 6 | |

| D | −1.530 | −1.529 | 2 | |

| 5 | A | 1.528 | 1.530 | 2 |

| B | 1.423 | 1.419 | 4 | |

| C | 0.468 | 0.463 | 4 | |

| D | 0.579 | 0.578 | 1 | |

| Average Difference (mm) | 3.4 |

| Serial Number | Location | Circumferential Seams in the Point Cloud (m) | Circumferential Seams Positioned by Du et al.’s Method (m) | Circumferential Seams Positioned by the Proposed Method (m) | D-Value between Point Cloud and Du et al.’s Method (mm) | D-Value between Point Cloud and the Proposed Method (mm) |

|---|---|---|---|---|---|---|

| 1 | Left waist | 19,144.535 | 19,144.500 | 19,144.537 | 35 | 3 |

| Vault | 19,144.490 | 19,144.500 | 19,144.497 | 10 | 7 | |

| Right waist | 19,144.462 | 19,144.500 | 19,144.459 | 38 | 3 | |

| 2 | Left waist | 19,145.740 | 19,145.690 | 19,145.744 | 50 | 4 |

| Vault | 19,145.690 | 19,145.690 | 19,145.696 | 0 | 6 | |

| Right waist | 19,145.658 | 19,145.690 | 19,145.651 | 32 | 7 | |

| 3 | Left waist | 19,146.940 | 19,146.890 | 19,146.942 | 50 | 3 |

| Vault | 19,146.895 | 19,146.890 | 19,146.896 | 5 | 1 | |

| Right waist | 19,146.860 | 19,146.890 | 19,146.852 | 30 | 8 | |

| 4 | Left waist | 19,148.135 | 19,148.090 | 19,148.141 | 45 | 6 |

| Vault | 19,148.087 | 19,148.090 | 19,148.092 | 3 | 5 | |

| Right waist | 19,148.058 | 19,148.090 | 19,148.056 | 32 | 2 | |

| 5 | Left waist | 19,149.340 | 19,149.290 | 19,149.342 | 50 | 1 |

| Vault | 19,149.295 | 19,149.290 | 19,149.299 | 5 | 4 | |

| Right waist | 19,149.267 | 19,149.290 | 19,149.258 | 23 | 9 | |

| 6 | Left waist | 19,150.554 | 19,150.500 | 19,150.548 | 54 | 6 |

| Vault | 19,150.495 | 19,150.500 | 19,150.498 | 5 | 3 | |

| Right waist | 19,150.472 | 19,150.500 | 19,150.479 | 28 | 4 | |

| 7 | Left waist | 19,151.745 | 19,151.690 | 19,151.746 | 55 | 2 |

| Vault | 19,151.695 | 19,151.690 | 19,151.697 | 5 | 2 | |

| Right waist | 19,151.660 | 19,151.690 | 19,151.651 | 30 | 9 | |

| 8 | Left waist | 19,152.950 | 19,152.890 | 19,152.954 | 60 | 4 |

| Vault | 19,152.895 | 19,152.890 | 19,152.897 | 5 | 2 | |

| Right waist | 19,152.865 | 19,152.890 | 19,152.867 | 25 | 2 | |

| 9 | Left waist | 19,154.149 | 19,154.090 | 19,154.151 | 59 | 2 |

| Vault | 19,154.095 | 19,154.090 | 19,154.097 | 5 | 3 | |

| Right waist | 19,154.068 | 19,154.090 | 19,154.063 | 22 | 5 | |

| Mean value | Left waist | 51 | 3 | |||

| Vault | 5 | 4 | ||||

| Right waist | 29 | 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, C.; Sun, H.; Zhong, R.; Li, J.; Han, Y. Precise Positioning Method of Moving Laser Point Cloud in Shield Tunnel Based on Bolt Hole Extraction. Remote Sens. 2022, 14, 4791. https://doi.org/10.3390/rs14194791

Ji C, Sun H, Zhong R, Li J, Han Y. Precise Positioning Method of Moving Laser Point Cloud in Shield Tunnel Based on Bolt Hole Extraction. Remote Sensing. 2022; 14(19):4791. https://doi.org/10.3390/rs14194791

Chicago/Turabian StyleJi, Changqi, Haili Sun, Ruofei Zhong, Jincheng Li, and Yulong Han. 2022. "Precise Positioning Method of Moving Laser Point Cloud in Shield Tunnel Based on Bolt Hole Extraction" Remote Sensing 14, no. 19: 4791. https://doi.org/10.3390/rs14194791

APA StyleJi, C., Sun, H., Zhong, R., Li, J., & Han, Y. (2022). Precise Positioning Method of Moving Laser Point Cloud in Shield Tunnel Based on Bolt Hole Extraction. Remote Sensing, 14(19), 4791. https://doi.org/10.3390/rs14194791