Axle Configuration and Weight Sensing for Moving Vehicles on Bridges Based on the Clustering and Gradient Method

Abstract

:1. Introduction

2. Methodology

2.1. Moses’ Axle Weight Estimating Algorithm

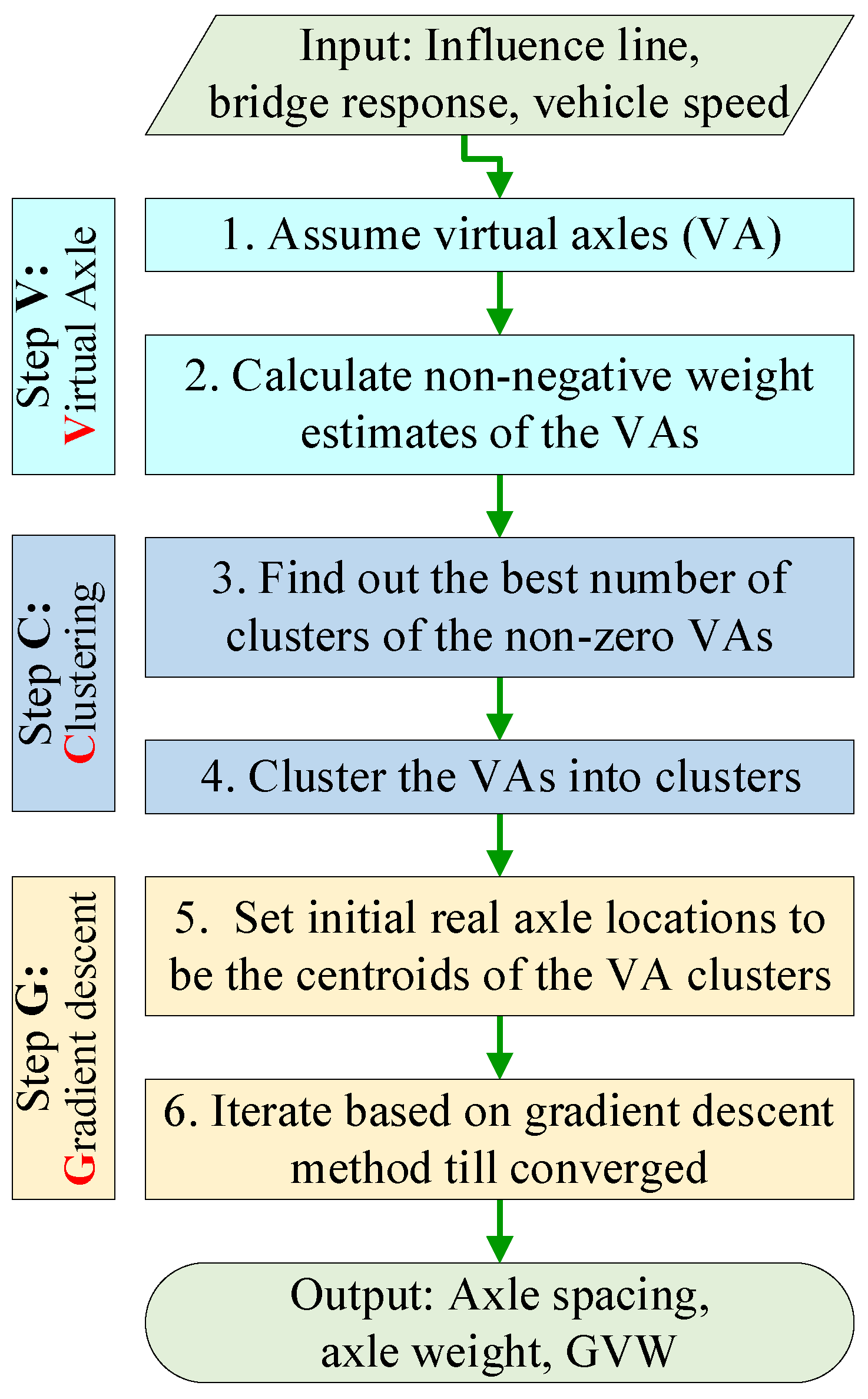

2.2. Overview of the Proposed Optimization Algorithm

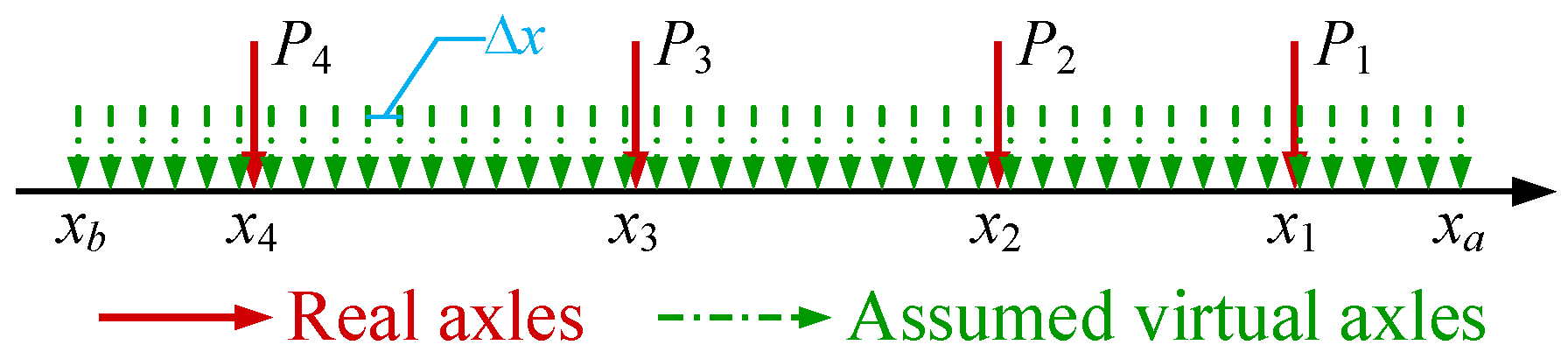

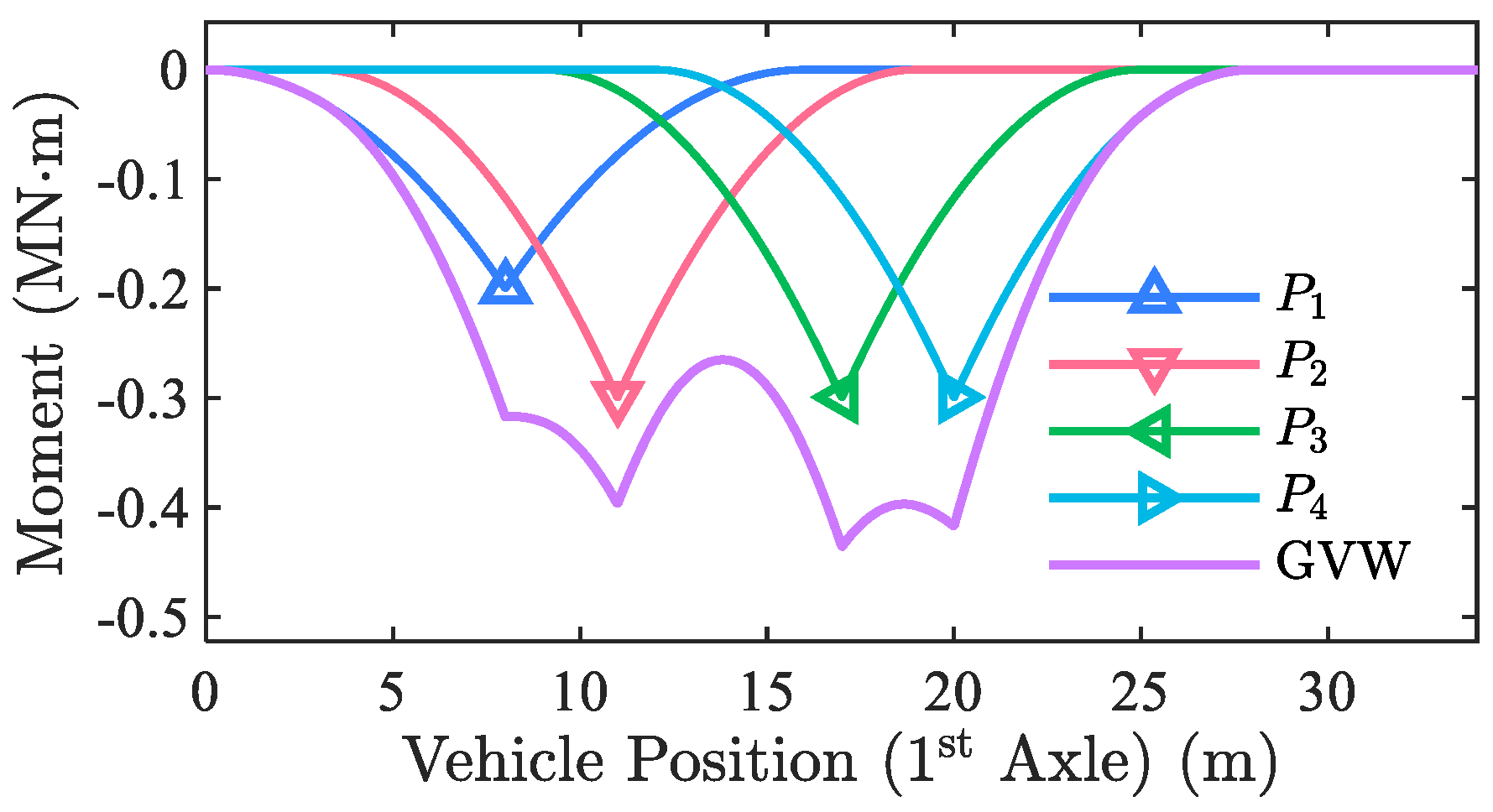

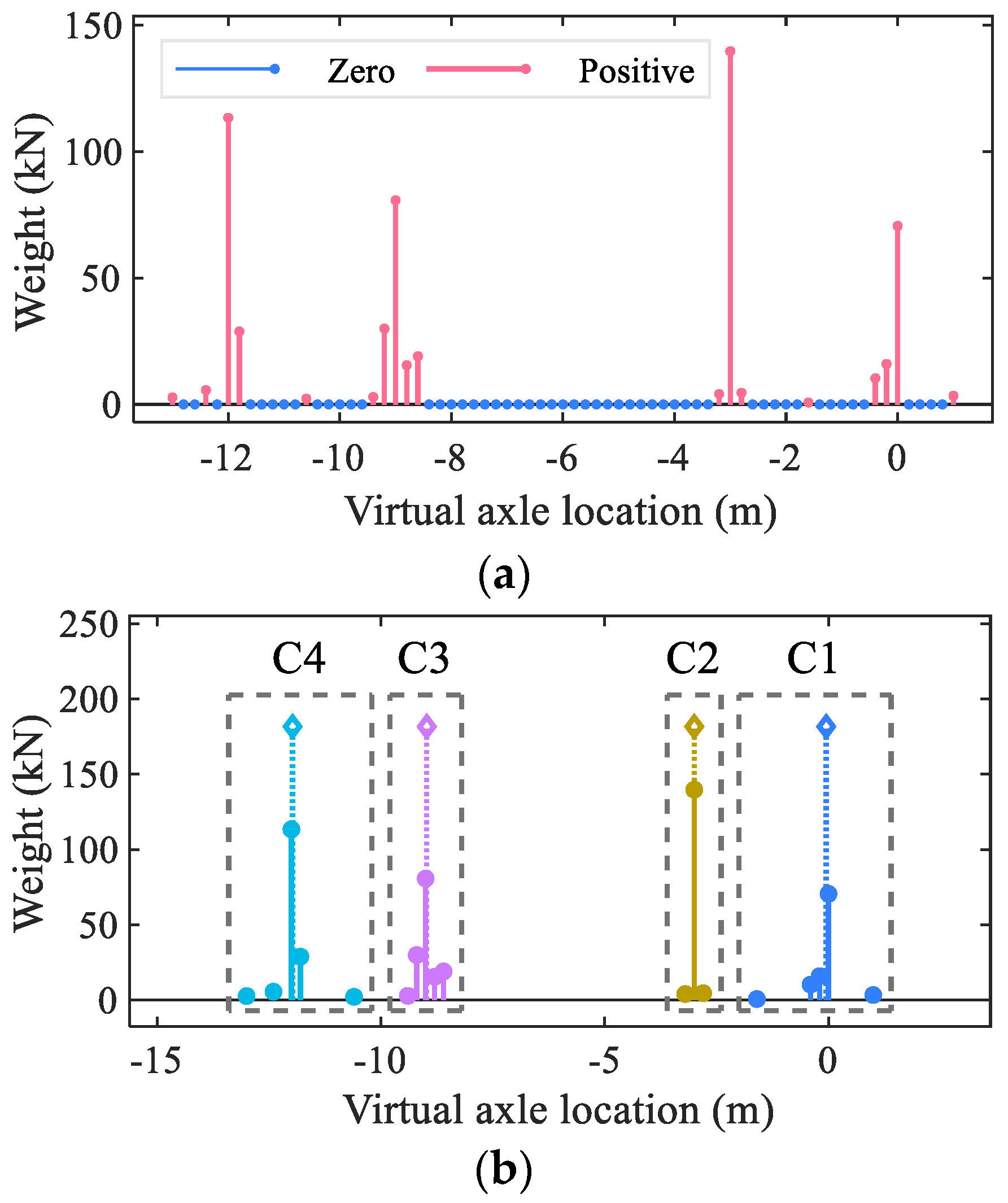

2.3. Virtual Axle Theory (Step V)

2.4. Virtual Axles Clustering (Step C)

2.5. Gradient Method (Step G)

3. Numerical Study

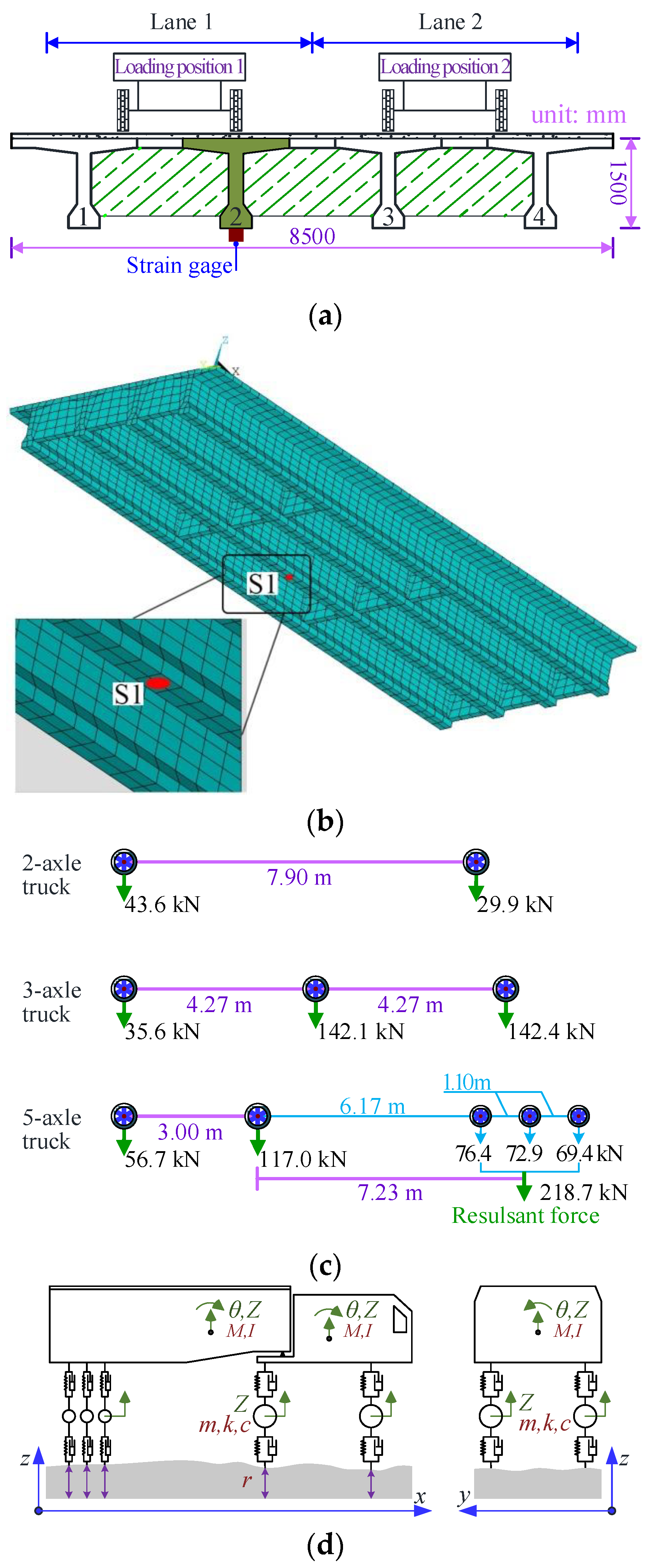

3.1. Vehicle–Bridge Coupled Vibration System

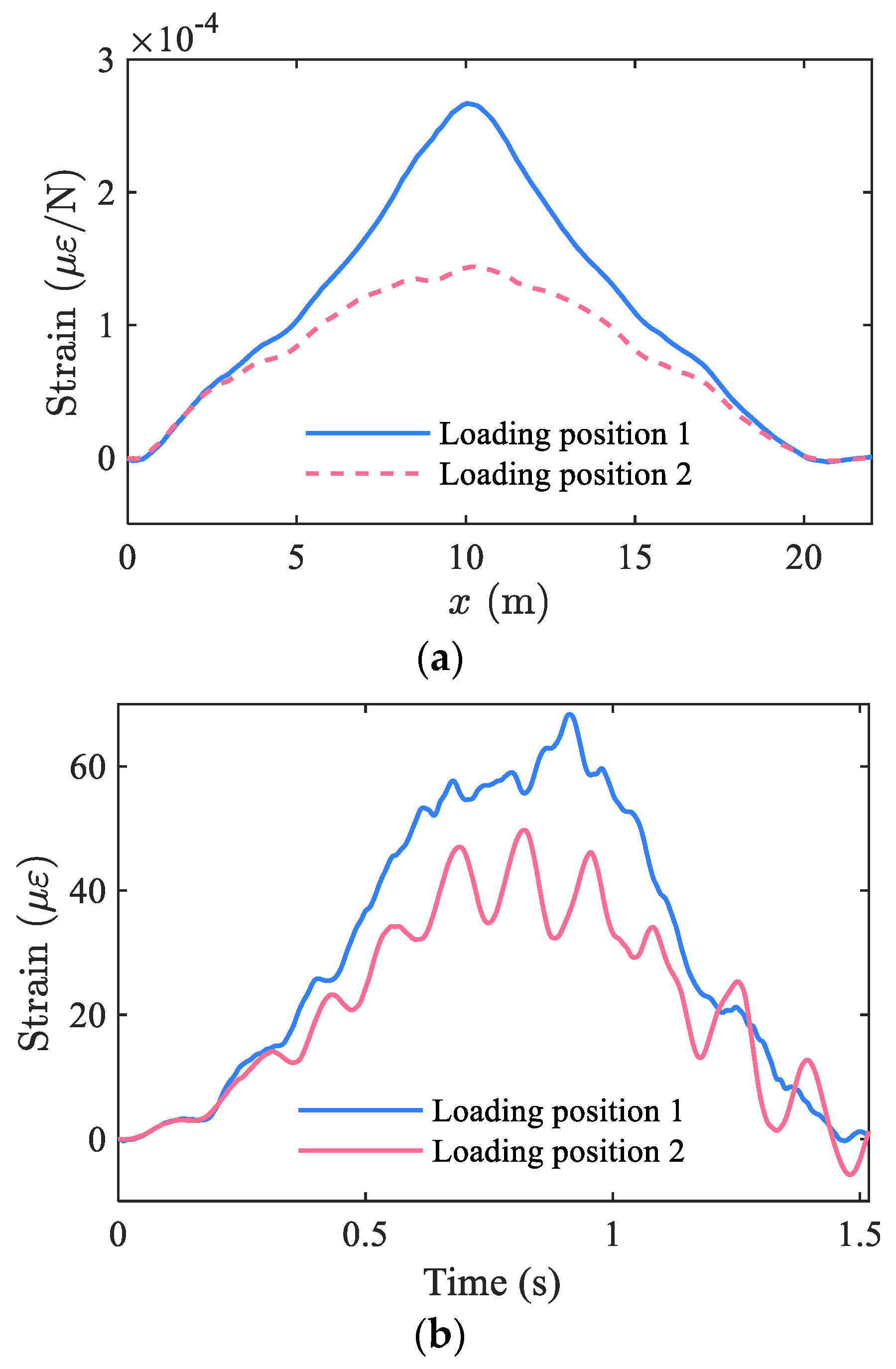

3.2. Simulation Setup

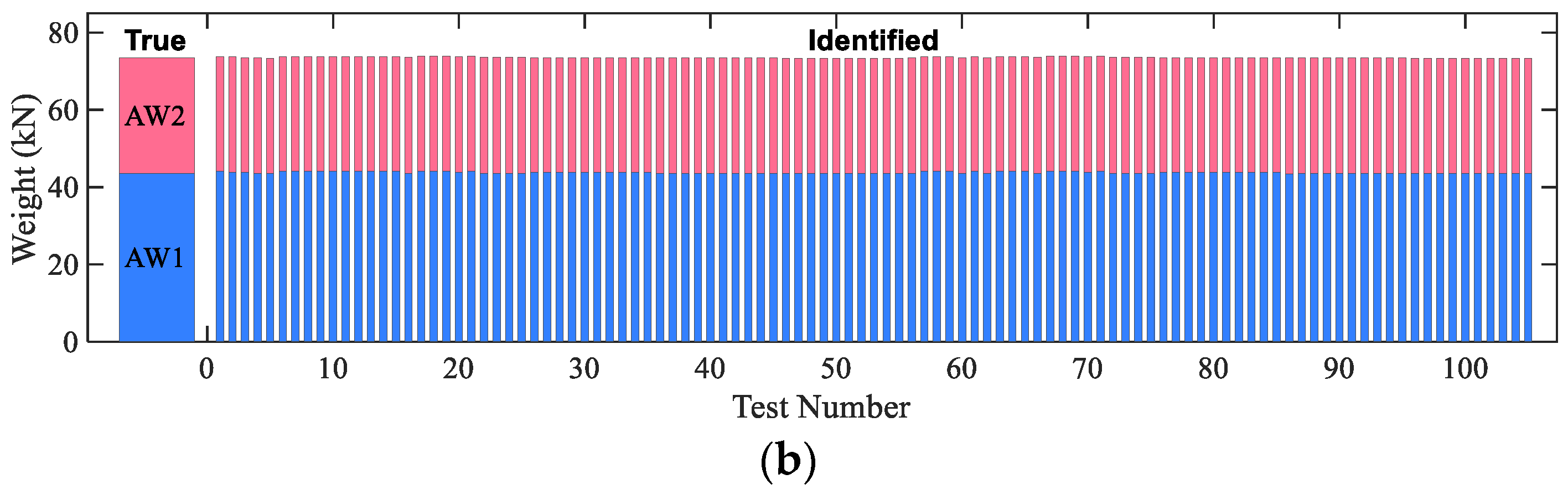

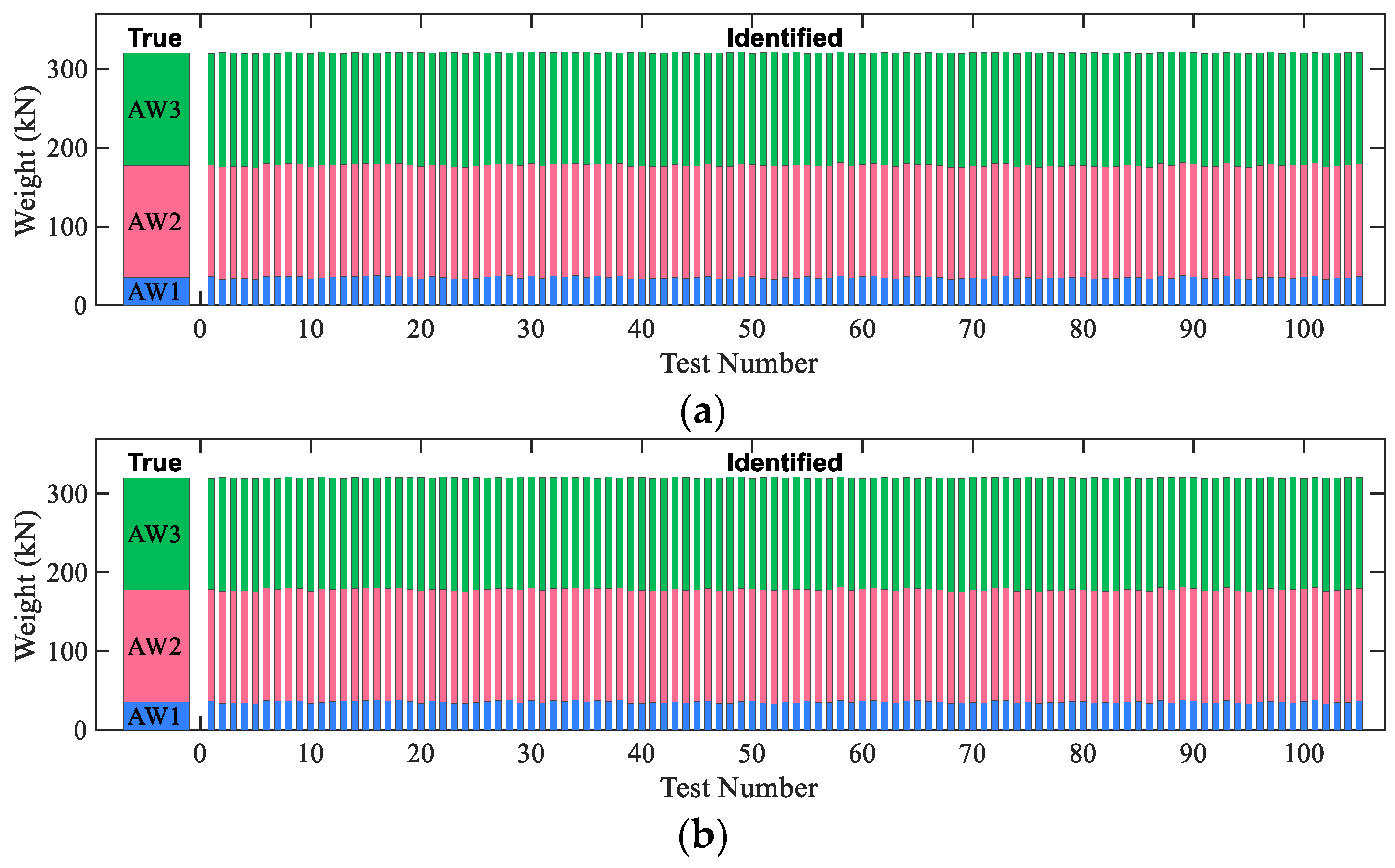

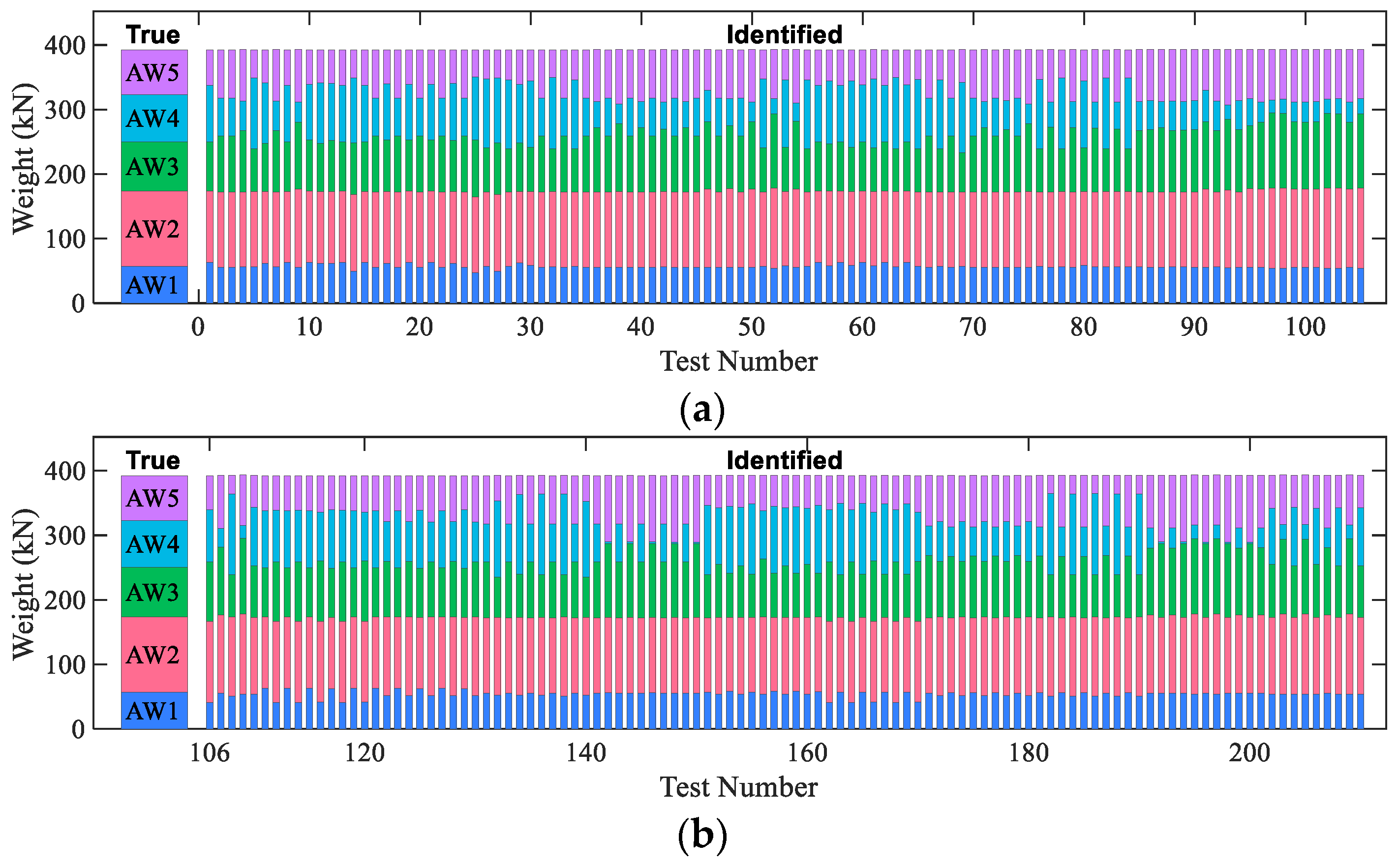

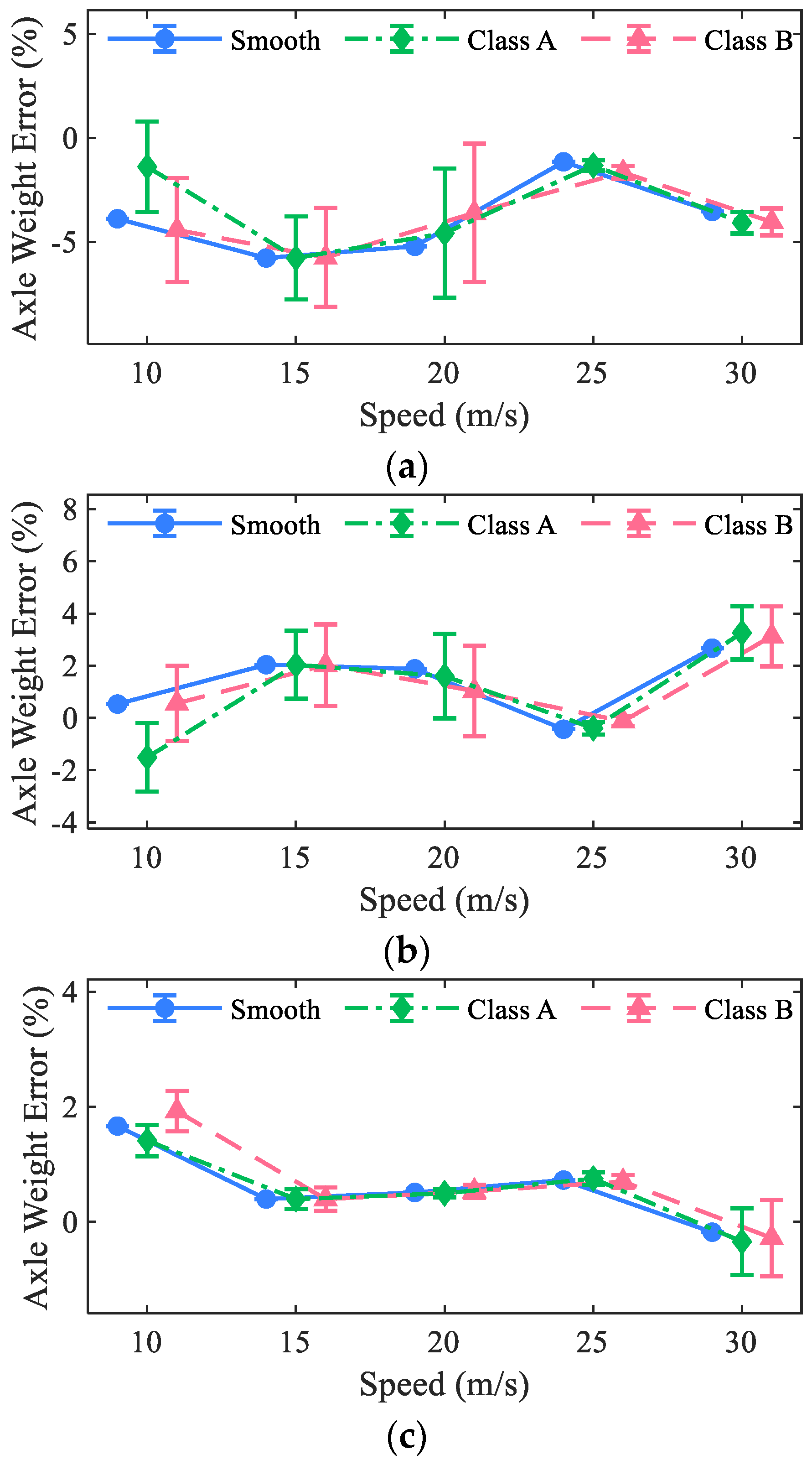

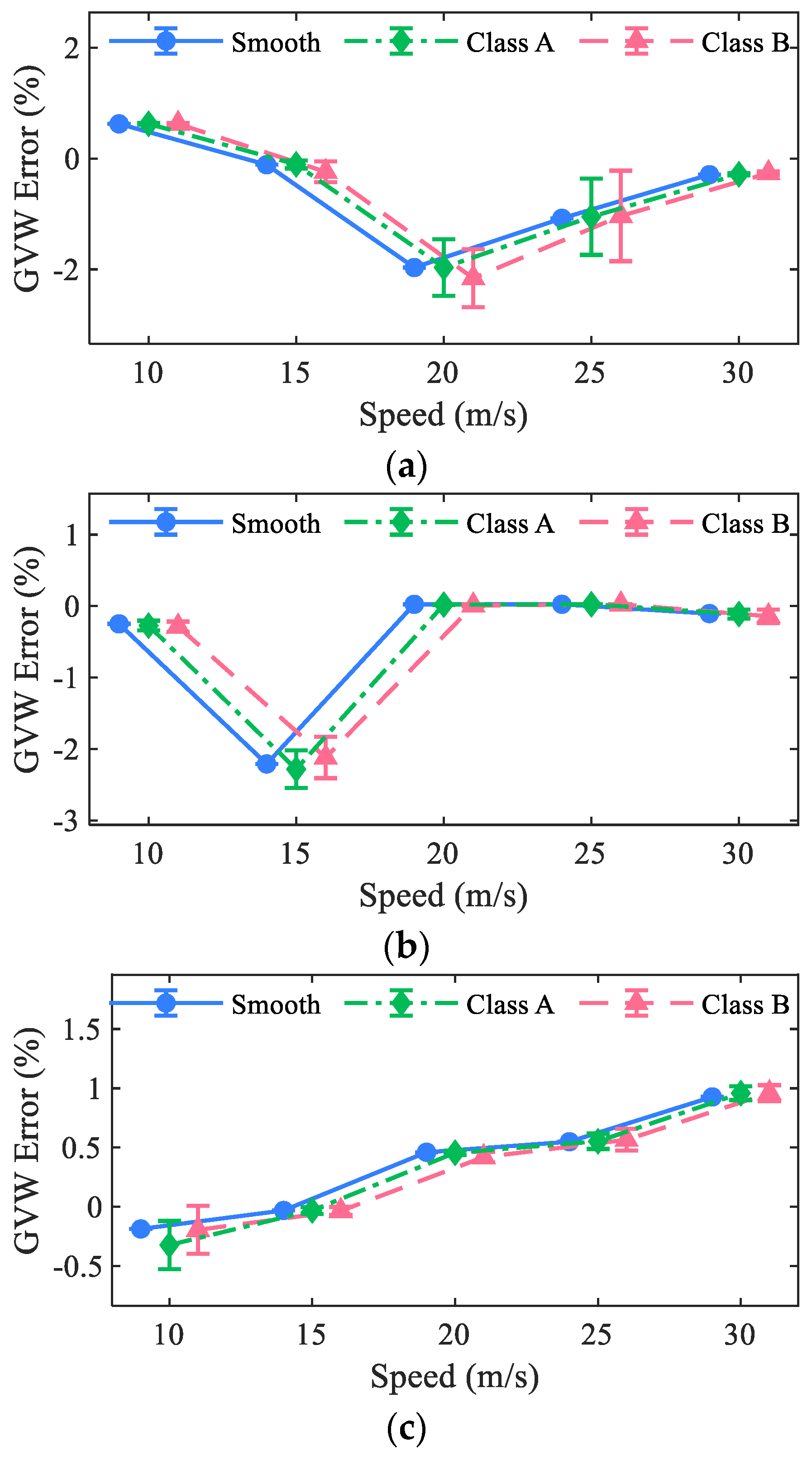

3.3. Results and Discussion

4. Experiment Validation

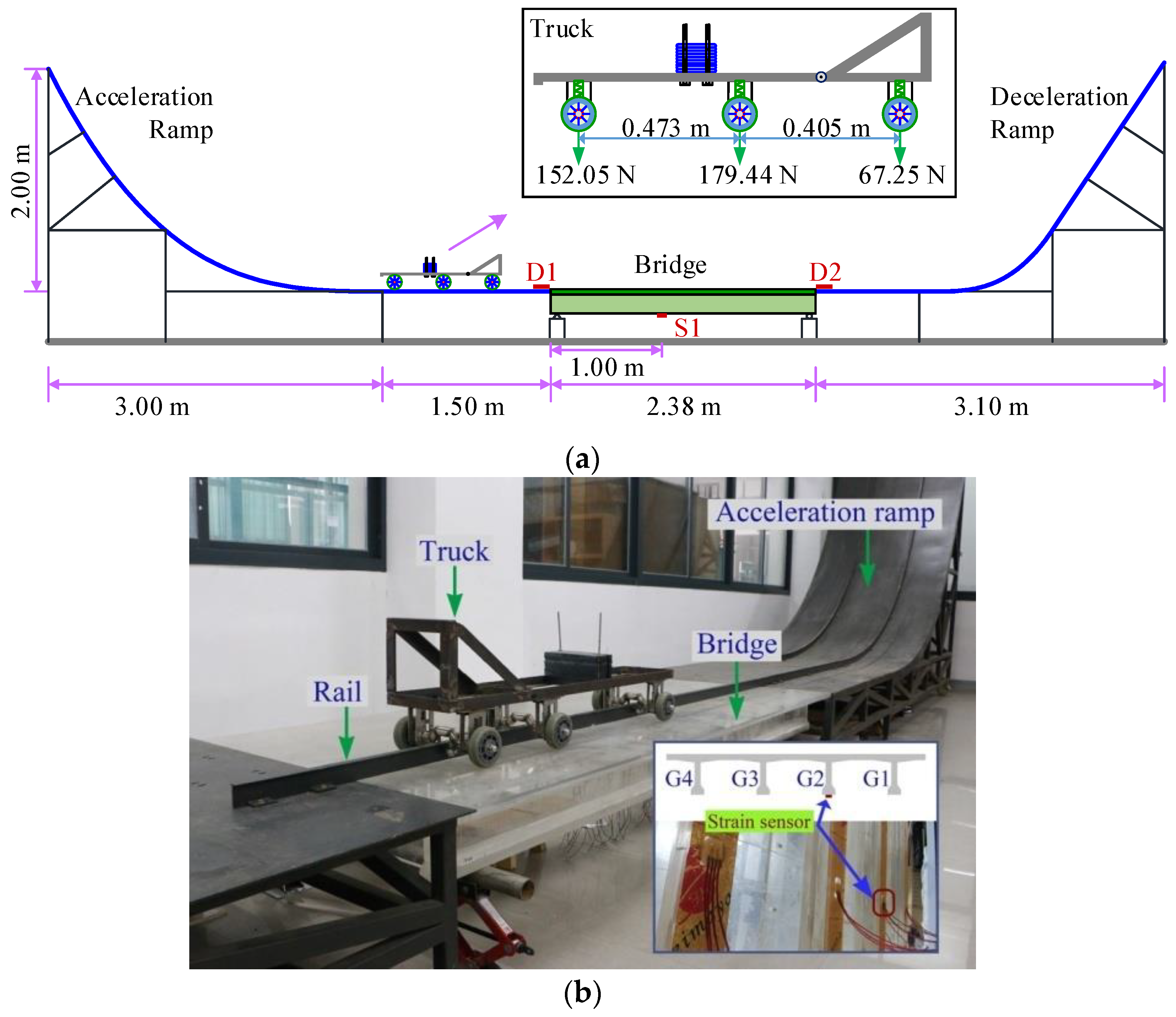

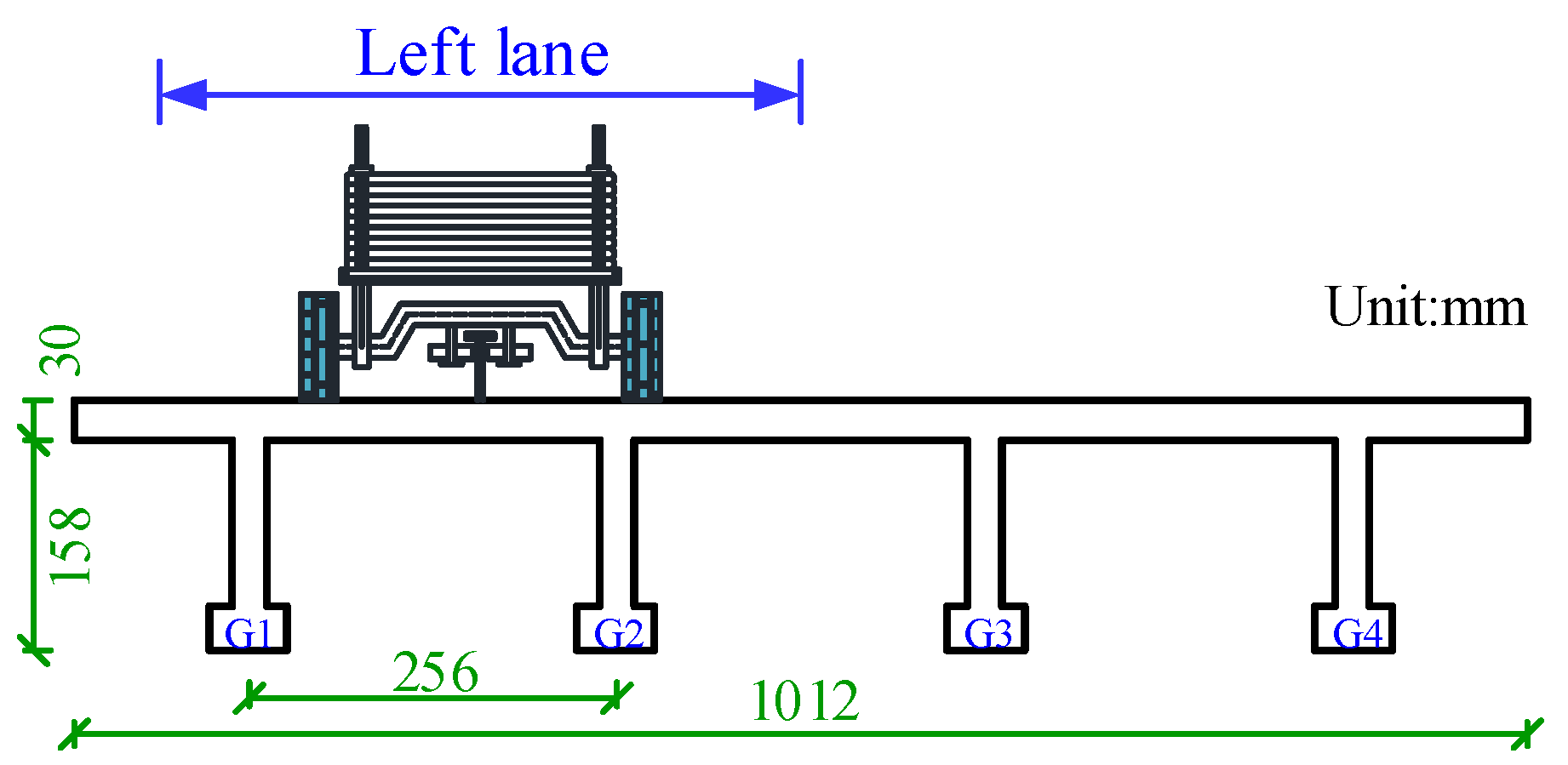

4.1. Test Setup

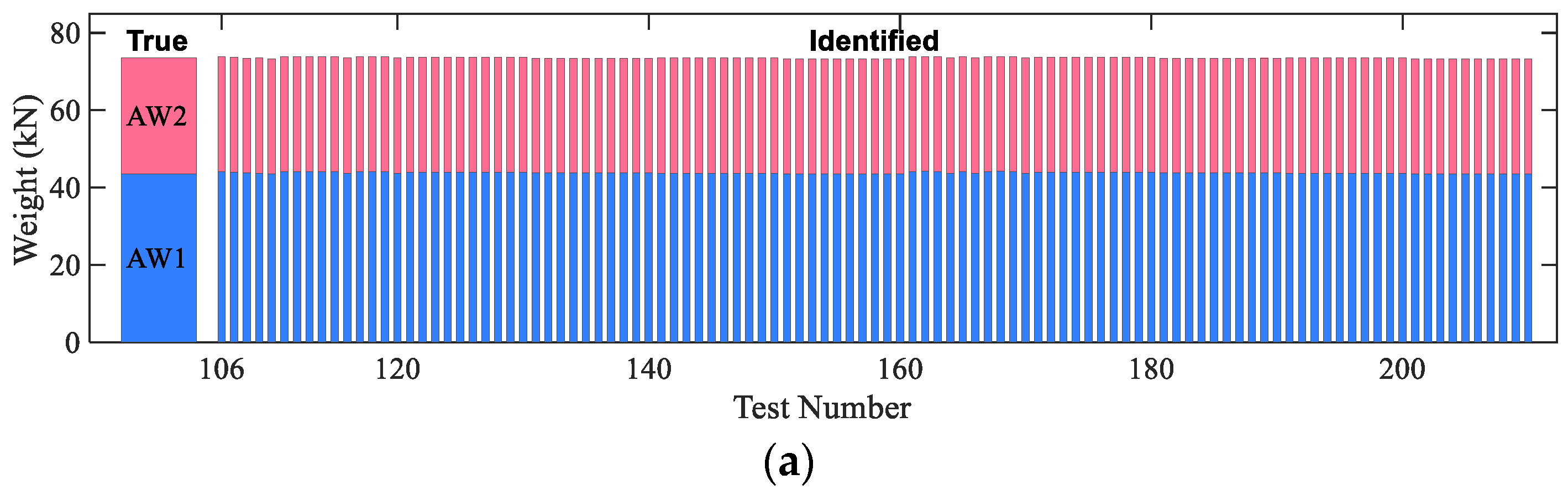

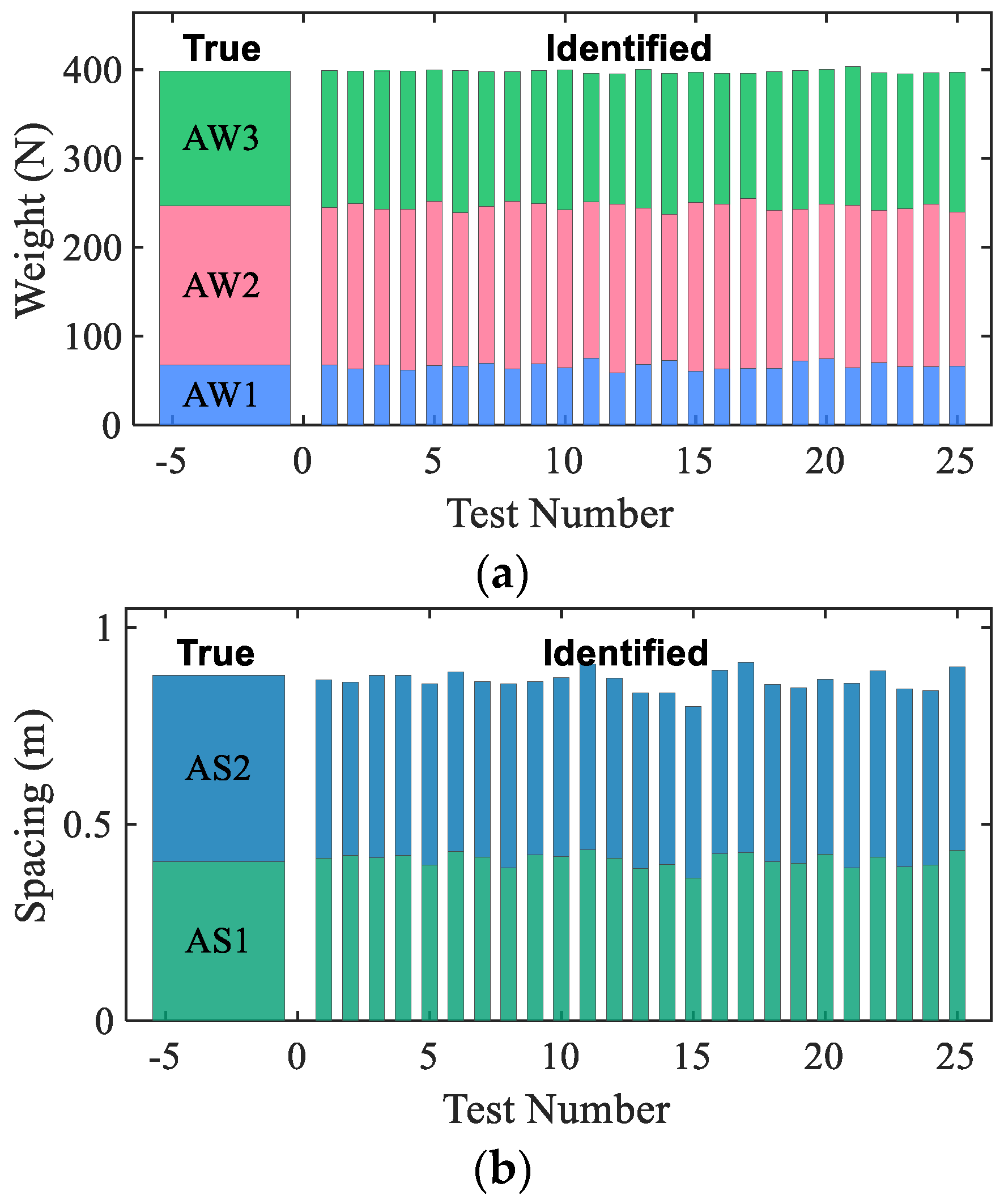

4.2. Results and Discussion

5. Conclusions

- (1)

- The weight of vehicle axles was correctly detected by the VCG method based on the bridge strain response and vehicle speed. The VCG method has similar accuracy as Moses’ algorithm on gross weight identification but has better accuracy than on axle weight identification.

- (2)

- The VCG method can also identify the location of vehicle axles. The identification accuracy was comparable to the direct method (using a pressure-sensitive sensor placed on the top surface of the road) but without the need for installing a dedicated axle detector.

- (3)

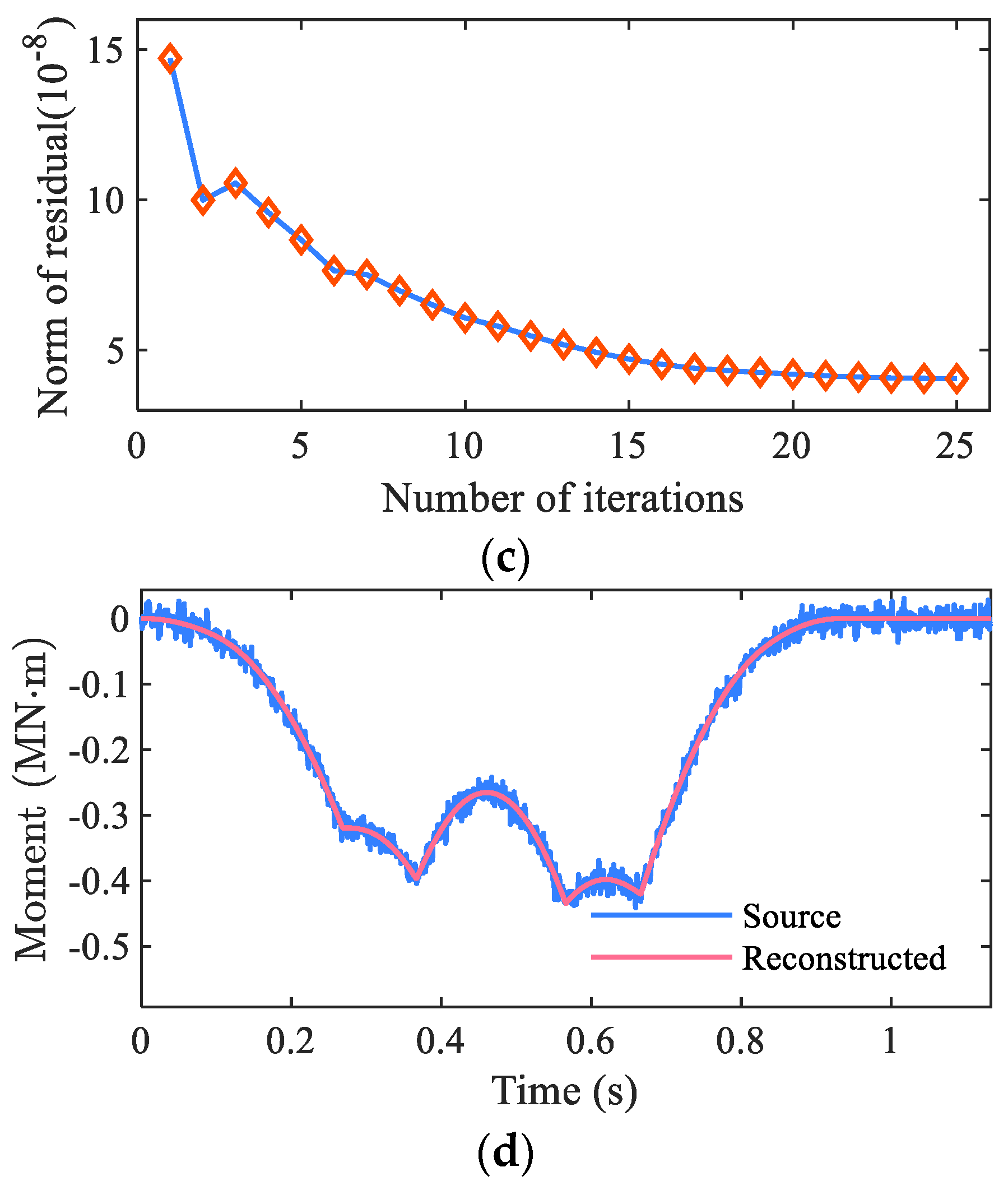

- The proposed method generally converges within dozens of iterations. The computation efficiency proves that it is suitable for real-time application.

Author Contributions

Funding

Conflicts of Interest

References

- Deng, L.; Bi, T.; He, W.; Wang, W. Vehicle weight limit analysis method for reinforced concrete bridges based on fatigue life. China J. Highw. Transp. 2017, 30, 72–78. [Google Scholar]

- Deng, L.; Duan, L.L.; He, W.; Ji, W. Study on vehicle model for vehicle-bridge coupling vibration of highway bridges in China. China J. Highw. Transp. 2018, 317, 92–100. [Google Scholar]

- Jacob, B.; Feypell-de La Beaumelle, V. Improving truck safety: Potential of weigh-in-motion technology. IATSS Res. 2010, 34, 9–15. [Google Scholar] [CrossRef] [Green Version]

- Richardson, J.; Jones, S.; Brown, A.; O’Brien, E.J.; Hajializadeh, D. On the use of bridge weigh-in-motion for overweight truck enforcement. Int. J. Heavy Veh. Syst. 2014, 21, 83–104. [Google Scholar] [CrossRef]

- Moses, F. Weigh-in-motion system using instrumented bridges. Transp. Eng. J. 1979, 105, 233–249. [Google Scholar] [CrossRef]

- Quilligan, M.; Karoumi, R.; O’Brien, E.J. Development and testing of a 2-dimensional multi-vehicle bridge-wim algorithm. In Proceedings of the 3rd International Conference on Weigh-in-Motion (ICWIM3), Orlando, FL, USA, 13–15 May 2002; Wiley: New York, NY, USA, 2002. [Google Scholar]

- Zhao, H.; Uddin, N.; O’Brien, E.J.; Shao, X.; Zhu, P. Identification of vehicular axle weights with a bridge weigh-in-motion system considering transverse distribution of wheel loads. J. Bridge Eng. 2014, 19, 165–184. [Google Scholar] [CrossRef] [Green Version]

- Yu, Y.; Cai, C.; Deng, L. State-of-the-art review on bridge weigh-in-motion technology. Adv. Struct. Eng. 2016, 19, 1514–1530. [Google Scholar] [CrossRef]

- Lydon, M.; Taylor, S.E.; Robinson, D.; Mufti, A.; Brien, E.J.O. Recent developments in bridge weigh in motion (B-WIM). J. Civ. Struct. Health Monit. 2015, 6, 69–81. [Google Scholar] [CrossRef] [Green Version]

- Ji, S.; Wang, R.; Shu, M.; Han, W.; Lan, X.; Wang, X.; Yin, W.; Cheng, Y. Improvement of vehicle axle load test method based on portable WIM. Meas. 2021, 173, 108626. [Google Scholar] [CrossRef]

- Jacob, B. Weighing-in-Motion of Axles and Vehicles for Europe (WAVE). Rep. of Work Package 1.2; Laboratoire Central des Ponts et Chaussées: Paris, France, 2001. [Google Scholar]

- Ieng, S.S.; Zermane, A.; Schmidt, F.; Jacob, B. Analysis of B-WIM signals acquired in Millau orthotropic viaduct using statistical classification. In Proceedings of the International Conference on Weigh-in-Motion (ICWIM 6), Dallas, TX, USA, 4–7 June 2012; Wiley: New York, NY, USA, 2012; pp. 43–52. [Google Scholar]

- Kalin, J.; Žnidarič, A.; Lavrič, I. Practical implementation of nothing-on-the-road bridge weigh-in-motion system. In Proceedings of the International Symposium on Heavy Vehicle Weights and Dimensions, State College, PA, USA, 18–22 June 2006; Pennsylvania State University: State College, PA, USA, 2006. [Google Scholar]

- Wall, C.J.; Christenson, R.E.; Mcdonnell, A.M.H.; Jamalipour, A. A Non-Intrusive Bridge Weigh-in-Motion System for a Single Span Steel Girder Bridge Using Only Strain Measurements; Rep. No. CT-2251-3-09-5, 9–10; Connecticut DOT: Rocky Hill, CT, USA, 2009.

- Kalhori, H.; Alamdari, M.M.; Zhu, X.; Samali, B.; Mustapha, S.J.M.S. Non-intrusive schemes for speed and axle identification in bridge-weigh-in-motion systems. Meas. Sci. Technol. 2017, 28, 025102. [Google Scholar] [CrossRef]

- O’Brien, E.J.; Hajializadeh, D.; Uddin, N.; Robinson, D.; Opitz, R. Strategies for axle detection in bridge weigh-in-motion systems. In Proceedings of the International Conference on Weigh-in-Motion (ICWIM 6), Dallas, TX, USA, 4–7 June 2012; Wiley: New York, NY, USA, 2012. [Google Scholar]

- Bao, T.; Babanajad, S.K.; Taylor, T.; Ansari, F. Generalized method and monitoring technique for shear-strain-based bridge weigh-in-motion. J. Bridge Eng. 2016, 21, 04015029. [Google Scholar] [CrossRef]

- Dunne, D.; O’Brien, E.J.; Basu, B.; Gonzalez, A. Bridge WIM systems with Nothing on the Road (NOR). In Proceedings of the Fourth International Conference on Weigh-in-Motion, Taipei, Taiwan, 20–23 February 2005. [Google Scholar]

- Chatterjee, P.; O’Brien, E.; Li, Y.; González, A. Wavelet domain analysis for identification of vehicle axles from bridge measurements. Comput. Struct. 2006, 84, 1792–1801. [Google Scholar] [CrossRef] [Green Version]

- Yu, Y.; Cai, C.; Deng, L. Vehicle axle identification using wavelet analysis of bridge global responses. J. Vib. Control. 2017, 23, 2830–2840. [Google Scholar] [CrossRef]

- Ojio, T.; Carey, C.H.; O’Brien, E.J.; Doherty, C.; Taylor, S.E. Contactless Bridge Weigh-in-Motion. J. Bridge Eng. 2016, 21, 04016032. [Google Scholar] [CrossRef] [Green Version]

- Xia, Y.; Jian, X.; Yan, B.; Su, D. Infrastructure Safety Oriented Traffic Load Monitoring Using Multi-Sensor and Single Camera for Short and Medium Span Bridges. Remote Sens. 2019, 11, 2651. [Google Scholar] [CrossRef] [Green Version]

- He, W.; Deng, L.; Shi, H.; Cai, C.S.; Yu, Y. Novel virtual simply supported beam method for detecting the speed and axles of moving vehicles on bridges. J. Bridge Eng. 2017, 22, 04016141. [Google Scholar] [CrossRef]

- Chen, S.Z.; Wu, G.; Feng, D.C.; Zhang, L. Development of a bridge weigh-in-motion system based on long-gauge fiber bragg grating sensors. J. Bridge Eng. 2018, 23, 18. [Google Scholar] [CrossRef]

- Deng, L.; He, W.; Yu, Y.; Cai, C.S. Equivalent shear force method for detecting the speed and axles of moving vehicles on bridges. J. Bridge Eng. 2018, 23, 04018057. [Google Scholar] [CrossRef]

- He, W.; Ling, T.; O’Brien, E.J.; Deng, L. Virtual axle method for bridge weigh-in-motion systems requiring no axle detector. J. Bridge Eng. 2019, 24, 04019086. [Google Scholar] [CrossRef]

- Thorndike, R.L. Who belongs in the family? Psychometrika 1953, 18, 267–276. [Google Scholar] [CrossRef]

- Lawson, C.L.; Hanson, R.J. Solving Least-Squares Problems; Prentice Hall: Upper Saddle River, NJ, USA, 1974; Chapter 23; p. 161. [Google Scholar]

- Lloyd, S. Least square quantization in pcm. Bell telephone laboratories paper. IEEE Trans. Inform. Theor. 1957, 18, 129–137. [Google Scholar]

- Best_Kmeans(X). Available online: https://www.mathworks.com/matlabcentral/fileexchange/49489-best_kmeans-x (accessed on 1 July 2021).

- Arthur, D.; Vassilvitskii, S. K-means++: The advantages of careful seeding. In Proceedings of the Eighteenth Annual ACM-SIAM Symposium on Discrete Algorithms (SODA 07), New Orleans, LA, USA, 7–9 January 2007; pp. 1027–1035. [Google Scholar]

- Deng, L.; Cai, C.S. Development of dynamic impact factor for performance evaluation of existing multi-girder concrete bridges. Eng. Struct. 2010, 32, 21–31. [Google Scholar] [CrossRef]

- Deng, L. System Identification of Bridge and Vehicle Based on Their Coupled Vibration. Ph.D. Thesis, Louisiana State University, Baton Rouge, LA, USA, 2009. [Google Scholar]

- He, W. Study of Dynamic Impact Factor for Medium and Small Span Beam Bridge. Master’s Thesis, Hunan University, Changsha, China, 2015. (In Chinese). [Google Scholar]

- O’Brien, E.J.; Rowley, C.W.; González, A.; Green, M.F. A regularised solution to the bridge weigh-in-motion equations. Int. J. Heavy Veh. Syst. 2009, 16, 310–327. [Google Scholar] [CrossRef]

| Average Speed (m/s) | Relative Error (%) | |||||||

|---|---|---|---|---|---|---|---|---|

| AW1 | AW2 | AW3 | GVW | |||||

| u | w | u | w | u | w | u | w | |

| 1.02 | 2.0 | 1.5 | −2.9 | 0.8 | 2.3 | 1.0 | −0.1 | 0.2 |

| 2.05 | 6.1 | 2.3 | −2.9 | 1.3 | −0.2 | 1.0 | −0.3 | 0.2 |

| 3.02 | 9.2 | 7.6 | −4.1 | 2.4 | −4.1 | 3.4 | −1.8 | 1.5 |

| 4.03 | 3.0 | 3.6 | −1.7 | 1.6 | −0.5 | 1.8 | −0.4 | 0.5 |

| 5.03 | −2.6 | 2.9 | 0.4 | 1.8 | −1.6 | 2.3 | −0.9 | 0.9 |

| Average Speed (m/s) | Relative Error (%) | |||||||

|---|---|---|---|---|---|---|---|---|

| AW1 | AW2 | AW3 | GVW | |||||

| u | w | u | w | u | w | u | w | |

| 1.02 | −3.7 | 1.0 | 6.6 | 1.7 | −5.4 | 2.0 | 0.3 | 0.2 |

| 2.05 | 0.7 | 2.0 | −0.4 | 1.2 | −0.1 | 1.0 | −0.1 | 0.2 |

| 3.02 | −2.7 | 3.8 | 1.1 | 1.5 | −0.6 | 1.1 | −0.2 | 0.8 |

| 4.03 | 5.5 | 4.7 | −2.5 | 3.1 | 0.8 | 3.3 | 0.1 | 0.7 |

| 5.03 | −9.7 | 2.1 | 3.1 | 2.5 | −1.8 | 1.8 | −0.9 | 1.3 |

| Average Speed (m/s) | Relative Error (%) | |||

|---|---|---|---|---|

| AS1 | AS2 | |||

| u | w | u | w | |

| 1.02 | 1.9 | 1.3 | −3.8 | 1.0 |

| 2.05 | 2.5 | 2.0 | −4.1 | 1.2 |

| 3.02 | −1.5 | 3.5 | −4.9 | 1.7 |

| 4.03 | 2.7 | 1.7 | −3.1 | 1.8 |

| 5.03 | −0.0 | 2.4 | −2.4 | 1.4 |

| Average Speed (m/s) | Relative Error (%) | |||

|---|---|---|---|---|

| AS1 | AS2 | |||

| u | w | u | w | |

| 1.02 | −0.9 | 0.1 | 7.6 | 0.4 |

| 2.05 | −1.7 | 0.1 | 2.7 | 0.4 |

| 3.02 | −0.8 | 0.4 | 0.1 | 0.2 |

| 4.03 | 2.4 | 0.4 | −1.5 | 0.4 |

| 5.03 | −4.0 | 1.4 | −0.6 | 0.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, W.; Liang, X.; Deng, L.; Kong, X.; Xie, H. Axle Configuration and Weight Sensing for Moving Vehicles on Bridges Based on the Clustering and Gradient Method. Remote Sens. 2021, 13, 3477. https://doi.org/10.3390/rs13173477

He W, Liang X, Deng L, Kong X, Xie H. Axle Configuration and Weight Sensing for Moving Vehicles on Bridges Based on the Clustering and Gradient Method. Remote Sensing. 2021; 13(17):3477. https://doi.org/10.3390/rs13173477

Chicago/Turabian StyleHe, Wei, Xiaodong Liang, Lu Deng, Xuan Kong, and Hong Xie. 2021. "Axle Configuration and Weight Sensing for Moving Vehicles on Bridges Based on the Clustering and Gradient Method" Remote Sensing 13, no. 17: 3477. https://doi.org/10.3390/rs13173477

APA StyleHe, W., Liang, X., Deng, L., Kong, X., & Xie, H. (2021). Axle Configuration and Weight Sensing for Moving Vehicles on Bridges Based on the Clustering and Gradient Method. Remote Sensing, 13(17), 3477. https://doi.org/10.3390/rs13173477