1. Introduction

As power supply demand grows rapidly, the demand for coal is also increasing. In the production and transshipment process of coal, stockpile is the basic unit for management. A large amount of stockpiles of coal have been formed while they are excavated and shipped at the mines, ports, power plants, etc. Since stockpiles take huge space, it becomes hard and time-consuming to monitor/measure them accordingly, which brings difficulty to the planning of coal production and consumption. It is necessary to quantitatively measure the coal stockpiles to facilitate the scientific storage and transportation management, as well as the maintenance of safety inventory during operation. This paper is then motivated to automatically reconstruct the stockpiles and measure their volume.

Commonly, the volume of the stockpile can be calculated once loaded on trucks or trains or from their weight. Besides, terrestrial geodetic methods using total station are often used to obtain information about the stockpile, which need to walk over the stockpile to manually sample many control points on the stockpile to estimate the volume. However, the above methods are time-consuming and laborious, and the precision is low. More effective and reliable methods for stockpile measurement should be utilized.

With the development of sensors and computer technology, three-dimensional (3D) point cloud data was involved to achieve better measuring accuracy and more detailed spatial morphology of the stockpiles. 3D point cloud collect the dense 3D coordinates of the stockpile surface, quantitative parameters of stockpile such as height, floor area and volume can then be computed through the processing of 3D point cloud data.

There are many ways to obtain 3D point cloud data, such as depth camera, stereo camera, laser scanner, etc. In some studies [

1,

2], depth cameras based on structure light or Time-of-Flight were used for 3D reconstruction. Combined with many denoising approach, the accuracy of 3D reconstruction and 3D point cloud data obtained by depth camera in real-time is acceptable. it is an easy-to-use and low-cost way to use depth camera, however, the effective distance of depth camera tend to be so short that depth camera is unsuitable to be performed in large field [

3] in the coal yard, and the sunlight can also impact the precision of depth camera under outdoor conditions [

4]. A method for 3D reconstruction using stereo vision camera pair has been described in [

5], by which objects can be reconstructed from the dense matching. The work in [

6] combined the efficient stereo matching with a multi-view linking scheme for generating consistent 3d point clouds, allowing real-time 3d reconstructions from large-scale imagery. The work in [

7] used UAV with stereoscopic aerial photographic pairs for capturing point cloud data and estimating stockpile volumes. 3D point cloud obtained by stereo vision technique have good quality and high resolution. But when it comes to some scene where the image features are not obvious, such as ground, coal, desert, etc., stereo vision technique is hard to work, as image matching, which is the most critical step for stereo vision, can‘t be achieved effectively if there exist little distinctive features.

Compared with image-based photogrammetry methods, or the manual survey using GPS and total station, laser scanning technique has better accuracy, robustness and efficiency. It is extensively used for topographic measurements in recent years. The work in [

8] estimated the errors and accuracy of laser data acquired by various laser scanning systems for topographic applications and the results showed that laser scanning can be used for the extraction of topographic information for various purposes. In [

9,

10], 3d Laser Scanning and GPS technology were used to acquire landslide point cloud data and to compute earthwork volume. In this paper, we take advantage of 3D point cloud data from the laser scanning to compute key parameters of stockpiles.

To measure such parameters as volume, height of stockpiles from the 3D point cloud data, work [

7,

11] studied cases in an open pot quarry and stockpile using Pix4D software. It achieved high accuracy of measurement and cost much less time than manual surveys. The work in [

12] also calculated the volume of stockpile using 123d software on point cloud data, and resulted in a higher speed and accuracy of volume measurement than conventional methods.

Although volume calculation methods using point cloud have better speed and accuracy than conventional methods, there are still challenges to obtain accurate quantitative parameters using 3D point cloud data. As the basic unit for the management of the actual production and transshipment process, different stockpiles may represent different production date, method, type, or transportation mode, and need to be distinguished accurately on the boundary even if they are overlapped between each other. Most of the existing researches need to delineate the boundary manually on the point cloud. Stockpiles of coal have irregular shape, size, and base conditions, and may be overlapped with each other, which make it hard to identify the boundaries clearly and measure stockpiles separately. Therefore, there is a need to automatically extract and measure the stockpiles from the 3D point cloud data.

Extracting the stockpiles from the whole scene can be regarded as a point cloud segmentation problem. Currently, the existing point cloud segmentation algorithms include region growing algorithms, model fitting algorithms, edge-based algorithms, etc.

(1) Region growing algorithms starts from seed points and then classifies the points with similar characteristics into one class, such as curvature [

13,

14], point normal direction [

15], local convexity and dimension features [

16], etc. And the work in [

17,

18] used an octree-based region growing method according to a coarse-to-fine concept, which improved the segmentation precision. However, these methods are sensitive to the location of initial seed points, and the inaccurate selection of seed points will affect the segmentation results. Moreover, these algorithms rarely consider the overgrowing between overlapped stockpiles.

(2) Model fitting algorithms can also segment point cloud accurately. In work [

19,

20], an automated detection of 3D geometric shapes from point cloud data was realized based on Hough Transform. The work in [

21] presented an iterative sphere fitting algorithm, which can extract both single spheres and multiple spheres. The work in [

22] completed cylindrical objects estimation in point cloud. It used RANSAC to estimate the center axis and radius using the trace of a sphere model, and confirmed of the constructed center axis data based on PCA. However, model fitting is mainly efficient for the detection of geometrically simple and regular shape such as cylinders, spheres, cones, cubes, etc. For stockpiles of coal, their shapes may be irregular, or even two of them may be overlapped, which is difficult to describe with any specific geometric models, so that the model fitting of the entire stockpile is not suitable for extracting it.

(3) Edge-based methods firstly detect edges to outline the borders of different regions according to point cloud features, such as normal vector orientation, elevation difference, etc., and then group the points based on the boundaries. The work in [

23] realized road boundaries extraction through detecting the curbs in real-world urban scenes, where there is either an elevation jump or a gradual elevation change. The work in [

24] put forward a hybrid method based on region growing and model fitting for edge detection by analyzing angular gap of neighborhoods. However, those method can only preform when the edges demonstrate the abrupt changes between the normal directions or elevations of adjacent surfaces, which is not suitable for detecting the continuous stockpiles of coal.

As a matter of fact, although a stockpile has three parts of crest, slope, and base, it is distinctive and perceptible for the crest, which can then act as the starting point to extract and measure the stockpile. However, due to the various height, shape, size, and base conditions, it is hard to locate the crest of different stockpiles. This paper first proposes an innovative perspective of directional curvature to extract the distinctive ridge of crest in the point cloud data. It characterizes the ridge using the curvature analysis along multiple directions and at multiple scales, resulting in invariant to the height, shape, size, and base conditions of different stockpiles. Then, starting with the crest points, a competitive growing strategy is proposed to accurately locate the points of slope in the stockpile, no matter whether there exist flatland, overlapping on the slope or not. Finally, the stockpile’s volume is calculated by reconstructing the complete points of crest and slope with many meshes and triangular prisms, which is simple yet general enough for different stockpiles.

The main advantages of this paper are as follow:

The proposed algorithm has great robustness not only to different stockpiles of various height, shape, and size, but also to different base conditions of various terrains where the stockpiles are located, as it can adaptively extract the crest and boundary of the stockpiles with the proposed directional curvature.

The proposed algorithm can achieve precise result of volume measurement for different stockpiles, by representing the structural features of stockpile into the volume element of triangular prisms.

The proposed algorithm can identify the overlapping between stockpiles with the competitive growing strategy, resulting in effective quantification of overlapped stockpiles.

3. Experimental Results

In order to evaluate the performance of the proposed algorithm for extracting and measuring stockpile, a diverse set of experiments are given with point cloud from both the synthetic and real yards of stockpiles. Stockpiles in the real yard could be very large and have arbitrary shape. It is hard and time-consuming to validate the algorithm accuracy for various stockpiles in the real yard. Therefore, a simulation device was designed which is able to collect point clouds of stockpiles of different shapes and sizes, and measure the ground truth of volume for the stockpiles. Experimental results with the synthetic and real data are evaluated both qualitatively and quantitatively to demonstrate the performance of the proposed algorithm.

The proposed algorithm is implemented in C++ language, and results of each algorithm step are also rendered carefully for better qualitative evaluation. For the voxelization of the point cloud from real yards, the grid size S is set according to the point density so that we can adaptively achieve a high precision of volume measurement without compromising the computation time cost. A large voxel size will speedup the computation but reduce the precision of volume, because the surface of stockpile becomes roughly sampled in this case. With a small voxel size, a high Precision of volume measurement will be achieved but it is time-consuming. Therefore, the choice of S is a balance between the precision and time, and keeps fixed to include around 20 points within a grid for real experiments. The curvature of a point is analyzed with 7 scales of 7, 9, 13, 19, 25, 35, 49 pixels and 4 directions of 0, 45, 90, 135 degree. The curvature threshold C is set according to the minimal perceptible stockpile (e.g., the stockpile of a 30-degree slope at the minimal scale) in the yard, and the gradient threshold of slope growing equals to 0.1 so that the growing will stop at the minimal slope of around 5 degree.

3.1. Performance Measure

To measure stockpiles that are of arbitrary shape and size, and located at varying subsurface base, the proposed algorithm includes three steps: crest extraction, slope extraction, and volume calculation, whose results are evaluated separately. For the extracted crest, whose number is small in most yards, it is easy to check whether there exist false positives and negatives. Thus, only qualitative rendering of crest point clouds is given for growing the slope of stockpiles, since the number of them has nothing with the growing. But the number of the complete point cloud of a stockpile is decided by the performance of extraction, and affects the precision of volume measurement. Therefore, the proposed algorithm is evaluated quantitatively in terms of accuracy of stockpile extraction and precision of volume calculation.

3.1.1. Accuracy of Stockpile Extraction

The accuracy of stockpile extraction from the point cloud is important for the stockpile measurement. To evaluate the extraction accuracy, the intersection-over-union (IoU) is employed as follows:

where

and

A are the set of points that are extracted by professional operators and the algorithm respectively. IoU measures the degree to which the algorithm mimics the operator in terms of extracting point cloud of stockpile. The higher IoU is, the more accurate the extraction result coincides with the ground truth. The ground truth for the evaluation is carefully set up manually with the point cloud selection tool of ArcGIS 10.2.

3.1.2. Precision of Volume Calculation

The precision of volume calculation is measured by the relative error of the algorithm compared to ground-truth volume. For the synthetic data, the ground truth is obtained with the volume measuring cup in ahead of creating a stockpile. The volume of stockpile in real yard is also carefully obtained by transportation vehicles with volume metering capability.

where

and

V denote the ground-truth and calculated volume of the proposed algorithm respectively for a stockpile. The higher Precision-of-Volume (

) is, the more precisely the algorithm measures the volume of a stockpile.

3.2. Experiments with Synthetic Data

To comprehensively evaluate the proposed algorithm, a diverse sets of synthetic point cloud with known ground truth are created with a simulation device. They include one or more stockpiles, and/or are overlapped with each other, and/or located at an uneven subsurface base in the yard. Certainly, the shape and size of the stockpile vary a lot with every creation.

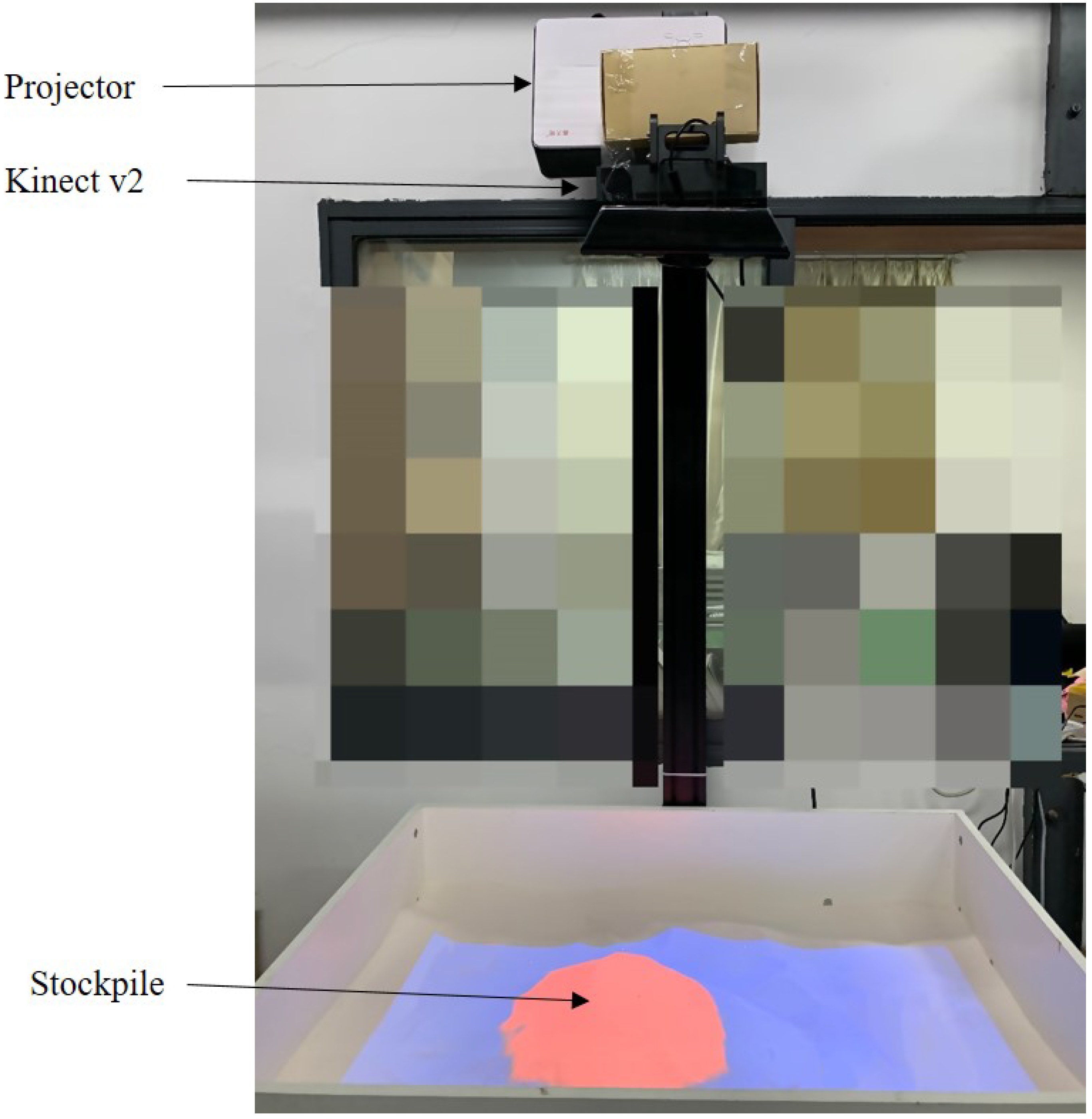

As shown in

Figure 17, the simulation device for collecting point clouds of arbitrary stockpile is inspired by [

26], which is composed of three parts: the Kinect V2 depth sensor, a projector and sandbox of stockpile(s). The whole device is placed on a horizontal level. The Kinect is installed downward and 2 m above the sandbox. It captures the distance of sandbox away from its imaging center, resulting in point clouds of the stockpiles in the sandbox, with the average depth resolution around 2 mm. The Kinect V2 has a depth image resolution of 512 × 424 pixels with a field of view of 70.6 × 60 degrees. Because of this installation, the complete stockpiles’ point clouds can be collected with the near and downward imaging. There is no need of stitching point cloud of multiple scans for a stockpile and then voxelizing point cloud. The projector is used to vividly render the stockpile by its volume, elevation, etc. once it is calibrated well with the Kinect depth sensor. Since the sand can be shaped arbitrarily, it is helpful to create stockpiles of various shape, size, overlapping, and subsurface base within the sandbox. For each stockpile, its volume can be readily metered in ahead of the creation, through which we have the ground truth regarding the stockpile’s volume. Once the point cloud of the stockpile is collected by the Kinect, the proposed algorithm is called to extract and measure it automatically. The performance of the algorithm is quantitatively evaluated with the ground truth.

3.2.1. Experimental Results with Typical Yard

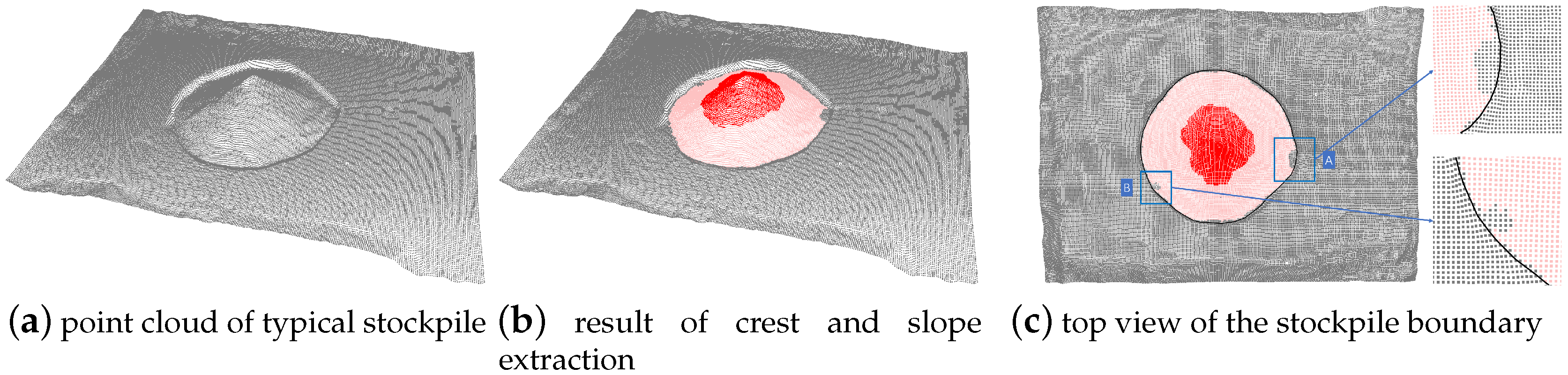

As shown in

Figure 17, the sand that fills up the 5 litres measuring cup is put into the sandbox and under the Kinect depth sensor. The point cloud of the sandbox looks like

Figure 18a, where the ridge of stockpile is obvious due to its protruding elevation. It is the typical yard with one significant stockpile in the middle.

After we get the stockpile’s point cloud with the Kinect, the crest and slope extraction results are shown in

Figure 18b, where the reddest points in the middle are the crest points and the red points located between the gray base and the crest denote the slope points. It can be seen that both the crest and the complete stockpile are extracted well.

Figure 18c is the top view of

Figure 18b to better demonstrate the accuracy of boundary delineation of the proposed algorithm, where the black edge between the slope and the base is delineated by a professional operator. It can be seen that the boundary of the slope growing matches well with the professional delineation. The little difference in the rectangle A and B of

Figure 18c could slightly reduce the IoU measure of slope extraction. But since they are located on the boundary, the elevation of A and B is very close to the base and cannot form perceptible prism at all, contributing little to the stockpile’s volume measurement.

The quantitative result of stockpile extraction and measurement of typical yards is given in

Table 1 for the proposed algorithm, where 10 experiments of stockpiles of different sizes are tested, and the IoU and precision are calculated for each experiment in the second and last column. From

Table 1, we can see that the average IoU and precision are 93.9% and 96.2%. The minimal extraction accuracy of stockpile point cloud is over 90%, and shows good matching with the human delineation. Due to the limit of Kinect’s resolution of depth measurement, the precision of volume measurement fluctuates a little, which relatively brings more impact on the extraction and measurement of small stockpile than on large stockpile. The minimal measurement precision is over 85%. It demonstrates that the proposed algorithm can measure stockpiles of different sizes precisely.

3.2.2. Experimental Results with Diverse Yard

Besides the typical stockpiles, there is possibly flatland in the slope, or uneven subsurface surrounding the stockpile, which brings difficulty for the crest or slope extraction by elevation. In addition, the occurrence of multiple stockpiles in a yard, possibly overlapped with each other, requires accurate location of the stockpile boundary at the end of slope growing. Therefore, a diverse set of yards are investigated to show the performance of the proposed algorithm in this section

(1) stockpile with flatland slope

As shown in

Figure 19a, there exists flatland in the rectangular area of the slope, where the gradient becomes close to zero although it is located on the slope. The gradient-based slope growing could stop early at the flatland instead of the subsurface base of the stockpile.

The final result of slope growing is shown in

Figure 19b, where the flatland doesn’t stop the location of the stockpile boundary and is successfully filled up. Since the slope points can be grown along all directions of the flatland boundary as long as the gradient is above the threshold, the flatland only stops partial directions of growing through it and enables the growing around it. Therefore, with the proposed omnidirectional spatial growing of slope, the slope points are completely extracted even there are flatland inside, as shown in the top view of flatland in

Figure 19c.

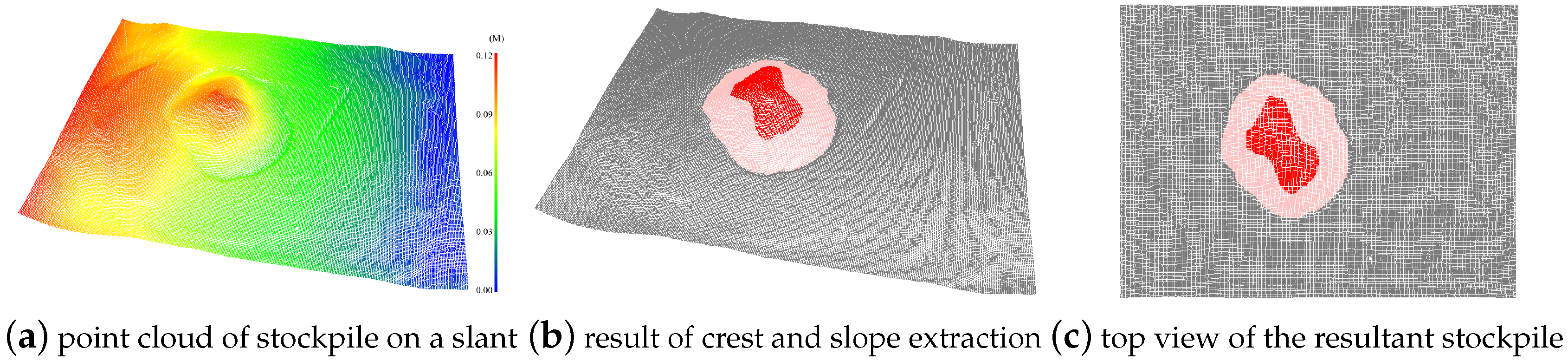

(2) stockpile on a slant

When the stockpile is located on a slant, it is difficult to extract it by elevation, as shown in

Figure 20a, where the points are rendered by the elevation. The result of crest and slope extraction is shown in

Figure 20b. Both the crest and slope are accurately extracted with the IoU of 95.9% and the precision of 97.8% for the volume measurement. Actually, after the normalization of point cloud, the effect of uneven base on the stockpile extraction is alleviated a lot. Additionally, the proposed multi-scale directional curvature analysis works at the change of slope gradient, thus it is robust to slant base during the crest extraction.

(3) multiple stockpiles

As shown in

Figure 21a, there are multiple stockpiles in the sandbox. The shape, size, and location of the stockpiles are quite different. With the proposed curvature analysis, the crest points of the stockpiles are first located with different colors, followed by the growing of slope points. The complete points of the stockpiles and their boundaries are separately shown in

Figure 21b,c. It can be seen that all the stockpiles are well extracted by the proposed algorithm. And the quantitative results of the extraction and measurement are listed in

Table 2, which achieves a high IoU of 94.4% and precision of 96.5%, demonstrating that the proposed algorithm performs well with various shape, size, and location of the stockpile.

(4) multiple stockpiles with overlapping between each other

For the first column of

Figure 22, there are overlapping between different stockpiles. In this case, the gradient-based slope growing could reach the overlapped boundary at different speeds, causing over-growing of the boundary of one stockpile into the other one’s. With the proposed strategy of competitive growing, points located at the overlapped area are assigned to the crest that is much closer to them. The extraction results of two, three, and four overlapped stockpiles are shown in the second column of

Figure 22, where no over-growing appears between stockpiles. It can also be seen from the third-column top view of the boundary in

Figure 22 that the intersecting boundary of differently-colored stockpiles matches well with the professional delineation.

Table 3 gives the quantitative results of

Figure 22, from which we can see that the proposed algorithm performs well for stockpiles of overlapping. The average IoU of extracting complete points of stockpile achieves 93.5%, and the volume is well measured with a precision of 93.7%.

3.3. Experiments with Real Data

Besides the synthetic experiments with the sandbox, real experimental results at a coal yard are given in this section. The size of the yard is 14,904 m

. There are four stockpiles of different shape and size inside the yard. The point cloud of the stockpiles and yard was collected by the SICK LD-LRS3611 which can work 250 m away the outdoor yard with the angle resolution of 0.125 degree and range resolution of 3.8 cm. Tested in the paper [

27], it was proved that this laser can obtain a very accurate range data of coal stockpiles even in the environment with dust, and is suitable for practical use in our experiments. To get the complete yard, it was collected using 15 scans at different positions/orientations and stitched together as a whole.

The ground truth boundary of the stockpile is then elaborately delineated by professional operators with the stitched point cloud of the yard, and the ground truth volume of the stockpile is obtained from the weighting outcome of professional measuring vehicle before the coal transportation.

3.3.1. Results of Preprocessing

Figure 23a–c shows the point cloud collected at three different positions of the yard. They reflect different views of the yard, but there are overlapping area between them. After the preprocessing of stitching and normalization, they are stitched together as

Figure 23d, where all sides of the stockpiles can be seen completely.

From

Figure 23d, we can see that there are 4 stockpiles a, b, c, and d of different size and shape. The stockpile a and b are connected with each other, and the size of stockpile d is very small. It is helpful to comprehensively evaluate the performance of the proposed algorithm with the yard.

3.3.2. Results of Crest Extraction

After the preprocessing, the multi-scale directional curvature is calculated in

Figure 24a. It can be seen that there are four blue areas with small curvatures after the the multi-scale directional curvature analysis. They exactly correspond to the crest of four stockpiles. To investigate the effect of the proposed curvature analysis, the results of the red rectangular area in

Figure 24a are detailed as an example in the

Figure 24b–e, where the first and second column are the result of vertical and horizontal curvature analysis; the first and second row denote the curvature at a scale of 49 pixels and 7 pixels, i.e., 34.3 m and 4.9 m respectively. The red rectangular area in

Figure 24a is located at a large stockpile spreading horizontally in the local neighborhood. It can be seen that the crest of the rectangle are not well located with the small scale of 7 pixels in

Figure 24d,e, but become perceptible with the large scale of 49 pixels in

Figure 24b,c. Meanwhile, the crest of the rectangle in

Figure 24b becomes more obvious with the vertical curvature analysis than the horizontal one in

Figure 24c. Therefore, the curvature of the rectangular area is decided by the vertical curvature at a large scale as

Figure 24b. As long as the curvature is greater than a threshold, the point is regarded as a crest point.

In the experiments, the curvature threshold

C is set to

according to the minimal perceptible stockpile of 7 pixels, and the result of crest extraction is shown in

Figure 25, where the curvature of a point is analyzed with 7 scales and 4 directions. It can be seen from the colored points that the crests of four stockpiles are well located after the multi-scale directional curvature analysis.

3.3.3. Results of Slope Extraction

Based on the result of crest extraction, the slope of the stockpiles are grown in

Figure 26. The gradient threshold of the slope growing is set as

, meaning that the growing will stop at the boundary of a slope of less than 5 degree. From the differently-colored points among the gray base of the coal yard, the complete points of the stockpiles are extracted well. The boundary of stockpile a and b is divided without over-growing due to the employment of competitive strategy during slope growing, as shown in

Figure 26b.

The quantitative results of the stockpile extraction and measurement are listed in

Table 4. For the stockpiles in the real yard, the average IoU of stockpile extraction is 93.9%, and precision of volume measurement achieves 94.6% on average. It demonstrates that the proposed algorithm performs well for stockpiles of different size and shape in the real yard.

5. Conclusions

With the rapid increase of power supply demand, a large amount of stockpiles of coal have been formed during the process of coal excavation and transportation between the mines, ports, power plants and etc. Quantitative parameters, especially the volume of stockpile are important for the planning of coal production and consumption. Although laser scanning can collect the dense 3D coordinates of the stockpile surface for its quantification, stockpiles of coal have irregular shape, size, height, and base conditions, and may be overlapped with each other, which makes it hard to measure the different stockpiles automatically and accurately.

This paper proposes an algorithm to extract and measure the stockpiles from the 3D point cloud data using the multi-scale directional curvature. Although a stockpile has three parts of crest, slope, and base, it is distinctive and perceptible for the crest, which can then act as the starting point to extract and measure the stockpile. Firstly, the second-order directional curvature along multiple directions and at multiple scales is analyzed to extract the distinctive ridge of crest in the point cloud of stockpiles, resulting in invariant to the height, shape, size, and base conditions of different stockpiles. Then, starting with the crest points, a competitive growing strategy is proposed to accurately locate the points of slope in the stockpile, no matter whether there exist flatland, overlapping on the slope or not. Finally, the stockpile’s volume is calculated by reconstructing the crest and slope points with many meshes and triangular prisms through the subsurface fitting and surface reconstruction, which is simple yet general enough for different stockpiles.

Through building a simulator system using a sandbox, Kinect depth sensor and projector, the effectiveness and accuracy of the proposed algorithm is comprehensively verified. Experiments on both the synthetic and real point cloud of stockpiles demonstrate that the proposed algorithm can extract the stockpiles with the average accuracy over 93.5% and measure the volume of stockpiles with the average precision over 93.7%. It is promising for automatically measuring the stockpiles like sand, soybean, etc., and facilitating the scientific storage and transportation management, as well as the maintenance of safety inventory during operation.

Although the proposed algorithm demonstrates its potential for extracting and measuring the stockpiles from point cloud, we suggest incorporating the analysis of boundary shape into the competitive strategy so that the boundary of a stockpile is not distorted a lot due to the over-growing.