1. Introduction

In recent years, consumer behavior in the field of food production has considerably changed. During the first 50 years of the century, immediately after the Second World War, foods were intended to only satisfy hunger and to provide essential nutrients. Nowadays, food quality is one of the main aspects that characterize the culture of a civilization and it is considered especially in terms of prevention of nutrition-related diseases and improvements of physical and mental well-being. On a global scale, climate change, growing world populations, and clear evidence of the reduction or damage to critical resources makes it imperative to take action to sustain and develop the capacity of agricultural and manufacturing systems to continue to provide food with high health benefits [

1]. Despite major advances in technology leading to more efficient food production, millions of people are severely undernourished, while an almost comparable number are dangerously overweight [

2]. At this significant point in human history, it is important to assess the sustainability of all processes and practices. In this context, functional foods represent one of the most interesting research and innovation areas in the food industry [

3]. The European Commission’s Concerted Action on Functional Food Science in Europe (FuFoSE) defined functional food as follows: ”a food product can only be considered functional if together with the basic nutritional impact it has beneficial effects on one or more functions of the human organism thus either improving the general and physical conditions or/and decreasing the risk of the evolution of diseases” [

4]. The enrichment of foods’ properties during processing has beneficial effects on population health and plays an important role in reducing or minimizing the risk of certain diseases [

5,

6,

7]. Examples of these foods are fruits and vegetables, whole grains, fortified foods and beverages, and some dietary supplements [

8]. Several research studies [

9,

10,

11] have sought to discover and study the functional components of many conventional foods (e.g., rice protein; soybeans protein, polysaccharides and micronutrients; polyphenolic compounds in legumes) and, on the other hand, to develop new food products [

12,

13,

14] that may be enriched with functional components (e.g., juices fortified with calcium, foods fortified with folic acid, yogurt naturally bio-enriched by using selected lactic acid bacteria). The capacity to contribute to public health is an important indicator of a sustainable food supply [

15]. Investing in the development of functional foods may be a sustainable practice if it can be demonstrated that they offer a measurable and distinct nutritional advantage for consumers.

Among products with health benefits, dried pasta is widespread in Italy because it is the basis of the Mediterranean diet. Actually, there is a wide range of “dried pasta” for the treatment of various disorders, such as gluten-free and low-protein pasta respectively for people with celiac and nephropathic diseases. Recently, a new kind of dried pasta enriched with β-glucans for the treatment of diabetes and related illnesses was produced [

3].

Moreover, several international patents [

16,

17,

18] are related to the production of bakery products and pasta enriched with

Opuntia. The great number of potentially active nutrients and their multifunctional properties make the cactus pear (

Opuntia) fruits and cladodes the perfect candidates for production of health-promoting food and supplements [

19]. In fact, cactus pear cladodes are known for their medicinal properties, such as an auxiliary treatment for obesity and gastrointestinal or cardiovascular disorders [

20]. They also decrease the levels of cholesterol, triglyceride, and serum glucose and they are used in treating many diseases such as diabetes, hepatitis, rheumatism, kidney stones, etc. [

21,

22]. Therefore, the development of a new kind of functional pasta enriched with

Opuntia could represent a high-quality product for its elevated nutritional value and potential beneficial properties. Agro-food products are sustainable from a nutritional-healthy point of view if they meet healthiness and quality criteria [

1].

In this research study, we tested eight different samples of two types of pasta (short and long) obtained with different concentrations of

Opuntia. The obtained products were initially tested by a panel of experts to evaluate their organoleptic characteristics, then the selection of the best recipe was performed by means of a Multi Criteria Decision Making (MCDM) technique based on a set of qualitative and quantitative criteria. In the literature, a vast number of multi-criteria models and approaches are available. For example, Velasquez and Hester (2013) [

23] show a literature review of the most common MCDM methods, highlighting their advantages and disadvantages. Referring to the application of MCDM techniques and approaches, Mardani et al. (2014) [

24] reviewed 393 papers published from 2000 to 2014 in more than 120 peer-reviewed journals extracted from Web of Science. However, the selection of the most suitable method is not easy and depends on several factors [

25] such as, for example, the specific considered problem, the objectives of the decision maker, the uncertainty and vagueness of data and information, the accessibility of the approach for users, etc. In this research study, the ELECTRE III methodology was selected because of its ability to take into account the fuzzy nature of decision-making (by using indifference and preference thresholds). Finally, a sensitivity analysis was conducted to assess the stability of the obtained solutions at varying ELECTRE III thresholds. The remainder of this paper is organized as follows:

Section 2 describes the materials and methods implemented in this study;

Section 3 shows the results obtained by an experimental test and proposes a ranking of short and long pasta recipes; finally,

Section 4 concludes the paper with a short discussion on the proposed methodology and an outlook into on-going research work.

2. Material and Methods

2.1. The Production Process

Eight samples of two types of functional dried pasta enriched with different concentrations of Opuntia were produced in a pilot plant operated by a local company (Tomasello Spa, Santa Flavia, Italy). The pilot plant consists of an extruder (MOD. MAC 60 VR) and of a static dryer (SANDY1-1 LAB) produced by Namad (Rome, Italy). After it was placed into a mixing basin, the dough was extruded and pushed into the pasta die. Finally, it was cut in the desired length and profile (rigatoni or spaghetti). The maximum production rate of the machine is 60 kg/h and it can vary in relation to the type of pasta produced and the row material used. The static dryer is equipped with a Programmable Logic Controller (PLC) for accurate and precise control of the drying cycle. The drying chamber is composed of panels of stainless steel, 60 mm in thickness, to ensure correct functioning until the maximum temperature of 75 °C. The experimental dryer machine has nine looms for short pasta and two looms for long pasta that hosting 15 sticks. Looms and sticks are made of stainless steel to facilitate their cleaning and sanitization. The production rate of the static dryer ranges from about 13 to 20 kg/cycle.

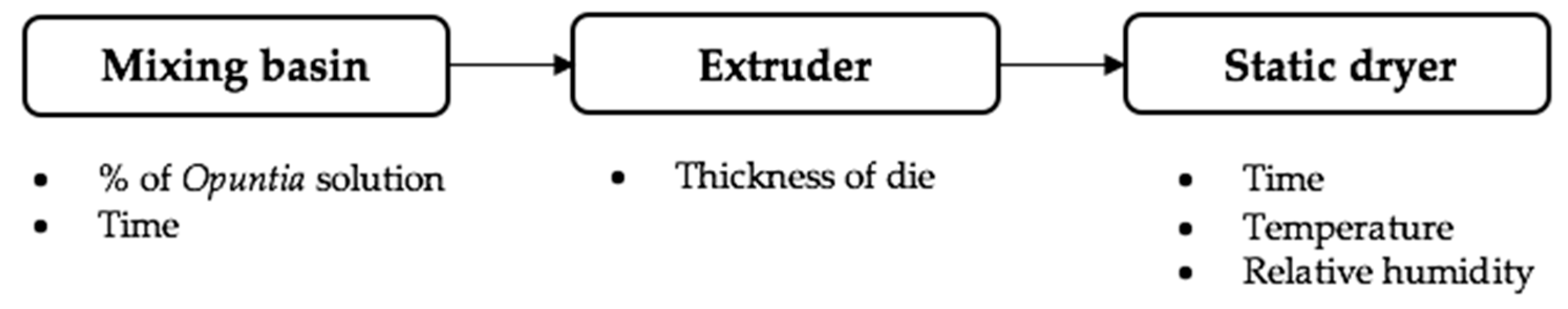

The block diagram scheme, reported in

Figure 1, shows the production process implemented in this research.

For each phase of the process, the production parameters used to define the different recipes are also reported in

Figure 1. These parameters were varied, starting from those generally used in the production of dried pasta and then experimentally changed on the basis of the obtained results and the experience of the producer.

The first step was to define the ideal conditions of the dough. The dough was made using durum wheat semolina with a particle size of 250–400 µm and a fluid

Opuntia solution that completely substitutes the water in the process. The use of the

Opuntia solution overcomes the problems of the

Opuntia flour in cooked macaroni, demonstrated by Garza-Lopez et al. (2006) [

17]. In fact, this patent reports that macaroni obtained with

Opuntia flour tends to easily break after it is cooked, losing its form and structure. The fiber concentration in the

Opuntia solution is 10 wt %. Eight different recipes were prepared for the production respectively of short and long pasta (

Table 1) enriched with

Opuntia.

In particular, the recipes for short pasta differ in Opuntia percentage and in the die thickness used, while the recipes for long pasta differ only in Opuntia percentage.

The last column in

Table 1 reports the percentage of

Opuntia fiber present in the final product considering an initial humidity of the semolina of about 15% and imposing a relative humidity in the dry pasta not higher than 12.5%, in accordance with the Italian legislation (D.P.R 187/01, art. 6). The

Opuntia quantity used for both the pasta types guarantee the presence of about 2 g of

Opuntia fiber per daily food portions (about 80 g of pasta). In fact, according to Cornelli (2009) [

16], a daily consumption of about 2 g of

Opuntia fiber for 15 days has healthy effects on cholesterol, body weight, plasma triglycerides, and glycaemia reduction.

Then, different times for dough mixing were tested (mixing time). It was observed that the mixing time was about the 25–30% higher with respect to the process using water due to the viscosity of the Opuntia solution, which slows the hydration of the wheat semolina. To overcome this problem, and hence to improve the hydration and the homogenization of the dough, the Opuntia solution was heated to 20 °C.

In

Table 2 the mixing times for short and long pasta are reported.

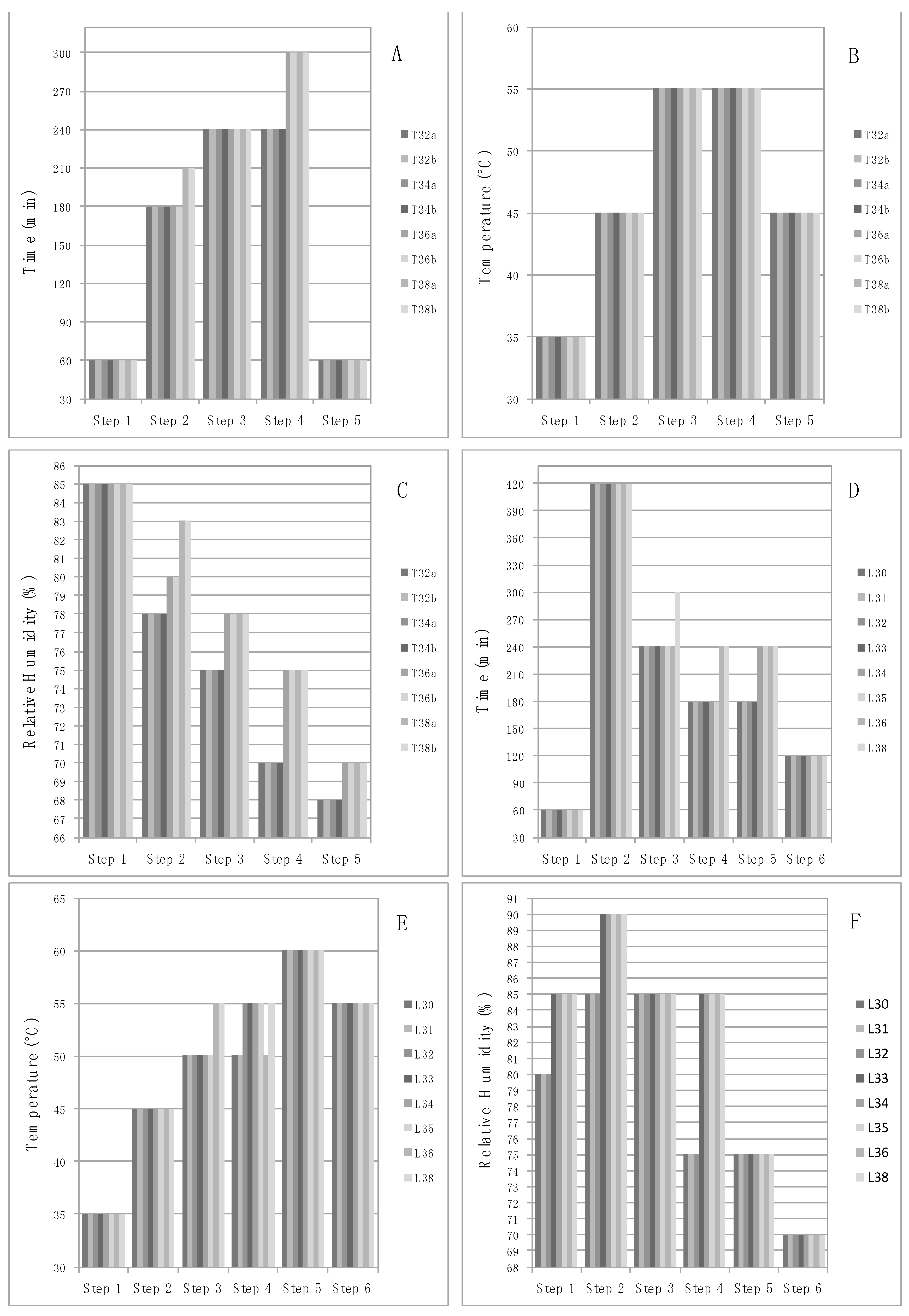

For each recipe, the drying steps were set using different values of temperature, relative humidity, and dryer time.

Figure 2 reports the drying process parameters for short and long pasta.

2.2. Evaluation Criteria

Textural characteristics of pasta play an essential role in determining the final acceptance by consumers [

26]. The quality of pasta resides in a series of characteristics that are affected both by the properties of the raw materials and the production process factors. This quality can be measured by considering parameters, such as, for example, color, firmness, texture, etc. Several authors have adopted the stickiness (or adhesiveness) of cooked pasta as the main quality parameter [

27], while in Antognelli (1980) [

28] and Pomeranz (1987) [

29] a good quality of pasta is reached with a high degree of firmness and elasticity. Pasta color is the first important quality characteristic that greatly influences consumer acceptance. Abecassis et al. (1984) [

30] show that the color mainly depends on the yellow index. Cubadda (1988) [

31] suggests a method based on the quality evaluation of the cooked pasta in terms of stickiness, firmness, and bulkiness. The relative humidity of the pasta is a critical parameter to the finished product quality; the relative humidity content is in fact a key safety criterion in dried pasta [

32]. Failure to achieve a reduction in relative humidity content during the drying, from approximately 31–32% to 12–13%, can result in microbiological growth with consequent product deterioration. Drying reduces the relative humidity content and makes pasta a stable product [

33]. Finally, thickness and bulkiness are important factors because they influence the digestibility of the final product [

26]. The first criterion is measured only for short pasta while the second is measured for long pasta. The production of pasta with high thickness and a consequent long cooking time involves poor-quality pasta, which once cooked will be coated in a sticky, starchy film, overcooked on the surface but raw inside and therefore difficult to digest. High values of bulkiness involve non-homogeneous cooking with a consequent presence of raw parts inside the product. The evaluation criteria adopted and the relative literature are summarized in the following table (

Table 3).

On the basis of these considerations, each sample of pasta obtained from a specific recipe was evaluated by a sensory analysis according to D’Egidio et al. (1990) [

34]. Each sample of pasta (100 g) was cooked in 1 L of boiling water, without salt, for 13 min and evaluated for firmness (resistance to chewing by the teeth), stickiness (amount of material adhering to the pasta surface), and bulkiness (adhesion of pasta strands to each other) by a trained panel of three experts. The Sensory Judgment (SJ) was calculated as the arithmetic mean of the scores for firmness (10–20 = absent, 21–40 = rare, 41–60 = sufficient, 61–80 = good, and 81–100 = very good), stickiness and bulkiness (10–20 = very high, 21–40 = high, 41–60 = rare, 61–80 = minimal, and 81–100 = absent).

- -

Firmness (10–100): this criterion measures, on a scale ranging from 10 to 100, the resistance of cooked pasta to teeth compression. This criterion score has to be maximized and thus there is an increasing preference towards the maximum.

- -

Stickiness (or adhesiveness) (10–100): this criterion is related to the presence, on cooked pasta, of a surface coating made of starch. It is evaluated on a scale ranging from 10 to 100 and the higher the presence of surface coating of starch, the less the score of criterion. A high concentration of starch on the surface of cooked pasta is considered a negative aspect. This phenomenon affects the appearance of the final product and it is generally caused by manufacturing errors and/or poor quality of semolina. The stickiness criterion score has to be maximized and as such there is an increasing preference towards absence of stickiness.

- -

Bulkiness (only for long pasta) (10–100): this criterion is a measure of the degree, in the cooked pasta, of the jamming among the long pasta. It is evaluated on a scale ranging from 10 to 100 and the smaller the tendency of the bulkiness is higher the score of criterion is. This criterion score has to be maximized and thus there is an increasing preference towards absence of bulkiness.

Each sample of pasta was also evaluated according to the yellow index, the relative humidity, and thickness (only for short pasta):

- -

Yellow index: this is the main criterion that refers to the appearance of the final product. The yellow index determines the degree of yellow under daylight illumination calculated from X, Y, and Z values of the Tristimulus colorimeter (Tristimulus colorimetry is based on the three-component theory of color vision, which states that the eye possesses receptors for three primary colors (red, green, blue) and that all colors are seen as mixtures of these three primary colors). It depends on the amount of carotenoid pigments in semolina and on the oxidative phenomena that occur during the process of pasta manufacturing (lipoxygenase). Both producer and consumer agree that a uniform yellow color of the pasta makes the final product more attractive. The yellow index criterion has to be maximized and thus there is an increasing preference for higher scores.

- -

Relative humidity (%): this criterion measures the percentage of liquid in the dried product. The Italian legislation establishes that for dried pasta this parameter must not be higher than 12.5% (in accordance with D.P.R 187/01, art. 6). Hence, the value 12.5% is the upper bound value for this criterion. It is not easy to determine the preference versus alternatives for this criterion, in fact, even if the relative humidity affects the shelf life of the final product, it is not clear how this value is related with its quality. The economic aspect was hence considered to establish the preference versus alternatives. According to the point of view of the producer, higher relative humidity values translate into a reduction of the semolina cost because the price of the pasta depends on its weight. On the contrary, according to the point of view of the consumer, the reduction of cost to acquire dried pasta is irrelevant. For these reasons, in this paper, the producer perspective is considered so that this criterion has to be maximized.

- -

Thickness (only for short pasta) (mm): this criterion is considered only for short pasta to take into account two different aspects. The Opuntia fiber results in a bulge in the product during the drawing process. For this reason, it is important to monitor this phenomenon as a function of the thickness. Moreover, the thickness of the final product affects the cooking time, this aspect was considered to determine the preference versus alternatives for the criterion. Short pasta with high thickness has a long cooking time, hence the thickness has to be minimized and thus it is characterized by a decreasing preference versus alternatives.

2.3. The Outranking Procedure

The aim of this section is to rank the different recipes described in

Section 2.1 and to evaluate the best one that guarantees good quality characteristics of the final products. Among the several classification methods described in literature, in this paper we used the ELECTRE III [

35] because it allows for the consideration of the imprecise, uncertain, and indeterminate nature of the decision-making process [

36]. In fact, these aspects can be considered by using pseudo-criteria constructed by means of the use of suitable thresholds (indifference and preference thresholds) [

37]. Moreover, the chosen methodology is not compensative; in other words, a really bad performance of an alternative with respect to a specific criterion is not compensated by a very good performance on the other criteria. This condition occurs if the smallest difference between the performances of two alternatives related to one criterion is greater than a fixed threshold, named veto threshold.

The methodology needs input data in the form of the following: a performance matrix reporting the scores of the alternatives in relation to the criteria, the weights and the three threshold values (preference, indifference, and veto threshold) for each identified criterion. The relative importance of criteria was calculated considering the judgments given by a panel of experts using the AHP (Analytic Hierarchy Process) method [

38]. In the present research study, four experts (two producers and two consumers), with different priorities in the decisional process, were considered. In particular, it was decided to give a higher priority to producers because they have a deeper knowledge of the production process, quality, and marketing of the pasta. The priority value is hence equal to 0.3 for the two producers and 0.2 for the two consumers. In the considered case, each expert makes a pairwise comparison of the criteria and his judgment is expressed by means of linguistic variables. The linguistic judgements are then converted to numerical values by means of the Saaty’s scale [

38]. The weighted geometric mean is applied to synthetize the pairwise comparison judgments of experts in a unique matrix. In

Table 4, the aggregate matrix and the weights of the criteria are shown for short and long pasta, respectively.

For each given criterion

k, belonging to the set

K of criteria, the three distinct thresholds used by the methodology, the indifference (

qk), the preference (

pk), and the veto (

vk) thresholds, have to respect the following relation:

The choice of appropriate thresholds is not easy, as they represent subjective input provided by the decision maker. For this reason, only the

j (

j = 1, 2) producers were interviewed and each of them gave, for each criterion, the value of indifference thresholds called

qk,j. According to the concept that such an indifference threshold expresses, the value assumed for

qk was fixed equal to:

The preference and veto thresholds were expressed proportionally to the

qk values. The threshold values are shown in

Table 5.

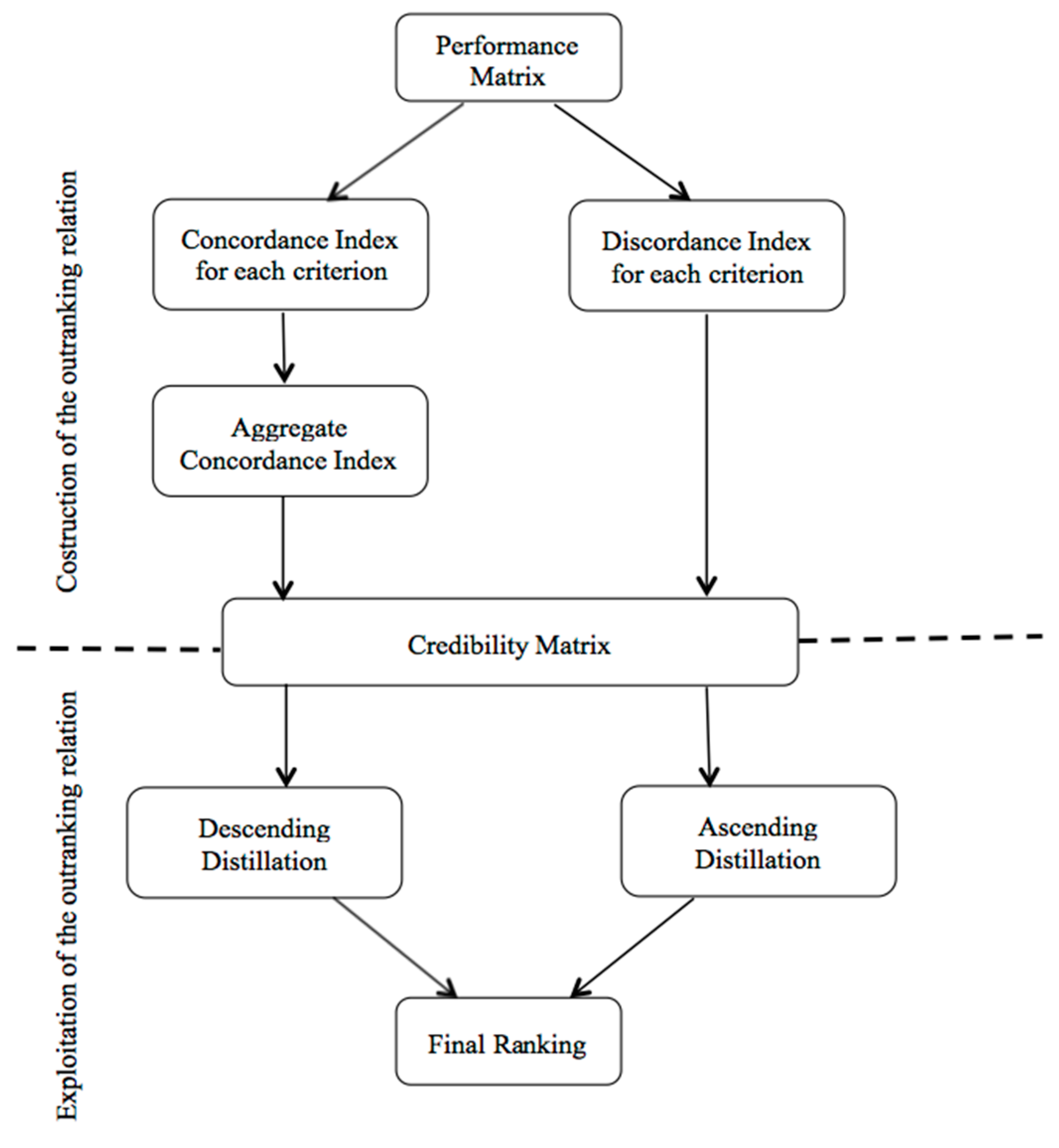

The ELECTRE III method is carried out in two main phases, as reported in

Figure 3.

The construction of the outranking relation: a pairwise comparison between the performances of two alternatives

Pi and

Pj on each criterion in order to verify the preference of

Pi over

Pj [

39]. In particular, the outranking approach confirms that

Pi outranks

Pj if the assertion “

Pi is at least as good as

Pj” is verified on a majority of criteria (concordance principle) while the minority of criteria does not support this statement, i.e., none of them is strong enough to refuse it (discordance principle) [

40]. Once the aggregate concordance and the discordance indices for each criterion are calculated, the credibility degree and, consequently, the credibility matrix, which represents the reliability of the outranking hypothesis, are evaluated.

The exploitation of the outranking relation: The ranking of the alternatives is performed by using two pre-ranking procedures, the descending and the ascending distillation. The descending procedure places in the first position the alternatives with the high qualification score, then it removes them from the credibility matrix and the process is re-iterated for all of the remaining alternatives until all of them are classified. The ascending procedure works similar to the previous one, except for the fact that it places in the last position the alternatives with the smallest qualification score. The combination of both orders gives the final ranking [

37].

3. Results and Discussion

The final products obtained were analyzed in the laboratory of the pasta manufacturing plant to test the chemical, physical, and organoleptic properties.

The structure of the final products obtained was similar to the traditional dried pasta, while the appearance was different because the color was almost green. Ten samples for each recipe were then cooked and the results obtained by means of a group of trained panelists showed that the taste and the physical characteristics such as stickiness, firmness, and bulkiness were similar to the traditional pasta. The mean values of the score obtained for each criterion are listed in in

Table 6 for short and long pasta, respectively.

As previously mentioned, in this paper, we considered the standards provided by the D.P.R 187/01. According to art. 6 of the above-mentioned standard, the relative humidity parameter cannot be higher than 12.5%; as such, the recipes T36a, T38a, T38b for short pasta and L35, L38 for long pasta are considered unfeasible solutions.

3.1. Ranking of the Short and Long Pasta Recipes

The result of the descending and ascending distillations are shown in

Figure 4 both for short pasta (

Figure 4a,b) and long pasta (

Figure 4c,d).

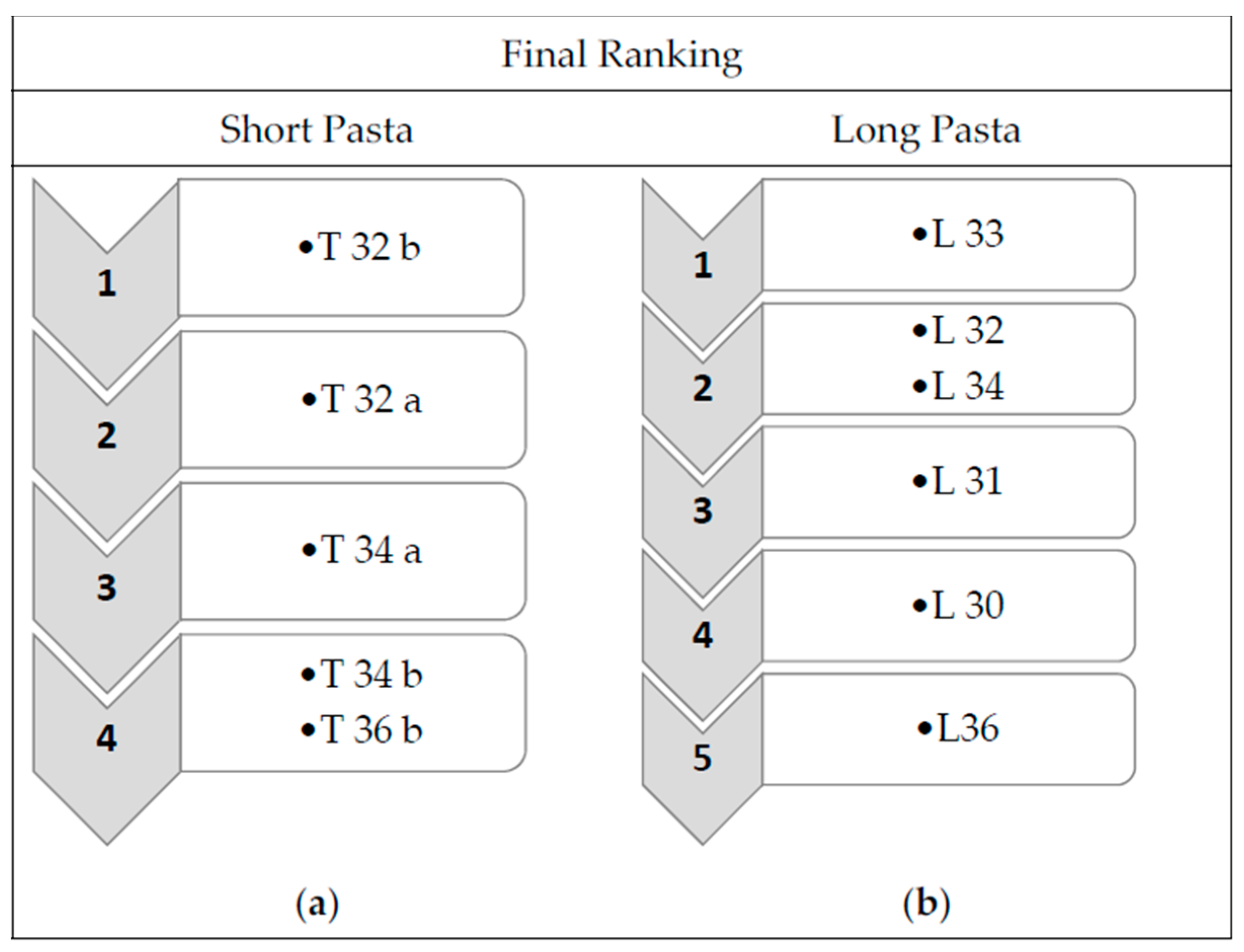

The final ranking is reported in

Figure 5a,b respectively, for short and long pasta.

As shown in

Figure 5, the best recipe for short pasta is T32b, whereas for long pasta the best recipe is L33. The first step of this research study was to achieve a structured methodology for determining the optimal combination in terms of quantity of food enriching substances and process parameters. In particular, the application of the ELECTRE III methodology allows the uncertainty associated to be taken into account with the values of the selected criteria. In fact, in order to establish the better recipe, physical and organoleptic aspects have been considered by means of the judgments of a panel of experts. In food related problem, several of these judgements are qualitatively expressed, and for this reason, this methodology also appears to be suitable in other food production systems.

3.2. Sensitivity Analysis

A sensitivity analysis has been carried out to show how different threshold values can influence the ranking of the solutions. For such a purpose, the indifference threshold for each criterion has been varied by ±5% and ±10%. The results of the sensitivity analysis are reported in

Table 7 for short pasta and long pasta. The best solutions obtained by means of the application of the ELECTRE III methodology are shown in bold.

The sensitivity analysis shows that the position of the best solutions remains stable enough. This result means that the best recipes identified by the methodology can also be considered suitable after factoring in uncertainty. The most significant industrial insight that can be obtained from our research is the development of a new functional pasta in which the point of view of different experts has been taken into account in the decisional process. Further investigations should be undertaken to also consider the economic sustainability of the whole process by involving economic criteria and different stakeholders in the selection of the panel of experts. The costs related to energy consumption resulting from the different recipes as well as the different percentage of Opuntia used could be economic indicators to obtain a trade-off assessment.

4. Conclusions

Functional foods are foods that have a potentially positive effect on health beyond basic nutrition. In this research, new dried pasta enriched with

Opuntia fiber was tested in order to optimize the production parameters in each step of the process. Two different type of pasta were produced, and eight recipes were prepared for each type by considering different combinations of

Opuntia quantity and process parameters. In order to valuate the organoleptic and physical properties, a set of criteria was identified and the relative importance of them was evaluated by means of the AHP methodology with multiple decision makers. The ranking of the recipes and the selection of the best one were evaluated by means of a multicriteria decision making methodology. In particular, the ELECTRE III methodology was applied and the results obtained showed that the optimal recipes for short and long pasta are T32b and L33, respectively. Finally, a sensitivity analysis was carried out to show how different threshold values can influence the ranking of the solution. The results show that the solutions found are stable under conditions of uncertainty. At this stage of assessment, the development of innovative functional foods would further challenge the capacity of consumers to make informed choices to protect their health through diet. This assumes that consumers are motivated and capable of accessing reliable information about the choices available to them, with implications for the ways complex science is translated into food labelling, advertising, and other communications [

1]. In this sense, further investigations on the market demand have to be conducted because consumer acceptance has been recognized as a key factor to successfully negotiate market opportunities. Finally, producing functional foods must be cost effective in conventional terms, by comparing the resources consumed relative to the benefits they provide [

41,

42]. Techno-economic analysis for the production of this new functional pasta is in fact necessary both for considering industrial scale dimension and legislative aspects as well as for evaluating the profitability of the investment and to measure the period of time required to recover the funds expended.