A Carbon Emission Evaluation for an Integrated Logistics System—A Case Study of the Port of Shenzhen

Abstract

:1. Introduction

2. Literature Review

3. Methods

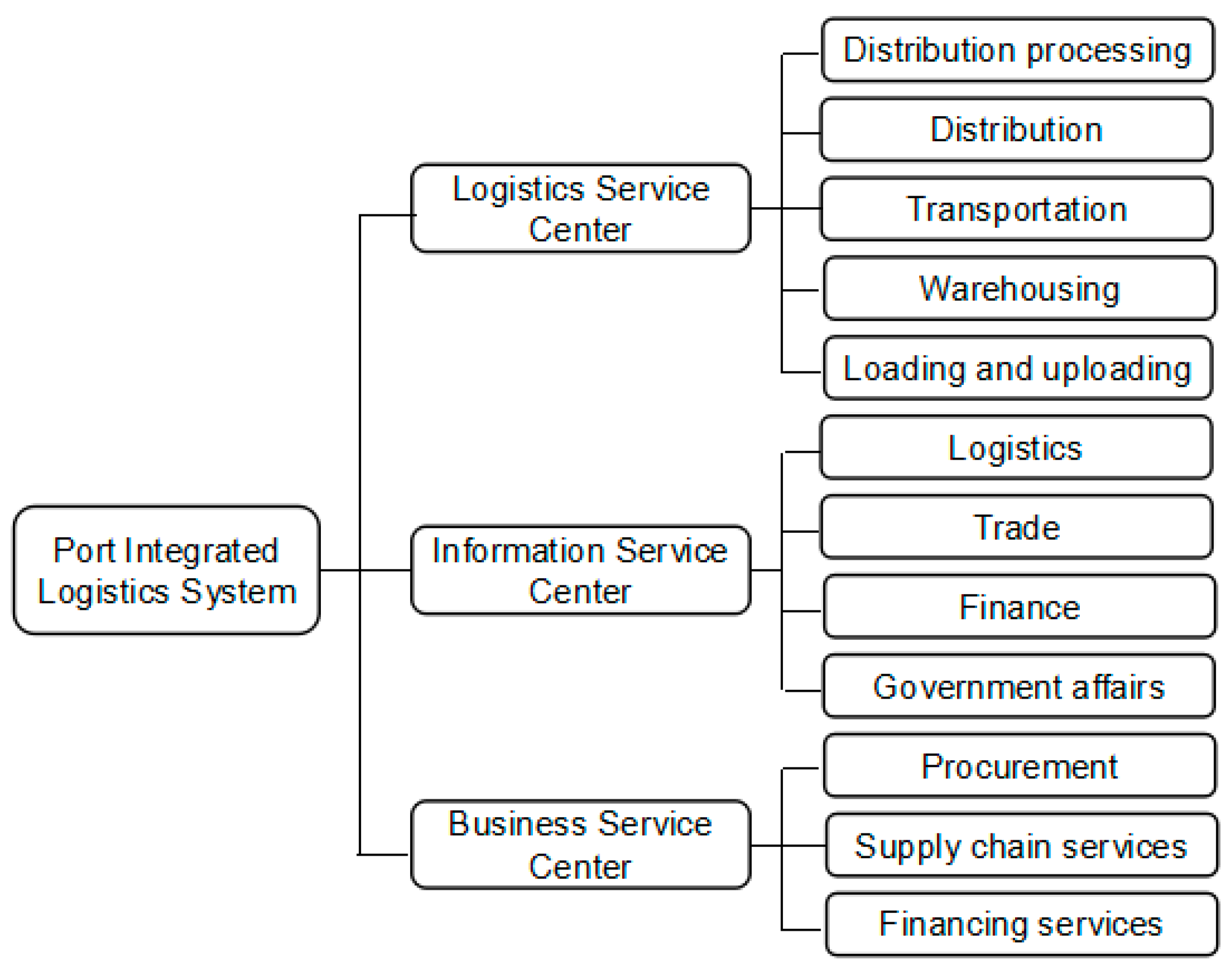

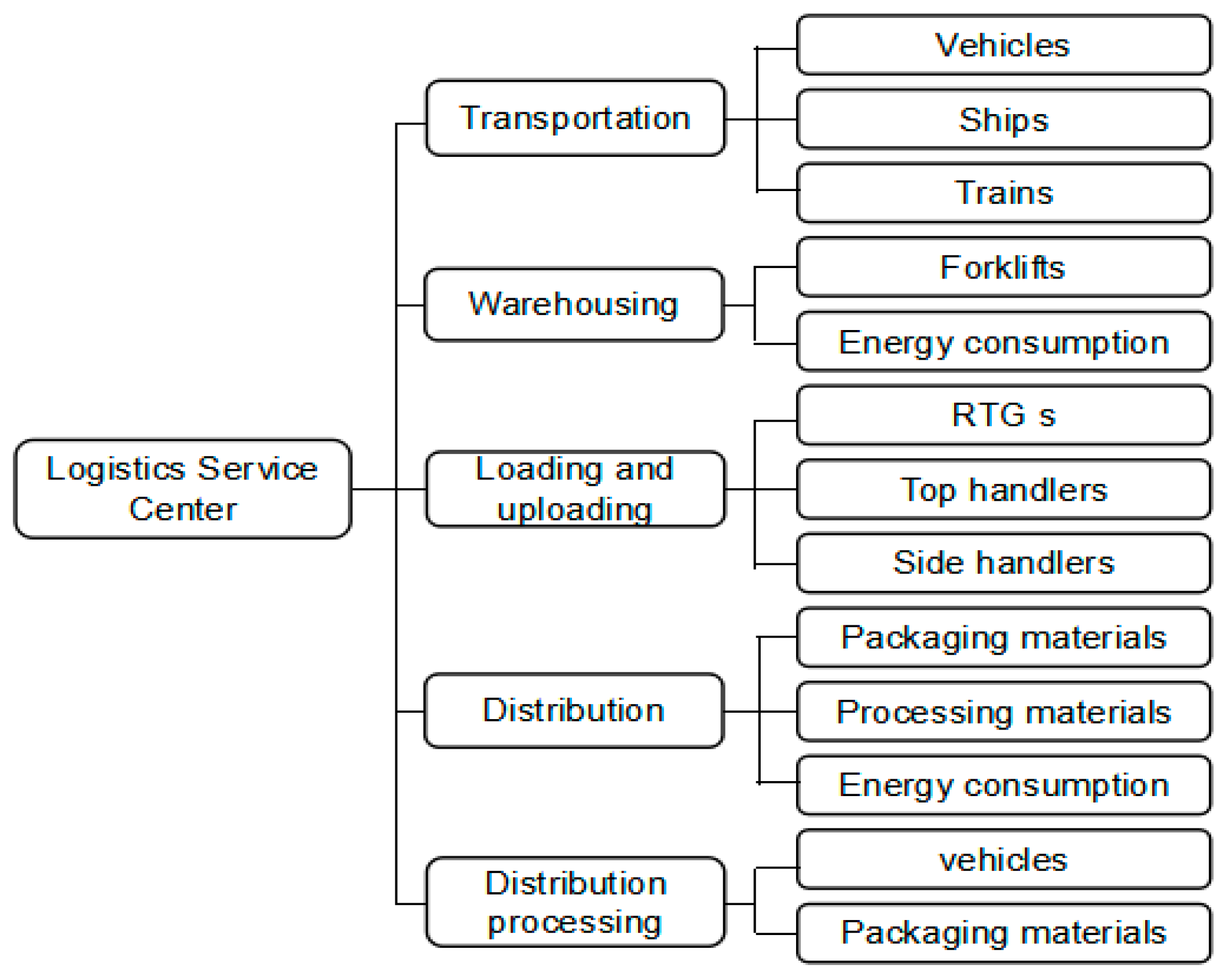

3.1. The Port-Integrated Logistics System

3.2. Carbon Emissions Sources

4. Models

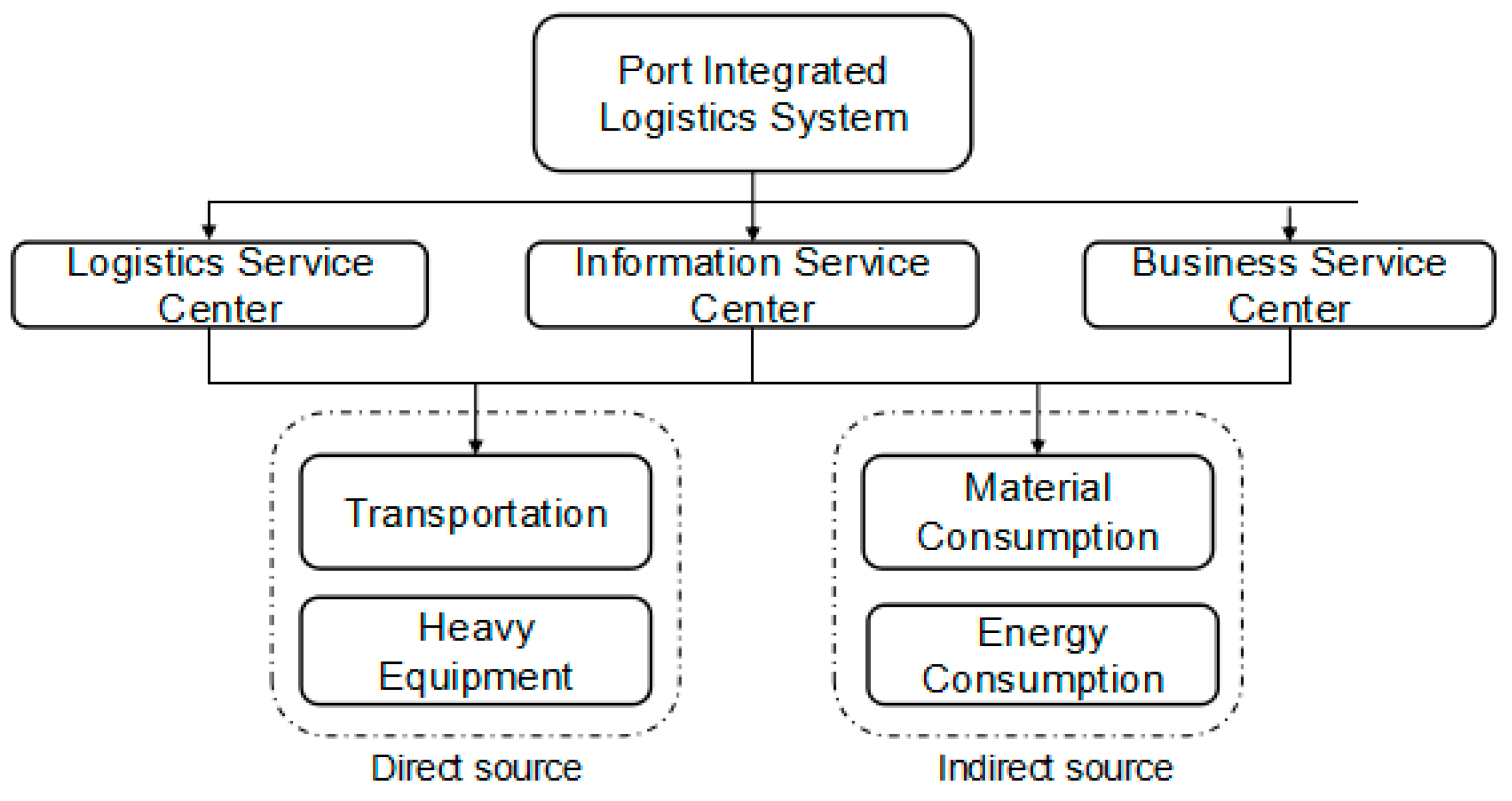

4.1. The Scope of Carbon Emissions in Port-Integrated Logistics

- (1)

- Carbon emissions from transportation: direct carbon emissions from trucks, ships, railway trains, and other vehicles, which consume energy to provide transportation services for customers.

- (2)

- Carbon emissions from heavy equipment: direct carbon emissions from the processes of port storage, loading and unloading, handling, and stacking services. The heavy equipment consumes fuel oils to provide warehousing, loading, and unloading services to customers.

- (3)

- Carbon emissions from material consumption: processing services and distribution, especially rework and packaging services, which produce carbon emissions during the recycling process. In addition, this paper takes documents’ consumption into consideration. Since these generally occur outside the port, they are considered indirect emissions in port-integrated logistics.

- (4)

- Carbon emissions from the consumption of electric power: these carbon emissions are mainly from the operation of information platforms and warehousing services, especially cold storage warehouses, which consume a large amount of electric power. Since these carbon emissions do not occur at the ports, they are also considered indirect.

4.2. The Classification Models of Carbon Emissions in Port-Integrated Logistics

5. Case Study—Port of Shenzhen

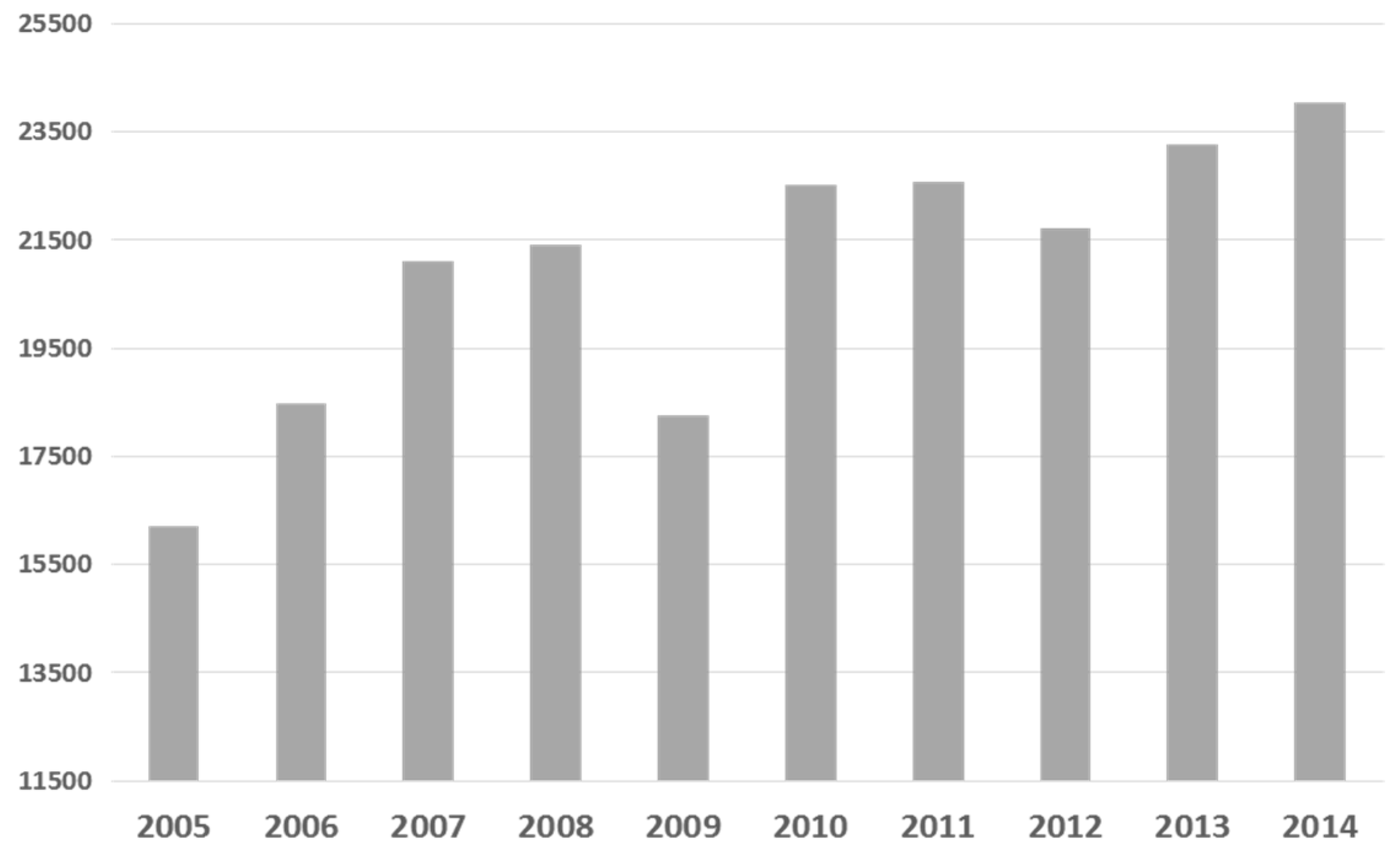

5.1. The Status of the Port-Integrated Logistics

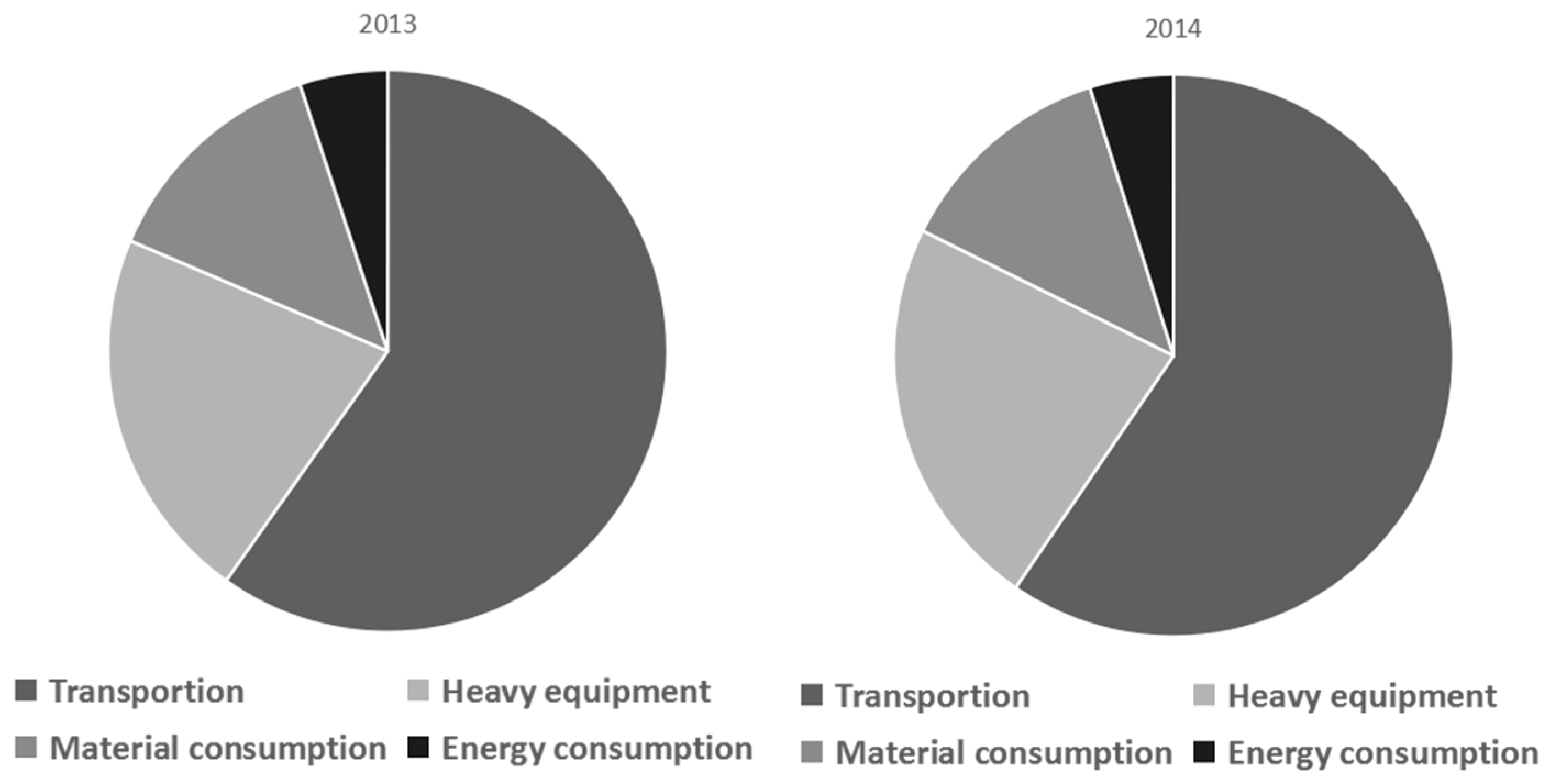

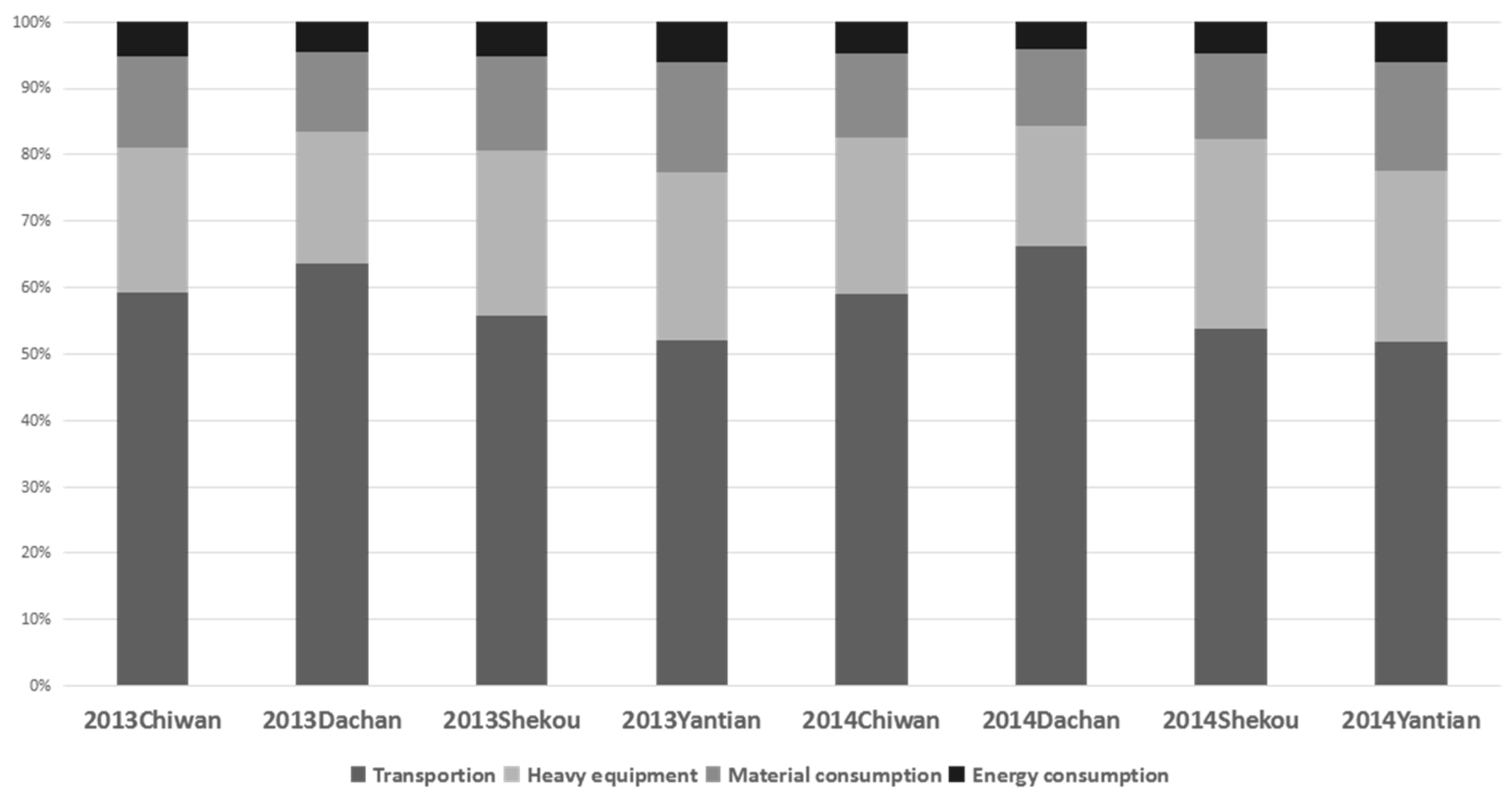

5.2. Characteristics of Carbon Emissions

5.3. Carbon Emissions Sources in the Port of Shenzhen

6. Suggestions

6.1. Improving the Efficiency of Loading and Unloading

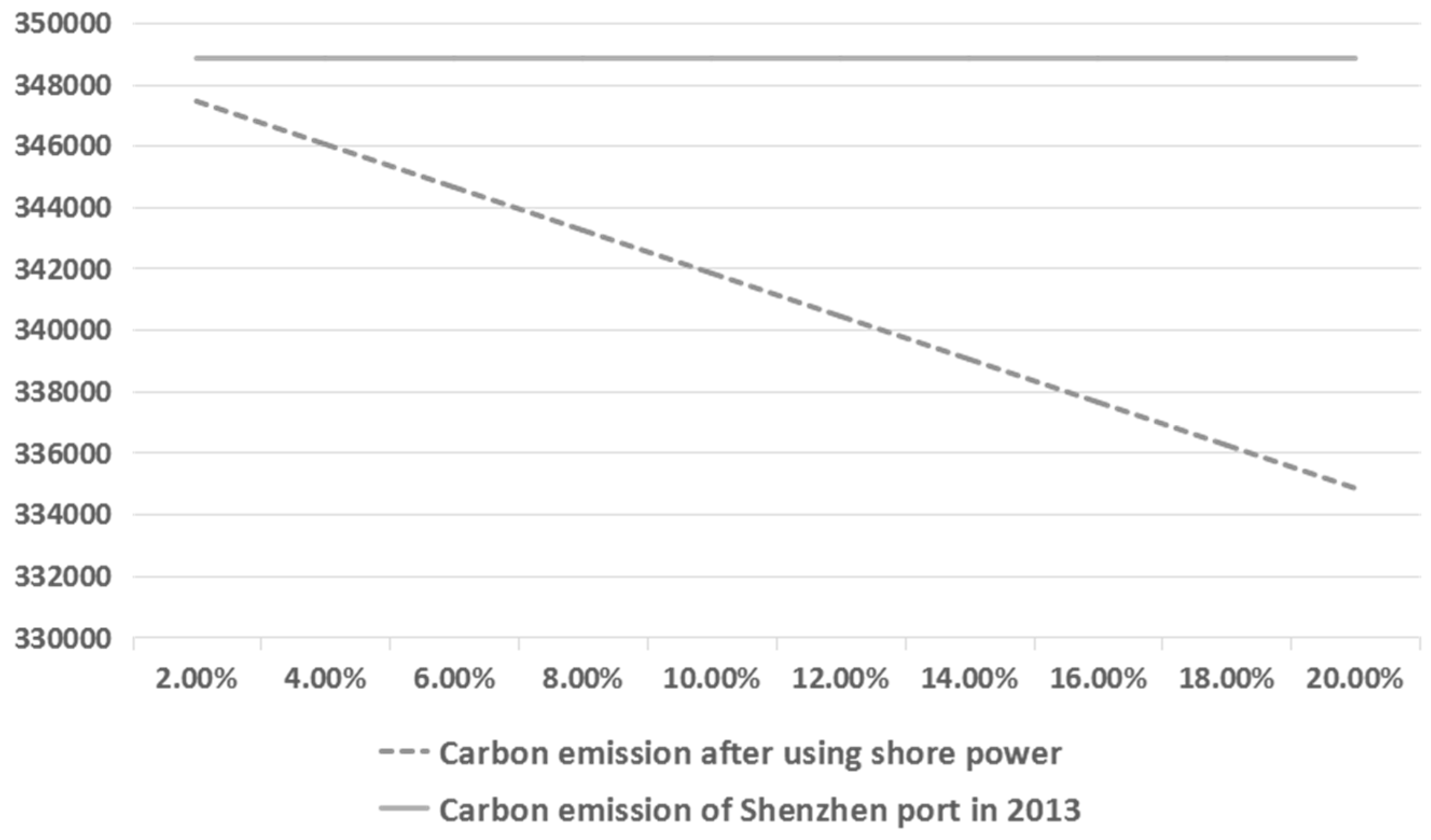

6.2. Using Shore Power

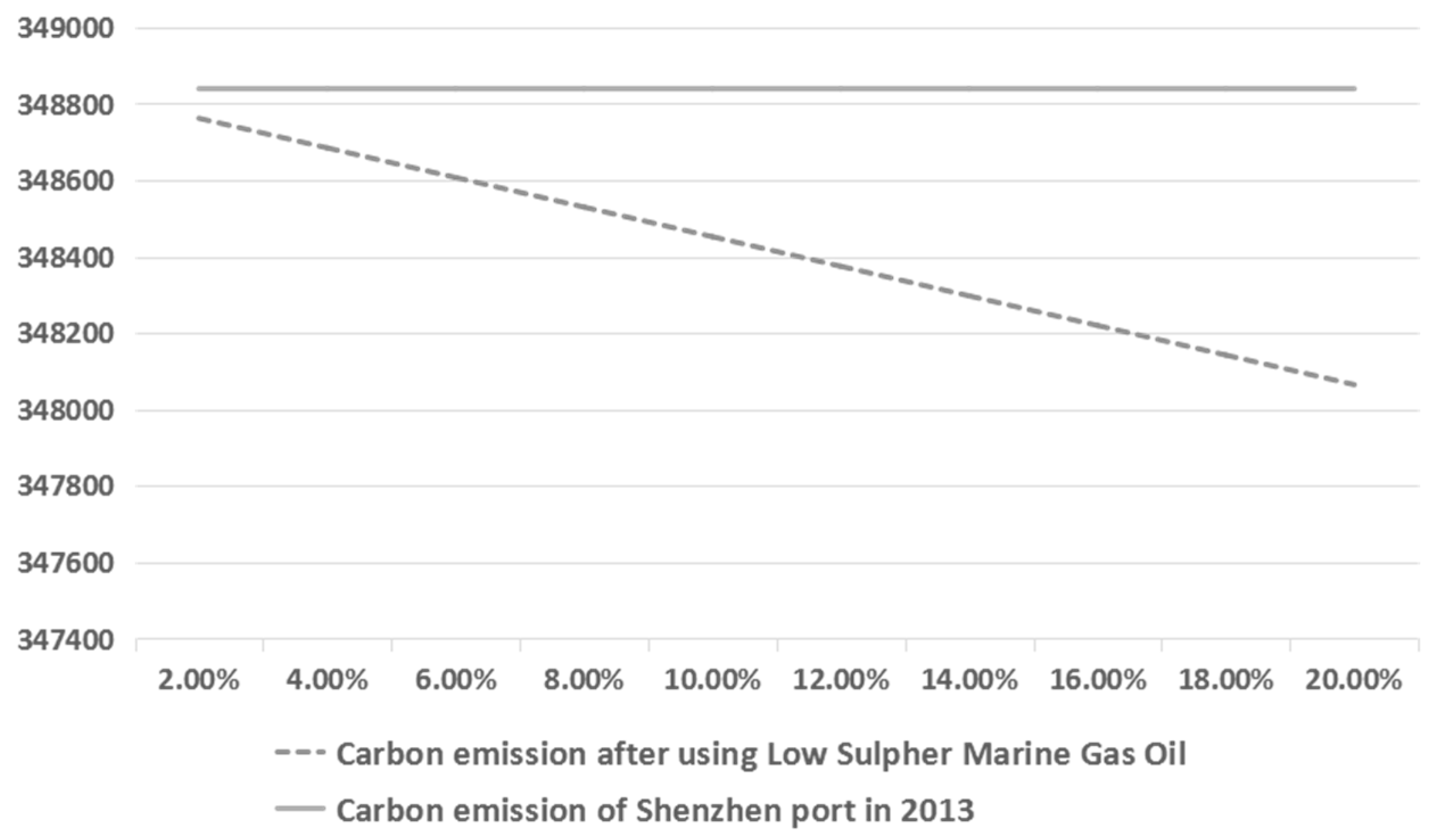

6.3. Using Marine Low Sulfur Fuel Oil

7. Discussion and Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A

| Speed | Emission Rate | Speed | Emission Rate |

|---|---|---|---|

| 0 | 4933 g/h | 26–30 km/h | 1355.248 g/km |

| 1–10 km/h | 2533.400 g/km | 31–40 km/h | 1264.525 g/km |

| 11–15 km/h | 2092.835 g/km | 41–50 km/h | 1187.473 g/km |

| 16–25 km/h | 1718.138 g/km | 51–60 km/h | 1122.848 g/km |

| Terminal | Variable | 2013 | 2014 | ||||

|---|---|---|---|---|---|---|---|

| Max | Min | Avg | Max | Min | Avg | ||

| Chiwan Container Terminal | Speed | 30 km/h | 5 km/h | 11.3 km/h | 30 km/h | 5 km/h | 11.3 km/h |

| Avg Distance * | —— | —— | 1.09 km | —— | —— | 1.09 km | |

| Idling time | 11 min | 0 | 3.8 min | 13 min | 0 | 3.7 min | |

| Total distance * | 577,498.78 km | 622,703.96 km | |||||

| Dachan Bay Terminal | Speed | 30 km/h | 5 km/h | 10 km/h | 30 km/h | 5 km/h | 10 km/h |

| Avg Distance * | —— | —— | 1.37 km | —— | —— | 1.37 km | |

| Idling time | 21 min | 0 | 5.2 min | 17 min | 0 | 4.6 min | |

| Total distance * | 184,333.32 km | 160,779.86 km | |||||

| Shekou Container Terminal | Speed | 30 km/h | 5 km/h | 11.5 km/h | 30 km/h | 5 km/h | 11.5 km/h |

| Avg Distance * | —— | —— | 1.12 km | —— | —— | 1.12 km | |

| Idling time | 14 min | 0 | 3.7 min | 14 min | 0 | 3.8 min | |

| Total distance * | 624,585.99 km | 722,486.71 km | |||||

| Yantian Port | Speed | 60 km/h | 5 km/h | 15.2 km/h | 60 km/h | 5 km/h | 15.2 km/h |

| Avg Distance * | —— | —— | 2.42 km | —— | —— | 2.42 km | |

| Idling time | 38 min | 0 | 4.4 min | 30 min | 0 | 4.2 min | |

| Total distance * | 3,026,111.76 km | 2,798,831.91 km | |||||

| Type | 2013 at Berth | 2013 at Anchorage | 2014 at Berth | 2014 at Anchorage |

|---|---|---|---|---|

| Container (0 TEU–1000 TEU) | 137.93 | 7.80 | 124.14 | 76.09 |

| Container (1000 TEU–2000 TEU) | 205.89 | 0.00 | 178.21 | 11.95 |

| Container (2000 TEU–3000 TEU) | 240.08 | 0.00 | 110.56 | 28.89 |

| Container (3000 TEU–4000 TEU) | 1113.46 | 0.00 | 560.62 | 22.63 |

| Container (4000 TEU–5000 TEU) | 855.42 | 0.29 | 360.30 | 31.51 |

| Container (5000 TEU–6000 TEU) | 4.70 | 0.00 | 26.78 | 0.00 |

| Container (6001 TEU–7000 TEU) | 39.96 | 0.38 | 32.39 | 0.43 |

| Container (7000 TEU–8000 TEU) | 290.52 | 0.00 | 894.42 | 72.44 |

| Container (8000 TEU–9000 TEU) | 176.93 | 1.35 | 362.54 | 24.87 |

| Container (9000 TEU–10000 TEU) | 36.91 | 1.86 | 290.40 | 29.04 |

| Container (10,000 TEU–11,000 TEU) | 130.77 | 0.17 | 301.59 | 26.55 |

| Container (11,000 TEU–12,000 TEU) | 22.44 | 0.00 | 11.18 | 0.00 |

| Container (12,000 TEU–13,000 TEU) | 48.51 | 0.11 | 161.34 | 13.20 |

| Container (>13,000 TEU) | 11.25 | 0.00 | 0.00 | 0.00 |

| Bulk carrier | 560.14 | 573.45 | 613.50 | 659.29 |

| Cruise | 73.95 | 0.00 | 141.57 | 0.00 |

| Others | 839.41 | 0.00 | 661.32 | 0.69 |

| Type | 2013 at Berth | 2013 at Anchorage | 2014 at Berth | 2014 at Anchorage |

|---|---|---|---|---|

| Container (0 TEU–1000 TEU) | 32.68 | 1.85 | 35.88 | 21.99 |

| Container (1000 TEU–2000 TEU) | 48.78 | 0.00 | 51.50 | 3.45 |

| Container (2000 TEU–3000 TEU) | 56.88 | 0.00 | 31.95 | 8.35 |

| Container (3000 TEU–4000 TEU) | 263.79 | 0.00 | 162.02 | 6.54 |

| Container (4000 TEU–5000 TEU) | 202.66 | 0.07 | 104.13 | 9.11 |

| Container (5000 TEU–6000 TEU) | 1.11 | 0.00 | 7.74 | 0.00 |

| Container (6001 TEU–7000 TEU) | 9.47 | 0.09 | 9.36 | 0.12 |

| Container (7000 TEU–8000 TEU) | 68.83 | 0.00 | 258.48 | 20.93 |

| Container (8000 TEU–9000 TEU) | 41.92 | 0.32 | 104.77 | 7.19 |

| Container (9000 TEU–10000 TEU) | 8.75 | 0.44 | 83.92 | 8.39 |

| Container (10,000 TEU–11,000 TEU) | 30.98 | 0.04 | 87.16 | 7.67 |

| Container (11,000 TEU–12,000 TEU) | 5.32 | 0.00 | 3.23 | 0.00 |

| Container (12,000 TEU–13,000 TEU) | 11.49 | 0.03 | 46.63 | 3.82 |

| Container (>13,000 TEU) | 2.67 | 0.00 | 0.00 | 0.00 |

| Bulk carrier | 132.70 | 135.86 | 177.30 | 190.53 |

| Cruise | 17.52 | 0.00 | 40.91 | 0.00 |

| Others | 198.87 | 0.00 | 191.12 | 0.20 |

| Type | 2013 at Berth | 2013 at Anchorage | 2014 at Berth | 2014 at Anchorage |

|---|---|---|---|---|

| Container (0 TEU–1000 TEU) | 166.30 | 9.40 | 135.48 | 83.04 |

| Container (1000 TEU–2000 TEU) | 248.23 | 0.00 | 194.49 | 13.04 |

| Container (2000 TEU–3000 TEU) | 289.46 | 0.00 | 120.66 | 31.53 |

| Container (3000 TEU–4000 TEU) | 1342.44 | 0.00 | 611.85 | 24.70 |

| Container (4000 TEU–5000 TEU) | 1031.33 | 0.34 | 393.22 | 34.39 |

| Container (5000 TEU–6000 TEU) | 5.67 | 0.00 | 29.23 | 0.00 |

| Container (6001 TEU–7000 TEU) | 48.18 | 0.46 | 35.35 | 0.47 |

| Container (7000 TEU–8000 TEU) | 350.26 | 0.00 | 976.14 | 79.06 |

| Container (8000 TEU–9000 TEU) | 213.31 | 1.62 | 395.67 | 27.14 |

| Container (9000 TEU–10000 TEU) | 44.51 | 2.24 | 316.93 | 31.69 |

| Container (10,000 TEU–11,000 TEU) | 157.66 | 0.20 | 329.14 | 28.98 |

| Container (11,000 TEU–12,000 TEU) | 27.06 | 0.00 | 12.21 | 0.00 |

| Container (12,000 TEU–13,000 TEU) | 58.48 | 0.13 | 176.08 | 14.41 |

| Container (>13,000 TEU) | 13.57 | 0.00 | 0.00 | 0.00 |

| Bulk carrier | 675.32 | 691.38 | 669.56 | 719.53 |

| Cruise | 89.16 | 0.00 | 154.51 | 0.00 |

| Others | 1012.03 | 0.00 | 721.74 | 0.75 |

| Type | 2013 at Berth | 2013 at Anchorage | 2014 at Berth | 2014 at Anchorage |

|---|---|---|---|---|

| Container (0 TEU–1000 TEU) | 303.34 | 17.15 | 320.07 | 83.04 |

| Container (1000 TEU–2000 TEU) | 452.79 | 0.00 | 459.47 | 13.04 |

| Container (2000 TEU–3000 TEU) | 527.99 | 0.00 | 285.05 | 31.53 |

| Container (3000 TEU–4000 TEU) | 2448.71 | 0.00 | 1445.44 | 24.70 |

| Container (4000 TEU–5000 TEU) | 1881.22 | 0.63 | 928.96 | 34.39 |

| Container (5000 TEU–6000 TEU) | 10.35 | 0.00 | 69.06 | 0.00 |

| Container (6001 TEU–7000 TEU) | 87.89 | 0.84 | 83.52 | 0.47 |

| Container (7000 TEU–8000 TEU) | 638.90 | 0.00 | 2306.05 | 79.06 |

| Container (8000 TEU–9000 TEU) | 389.10 | 2.96 | 934.73 | 27.14 |

| Container (9000 TEU–10000 TEU) | 81.18 | 4.09 | 748.73 | 31.69 |

| Container (10,000 TEU–11,000 TEU) | 287.59 | 0.37 | 777.57 | 28.98 |

| Container (11,000 TEU–12,000 TEU) | 49.36 | 0.00 | 28.84 | 0.00 |

| Container (12,000 TEU–13,000 TEU) | 106.67 | 0.24 | 415.98 | 14.41 |

| Container (>13,000 TEU) | 24.75 | 0.00 | 0.00 | 0.00 |

| Bulk carrier | 1231.84 | 1261.12 | 1581.78 | 719.53 |

| Cruise | 162.63 | 0.00 | 365.01 | 0.00 |

| Others | 1846.01 | 0.00 | 1705.05 | 0.75 |

| Fuel | Auxiliary Engine | Boiler |

|---|---|---|

| HFO | 683 g/kw-h | 970 g/kw-h |

| MLSFO | 649 g/kw-h | 922 g/kw-h |

| Type | Auxiliary Engine at Berth | Auxiliary Engine at Anchorage | Boiler |

|---|---|---|---|

| Container (0 TEU–1000 TEU) | 720 | 957 | 241 |

| Container (1000 TEU–2000 TEU) | 1039 | 985 | 325 |

| Container (2000 TEU–3000 TEU) | 641 | 747 | 474 |

| Container (3000 TEU–4000 TEU) | 1136 | 1403 | 492 |

| Container (4000 TEU–5000 TEU) | 1128 | 1316 | 630 |

| Container (5000 TEU–6000 TEU) | 804 | 1162 | 565 |

| Container (6001 TEU–7000 TEU) | 845 | 1220 | 551 |

| Container (7000 TEU–8000 TEU) | 1008 | 1457 | 525 |

| Container (8000 TEU–9000 TEU) | 1030 | 1488 | 547 |

| Container (9000 TEU–10000 TEU) | 1075 | 1375 | 749 |

| Container (10,000 TEU–11,000 TEU) | 1500 | 2000 | 600 |

| Container (11,000 TEU–12,000 TEU) | 2000 | 2500 | 600 |

| Container (12,000 TEU–13,000 TEU) | 1700 | 2600 | 600 |

| Container (>13,000 TEU) | 3000 | 3000 | 700 |

| Bulk carrier | 221 | 318 | 132 |

| Cruise | 5445 | 5445 | 1393 |

| Others | 718 | 661 | 254 |

| Terminal | Equipment | Fuel | Avg Power | Avg Load | 2013 Operation Time | 2014 Operation Time |

|---|---|---|---|---|---|---|

| Chiwan Container Terminal | RTG | Diesel/electric | 617.4 kw | 22% | 48,557.48 h | 52,198.50 h |

| Top handlers and side handlers | Diesel | 148.9 kw | 58% | 120,102.02 h | 139,388.32 h | |

| forklifts | Diesel/LPG | 73.9 kw | 31% | 31,542.51 h | 32,225.95 h | |

| other equipment | Diesel/LPG/electric | 115.2 kw | 57% | 6676.26 h | 7027.64 h | |

| Dachan Bay Terminal | RTG | Electric | 617.4 kw | 22% | 12,293.23 h | 13,215.03 h |

| Top handlers and side handlers | Diesel | 148.9 kw | 58% | 30,406.07 h | 35,288.76 h | |

| forklifts | Diesel/LPG | 73.9 kw | 31% | 7985.58 h | 8158.60 h | |

| other equipment | Diesel/LPG/electric | 115.2 kw | 57% | 1690.22 h | 1779.18 h | |

| Shekou Container Terminal | RTG | Diesel/electric | 617.4 kw | 22% | 51,067.07 h | 54,896.27 h |

| Top handlers and side handlers | Diesel | 148.9 kw | 58% | 126,309.24 h | 146,592.32 h | |

| forklifts | Diesel/LPG | 73.9 kw | 31% | 33,172.72 h | 33,891.48 h | |

| other equipment | Diesel/LPG/electric | 115.2 kw | 57% | 7021.31 h | 7390.85 h | |

| Yantian Port | RTG | Diesel/electric | 617.4 kw | 22% | 114,401.72 h | 122,979.98 h |

| Top handlers and side handlers | Diesel | 148.9 kw | 58% | 282,961.09 h | 328,399.74 h | |

| forklifts | Diesel/LPG | 73.9 kw | 31% | 74,314.34 h | 75,924.53 h | |

| other equipment | Diesel/LPG/electric | 115.2 kw | 57% | 15,729.30 h | 16,557.16 h |

| Fuel | Power | Emission Rate |

|---|---|---|

| Diesel | 762 g/kw-h | |

| LPG | 0–38 kw | 1050 g/kw-h |

| LPG | 39–90 kw | 1038 g/kw-h |

| LPG | 91–999 kw | 981 g/kw-h |

| Material | Emission Rate |

|---|---|

| Paper material | 0.25 |

| Plastic material | 0.37 |

| Wood and other materials | 0.19 |

| Terminal | Material | 2013 | 2014 |

|---|---|---|---|

| Chiwan Container Terminal | Paper material | 30,005 | 27,827 |

| Plastic material | 26,761 | 24,819 | |

| Wood and other materials | 2432 | 2256 | |

| Dachan Bay Terminal | Paper material | 6149 | 7047 |

| Plastic material | 5484 | 6285 | |

| Wood and other materials | 498 | 571 | |

| Shekou Container Terminal | Paper material | 33,900 | 29,282 |

| Plastic material | 30,235 | 26,116 | |

| Wood and other materials | 2748 | 2374 | |

| Yantian Port | Paper material | 60,593 | 65,431 |

| Plastic material | 54,042 | 58,358 | |

| Wood and other materials | 4912 | 5305 |

| Terminal | 2013 | 2014 |

|---|---|---|

| Chiwan Container Terminal | 10,608 | 9838 |

| Dachan Bay Terminal | 2174 | 2491 |

| Shekou Container Terminal | 11,985 | 10,352 |

| Yantian Port | 21,422 | 23,132 |

References

- Amit, G.; Manmohan, K. The sectoral trends of multi-gas emissions inventory of India. Atmos. Environ. 2006, 40, 4608–4620. [Google Scholar]

- Port Economy Becomes the Engine of Shenzhen Economy. Shenzhen Business Newspaper. 2003. Available online: http://www.docin.com/p-1087726194.html (accessed on 10 March 2015).

- Guangdong Province the 13th “Five-Year” Planning about Energy and Emissions Reduction in Transportation. 2016. Available online: http://max.book118.com/html/2016/1208/69952439.shtm (accessed on 8 December 2016).

- An, X.; Huang, Z. The advent of the era of integrated logistics and the evolution of the port function. Trop. Geogr. 2001, 21, 276–281. [Google Scholar]

- Khalid, B.; Richard, G. A logistics and supply chain management approach to port performance measurement. Marit. Policy Manag. 2007, 31, 47–67. [Google Scholar]

- Lu, Y.; Hu, W. Sydney harbour green port practice and its enlightenment to our country. Chin. Navig. 2009, 32, 72–76. [Google Scholar]

- Winebrake, J.J.; Corbett, J.J. Mitigating the health impacts of pollution from oceangoing shipping: An assessment of low-sulfur fuel mandates. Environ. Sci. Technol. 2009, 43, 4776–4782. [Google Scholar] [CrossRef] [PubMed]

- Karim, A. Sustainable and green ports: Application of sustainability principles to port development and operation. In Proceedings of the 11th Triennial International Conference on Ports, San Diego, CA, USA, 25–28 March 2007; pp. 25–28.

- Liu, C.; Gao, B. Analysis of energy-saving measures in ports. In Proceedings of the 2010 Asia-Pacific Power and Energy Engineering Conference (APPEEC), Chengdu, China, 28–31 March 2010; pp. 28–31.

- Berechman, J.; Tseng, P. Estimate the environmental costs of port related emissions: The case of Kaohsiung. Transp. Res. Part D Transp. Environ. 2012, 1, 35–38. [Google Scholar] [CrossRef]

- Goulielmos, M. European Policy on Port Environmental Protection. Glob. NEST 2000, 2, 189–197. [Google Scholar]

- Shang, R. Port environmental protection counter-measure research based on the sustainable development. Adv. Mater. Res. 2013, 8, 726–731. [Google Scholar]

- Xu, B. The planning and layout of green port. China’s Water Transp. 2015, 4, 12–21. [Google Scholar]

- Acciaro, M.; Lee, K. Environmental sustainability in seaports: A framework for successful innovation. Marit. Policy Manag. 2014, 8, 480–500. [Google Scholar] [CrossRef]

- Palantzas, G. Management of environmental issues in port activities: The Hellenic caste study. Int. J. Inf. Syst. Supply Chain Manag. 2014, 7, 40–55. [Google Scholar] [CrossRef]

- Gou, M. The 2nd international conference on computer and automation engineering. IEEE Comput. Soc. 2010, 4, 26–28. [Google Scholar]

- Ling, Q. Study on the evaluation index system of green port. Shanghai Port Technol. 2010, 1, 4–7. [Google Scholar]

- Yang, B.; Gao, Y. Research on the energy consumption evaluation model of container terminal logistics system. J. Appl. Mech. Mater. 2012, 157, 1224–1229. [Google Scholar] [CrossRef]

- Liu, J.; Bian, Z. Evaluation of energy-efficient production for container terminal. J. Appl. Mech. Mater. 2012, 524, 2557–2561. [Google Scholar]

- Liu, Q. Based on principal component analysis of Tianjin port logistics development trend research. Manag. Sci. 2010, 10, 39. [Google Scholar]

- Yu, H. The Coal Supply Chain Carbon Emissions Measurement and Control Research. Master’s Thesis, Beijing Jiaotong University, Beijing, China, 2011. [Google Scholar]

- Song, Y. Low Carbon Construction Cycle Logistics System Effect Research. Master’s Thesis, Beijing Jiaotong University, Beijing, China, 2011. [Google Scholar]

- Benjaafar, S.; Li, Y. Carbon Footprint and the Management of Supply Chains: Insights from Simple Models. IEEE Trans. Autom. Sci. Eng. 2013, 10, 99–116. [Google Scholar] [CrossRef]

- Kim, N.S.; Janic, M. Trade-off between Carbon Dioxide Emissions and Logistics Costs Based on Multi-objective Optimization. Transp. Res. 2009, 2139, 107–116. [Google Scholar]

- Balan, S.; Robertde, S. Modeling Carbon Footprints across the Supply Chain. Int. J. Prod. Econ. 2010, 128, 43–50. [Google Scholar]

- Peng, C. Port carbon accounting methods—Case study of Jurong Port carbon footprint report 2010 in Singapore. Navig. Res. 2012, 7, 5–9. [Google Scholar]

- Wang, W.; Zhang, Y. Carbon emissions calculation methods of port container handling operation. Port Tech. 2013, 50, 6–7. [Google Scholar]

- Chim, H.; Po-Hsing, T. The impact of an emerging port on the carbon dioxide emissions of inland Container transport: An empirical study of Taipei port. Energy Policy 2010, 38, 5251–5257. [Google Scholar]

- Warren, B.F.; Howitt, A. Green-house gas emissions from the international maritime transport of New Zealand’s imports and exports. Energy Policy 2011, 39, 1521–1531. [Google Scholar]

- Xiao, Y.; Liu, S. Study on measurement of energy consumption for cranes and designing of energy saving device. Appl. Mech. Mater. 2012, 159, 326–330. [Google Scholar] [CrossRef]

- The Intergovernmental Panel on Climate Change (IPCC). The 2006 IPCC National Greenhouse Gas Emissions Listing Guide; Japan Hayama Global Environmental Institute for Strategic Studies (IGES): Miura District, Japan, 2006. [Google Scholar]

- The Air China Trade. Available online: http://www.snet.com.cn/106/2016_3_3/3_106_323392_373_1_1456979400406.html (accessed on 3 March 2016).

- Whall, C.; Cooper, D.; Archer, K. Quantification of Emissions from Ships Associated with Ship Movements between Ports in the European Community; Entec UK Ltd.: Halesowen, UK, 2002. [Google Scholar]

- Port of Long Beach 2012–2014 Air Emissions Inventory; Port of Long Beach The Green Port. Available online: http://www.polb.com/environment/air/emissions.asp (accessed on 10 February 2015).

- Diane, B.; Gina, S. Pollution prevention at ports: Clearing the air. Environ. Impact Assess. Rev. 2004, 24, 749–774. [Google Scholar]

- Top 10 Events in Shenzhen Port and Waterway. Jinyang Network News. Available online: http://news.163.com/17/0110/18/CAEKTERU00014AEE.html (accessed on 10 January 2017).

- Shenzhen Special Zone Newspaper. Available online: http://sz.people.com.cn/n2/2017/0213/c202846-29704755.html (accessed on 13 February 2017).

| Source | Characteristics | Factors |

|---|---|---|

| Transportation | Few railways in terminals | Road is more convenient for container transport |

| Less carbon emissions from ships at berth | High loading and unloading efficiency, short berthed time | |

| Heavy Equipment | Heavy equipment is mainly for container operations | Mainly engaged in container cargo |

| Little carbon emissions from rubber-tired gantry (RTG) crane | Use electric RTG crane only | |

| Material Consumption | Large material consumption, especially packaging materials | Many kinds of distribution processing and rework services, especially in bonded zone |

| Energy Consumption | Energy consumption, especially on the cold chain storage | Cold chain logistics develops quickly in the western port area |

| Consumption on information system operation | Information communication obstacles bring the extra work |

| Terminals | Emissions Sources | Details | 2013 | 2014 |

|---|---|---|---|---|

| Chiwan Container Terminal | Transportation | Vehicles on road | 9982.86 | 9258.15 |

| Vehicles idling | 4000.89 | 3810.72 | ||

| Ships at berth | 55,161.72 | 53,163.42 | ||

| Ships at anchorage | 7418.43 | 10,978.32 | ||

| Heavy equipment | RTG | 360.00 | 386.99 | |

| Top handlers and side handlers | 12,048.85 | 13,983.69 | ||

| Forklifts | 768.43 | 785.08 | ||

| Other equipment | 14,776.99 | 15,554.72 | ||

| Material consumption | Paper material | 7531.25 | 6984.53 | |

| Plastic material | 9981.93 | 9257.30 | ||

| Wood and other materials | 479.27 | 444.47 | ||

| Energy consumption | 6766.65 | 6275.47 | ||

| Dachan Bay Terminal | Transportation | Vehicles on road | 2730.24 | 3130.20 |

| Vehicles idling | 868.41 | 1125.51 | ||

| Ships at berth | 14,149.68 | 16,634.97 | ||

| Ships at anchorage | 1522.35 | 3435.06 | ||

| Heavy equipment | RTG | 0 | 0 | |

| Top handlers and side handlers | 2632.67 | 3055.43 | ||

| Forklifts | 167.90 | 171.54 | ||

| Other equipment | 3228.76 | 3398.70 | ||

| Material consumption | Paper material | 1543.41 | 1768.77 | |

| Plastic material | 2045.64 | 2344.34 | ||

| Wood and other materials | 98.22 | 112.57 | ||

| Energy consumption | 1386.73 | 1589.20 | ||

| Shekou Container Terminal | Transportation | Vehicles on road | 10,996.98 | 9506.85 |

| Vehicles idling | 4513.53 | 3799.23 | ||

| Ships at berth | 56,572.68 | 49,355.46 | ||

| Ships at anchorage | 7608.18 | 10,191.99 | ||

| Heavy equipment | RTG | 427.86 | 459.94 | |

| Top handlers and side handlers | 15,255.86 | 17,705.69 | ||

| Forklifts | 972.96 | 994.04 | ||

| Other equipment | 18,710.14 | 19,694.88 | ||

| Material consumption | Paper material | 8508.92 | 7349.81 | |

| Plastic material | 11,277.73 | 9741.42 | ||

| Wood and other materials | 541.48 | 467.72 | ||

| Energy consumption | 7645.10 | 6603.67 | ||

| Yantian Port | Transportation | Vehicles on road | 40,461.87 | 43,747.59 |

| Vehicles idling | 8026.80 | 8890.29 | ||

| Ships at berth | 108,346.98 | 122,422.14 | ||

| Ships at anchorage | 14,571.06 | 10,701.03 | ||

| Heavy equipment | RTG | 677.95 | 728.79 | |

| Top handlers and side handlers | 24,173.12 | 28,054.9 | ||

| Forklifts | 1541.66 | 1575.06 | ||

| Other equipment | 29,646.47 | 31,206.81 | ||

| Material consumption | Paper material | 15,208.87 | 16,423.41 | |

| Plastic material | 20,157.85 | 21,767.61 | ||

| Wood and other materials | 967.85 | 1045.14 | ||

| Energy consumption | 13,664.84 | 14,756.09 |

| Comparison between Marine Diesel and Shore Power | Marine Diesel Generating Electricity | Shore Power | |||

|---|---|---|---|---|---|

| IFO Consumption | Unit Price | MGO Consumption | Unit Price | Unit Price | |

| 0.216 kg/kWh | 3.85 yuan/kg | 0.216 kg/kWh | 6.59 yuan/kg | 1.10 yuan/kWh | |

| Fee | 0.83 yuan/kWh | 1.41 yuan/kWh | 1.10 yuan/kWh | ||

| Compare with shore power | Lower 0.27 yuan | Higher 0.31yuan | / | ||

| The Scenario in Which a Company Uses Shore Power | |

|---|---|

| 1 | Country has stricter air pollution control regulations, mandatory banning the use of heavy oil power generation |

| 2 | International oil prices rise, with heavy oil power generation cost is greater than the cost of the shore power |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, L.; Cai, Y.; Zhong, X.; Shi, Y.; Zhang, Z. A Carbon Emission Evaluation for an Integrated Logistics System—A Case Study of the Port of Shenzhen. Sustainability 2017, 9, 462. https://doi.org/10.3390/su9030462

Yang L, Cai Y, Zhong X, Shi Y, Zhang Z. A Carbon Emission Evaluation for an Integrated Logistics System—A Case Study of the Port of Shenzhen. Sustainability. 2017; 9(3):462. https://doi.org/10.3390/su9030462

Chicago/Turabian StyleYang, Lei, Yiji Cai, Xiaozhe Zhong, Yongqiang Shi, and Zhiyong Zhang. 2017. "A Carbon Emission Evaluation for an Integrated Logistics System—A Case Study of the Port of Shenzhen" Sustainability 9, no. 3: 462. https://doi.org/10.3390/su9030462

APA StyleYang, L., Cai, Y., Zhong, X., Shi, Y., & Zhang, Z. (2017). A Carbon Emission Evaluation for an Integrated Logistics System—A Case Study of the Port of Shenzhen. Sustainability, 9(3), 462. https://doi.org/10.3390/su9030462