Centrifugation of Digestate: The Effect of Chitosan on Separation Efficiency

Abstract

1. Introduction

2. Materials and Methods

2.1. Anaerobic Co-Digestion and Sample Collection

2.2. Experimental Set-Up

- (i)

- dose optimization tests, in which the proper dose of chitosan was determined for the co-digestate, and

- (ii)

- centrifugation tests, in which centrifugation was performed on co-digestate alone (CENT) and after chitosan addition (C+CENT).

2.2.1. Dose Optimization Tests

2.2.2. Centrifugation Tests

2.3. Chemical Analyses and Calculations

2.4. Statistical Analysis

3. Results and Discussion

3.1. Chemical Characteristics of Co-Digestate (Input Material)

3.2. Floculation Tests

3.2.1. Dry Matter and Mass Balance of Separated Fractions

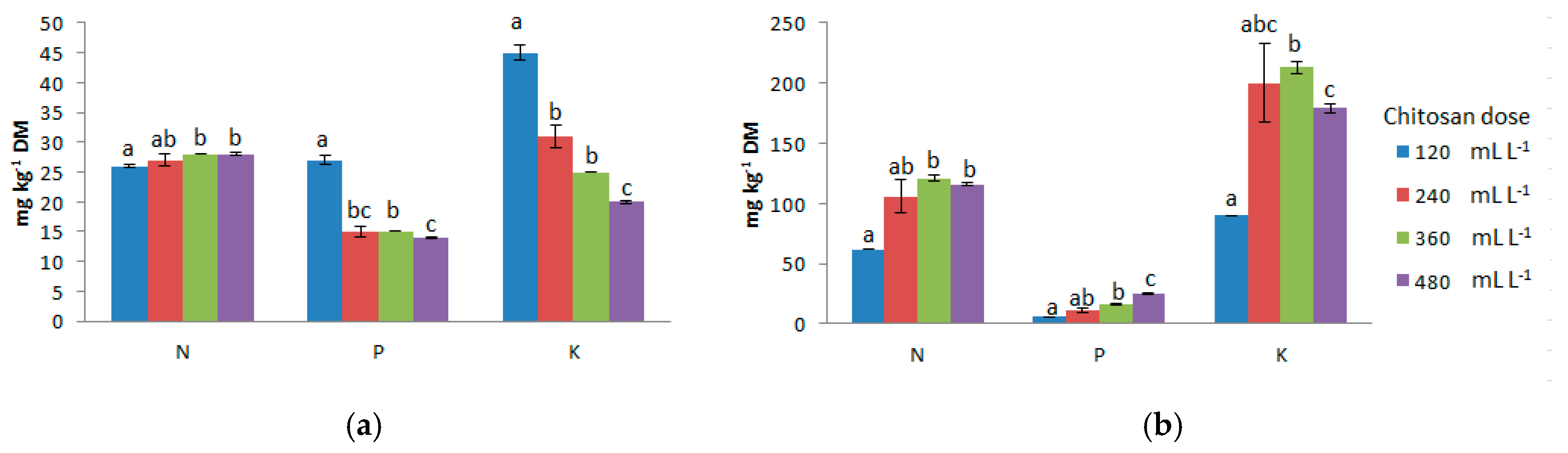

3.2.2. Nutrient (N, P, K) and Metal (Cu and Zn) Content of Produced Fractions

3.2.3. Choosing an Optimal Dose

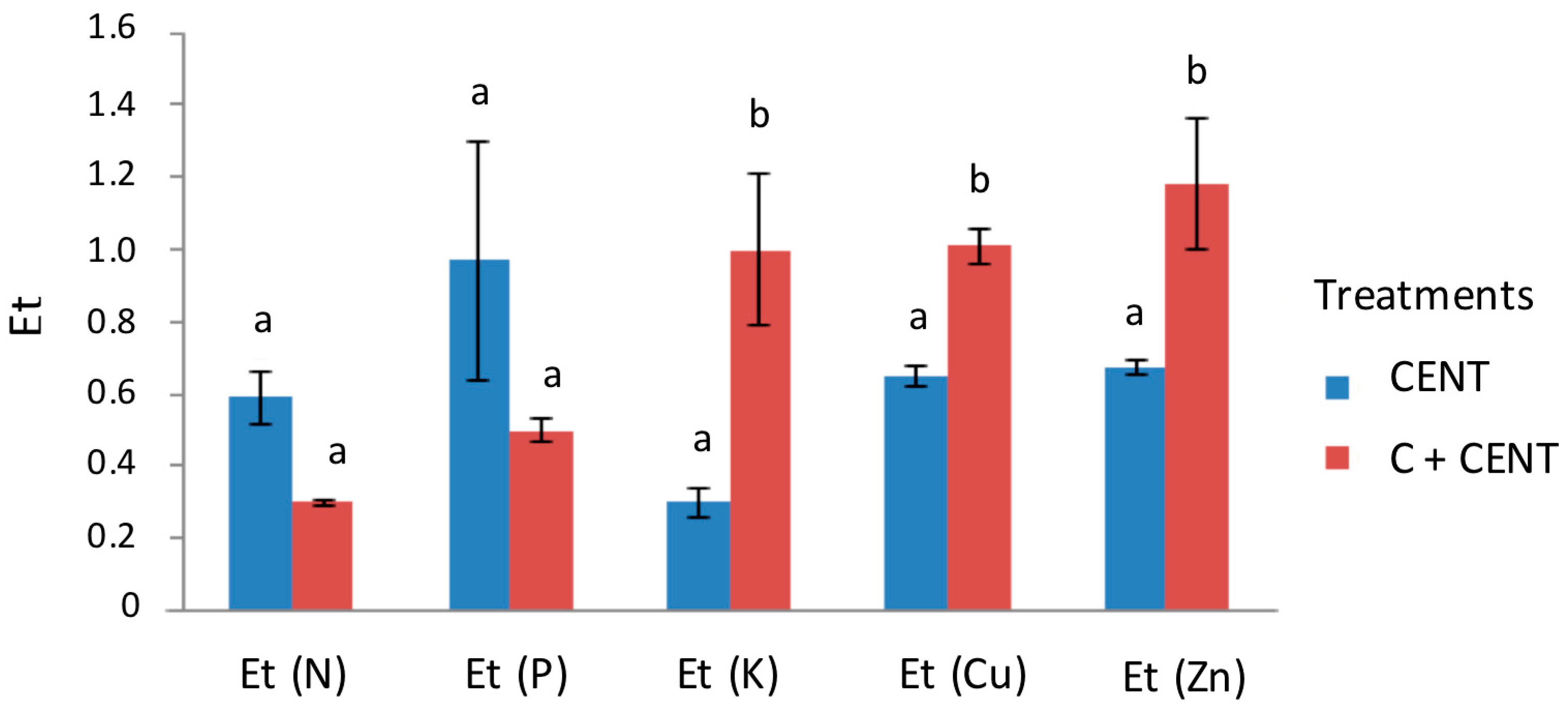

3.2.4. Separation Efficiency of Centrifugation after Chitosan Addition

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Dinuccio, E.; Balsari, P.; Gioelli, F.; Menardo, S. Evaluation of the biogas productivity potential of some Italian agro-industrial biomasses. Bioresour. Technol. 2010, 101, 3780–3783. [Google Scholar] [CrossRef] [PubMed]

- Marcato, C.E.; Mohtar, R.; Revel, J.C.; Pouech, P.; Hafidi, M.; Guiresse, M. Impact of anaerobic digestion on organic matter quality in pig slurry. Int. Biodeterior. Biodegrad. 2009, 63, 260–266. [Google Scholar] [CrossRef]

- Moller, H.B.; Hansen, J.D.; Sorensen, C.A.G. Nutrient recovery by solid-liquid separation and methane productivity of solids. Trans. ASABE 2007, 50, 193–200. [Google Scholar] [CrossRef]

- Cocolo, G.; Curnis, S.; Hjorth, M.; Provolo, G. Effect of different technologies and animal manures on solid-liquid separation efficiencies. J. Agric. Eng. 2012, 43, 55–64. [Google Scholar] [CrossRef]

- Hjorth, M.; Christensen, K.V.; Christensen, M.L.; Sommer, S.G. Solid–liquid separation of animal slurry in theory and practice. A review. Agron. Sustain. Dev. 2010, 30, 153–180. [Google Scholar] [CrossRef]

- Masse, L.; Masse, D.I.; Beaudette, V.; Muir, M. Size distribution and composition of particles in raw and anaerobically digested swine manure. Trans. ASAE 2005, 4, 1943–1949. [Google Scholar] [CrossRef]

- Yang, Z.; Shang, Y.; Lu, Y.; Chen, Y.; Huang, X.; Chen, A.; Jiang, Y.; Gu, W.; Qian, X.; Yang, H.; et al. Flocculation properties of biodegradable amphoteric chitosan-based flocculants. Chem. Eng. J. 2011, 172, 287–295. [Google Scholar] [CrossRef]

- Rhazi, M.; Desbrieres, J.; Tolaimate, A.; Rinaudo, M.; Vottero, P.; Alagui, A.; El Meray, M. Influence of the nature of the metal ions on the complexation with chitosan. Application to the treatment of liquid waste. Eur. Polym. J. 2002, 38, 1523–1530. [Google Scholar] [CrossRef]

- Guibal, E. Interactions of metal ions with chitosan-based sorbents: A review. Sep. Purif. Technol. 2004, 38, 43–74. [Google Scholar] [CrossRef]

- Salehizadeh, H.; Shojaosadati, S.A. Extracellular biopolymeric flocculants: Recent trends and biotechnological importance. Biotechnol. Adv. 2001, 19, 371–385. [Google Scholar] [CrossRef]

- Garcia, M.C.; Szogi, A.A.; Vanotti, M.B.; Chastain, J.P.; Millner, P.D. Enhanced solid–liquid separation of dairy manure with natural flocculants. Bioresour. Technol. 2009, 100, 5417–5423. [Google Scholar] [CrossRef] [PubMed]

- Popovic, O.; Gioelli, F.; Dinuccio, E.; Balsari, P. Improved pig slurry mechanical separation using chitosan and biochar. Biosyst. Eng. 2014, 127, 115–124. [Google Scholar] [CrossRef]

- VDI 4630-Fermentation of Organic Materials, Characterisation of the Substrates, Sampling, Collection of Material Data, Fermentation Tests. In VDI-Handbuch Energietechnik; Beuth Verlag GmbH: Berlin, Germany, 2006; p. 92. Available online: http://www.vdi.eu/uploads/tx_vdirili/pdf/2385990.pdf (accessed on 11 December 2017).

- USEPA. SW-846 Methods for the Analysis of Hazardous Waste; US Environmental Protection Agency: Washington, DC, USA, 2007. Available online: https://www.epa.gov/hw-sw846/sw-846-compendium (accessed on 11 December 2017).

- Peters, K.; Hjorth, M.; Jensen, L.S.; Magid, J. Carbon, nitrogen and phosphorus distribution in particle size-fractionated separated pig and cattle slurry. J. Environ. Qual. 2011, 40, 224–232. [Google Scholar] [CrossRef] [PubMed]

- Popovic, O.; Hjorth, M.; Jensen, S.L. Phosphorus, copper and zinc in solid and liquid fractions from separated pig slurry. Environ. Technol. 2012, 33, 2119–2131. [Google Scholar] [CrossRef] [PubMed]

- Menardo, S.; Gioelli, F.; Balsari, P. The methane yield of digestate: Effect of organic loading rate, hydraulic retention time, and plant feeding. Bioresour. Technol. 2011, 102, 2348–2351. [Google Scholar] [CrossRef] [PubMed]

- Hjorth, M.; Christensen, M.L. Evaluation of methods to determine flocculation procedure for manure separation. Trans. ASABE 2008, 51, 2093–2103. [Google Scholar] [CrossRef]

- Marcato, C.E.; Pinelli, E.; Cecchi, M.; Winterton, P.; Guiresse, M. Bioavailability of Cu and Zn in raw and anaerobically digested pig slurry. Ecotoxicol. Environ. Saf. 2009, 72, 1538–1544. [Google Scholar] [CrossRef] [PubMed]

- Dinuccio, E.; Gioelli, F.; Cuk, D.; Rollè, L.; Balsari, P. The use of co-digested solid fraction as feedstock for biogas plants. J. Agric. Eng. 2013, 44, 573–578. [Google Scholar] [CrossRef]

| DM (%) | pH | Tot N (mg g−1) | Tot P (mg g−1) | Tot K (mg g−1) | Tot Cu (µg g−1) | Tot Zn (µg g−1) |

|---|---|---|---|---|---|---|

| 4.56 (0.16) | 7.38 (0.03) | 57 (5.28) | 8.31 (2.1) | 63.8 (6.23) | 106 (14.9) | 539 (92.9) |

| Dose (mL L−1) | Mass Balance (%) | Floc | Foam | Solid DM (%) | Liquid DM (%) | Turbidity of Liquids | Et | Recovery (%) |

|---|---|---|---|---|---|---|---|---|

| Dose 1 | 58a | 4 * | 1 ** | 5.5a | 2.8a | 4 *** | 0.7a | 98 |

| (120) | (4.93) | (0.25) | (0.00) | (0.03) | ||||

| Dose2 | 44ab | 3 | 2 | 8.1ab | 1.1b | 2 | 0.8a | 97 |

| (240) | (5.86) | (0.90) | (0.27) | (0.03) | ||||

| Dose 3 | 38b | 1 | 3 | 9.2b | 0.9b | 1 | 0.8a | 99 |

| (360) | (1.15) | (0.01) | (0.04) | (0.02) | ||||

| Dose 4 | 35ab | 2.1 | 4 | 9b | 0.9b | 2.3 | 0.7a | 97 |

| (480) | (3.21) | (0.17) | (0.04) | (0.07) |

| Treatment | DM (%) | pH | Tot N (mg g−1) | Tot P (mg g−1) | Tot K (mg g−1) | Tot Cu (µg g−1) | Tot Zn (µg g−1) |

|---|---|---|---|---|---|---|---|

| Solids | |||||||

| CENT | 10.4a * | 8.31a | 49a | 20a | 21a | 111a | 542a |

| (0.42) | (0.02) | (6.37) | (7.18) | (2.4) | (8.82) | (19) | |

| C+CENT | 8.8b | 7.99a | 53a | 14a | 89b | 223b | 1218b |

| (0.44) | (0.33) | (2.4) | (1.01) | (13.8) | (14) | (161) | |

| Liquids | |||||||

| CENT | 1.7a | 7.86a | 134a | 38a | 115a | 316a | 1267a |

| (0.01) | (0.05) | (0.82) | (4.75) | (57.0) | (56) | (110) | |

| C+CENT | 0.9b | 6.64b | 101a | 21b | 236b | 4b | 24b |

| (0.01) | (0.05) | (72.4) | (1.73) | (23.6) | (2.5) | (9.7) |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Popovic, O.; Gioelli, F.; Dinuccio, E.; Rollè, L.; Balsari, P. Centrifugation of Digestate: The Effect of Chitosan on Separation Efficiency. Sustainability 2017, 9, 2302. https://doi.org/10.3390/su9122302

Popovic O, Gioelli F, Dinuccio E, Rollè L, Balsari P. Centrifugation of Digestate: The Effect of Chitosan on Separation Efficiency. Sustainability. 2017; 9(12):2302. https://doi.org/10.3390/su9122302

Chicago/Turabian StylePopovic, Olga, Fabrizio Gioelli, Elio Dinuccio, Luca Rollè, and Paolo Balsari. 2017. "Centrifugation of Digestate: The Effect of Chitosan on Separation Efficiency" Sustainability 9, no. 12: 2302. https://doi.org/10.3390/su9122302

APA StylePopovic, O., Gioelli, F., Dinuccio, E., Rollè, L., & Balsari, P. (2017). Centrifugation of Digestate: The Effect of Chitosan on Separation Efficiency. Sustainability, 9(12), 2302. https://doi.org/10.3390/su9122302