A Review on Building Integrated Photovoltaic Façade Customization Potentials

Abstract

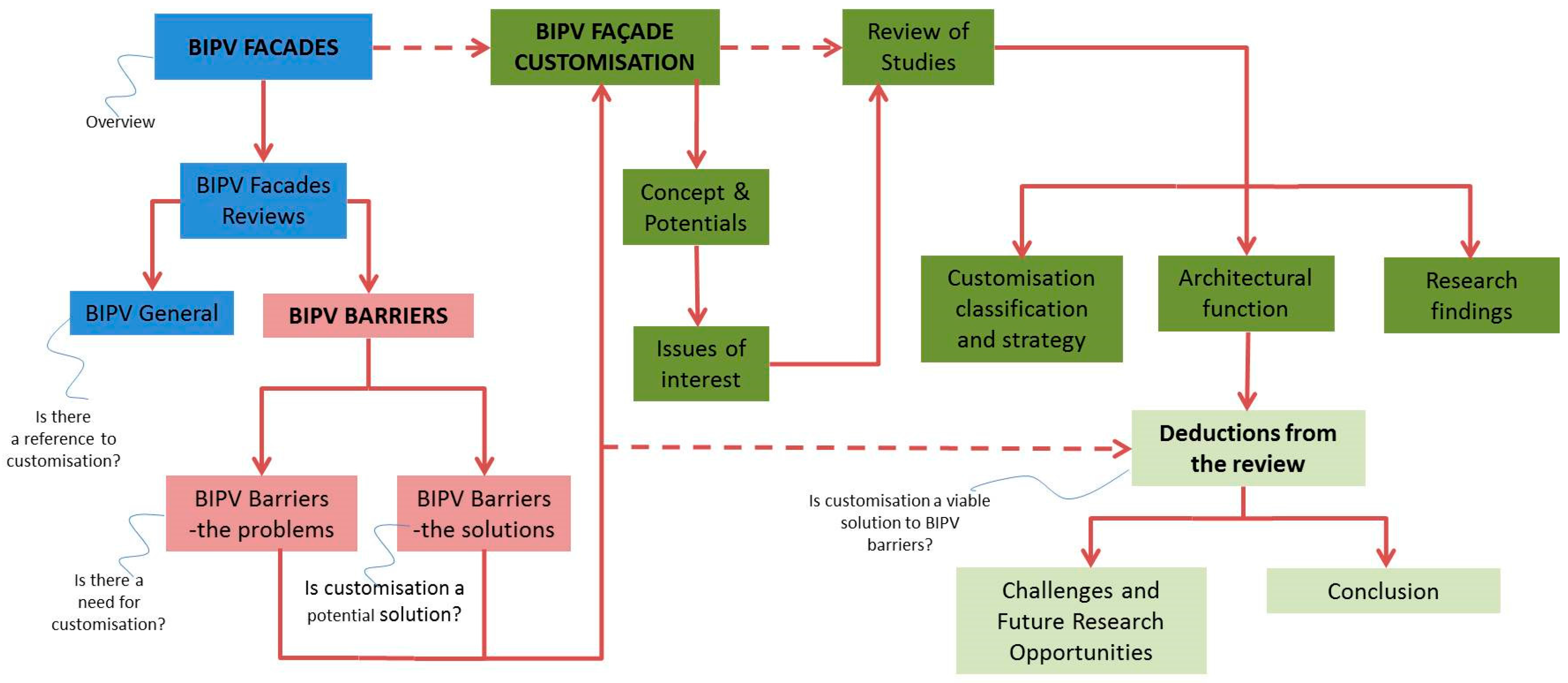

1. Introduction

1.1. BIPV Customisation: Working Definition

1.2. Research Design

2. Overview on BIPV Façade Applications

Strategic Benefits of BIPV

- Design Benefits: relating to architectural integration and function of BIPV as a building component

- Economic Benefits: relating to financial advantages accrued as a result of BIPV application

- Environmental Benefits: relating to micro or macro environment improvements due to BIPV application

- Design-related benefits

- Economic Benefits

- Material and labour savings as well as electrical cost reductions [36].

- Environmental Benefits

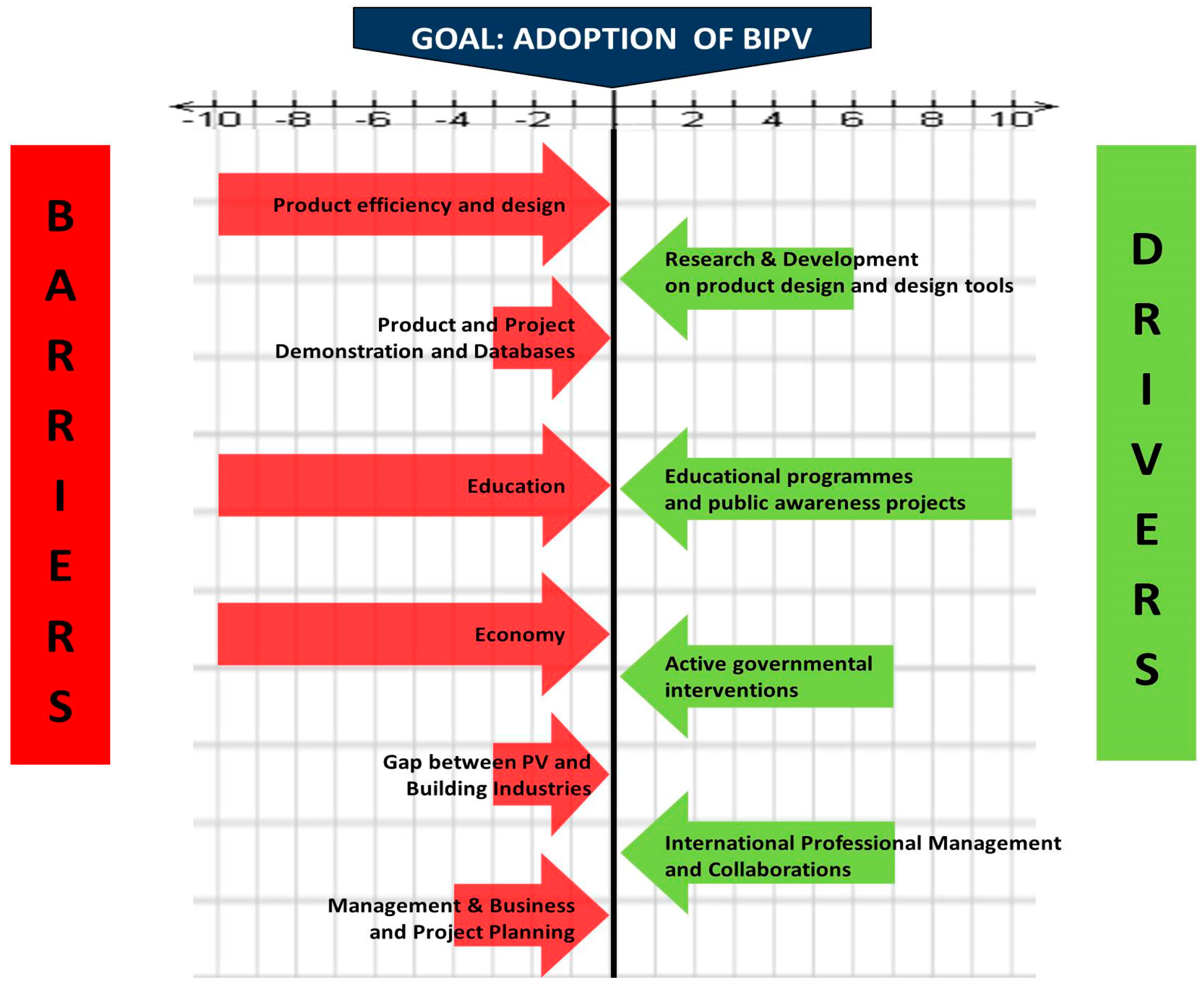

3. BIPV Façade Applications: Barriers and Strategies

Force Field Analysis: Comparison of Barriers and Strategies

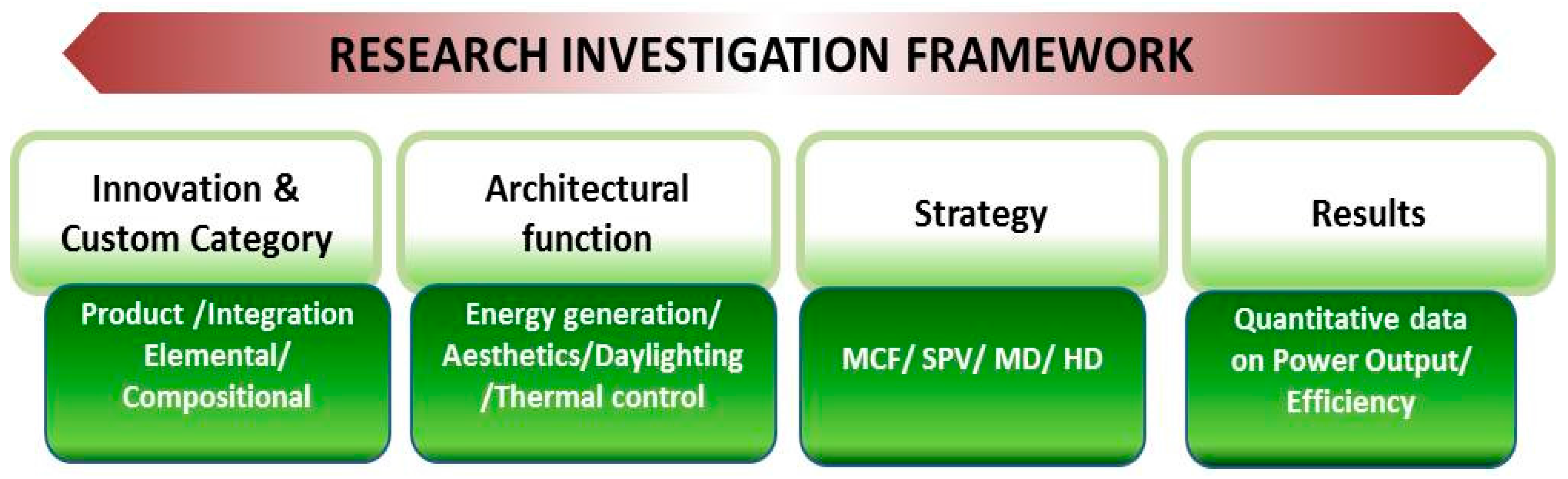

4. BIPV Façade Customization: Critical Review of Investigations

4.1. Methodological Approach

- The Elemental Level: this represents the breakdown of a BIPV module into various components i.e., the solar cells, frame, glass and other protective layers; reflecting customization of cell or glass or layer type; colors or efficiencies.

- The Compositional Level: this represents the composition of the cells of the BIPV module (module-level), relating to cell spacing and the modules of the BIPV façade (façade-level), relating to tilt angle or spacing from wall for example.

- Systematic Parametric Variation (SPV): iterative parametric changes to reach an optimum goal

- Modification of Conventional Features (MCF): modification of conventional BIPV parts

- Enhanced Design Modularization (EDM): upgrade of BIPV façade types into unique modules

- Compositional Modification and Hybridization (CMH): combination of special materials with BIPV

- A comparison with a base case (standard BIPV);

- Hot climate results as representative of intense scenarios (where multiple climatic data was presented), or

- Highest output (where optimization based on parametric variation was investigated)

4.2. Assessment of BIPV Customization Parameters

4.2.1. Innovation and Custom Category

4.2.2. Customization Strategy

4.2.3. Architectural Function

4.2.4. Results

5. Challenges and Future Prospects

6. Conclusions

- Flexibility and applicability at an elemental and compositional level

- Versatility in development of both custom BIPV products and custom BIPV integration schemes

- Multiple type strategies in single or combined scenarios can be used to achieve objectives

- Increase in power output and performance is possible in a range of 2–80% based on design

- Although, reduction in power output and performance occurs also at a range of 4–70% based on design

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Nejat, P.; Jomehzadeh, F.; Taheri, M.M.; Gohari, M.; Majid, M.Z.A. A global review of energy consumption, CO2 emissions and policy in the residential sector (with an overview of the top ten CO2 emitting countries). Renew. Sustain. Energy Rev. 2015, 43, 843–862. [Google Scholar] [CrossRef]

- World Energy Council (WEC). World Energy Resources 2013 Survey; World Energy Council: London, UK, 2013. [Google Scholar]

- De la Cruz-Lovera, C.; Perea-Moreno, A.J.; de la Cruz-Fernández, J.L.; Alvarez-Bermejo, J.A.; Manzano-Agugliaro, F. Worldwide Research on Energy Efficiency and Sustainability in Public Buildings. Sustainability 2017, 9, 1294. [Google Scholar] [CrossRef]

- Woodcock, J.; Edwards, P.; Tonne, C.; Armstrong, B.G.; Ashiru, O.; Banister, D.; Beevers, S.; Chalabi, Z.; Chowdhury, Z.; Cohen, A.; et al. Public health benefits of strategies to reduce greenhouse-gas emissions: Urban land transport. Lancet 2009, 374, 1930–1943. [Google Scholar] [CrossRef]

- Adewuyi, A.O.; Awodumi, O.B. Renewable and non-renewable energy-growth-emissions linkages: Review of emerging trends with policy implications. Renew. Sustain. Energy Rev. 2017, 69, 275–291. [Google Scholar] [CrossRef]

- Wang, F.; Wang, C.; Su, Y.; Jin, L.; Wang, Y.; Zhang, X. Decomposition Analysis of Carbon Emission Factors from Energy Consumption in Guangdong Province from 1990 to 2014. Sustainability 2017, 9, 274. [Google Scholar] [CrossRef]

- Rodhe, H. A comparison of the contribution of various gases to the greenhouse effect. Science 1990, 248, 1217. [Google Scholar] [CrossRef] [PubMed]

- Lashof, D.A.; Ahuja, D.R. Relative contributions of greenhouse gas emissions to global warming. Nature 1990, 344, 529–531. [Google Scholar] [CrossRef]

- Jiang, W.; Liu, J.; Liu, X. Impact of carbon quota allocation mechanism on emissions trading: An agent-based simulation. Sustainability 2016, 8, 826. [Google Scholar] [CrossRef]

- Camanzi, L.; Alikadic, A.; Compagnoni, L.; Merloni, E. The impact of greenhouse gas emissions in the EU food chain: A quantitative and economic assessment using an environmentally extended input-output approach. J. Clean. Prod. 2017, 157, 168–176. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change (IPCC). Climate Change 2007: Synthesis Report; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2007; pp. 45–54. [Google Scholar]

- Liu, W.Y.; Lin, C.C.; Chiu, C.R.; Tsao, Y.S.; Wang, Q. Minimizing the carbon footprint for the time-dependent heterogeneous-fleet vehicle routing problem with alternative paths. Sustainability 2014, 6, 4658–4684. [Google Scholar] [CrossRef]

- Knera, D.; Knera, D.; Heim, D.; Heim, D. Application of a BIPV to cover net energy use of the adjacent office room. Manag. Environ. Qual. Int. J. 2016, 27, 649–662. [Google Scholar] [CrossRef]

- Evola, G.; Margani, G. Renovation of apartment blocks with BIPV: Energy and economic evaluation in temperate climate. Energy Build. 2016, 130, 794–810. [Google Scholar] [CrossRef]

- Jayathissa, P.; Luzzatto, M.; Schmidli, J.; Hofer, J.; Nagy, Z.; Schlueter, A. Optimising building net energy demand with dynamic BIPV shading. Appl. Energy 2017, 202, 726–735. [Google Scholar] [CrossRef]

- Wong, P.W.; Shimoda, Y.; Nonaka, M.; Inoue, M.; Mizuno, M. Semi-transparent PV: Thermal performance, power generation, daylight modelling and energy saving potential in a residential application. Renew. Energy 2008, 33, 1024–1036. [Google Scholar] [CrossRef]

- Peng, J.; Curcija, D.C.; Lu, L.; Selkowitz, S.E.; Yang, H.; Zhang, W. Numerical investigation of the energy saving potential of a semi-transparent photovoltaic double-skin facade in a cool-summer Mediterranean climate. Appl. Energy 2016, 165, 345–356. [Google Scholar] [CrossRef]

- Bayoumi, M. Impacts of window opening grade on improving the energy efficiency of a façade in hot climates. Build. Environ. 2017, 119, 31–43. [Google Scholar] [CrossRef]

- Elinwa, U.K.; Radmehr, M.; Ogbeba, J.E. Alternative Energy Solutions Using BIPV in Apartment Buildings of Developing Countries: A Case Study of North Cyprus. Sustainability 2017, 9, 1414. [Google Scholar] [CrossRef]

- Song, A.; Lu, L.; Liu, Z.; Wong, M.S. A Study of Incentive Policies for Building-Integrated Photovoltaic Technology in Hong Kong. Sustainability 2016, 8, 769. [Google Scholar] [CrossRef]

- Norton, B.; Eames, P.C.; Mallick, T.K.; Huang, M.J.; McCormack, S.J.; Mondol, J.D.; Yohanis, Y.G. Enhancing the performance of building integrated photovoltaics. Sol. Energy 2011, 85, 1629–1664. [Google Scholar] [CrossRef]

- Agathokleous, R.A.; Kalogirou, S.A. Double skin facades (DSF) and building integrated photovoltaics (BIPV): A review of configurations and heat transfer characteristics. Renew. Energy 2016, 89, 743–756. [Google Scholar] [CrossRef]

- Zhang, W.; Lu, L.; Peng, J. Evaluation of potential benefits of solar photovoltaic shadings in Hong Kong. Energy 2017. [Google Scholar] [CrossRef]

- Ritzen, M.; Reijenga, T.; El Gammal, A.; Warneryd, M.; Sprenger, W.; Rose-Wilson, H.; Payet, J.; Morreau, V.; Boddaert, S. IEA-PVPS Task 15: Enabling Framework for BIPV Acceleration. (IEA-PVPS). In Proceedings of the 48th IEA PVPS Executive Commitee Meeting, Vienna, Austria, 16 November 2016. [Google Scholar]

- Tabakovic, M.; Fechner, H.; Van Sark, W.; Louwen, A.; Georghiou, G.; Makrides, G.; Loucaidou, E.; Ioannidou, M.; Weiss, I.; Arancon, S.; et al. Status and outlook for building integrated photovoltaics (BIPV) in relation to educational needs in the BIPV sector. Energy Procedia 2017, 111, 993–999. [Google Scholar] [CrossRef]

- Prieto, A.; Knaack, U.; Auer, T.; Klein, T. Solar façades-Main barriers for widespread façade integration of solar technologies. J. Façade Des. Eng. 2017, 5, 51–62. [Google Scholar] [CrossRef]

- Goh, K.C.; Goh, H.H.; Yap, A.B.K.; Masrom, M.A.N.; Mohamed, S. Barriers and drivers of Malaysian BIPV application: Perspective of developers. Procedia Eng. 2017, 180, 1585–1595. [Google Scholar] [CrossRef]

- Yang, R.J.; Zou, P.X. Building integrated photovoltaics (BIPV): Costs, benefits, risks, barriers and improvement strategy. Int. J. Constr. Manag. 2016, 16, 39–53. [Google Scholar] [CrossRef]

- Karakaya, E.; Sriwannawit, P. Barriers to the adoption of photovoltaic systems: The state of the art. Renew. Sustain. Energy Rev. 2015, 49, 60–66. [Google Scholar] [CrossRef]

- Yang, R.J. Overcoming technical barriers and risks in the application of building integrated photovoltaics (BIPV): Hardware and software strategies. Autom. Constr. 2015, 51, 92–102. [Google Scholar] [CrossRef]

- Azadian, F.; Radzi, M.A.M. A general approach toward building integrated photovoltaic systems and its implementation barriers: A review. Renew. Sustain. Energy Rev. 2013, 22, 527–538. [Google Scholar] [CrossRef]

- Koinegg, J.; Brudermann, T.; Posch, A.; Mrotzek, M. “It Would Be a Shame if We Did Not Take Advantage of the Spirit of the Times”. An Analysis of Prospects and Barriers of Building Integrated Photovoltaics. GAIA Ecol. Perspect. Sci. Soc. 2013, 22, 39–45. [Google Scholar] [CrossRef]

- Probst, M.M.; Roecker, C. Criteria for architectural integration of active solar systems IEA Task 41, Subtask A. Energy Procedia 2012, 30, 1195–1204. [Google Scholar] [CrossRef]

- Taleb, H.M.; Pitts, A.C. The potential to exploit use of building-integrated photovoltaics in countries of the Gulf Cooperation Council. Renew. Energy 2009, 34, 1092–1099. [Google Scholar] [CrossRef]

- Tripathy, M.; Sadhu, P.K.; Panda, S.K. A critical review on building integrated photovoltaic products and their applications. Renew. Sustain. Energy Rev. 2016, 61, 451–465. [Google Scholar] [CrossRef]

- Jelle, B.P. Building integrated photovoltaics: A concise description of the current state of the art and possible research pathways. Energies 2016, 9, 21. [Google Scholar] [CrossRef]

- Heinstein, P.; Ballif, C.; Perret-Aebi, L.E. Building integrated photovoltaics (BIPV): Review, potentials, barriers and myths. Green 2013, 3, 125–156. [Google Scholar] [CrossRef]

- Cerón, I.; Caamaño-Martín, E.; Neila, F.J. ‘State-of-the-art’ of building integrated photovoltaic products. Renew. Energy 2013, 58, 127–133. [Google Scholar] [CrossRef]

- Bonomo, P.; Chatzipanagi, A.; Frontini, F. Overview and analysis of current BIPV products: New criteria for supporting the technological transfer in the building sector. VITRUVIO Int. J. Archit. Technol. Sustain. 2015, 67–85. [Google Scholar] [CrossRef]

- Shukla, A.K.; Sudhakar, K.; Baredar, P. Recent advancement in BIPV product technologies: A review. Energy Build. 2017. [Google Scholar] [CrossRef]

- Ibraheem, Y.; Farr, E.R.; Piroozfar, P.A. Embedding passive intelligence into building envelopes: A review of the state-of-the-art in integrated photovoltaic shading devices. Energy Procedia 2017, 111, 964–973. [Google Scholar] [CrossRef]

- Shukla, A.K.; Sudhakar, K.; Baredar, P. A comprehensive review on design of building integrated photovoltaic system. Energy Build. 2016, 128, 99–110. [Google Scholar] [CrossRef]

- Skandalos, N.; Karamanis, D. PV glazing technologies. Renew. Sustain. Energy Rev. 2015, 49, 306–322. [Google Scholar] [CrossRef]

- Jelle, B.P.; Breivik, C.; Røkenes, H.D. Building integrated photovoltaic products: A state-of-the-art review and future research opportunities. Sol. Energy Mater. Sol. Cells 2012, 100, 69–96. [Google Scholar] [CrossRef]

- Jelle, B.P.; Breivik, C. The path to the building integrated photovoltaics of tomorrow. Energy Procedia 2012, 20, 78–87. [Google Scholar] [CrossRef]

- Hammond, G.P.; Harajli, H.A.; Jones, C.I.; Winnett, A.B. Whole systems appraisal of a UK Building Integrated Photovoltaic (BIPV) system: Energy, environmental, and economic evaluations. Energy Policy 2012, 40, 219–230. [Google Scholar] [CrossRef]

- Scognamiglio, A.; Røstvik, H.N. Photovoltaics and zero energy buildings: A new opportunity and challenge for design. Prog. Photovolt. Res. Appl. 2013, 21, 1319–1336. [Google Scholar] [CrossRef]

- Scognamiglio, A.; Farkas, K.; Frontini, F.; Maturi, L. Architectural quality and photovoltaic products. In Proceedings of the 27th European Photovoltaic Solar Energy Conference and Exhibition (EU PVSEC), Frankfurt, Germany, 24–28 September 2012; pp. 24–28. [Google Scholar]

- Stevenson, A. (Ed.) Oxford dictionary of English; Oxford University Press: New York, NY, USA, 2010. [Google Scholar]

- Pine, B.J. Mass customizing products and services. Plan. Rev. 1993, 21, 6–55. [Google Scholar] [CrossRef]

- Lien, S.Y. Artist Photovoltaic Modules. Energies 2016, 9, 551. [Google Scholar] [CrossRef]

- Hardy, D.; Kerrouche, A.; Roaf, S.C.; Richards, B.S. Improving the Aesthetics of Photovoltaics through Use of Coloured Encapsulants. In Proceedings of the PLEA 2013—29th Conference, Sustainable Architecture for a Renewable Future, Munich, Germany, 10–12 September 2013. [Google Scholar]

- Nagy, Z.; Svetozarevic, B.; Jayathissa, P.; Begle, M.; Hofer, J.; Lydon, G.; Willmann, A.; Schlueter, A. The adaptive solar facade: From concept to prototypes. Front. Archit. Res. 2016, 5, 143–156. [Google Scholar] [CrossRef]

- Keller, A.F. Recharging the Facade: Designing and Constructing Novel BIPV Assemblies. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2013. [Google Scholar]

- Hasan, A.; McCormack, S.J.; Huang, M.J.; Norton, B. Energy and cost saving of a photovoltaic-phase change materials (PV-PCM) system through temperature regulation and performance enhancement of photovoltaics. Energies 2014, 7, 1318–1331. [Google Scholar] [CrossRef]

- Hasan, A.; McCormack, S.J.; Huang, M.J.; Sarwar, J.; Norton, B. Increased photovoltaic performance through temperature regulation by phase change materials: Materials comparison in different climates. Sol. Energy 2015, 115, 264–276. [Google Scholar] [CrossRef]

- Hasan, A.; Sarwar, J.; Alnoman, H.; Abdelbaqi, S. Yearly energy performance of a photovoltaic-phase change material (PV-PCM) system in hot climate. Sol. Energy 2017, 146, 417–429. [Google Scholar] [CrossRef]

- Baum, R. Architectural integration of light-transmissive photovoltaic (LTPV). In Proceedings of the 26th European Photovoltaic Solar Energy Conference and Exhibition (EU PVSEC), Hamburg, Germany, 5–9 September 2011; pp. 5–9. [Google Scholar]

- Munari Probst, M.C.; Roecker, C.; Frontini, F.; Scognamiglio, A.; Farkas, K.; Maturi, L.; Zanetti, I. Solar Energy Systems in Architecture-integration criteria and guidelines. In International Energy Agency Solar Heating and Cooling Programme; Probst, M., Cristina, M., Roecker, C., Eds.; International Energy Agency: Paris, France, 2013. [Google Scholar]

- Farkas, K.; Frontini, F.; Maturi, L.; Munari Probst, M.C.; Roecker, C.; Scognamiglio, A. Designing Photovoltaic Systems for Architectural Integration; Farkas, K., Ed.; International Energy Agency: Paris, France, 2013. [Google Scholar]

- Montoro, D.F.; Vanbuggenhout, P.; Ciesielska, J. Building Integrated Photovoltaics: An overview of the existing products and their fields of application. In Report Prepared in the Framework of the European Funded Project; SUNRISE: Saskatoon, Canada, 2011. [Google Scholar]

- Thomas, R. (Ed.) Photovoltaics and Architecture; Taylor & Francis: Didcot, UK, 2003. [Google Scholar]

- Clua Longas, A.; Lufkin, S.; Rey, E. Towards Advanced Active Façades: Analysis of façade requirements and development of an innovative construction system. In Proceedings of the PLEA 2017, Edinburgh, UK, 3–5 July 2017; Volume 1, pp. 192–199. [Google Scholar]

- Luo, Y.; Zhang, L.; Wang, X.; Xie, L.; Liu, Z.; Wu, J.; Zhang, Y.; He, X. A comparative study on thermal performance evaluation of a new double skin façade system integrated with photovoltaic blinds. Appl. Energy 2017, 199, 281–293. [Google Scholar] [CrossRef]

- Tabriz, S.N.; Fard, F.; Partovi, N. Review of architectural day lighting analysis of photovoltaic panels of BIPV with zero energy emission approach. Res. J. Appl. Sci. 2016, 11, 735–741. [Google Scholar]

- Pagliaro, M.; Ciriminna, R.; Palmisano, G. BIPV: Merging the photovoltaic with the construction industry. Prog. Photovolt. Res. Appl. 2010, 18, 61–72. [Google Scholar] [CrossRef]

- Oliver, M.; Jackson, T. Energy and economic evaluation of building-integrated photovoltaics. Energy 2001, 26, 431–439. [Google Scholar] [CrossRef]

- Bakos, G.C.; Soursos, M.; Tsagas, N.F. Technoeconomic assessment of a building-integrated PV system for electrical energy saving in residential sector. Energy Build. 2003, 35, 757–762. [Google Scholar] [CrossRef]

- Sharples, S.; Radhi, H. Assessing the technical and economic performance of building integrated photovoltaics and their value to the GCC society. Renew. Energy 2013, 55, 150–159. [Google Scholar] [CrossRef]

- Byrnes, L.; Brown, C.; Foster, J.; Wagner, L.D. Australian renewable energy policy: Barriers and challenges. Renew. Energy 2013, 60, 711–721. [Google Scholar] [CrossRef]

- Morris, S. Improving Energy Efficient, Sustainable Building Design and Construction in Australia—Learning from Europe; ISS Institute: Carlton, Australia, 2013. [Google Scholar]

- Abdullah, A.S.; Abdullah, M.P.; Hassan, M.Y.; Hussin, F. Renewable energy cost-benefit analysis under Malaysian feed-in-tariff. In Proceedings of the 2012 IEEE Student Conference on Research and Development (SCOReD), Pulau Pinang, Malaysia, 5–6 December 2012; pp. 160–165. [Google Scholar]

- Sintov, N.D.; Schultz, P. Adjustable Green Defaults Can Help Make Smart Homes More Sustainable. Sustainability 2017, 9, 622. [Google Scholar] [CrossRef]

- Martyn, A.S. Some problems in managing complex development projects. Long Range Plann. 1975, 8, 13–26. [Google Scholar] [CrossRef]

- Attoye, D.E.; Tabet Aoul, K.A.; Hassan, A. Potentials and Benefits of Building Integrated Photovoltaics. In Proceedings of the United Arab Emirates Graduate Student Conference (UAEGSRC), Al Ain, UAE, 27–28 April 2016. [Google Scholar]

- Jahanara, A. Strategy towards Solar Architecture by Photovoltaic for Building Integration. Ph.D. Thesis, Eastern Mediterranean University (EMU), Famagusta, Turkey, 2013. [Google Scholar]

- Wu, Y.; Krishnan, P.; Liya, E.Y.; Zhang, M.H. Using lightweight cement composite and photocatalytic coating to reduce cooling energy consumption of buildings. Constr. Build. Mater. 2017, 145, 555–564. [Google Scholar] [CrossRef]

- Biyik, E.; Araz, M.; Hepbasli, A.; Shahrestani, M.; Yao, R.; Shao, L.; Essah, E.; Oliveira, A.C.; del Caño, T.; Rico, E.; et al. A key review of building integrated photovoltaic (BIPV) systems. Eng. Sci. Technol. Int. J. 2017. [Google Scholar] [CrossRef]

- Tak, S.; Woo, S.; Park, J.; Park, S. Effect of the Changeable Organic Semi-Transparent Solar Cell Window on Building Energy Efficiency and User Comfort. Sustainability 2017, 9, 950. [Google Scholar] [CrossRef]

- Peharz, G.; Berger, K.; Kubicek, B.; Aichinger, M.; Grobbauer, M.; Gratzer, J.; Nemitz, W.; Großschädl, B.; Auer, C.; Prietl, C.; et al. Application of plasmonic coloring for making building integrated PV modules comprising of green solar cells. Renew. Energy 2017, 109, 542–550. [Google Scholar] [CrossRef]

- Van Berkel, T.; Minderhoud, T.; Piber, A.; Gijzen, G. Design Innovation from PV-Module to Building Envelope: Architectural Layering and Non Apparent Repetition. In Proceedings of the 29th European Photovoltaic Solar Energy Conference and Exhibition, Amsterdam, The Netherlands, 22–26 September 2014; pp. 366–372. [Google Scholar]

- Lim, J.W.; Kim, G.; Shin, M.; Yun, S.J. Colored a-Si: H transparent solar cells employing ultrathin transparent multi-layered electrodes. Sol. Energy Mater. Sol. Cells 2017, 163, 164–169. [Google Scholar] [CrossRef]

- Wang, M.; Peng, J.; Li, N.; Yang, H.; Wang, C.; Li, X.; Lu, T. Comparison of energy performance between PV double skin facades and PV insulating glass units. Appl. Energy 2017, 194, 148–160. [Google Scholar] [CrossRef]

- Peng, J.; Lu, L.; Yang, H.; Sing, A.; Ma, T. 182: Investigation on the overall energy performance of an a-si based photovoltaic double-skin facade in Hong Kong. In Proceedings of the Sustainable Energy for a Resilient Future: The 14th International Conference on Sustainable Energy Technologies, Nottingham, UK, 25–27 August 2015; Rodrigues, L., Ed.; University of Nottingham: Nottingham, UK, 2015; Volume 1, pp. 263–271. [Google Scholar]

- Chatzipanagi, A.; Frontini, F.; Virtuani, A. BIPV-temp: A demonstrative Building Integrated Photovoltaic installation. Appl. Energy 2016, 173, 1–2. [Google Scholar] [CrossRef]

- Wang, M.; Peng, J.; Li, N.; Lu, L.; Ma, T.; Yang, H. Assessment of energy performance of semi-transparent PV insulating glass units using a validated simulation model. Energy 2016, 112, 538–548. [Google Scholar] [CrossRef]

- Do, S.L.; Shin, M.; Baltazar, J.C.; Kim, J. Energy benefits from semi-transparent BIPV window and daylight-dimming systems for IECC code-compliance residential buildings in hot and humid climates. Sol. Energy 2017, 155, 291–303. [Google Scholar] [CrossRef]

- Hachem, C.; Elsayed, M. Patterns of façade system design for enhanced energy performance of multistory buildings. Energy Build. 2016, 130, 366–377. [Google Scholar] [CrossRef]

- Huang, Y.C.; Lee, S.K.; Chan, C.C.; Wang, S.J. Full-scale evaluation of fire-resistant building integrated photovoltaic systems with different installation positions of junction boxes. Indoor Built Environ. 2017. [Google Scholar] [CrossRef]

- Elarga, H.; Zarrella, A.; De Carli, M. Dynamic energy evaluation and glazing layers optimization of facade building with innovative integration of PV modules. Energy Build. 2016, 111, 468–478. [Google Scholar] [CrossRef]

- Curpek, J.; Hraska, J. Simulation Study on Thermal Performance of a Ventilated PV Façade Coupled with PCM. In Applied Mechanics and Materials; Trans Tech Publications: Zürich, Switzerland, 2017; Volume 861, pp. 167–174. [Google Scholar]

- Gaillard, L.; Giroux-Julien, S.; Ménézo, C.; Pabiou, H. Experimental evaluation of a naturally ventilated PV double-skin building envelope in real operating conditions. Sol. Energy 2014, 103, 223–441. [Google Scholar] [CrossRef]

- Bahr, W. A comprehensive assessment methodology of the building integrated photovoltaic blind system. Energy Build. 2014, 82, 703–708. [Google Scholar] [CrossRef]

- Peng, J.; Lu, L.; Yang, H.; Han, J. Investigation on the annual thermal performance of a photovoltaic wall mounted on a multi-layer façade. Appl. Energy 2013, 112, 646–656. [Google Scholar] [CrossRef]

- Buscemi, A.; Calabrò, C.; Corrao, R.; Di Maggio, M.S.; Morini, M.; Pastore, L. Optical Performance Evaluation of DSSC-integrated Glassblocks for Active Building Façades. Int. J. Mod. Eng. Res. 2015, 5, 1–6. [Google Scholar]

- Valckenborg, R.M.E.; van der Wall, W.; Folkerts, W.; Hensen, J.L.M.; de Vries, A. Zigzag Structure in Façade Optimizes PV Yield While Aesthetics are Preserved. In Proceedings of the 32nd European Photovoltaic Solar Energy Conference and Exhibition, Munich, Germany, 20–24 June 2016; European Commission: Brussels, Belgium; pp. 647–650. [Google Scholar]

- Wall, M.; Probst, M.C.M.; Roecker, C.; Dubois, M.C.; Horvat, M.; Jørgensen, O.B.; Kappel, K. Achieving solar energy in architecture-IEA SHC Task 41. Energy Procedia 2012, 30, 1250–1260. [Google Scholar] [CrossRef][Green Version]

- Benemann, J.; Chehab, O.; Schaar-Gabriel, E. Building-integrated PV modules. Sol. Energy Mater. Sol. Cells 2001, 67, 345–354. [Google Scholar] [CrossRef]

- Zanetti, I.; Bonomo, P.; Frontini, P.; Saretta, E.; Verberne, G.; Van Den Donker, M.; Sinapis, K.; Folkerts, W. Building Integrated Photovoltaics. Report 2017; SUPSI—University of Applied Sciences and Arts of Southern Switzerland, Ed.; SUPSI: Lugano, Switzerland, 2017. [Google Scholar]

- Cannavale, A.; Hörantner, M.; Eperon, G.E.; Snaith, H.J.; Fiorito, F.; Ayr, U.; Martellotta, F. Building integration of semitransparent perovskite-based solar cells: Energy performance and visual comfort assessment. Appl. Energy 2017, 194, 94–107. [Google Scholar] [CrossRef]

- Pandey, A.K.; Tyagi, V.V.; Jeyraj, A.; Selvaraj, L.; Rahim, N.A.; Tyagi, S.K. Recent advances in solar photovoltaic systems for emerging trends and advanced applications. Renew. Sustain. Energy Rev. 2016, 53, 859–884. [Google Scholar] [CrossRef]

- Chemisana, D. Building integrated concentrating photovoltaics: A review. Renew. Sustain. Energy Rev. 2011, 15, 603–611. [Google Scholar] [CrossRef]

- Hyder, F.; Sudhakar, K.; Mamat, R. Solar PV tree design: A review. Renew. Sustain. Energ. Rev. 2018, 82, 1079–1096. [Google Scholar] [CrossRef]

| Reference | Title/Focus | Customization-Related Content |

|---|---|---|

| [40] | Recent advancement in BIPV product technologies: a review | - |

| [41] | Embedding passive intelligence into building envelopes: a review | Reference to a system-based process design |

| [35] | A critical review on building integrated photovoltaic products and their applications | Brief mention |

| [22] | Double skin façades (DSF) and BIPV: a review of configurations and heat transfer characteristics | Inference to different design modes |

| [42] | A comprehensive review on design of building integrated photovoltaic system | Reference made to an energy-conscious process design |

| [39] | Overview and analysis of current BIPV products: new criteria for supporting the technological transfer in the building sector | Possibilities, market options, aesthetic levels; an architectural layering process design approach |

| [43] | PV glazing technologies | - |

| [36] | Building Integrated Photovoltaics: a Concise. Description of the Current State of the Art and Possible Research Pathways | Brief mention |

| [37] | Building Integrated Photovoltaics (BIPV): review, Potentials, Barriers and Myths | Brief mention of the need, possibilities and challenges |

| [38] | ‘State-of-the-art’ of building integrated photovoltaic products | Details on available custom products in the market |

| [44] | Building integrated photovoltaic products: a state-of-the-art review and future research opportunities | Possibilities and available custom products in the market |

| [45] | The path to the building integrated photovoltaics of tomorrow | Brief mention of possible future in product variety |

| [46] | Whole systems appraisal of a UK Building Integrated Photovoltaic (BIPV) system: energy, environmental, and economic evaluations | - |

| [47] | Photovoltaics and zero energy buildings: a new opportunity and challenge for design | - |

| [48] | Architectural Quality and Photovoltaic Products | Mention of examples, function and challenges |

| BIPV Façade Type | Design Impact |

|---|---|

| 1. Curtain Wall/Cladding Systems | • Advantages

|

| Solar panels integrated as a conventional cladding system for curtain walls and single layer façades [37]. | |

| |

| a. | |

| 2. Solar Glazing and Windows | • Advantages

|

| Applied as semi-transparent/translucent parts of the façade based on solar cell transparency. They can be integrated into windows, glazing panels, for view or daylighting [59]. | |

| |

| b. | |

| 3. External Devices/Accessories | • Advantages

|

| Sunshades and sunscreens, spandrels, balconies parapets, elements of visual and acoustic shielding [61]. | |

| |

| c. | |

| 4. Advanced/Innovative Envelope Systems | • Advantages

|

| Such as double skin façades, active skins, rotating or moving façade parts, etc. [59] | |

| |

| d. |

| Barriers | Drivers |

|---|---|

| 1. Product efficiency and design | 1. Research & Development on product design and design tools |

| 2. Product and project demonstration and databases [24,25,26] | 2. Educational programs and public awareness projects |

| 3. Education | |

| 4. Economy | 3. Active governmental interventions |

| 5. Gap between PV and building industry [29,30,32] | 4. International professional management and collaborations |

| 6. Management & business and project planning [24,28,29,32] |

| Reference | Country of Study (BIPV Location on Façade) | Deductions from Experimental Investigations | Research Results | ||||

|---|---|---|---|---|---|---|---|

| Objective | Custom Category/Class of Study | Customization Level Investigated | Strategy (Description) | Architectural Potential | |||

| [51] | Taiwan (Wall) | Development and analysis of a full-colour PV module | Product/Design and fabrication | Elemental (Full-colour and monochromatic coloration of module parts) | Modification of conventional features (MCF) (Color image on backsheetglass with applied grayscale mask) | Energy generation; Aesthetics | Short Current density: 0–14% reduction Cell efficiency : drop to max of 10% Power: 14.2% reduction |

| [53] | Switzerland (External Device) | Design, fabrication and testing of an adaptive solar façade | Product & Integration/Design and fabrication; Performance Optimisation; Architectural Integration | Compositional @Façade-level (dynamic façade patterns and flexible tilt angle) | Enhanced design modularization (EDM) (Highly modular dynamic BIPV façade with a suitable support structure, tracking and control systems) | Energy generation; Thermal Control; Energy saving; Aesthetics | Power: 36% increase Total energy savings: 31% increase Energy consumption: 8.9% decrease CO2 offset: 15.3 kg CO2-eq per year based on the European Union grid mix. |

| [80] | Austria (Glazing) | Plasmonic coloring on c-Si PV modules | Product/Design and fabrication | Elemental (Cell coloration) | MCF; (Silver film deposition on c-Si modules with Ag thermal annealing.) | Energy generation; Aesthetics | Short circuit current: average of 10.7% reduction Open circuit voltage: average of 1.1% increase Fill factor: average of 3.07% increase Maximum Power/Efficiency: average of 8.3% reduction |

| [81] | South Korea (External Shading) | Application of layering effects to a BIPV façade | Product/Design and fabrication; Architectural Integration | Compositional @Module-level (Coloration of backsheet and Cell arrangement) | EDM (Layered effects to BIPV module: unique architectural finishing of glass sheets, coloration of backsheet with patterned cell arrangement.) | Energy generation; Daylighting; Aesthetics | Architectural layering and modularization approach enabled application and adaptation of the described effects specifically developed to meet unique requests from clients; No performance data was available. |

| Modular retrofitting of a BIPV façade | Integration/Architectural Integration | Compositional @façade-level (tilt angle) | EDM (Modular retrofit and prototyping based on design of conventional façades) | Energy generation; Daylighting; Aesthetics | |||

| [63] | Switzerland (Cladding) | Retrofitting of a prototype residential block with BIPV | Integration/Architectural Integration | Elemental (Cell transparency); Compositional @Façade-level (Module position) | EDM (adaptation of BIPV typologies to blend with convemtional facade prototypes) | Energy generation; Thermal control; Daylighting; Retrofitting; Aesthetics | No extra complexity recorded in application of the method and façade construction. Qualitative assessment of interviewed professional adjudge that aesthetical aspects as positive . |

| [82] | Korea (Window) | Colored a-Si:H transparent solar cells employing ultrathin transparent multi-layered electrodes. | Product/Performance and Optimization; Architectural Integration | Elemental (Electrode and Backsheet transparency, Colour variability) | EDM; systematic parametric variation (SPV); MCF (Transparent multi-layered electrodes (TMEs) with customizable coloration of optoelectronic controlling layer (OCL) | Energy generation; Aesthetics; Daylighting | Cell Efficiency: average of 6.36% at 23.5% average transmittance with TME @500–800 nm Ave Open circuit voltage: 0.8 V Ave Fill factor: 54.66% |

| [83] | China (Window & Double Skin Façade) | Comparison of energy performance between PV double skin façades and PV insulating glass units | Product/Design and fabrication; Performance and Optimization; Architectural Integration | Compositional @Module-level (Module Position, Air gap) | MCF; SPV; (Regulation of air gap) | Energy generation; Thermal control; Daylighting; Energy saving; Aesthetics | Ave. SHGCs: 0.152 (PV-DSF) and 0.238 (PV-IGU) Ave. U-value: 2.535 W/m2K (PV-DSF)and 2.281 W/m2K (PV-IGU) Conversion efficiency of PV-DSF is 1.8% better than PV-IGU Approx. power output: 0.01–0.3 kWh (PV-DSF); 0.01–0.32 kWh (PV-IGU) Energy Saving potential: 28.4% (PV-DSF) and 30% (PV-IGU) |

| [84] | China (Double Skin Façade) | Overall energy performance of an a-si based photovoltaic double-skin façade | Integration/Design and fabrication; Performance and optimization; Architectural Integration; | Compositional @Façade-level (Ventilation mode) | MCF; SPV; (Change in ventilated modes for PV-DSF) | Energy generation; Thermal control | Ave SHGC: 0.14 (Non-Ventilated), 0.15 (Naturally-Ventilated), 0.125 (Ventilated) U-value: 3.3 (Non-Ventilated), 3.7 (Naturally-Ventilated), 4.65 (Ventilated) |

| [85] | Switzerland (Window & Wall) | Performance investigation of selected BIPV façade types. | Product & Integration/Design and fabrication; Performance and optimization; Architectural Integration | Elemental (Cell technology, cell transparency); Compositional @Module-level & Façade-level (Module Position, Air gap, Tilt angle) | SPV; Variation of BIPV module position and ventilation mode | Energy generation Thermal control Daylighting Shading Aesthetics | Approx. power output: 3–11 kWh (c-Si @30°); 2.5–8 kWh (c-Si @90°); 0.6–2.1 kWh (a-Si @30°); 0.5–1.45 kWh (a-Si @90°); 0.8–2 kWh (a-Si @90°-ventilated) |

| [86] | China (Window) | Assessment of energy performance of semi-transparent PV insulating glass units | Product & Integration/Design and fabrication; Performance and optimization; Architectural Integration | Elemental (Backsheet); Compositional @Façade-level (Air gap) | MCF; SPV; (Variation of air gap and backsheet material) | Energy generation; Thermal control; Daylighting; Energy saving | Ave. PV temp: 23–42 °C Ave. Daylight illuminance: 0–360 lux Ave. Heat gain: −12.5–165 W/m2 Power output @ air gap: 67.41 kWh @3 mm; 67.35 kWh @6 mm; 67.32 kWh @9 mm; 67.3 kWh @12 mm; 67.29 kWh @15 mm Power output @backsheet type: 67.32 kWh (Clear glass); 66.84 kWh (Low-e glass); 67.4 kWh (Low iron glass): 67.2 kWh (Tinted glass) |

| [87] | USA (Window) | Energy benefits from semi-transparent BIPV window and daylight-dimming systems | Product & Integration/Performance and Optimization; Architectural Integration | Elemental (Cell transparency and efficiency); Compositional @Façade-level (Orientation and WWR) | MCF; SPV; (Use of a DOE-2 based calculation algorithm simulations of parameterised vaules) | Energy generation; Thermal control; Daylighting; Shading; Energy savings | Power output range on south façade/month: 35.1–71.9 kWh @6.65 efficiency, 40% transparency, 48 W 46.4–95.4 kWh @8.82 efficiency, 20% transparency, 64 W 52.4–107.2 kWh @9.91 efficiency, 10% transparency, 72 W Approx. Annual Power output @WWR: 1165 kWh @10%; 3496 kWh @30%; 8157 @70% |

| [88] | Canada (Double Skin Façade) | Patterns of façade system design for enhanced energy performance | Product & Integration/Performance and Optimization; Architectural Integration | Compositional @Module-level (Module placement/arrangement) | MCF; SPV; EDM (Manipulation of planar geometry to induce increase in solar capture) | Energy generation; Thermal control; Aesthetics | Comparison with base case: Power Output: 20–80% increase Heating load: about 200% increase (worst case) Cooling load: about 52% reduction (best case) Peak electricity: peak spread of 4–5 h. |

| [55] | Pakistan (Wall) | Energy and Cost Saving of a Photovoltaic-Phase Change Material (PV-PCM) System | Product/Design and fabrication; Performance and Optimization; Cost | Elemental (Phase-change materials); Compositional @Module-level (Module design) | SPV;CHM; EDM (Passive cooling of BIPV with solid-liquid PCMs) | Energy generation; Thermal control | Temperature drop: 16% (PV PCM-1); 32.5% (PV PCM-2) Ave energy efficiency increase: 7% (PV PCM-1); 10% (PV PCM-2) |

| [89] | China (Wall) | Analysis and monitoring results of a BIPV façade using PV ceramic tiles | Product/Design and fabrication; Performance and Optimization; Architectural Integration | Compositional @Module-level (Module Position/Module Arrangement) | MCF(Replacement of module backsheet with ceramic tile) | Energy generation; Thermal control; Aesthetics | Ave. power output: 15–72 kWh (east); 15–65 kWh (West); 1–72 kWh (south); 0–18 kWh (North) |

| [90] | UAE (Double Skin Façade) | Performance and energetic improvements due to installation of semi-transparent PV cells | Product & Integration/Design and fabrication; Performance and Optimization; Architectural Integration | Compositional @Module-level & Façade-level (Number of glass layers, Ventilation mode) | MCF; SPV; (Application of alternate ventilation modes and number of glass layers) | Energy generation; Cladding | Sensible cooling energy need reduction: 1.5% (DSF forced vs. natural), 1.9% (Single Layer forced vs. natural) Peak power drop: 4% (DSF forced vs. natural), 2.3% (Single Layer forced vs. natural) Annual energy production increased by 2.5 (DSF) 6% (Single Layer) |

| [17] | USA (Ventilated Double Skin Façade) | Numerical investigation of the energy saving potential of a semi-transparent photovoltaic double-skin façade | Product & Integration/Performance and Optimization; Architectural Integration | Compositional @Façade-level (Air gap, Orientation) | MCF; SPV; EDM (Application of alternate air gaps and orientation in office room prototype room) | Energy generation; Thermal control; Daylighting; Shading | Approx. ave. electricity use: 300 kWh (100 mm); 310 kWh (200 mm); 285 kWh (400 mm); 270 kWh (600 mm) With 400 mm: Max power output range on south façade/month: 10.3 kWh (June)–20 kWh (November) Approx. Annual Energy output: 48 kWh/m2 (East), 64 kWh/m2 (South), 54 kWh/m2 (West) Approx. cooling need: 18–270 MJ Approx. heating need: 0–35 MJ Ave. daylighting illuminance/month: 130–300 lux Observed 50% less net electricity that conventional glazing systems |

| [91] | Slovakia (Ventilated PV Façade) | Thermal Performance of a Ventilated PV Façade Coupled with PCM | Product & Integration/Design, Performance and Optimization; Architectural Integration | Compositional @Module-level (Module design—addition of PCM) | CMH; SPV (Hybridisation of BIPV with PCM layer) | Thermal control | PV temp decrease: up to 20 °C Peak temp. shift: more than 5 h |

| [92] | France (Ventilated PV Façade) | Experimental evaluation of a naturally ventilated PV double-skin building envelope in real operating conditions | Product & Integration/Design and fabrication; Performance and Optimization; Architectural Integration | Compositional @Module-level (Module arrangement) | MCF; SPV (Utilising the stack effect to cool a prototype pleated PV double façade) | Energy generation; Thermal control; Daylighting; Shading; Aesthetics | Approx. Peak power output per plane: 165 kW (Bloc1); 200 kW (Bloc2); 210 kW (Bloc3) Prismatic configuration was chosen to compensate for façade azimuth—overshadowing in part; improvement in electrical performance by a more favorable orientation of solar cells |

| [93] | UAE (Window Blinds) | Energy, Cooling and Cost analysis of BIPV blind system | Product & Integration/Design and fabrication; Performance and Optimization; Architectural Integration; Cost | Elemental (cell technology); Compositional (Module position) | EDM; SPV (Prototyping based on conventional façade design component) | Energy generation; Thermal control; Cost issues | Ave. power output: 41.55 kWh/m2 (c-Si); 43.22 kWh/m2 (a-Si) Cooling load Energy Saved: 7.11 kWh/m2 (c-Si); 6.89 kWh/m2 (a-Si) |

| [64] | China (PV-Blinds in Double Skin Façade) | Comparative study on thermal performance evaluation of a new double skin façade system integrated with photovoltaic blinds | Product & Integration/Design and fabrication; Performance and Optimization; Architectural Integration | Compositional @Module-level (Module Position/Tilt angle) | SPV (Experimentation on different system ventilation modes and blind parameters) | Energy generation; Thermal control; Daylighting | Approx. SGHC peak (@4.5 cm spacing): 0.75 (30°); 0.95 (45°); 0.97 (60°); (based on ventilation mode): 0.499 (Mechanical); 0.531 (Natural) About 12.16% and 25.57% compared with reference DSF cases |

| [94] | China (Ventilated Double Skin Façade) | Thermal performance of a photovoltaic wall mounted on a multi-layer façade | Integration/Performance and Optimization; Architectural Integration | Compositional @Facade-level (ventilation mode) | SPV (Mathematical modelling and variation of ventilation modes) | Energy generation; Thermal control | Ave SHGC: 0.14 (Non-Ventilated), 0.15 (Naturally-Ventilated), 0.125 (Ventilated) U-value: 3.3 (Non-Ventilated), 3.7 (Naturally-Ventilated), 4.65 (Ventilated) |

| [52] | (Glazing) | Aesthetic improvement of PV for Building integration Encapsulants | Product/Design and fabrication; Architectural Integration | Elemental (Encapsulant material) | MCF (Coloration of encapsulant material using florescence dyes) | Energy generation; Aesthetics | Power output increase: 2.0% (Clear Sylgard 184); 2.5% (Red 100 ppm Lumogen dye in Sylgard 184) |

| [95] | Italy (Glassblocks) | Evaluation of prototype BIPV optical performance | Product/Design and Fabrication; Performance optimization | Compositional @Module-level (position of solar cells) | CMH; EDM (Prototyping based on conventional façade design component) | Energy generation; Aesthetics; Daylighting; Thermal Control | Power output reductions: 19.67% (DSSC Part of Surface); 6.01% (All of Surface); 54.09% (Interior of Surface); 69.94% (Middle of Block) |

| [96] | Netherlands (Wall) | Aesthetics preservation BIPV façade using Zigzag geometry | Product/Design and Fabrication; Architectural integration | Elemental (colour of reflector layer); Compositional @Facade-level (tilt angle) | EDM; MCF; SPV (Concealment of PV via zigzag geometry to enhance solar capture) | Energy generation; Aesthetics | Monthly Power output: 28.6 kWh (Grey), 30.7 kWh (White) Performance ratio increase (ref. vertical panels): 43.75% (Grey), 53.75% (White) |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Attoye, D.E.; Tabet Aoul, K.A.; Hassan, A. A Review on Building Integrated Photovoltaic Façade Customization Potentials. Sustainability 2017, 9, 2287. https://doi.org/10.3390/su9122287

Attoye DE, Tabet Aoul KA, Hassan A. A Review on Building Integrated Photovoltaic Façade Customization Potentials. Sustainability. 2017; 9(12):2287. https://doi.org/10.3390/su9122287

Chicago/Turabian StyleAttoye, Daniel Efurosibina, Kheira Anissa Tabet Aoul, and Ahmed Hassan. 2017. "A Review on Building Integrated Photovoltaic Façade Customization Potentials" Sustainability 9, no. 12: 2287. https://doi.org/10.3390/su9122287

APA StyleAttoye, D. E., Tabet Aoul, K. A., & Hassan, A. (2017). A Review on Building Integrated Photovoltaic Façade Customization Potentials. Sustainability, 9(12), 2287. https://doi.org/10.3390/su9122287