Reducing Impact of Negative Complexity on Sustainability of Mass Customization

Abstract

1. Introduction

2. Literature Review

2.1. Studies on Determining Extent of Product Platform

2.2. Studies on the Relation between Variety Induced Complexity and Customer Perception

2.3. Studies on the Relationship between MC and Sustainability

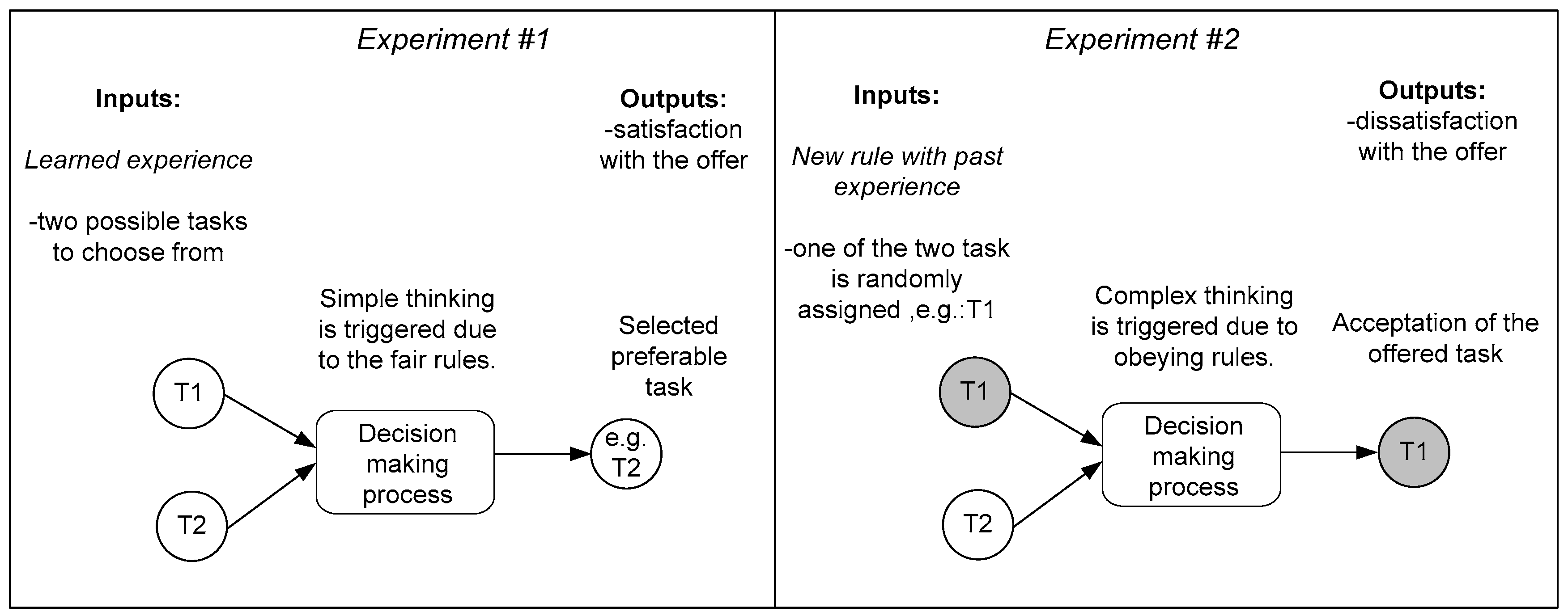

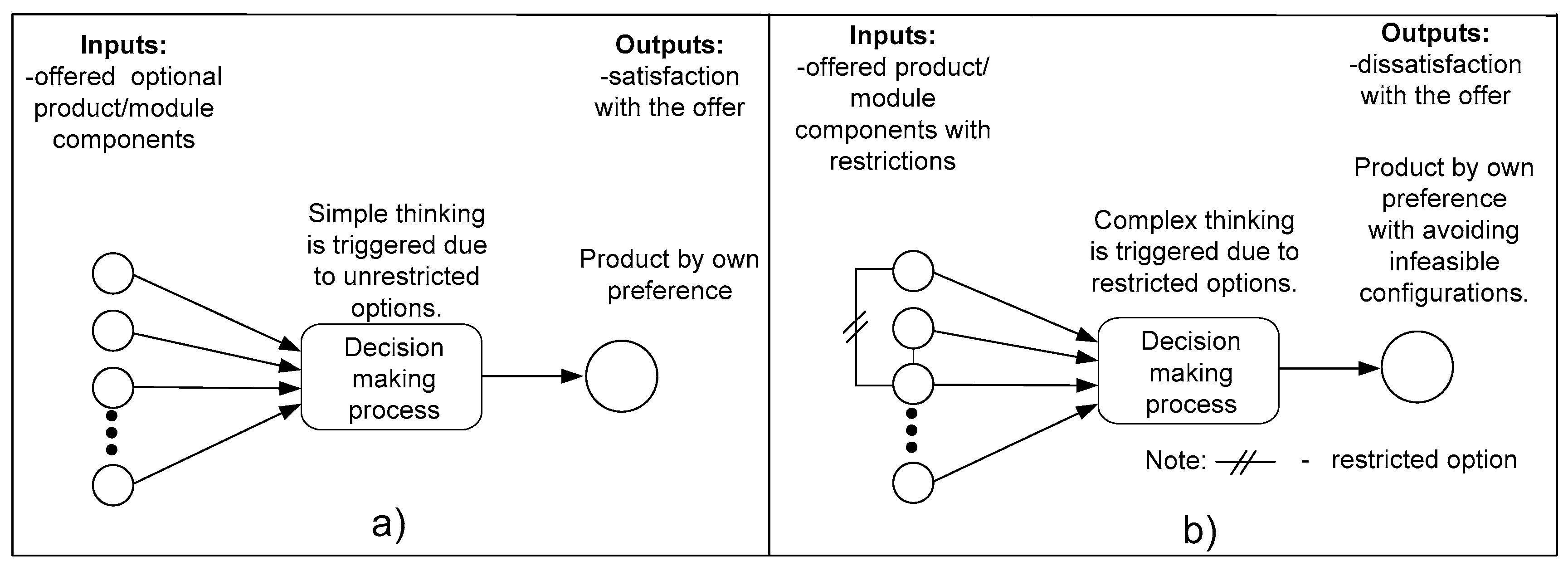

3. Customer Dissatisfaction Due to Infeasible Product Combinations

- (a)

- (b)

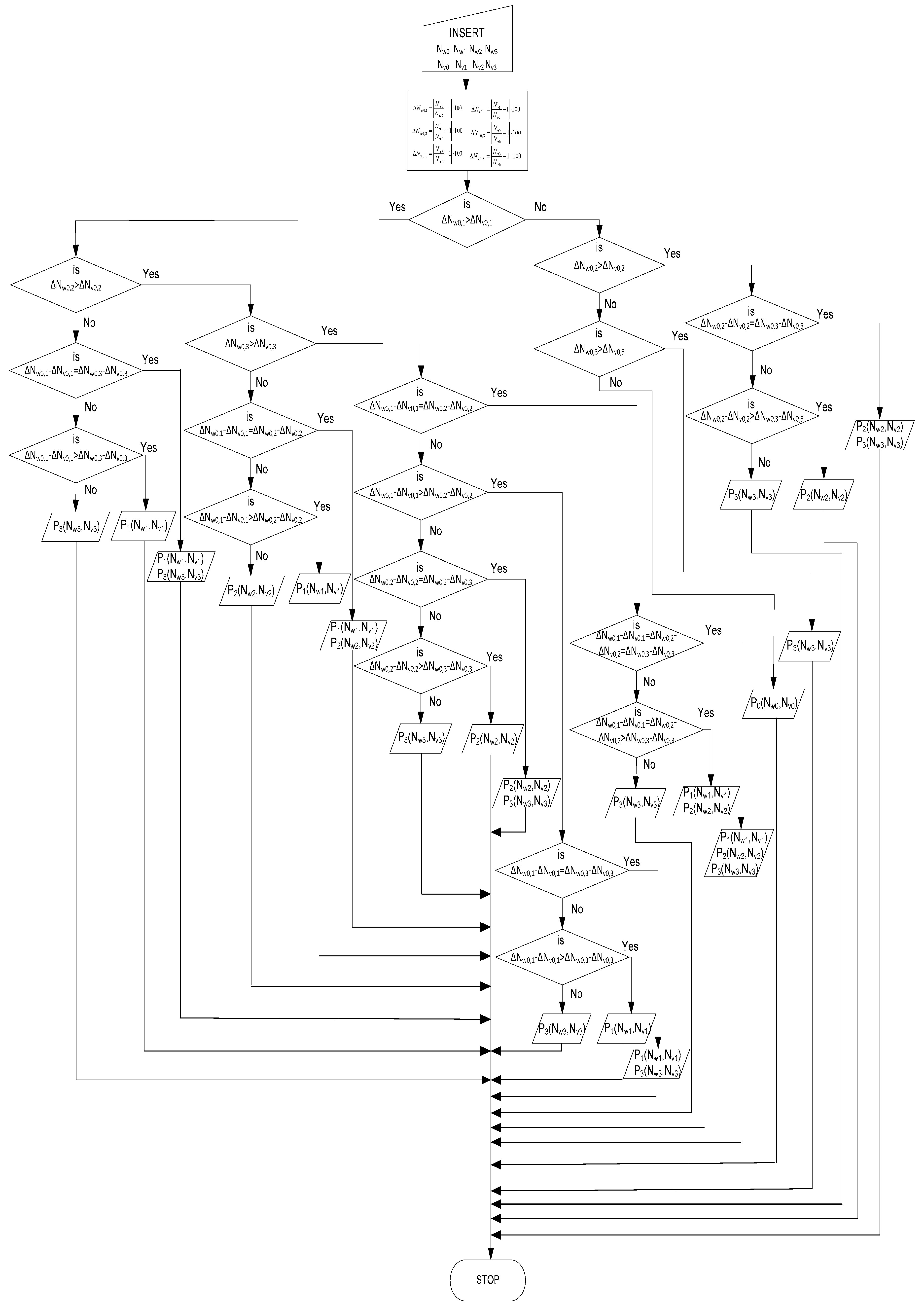

4. Proposed Algorithm for Selection of Optimized Product Platform

- I.

- If ∆Nw0,1 > ∆Nv0,1, then product platform P1 is more suitable than P0.

- II.

- If ∆Nw0,2 > ∆Nv0,2, then product platform P2 is more suitable than P0.

- III.

- If ∆Nw0,1 − ∆Nv0,1 > ∆Nw0,2 − ∆Nv0,2, then product platform P1 is more suitable than P2.

- IV.

- If ∆Nw0,1 − ∆Nv0,1 < ∆Nw0,2 − ∆Nv0,2, then product platform P2 is more suitable than P1.

- V.

- If ∆Nw0,1 − ∆Nv0,1 = ∆Nw0,2 − ∆Nv0,2, then both product platforms P1, and P2 are equally preferable for buyers.

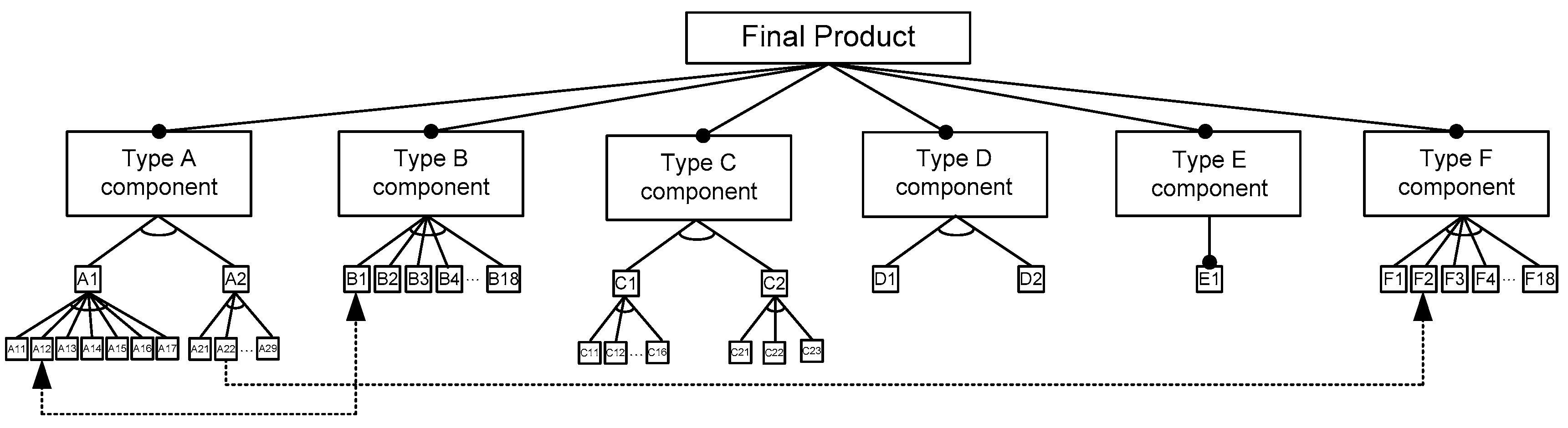

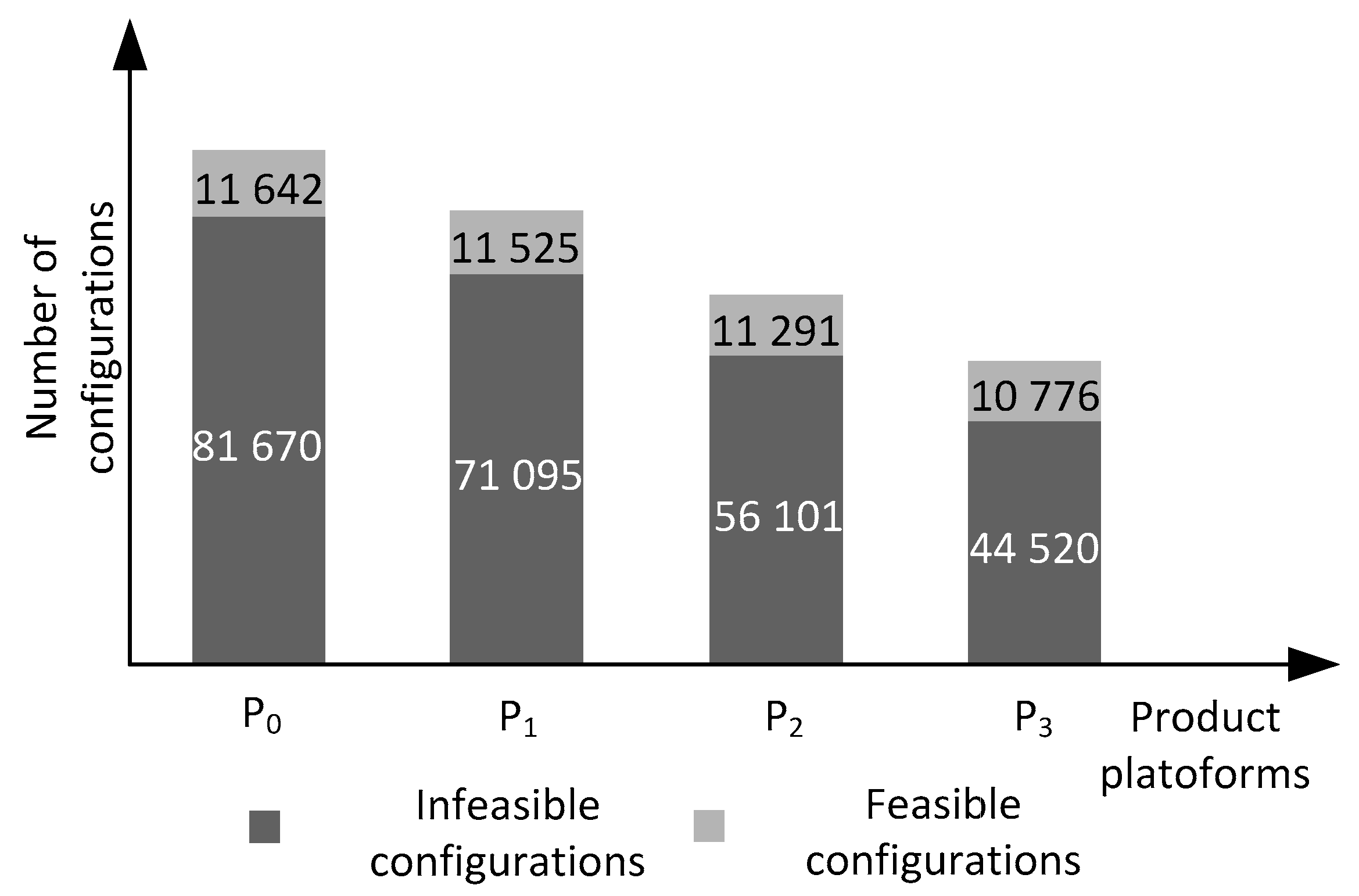

5. Testing of the Proposed Method

6. Discussion and Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

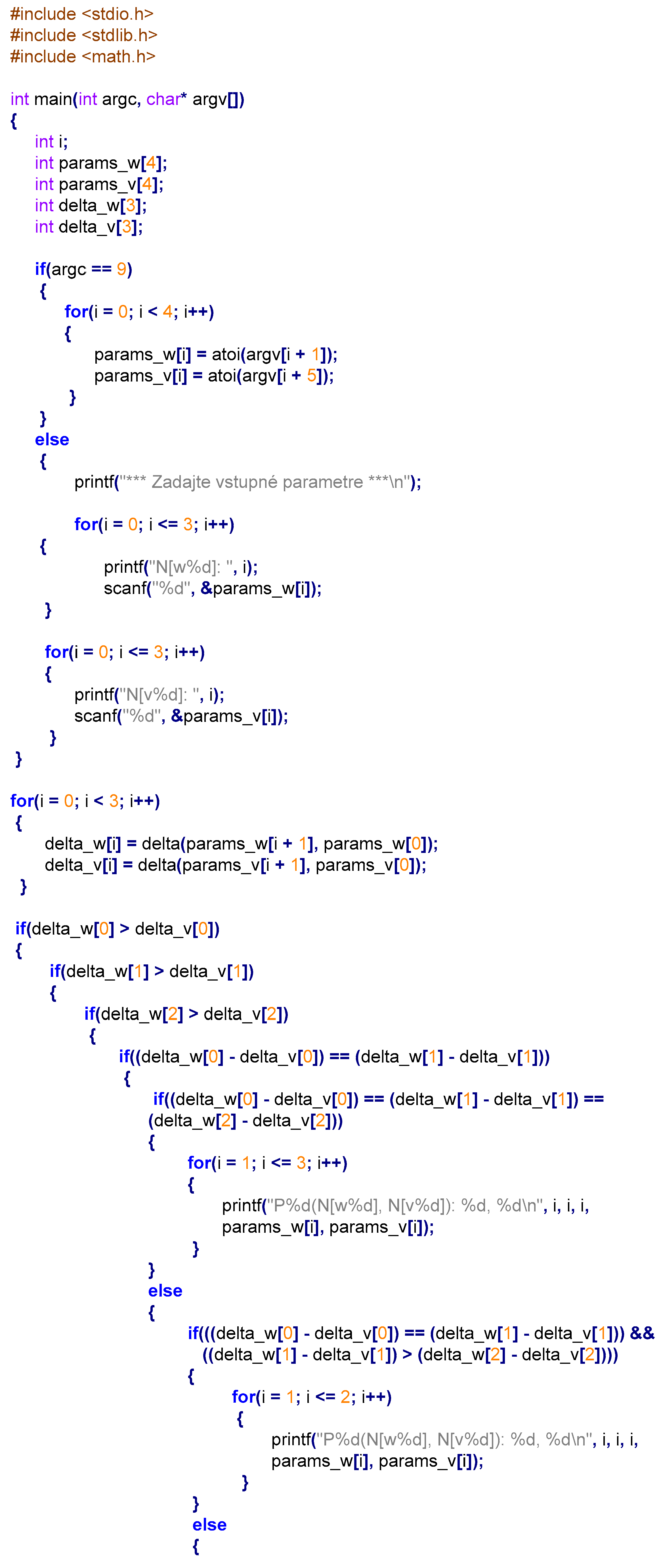

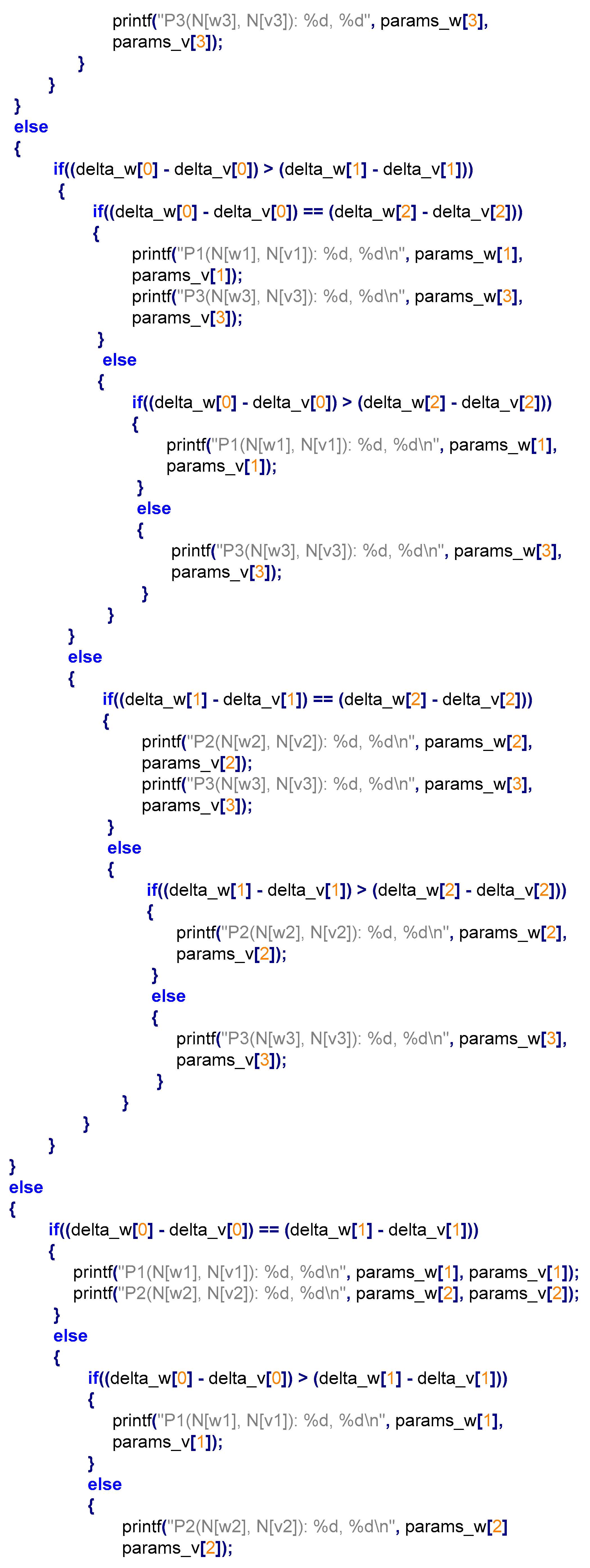

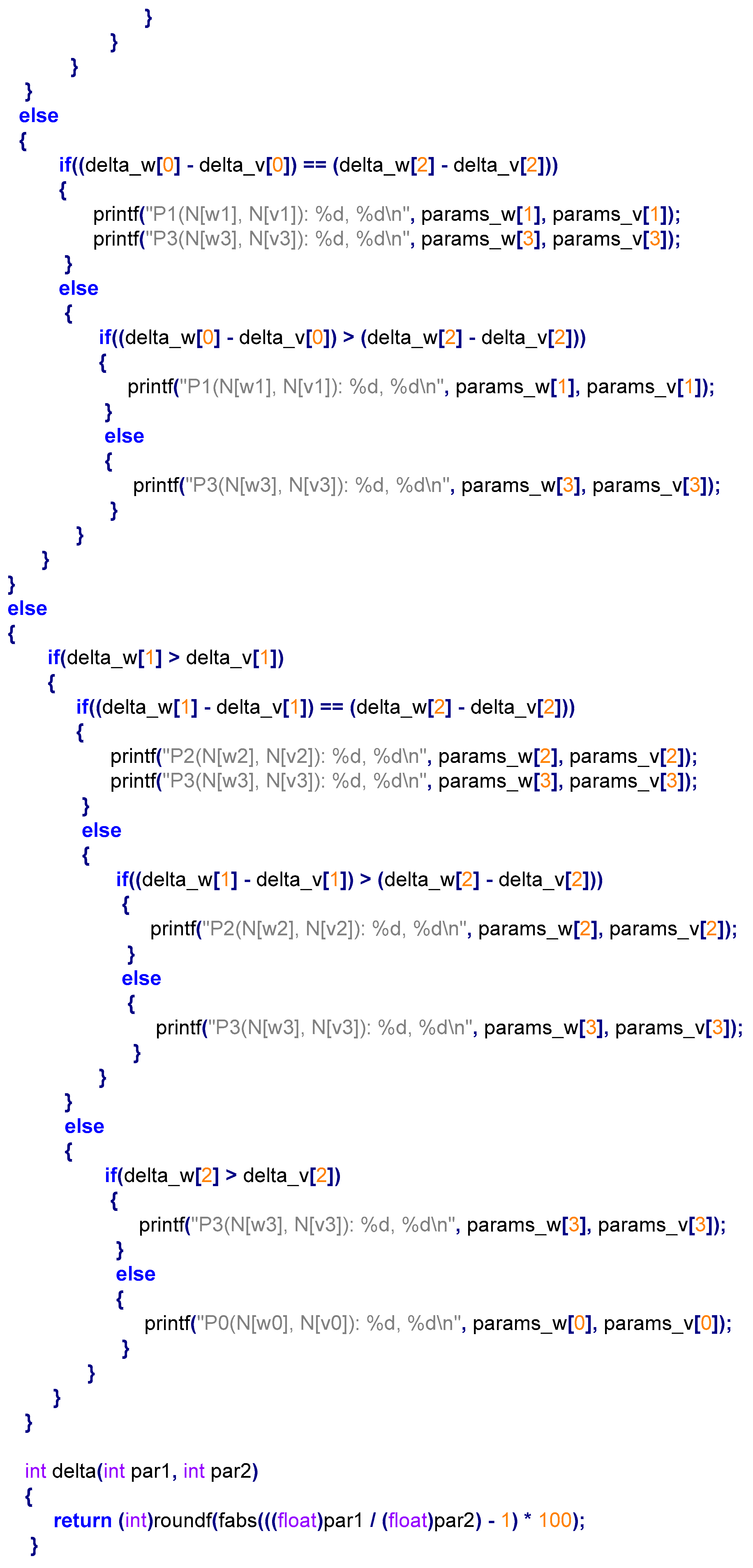

Appendix A

References

- Davis, S.M. Future perfect. In Human Resource Management in International Firms; Palgrave Macmillan: Basingstoke, UK, 1990; pp. 18–28. [Google Scholar]

- Tseng, M.M.; Jiao, J.; Merchant, M.E. Design for mass customization. CIRP Ann. Manuf. Technol. 1996, 45, 153–156. [Google Scholar] [CrossRef]

- ElMaraghy, H. (Ed.) Enabling Manufacturing Competitiveness and Economic Sustainability. In Proceedings of the 4th International Conference on Changeable, Agile, Reconfigurable and Virtual Production, Montreal, QC, Canada, 2–5 October 2011; Springer: New York, NY, USA, 2011. [Google Scholar]

- De Weck, O.L.; (Massachusetts Institute of Technology, Cambridge, MA, USA); Suh, E.S.; (Massachusetts Institute of Technology, Cambridge, MA, USA); Chang, D.; (General Motors Research and Development, Warren, MI, USA). Product Family Strategy and Platform Design Optimization. Working Paper. 2004. Available online: http://web.mit.edu/deweck/www/PDF_archive/2%20Refereed%20Journal/2_14_JIM_portfolio_optimization_v1.pdf (accessed on 21 August 2014).

- Crippa, R.; Bertacci, N.; Larghi, L. Representing and Measurement Manufacturing Flow Complexity in the Extended enterprise: The D4G Approach. In Proceedings of the 6th International Congress of Logistics Research RIRL, Pontremoli, Italy, 3–6 September 2006; pp. 231–242. [Google Scholar]

- Götzfried, M. Managing Complexity Induced by Product Variety in Manufacturing Companies: Complexity Evaluation and Integration in Decision-Making. Ph.D. Dissertation, University of St. Gallen, St. Gallen, Switzerland, 2013. Available online: https://www1.unisg.ch/www/edis.nsf/SysLkpByIdentifier/4148/$FILE/dis4148.pdf (accessed on 17 May 2013).

- Seepersad, C.C.; Hernandez, G.; Allen, J.K. A Quantitative Approach to Determining Product Platform Extent. In Proceedings of the ASME Advances in Design Automation Conference, Baltimore, MD, USA, 10–13 September 2000; Available online: https://www.researchgate.net/publication/245017801_A_Quantitative_Approach_to_Determining_Product_Platform_Extent (accessed on 19 May 2014).

- De Weck, O.L. Determining product platform extent. In Product Platform and Product Family Design; Simpson, T.W., Siddique, Z., Jiao, R.J., Eds.; Springer: New York, NY, USA, 2006; pp. 241–301. ISBN 978-0-387-29197-0. [Google Scholar]

- Michaelis, M.T.; Johannesson, H.; ElMaraghy, H.A. Function and process modeling for integrated product and manufacturing system platforms. J. Manuf. Syst. 2015, 36, 203–215. [Google Scholar] [CrossRef]

- Heradio, R.; Perez-Morago, H.; Alférez, M.; Fernandez-Amoros, D.; Alférez, G.H. Augmenting measure sensitivity to detect essential, dispensable and highly incompatible features in mass customization. Eur. J. Oper. Res. 2016, 248, 1066–1077. [Google Scholar] [CrossRef]

- Bonev, M.; Hvam, L.; Clarkson, J.; Maier, A. Formal computer-aided product family architecture design for mass customization. Comput. Ind. 2015, 74, 58–70. [Google Scholar] [CrossRef]

- Hu, S.J.; Zhu, X.; Wang, H.; Koren, Y. Product variety and manufacturing complexity in assembly systems and supply chains. CIRP Ann. Manuf. Technol. 2008, 57, 45–48. [Google Scholar] [CrossRef]

- Modrak, V. (Ed.) Mass Customized Manufacturing: Theoretical Concepts and Practical Approaches; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Rauch, E.; Dallasega, P.; Matt, D.T. Sustainable production in emerging markets through Distributed Manufacturing Systems (DMS). J. Clean. Prod. 2016, 135, 127–138. [Google Scholar] [CrossRef]

- Sonsino, D.; Benzion, U.; Mador, G. The complexity effects on choice with uncertainty–Experimental evidence. Econo J. 2002, 112, 936–965. [Google Scholar] [CrossRef]

- Rice, J. Will an ecosystem approach mitigate the factors of unsustainability? FAO Fish. Rep. 2005, 782, 191. [Google Scholar]

- Abdelkafi, N. Variety Induced Complexity in Mass Customization: Concepts and Management; Erich Schmidt Verlag GmbH & Co KG: Berlin, Germany, 2008. [Google Scholar]

- Huffman, C.; Kahn, B.E. Variety for sale: Mass customization or mass confusion? J. Retail. 1998, 74, 491–513. [Google Scholar] [CrossRef]

- Boër, C.R.; Dulio, S. Mass Customization and Footwear: Myth, Salvation or Reality? A Comprehensive Analysis of the Adoption of the Mass Customization Paradigm in Footwear, from the Perspective of the EUROShoE (Extended User Oriented Shoe Enterprise) Research Project; Springer: Berlin, Germany, 2007. [Google Scholar]

- Ulrich, K.T.; Eppinger, S.D. Product Design and Development; McGraw-Hill: New York, NY, USA, 2004. [Google Scholar]

- Pitiot, P.; Aldanondo, M.; Vareilles, E. Concurrent product configuration and process planning: Some optimization experimental results. Comput. Ind. 2014, 65, 610–621. [Google Scholar] [CrossRef]

- Helo, P.T.; Xu, Q.L.; Kyllönen, S.J.; Jiao, R.J. Integrated vehicle configuration system connecting the domains of mass customization. Comput. Ind. 2010, 61, 44–52. [Google Scholar] [CrossRef]

- Mailharro, D. A classification and constraint-based framework for configuration. Artif. Intell. Eng. Des. Anal. Manuf. 1998, 12, 383–397. [Google Scholar] [CrossRef]

- Aldanondo, M.; Vareilles, E.; Djefel, M. Towards an association of product configuration with production planning. Int. J. Mass Cust. 2010, 3, 316–332. [Google Scholar] [CrossRef]

- Quelch, J.A.; Jocz, K.E. Greater Good: How Good Marketing Makes for Better Democracy, 1st ed.; Harvard Business Review Press: Brighton, MA, US, 2008; p. 339. [Google Scholar]

- Orsvärn, K.; Axling, T. The Tacton view of configuration tasks and engines. In Workshop on Configuration, Proceedings of the Sixteenth National Conference on Artificial Intelligence (AAAI-99), Orlando, FL, USA, 18–22 July 1999. [Google Scholar]

- Fraizer, S.; Wells, R. System for Presenting Customer Constrained Purchase Choices in an On-Line Store. W.O. Patent 2001091019 A1 filed; 25 May 2001 and issued 29 November 2001,

- Hora, M.; Hankammer, S.; Canetta, L.; Sel, S.K.; Gomez, S.; Gahrens, S. Designing Business Models for Sustainable Mass Customization: A Framework Proposal. Int. J. Ind. Eng. Manag. 2016, 7, 143–152. [Google Scholar]

- Osorio, J.; Romero, D.; Betancur, M.; Molina, A. Design for Sustainable Mass-Customization: Design Guidelines for Sustainable Mass-Customized Products. In Proceedings of the 2014 International Conference on Engineering, Technology and Innovation (ICE), Bergamo, Italy, 23–25 June 2014; pp. 1–9. [Google Scholar]

- Spinney, L. Roots of brutality. New Sci. 2015, 228, 40–43. [Google Scholar] [CrossRef]

- Gromet, D.M.; Goodwin, G.P.; Goodman, R.A. Pleasure from another’s pain: The Influence of a Target’s Hedonic States on Attributions of Immorality and Evil. Personal. Soc. Psychol. Bull. 2016, 42, 1077–1091. [Google Scholar] [CrossRef] [PubMed]

- Fried, I. Syndrome, E. Lancet 1997, 350, 1845–1847. [Google Scholar] [CrossRef]

- Krus, P. Design Space Configuration for Minimizing Design Information Entropy. In ICoRD’15—Research into Design across Boundaries: Theory, Research Methodology, Aesthetics, Human Factors and Education; Springer: Berlin, Germany, 2015; Volume 1, pp. 51–60. ISBN 978-81-322-2231-6. [Google Scholar]

- Modrak, V.; Krus, P.; Bednar, S. Approaches to product variety management assuming configuration conflict problem. FME Trans. 2015, 43, 271–278. [Google Scholar] [CrossRef]

- Modrak, J. Product Platform Calculator. Available online: http://www.fvt.tuke.sk/download/algoritmus.html (accessed on 17 September 2017).

- Mercedes-Benz Configurator. Available online: https://toc.mercedes-benz.com/lkw_konfigurator_toc_uk1/toc.dll (accessed on 10 August 2017).

- Benavides, D.; Segura, S.; Ruiz-Cortés, A. Automated analysis of feature models 20 years later: A literature review. Inf. Syst. 2010, 35, 615–636. [Google Scholar] [CrossRef]

- Bontemps, Y.; Heymans, P.; Schobbens, P.Y.; Trigaux, J.C. Generic Semantics of Feature Diagrams Variants. FIW 2005, 51, 58–77. [Google Scholar]

- Yang, D.; Dong, M. A constraint satisfaction approach to resolving product configuration conflicts. Adv. Eng. Inf. 2012, 26, 592–602. [Google Scholar] [CrossRef]

- Software Product Lines Online Tools. Available online: www.splot-research.org (accessed on 5 July 2017).

| No. | Rule Description | |

|---|---|---|

| R#1 | Require Rules | Com A21 → ComF5, F6, F7, and F8 |

| R#2 | Com A22 → Com F2 | |

| R#3 | Com A23 → Com F1 | |

| R#4 | Com A24 → Com F3, F4, F5, and F8 | |

| R#5 | Com A25 → Com F3, F4, F5, and F8 | |

| R#6 | Com A26 → Com F5, F6, F7, and F8 | |

| R#7 | Com A27 → Com F1 | |

| R#8 | Com A28 → Com F3, F4, and F5 | |

| R#9 | Com A29 → Com F3, F4, and F5 |

| No. | Rule Description | No. | Rule Description | |

|---|---|---|---|---|

| R#1 | Incompatible Rules | ⌐ (Com A11˄ Com F1, F2, F3, F4, F5, F7, F9) | R#26 | ⌐ (Com A25 ˄ Com D1) |

| R#2 | ⌐ (Com A12 ˄ ComB1) | R#27 | ⌐ (Com A26 ˄ Com D1) | |

| R#3 | ⌐ (Com A12 ˄ Com F1, F2, F3, F4, F5, F6, F7, F9, F17, F18) | |||

| R#4 | ⌐ (Com A13 ˄Com B1, B8, B9, B18) | R#28 | ⌐ (Com A27 ˄ Com B1) | |

| R#5 | ⌐ (Com A13 ˄Com D1) | R#29 | ⌐ (Com A27 ˄ Com D1) | |

| R#6 | ⌐ (Com A13 ˄Com F1, F2, F4, F6, F8, F10, F11, F12, F13, F14, F15, F16, F17, F18) | R#30 | ⌐ (Com A28 ˄ Com B1) | |

| R#7 | ⌐ (Com A14 ˄ Com B1, B2, B10, B11, B12) | R#31 | ⌐ (Com A28 ˄ Com D1) | |

| R#8 | ⌐ (Com A14 ˄ Com D1) | R#32 | ⌐ (Com A29 ˄ Com B1) | |

| R#9 | ⌐ (Com A14 ˄ Com F1, F2, F3, F4, F5, F7, F9, F16, F17, F18) | R#33 | ⌐ (Com A29 ˄ Com D1) | |

| R#10 | ⌐ (Com A15 ˄ Com D1) | R#34 | ⌐ (Com B1 ˄ Com C2, C11, C12) | |

| R#11 | ⌐ (Com A15 ˄ Com F1, F2, F3, F4, F5, F8, F9) | R#35 | ⌐ (Com B1 ˄ Com F1, F2, F3, F4, F9) | |

| R#12 | ⌐ (Com A16 ˄ Com D1) | R#36 | ⌐ (Com B2 ˄ Com C2, C11, C12) | |

| R#13 | ⌐ (Com A16 ˄ Com B1) | R#37 | ⌐ (Com B5 ˄ Com C15, C16) | |

| R#14 | ⌐ (Com A16 ˄Com F1, F2, F3, F4, F5, F7, F9, F16, F17, F18) | R#38 | ⌐ (Com B6 ˄ Com C15, C16) | |

| R#15 | ⌐ (Com A17 ˄Com D1) | R#39 | ⌐ (Com B7 ˄ Com C15, C16) | |

| R#16 | ⌐ (Com A17 ˄ Com B1, B8, B9, B18) | R#40 | ⌐ (Com B8 ˄ Com C15, C16) | |

| R#17 | ⌐ (Com A17 ˄ Com F1, F2, F3, F4, F5, F6, F7, F9, F17, F18) | R#41 | ⌐ (Com B8 ˄ Com F9) | |

| R#18 | ⌐ (Com A21 ˄ Com D1) | R#42 | ⌐ (Com B9 ˄ Com C15, C16) | |

| R#19 | ⌐ (Com A22 ˄ Com B1) | R#43 | ⌐ (Com B9 ˄ Com F9) | |

| R#20 | ⌐ (Com A22 ˄ Com D1) | R#44 | ⌐ (Com B10 ˄ Com C2, C11, C12) | |

| R#21 | ⌐ (Com A23 ˄ Com B1) | R#45 | ⌐ (Com B11 ˄ Com C2, C11, C12) | |

| R#22 | ⌐ (Com A23 ˄ Com D1) | R#46 | ⌐ (Com B12 ˄ Com C2, C11, C12) | |

| R#23 | ⌐ (Com A24 ˄ Com B1) | R#47 | ⌐ (Com B16 ˄ Com C15, C16) | |

| R#24 | ⌐ (Com A24 ˄ Com D1) | R#48 | ⌐ (Com B17 ˄ Com C15, C16) | |

| R#25 | ⌐ (Com A25 ˄ Com B1, B2, B10, B11, B12) | R#49 | ⌐ (Com B18 ˄ Com C15, C16) | |

| R#50 | ⌐ (Com B18 ˄ Com F9) |

| Product Platform | ∆Nv0,i i = 1, 2, 3 | ∆Nw0,i i = 1, 2, 3 |

|---|---|---|

| P0 | - | - |

| P1 | 1 | 13 |

| P2 | 3 | 31 |

| P3 | 7 | 46 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Modrak, V.; Soltysova, Z.; Modrak, J.; Behunova, A. Reducing Impact of Negative Complexity on Sustainability of Mass Customization. Sustainability 2017, 9, 2014. https://doi.org/10.3390/su9112014

Modrak V, Soltysova Z, Modrak J, Behunova A. Reducing Impact of Negative Complexity on Sustainability of Mass Customization. Sustainability. 2017; 9(11):2014. https://doi.org/10.3390/su9112014

Chicago/Turabian StyleModrak, Vladimir, Zuzana Soltysova, Jan Modrak, and Annamaria Behunova. 2017. "Reducing Impact of Negative Complexity on Sustainability of Mass Customization" Sustainability 9, no. 11: 2014. https://doi.org/10.3390/su9112014

APA StyleModrak, V., Soltysova, Z., Modrak, J., & Behunova, A. (2017). Reducing Impact of Negative Complexity on Sustainability of Mass Customization. Sustainability, 9(11), 2014. https://doi.org/10.3390/su9112014