1. Introduction

Information and communications technology (ICT) solutions have an impact on the quality and safety of any product and they are necessary to optimize the information flow between farmers and stakeholders, and to improve traceability in the food supply chain.

Tracing food and feed throughout the food chain is very important for the protection of consumers, particularly when food and feed are found to be faulty.

The current food labeling system cannot guarantee food quality and safety. A good traceability system is a useful tool to overcome this problem, thereby minimizing the potential of bad publicity, and enhancing consumer confidence.

Today’s consumer is increasingly sensitive and aware of the many issues related to food safety and quality. In recent years, many events related to food and public health, such as bovine spongiform encephalopathy (BSE), dioxin, bird flu, and swine flu, brought the issue of food security to the center of international attention. The consumer asks for food quality, according to a concept that goes beyond the hygienic and organoleptic prerequisite, requiring specific origin guarantees of finished products and transparency concerning the raw materials that compose them. Traceability is the ability to maintain the identification of products, all along the production chain. It represents an essential tool to safeguard public health and to valorize typical production systems [

1].

The main requirements of a traceability system for food products are summarized in

Table 1. The ICT is already able to give a possible solution to many of the requirements, and some solutions have already been applied in real cases, as it will be shown in the next section.

The implementation of the complete and integrated information system is too expensive for a small medium enterprise (SME) [

2]. The use of the NFC technology allows a low cost information system accessible to SME.

The consumer is increasingly interested in quality, environmental impact and sustainability of food production. He is looking for certified quality, and ethical products with respect to the environment and law. For example, the percentage of consumers in the Italian market who use typical regional products (DOP—Protected Designation of Origin or IGP—Protected Geographical Indication) is 46%, organic products is 40%, ethical products is 31%, and products for particular food requirements (gluten free, OGM free, etc.) is 25% [

3]. Seventy percent of Italian consumers are declared to be in favor of products that improve sustainability, are recyclable and reduce environmental impact (energy, soil, etc.) [

3].

The consumer is now using web and smartphone apps to choose the products to buy. For example, 50% of Italians read comments on products on social networks and blogs to decide if and what to buy, while 44% use advanced tools such as apps on smartphones to receive information on promotions and offers [

3].

The use of NFC technology in the complete chain up to the consumer, as proposed in this paper, has never been proposed and applied in the food chain. In addition to low cost, another advantage is the involvement of the final consumer.

The paper is organized as follows. In

Section 2, the state of the art on food traceability is reported. The EU and international legislation point of view is reported in

Section 2.1, a short description of the standard used for data exchange is outlined in

Section 2.2, and RFID, QRcode and NFC technologies are described in

Section 2.3,

Section 2.4 and

Section 2.5.

The proposed methodology for food traceability using NFC is reported in

Section 3.

Section 4 and

Section 5 report the system architecture and implementation on a real test case.

2. State of the Art of ICT for Food Traceability

2.1. Legislation for Food Traceability

Traceability is generally imposed by international and national control organizations for all types of foods. In recent years, all countries have updated their regulations on food traceability and labeling.

The guidance document [

4] on the best practices in food traceability presents an overview of the international regulations. It presents a best practice guidance for food traceability applied to different food sectors such as bakery, dairy, meat and poultry, processed foods and seafood.

In January 2011, the US government published the FDA Food Safety Modernization Act (111th Congress Public Law 353 [

5]) with the aim of improving capacity to prevent and detect food safety problems.

In December 2014, the Chinese National People’s Congress published the Second Draft of its Food Safety Law [

6].

In Japan, the legislation, reported in [

7], allows the consumer to access the information on the source of the beef and the methods used to rear the animal.

The European General Food Law Regulation (EC 178/2002) [

8] lays down the general principles and requirements of food law, establishes the European Food Safety Authority and lays down procedures in matters of food safety. EC 178/2002 came into effect in January 2005 to ensure:

- (1)

Security, meaning the ability to handle any problems or medical emergencies;

- (2)

Consumer confidence; and

- (3)

Control by the public authorities.

In particular, article 18 of EC 178/2002 defines scope and implementation of food traceability. It defines traceability as the ability to trace and follow food, feed and ingredients through all stages of production, processing and distribution.

As indicated in the EC 178/2002, traceability:

- (1)

facilitates withdrawal of faulty food and feed from the market;

- (2)

provides consumers with targeted and accurate information on specific products;

- (3)

covers all food and feed, all food and feed business operators; and

- (4)

affects importers who are required to be able to identify from whom the product was exported in the country of origin.

In January 2010, the EU Standing Committee on the Food Chain and Animal Health approved the new version of the guidance document [

9].

In December 2014, the EU’s new “Food Information to Consumers (FIC)” regulation 1169/2011 [

10], which defines the food labeling requirements, became applicable to all pre-packaged food and drink products marketed in the EU, including those imported from outside countries. The mandatory nutrition declaration requirement, introduced by the new FIC regulation, has been applied in December 2016.

2.2. Standards for Data Exchange

A relevant aspect for the exchange of information needed for food traceability is the data exchange protocol [

11].

Data exchange protocols involve EDI (Electronic Data Interchange) and are standards for the exchange of data on product movement.

An appropriate standard that can be used for food traceability is the Electronic Product Code (EPC) standard [

12], complementary to EDI. EPCs are worldwide standards managed by the GS1 organization. The major advantage of the adoption of EPCs is that they are pervasive within manufacturing and supply industries.

Agro-XML [

13] is a language for data structuring, based on XML. It employs a data model that covers processes in agricultural production with a view on farm management information systems. Data elements in agro-XML are defined using the XML scheme.

ISOagriNET [

14] is a data exchange standard for livestock farming.

Among the automatic identification systems of objects that can be used to food traceability, the most popular are: OCR, Barcode, RFID, QRcode (Quick Response Code), and NFC.

2.3. RFID for Food Traceability

RFID technology (Radio Frequency Identification) is a radio technology for the identification and or data storage [

15,

16].

There are many applications of RFID; a recent example is localization and tracking [

17].

Since the 2000s, RFID technology has been applied in the food chain process with high costs and high complexity allowing the adoption only for big companies.

Compared with the popular bar code, RFID technology has many advantages that can help enterprises to speed up the exchange of information and to save on production and distribution costs.

Different subjects in the supply chain are involved in the tracking and tracing process:

- (1)

Manufacturer: The product is identified by an RFID. Information, regarding the production methods and transport timing, is stored into a centralized database through a web application.

- (2)

Wholesalers, Resellers and Retailers: They can monitor the supply chain and optimize the stock management.

- (3)

Consumers: The consumers can control the supply chain of each product using the RFID readers provided by the resellers.

- (4)

Institutions and Statistics and Market agencies: Through the centralized database, the information collected can be used for statistics and marketing purposes.

Decathlon, one of the world’s major retailers of sporting goods and equipment, in 2010 started using RFID tagging in all steps of their supply chain in all distribution centers and stores. Decathlon tracks products throughout the entire supply chain, from factories to the distribution centers and stores. In total, more than 85% of products are RFID tagged, even low price products are tagged [

18]. The main goal was to increase product availability in stores. In addition, Decathlon also installed RFID based check-out systems to facilitate and accelerate the payment process. Thanks to the RFID tagging, a full store inventory can be performed every 1–4 weeks, instead of twice per year using barcodes. Decathlon sales have increased 11% by using RFID, while the loss of products has been reduced of 9% [

18]. On the other hand, Decathlon does not bring all information to the consumer. The consumer cannot trace the story of the product he is buying and verify the quality of the product.

The brand Bon-Ton since 2017 is using the UHF RFID technology to track whether the shoes and luggage it had on sale were available on display. The system has enabled the retailer to reduce its non-compliance of display items at 180 stores [

19].

Gay et al. [

20] and Ruiz-Grazia et al. [

21] present a comprehensive literature review on the aspects of food supply chain management, addressing the following technologies: bar code, QRcode and RFID devices.

Among the other applications, FIspace (a platform financed by the European community) [

22] has been used for tracking and tracing meat for supply chain partners and consumer. Barcode and RFID technologies are used in the supply chain. The consumer is allowed to access meat information (date of slaughtering, place of birth, etc.) by scanning the QR-label. In particular, the methodology has been presented in [

23] and applied on a fish supply chain, but, in this example, the consumer is not considered. Walmart in conjunction with IBM and Tsinghua University announced a collaboration to improve the way food is tracked, transported and sold to consumers across China [

24]. Walmart wanted to investigate whether blockchain could serve as an alternative to paper tracking and manual inspection systems, which can “leave supply chains vulnerable to inaccuracies”. Nevertheless, blockchain is not directly brought to the consumer using easy to use technologies such as smartphone and NFC.

Many authors present their own overview [

11,

25,

26,

27,

28,

29,

30] of agri-food traceability characteristics using RFID technology, how RFID technology can be applied to traceability activities identifying benefits and drawbacks of the exploitation of RFID.

An extremely wide list of application examples is reported in [

26] in horticultural, meat, diary, fishery, bakery, and beverage sectors. RFID technologies are still limited because of various technical and economical obstacles, for example the limited use of new web-based Cloud Computing [

26].

Kadir et al. [

27] propose a methodology for food traceability from farming (production/manufacturing) until consumer, using the EPCIS standard and RFID. The customer is able to check the food product before buying in the supermarket, using the smartphone to scan a QRcode on the product. However, the QRcode is simply a link to a web site; it is not a direct link to the tracing system. Many disadvantages with respect to NFC are shown in detail in

Section 2.5. Furthermore, the proposed methodology in [

27] has not been applied in any specific product with a detailed, description, and it is not clear how the consumer is involved and what information is shown to the consumer.

Kumar et al. [

28] present some technical working principles and challenges of RFID and numerous applications of RFID technology in the food industry are discussed. In [

31], different aspects of a Farm Management Information System (FMS) are faced. FMS is a system for collecting, processing, storing and disseminating farm data. A relevant aspect is the interoperability between different FMSs that is faced in [

31] with the FIWARE platform [

32].

Fenu and Garau [

33] applied RFID in the traceability of pig meat in Italy; in particular, the chain of farm, slaughterhouse, distribution center, and retail outlets. In the farm, a long distance RFID working at 134.2 Khz has been used, while RFID working at 13.56 MHz has been used in the processing chain, distribution and retail outlets suitable for reading at short distances (range of 15–40 cm). The end user can have information connecting to a web site using the alphanumeric code printed on the paper ticket. A disadvantage of the solution proposed in [

33], in which the traceability has been performed using RFID, is that the information cannot be simply brought to the consumer. For example, the consumer can read the RFID of the product using a reader placed in a fixed location in a supermarket.

Ren et al. [

34] used RFID in the traceability of meat in China, but the paper does not report details and how the information is given to the consumer. However, the method reported in [

33] is probably the one used.

Philippos et al. [

35] proposed a RFID data model and system for the slaughterhouse. The consumer can access to all the relevant information that refers to the product that he is willing to buy using a touch screen and an RFID reader provided in the supermarket.

An RFID system has been proposed in [

36] for traceability purposes in different areas within the food sector such as wine, meat and fish. The system enables an important reduction of the work time in the farming and processing phases, due to the replacement of paper documentation with the electronic collection and exchange of data. However, the system has not been brought to the final consumer.

Other examples of beef or pig food traceability can be seen in [

37,

38,

39,

40].

In conclusion, analyzing all the solutions proposed in the literature, RFID is widely used by medium high dimension food producers during the production chain. Many companies are already using their own traceability systems based on RFID, but the preferred identification technology in the food sector is still based on barcodes. There are still insufficiencies in the data-flow connection when several actors are working along the supply chain.

The complexity and cost of RFID-based systems makes it inapplicable for small and medium enterprises (SMEs) or even individuals who typically works in the food chain [

2].

Furthermore, the impact on the final consumer is extremely limited through the use of reader in the supermarket or using a PC at home through a printer code that the consumer reads on a printed label and enters on a specific web site.

RFID has been widely used in retail and apparel for logistic purposes: inventory accuracy increase, out-of-stocks reporting, product location identification, and loss detection. The objective of enhancing the customer experience cannot be reached because the user does not personally have a RFID reader.

2.4. QRcode for Food Traceability

More recently, the QRcode, an extension of barcode, has been used in the final product, for example, applied in a bottle of wine ([

41] and references therein), to show information through the consumer smartphone. Essentially, QRcode is used as a fast link to the company web site. It is not a system of food traceability. QRcode does not carry tracing information of the product to the consumer due to the small amount of data that can be stored.

The great innovation of QRcode is the possibility for the consumer to have information related to the company using his smartphone.

Results reported in [

41] suggest that wine consumers who consider themselves wine connoisseurs or experts are more likely to employ technology in their wine purchase decision. QRcode and mobile phone applications have generated interest, because of their high level of consumer engagement and consequent user’s attitude toward the brand [

41,

42].

2.5. NFC

Near Field Communication (NFC) is a wireless close-range (few centimeters) connectivity technology derived from RFID technology. It allows data trade between two devices.

The main difference between NFC and RFID is in the fact that the NFC has been widely integrated in mobile devices such as smartphones, tablets and notebooks. This allowed the development of applications directly addressed to the end user.

The fact that the NFC works at short distance ensures that exchange of data between the two devices is made with the express wish of the owners of the devices, for example in payment.

NFC operates at 13.56 MHz and at rates ranging from 106 kbps to 424 kbps. NFC always involves an initiator and a target; the initiator actively generates an RF field that can power a passive target.

The use of NFC is much more immediate than QRcode: in the case of a QRcode, it is necessary to launch the application that performs the function of the scanner, to frame the QRcode in favorable light conditions, to read the QRcode and to acknowledge the contents of the URL from the browser. In the case of NFC, simply the approach of the smartphone to the object automatically launches the application that reads all the data from the tag. The application can make a connection to a website that stores the data, but it can also automatically activate in the smartphone much more complex actions (start a call, send text messages, send information about GPS location, etc.).

The advantages of NFC, with respect to the QRcode, are:

- (1)

Possibility of rewriting data several times;

- (2)

Possibility of data encryption;

- (3)

Ability to protect rewriting of data with a password;

- (4)

No optical readers but only a NFC reader integrated in the smartphone at no additional cost;

- (5)

It requires no special lighting conditions and pointing to a figure; and

- (6)

The user does not have to perform complex operations to read the TAG; he must simply approach the smartphone to the TAG. This facilitates the use of non-expert users of smartphones.

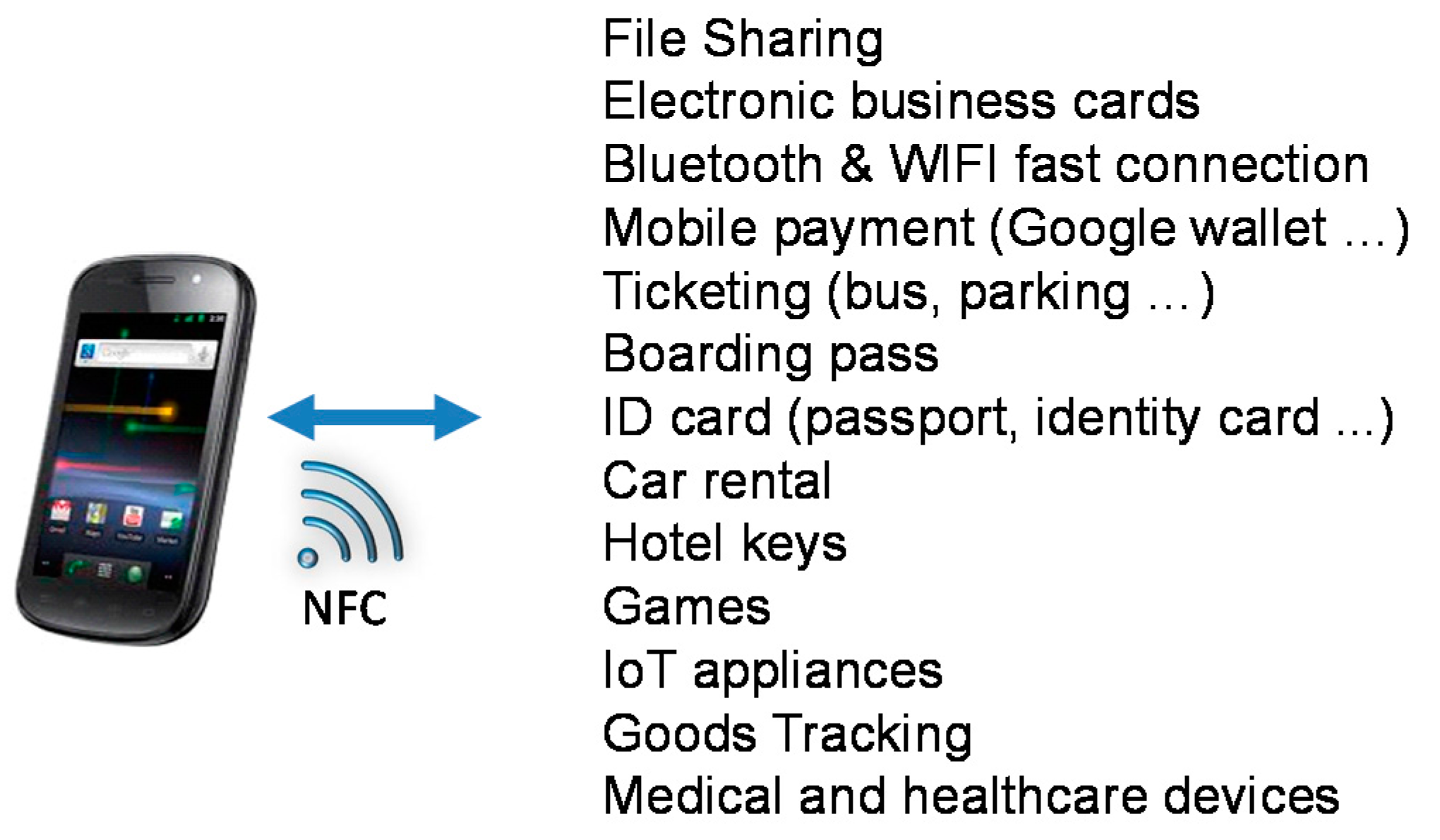

Many are the NFC applications in commercial products, as summarized in

Figure 1.

Many different applications have been developed that use smartphone with NFC to involve the final user in a direct and easy way: for example, in Ambient Assisted Living Applications [

43] and for services for the recharge of electric vehicles [

44,

45].

The following are two recent and relevant examples of application of NFC on food with the aim of adding value to the product: Bertolli olive oil in the North American market [

46], and Johnnie Walker whiskey [

47]. In both cases, NFC is not used for food traceability; it is only as a link to a web site without the integration with a food traceability system.

The Bertolli and Johnnie Walker marketing strategies show that the consumer is ready to appreciate information on the product with smartphone and NFC.

In the case of Johnnie Walker blue label whiskey, the tag is placed within the label and it is marked with the symbol of the wireless link next to the brand, with the commercial meaning of giving added value to the brand.

Furthermore, unlike conventional QRcodes, the app installed in the consumer smartphone allows a bidirectional interaction between the company and the consumer. This allows market analysis and gives the company feedback on consumer habits, taste and preferences fundamental for market purposes.

In addition, the NFC tag can ensure the authenticity of the product.

3. Proposed NFC-Based Food Traceability

The ability of RFID technology of reading tags at long distance (meters) makes RFID preferable to NFC for management of transport and distribution of products.

On the other hand, the wide diffusion of smartphones with NFC, the easiness of use of smartphone apps for consumer and for small size farm and food producers, the availability of cloud storage, and the diffusion of platforms for Internet of Things such as FIWARE [

32] or OpenStack, suggest the use of smartphones with NFC for food chain traceability.

The purpose and the novelty of the project, presented in this paper, are to use the same NFC technology for food traceability from production directly to the consumer.

NFC and cloud storage are used in each phase of the food supply chain (production, processing, distribution, and retail and consumer). They allow sharing information among farmers involved in the same production chain, farmer consortium (e.g., Bio-consortium, protected designation of origin, protected geographical indication, and traditional specialties guaranteed), government institutions and authorities responsible for controls (Payment Agencies, certification bodies, etc.) and final consumers. The solution allows an easy management of data by the farmers, for internal use, and to fulfill the requirements of the control authorities.

During the production chain from field treatments to packaging, all information of previous production steps is obtained approaching the smartphone of the farmer to the tag placed in the object; additional information is added and stored in a cloud database and written in another tag.

The final consumer can read all of the information, or what the farmer or the law want to show, about the supply chain by simply moving his smartphone to the tag placed on the food products.

Furthermore, the developed system can support the Integrated Administration and Control System (IACS) procedure, since the information recorded and produced by the proposed system can be used in the IACS, facilitating different administrative and control procedures.

The recorded information may be used by public institutions for the administrative checks and by controllers, reducing the time of the controls and carrying fewer disturbances to the farmers.

The system could automatically support farmers’ declaration and administrative documents that could be instantaneously sent to the cloud database accessible by all control institutions, as suggested by the EU institutions in [

48]. The developed apps for smartphone will help the farmers verify the compliance of the action they are making with the legislation. The farmers can correct the formal errors as well as correct inappropriate actions (for example, the incorrect use of pesticide on a particular field).

Through the proposed system, data and activities are automatically time and geo referenced. Consequently, it ensures quick and accurate trace-back when necessary. It provides information on meat and agricultural products provenance to the public [

48]. This is a growing requirement from food safety agencies, certification bodies, and consumers.

Moreover, the instantaneous update of the cloud database could be used for example to monitor pathogen diffusion in the fields and to alert both the farmers close to that field and the local authorities.

The implementation of NFC technology increases food safety, not only for the agents of each phase of the supply chain, but also for the final consumer. In addition, the app can promote sustainable production and product quality with the final effect of improving consumer confidence.

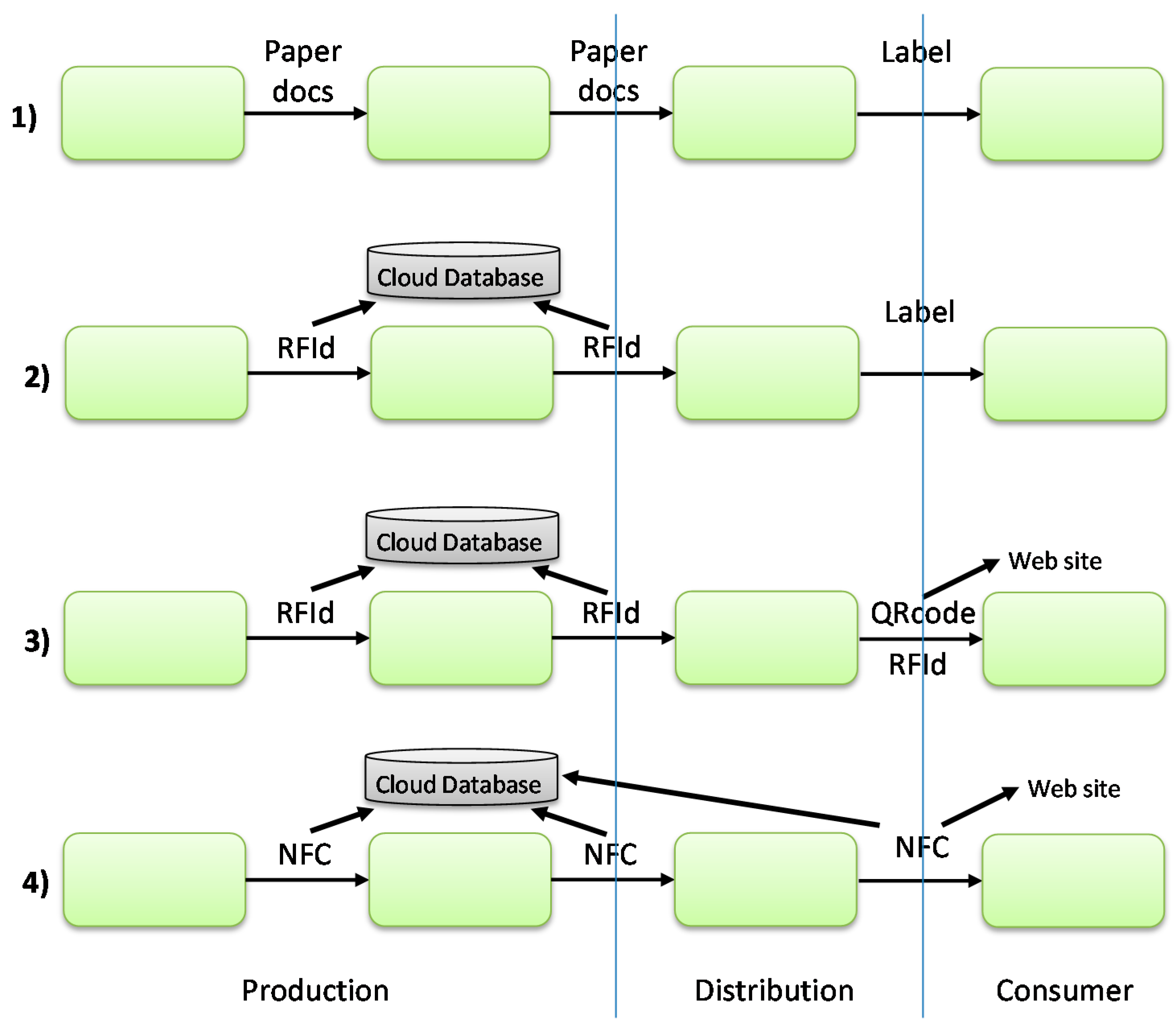

Figure 2 summarizes different tracing methodologies:

- (1)

Traditional paper based tracing.

- (2)

RFID based tracing methodologies: Only the label gives information to the user. No tracing information is given to the user (Decathlon, Bon-Thon, Walmart, etc.) [

18,

19,

20,

21,

24,

25,

26,

31,

36,

37,

38,

39,

40].

- (3)

RFID based tracing methodologies and QRcode: Label and QRcode or RFID using the reader of the store give information to the user. No direct tracing information is given [

22,

23,

27,

33,

34,

35]. In the case of [

41,

42], the QRcode is used by the consumer and no tracing is performed. In the cases of Bertolli and Johnnie Walker [

46,

47], only the NFC is used by the consumer and no tracing is performed.

- (4)

NFC based tracing methodologies, proposed in this work: The production and distribution tracing is performed with traditional smartphone and tracing information is directly given to the consumer. Another possible solution is the use of RFID in during production and distribution, and NFC to the user, but connected to the tracing database.

Table 2 summarizes the characteristics of the different technologies that can be used for food traceability and some references that used the technologies for real applications or test cases.

The advantage of using NFC in the complete supply chain and in the final product is the possibility of easily integrating the tracing into the complete production chain, automatically fulfilling the regulation and avoiding paper documentation. Furthermore, the quality of the product is shown directly to the final user, who can see the data of the complete production chain.

4. System Architecture

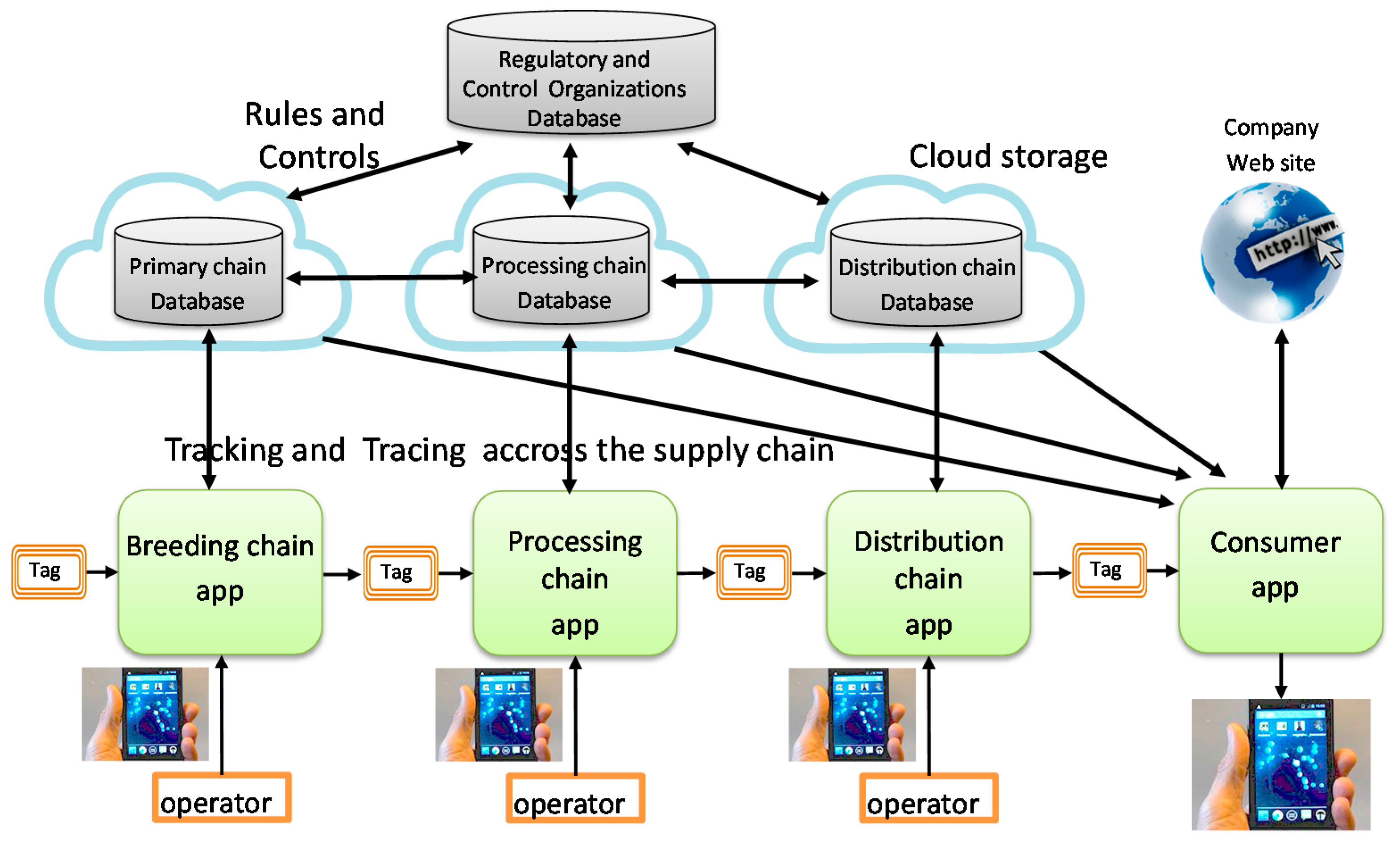

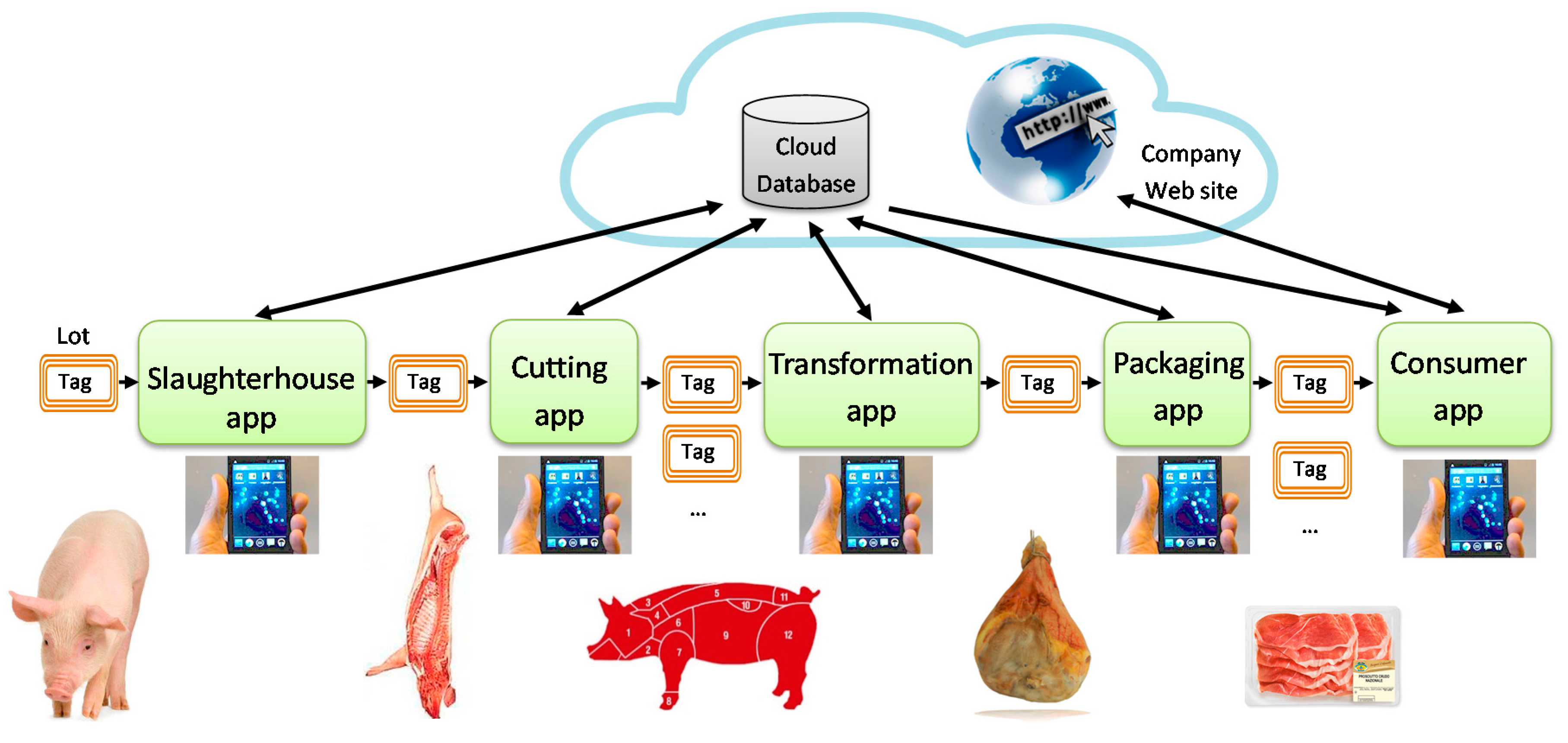

The architecture of the proposed system is reported in

Figure 3. The food chain represented is a generic chain with different agents: breeding, processing, distribution and final user. In each phase of the chain, the operators associates a tag to the object (animals, carcasses, and packages). When an operation is applied to the object, the following steps are performed:

- (1)

the operator reads the tag of the object with the device (smartphone or tablet);

- (2)

the tag contains a link to a remote database of the company;

- (3)

the history of the object is displayed to the operator;

- (4)

the operator updates the information on the remote database, adding information on GPS localization, code of the operator, timestamp; and

- (5)

if one or more objects are generated from the processed object (for example, a piece of meat is cut into pieces), additional records in the database are added and the tags are generated containing a link to the corresponding new record of the database, and the new record stores the link to the “father” object.

The tag contains only a link to the information in the cloud database and other information for security reasons. When the object is moved from one company to another (for example, an animal is brought to the slaughterhouse), the tag acts as an accompanying document and part of the information in the breeding database is available to the slaughterhouse database. Using facilities and services of cloud storage, such as FIWARE [

32] or OpenStack, the exchange of information among the databases can be easily performed, even if different software houses manage the two databases.

Furthermore, software in the app of the operator will notify him if he is making actions that are not allowed by the regulatory organizations. The regulatory organizations can have partial access to the company database performing formal control of the procedures in real time and in an automatic way.

Finally, the consumer, using the same methodology, reads the history of the product he is buying in the supermarket, eating in a restaurant or cooking at home. The easiness of using the smartphone apps for performing all these operations makes the procedure usable for SME producers.

5. System Implementation and Application to Pig Meat Supply Chain

As an application, we applied the methodology to the traceability of pig meat, in a real test case of the regional QM system of the Marche Region in Italy [

49]. The definition of the specifications of the system has been carried out through a cooperation with the regional institution for control in agriculture (ASSAM, Regione, Italy) and experts in the field. We developed the structure of the database for slaughtering and food processing for pig meat; we implemented the database on altervista; we developed the apps for the production chain and the app for the users; we tested the app; and we received some feedback from some of the users.

The methodology proposed is of general applicability and it can be used in many different applications of food traceability.

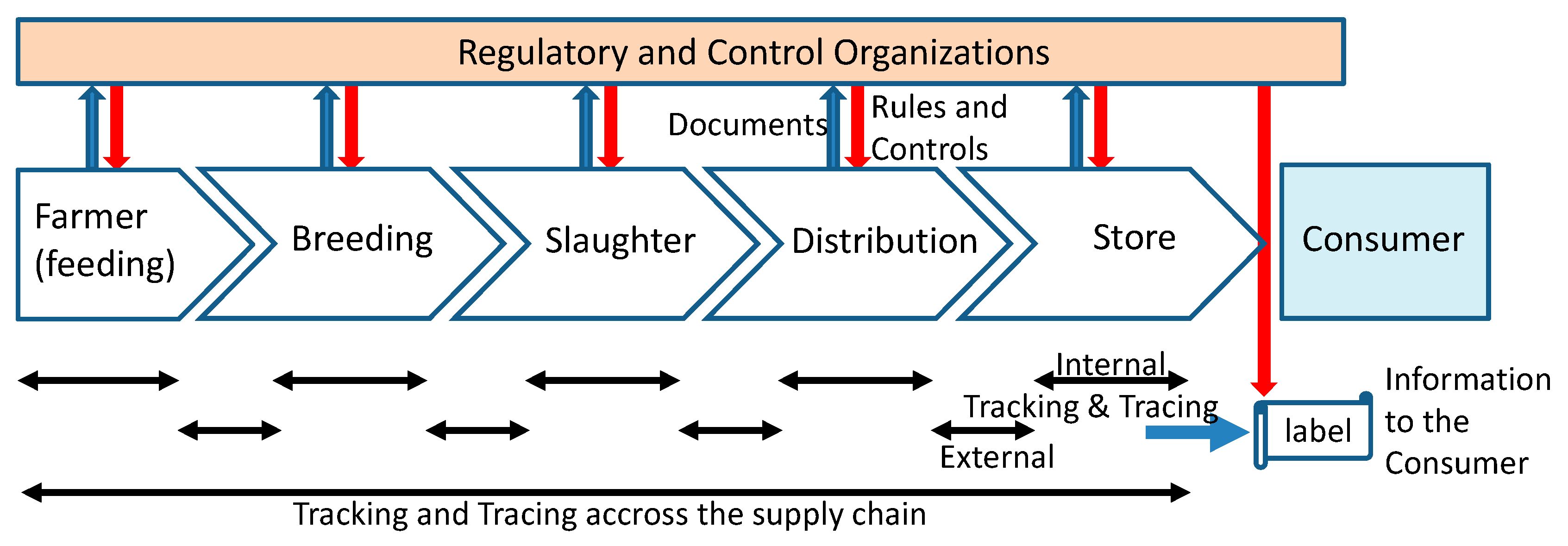

The complete supply chain is reported in

Figure 4.

Six different entities are involved:

- (1)

farmers providing the food for the animals (the traceability of what the pig is eating is important for the quality and safety of the meat);

- (2)

the breeders;

- (3)

slaughterhouse;

- (4)

distributers;

- (5)

retailers; and

- (6)

consumer.

Some of these agents may be owned by the same company, but the proposed procedure does not require a single control center of the supply chain.

The regulatory organizations impose rules in each stage, requiring internal documents and documents that must be passed between the different agents of the chain. These “paper” documents act as internal and external tracking and tracing across the supply chain. Furthermore, the control organizations periodically and randomly perform controls of the documents and on the spot checks and inspections.

In addition, rules and controls are imposed on the information available to the consumer in the label of the product.

The proposed solution substitutes the “paper” documentation with the tag and the cloud database.

The developed prototype provides the pig traceability from the slaughterhouse to the consumer, as indicated in

Figure 5, in which all the phases of slaughtering and food processing for pig meat are considered.

The supply chain implemented and presented in this paper begins with the arrival of the pig at the slaughterhouse. The information on meat processing is written in an NFC tag applied to the half-carcass and the data are automatically stored in the online database. The half-carcass is then transferred to the cutting plant where it is divided into various cuts. The contents of the “father” tag have to be copied and saved in all the “children” tags applied to related cuts. The information about the new processing is added to the “children” tags. Later, the meat arrives in the laboratory of transformation, where it is processed and packaged. The data related to the meat processing are always saved in the database and written in the corresponding tag. Once packaged, the product arrives in the store where the consumer can read all the information gathered throughout the supply chain by approaching his smartphone to the tag.

5.1. Supply Chain

In our case study, we implemented the complete supply chain of the “fresh and processed pork” of the regional QM system [

49], with possible specific application on the “suino della Marca” [

50], a local breed, officially recorded in Swine Hybrids Bulletin Board Registers. The QM mark is a quality mark established by the Marche Region in Italy and approved by the European Commission, as an instrument of exploitation of the Marche Region food system.

The supply chain is divided into the following phases:

- (1)

slaughter;

- (2)

cutting;

- (3)

transforming;

- (4)

packaging; and

- (5)

sale.

The tracked subjects are:

- (1)

breeder of origin;

- (2)

slaughterhouses;

- (3)

cutting plants;

- (4)

transforming and packaging laboratories; and

- (5)

retail stores.

In this chain, the slaughter and cutting are considered to take place in different factories, while transforming and packaging are carried out at different stages but in the same laboratory. The chain follows the pig from the arrival at the slaughterhouse to the arrival on the tables of consumers.

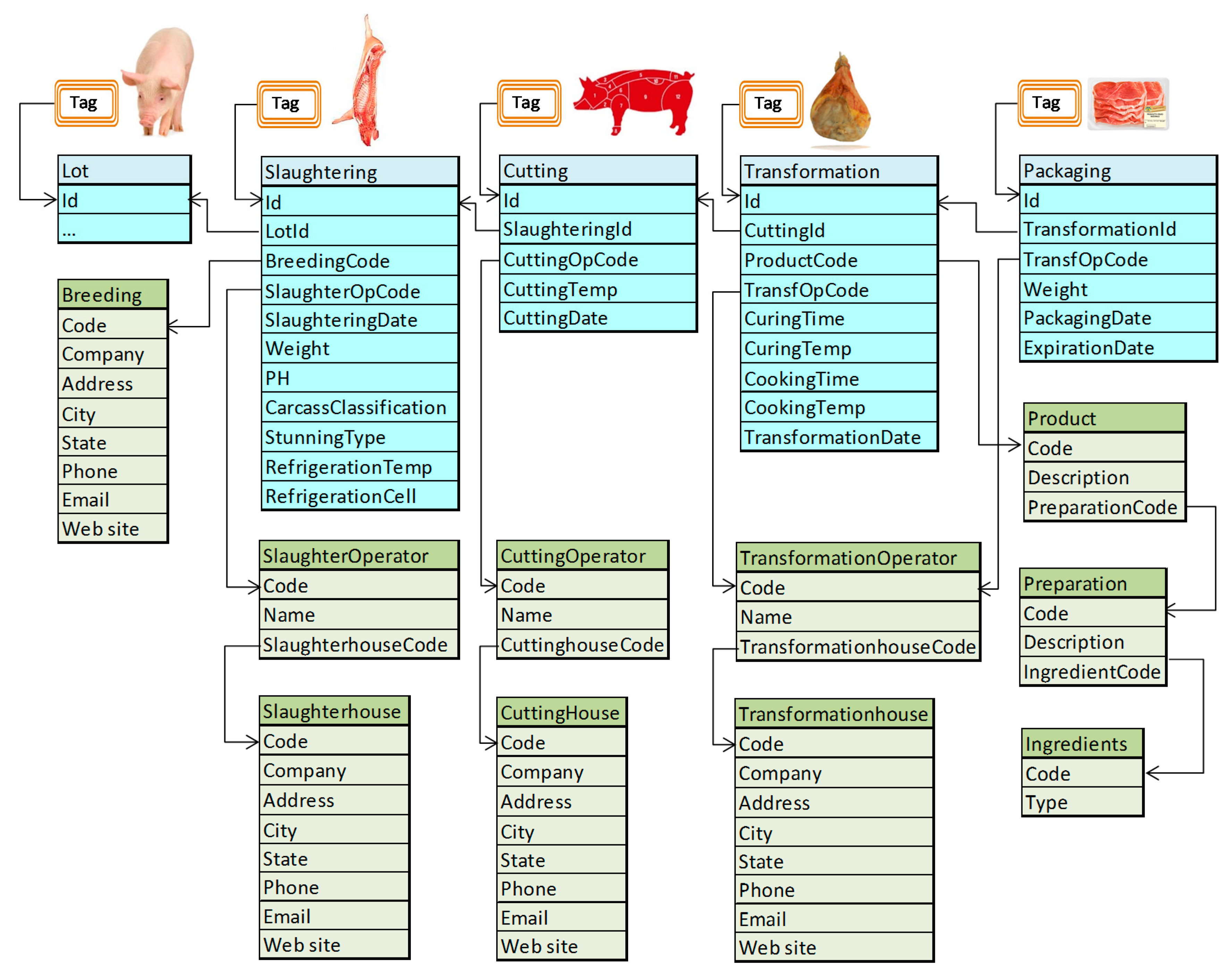

5.2. Database Structure

Based on the supply chain, a MySQL database was designed taking into account all the stages of processing along the supply chain and operators involved. Therefore, the complete traceability of the final product is obtained.

The tables specifying breeding, slaughterhouses, cutting plants, transforming and packaging laboratories, ingredients, products and operators are populated with certain values and can only be read by Android applications, but not changed.

The tables specifying slaughters, cutting, transforming and packaging represent phases of the supply chain and are the tables where their Android applications will write. Being pigs tracked by lot and not for single animal, it was decided to use the lot identifier on the various stages of processing to maintain the traceability of each single product. The records, the tables and the relations of the database are reported in

Figure 6. Each tag contains the name of the table and the id. The second field of each record contains the link to the id of the generating table, allowing a complete trace back of the system.

The database, shown in

Figure 6, has been implemented using the services of

www.altervista.com, but it can be easily moved to the EU FIWARE platform. In light blue are indicated the fields filled by the operator during the process, in light green the fixed data.

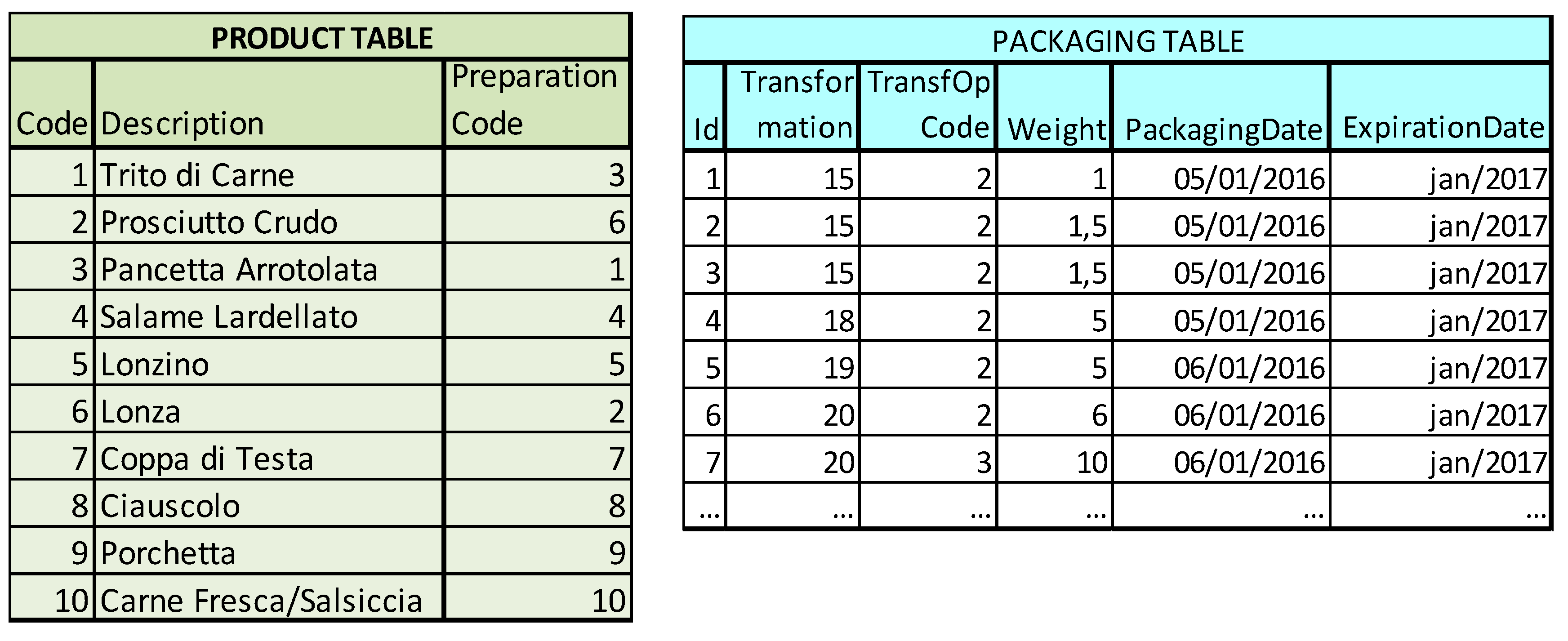

For example,

Figure 7 shows the table with the fixed data of the 10 types of products that the operator can select, and the packaging table in which the operator inserts a new record every time he makes a new package and writes it on a new tag.

5.3. Android Apps

The applications have been developed using the Eclipse and the Android Developer Tools plugin. We used the NTAG212 tags for the development of the prototype.

The project was divided into five applications, as indicated in

Figure 6:

- (1)

Slaughterhouse app;

- (2)

Cutting app;

- (3)

Transformation app;

- (4)

Packaging app; and

- (5)

Consumer app.

All applications communicate with the database.

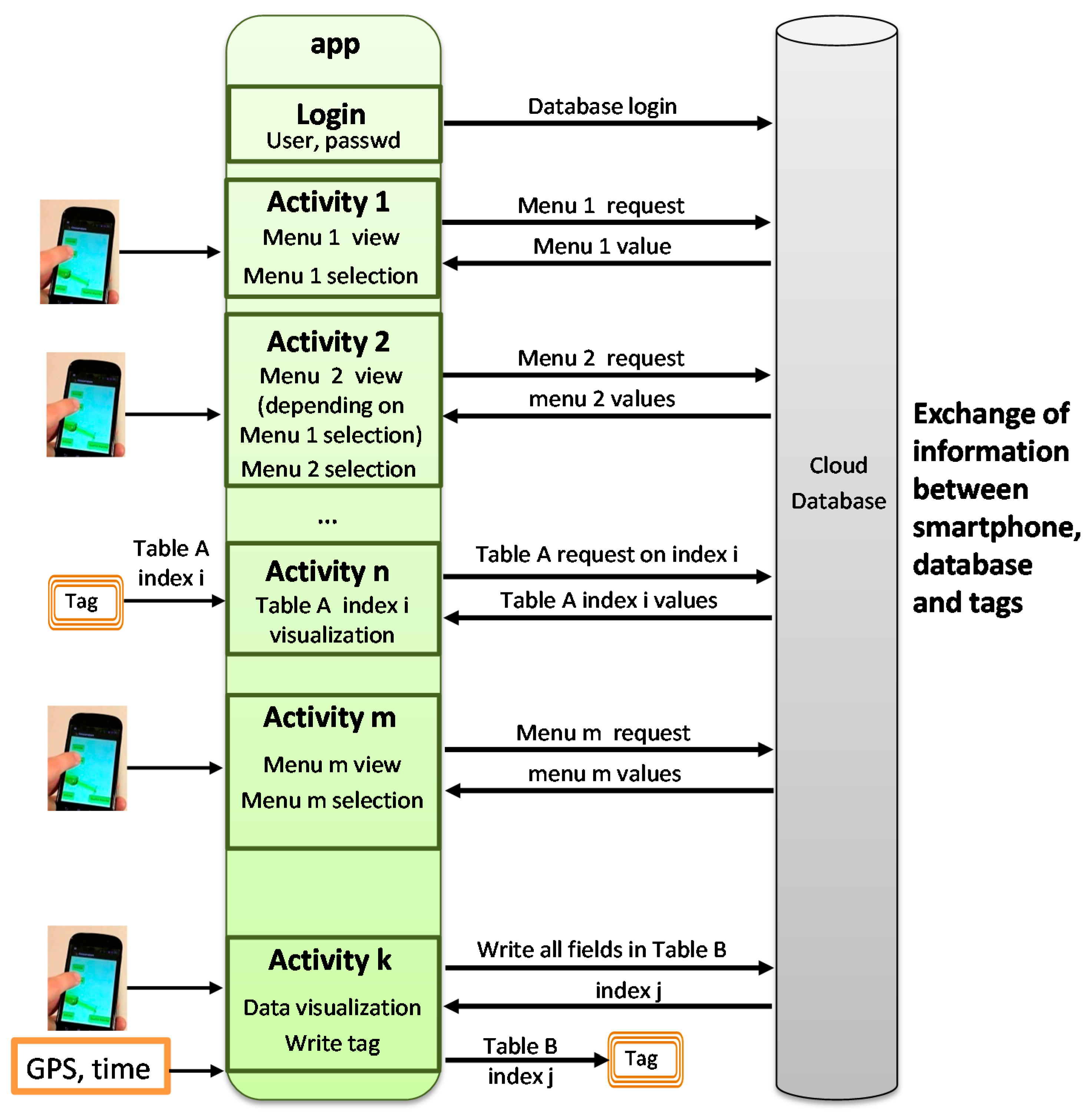

Two records are written in each tag: the first record contains the id and the name of its processing; and the second record contains the Android Application Record (AAR), which is used to launch the next application with only the approach of the device to the tag. All other information is retrieved by querying the database. The devices (Android smartphones or tablets) should be equipped with NFC technology and Internet connection.

Figure 8 reports the general organization of the apps. The operator launches the app and inserts username and password to be identified. Another possibility is that the access to the database is possible only to smartphones with specific android_id defined in a list of the database.

Then, sequential activities are performed. The smartphone asks to the database the data to be displayed (for example, the selection of the slaughterhouse where the operator is working).

When a specific object has to be processed, the smartphone reads the tag and takes the data from the database in the specific table and record indicated in the tag. The information is displayed to the operator allowing a control of the correctness of the operation.

The processing information is filled by the operator, for example the temperature of the processing or the weight of the piece of meat.

Finally, a new record is created in the table of the processed objects with the new data, and the specific table and record number are written in the tag.

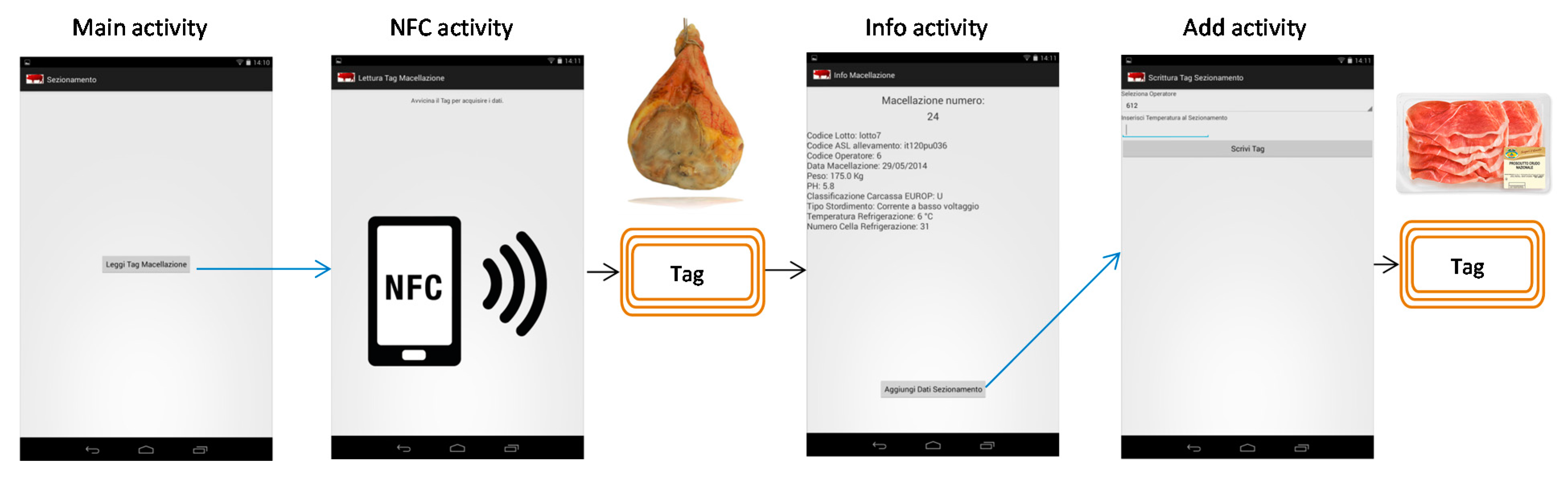

In particular, the operations performed by the five apps are the following

- (1)

Slaughterhouse app: The pig arrives at the slaughterhouse where the slaughter takes place. The operator launches the application on his device and stores information about the processing using the menu of the application. Once this phase has been completed, approaching the device to the tag and clicking on “Write Tag”, the information is stored in the remote database. At the same time, the id and the name of the process are written in the tag that is placed on the half-carcass.

- (2)

Cutting app: The half-carcass comes to the cutting zone, where it is divided into various cuts. The tag from the slaughter is read and the content is saved in all other tags to be applied to the various cuts. Then, additional information about the cutting, such as the code of the operator and the temperature, is stored.

- (3)

Transformation app: The tag coming from cutting is read, then the operator must indicate the type of product to be made, as indicated in the table of

Figure 7. If the operator selects fresh products, he will be directed to the screen of the fresh products, where no additional information has to be added. If the operator selects cooked products, they will be shown on the screen, and the operator will add additional information, such as the cooking time and the cooking temperature. If the operator selects cured products, the corresponding screen will be addressed, which will ask information, such as the curing time and curing temperature.

- (4)

Packaging app: The tag coming from transformation process is read, then the operator has to add information such as net weight and expiration date. The menu and the activities of this app are shown in

Figure 9.

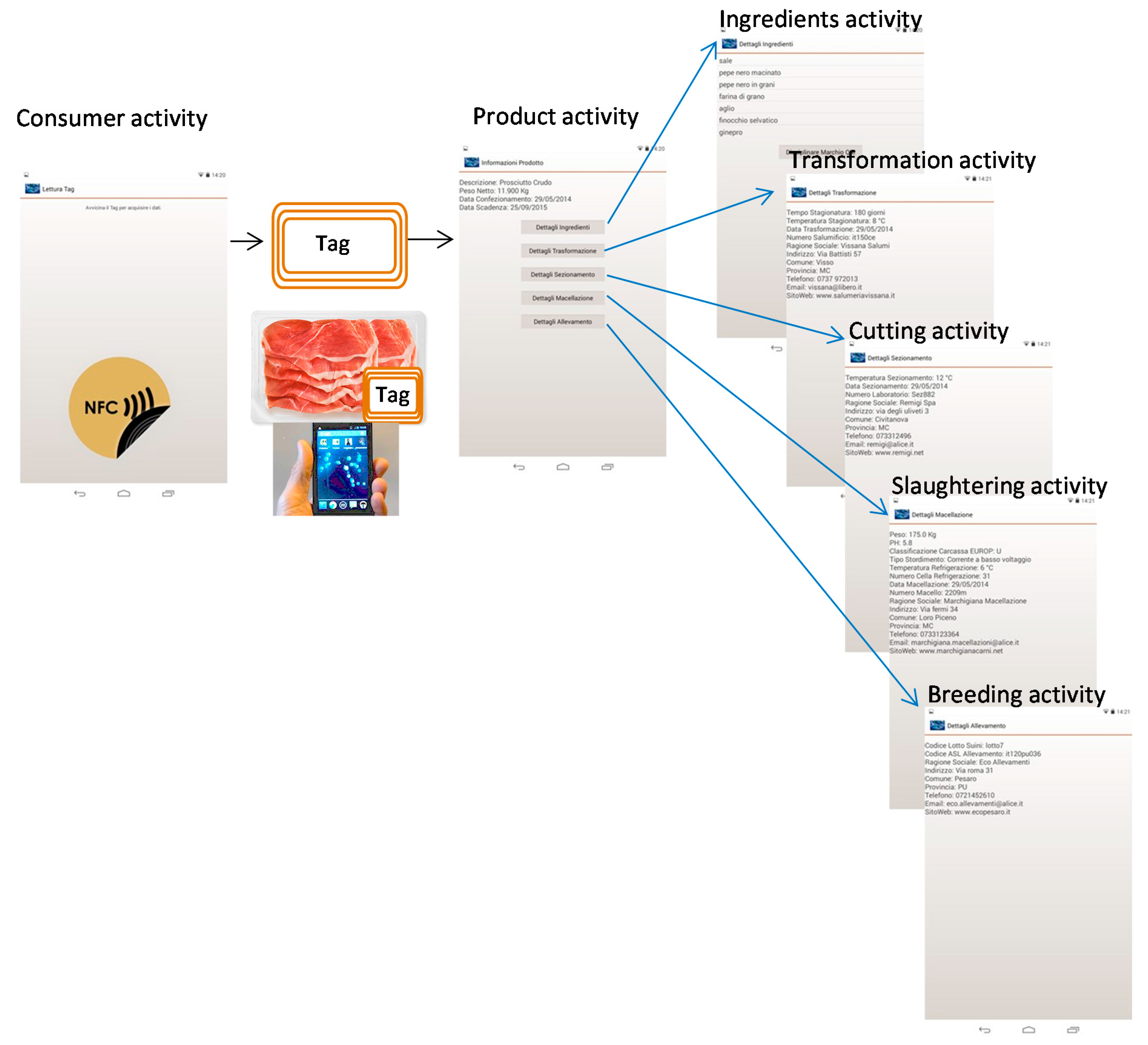

- (5)

Consumer app: The packaged product arrives at the retail store. The consumer can read all the information gathered throughout the supply chain by bringing its device to the tag applied to the product. The menus of this app are shown in

Figure 10. The consumer can read all the information the producer allows him to see, about breeding, slaughtering, cutting, transformation, and ingredients of the product he his buying. Additional information can be displayed for marketing purposes.

6. Conclusions

Several traceability systems are currently available, but, due to the heterogeneity of the possible implementations, the exchange of information among the different actors involved in the production process is very difficult. In many cases, the only way to achieve traceability is through paper-based systems. For this reason, information cannot be made rapidly available and cannot be used to improve the quality of meat processing and, consequently, of the final product. This paper proposes a complex traceability system based on NFC identification and applied as a test case to the pig meat supply chain.

RFID is widely used The novelty of the paper is the idea of connecting the traceability chain to the consumer using smartphone and NFC, and the possibility of automatic tracing for SME food producers due to the easy to use and low cost of the app and hardware required.

RFID is used in the food chain, but the information is not given to the final user.

The use of NFC allows bringing information to the end user. This enforces the customer fidelity to the brand, and provides additional services. The app can be used for marketing purposes (more or less hidden) with the possibility of storing the tastes and the location of the customer for commercial purposes. NFC apps can be used to know when and where the customer is buying and consuming the product, and to send advertising messages of a new product.

The cost of the tag is so amply rewarded by these marketing aspects.

The NFC tag, when compared to QRcode, can be read in any condition of visibility and more easily, but this advantage is very small compared to the services and additional loyalty programs that are possible with the NFC.

In food traceability, the NFC has not yet been used, as far as we know, to show to the consumer the tracing of the product that he is going to eat or buy.

In summary, the important technical aspects on the choice of the type of tag to be used in the final product are:

Cost: The cost is critical, especially if the product cost is low, as for example for fruits and vegetables. Thus, the customization on the type of material is not convenient. The best solution is a paper tag with the logo or without logo but inserted under the label that is normally used, suitably modified to highlight the presence of the tag.

Security: Passwords could be written down or broken if detached and reattached elsewhere. A deeper study, however, is to be done with regards to the frauds.

Ecological aspects: The tag is an electronic circuit that is part of the waste packaging; it is important to study how to dispose or reuse it (for example, similar to glass bottles). In the case of reuse, more resistant materials, even if more expensive, can be used.

The added value, given to the customer using the NFC, is the information and services of the app. The additional cost of NFC is justified by the exploitation of this potential.

The proposed methodology has been applied in a real test case of a pig production chain of the Marche region in Italy. The app for operators of the production chain must be easy to use and acceptable to non-expert users. Despite the fact that we tried to design the app facing this aspect from the beginning, we were made modifications to the app due to early feedback from some operators.

In particular:

- (1)

some fields have been set to a default value that can be changed by the user to reduce the number of fields to be filled and to the speedup the tracing procedure; and

- (2)

the tables have been modified and customized for the different operators.

The system has not yet been applied in the production chain of companies.

Future work will be done in bringing the system to the market and verifying the consumer acceptance of the proposed methodology.

Furthermore, the NFC based tracing system is under development by the authors in the wine and olive oil production sectors [

51,

52]; preliminary results have been presented at the Expo 2015 in Milano.

The cost of the development of the app for the operators of the production chain and for the consumer is relatively low. The main problem of the proposed solution is the user acceptability and to find the match between producer and consumer interests. These aspects depend on the specific product under consideration. The app must show the information the consumer really wants to know in a user friendly way.