Life Cycle CO2 Assessment by Block Type Changes of Apartment Housing

Abstract

:1. Introduction

2. Literature Review

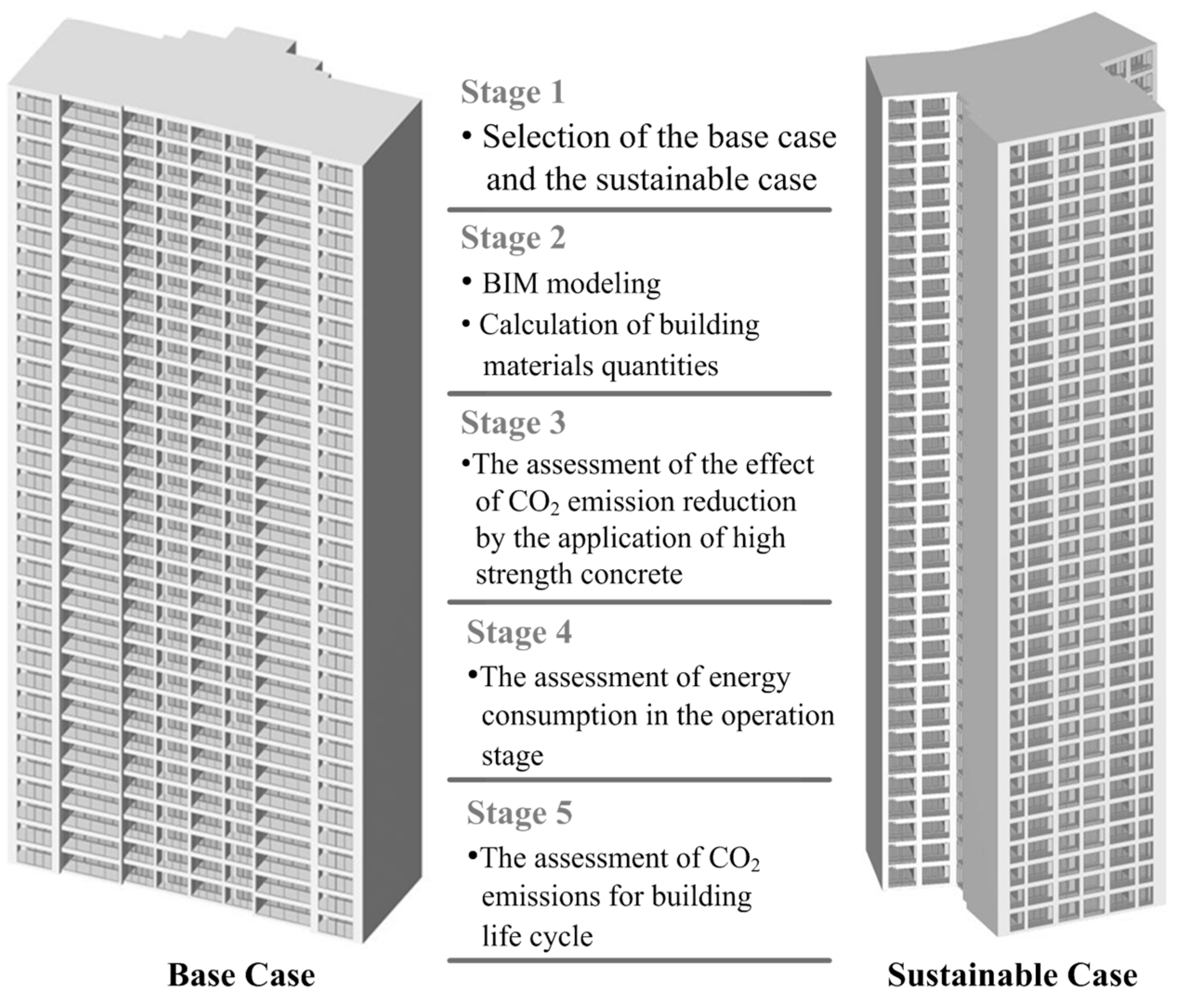

3. Assessment Method

Theory of the Building LCA Assessment Method

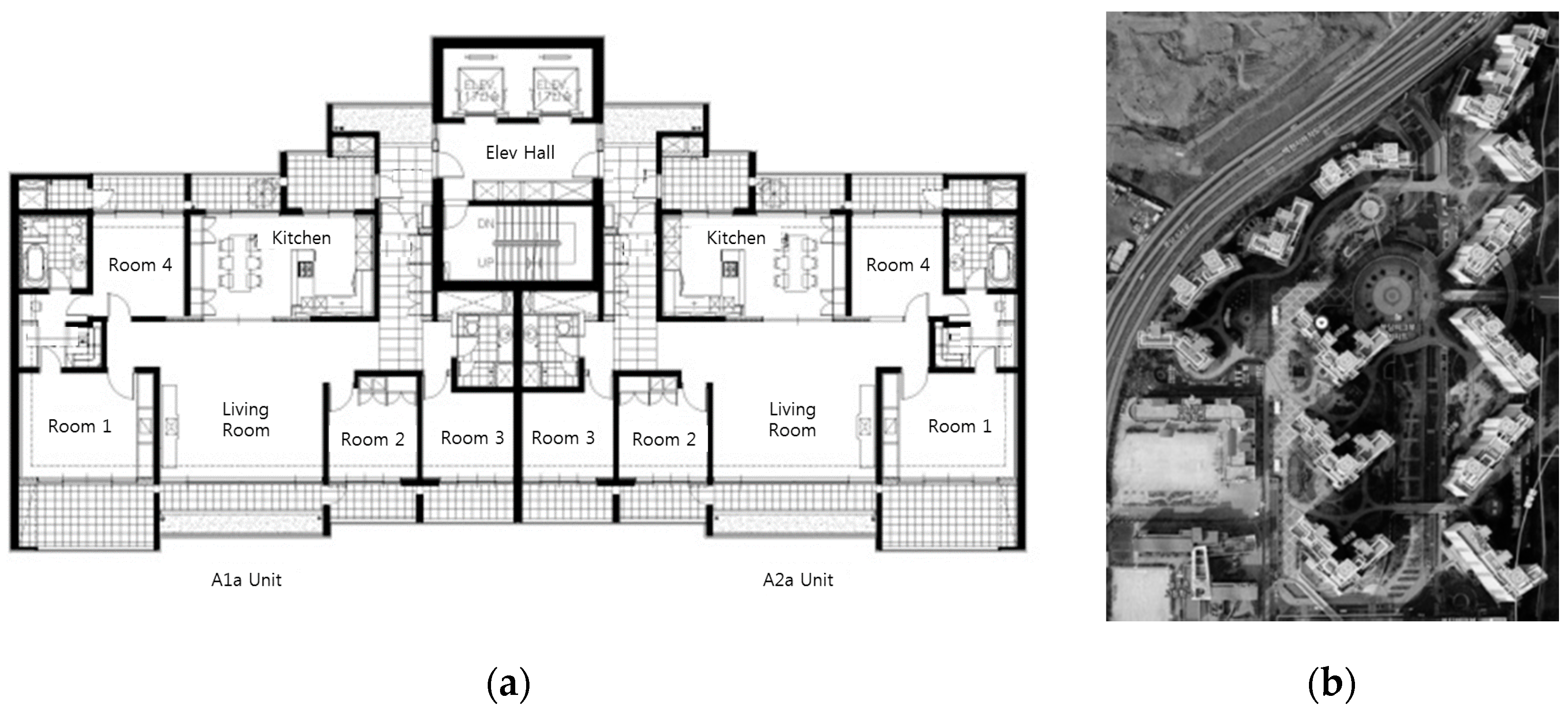

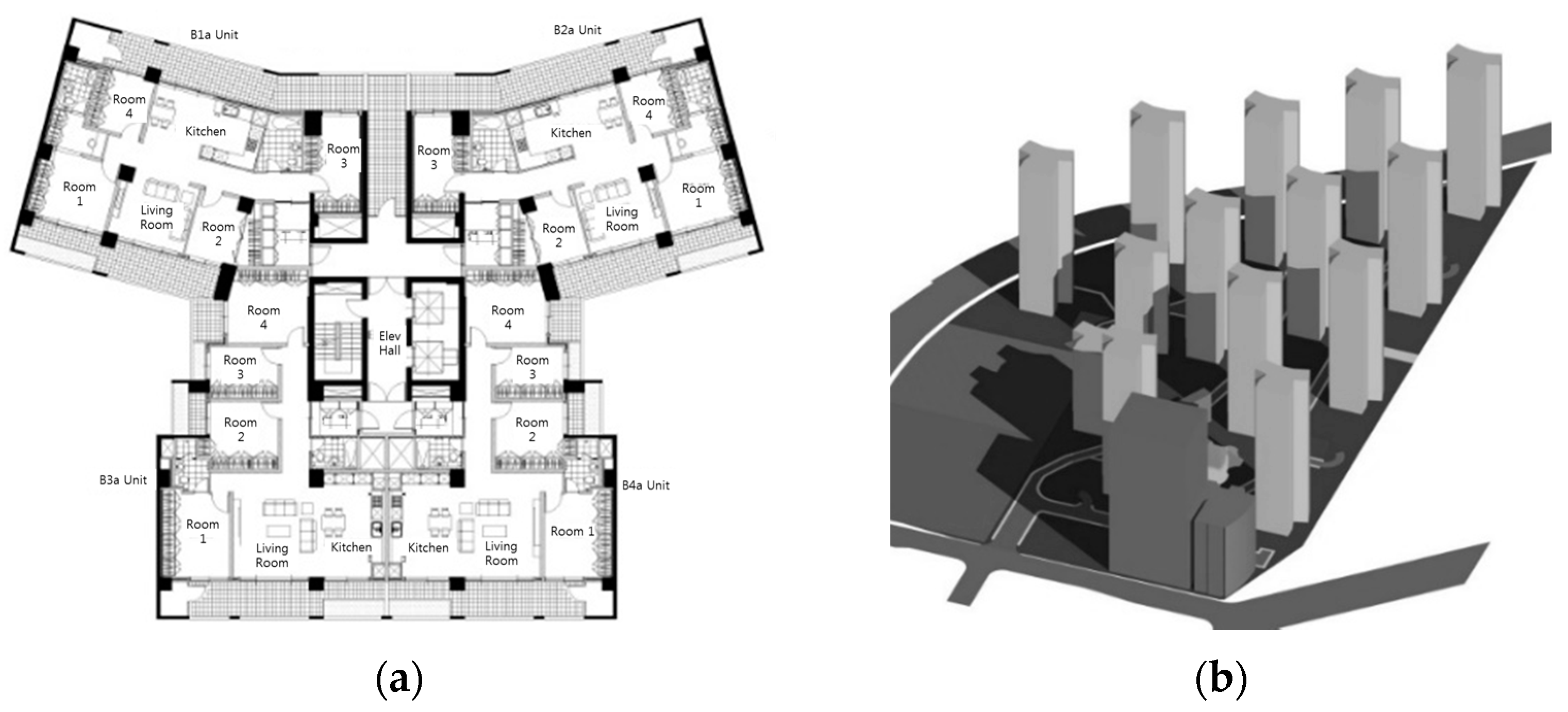

4. Reference Case and Alternative Case Proposal

5. Assessment of CO2 Emissions by Changes in Building Form

5.1. Comparison of the Amount of Major Materials and an Assessment of CO2 Emissions

5.2. Assessment of Changes in CO2 Emissions Due to High Strength Concrete

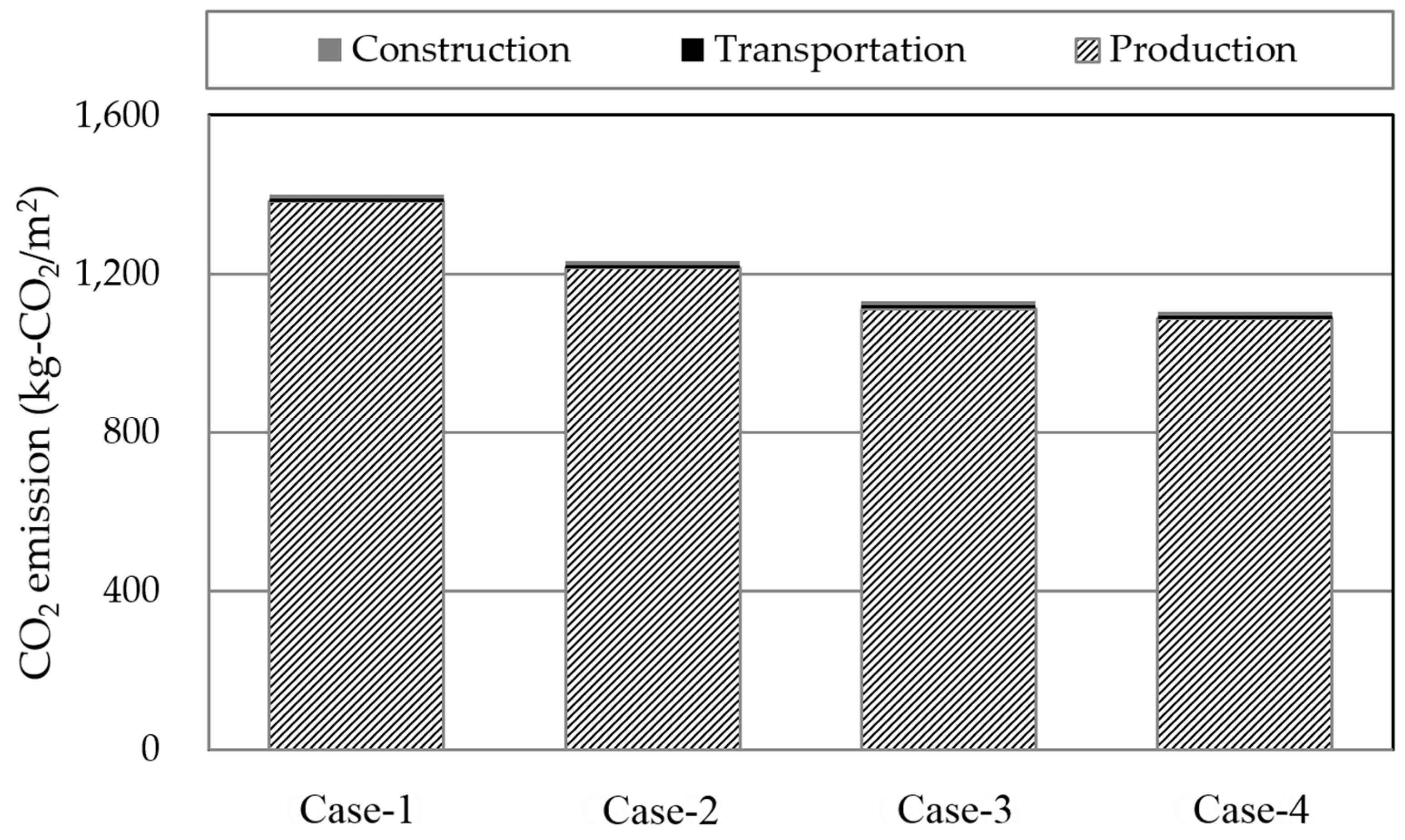

5.2.1. Consideration of the Building Life Cycle

5.2.2. Quantifying the Reduction of CO2 Emissions by Using High-Strength Concrete

5.2.3. CO2 Emission for the Construction Stage

5.3. Assessment of Energy Consumption and CO2 Emissions in the Operation Stage

5.4. Discussion about Assessment of CO2 Emissions for Building Life Cycle

6. Conclusions

- By changing the bearing wall system of the ‘flat-type’ block to the ‘column and beam’ system of the ‘T-type’ block, the alternative case decreased the concrete and rebar used by 11% and 36%, respectively, compared with the ba3se case and as a result, CO2 emission decreased by 9.45%.

- When concrete strength was raised in order to decrease carbonation and increase durability in the ‘T-type’ block, CO2 emissions of the concrete and rebar in the alternative case decreased by 35.39% compared with the reference case. Moreover, there was an additional 2.6% reduction when the blast furnace slag was substituted at 20%.

- By changing the building forms, the envelope volume ratio of the ‘T-type’ block decreased by 24% compared with the ‘flat-type’ block and, as a result, the CO2 emissions of the alternative case during the operation stage decreased by 33.1%.

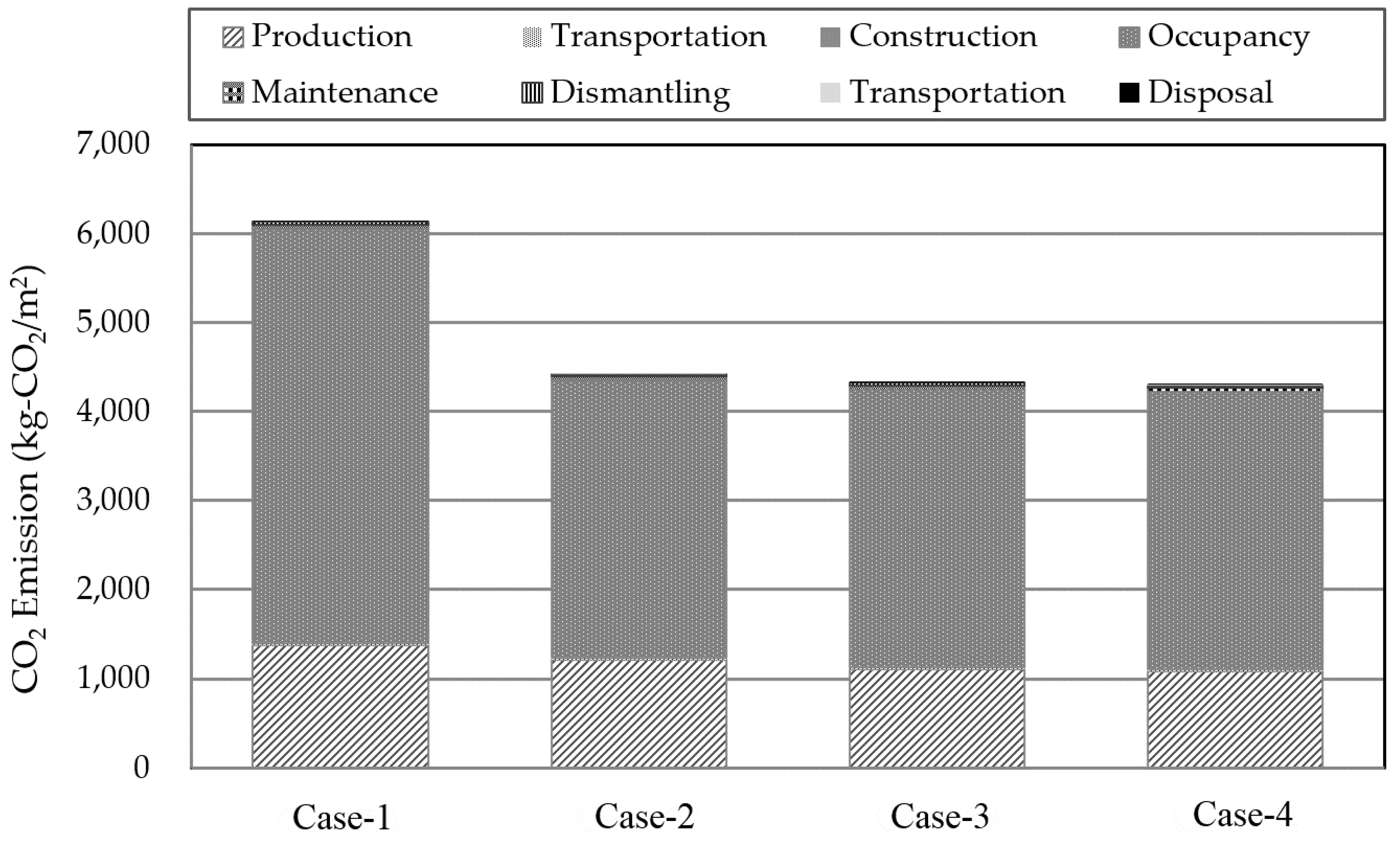

- LCCO2 emission of Case 4 was 4299 kg-CO2/m2, which consisted of 26% of the construction stage, 73% of the operational stage, and 1% of the dismantling and disposal stage. The total emissions were 30% less than Case 1.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Cabeza, L.; Rincon, L.; Vilarino, V.; Perez, G.; Castell, A. Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector: A review. Renew. Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- Dixit, M.; Culp, C.; Fernandez-Solis, J. System boundary for embodied energy in buildings: A conceptual model for definition. Renew. Sustain. Energy Rev. 2013, 21, 153–164. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Energy Technology Perspectives 2010; OECD/IEA: Washington, DC, USA, 2010. [Google Scholar]

- UNEP. Overview of the Republic of Korea’s National Strategy for Green Growth. 2010. Available online: http://www.unep.org/PDF/PressReleases/201004_UNEP_NATIONAL_STRATEGY.pdf (accessed on 25 July 2016).

- Tae, S.; Shin, S. Current Work & Future Trends for Sustainable Buildings in South Korea. Renew. Sustain. Energy Rev. 2009, 13, 1910–1921. [Google Scholar]

- Yi, I.S.; Seo, K.S. Social Indicators in Korea; National Statistical Office: Seoul, Korea, 2010. [Google Scholar]

- Federica, C.; Idiano, D.; Massimo, G. Sustainable management of waste-to-energy facilities. Renew. Sustain. Energy Rev. 2014, 33, 719–728. [Google Scholar]

- March, L.; Trace, M. The Land-Use Performances of Selected Arrays of Built Forms, Land Use and Built form Studies; University of Cambridge: Cambridge, UK, 1968. [Google Scholar]

- Fathy, H. Natural Energy and Vernacular Architecture; The University of Chicago Press: Chicago, IL, USA, 1986. [Google Scholar]

- Berköz, E. Energy Efficient Building and Settlement Design; Research Report, INTAG 201; The Scientific and Technical Research Council of Turkey: Istanbul, Turkey, 1995; pp. 98–138. [Google Scholar]

- Givoni, B. Climate Considerations in Buildings; Van Nostrand Reinhold: Hoboken, NJ, USA, 1998. [Google Scholar]

- Ratti, C.; Raydan, D.; Steemers, K. Building form and environmental performance: Archetypes, and arid climate. Energy Build. 2003, 35, 49–59. [Google Scholar] [CrossRef]

- Ba, G.; Gong, G. Research on passive solar ventilation and building self-sunshading. In Proceedings of the International Conference on Computer Distributed Control and Intelligent Environmental Monitoring, CDCIEM, Changsha, China, 19–20 February 2011; pp. 950–953.

- International Organization for Standardization. ISO 14040: Environmental Management-Life Cycle Assessment-Principles and Framework; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Ali, H.H.; Nsairat, S.A. Developing a green building assessment tool for developing countries—Case of Jordan. Build. Environ. 2009, 44, 1053–1064. [Google Scholar] [CrossRef]

- Haapio, A.; Viitaniemi, P. A critical review of building environmental assessment tools. Environ. Impact Assess. Rev. 2008, 28, 469–482. [Google Scholar] [CrossRef]

- Sharifi, A.; Murayama, A. A critical review of seven selected neighborhood sustainability assessment tools. Environ. Impact Assess. Rev. 2013, 38, 73–87. [Google Scholar] [CrossRef]

- Shin, S.; Tae, S.; Woo, J.; Roh, S. The development of apartment house life cycle CO2 simple assessment system using standard apartment houses of South Korea. Renew. Sustain. Energy Rev. 2011, 15, 1454–1467. [Google Scholar]

- Jukka, H.; Antti, S.; Juha-Matti, J.; Amalia, P.; Seppo, J. Pre-use phase LCA of a multi-story residential building: Can greenhouse gas emissions be used as a more general environmental performance indicator? Build. Environ. 2016, 95, 116–125. [Google Scholar]

- Saxena, A.; Sethi, M.; Varun, V. Life cycle assessment of buildings: A review. Renew. Sustain. Energy Rev. 2011, 15, 871–875. [Google Scholar]

- Hakkinen, T.; Huovila, P.; Tattari, K. Eco-efficient Building Process, VTT ProP Systematics on Building Headings. 2001. Available online: http://virtual.vtt.fi/virtual/environ/sb02-eco-efficient%20b_process2.pdf (accessed on 25 July 2016).

- Roh, S.; Tae, S.; Shin, S.; Woo, J. Development of an optimum design program (SUSB-OPTIMUM) for the life cycle CO2 assessment of an apartment house in Korea. Build. Environ. 2014, 73, 40–54. [Google Scholar] [CrossRef]

- Watson, P.; Mitchell, P.; Jones, D. Environmental Assessment for Commercial Buildings: Stakeholder Requirements and Tool Characteristics, Environmental Assessment Systems for Commercial Buildings. 2004. Available online: http://www.sbenrc.com.au/wp-content/uploads/2013/10/20-environmentalassessmentforcommercialbuildings.pdf (accessed on 25 July 2016).

- Baek, C.; Park, S.; Suzuki, M.; Lee, S. Life cycle carbon dioxide assessment tool for buildings in the schematic design phase. Energy Build. 2013, 611, 75–87. [Google Scholar] [CrossRef]

- AIA. AIA Guide to Building Life Cycle Assessment in Practice; The American Institute of Architects: Washington, DC, USA, 2010. [Google Scholar]

- ATHENA Sustainable Materials Institute—Athena EcoCalcuator. Available online: http://calculatelca.com/software/ecocalculator (accessed on 25 July 2016).

- US Life Cycle Inventory Database. Available online: http://www.nrel.gov/lci (accessed on 25 July 2016).

- Lee, K.; Tae, S.; Shin, S. Development of a Life Cycle Assessment Program for building (SUSB-LCA) in South Korea. Renew. Sustain. Energy Rev. 2009, 13, 1994–2002. [Google Scholar] [CrossRef]

- Lombera, J.S.; Rojo, J.C. Industrial building design stage based on a system approach to their environmental sustainability. Constr. Build. Mater. 2010, 24, 438–447. [Google Scholar] [CrossRef]

- Tae, S.; Baek, C.; Shin, S. Life cycle CO2 evaluation on reinforced concrete structure with high-strength concrete. Environ. Impact Assess. Rev. 2011, 31, 253–260. [Google Scholar] [CrossRef]

- Shin, S.; Tae, S.; Woo, J.; Roh, S. The development of environmental load evaluation system of a standard Korean apartment house. Renew. Sustain. Energy Rev. 2011, 15, 1239–1249. [Google Scholar] [CrossRef]

- Sisomphon, K.; Franke, L. Carbonation rates of concrete containing high volume of pozzolanic materials. Cem. Concr. Res. 2007, 37, 1647–1653. [Google Scholar] [CrossRef]

- Chang, C.F.; Chen, J.W. The experimental investigation of concrete carbonation depth. Cem. Concr. Res. 2006, 36, 1760–1767. [Google Scholar] [CrossRef]

- Tae, S.; Ujiro, T. A study on the corrosion resistance of Cr-bearing rebar in mortar in corrosive environments involving chloride attack and carbonation. ISIJ Int. 2007, 47, 715–722. [Google Scholar] [CrossRef]

- AIJ (Architectural Institute of Japan). Recommendations for Durability Design and Construction Practice of Reinforced Concrete; Architectural Institute of Japan: Tokyo, Japan, 2004. (In Japanese) [Google Scholar]

- Yuksel, I.; Bilir, T.; Ozkan, O. Durability of concrete incorporating non-ground blast furnace slag and bottom ash as fine aggregate. Build. Environ. 2007, 42, 2676–2685. [Google Scholar] [CrossRef]

- Robeyst, N.; Gruyaert, E.; Grosse, C.U.; Belie, N.D. Monitoring the setting of concrete containing blast-furnace slag by measuring the ultrasonic p-wave velocity. Cem. Concr. Res. 2008, 38, 1169–1176. [Google Scholar] [CrossRef]

- JSCE (Japan Society of Civil Engineers). Standard Specifications of Concrete—Part Maintenance; Japan Society of Civil Engineers: Tokyo, Japan, 2004. (In Japanese) [Google Scholar]

- The Energy Information Administration (EIA). Annual Energy Outlook—Fossil Fuels Remain Dominant through 2040; EIA: Washington, DC, USA, 2014. [Google Scholar]

| Category | Contents |

|---|---|

| Building Size | Above Ground 35 Stories, Basement 3 Stories |

| Structural system | Reference case: reinforced concrete, bearing wall structure |

| Alternative case: reinforced concrete, column and beam structure | |

| Concrete compressive strength | Reference case: Classified into 4 segments: 24, 27, 30, 35 MPa |

| Alternative case: Classified into 4 segments: 24, 30, 40, 50 MPa | |

| Others | Concrete and rebar quantities were reviewed comparatively based on the sum of the horizontal and vertical members. |

| Materials | Reference Case (70 Households, Total Floor Area: 11,400.9 m2) | Alternative Case (140 Households, Total Floor Area: 19,302.5 m2) | ||

|---|---|---|---|---|

| Total | Quantity per Unit Area | Total | Quantity per Unit Area | |

| Concrete | ||||

| Slab | 3256.68 m3 | 0.2856 m3/m2 | 5999.35 m3 | 0.3108 m3/m2 |

| Column | - | - | 2207.45 m3 | 0.1143 m3/m2 |

| Beam | - | - | 1388.93 m3 | 0.0719 m3/m2 |

| Wall | 4706.8 m3 | 0.4128 m3/m2 | 2350.6 m3 | 0.1217 m3/m2 |

| Total | 7963.48 m3 | 0.6984 m3/m2 | 11,946.33 m3 | 0.6189 m3/m2 |

| Rebar | 944,656 kg | 82.8 kg/m2 | 1026.080 kg | 53.1 kg/m2 |

| Cement brick | 506,832 EA | 44.455 EA/m2 | 2,883,571 EA | 149.388 EA/m2 |

| Tile | ||||

| Porcelain tile (floor) | 64,680 kg | 5.673 kg/m2 | 91,272 kg | 4.7285 kg/m2 |

| Porcelain tile (wall) | 74,760 kg | 6.557 kg/m2 | 130,416 kg | 6.7564 kg/m2 |

| Expandable polystyrene | 7949.4 kg | 0.6972 kg/m2 | 20,599.5 kg | 1.0671 kg/m2 |

| Plasterboard | 154,918.4 kg | 13.5882 kg/m2 | 417,826.5 kg | 21.6462 kg/m2 |

| PVC windows | 11,945.85 kg | 1.0477 kg/m2 | 17,159.29 kg | 0.8889 kg/m2 |

| Glass | 6877.77 m2 | 0.6032 m2/m2 | 7466.25 m2 | 0.3868 m2/m2 |

| Materials | Unit | CO2 Emissions Unit (kg-CO2/Unit) | Reference Case | Alternative Case | ||

|---|---|---|---|---|---|---|

| CO2 Emissions (kg-CO2) | CO2 Emissions (kg-CO2/m2) | CO2 Emission (kg-CO2) | CO2 Emissions (kg-CO2/m2) | |||

| Concrete | ||||||

| 24 MPa | m3 | 329.37 | 1,471,295.79 | 129.05 | 2,433,385.56 | 126.07 |

| 27 MPa | m3 | 353.02 | 332,191.82 | 29.14 | 0.00 | 0.00 |

| 30 MPa | m3 | 383.77 | 516,170.65 | 45.27 | 749,502.81 | 38.83 |

| 35 MPa | m3 | 406.71 | 492,119.10 | 43.16 | 0.00 | 0.00 |

| 40 MPa | m3 | 429.65 | 0.00 | 0.00 | 559,404.30 | 28.98 |

| 50 MPa | m3 | 508.39 | 0.00 | 0.00 | 661,923.78 | 34.29 |

| Rebar | kg | 3.84 | 3,627,479.04 | 318.17 | 3,940,147.20 | 204.13 |

| Cement Block | EA | 0.27 | 136,844.64 | 12.00 | 778,564.17 | 40.33 |

| Tile | kg | 13.80 | 1,924,272.00 | 168.78 | 3,059,294.40 | 158.49 |

| Expandable Polystyrene | kg | 12.73 | 101,195.86 | 8.88 | 262,231.64 | 13.59 |

| Plasterboard | kg | 4.45 | 689,386.88 | 60.47 | 1,859,327.93 | 96.33 |

| PVC Windows | kg | 12.10 | 144,544.79 | 12.68 | 207,627.41 | 10.76 |

| Glass | m2 | 27.33 | 187,969.45 | 16.49 | 204,052.61 | 10.57 |

| Total | 10,748,180.97 | 942.75 | 15,988,617.15 | 853.63 | ||

| Variable | Details | Applied Value |

|---|---|---|

| α1 | Concrete type | Normal concrete → 1 |

| α2 | Cement type | Normal concrete → 1 |

| α3 | Water to binder ratio | W/B = 0.6 → 0.22 |

| β1 | Temperature | Annual average temperature 15.9 °C → 1 |

| β2 | Humidity | Annual average humidity 63% → 1 |

| β3 | Carbon dioxide concentration | CO2 concentration 0.05% → 1 |

| Case-1 (Reference Case) | Case-2 (Alternative Case 1) | Case-3 (Alternative Case 2) | Case-4 (Alternative Case 3) | |

|---|---|---|---|---|

| Structural system | bearing wall | columns and beams | columns and beams | columns and beams |

| If carbonation is considered or not | Not considered | Not considered | Considered | Considered |

| Concrete strength | 24, 27, 30, 35 MPa | 24, 30, 40, 50 MPa | 35, 40, 50 MPa | 35, 40, 50 MPa |

| Whole repair | Once | Once | Unnecessary | Unnecessary |

| Blast furnace slag | Not used | Not used | Not used | Used (substitution rate 20%) |

| Unit | Case-1 (Reference Case) | Case-2 (Alternative Case 1) | Case-3 (Alternative Case 2) | Case-4 (Alternative Case 3) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Volume | CO2 Emission (kg-CO2/m2) | Volume | CO2 Emission (kg-CO2/m2) | Volume | CO2 Emission (kg-CO2/m2) | Volume | CO2 Emission (kg-CO2/m2) | |||

| Concrete | 24 MPa | m3 | 4467 | 129.05 | 7388 | 126.07 | - | - | - | - |

| 27 MPa | m3 | 941 | 29.14 | - | - | - | - | - | - | |

| 30 MPa | m3 | 1345 | 45.27 | 1953 | 33.83 | - | - | - | - | |

| 35 MPa | m3 | 1210 | 43.16 | - | - | 9301 | 195.98 | 9301 | 183.00 | |

| 40 MPa | m3 | - | - | 1302 | 28.98 | 1302 | 28.98 | 1302 | 27.00 | |

| 50 MPa | m3 | - | - | 1302 | 34.29 | 1302 | 34.29 | 1302 | 32.00 | |

| Repair | - | - | 98.65 | - | 91.27 | 0 | - | 0 | - | |

| Sub-total | m3 | 7963 | 345.28 | 11,945 | 319.44 | 11,905 | 259.25 | 11,905 | 242.00 | |

| Rebar | kg | 944,656 | 318.17 | 1,026,080 | 204.13 | 851,646 | 169.42 | 851,646 | 169.42 | |

| Total | - | 663.45 | - | 523.57 | - | 428.68 | - | 411.42 | ||

| Ratio of reduction over case 1 | 21.08% | 35.39% | 37.99% | |||||||

| Mechanical Electrical and Plumbing System | Value | |

|---|---|---|

| Heating and Cooling | Hot Water Generation | 60 °C |

| Cooling Type | Natural | |

| Ventilation | Ventilation Type | Natural |

| Air Change per Hour | 0.7 times/hour | |

| Energy Source | Heating | Natural Gas |

| Other energy use | Electricity |

| Facing Direction | Annual Energy Consumption | Annual CO2 Emission | |

|---|---|---|---|

| Reference case | South | 130.848 kWh/m2 | 26.43 kgCO2/m2 |

| Southeast | 134.234 kWh/m2 | 27.11 kg CO2/m2 | |

| Southwest | 137.592 kWh/m2 | 27.79 kg CO2/m2 | |

| Alternative case | South | 87.547 kWh/m2 | 17.68 kg CO2/m2 |

| CO2 Assessment Stage | LCCO2 Emissions (kg-CO2/m2) | ||||

|---|---|---|---|---|---|

| Case-1 | Case-2 | Case-3 | Case-4 | ||

| Construction | Production | 1381.52 | 1213.83 | 1111.87 | 1086.59 |

| Transportation | 7.39 | 7.39 | 7.39 | 7.39 | |

| Construction | 10.96 | 10.96 | 10.96 | 10.96 | |

| Sub-total | 1399.87 | 1232.19 | 1130.22 | 1104.95 | |

| Operation | Occupancy | 4656.10 | 3115.27 | 3115.27 | 3115.27 |

| Maintenance | 42.40 | 42.40 | 42.40 | 42.40 | |

| Sub-total | 4698.50 | 3157.67 | 3157.67 | 3157.67 | |

| Dismantling and Disposal | Dismantling | 32.40 | 32.40 | 32.40 | 32.40 |

| Transportation | 3.60 | 3.60 | 3.60 | 3.60 | |

| Disposal | 0.58 | 0.58 | 0.58 | 0.58 | |

| Sub-total | 36.58 | 36.58 | 36.58 | 36.58 | |

| TOTAL | 6134.95 | 4426.44 | 4324.47 | 4299.20 | |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baek, C.; Tae, S.; Kim, R.; Shin, S. Life Cycle CO2 Assessment by Block Type Changes of Apartment Housing. Sustainability 2016, 8, 752. https://doi.org/10.3390/su8080752

Baek C, Tae S, Kim R, Shin S. Life Cycle CO2 Assessment by Block Type Changes of Apartment Housing. Sustainability. 2016; 8(8):752. https://doi.org/10.3390/su8080752

Chicago/Turabian StyleBaek, Cheonghoon, Sungho Tae, Rakhyun Kim, and Sungwoo Shin. 2016. "Life Cycle CO2 Assessment by Block Type Changes of Apartment Housing" Sustainability 8, no. 8: 752. https://doi.org/10.3390/su8080752

APA StyleBaek, C., Tae, S., Kim, R., & Shin, S. (2016). Life Cycle CO2 Assessment by Block Type Changes of Apartment Housing. Sustainability, 8(8), 752. https://doi.org/10.3390/su8080752