1. Background

It is predicted that, by 2020, carbon emission of infrastructure projects in China will reach 0.197 billion tons [

1]. Pavement construction is one of the significant contributors. According to the China Statistical Yearbook (2012), the numbers of municipal projects including pavement projects under construction and planned were 47097 and 30079, respectively in 2011 [

2]; and these numbers are still increasing along with the rapid urbanization. To reduce carbon emissions, quantifying them is of significant importance. While various methodologies are available for quantifying carbon emission of pavement construction worldwide, adopting and promoting the existing tools to China’s market is found to be fairly challenging due to the institutional constraints. Research widely recognized that carbon emission calculation varies across different countries due to difference associated with parameters, data source, construction methods and regional conditions [

3,

4]. This renders the comparison between different countries complex and difficult [

4]. Another hindrance to carbon emission estimation for pavement construction is the scarcity of reliable data [

5]. It is worth noting that, recently, Wang et al.’s (2015) and Ma et al.’s (2016) studies presented a list of carbon emission factors for pavement construction in China [

6,

7]. However, uptake of these factors would face challenges as practitioners have to collect a separate panel of data for the calculation methodology.

The objectives of this study are to develop a carbon emission calculation methodology with a customized database; and develop an automatic tool for carbon emission estimation. The customized database is compatible with the fixed pricing systems (Dinge) prevalent in China. Therefore, practitioners could calculate carbon emissions based on the bill of quantities which could be directly extracted from the project cost estimation software.

The structure of this paper is organized as follows. In

Section 2, a literature review of tools for measuring carbon emissions of pavement construction is carried out, and their applicability to the China’s context is discussed.

Section 3 reports the proposed methodology and

Section 4 focuses on developing specific parameters for the methodology application.

Section 5 introduces a C# based tool which embeds the proposed methodology and derived parameters. The methodology and the automatic tool are, in the end, validated in a real case in

Section 6. The last section provides the conclusions and recommendations.

2. Literature Review

LCA tools for measuring carbon emissions are formalized by the International Organization for Standardization (ISO) 14040 series, particularly the ISO 14040:2006−Principles and Framework [

8] and ISO 14044:2006—Requirements and Guidelines [

9]. These two together describe the basic concepts and methodologies for LCA studies. For measuring carbon emissions of pavement projects, various practical tools have been developed. For instance, in 1997–1999, Euro bitume conducted an LCI study on paving grade bitumen. A new version in 2011 included polymer-modified binder and bitumen emulsion [

10]. The bitumen LCI as a cradle to gate study covers: extraction of crude oil; transport to Europe including pipeline and ship transport; manufacturing of bitumen; and hot storage of the product. It also takes into account the construction of production facilities [

10].

In 2011, UK Transport Research Laboratory, in collaboration with the Highways Agency, Mineral Products Association and Refined Bitumen Association, built an asphalt Pavement Embodied Carbon Tool (asPECT) [

11]. This UK-based tool is able to produce PAS (Publicly Available Specification) 2050-compliant cradle-to-grave carbon footprint reports for asphalt [

12]. The boundary covers: the cradle to gate CO

2e (CO

2 equivalent) of each constituent material and ancillary material; the transport CO

2e from factory gate to plant; CO

2e arising from all forms of energy involved in producing the asphalt at the mixing plant, other than that involved in heating and drying, but including energy for offices on site; and CO

2e arising from the process of heating [

11].

Huang et al. (2009) developed a spreadsheet-based LCA tool for construction and maintenance of asphalt pavements. The model consists of five worksheets. These are process parameters (e.g., energy in transportation), pavement parameters (e.g., pavement dimensions), unit inventory (i.e., energy production), project inventory (e.g., production process), and characterization results (e.g., global warming) [

3].

International Road Federation designed a greenhouse gas calculator—Calculator for Harmonized Assessment and Normalization of Greenhouse-gas Emissions for Roads (CHANGER)—for road infrastructure projects. It is compatible with the International Panel on Climate Change (IPCC) guidelines and could be used to monitor and assess greenhouse gas emissions (GHG) generated during the different stages of the road construction process [

13,

14].

In 2007, Portland Cement Association published Environmental Life Cycle Inventory of Portland Cement Concrete, originally published in 2000 and updated in 2002 [

15]. This report presents the results of the LCI of three concrete products, namely ready mixed concrete, concrete masonry, and precast concrete. The system boundary includes cement and slag cement manufacture, aggregate production, transportation of fuel, cement, supplementary cementitious materials, and aggregates to the concrete plant, and concrete plant operations [

15].

Infrastructure Voluntary Evaluation Sustainability Tool (INVEST) was developed by the Federal Highway Administration. INVEST considers the lifecycle of projects and has three modules to evaluate the lifecycle of transportation services, including system planning, project development, and operations and maintenance. Each of these modules is based on a separate collection of criteria and can be evaluated separately [

16].

Roadprint is an Excel-based tool, which can facilitate knowledge that will: implement pavement LCA in a standardized and reproducible manner; conduct probabilistic analysis; and generate well-analyzed presentations of results to interpret LCA outputs [

17].

The BE2ST-in-Highways system incorporates standardized measurement methods of LCA and life-cycle cost analysis (LCCA) [

18]. The system is equipped with a tool to weight sustainability indexes using the analytical hierarchy process and is embedded in an Excel spreadsheet. The evaluation steps include creating alternative pavement designs, predicting the service life of each design, identifying rehabilitation strategies, and conducting LCA and LCCA. Four criteria were considered in LCA: energy consumption, GHG emissions, water consumption, and generation of hazardous wastes. These four are defined by the U.S. Resource Conservation and Recovery Act.

Although various tools have been developed worldwide, it is widely recognized that a LCA model from one country cannot be simply applied to another due to difference between construction materials, construction techniques, and the validity and applicability of the data [

3]. Yu and Lu (2012) argued that it seems impossible to perform straightforward comparison of the results due to the differences in approach, functional units, analysis periods, system boundaries, regional differences, and difference in input data [

4]. Especially, the scarcity of reliable data would undermine the quality of carbon emission calculation [

5]. Thus, for measuring carbon emissions of pavement construction in China, the methodology should be localized, with supporting database customized to the local context.

Ma et al. (2016) established an inventory analysis method to evaluate the greenhouse gas emissions from Portland cement concrete pavement construction in the west of China. The boundary of the concrete pavement construction process consists of raw material production, concrete manufacture, and pavement onsite construction. However, they failed to provide a transparent method to calculate the quantity of energy and material consumption. This might impede the uptake of this tool in practice [

7].

In addition, Wang et al. (2015) estimated carbon emissions for three types of projects, namely subgrade, pavement, and bridges and tunnels [

6]. The boundary comprises raw material production, material transportation, and onsite construction. They derived the material and energy consumption and machine working hours from the budget sheet. However, they did not provide evidence on scope match between emission factors and bill of quantities. For example, material wastes are often incurred on site, but might not be directly calculated in the carbon emission.

A lack of sufficient professionals in quantifying carbon emissions is another significant hindrance to the tool adoption. There is a huge deficiency of trained professionals in evaluating carbon emissions if the government is going to initiate carbon emission calculation or audit in road projects either in a voluntary or mandatory manner. The challenges to train a large group of professionals in a short term will be enormous. Thus, it will be more feasible to develop a methodology which is featured by labor-saving.

This study aimed to propose a methodology for measuring the carbon emissions of pavement construction compatible with the fixed pricing systems prevalent in China and develop a tool with built-in database of carbon emission factors to assist in the carbon estimations. This tool has the advantages of embedding a China contextualized database and being labor-saving.

3. Quantifying Carbon Emissions of Road Construction Projects

The boundary of carbon emission comprises four stages: material manufacture, transportation, construction, and disposal (see Equation (1))

where

: Carbon emissions at the material manufacture stage;

: Carbon emissions at the material transportation stage;

: Carbon emissions at the construction stage;

: Carbon emissions at the disposal stage.

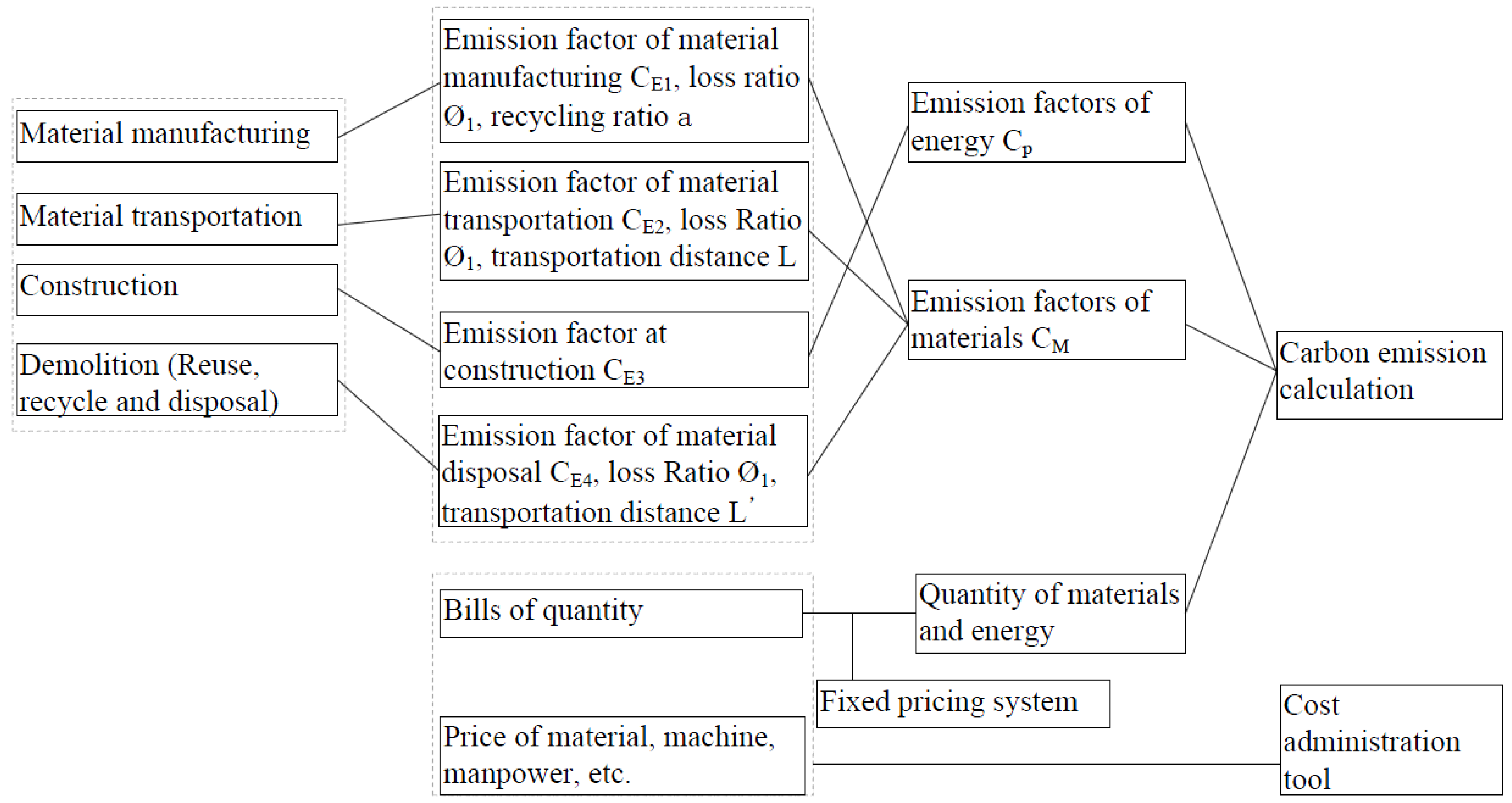

Equation (1) could be further converted in to the Equation (2) in accordance with the methodology shown in

Figure 1. In the end, the total carbon emissions are aggregated under the energy consumption and materials used. For calculating Equation (2), quantity of energy consumption and material usage could be directly accessible by combing the bills of quantity and the fixed pricing system. The fixed price system in China is developed and maintained by the Ministry of Housing and Urban-Rural Development, China. The cost administration agency in each city and province could calibrate this system to its local context. This fixed price system has an authorized database for quantifying the material usage and energy consumptions. The database is updated on a regular basis. Therefore, the accuracy of calculating carbon emission could be guaranteed when it is designed to be compatible with the database.

where

: emission factors of materials;

: quantities of materials (including wastes).

As can be seen from Equation (2) and

Figure 1, two major steps of this methodology are to identify quantities of energy consumptions and material usage, and estimate a set of composite emission factors (i.e.,

,

) (see

Figure 1). The first step could be easily completed by using the bill of quantity and the existing cost management system. The estimation of a set of composite emission factors is elaborated below.

The composite emission factors of materials () are transformed from emission factors of material manufacturing , material transportation , material disposal . The emission factor of energy () is estimated from construction stage emission factors ().

3.1. Material Manufacture Stage

At the material manufacture stage, the boundary of carbon emissions is defined from raw material to the final product, including energy use, transportation, and manufacturing process. Equation (3) is used to quantify carbon emission at the manufacture stage. Wastes during the construction are also taken into account.

where

: net quantity of material use;

: emission factors of the material at the manufacture stage;

: percentage of wastes;

i: type of materials.

In Equation (3), the emission factors for the materials at the manufacture stage

are calculated using Equations (4) and (5).

where

: emission factors for the raw material manufacture;

: emission factors for the raw material transportation;

: emissions factors for energy use at the manufacture stage;

: percentage of material recycled; and

: emission factors for using the re-cycled material.

where

where

: energy consumption at the material manufacturing;

: emission factors of stationary energy;

: emission factors of type

k GHG for type

j energy;

: GWP;

j: type of energy;

k: type of GHG (i.e., CO

2, CH

4, N

2O).

3.2. Material Transportation

At the material transportation stage, energy consumption for transporting materials from the manufacture site to the construction site is the principal source of CO

2e emission. Carbon emission at the material transportation stage could be estimated by using Equation (6). The emission factors are calculated by using Equation (7). In Equation (7),

denotes the intensity of carbon emissions, with the unit of carbon emission per unit of material per unit distance.

where

: Net material use;

: Emission factors of the materials at the transportation stage.

where

where

: Distance from manufacture site to the construction site;

: Energy consumptions per distance per unit of material;

: Emission factors for the mobile source;

: Emission factors of

k type GHG for

j type energy.

3.3. Construction Stage

At the construction stage, CO

2e is mainly emitted from the energy consumption (i.e., electricity, diesel, petroleum gas) in the machinery operation. Thus, the carbon emission could be quantified using Equations (8) and (9).

where

: Energy consumptions;

: Emission factors during the construction stage;

j: types of energy.

where

: Emission factors of type

k GHG for type

j energy.

3.4. Construction Waste Disposal Stage

During the waste disposing stage, energy is consumed for transporting waste to landfill site. It is assumed that the vehicles are fully loaded and only one-way energy use is considered. It is also assumed that two recyclable materials are steel and aluminum given a high recycling ratio of these two materials. The equations are presented in Equations (10) and (11).

where

: quantity of waste;

: emission factors of waste disposal.

where

: the distance from the construction site to the landfill site;

: emission factors for mobile sources.

5. A C# Based Tool for Carbon Emission Calculation

This methodology was programmed into a tool with the help of C# and Visual Studio 2010. This tool has multiple features. First, it is compatible with the outputs of all cost management software currently available in China. Thus, adoption of this tool would contribute to boost productivity of quantifying carbon emission. Second, the tool is user-friendly as it is designed with a similar interface to Microsoft Office. Third, the quantification process is transparent and verifiable, with the aid of a reliable database. In addition, the emission factors and associated basic parameters could be further fine-tuned to any specific project if following the methodology proposed in this study.

Besides the basic function of carbon emission estimation, this tool also produces project background reports, has the function of managing the database of emission factors, and generates a carbon emission report. The carbon emission report comprises the total carbon emission and breakdown of the carbon emission of each type of material and energy. All the functions are shown in

Table 8.

Operating the tool includes four steps: coding the material types; specifying the unit of each type of materials; inputting the database of the composite emission factors; and inputting quantity of materials and energy consumption. As the tool is compatible with spreadsheet format data, users can use the spreadsheet to prepare the material codes, unit of the material, and emission factor database.

6. Case Study

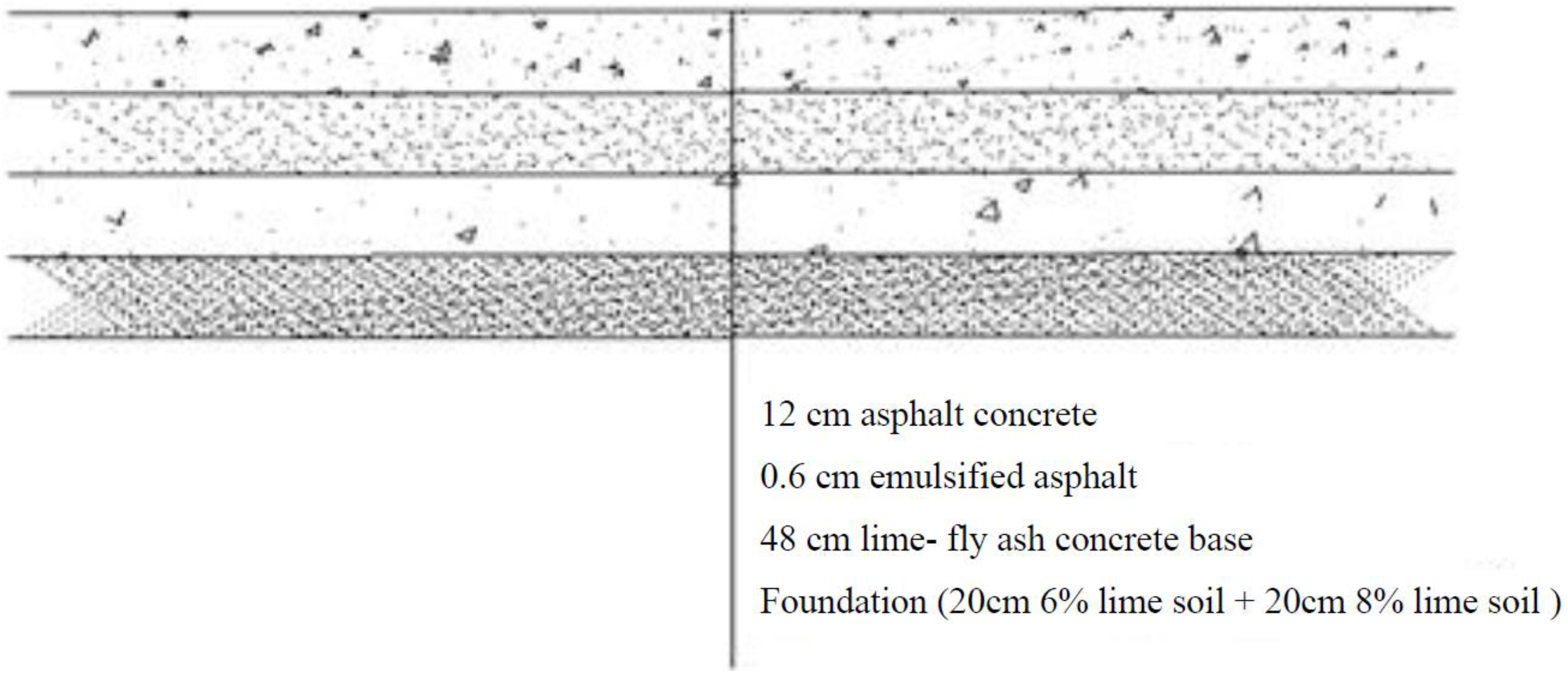

In order to verify the effectiveness of the tool, a road project located in Suzhou city, Jiangsu province, China was examined. Another purpose of the case study is to reach an initial recognition of the intensity of carbon emissions in China’s pavement construction. The structure of the road is shown in

Figure 2. The project comprised road and affiliated drainage works and pedestrian roads. It was about 0.56 km long and 26 m wide, with four 3.75 m lanes, plus a 3.5 m bicycle lane and 2 m sidewalk on both sides.

The boundary of carbon emission comprises material manufacture and transportation, construction, and construction waste disposal. The physical boundary contains construction of the road, affiliated drainage, and sidewalks. The functional unit is one-km four-lane road.

As shown in

Figure 1, quantifying carbon emissions requires inputs of quantities of materials and energy consumptions and the composite emission factors. The quantities of materials were directly accessed from commercial software used for cost administration. In this case, it is “weilai qingdan”. The mechanism for calculating the quantity of energy consumptions and material usage is based on the fixed pricing system, which is built in “weilai qingdan”. The final results could be saved in a spreadsheet as an input for the carbon emission calculation.

The procedure of operating the tool consisted of creating a new project, inputting the list of quantity of materials and energy consumptions; selecting the emission factor for each type of materials; and clicking the calculation button. In the end, a report of carbon emission was obtained. For this case, the total carbon emission is 3744.457 t (see

Figure 3). Thus, the carbon emission per functional unit is 1672 t/lane km. The breakdown of carbon emissions shows that the use of lime accounts for 70% of the carbon emissions.

7. Conclusions and Recommendations

While a number of methodologies for quantifying carbon emissions of road projects are developed in China and worldwide, adopting and promoting these tools to the China market is found fairly challenging due to the institutional constraints. To fill in this knowledge gap, a carbon emission calculation methodology compatible with the current fixed pricing systems used in China was proposed in this study. This methodology was programmed into a C# and Visual 2010-based tool and further validated in a real case.

This study contributes to the extant literature by presenting a carbon emission calculation tool customized to the China’s context. This tool developed was proven to be user-friendly through the case study. The methodology underpinning the practical tool could generate a reliable database, thereby ensuring accurate carbon emission quantification. The proposed methodology and tool also have advantages of facilitating the uptake as the quantity of the material and energy consumption could be directly obtained from the existing cost management software. This tool provides practitioners with an accurate and user-friendly platform to estimate carbon emissions of pavement construction. Besides, this study established a database of composite emissions factors for energy and materials for the Jiangsu Province context.

Generalizing such methodology to other countries or regions should be read with caution as the advantage of such a tool is its compatibility with the fixed pricing system in China and the emission factors are suitable for the Jiangsu Province context. However, this limitation is not unique to this study given that the boundary and methodology used in carbon calculation tools are expected to be compliant with the existing regulations and policy. The regulations and policy would vary considerably across geographic regions.

Another limitation is that this study did not consider the carbon emission from operation and maintenance stages. Thus, for future studies, adopting an LCA approach is suggested (see life cycle approach in [

28,

29,

30]). In addition, the environmental impact of pavement construction, other than the carbon emissions, could be incorporated in the LCA (see [

28,

30]). The emission factors for 29 types of materials and energy were identified in this study. Although most of them are the major materials in construction, they only constitute a small proportion of construction materials. Nonetheless, the methodology used in this study is applicable for calculating emission factors for other types of materials. Thus, future studies that enlarge this database are recommended.

The third limitation is concerned with the effects of concrete on carbon emission. This study mainly focused on the concrete which contributes to carbon emission. However, increasing studies found that high performance concrete would expand their lifespan and generate less carbon emissions (e.g., [

31,

32]). Thus, future studies that examine different types of concrete should take the variation of carbon emission factors into account.

This study assumed that all data source and input parameters are fixed across different project types. However, this assumption might not hold true as data sources and input parameters are subject to various uncertainties (see [

28]). Thus, future studies that examine the uncertainty effect of the key data sources and input parameters would be suggested.

The last limitation is the simplification of concrete structure demolition. This study only takes the transportation of waste during the disposal stage into account. Existing studies found that extra carbon emission could also be generated during the disposal stage (see [

33]). Future studies that present a holistic approach to investigate the carbon emissions during the disposal stage would be recommended.