State-of-the-Art Review on Sustainable Design and Construction of Quieter Pavements—Part 2: Factors Affecting Tire-Pavement Noise and Prediction Models

Abstract

:1. Introduction

2. Factors Affecting Tire-Pavement Noise

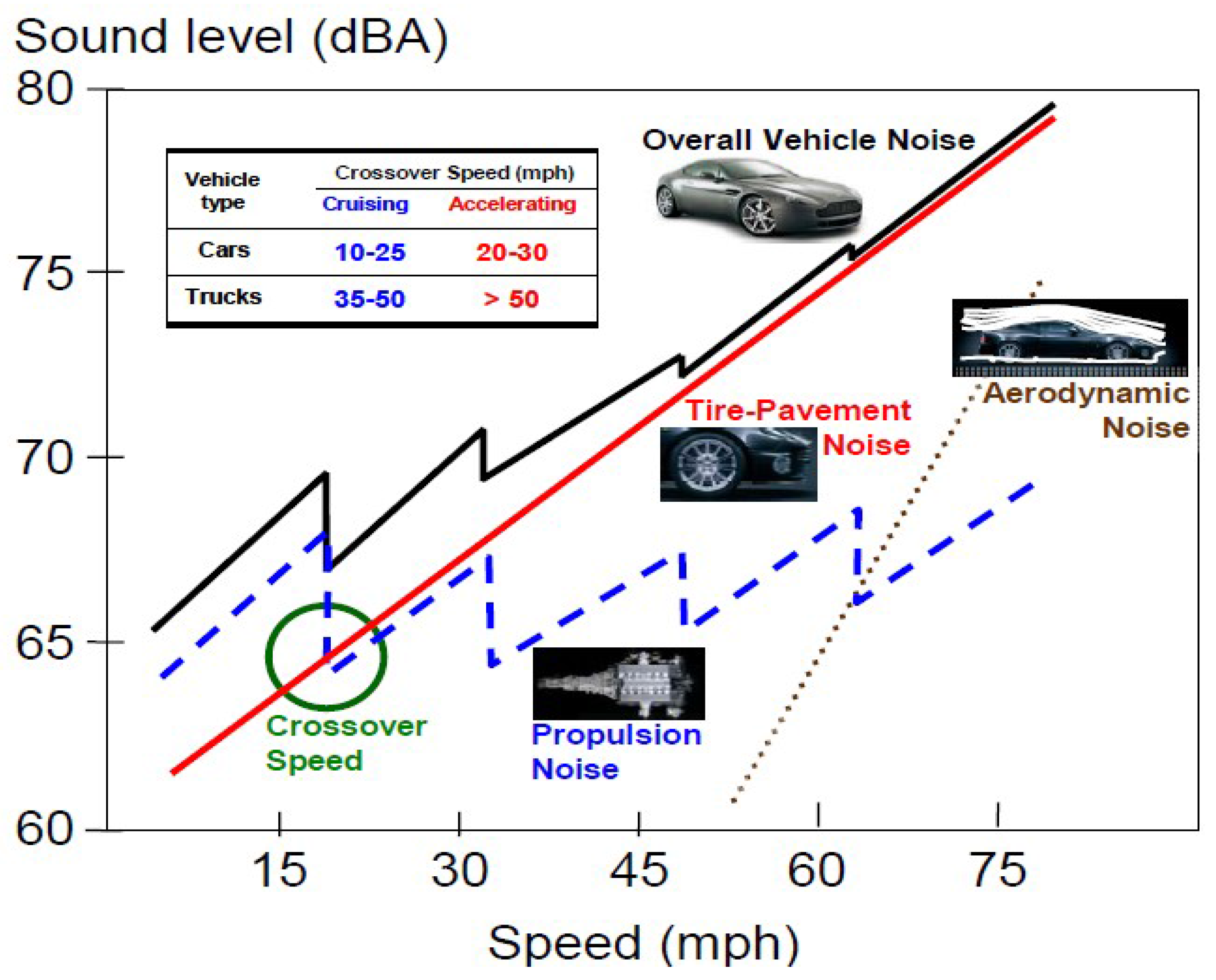

2.1. Type of Vehicle

2.2. Vehicle Speed

2.3. Temperature

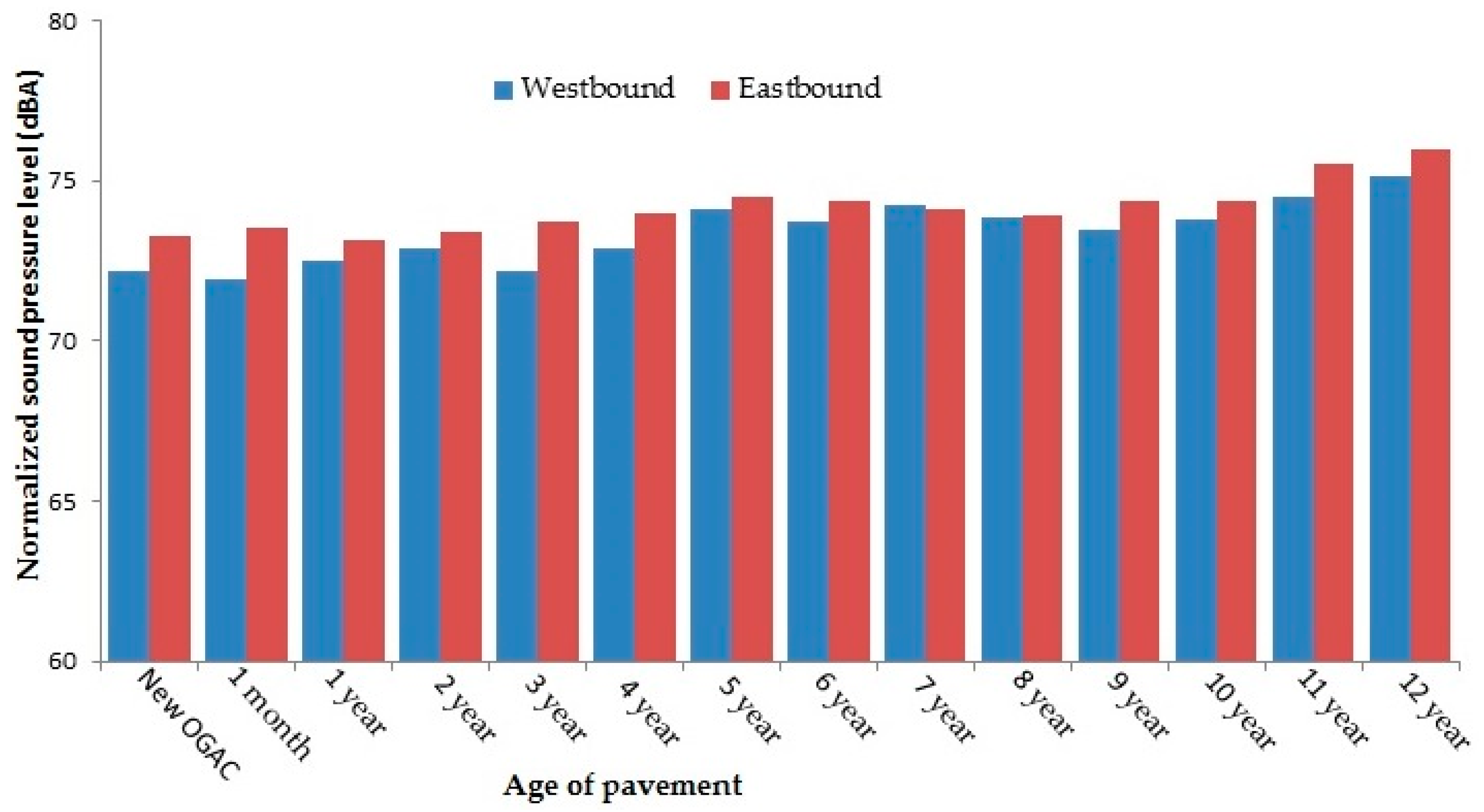

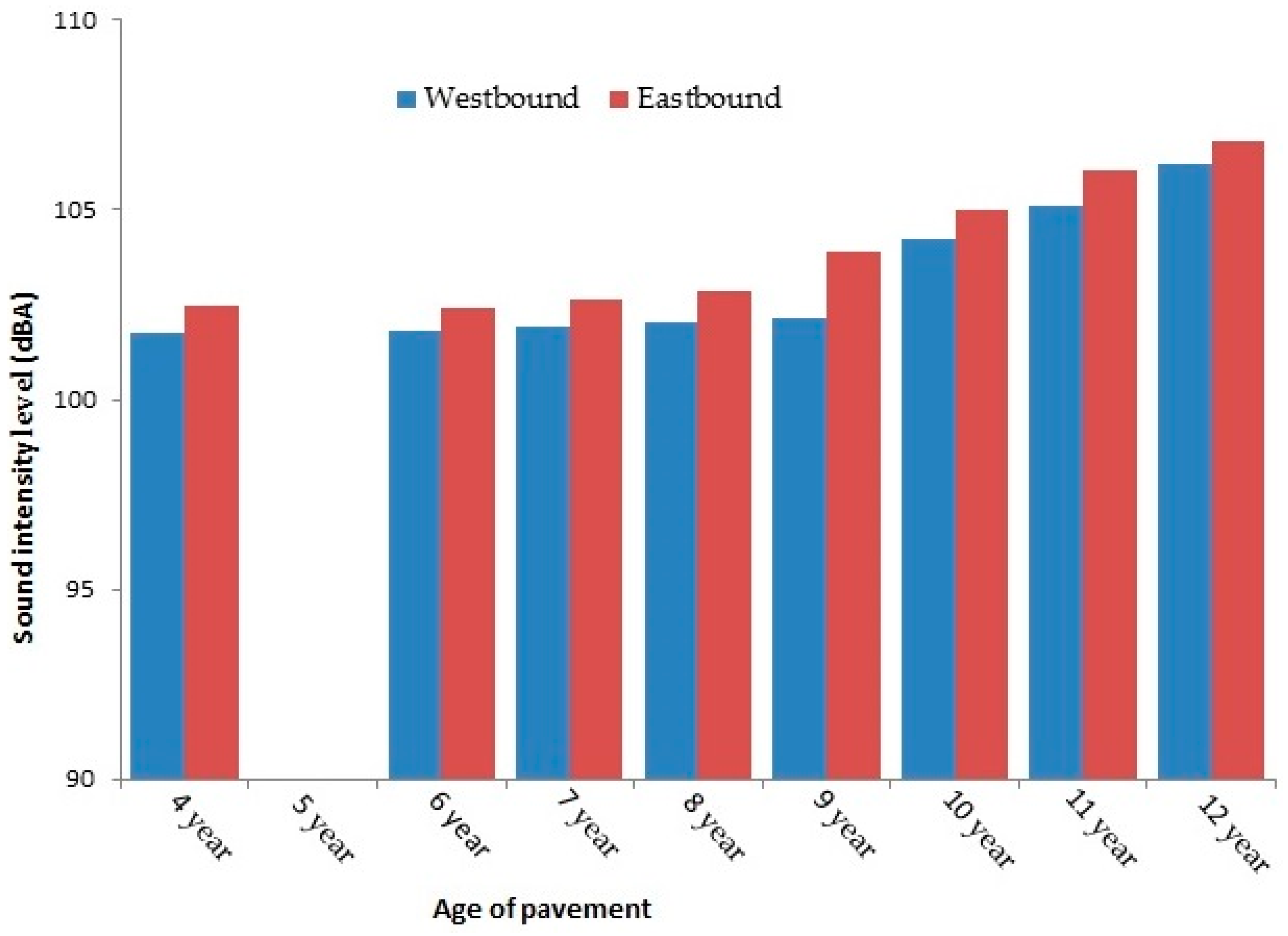

2.4. Aging of Pavement Surface

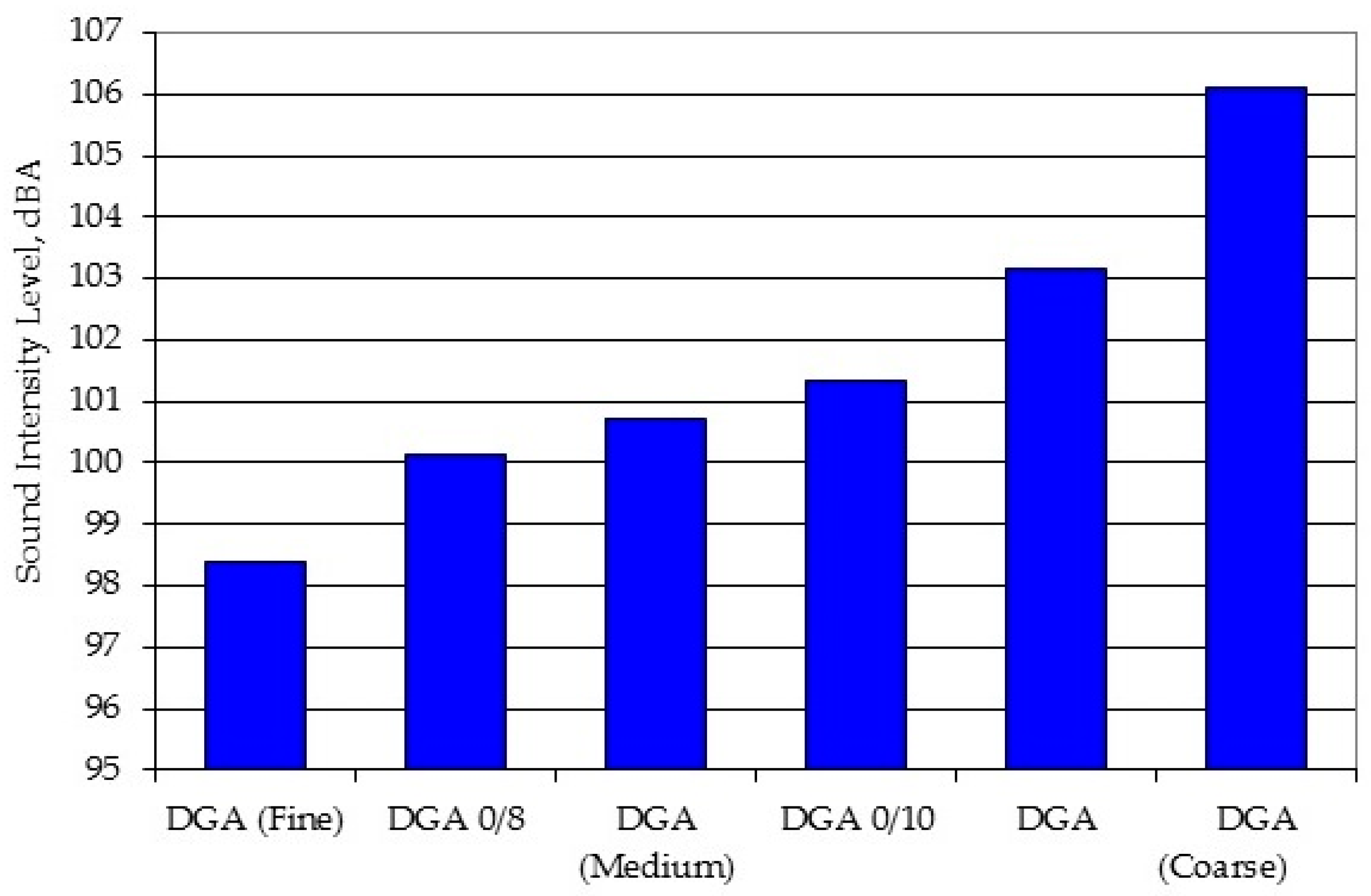

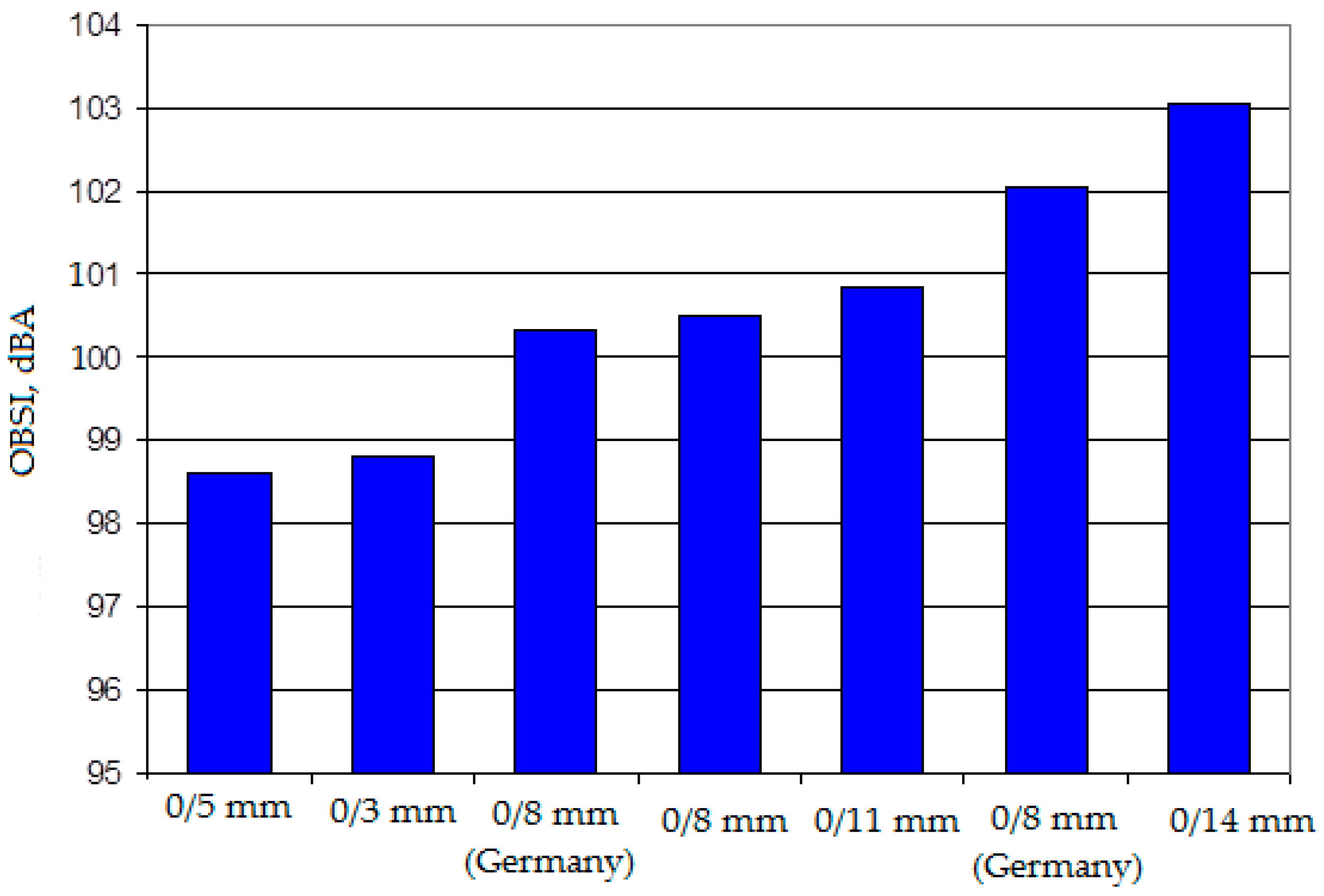

2.5. Maximum Aggregate Size and Gradation

2.6. Air Void Content

2.7. Surface Type

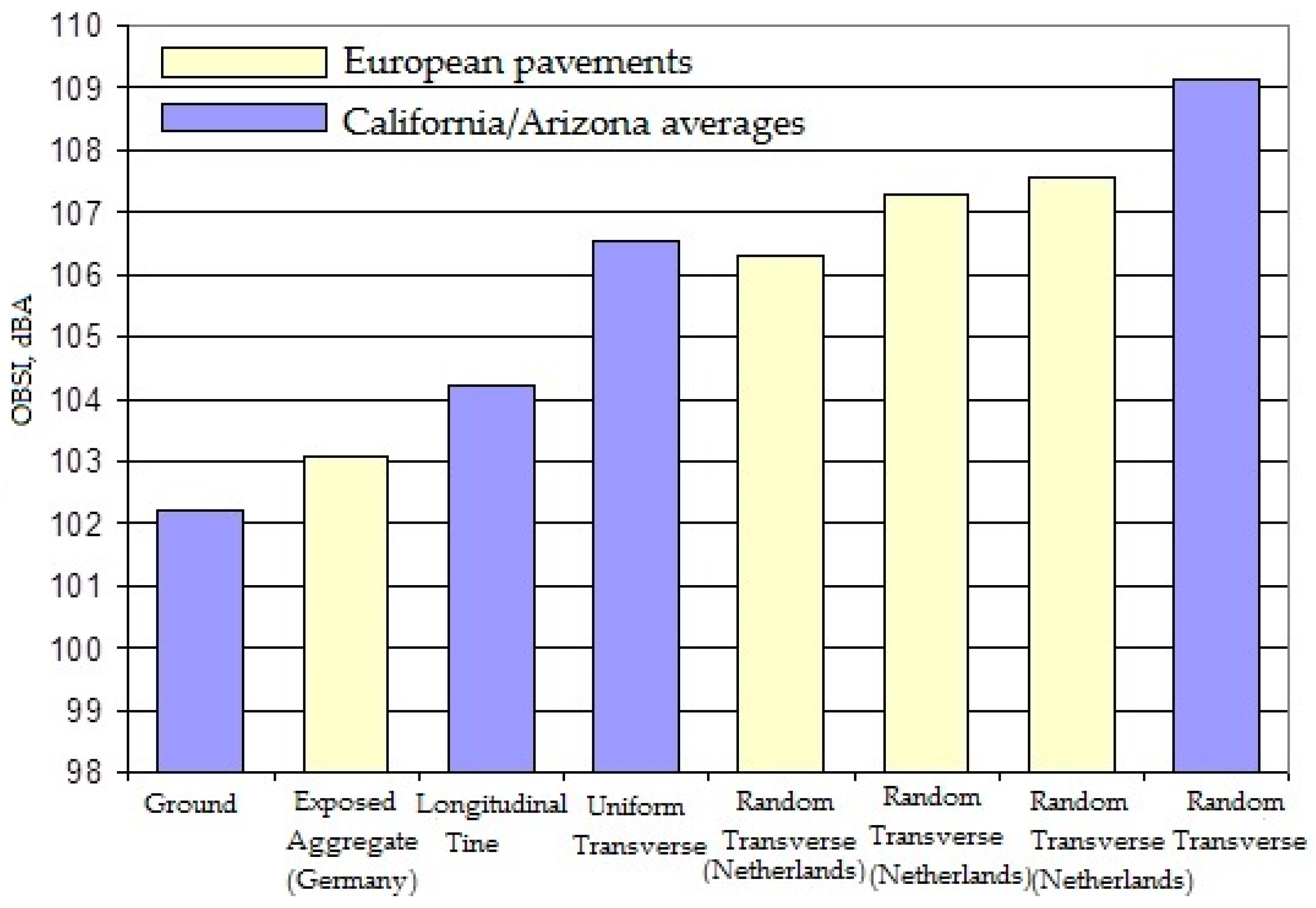

2.8. Surface Texture

2.9. Aggregate Type

2.10. Thickness of Pavement Surface

2.11. Stiffness of Pavement Surface

2.12. Effect of Sound Absorption on Tire-Pavement Noise

2.13. Effect of Surface Friction on Tire-Pavement Noise

3. Noise Prediction Models

4. Future Research Direction

- Various factors affected the tire-pavement noise as reported in literature. Of them, temperature plays an important role in generating tire-pavement noise. The literature survey showed that the highest air temperature used in previous studies is limited to 95 °F [17]. Donavan and Lodico [120] conducted a study on precision and bias of OBSI testing (which is the basis of current AASHTO standard) and restricted temperature for noise testing within 20 to 100 °F. However, in some regions especially in the Middle East, temperature often exceeds 100 °F during summer time. Therefore, a comprehensive testing program incorporating a wide range of temperatures is needed to evaluate the temperature effect on tire-pavement noise.

- Porous pavement is widely accepted as a low noise surface. However, researchers hypothesize that the voids of this surface fill with dirt over time, which in turn increases noise. This is particularly important in the Middle East region, where large amounts of dirt are present in atmosphere. Therefore, a systematic laboratory experimental program is needed to evaluate the clogging effect on the noise properties of the mixtures.

- The literature survey also suggests that there is a potential correlation between acoustic absorption properties measured in the laboratory and tire-pavement noise measured in the field. Some research studies have been performed to validate this relationship but observed conflicting trends. Therefore, a comprehensive evaluation of the relationship between acoustic absorption characteristics and tire-pavement interaction noise has to be conducted, which will assist engineers to optimize the design and material selection of roadway construction in order to provide a low level of road noise.

- Surface friction of a pavement is a key safety issue. In general, tire-pavement noise and pavement surface friction appears to be inversely related. Therefore, more research is needed in order to optimize these two conflicting pavement properties.

- Traditionally, noise prediction models have been developed by using a reference pavement (either a national average or standard pavement type) in order to predict noise impacts and determine abatement measures. Recent research showed the contribution of pavement effects on noise prediction can be incorporated in noise models. For the FHWA TNM, further work is needed to incorporate a broad range of pavements into the model.

5. Conclusions

Acknowledgments

Conflicts of Interest

References

- WHO. Night Noise Guidelines for Europe; Regional Office for Europe: Copenhagen, Denmark, 2009; Available online: http://www.euro.who.int/__data/assets/pdf_file/0017/43316/E92845.pdf (accessed on 12 May 2016).

- Rasmussen, R.; Bernhard, R.; Sandberg, U.; Mun, E. The Little Book of Quieter Pavements; Report No. FHWA-IF-08-004; Federal Highway Administration: Washington, DC, USA, 2007.

- Sandberg, U. Tire-road noise-myths and realities. In Proceedings of the Inter-Noise, The Hague, The Netherlands, 27–30 August 2001.

- Sandberg, U.; Ejsmont, J. Tire-Road Noise Reference Book; Informex: Kisa, Sweden, 2002. [Google Scholar]

- Donavan, P.; Rymer, B. Assessment of highway pavements for tire-road noise generation. In Proceedings of the Society of Automotive Engineers Noise and Vibration, Grand Traverse, MI, USA, 3 May 2003.

- Bennert, T.; Hanson, D.; Maher, A.; Vitillo, N. Influence of pavement surface type on tire-pavement generated noise. J. Test. Eval. 2005, 33, 94–100. [Google Scholar]

- Cho, D.; Mun, S. Study to analyze the effect of vehicles and pavement surface types on noise. J. Appl. Acoust. 2008, 69, 833–843. [Google Scholar] [CrossRef]

- Donavan, P.; Lodico, D. Measuring Tire-Pavement Noise at the Source; National Cooperative Highway Research Program, NCHRP Project: 1-44, Report No. 630; Transportation Research Board: Washington, DC, USA, 2009. [Google Scholar]

- Edwin, H. Evaluating Tire-Pavement Noise Utilizing the on-Board Sound Intensity Method. Master’s Thesis, The State University of New Jersey, New Brunswick, NJ, USA, 2013. [Google Scholar]

- Leung, Y.; Tighe, S.; MacDonald, G.; Penton, S. Development of tools to evaluate quiet pavements in the laboratory and field. In Proceedings of the Annual Conference & Exhibition of the Transportation Association of Canada, Charlottetown, PE, Canada, 17–20 September 2006.

- Mogrovejo, D.; Flintsch, G.; León, E.; McGhee, I. Effect of air temperature and vehicle speed on tire-pavement noise measured with on-board sound intensity methodology. In Proceedings of the Transportation Research Board 92nd Annual Meeting, Washington, DC, USA, 13–17 January 2013; National Research Council: Washington, DC, USA, 2013. [Google Scholar]

- Rochat, J.; Read, D.; Fleming, G. Caltrans Thin Lift Study: Effects of Asphalt Pavements on Wayside Noise; Caltrans Report No. CA 10-0146; California Department of Transportation: Sacramento, CA, USA, 2010.

- Wang, G.; Shores, R.; Botts, J.; Hibbett, H. On-Board Sound Intensity Tire-Pavement Noise Study in North Carolina; Report No. FHWA/NC/2010-1; North Carolina Department of Transportation: Raleigh, NC, USA, 2011.

- National Center for Asphalt Technology (NCAT). Tire-Pavement Noise Study for the Michigan Department of Transportation; Michigan Department of Transportation: Lansing, MI, USA, 2003.

- Wang, G.; Smith, G.; Shores, R. Pavement noise investigation on North Carolina highways: An on-board sound intensity approach. Can. J. Civ. Eng. 2012, 39, 878–886. [Google Scholar] [CrossRef]

- Lédée, A.; Pichaud, F. Temperature effect on tire-road noise. J. Appl. Acoust. 2007, 68, 1–16. [Google Scholar] [CrossRef]

- Rochat, J. Investigation of Temperature Correction for Tire-Pavement Noise Measurements; FHWA Report No. FHWA-HEP-11-005; John A. Volpe National Transportation Systems Center: Cambridge, MA, USA; U.S. Department of Transportation: Washington, DC, USA, 2010. [Google Scholar]

- ADOT QPPP. Progress Report No. 2 Quiet Pavement Pilot Program. Available online: http://www.rubberpavements.org/Library_Information/SpecificationsHandbook/Section_07_ADOT_Quiet_Pavement_Pilot_Program/7A_ADOT_Quiet_Pavement_Progress_Report_No_2.pdf (accessed on 18 July 2016).

- Volpe. FHWA TNM Pavement Effect Implementation Study; U.S. DOT/RITA: Cambridge, MA, USA, 2008. [Google Scholar]

- Bendtsen, H.; Lu, Q.; Kohler, E. Temperature Influence on Road Traffic Noise-Californian OBSI Measurement Study; Report 169; Road Directorate, Danish Road Institute: Copenhagen, Denmark, 2009. [Google Scholar]

- Sandberg, U. Semi-generic temperature corrections for tire-road noise. In Proceedings of the Inter-Noise, Prague, Czech Republic, 22–25 August 2004.

- ASTM F2493-08. Standard Specification for P225/65R16 97S Radial Standard Reference Test Tire; American Society for Testing and Materials: Philadelphia, PA, USA, 2008. [Google Scholar]

- Bendtsen, H.; Lu, Q.; Kohler, E. Acoustic Aging of Asphalt Pavements: A Californian/Danish Comparison; Report No. UCPRC-RP-2010-0; California Department of Transportation: Berkeley, CA, USA, 2010.

- Bühlmann, E.; Ziegler, T. Temperature effects on tire/road noise measurements and the main reasons for their variation. In Proceedings of the Inter-Noise, Innsbruck, Austria, 15–18 September 2013.

- Dare, T.; McDaniel, R.; Shah, A.; Bernhard, R. Hot Mix Asphalt Surface Characteristics Related to Ride, Texture, Friction, Noise and Durability; Report No. MN/RC 2014-07; Minnesota Department of Transportation: Saint Paul, MN, USA, 2014.

- Irali, F.; Gonzalez, M.; Tighe, S.; Simone, A. Temperature and ageing effects on tire-pavement noise generation in Ontarian road pavements. In Proceedings of the Transportation Research Board 94th Annual Meeting, Washington, DC, USA, 11–15 January 2015.

- Bendtsen, H.; Andersen, B. Thin Noise Reducing Pavements-Experiences; Report No. 145; Road Directorate, Danish Road Institute: Copenhagen, Denmark, 2005. [Google Scholar]

- Bendtsen, H.; Andersen, B. Noise-reducing pavements for highways and urban roads-state of the art in Denmark. In Proceedings of the Association of Asphalt Paving Technologists Technical Sessions, Long Beach, CA, USA, 7–9 March 2005.

- European Asphalt Pavement Association (EAPA). Abatement of Traffic Noise—The Arguments for Asphalt; EAPA: Brussels, Belgium, 2007. [Google Scholar]

- Kohler, E. Findings from the tire-pavement noise study at the UC Pavement research center, part of Caltrans quiet pavement research (QPR) program. In Proceedings of the TRB Summer Meeting, San Luis Obispo, CA, USA, 13–14 June 2007.

- Kephalopoulos, S.; Paviotti, M.; Lédée, F. Common Noise Assessment Methods in Europe (CNOSSOS-EU); Report EUR 25379 EN; Publications Office of the European Union: Ispra, Italy, 2012. [Google Scholar]

- Trevino, M.; Dossey, T. Noise Measurements of Highway Pavements in Texas; Research Report No. FHWA/TX-10/0-5185-3; Center for Transportation Research, The University of Texas at Austin: Austin, TX, USA, 2009. [Google Scholar]

- Nicholls, J. Review of UK Porous Asphalt Trials; Report TRL264; Transport Research Laboratory: Crowthorn, UK, 1997. [Google Scholar]

- Scofield, L.; Donavan, P. Development of Arizona’s Quiet Pavement Research Program; Arizona Department of Transportation: Phoenix, AZ, USA, 2004.

- Donavan, P. Quiet Pavement Pilot Program: Progress Report 3; Report No. FHWA AZ-12-577; Arizona Department of Transportation: Phoenix, AZ, USA, 2012.

- Tehrani, F. Noise abatement of hot mix asphalt: A brief review. Int. J. Pavement Res. Technol. 2014, 8, 58–61. [Google Scholar]

- Illingworth & Rodkin, Inc. I-80 Davies OGAC Pavement Noise Study—A 12 Year Summary Report, 2012. Available online: http://www.dot.ca.gov/hq/env/noise/pub/Davis_12Yr_QPR_Study_May11.pdf (accessed on 20 May 2016).

- Hanson, D.; Waller, B. 2005 Colorado DOT Tire-Pavement Noise Study; Report No. CDOT-2006-18; Colorado Department of Transportation: Denver, CO, USA, 2006.

- Hanson, D.; James, R.; NeSmith, C. Tire-Pavement Noise Study; National Center for Asphalt Technology: Auburn, AL, USA, 2004. [Google Scholar]

- Sandberg, U. Road traffic noise-the influence of the road surface and its characterization. J. Appl. Acoust. 1987, 21, 97–118. [Google Scholar] [CrossRef]

- Rasmussen, R.; Sohaney, C. Tire-Pavement and Environmental Traffic Noise Research Study; The Transtec Group, Inc.: Austin, TX, USA, 2012. [Google Scholar]

- Wayson, R.; MacDonald, M.; Martin, A. On-Board Sound Intensity (OBSI) Study-Phase II; John A. Volpe National Transportation Systems Center: Cambridge, MA, USA; Florida Department of Transportation: Tallahassee, FL, USA, 2014. [Google Scholar]

- Kowalski, K. Influence of Mixture Composition on the Noise and Frictional Characteristics of Flexible Pavements. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 2007. [Google Scholar]

- Laboratoire Régional des Ponts et Chaussée (LRFC). The SPB Database of the Strasbourg LRPC in France; Regional Laboratory for Roads and Bridges: Strasbourg, France, 2005. [Google Scholar]

- Donavan, P. Comparative Measurements of Tire-Pavement Noise in Europe and the United States; Report Number: FHWA/CA/MI-2006/09; California Department of Transportation: Sacramento, CA, USA, 2006.

- Timm, D.; West, R.; Priest, A.; Powell, B.; Selvaraj, I.; Zhang, J.; Brown, R. Phase II NCAT Test Track Results; NCAT Report No. 06-05; National Center for Asphalt, Technology: Auburn, AL, USA, 2006. [Google Scholar]

- Sousa, J.; Way, G.; Zhu, H. Asphalt-Rubber Noise Data Compilation (Synthesis of Current Practices). Available online: http://www.asphaltrubber.org/Noise_Report_Synthesis/Noise_Report_October_2004 (accessed on 14 April 2015).

- Meiarashi, S.; Ishida, M.; Fujiwara, T.; Hasebe, M.; Nakatsuji, T. Noise reduction characteristics of porous elastic road surfaces. J. Appl. Acoust. 1996, 47, 239–250. [Google Scholar] [CrossRef]

- Bernhard, R.; Wayson, R. An Introduction to Tire-Pavement Noise; Final Research Report SQDH 2005-1; Purdue University: West Lafayette, IN, USA, 2005. [Google Scholar]

- McDaniel, R. Design of fine-graded superpave mixes. In Proceedings of the A Tire-Pavement Noise Symposium, Lafayette, IN, USA, 1–3 November 2005.

- Ongel, A.; Kohler, E.; Nelson, J. Acoustical Absorption of Open-Graded, Gap-Graded, and Dense-Graded Asphalt Pavements; Research Report No. UCPRC-RR-2007-12; California Department of Transportation: Sacramento, CA, USA, 2007.

- Descornet, G. Low-noise road surfaces: European state of the art. J. Assoc. Asph. Paving Technol. 2005, 74, 1059–1083. [Google Scholar]

- Huschek, S. Influence of road surface roughness on tire noise generation in the Federal Republic of Germany. In Surface Characteristics of Roadways: International Research and Technologies; Meyer, W.E., Reichert, J., Eds.; ASTM STP 1031; American Society for Testing and Materials: Philadelphia, PA, USA, 1990; pp. 430–441. [Google Scholar]

- Faure, B.; Hamet, J.F.; Kestemont, X.; Luminari, M.; Quaresma, L.; Sandulli, D. Traffic Noise and Road Surfaces: State of the Art; Belgian Road Research Centre: Brussels, Belgium, 2000. [Google Scholar]

- Izevbekhai, B. Tire-Pavement Interaction Noise of Concrete Pavements. Ph.D. Thesis, University of Minnesota, Minneapolis, MN, USA, 2012. [Google Scholar]

- Rasmussen, R.; Garber, S.; Fick, G.; Ferragut, T.; Wiegand, P. How to Reduce Tire-Pavement Noise: Interim Better Practices for Constructing and Texturing Concrete Pavement Surface; Research Report Pooled Fund TPF-5(139); National Concrete Pavement Technology Center: Ames, IA, USA, 2008. [Google Scholar]

- Rochat, J.; Hastings, A.; Read, D.; Lau, M. FHWA Traffic Noise Model (TNM) Pavement Effects Implementation Study: Progress Report 1; Research Report No. DOTVNTSC-FHWA-12-01; U.S. Department of Transportation; Federal Highway Administration: Washington, DC, USA, 2012.

- Samuels, S.; Hall, A. The acoustics attributes of Queensland pavement surfaces-the QDMR pavement surface noise resources manual. In Proceedings of the Australian Acoustical Society Annual Conference, Busselton, Australia, 9–11 November 2005; pp. 259–263.

- Sandberg, U.; Ejsmont, J. Texturing of cement concrete pavements to reduce traffic noise. J. Noise Control Eng. 1998, 46, 231–243. [Google Scholar] [CrossRef]

- Smit, F. Synthesis of NCAT Low-Noise HMA Studies; NCAT Report 08-01; National Center for Asphalt Technology: Auburn, AL, USA, 2008. [Google Scholar]

- Swift, J.; Bris, P.; Horoshenkov, K. Acoustic absorption in re-cycled rubber granulate. J. Appl. Acoust. 1999, 57, 203–212. [Google Scholar] [CrossRef]

- Shatanawi, K. The Effects of Crumb Rubber Particles on Highway Noise Reduction—A Laboratory Study. Ph.D. Thesis, Clemson University, Clemson, SC, USA, 2008. [Google Scholar]

- Biligiri, K. Effect of pavement materials’ damping properties on tire-road noise characteristics. J. Constr. Build. Mater. 2013, 49, 223–232. [Google Scholar] [CrossRef]

- Liao, G.; Sakhaeifer, M.; Heitzman, M.; West, R.; Waller, B.; Wang, S.; Ding, Y. The effects of pavement surface characteristics on tire-pavement noise. J. Appl. Acoust. 2014, 76, 14–23. [Google Scholar] [CrossRef]

- Paje, S.; Bueno, M.; Teran, F.; Miro, R.; Perez-Jiminez, F. Acoustic field evaluation of asphalt mixtures with crumb rubber. J. Appl. Acoust. 2010, 71, 578–582. [Google Scholar] [CrossRef]

- Paje, S.; Luong, J.; Vázquez, V.; Bueno, M.; Miró, R. Road pavement rehabilitation using a binder with a high content of crumb rubber: Influence on noise reduction. J. Constr. Build. Mater. 2013, 47, 789–798. [Google Scholar] [CrossRef]

- Parnell, J.; Samuel, S. A comparison of tire-pavement noise generated on NSW pavements to international studies. In Proceedings of the Acoustics, Christchurch, New Zeland, 22–26 November 2006.

- Harvey, J.; Kohler, E. Quieter Pavement Research: Concrete Pavement Tire Noise; Report No. CA12-1200; California Department of Transportation: Sacramento, CA, USA, 2011.

- Dare, T.; Bernhard, R. Predicting tire-pavement noise on longitudinally ground pavements using a nonlinear model. In Proceeding of the Inter-Noise, Ottawa, ON, Canada, 23–26 August 2009; p. 4047.

- Cesbron, J.; Ledee, F.; Duhamel, D.; Yin, H.; Houedec, D. Experimental study of tire-road contact forces in rolling conditions for noise prediction. J. Sound Vib. 2009, 320, 125–144. [Google Scholar] [CrossRef]

- Rasmussen, R.; Mun, E.; Farragut, T.; Wiegand, P. A comprehensive field study on concrete pavement solutions for reducing tire-pavement noise. In Proceedings of the Inter-Noise, Honolulu, HI, USA, 3–6 December 2006; p. 3900.

- Rasmussen, R.; Mun, E.; Karamihas, S.; Chang, G. Relating pavement texture to tire-pavement noise. In Proceedings of the Inter-Noise, Honolulu, HI, USA, 3–6 December 2006; p. 3910.

- Abo-Quadis, S.; Alhiary, A. Effect of traffic characteristics and road geometric parameters on developed traffic noise levels. In Proceedings of the 83rd Transportation Research Board Annual Meeting (CD), Washington, DC, USA, 11–15 January 2004.

- Gardziejczyk, W.; Berengier, M. Tire-road noise in aspect of road surface construction technology. Arch. Civ. Eng. 2000, 46, 25–38. [Google Scholar]

- Canale, S.; Malgarini, M.; Puzelli, G.; Ricci, R. The differences of sound pressure level on Italian highway pavements. In Proceedings of the International Tire-Road Noise Conference, Gothenburg, Sweden, 8–10 August 1990.

- Huang, S.; Branthaver, J.; Robertson, R.; Kim, S. Effect of film thickness on the rheological properties of asphalts in contact with aggregate surface. J. Transp. Res. Board 1998, 1638, 31–39. [Google Scholar] [CrossRef]

- Von Meier, A.; Van Mokland, G.J.; Heerken, J.C. Noise optimized road surfaces and further improvements by tire choice. In Proceedings of the International Tire-Road Noise Conference-1990, Gothenburg, Sweden, 8–10 August 1990.

- Rochat, J.; Read, D. Effective flow resistivity of highway pavements. J. Acoust. Soc. Am. 2013, 134, 4710. [Google Scholar] [CrossRef] [PubMed]

- Marolf, A.; Neithalath, N.; Sell, E.; Weiss, J.; Olek, J. Influence of aggregate size and gradation on the acoustic absorption of enhanced porosity concrete. ACI Mater. J. 2004, 101, 82–91. [Google Scholar]

- Crocker, M.; Hanson, D.; Li, Z.; Karjatkar, R.; Vissamraju, K. Measurement of acoustical and mechanical properties of porous road surfaces and tire and road noise. J. Transp. Res. Board 2004, 1891, 16–22. [Google Scholar] [CrossRef]

- Kumar, A.; Mondal, P.; Vijay, P.; Bhangale, U.; Tyagi, D. Comparative study of sound absorption coefficients on different types of road surfaces using non-destructive method as per ISO 13472-2:2010. Phys. Rev. Res. Int. 2011, 1, 45–56. [Google Scholar]

- Rochat, J.; Donavan, P. Investigations of effect of porous pavement on traffic noise and traffic noise prediction. J. Transp. Res. Board 2013, 2362, 42–48. [Google Scholar] [CrossRef]

- Rochat, J.; Donavan, P.; Seybert, A.; Dare, T. Pavement sound absorption measurements in the USA. In Proceedings of the Inter-Noise, New York, NY, USA, 19–22 August 2011.

- Sohaney, R.; Rasmussen, R.; Seybert, A.; Donavan, P. New ISO test track specification for measuring tire and vehicle noise. In Proceedings of the INCE 25th Annual Conference, Portland, OR, USA, 25–27 July 2011.

- Nelson, J.; Kohler, E.; Rymer, B.; Ongel, A. Acoustical absorption of porous pavement. In Proceedings of the 87th Annual Meeting of Transportation Research Board (TRB), Washington, DC, USA, 13–17 January 2008; National Research Council: Washington, DC, USA, 2008. [Google Scholar]

- ANSI S1.18. Template Method for Ground Impedance; American National Standards Institute (ANSI) and Acoustical Society of America Standards: New York, NY, USA, 1999. [Google Scholar]

- Sachakamol, P.; Dai, L. Parametric influence on the sound absorption coefficient of porous asphalt. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Lake Buena Vista, FL, USA, 13–19 June 2009.

- Raimundo, I.; Freitas, E.; Inácio, O.; Pereira, P. Sound absorption coefficient of wet gap graded asphalt mixtures. In Proceedings of the Inter-Noise, Lisbon, Portugal, 13–16 June 2010.

- Descornet, G. A criterion for optimizing surface characteristics. J. Transp. Res. Board 1989, 1215, 173–177. [Google Scholar]

- Ahammed, A.; Tighe, S. Pavement surface mixture, texture and skid resistance: A factorial analysis. In Proceedings of the Airfield and Highway Pavements Conference, Seattle, WA, USA, 15–18 October 2008; pp. 370–384.

- Franklin, R.; Harland, D.; Nelson, P. Road Surfaces and Traffic Noise; TRRL Report No. 89; Publication of the Transport and Road Research Laboratory (TRRL), Department of Transport: Berkshire, UK, 1979.

- Jaeckel, J.; Kuemmel, D.; Becker, Z.; Satanovsky, A.; Sonntag, R. Noise Issues of Concrete-Pavement Texturing. J. Transp. Res. Board 2000, 1702, 69–79. [Google Scholar] [CrossRef]

- Wielen, F. Vehicle noise on experimental concrete surfaces. In Proceedings of the Annual Transportation Convention-1989, Pretoria, South Africa, 1989; p. 1.

- Schlaefer, J.; LaForce, R. Noise and Skid Measurements on US 285 in the Turkey Creek Canyon Area; Report No. CDOT-R1-R-2001-9; Colorado Department of Transportation: Aurora, CO, USA, 2001.

- Kuemmel, D.; Sonntag, R.; Crovetti, J.; Becker, Y.; Jaeckel, J.; Satanovsky, A. Noise and Texture on PCC Pavements-Results of a Multi-State Study; Report No. WI/SPR-08-99; Wisconsin Department of Transportation: Madison, WI, USA, 2000.

- Ahammed, M. Safe, Quiet and Durable Pavement Surfaces. Ph.D. Thesis, University of Waterloo, Waterloo, ON, Canada, 2009. [Google Scholar]

- Ahammed, M.; Tighe, S. Quiet Pavements: Fact or Fiction? Materials Engineering and Research Office Report; 2007 Highway Infrastructure Innovation Funding Program Research Project No. 999; Ministry of Transportation Ontario: Toronto, ON, Canada, 2008. [Google Scholar]

- McDaniel, R.; Thornton, W. Field evaluation of a porous friction course for noise control. In Proceedings of the 84th Annual Meeting of Transportation Research Board (TRB), Washington, DC, USA, 9–13 January 2005; National Research Council: Washington, DC, USA, 2005. [Google Scholar]

- Kugler, B.; Commins, D.; Galloway, W. Highway Noise; a Design Guide for Prediction and Control; National Cooperative Highway Research Program, Report 174; Transportation Research Board, National Research Council: Washington, DC, USA, 1974. [Google Scholar]

- Wayson, R.; Chovarelli, M.; MacDonald, M. Testing the AAMA community noise model. In Proceedings of the 78th Transportation Research Board Annual Meeting (CD), Washington, DC, USA, 10–14 January 1999.

- TemaNord. Road Traffic Noise-Nordic Prediction Method; Report 1996:525; Nordic Council of Ministers: Copenhagen, Denmark, 1996. [Google Scholar]

- Jonasson, H.; Storeheier, S. Nord 2000: New Nordic Prediction Method for Road Traffic Noise; SP Report 2001-10; Swedish National Testing and Research Institute (SP): Boras, Sweden, 2001. [Google Scholar]

- Descornet, G.; Sandberg, U. Road surface influence on tire/road noise-part II. In Proceedings of the Inter-Noise, Miami, FL, USA, 8–10 December 1980.

- Sandberg, U.; Descornet, G. Road surface influence on tire-road noise—Part I. In Proceedings of the Inter-Noise Conference, Miami, FL, USA, 8–10 December 1980.

- Rasmussen, R. Measuring and modeling tire-pavement noise on various concrete pavement textures. J. Noise Control Eng. 2009, 57, 139–147. [Google Scholar] [CrossRef]

- Fujikawa, T.; Oshino, Y.; Mikami, T.; Tachibana, H. Examination of road roughness parameters for abating tire vibration and radiated noise. J. Noise Control Eng. 2009, 57, 77–83. [Google Scholar] [CrossRef]

- Reyes, C.; Harvey, J. A method for prediction sound intensity noise levels using laboratory pavement cores. In Proceedings of the Noise-Con, Portland, OR, USA, 25–27 July 2011.

- Brinkmeier, M.; Nackenhorst, U.; Estorff, O.; Petersen, S. Physically based modelling of tire-rolling-noise by a finite element approach. In Proceedings of the Inter-Noise, Prague, Czech Republic, 22–25 August 2004.

- Brinkmeier, M.; Nackenhorst, U.; Biermann, J.; Estorff, O. Prediction of tire/road noise-modelling and validation. In Proceedings of the Inter-Noise, Istanbul, Turkey, 28–31 August 2007.

- Doelman, N.; Mulder, H.; Eerden, F.; Roo, F. 3-D characterization of road surface textures in TRIAS. In Proceedings of the Inter-Noise, Prague, Czech Republic, 22–25 August 2004.

- Eerden, F.; Gerretsen, E.; Roo, F.; Mulder, E.; Schoen, E. A parameter study with the tire-road noise simulation tool TRIAS. In Proceedings of the Inter-Noise, Dearborn, MI, USA, 19–21 August 2002.

- Roo, F.; Gerretsen, E.; Hoffmans, W.; Doelman, N. Dutch tire road noise emission model-adjustments and validation. In Proceedings of the Inter-Noise, Fort Lauderdale, FL, USA, 2–4 December 1999.

- Roo, F.; Gerretsen, E. TRIAS—Tire road interaction acoustic simulation model. In Proceedings of the Inter-Noise, Nice, France, 27–30 August 2000.

- Roo, F.; Gerretsen, E.; Mulder, E. Predictive performance of the tire road noise model TRIAS. In Proceedings of the Inter-Noise, The Hague, The Netherland, 27–30 August 2001.

- Anderson, G.; Lee, C.; Fleming, G.; Menge, C. FHWA Traffic Noise Model, Version 1.0: User’s Guide; John, A., Ed.; Report No. FHWA-PD-96-009 and DOT VNTSC-FHWA-98-1; Volpe National Transportation Systems Center: Cambridge, MA, USA, 1998.

- Cynthia, S.; Rochat, J.; Fleming, G. FHWA Traffic Noise Model® User’ Guide (Version 2.0 Addendum); FHWA: Washington, DC, USA, 2002. [Google Scholar]

- Menge, C.; Rossano, F.; Anderson, G.; Bajdek, C. FHWA Traffic Noise Model, version 1.0: Technical Manual; Report No. FHWA-PD-96-010 and DOT-VNTSC FHWA-98-02; U.S. Department of Transportation: Washington, DC, USA; John A. Volpe National Transportation Systems Center: Cambridge, MA, USA, 1998. [Google Scholar]

- Burge, P.; Travis, K.; Rado, Z. Transverse-tined and longitudinal diamond-ground texturing for newly constructed concrete pavement: A comparison. J. Transp. Res. Board 2002, 1792. [Google Scholar] [CrossRef]

- Rochat, J.; Fleming, G. Addendum to Validation of FHWA’s Traffic Noise Model® (TNM): Phase 1; Report No. FHWA-EP-02-031 Addendum and DOT-VNTSC-FHWA-02-01 Addendum; U.S. Department of Transportation: Washington, DC, USA; Volpe National Transportation Systems Center: Cambridge, MA, USA, 2004. [Google Scholar]

- Donavan, P.; Lodico, D. Measuring Tire-Pavement Noise at the Source: Precision and Bias Statement; National Cooperative Highway Research Program, NCHRP Project: 1-44; Transportation Research Board: Washington, DC, USA, 2011. [Google Scholar]

© 2016 by the author; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sirin, O. State-of-the-Art Review on Sustainable Design and Construction of Quieter Pavements—Part 2: Factors Affecting Tire-Pavement Noise and Prediction Models. Sustainability 2016, 8, 692. https://doi.org/10.3390/su8070692

Sirin O. State-of-the-Art Review on Sustainable Design and Construction of Quieter Pavements—Part 2: Factors Affecting Tire-Pavement Noise and Prediction Models. Sustainability. 2016; 8(7):692. https://doi.org/10.3390/su8070692

Chicago/Turabian StyleSirin, Okan. 2016. "State-of-the-Art Review on Sustainable Design and Construction of Quieter Pavements—Part 2: Factors Affecting Tire-Pavement Noise and Prediction Models" Sustainability 8, no. 7: 692. https://doi.org/10.3390/su8070692

APA StyleSirin, O. (2016). State-of-the-Art Review on Sustainable Design and Construction of Quieter Pavements—Part 2: Factors Affecting Tire-Pavement Noise and Prediction Models. Sustainability, 8(7), 692. https://doi.org/10.3390/su8070692