Investigation on the Effect of Recycled Asphalt Shingle (RAS) in Portland Cement Mortar

Abstract

:1. Introduction

2. Materials and Testing Methods

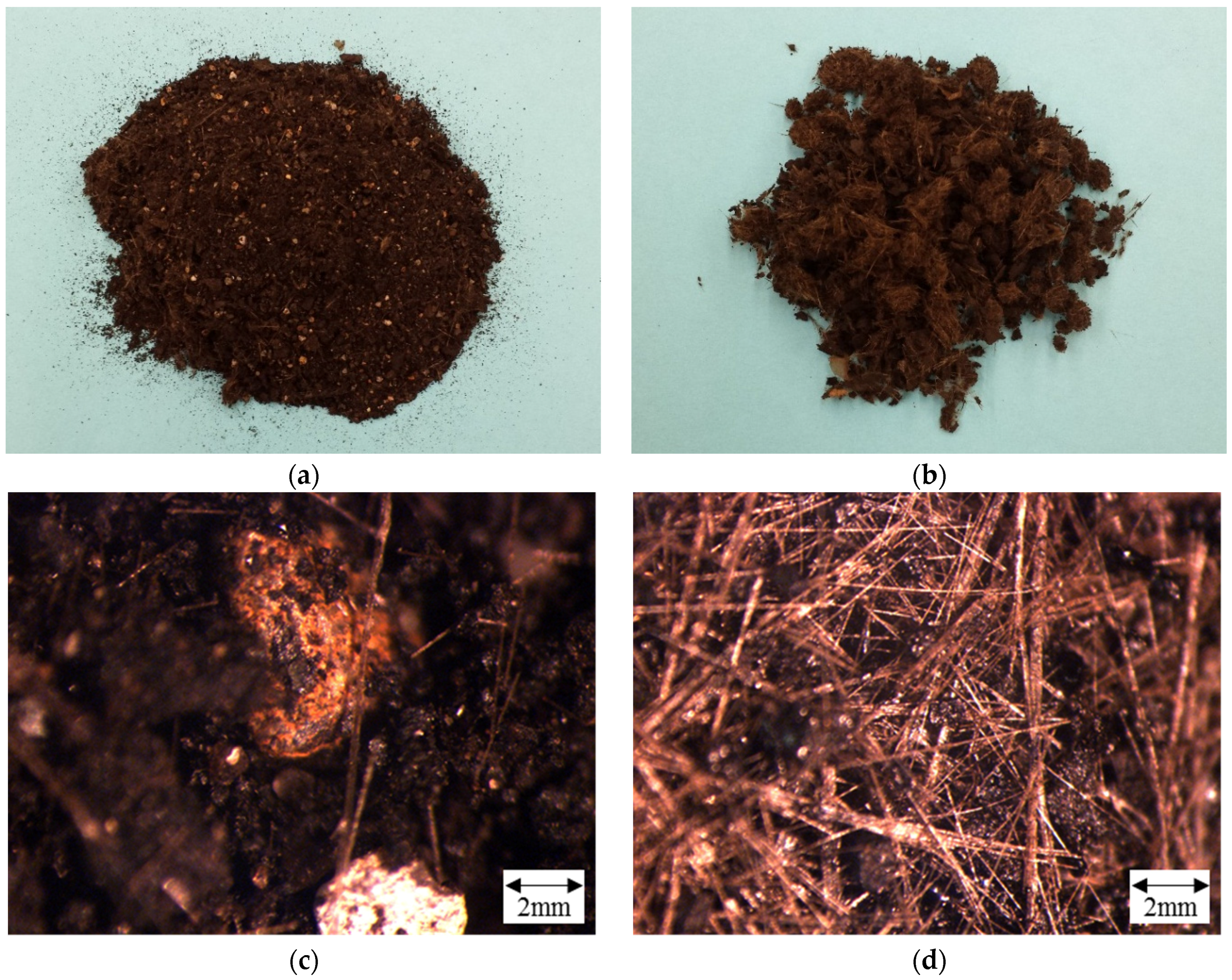

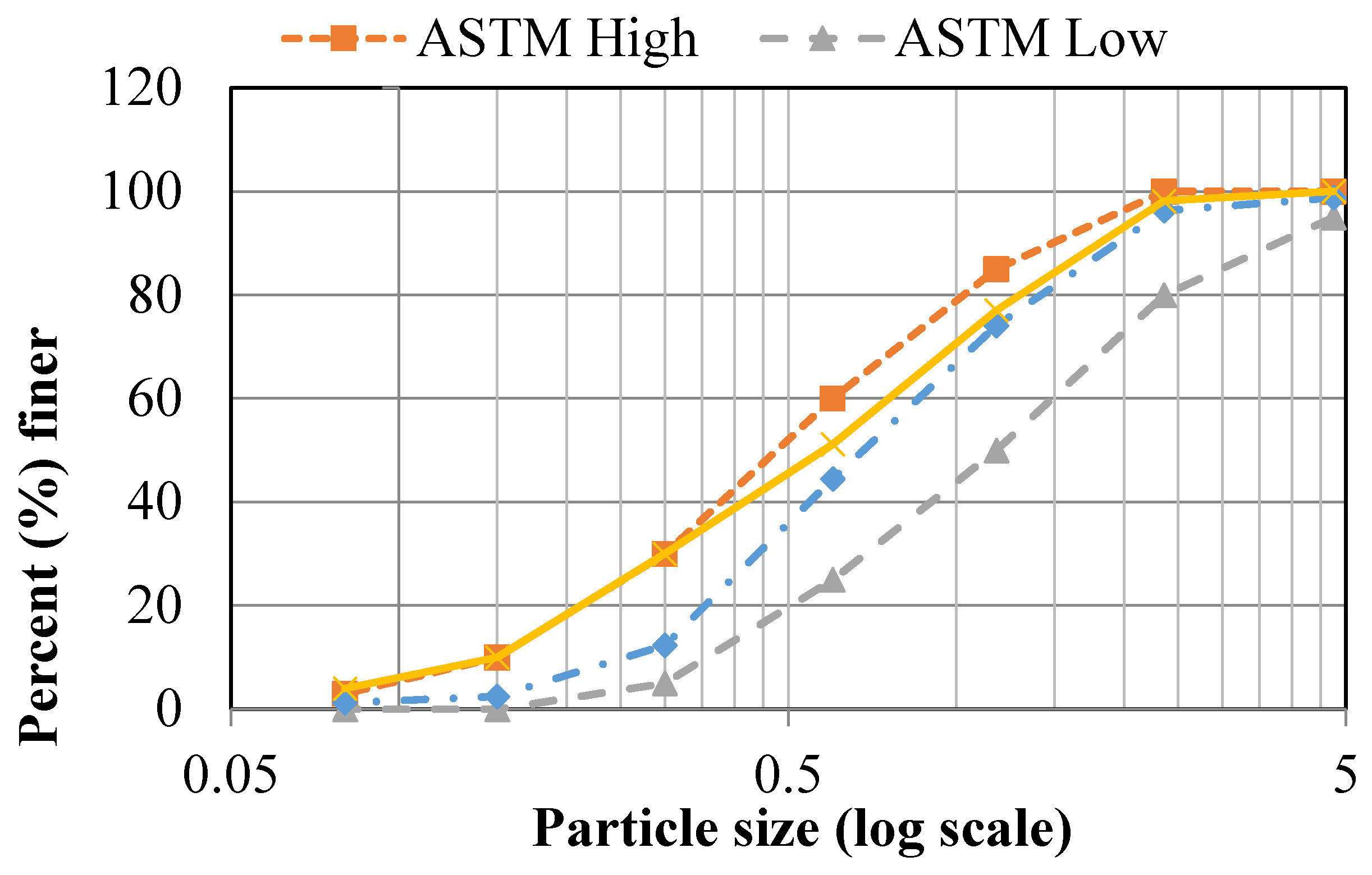

2.1. Materials Physical Properties

2.2. Mixture Proportioning

2.3. Properties of Fresh Mortar

2.4. Properties of Harden Mortar

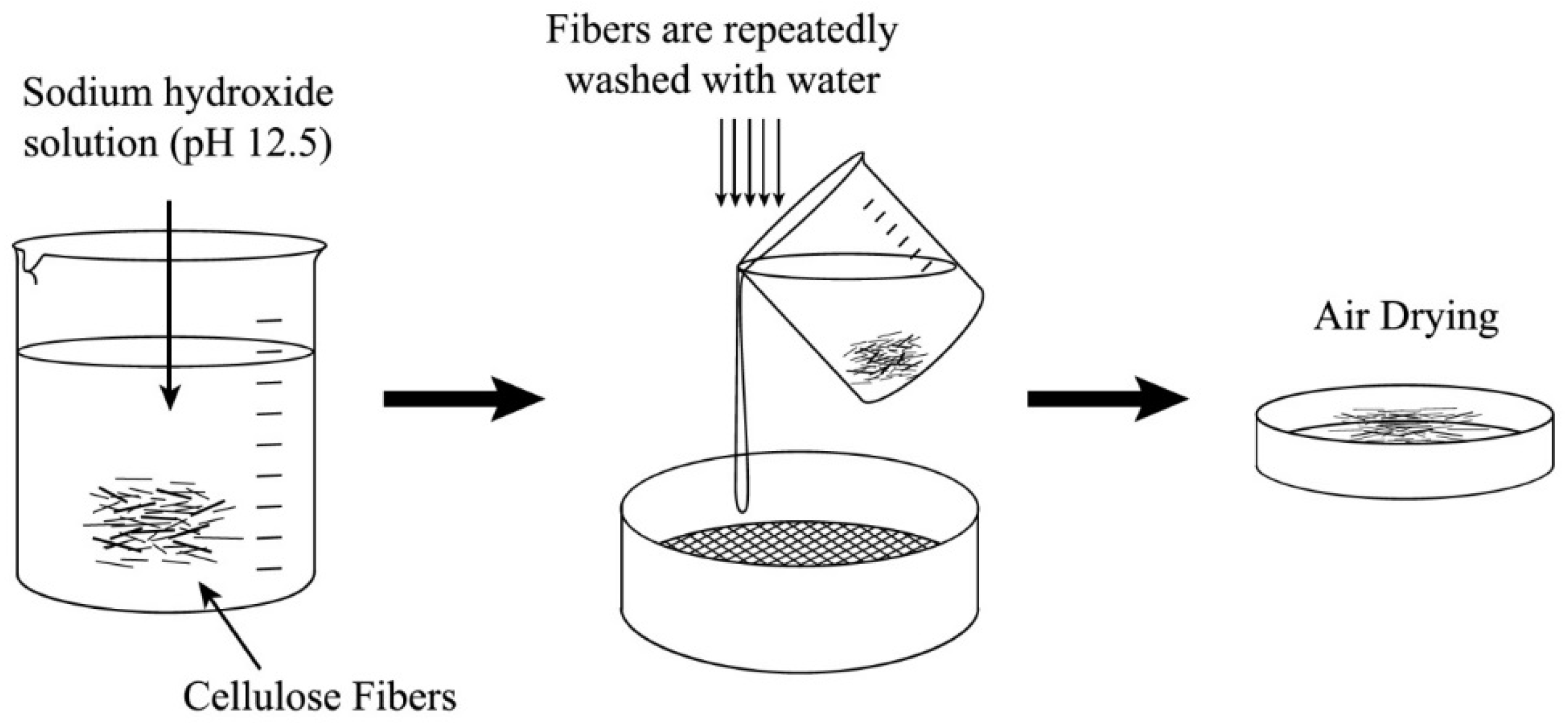

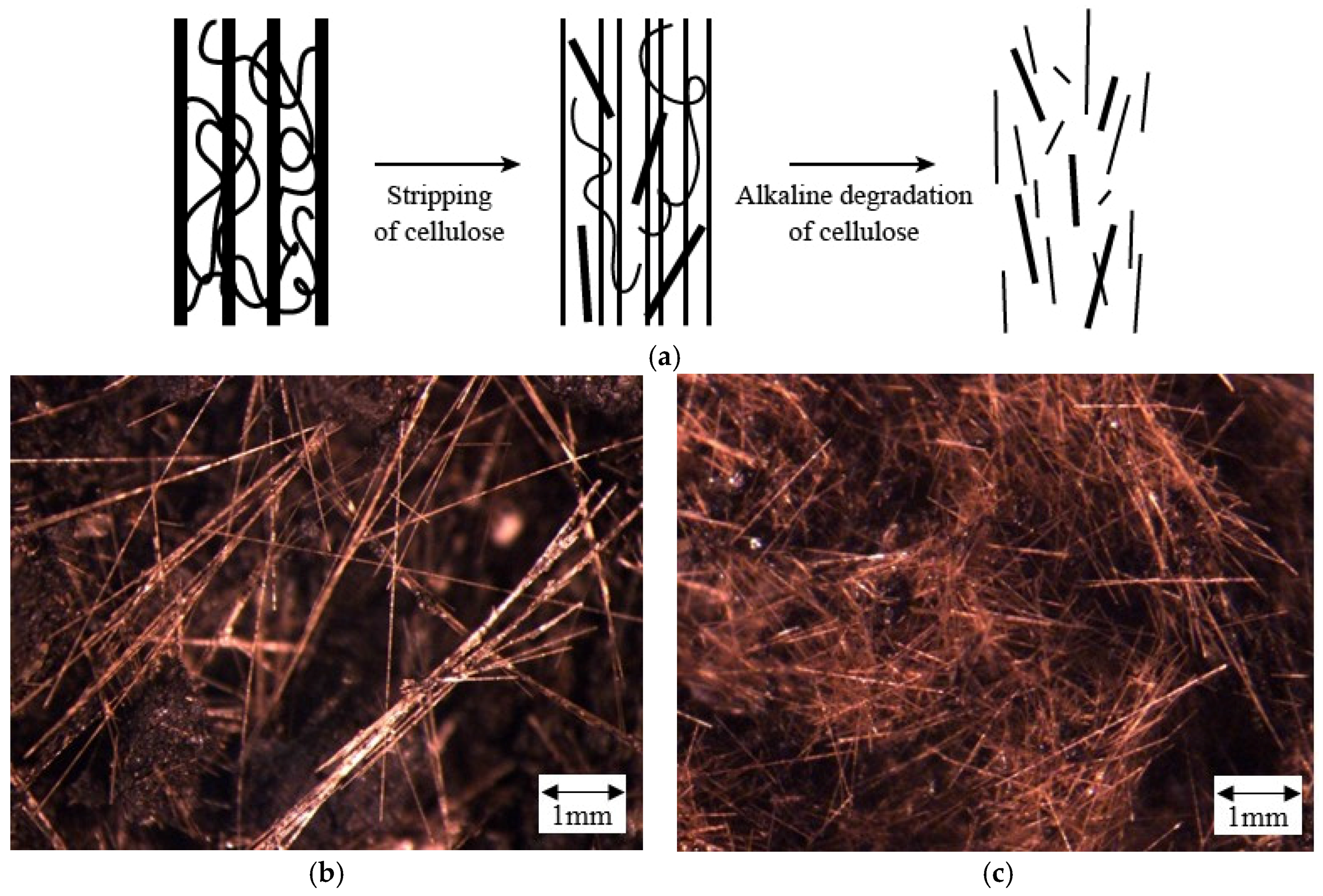

2.5. Degradation Check of RAS at High pH

3. Results and Discussion

3.1. Heat of Hydration

3.2. Setting Time

3.3. Compressive Strength Measurement

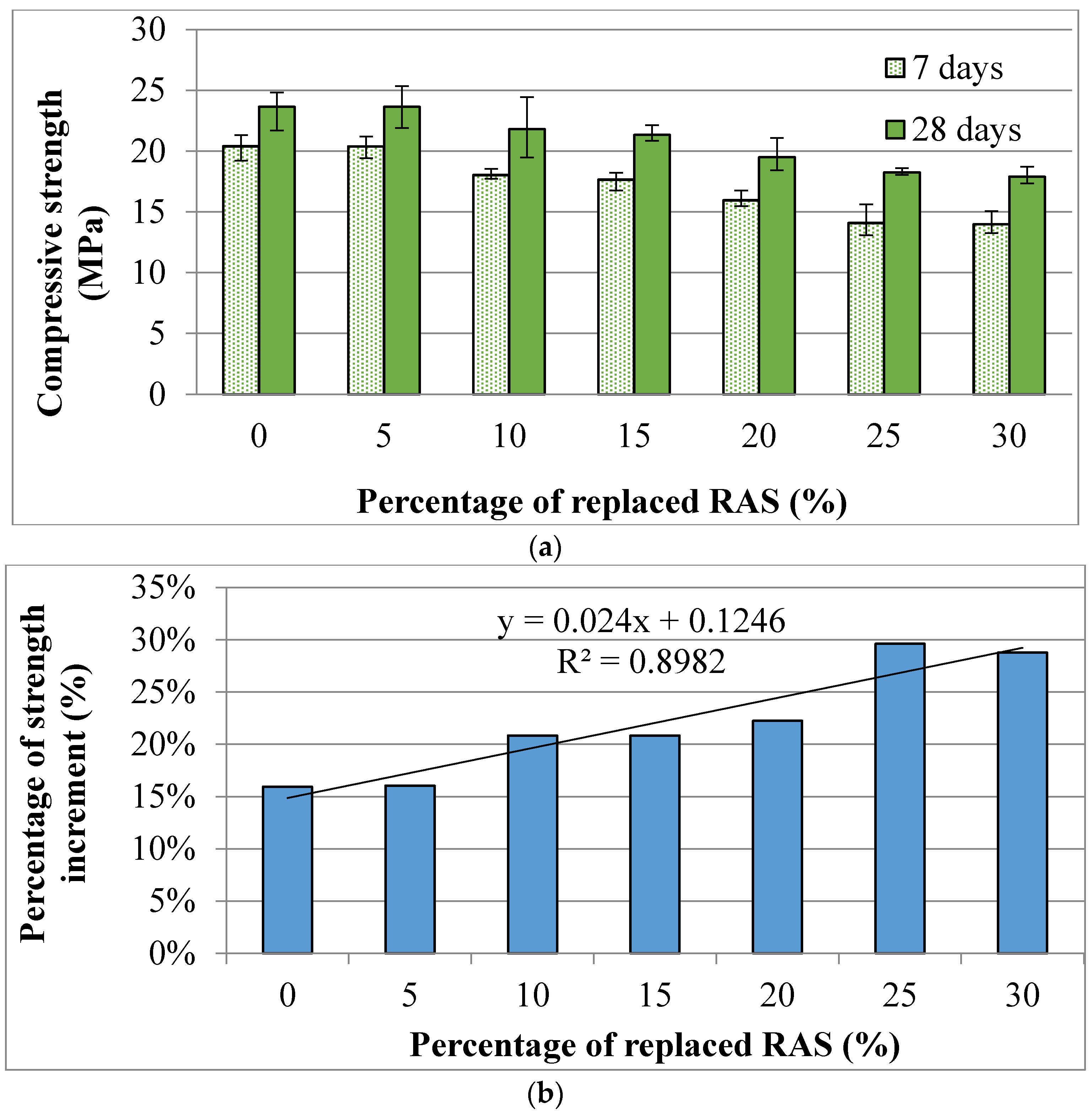

3.4. Porosity Measurement

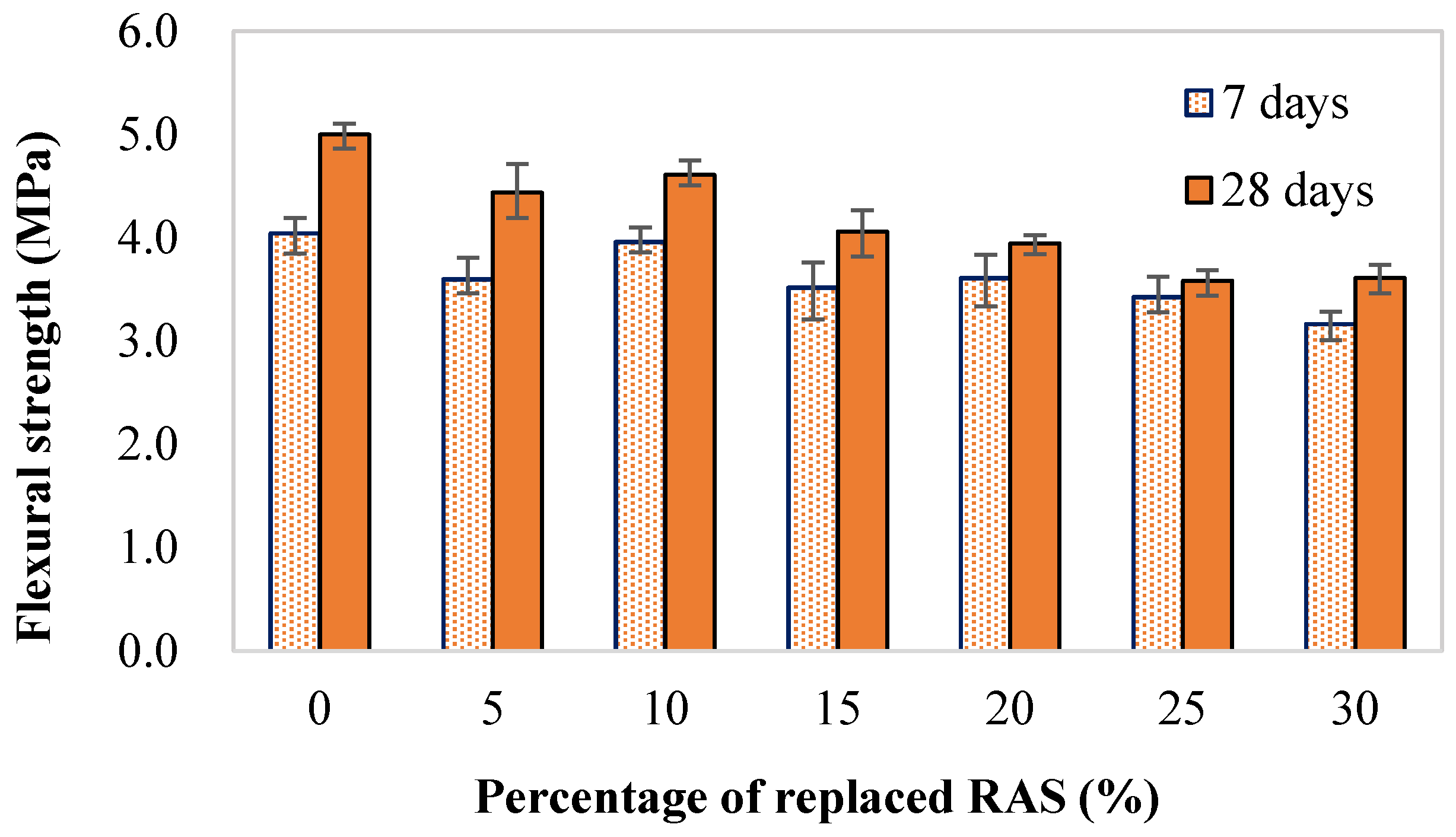

3.5. Flexural Strength

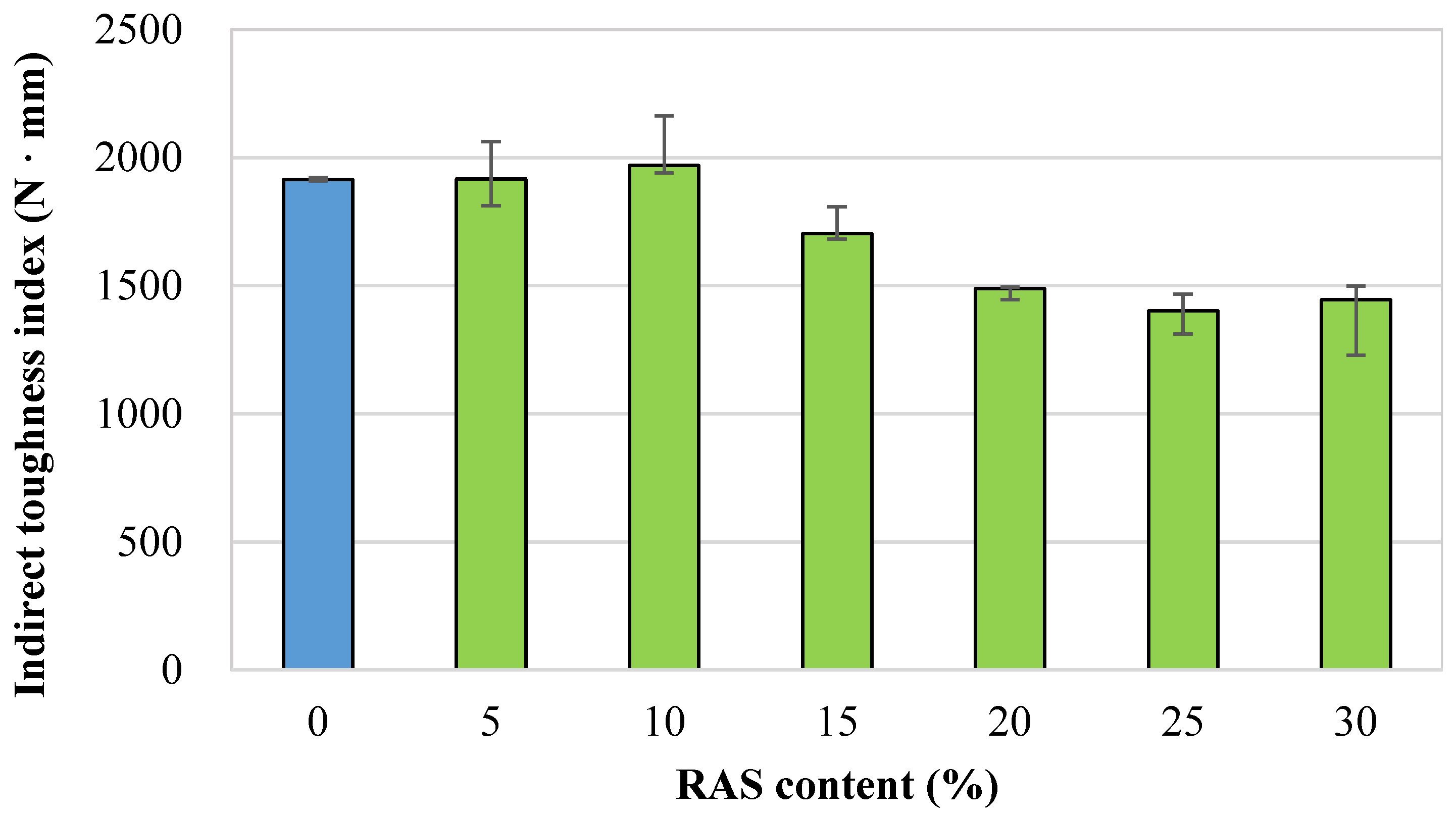

3.6. Effect of RAS in Cement Mortar

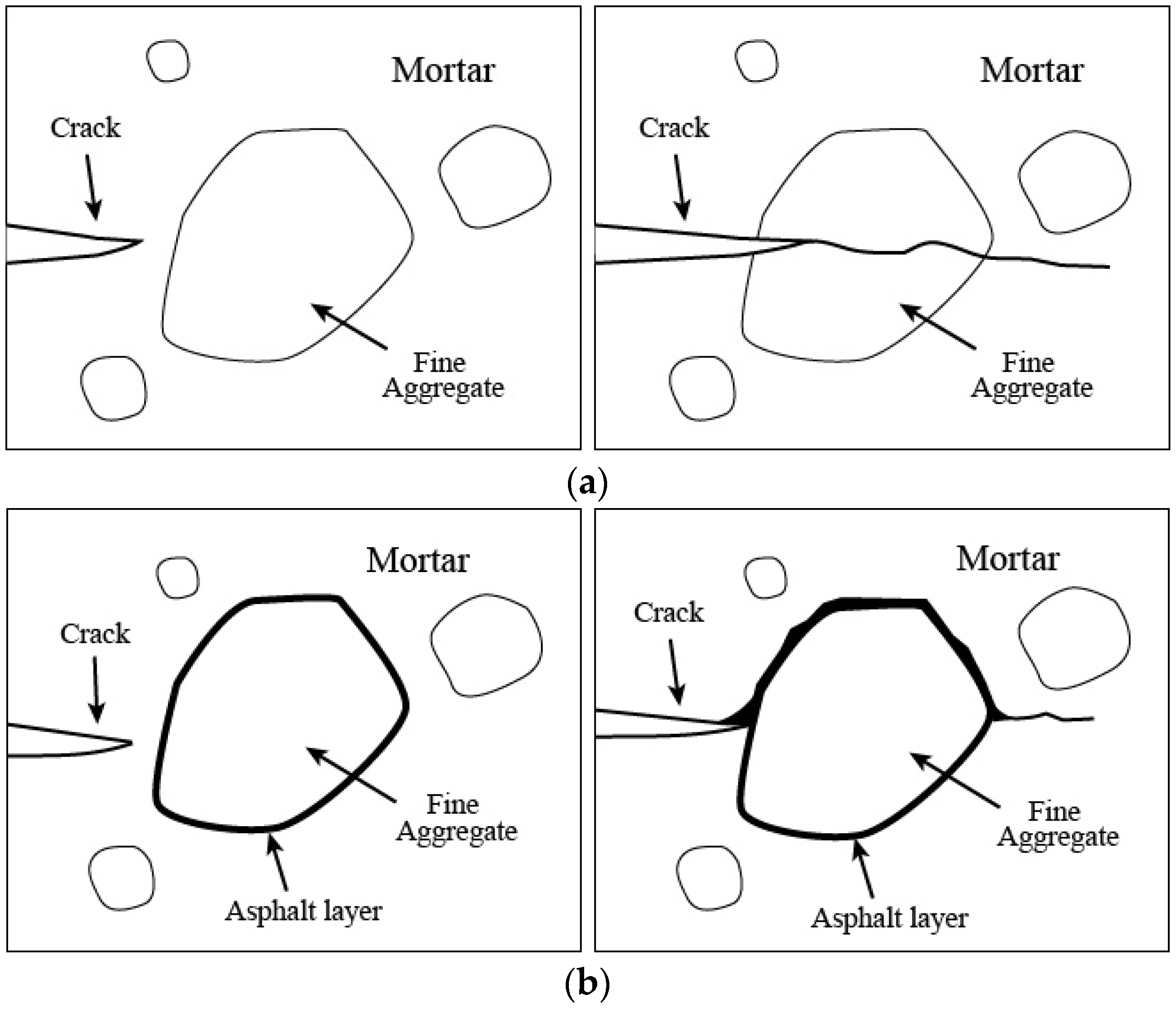

3.6.1. Influence of the Asphalt Binder

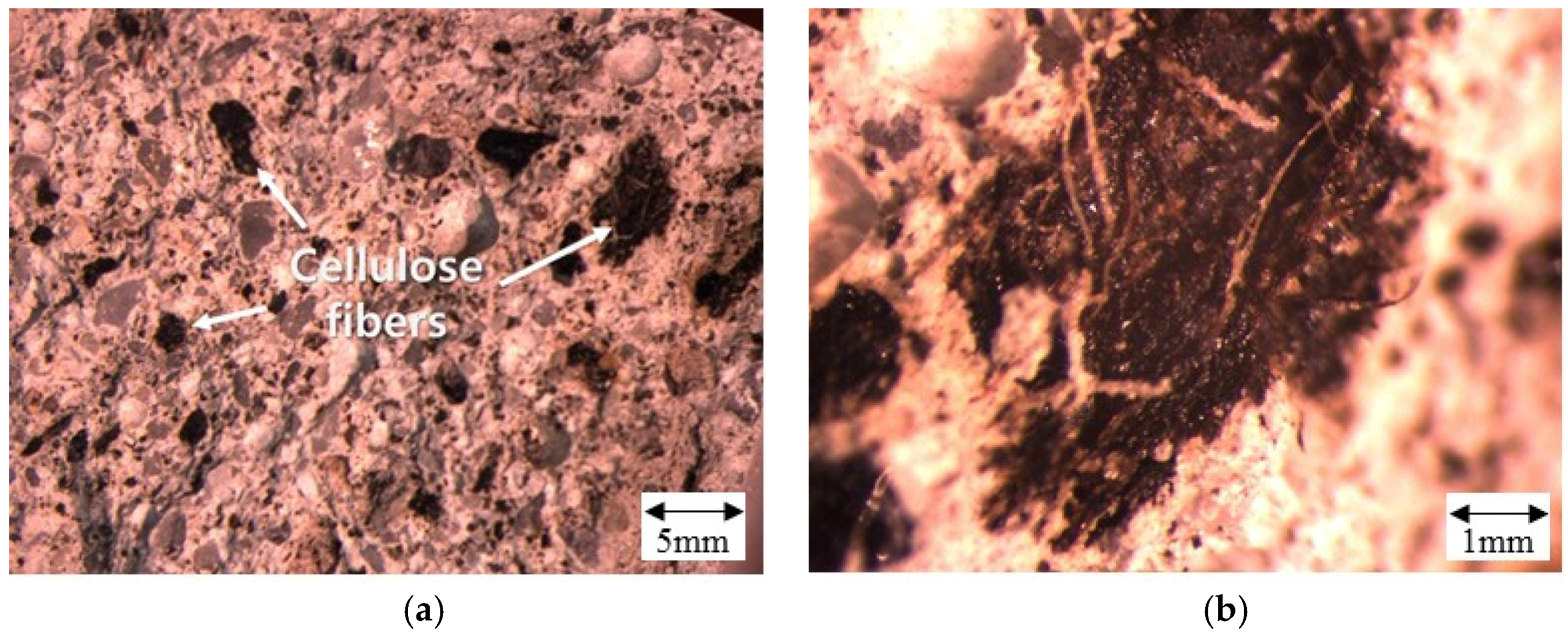

3.6.2. Influence of the Cellulose Fiber

4. Conclusions

- The particle size distributions of ground RAS meets ASTM C33 grading requirements of fine aggregate for Portland cement concrete (PCC); thus, ground RAS as received could be used as replacement of sand in mortar and PCC.

- Overall the usage of RAS in mortar causes reduction in compressive and flexural strengths, which can be explained by the mechanism that high absorption capacity of RAS may cause reduced effective water to participate in cement hydration. It is concluded that an optimum mixture proportion for compressive strength of mortar is 5% and that for toughness is 10% RAS replacement.

- The asphalt film layer by RAS likely impedes the crack propagation so that the mortar samples containing RAS shows more ductile behavior than the control under flexural loading; however, the improvement is slight.

- The alkaline degradation of cellulose fibers due to high pH condition in cement matrix can cause the disconnection of discrete cellulose fiber-cement matrix. Thus, bridging effect of cellulose fibers in the cement matrix may not be significant. However, reusing RAS containing glass fibers in cementitious materials can result in positive influence because glass fiber has higher resistance to alkali attack than cellulose fiber.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- United States Environmental Protection Agency. Municipal Solid Waste Generation, Recycling, and Disposal in the United States: Facts and Figures for 2010. Available online: https://www3.epa.gov/epawaste/nonhaz/municipal/pubs/2012_msw_fs.pdf (accessed on 14 April 2010).

- U.S. EPA Office of Solid Waste and Emergency Response. Recycling Tear-off Asphalt Shingles: Best Practices Guide. Available online: https://www.shinglerecycling.org/sites/www.shinglerecycling.org/files/shingle_PDF/ShingleRecycling-BPG-DFK-3-22-2010.pdf (accessed on 15 April 2015).

- Kim, J.; Nam, B.H.; Al Muhit, B.A.; Tasneem, K.M.; An, J. Effect of chemical treatment of MSWI bottom ash for its use in concrete. Mag. Concr. Res. 2014, 67, 179–186. [Google Scholar] [CrossRef]

- Kim, J.; Tasneem, K.M.; Nam, B.H. Material characterization of municipal solid waste incinerator (MSWI) ash as road construction material. In Pavement Performance Monitoring, Modeling, and Management, Geo-Hubei 2014, GSP 254, Proceedings of the Geo-Hubei 2014 International Conference on Sustainable Civil Infrastructure, Yichang, China, 20–22 July 2014; Steyn, W.J., Chen, X., Nam, B., Eds.; American Society of Civil Engineers: Reston, VA, USA, 2014; pp. 100–108. [Google Scholar]

- Kim, J.; An, J.W.; Nam, B.H.; Tasneem, K.M. Investigation on the Side Effects of Municipal Solid Waste Incineration Ashes when Used as Mineral Additions in Cement-Based Materials. Road Mater. Pavement Des. 2015. [Google Scholar] [CrossRef]

- Nam, B.H.; Behring, Z.; Kim, J.; Chopra, M.; Shoucair, J.; Park, C.S. Evaluating the Use of Recycled Concrete Aggregate in a French Drain Applications. J. Test. Eval. 2015, 43, 237–247. [Google Scholar] [CrossRef]

- Kim, J.Y.; Nam, B.H.; Behring, Z.; Al Muhit, B. Evaluation of Re-Cementation Reactivity of Recycled Concrete Aggregate Fines. Transp. Res. Rec. 2014, 2401, 44–51. [Google Scholar] [CrossRef]

- An, J.; Golestani, B.; Nam, B.H.; Lee, J. Sustainable utilization of MSWI bottom ash as road construction materials, Part I: Physical and mechanical evaluation. In Proceedings of the International Airfield and Highway Pavements Conference 2015, Miami, FL, USA, 7–10 June 2015; pp. 225–235.

- Tasneem, K.M.; Nam, B.H.; Eun, J.W. Sustainable utilization of MSWI bottom ash as road construction materials, Part II: Chemical and environmental characterization. In Proceedings of the International Airfield and Highway Pavements Conference 2015, Miami, FL, USA, 7–10 June 2015; pp. 225–235.

- Behring, Z.; Nam, B.H.; Chopra, M. Investigation on Clogging potential of Reclaimed Concrete Aggregate in French Drain Systems. In Proceedings of International Foundations Congress and Equipment Expo (IFCEE) 2015, San Antonio, TX, USA, 19 March 2015.

- Al Muhit, B.A.; Nam, B.H. Recycling of Municipal Solid Waste Incineration (MSWI) Ash as Aggregate Replacement in Portland Cement Concrete. In Proceedings of International Foundations Congress and Equipment Expo (IFCEE) 2015, San Antonio, TX, USA, 19 March 2015.

- An, J.W.; Nam, B.H.; Kim, J. Investigation on chemical and physical effects of municipal solid waste incineration (MSWI) ashes in cement hydration. In Proceedings of Transportation Research Board 94th Annual Meeting, Washington, DC, USA, 11–15 January 2015.

- Behring, Z.; Kim, J.; Nam, B.H.; Chopra, M.; Shoucair, J. Drainage Performance Evaluation of Recycled Concrete Aggregate in Road Drainage; Wu, J.Y., Chao, S.-J., Dai, K., Yang, S.-R., Eds.; American Society of Civil Engineers: Restone, VA, USA, 2014; pp. 33–40. [Google Scholar]

- An, J.; Kim, J.; Golestani, B.; Tasneem, K.; Al Muhit, B.; Nam, B.H.; Behzadan, A. Evaluating the Use of Waste-to-Energy Bottom Ash as Road Construction Materials; Report No. BDK78-977-20; Florida Department of Transportation: Tallahassee, FL, USA, 2014. [Google Scholar]

- NAHB Research Centre. From Roofs to Roads… Recycling Asphalt Roofing Shingles into Paving Materials. 2012. Available online: http://www.epa.gov/wastes/conserve/imr/cdm/pubs/roof_br.pdf (accessed on 19 April 2016). [Google Scholar]

- BioCycle. Analyzing What’s Recyclable in C&D Debris. Available online: https://www3.epa.gov/climatechange/wycd/waste/downloads/Analyzing_C_D_Debris.pdf (accessed on 30 November 2003).

- Brock, J.D.; Shaw, D. From Roofing Shingles to Road; Technical paper T-120; Astec Industries: Chattanooga, TN, USA, 1989. [Google Scholar]

- Sengoz, B.; Topal, A. Use of asphalt roofing shingle waste in HMA. Constr. Build. Mater. 2005, 19, 337–346. [Google Scholar] [CrossRef]

- Foo, K.Y.; Hanson, D.I.; Lynn, T.A. Evaluation of roofing shingles in hot mix asphalt. J. Mater. Civ. Eng. 1999, 11, 15–20. [Google Scholar] [CrossRef]

- Nam, B.; Maherinia, H.; Behzadan, A. Mechanical characterization of asphalt tear-off roofing shingles in Hot Mix Asphalt. Constr. Buildi. Mater. 2014, 50, 308–316. [Google Scholar] [CrossRef]

- Golestani, B.; Maherinia, H.; Nam, B.H.; Behzadan, A. Beneficial utilization of asphalt tear-off roofing shingle in Hot-Mix Asphalt. In Proceedings of the ASCE/T&DI Airfield, Highway Pavement Conference 2015, Miami, FL, USA, 7–10 June 2015.

- Yang, J.; Ddamba, S.; UL-Islam, R.; Safiuddin, M.; Tighe, S. Investigation on use of recycled asphalt shingles in Ontario hot mix asphalt: A Canadian case study. Can. J. Civ. Eng. 2014, 41, 136–143. [Google Scholar] [CrossRef]

- Tia, M.; Hossiney, N.; Su, Y.M.; Chen, Y.; Do, T.A. Use of Reclaimed Asphalt Pavement in Concrete Pavement Slabs; Technical report: BDK75 977-34; Florida Department of Transportation: Tallahassee, FL, USA, 2012. [Google Scholar]

- Abdel-Mohti, A.; Shen, H.; Khodair, Y. Characteristics of self-consolidating concrete with RAP and SCM. Constr. Build. Mater. 2016, 102, 564–573. [Google Scholar] [CrossRef]

- Erdem, S.; Blankson, M.A. Environmental performance and mechanical analysis of concretec ontaining recycled asphalt pavement (RAP) and waste precastconcrete as aggregate. J. Hazard. Mater. 2014, 264, 403–410. [Google Scholar] [CrossRef] [PubMed]

- Savastano, H.; Warden, P.G.; Coutts, R.S.P. Mechanically pulped sisal as reinforcement in cementitious matrices. Cement Concr. Compos. 2003, 25, 311–319. [Google Scholar] [CrossRef]

- Morton, J.H.; Cooke, T.; Akers, S.A.S. Performance of slash pine fibers in fiber cement products. Constr. Build. Mater. 2014, 24, 165–170. [Google Scholar] [CrossRef]

- Tolêdo-Filho, R.D.; Ghavami, K.; England, G.L.; Scrivener, K. Development of vegetable fibre-mortar composites of improved durability. Cem. Concr. Compos. 2003, 25, 185–196. [Google Scholar] [CrossRef]

- Ardanuy, M.; Claramunt, J.; García-Hortal, J.A.; Barra, M. Fiber-matrix interactions in cement mortar composites reinforced with cellulosic fibers. Cellulose 2011, 18, 281–289. [Google Scholar] [CrossRef]

- Mohr, B.J.; Nanko, H.; Kurtis, K.E. Durability of kraft pulp fiber–cement composites to wet/dry cycling. Cem. Concr. Compos. 2005, 27, 435–448. [Google Scholar] [CrossRef]

- Mohr, B.J.; Biernacki, J.J.; Kurtis, K.E. Microstructural and chemical effects of wet/dry cycling on pulp fiber–cement composites. Cem. Concr. Res. 2006, 36, 1240–1251. [Google Scholar] [CrossRef]

- Tolêdo Filho, R.D.; Scrivener, K.; England, G.L.; Ghavami, K. Durability of alkali-sensitive sisal and coconut fibres in cement mortar composites. Cem. Concr. Compos. 2000, 22, 127–143. [Google Scholar] [CrossRef]

- Huang, B.; Shu, X.; Li, G. Laboratory Investigation of Portland Cement Concrete Containing Recycled Asphalt Pavements. Cement Concr. Res. 2008, 35, 2008–2013. [Google Scholar] [CrossRef]

- Huang, B.; Shu, X.; Burdette, E.G. Mechanical properties of concrete containing recycled asphalt pavements. Mag. Concr. Res. 2006, 58, 313–320. [Google Scholar] [CrossRef]

- Soleimanbeigi, A.; Edil, T.; Benson, C. Effect of Temperature on Geotechnical Properties of Recycled Asphalt Shingle Mixtures. Geotech. Geol. Eng. 2015. [Google Scholar] [CrossRef]

- Krivit, D. Recycling of Tear-off Shingles: Best Practices Guide; Construction Materials Recycling Association: Aurora, IL, USA, 2007. [Google Scholar]

- American Society for Testing and Materials (ASTM). ASTM C33/C33M-13 Standard Specification for Concrete Aggregates; ASTM: West Conshohocken, PA, USA, 2008. [Google Scholar]

- American Society for Testing and Materials (ASTM). ASTM C186-15a Standard Test Method for Heat of Hydration of Hydraulic Cement; ASTM: West Conshohocken, PA, USA, 2015. [Google Scholar]

- American Society for Testing and Materials (ASTM). ASTM C807-13 Standard Test Method for Time of Setting of Hydraulic Cement Mortar by Modified Vicat Needle; ASTM: West Conshohocken, PA, USA, 2013. [Google Scholar]

- American Society for Testing and Materials (ASTM). ASTM C1754 / C1754M–12 Standard test method for density and void content of hardened pervious concrete; ASTM: West Conshohocken, PA, USA, 2012. [Google Scholar]

- American Society for Testing and Materials (ASTM). ASTM C109 / C109M-13e1Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens); ASTM: West Conshohocken, PA, USA, 2013. [Google Scholar]

- American Society for Testing and Materials (ASTM). ASTM C348–14 Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars; ASTM: West Conshohocken, PA, USA, 2014. [Google Scholar]

- Mohammed, B.; Abdullahi, M.; Hoong, C. Statistical models for concrete containing wood chipping as partial replacement to fine aggregate. Construct Build. Mater. 2014, 55, 13–19. [Google Scholar] [CrossRef]

- Wei, J.Q.; Meyer, C. Degradation mechanisms of natural fiber in the matrix of cement composites. Cement Concr. Res. 2015, 73, 1–16. [Google Scholar] [CrossRef]

- Mostefai, N.; Hamzaoui, R.; Guessasma, S.; Awb, A.; Nouri, H. Microstructure andmechanical performance of modified hemp fibre and shiv mortars: Discovering the optimal formulation. Mater. Des. 2015, 84, 359–371. [Google Scholar]

- Fenu, L.; Forni, D.; Cadoni, E. Dynamic behaviour of cement mortars reinforced with glass and basalt fibres. Compos. B. Eng. 2016, 92, 142–150. [Google Scholar] [CrossRef]

- Criado, M.; García-Díaz, I.; Bastidas, J.M.; Alguacil, F.J.; López, F.A.; Monticelli, C. Effect of recycled glass fiber on the corrosion behavior of reinforced mortar. Constr. Build. Mater. 2014, 64, 261–269. [Google Scholar] [CrossRef]

| Measured Property | Cement | Fine Aggregate (Sand) | RAS | Reference |

|---|---|---|---|---|

| Fineness modulus | N/A | 2.36 | 2.25 | ASTM C 33 |

| Specific gravity (OD) | 3.15 | 2.66 | 2.17 | ASTM C 127 and C128 |

| Absorption capacity (%) | N/A | 2.0 | 7.0 | ASTM C 127 and C128 |

| Sample ID | w/c | Water (kg/m3) | Cement (kg/m3) | Fine Aggregate (kg/m3) | RAS (kg/m3) | Slump (cm) |

|---|---|---|---|---|---|---|

| C | 0.5 | 180 | 360 | 760 | - | 18 |

| R5 | 180 | 360 | 722 | 38 | 16 | |

| R10 | 180 | 360 | 684 | 76 | 15 | |

| R15 | 180 | 360 | 646 | 114 | 13 | |

| R20 | 180 | 360 | 608 | 152 | 11 | |

| R25 | 180 | 360 | 570 | 190 | 10 | |

| R30 | 180 | 360 | 532 | 228 | 8 |

| Sample | Time (mins) |

|---|---|

| Control | 210 |

| 10% RAS | 200 |

| 20% RAS | 200 |

| 30% RAS | 195 |

| Mortar (Current Study) | Compressive Strength | Flexural Strength | Mortar [45] (Hemp Fiber) | Compressive Strength | Flexural Strength | Mortar [46] (Glass Fiber) | Compressive Strength (MPa) | Flexural Strength (MPa) |

|---|---|---|---|---|---|---|---|---|

| C | 23.64 (100%) | 5.1 (100%) | Control | 32.4 (100%) | 9.1 (100%) | Control | 70.2 (100%) | 6.57 (100%) |

| R5 | 23.65 (100%) | 4.4 (86.3%) | Hemp fiber 1% | 32.3 (99.7%) | 8.2 (90.1%) | Glass fiber 3% | 57.58 (82%) | 7.78 (118.4%) |

| R10 | 21.8 (92.2%) | 4.6 (90.2%) | Hemp fiber 2% | 27.2 (83.9%) | 5.6 (61.5%) | Glass fiber 5% | 50.46 (71.9%) | 8.37 (127.4%) |

| R15 | 21.34 (90.3%) | 4.1 (80.4%) | Hemp fiber 4% | 25.1 (77.5%) | 5.6 (61.5%) | Basalt Fiber 3% | 57.15 (81.4%) | 8.72 (132.7%) |

| R20 | 19.5 (82.5%) | 3.9 (76.5%) | Hemp fiber10% | 16.1 (49.7%) | 5.9 (64.8%) | Basalt Fiber 5% | 52.10 (74.2%) | 8.53 (129.8%) |

| R25 | 18.25 (77.2%) | 3.6 (70.6%) | - | - | - | - | - | - |

| R30 | 17.9 (75.7%) | 3.6 (70.6%) | - | - | - | - | - | - |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

An, J.; Nam, B.H.; Youn, H. Investigation on the Effect of Recycled Asphalt Shingle (RAS) in Portland Cement Mortar. Sustainability 2016, 8, 384. https://doi.org/10.3390/su8040384

An J, Nam BH, Youn H. Investigation on the Effect of Recycled Asphalt Shingle (RAS) in Portland Cement Mortar. Sustainability. 2016; 8(4):384. https://doi.org/10.3390/su8040384

Chicago/Turabian StyleAn, Jinwoo, Boo Hyun Nam, and Heejung Youn. 2016. "Investigation on the Effect of Recycled Asphalt Shingle (RAS) in Portland Cement Mortar" Sustainability 8, no. 4: 384. https://doi.org/10.3390/su8040384

APA StyleAn, J., Nam, B. H., & Youn, H. (2016). Investigation on the Effect of Recycled Asphalt Shingle (RAS) in Portland Cement Mortar. Sustainability, 8(4), 384. https://doi.org/10.3390/su8040384