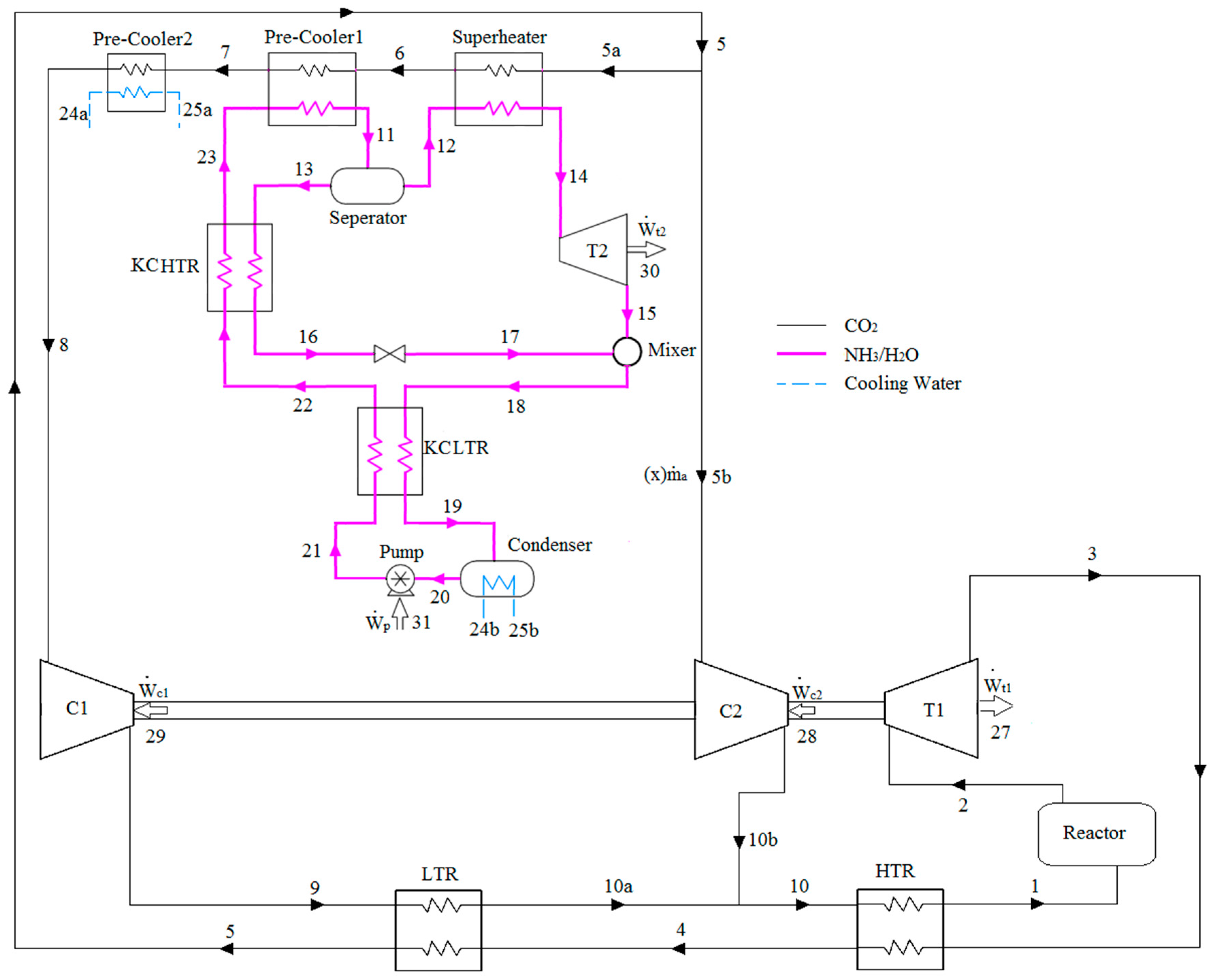

5.1. Parametric Study

Parametric studies are performed to reveal the effects on thermodynamic and thermoeconomic performances of the SCRB/KC of modifying various decision variables: compressor pressure ratio (PRC), pump pressure ratio (PRp), minimum temperature difference in the superheater (), ammonia concentration in the ammonia–water mixture leaving the condenser (X20), pinch point temperature difference in pre-cooler1 (), and temperature of ammonia–water solution exiting pre-cooler1 (T11). For the SCRBC, the only decision parameter is taken to be the compressor pressure ratio (PRC).

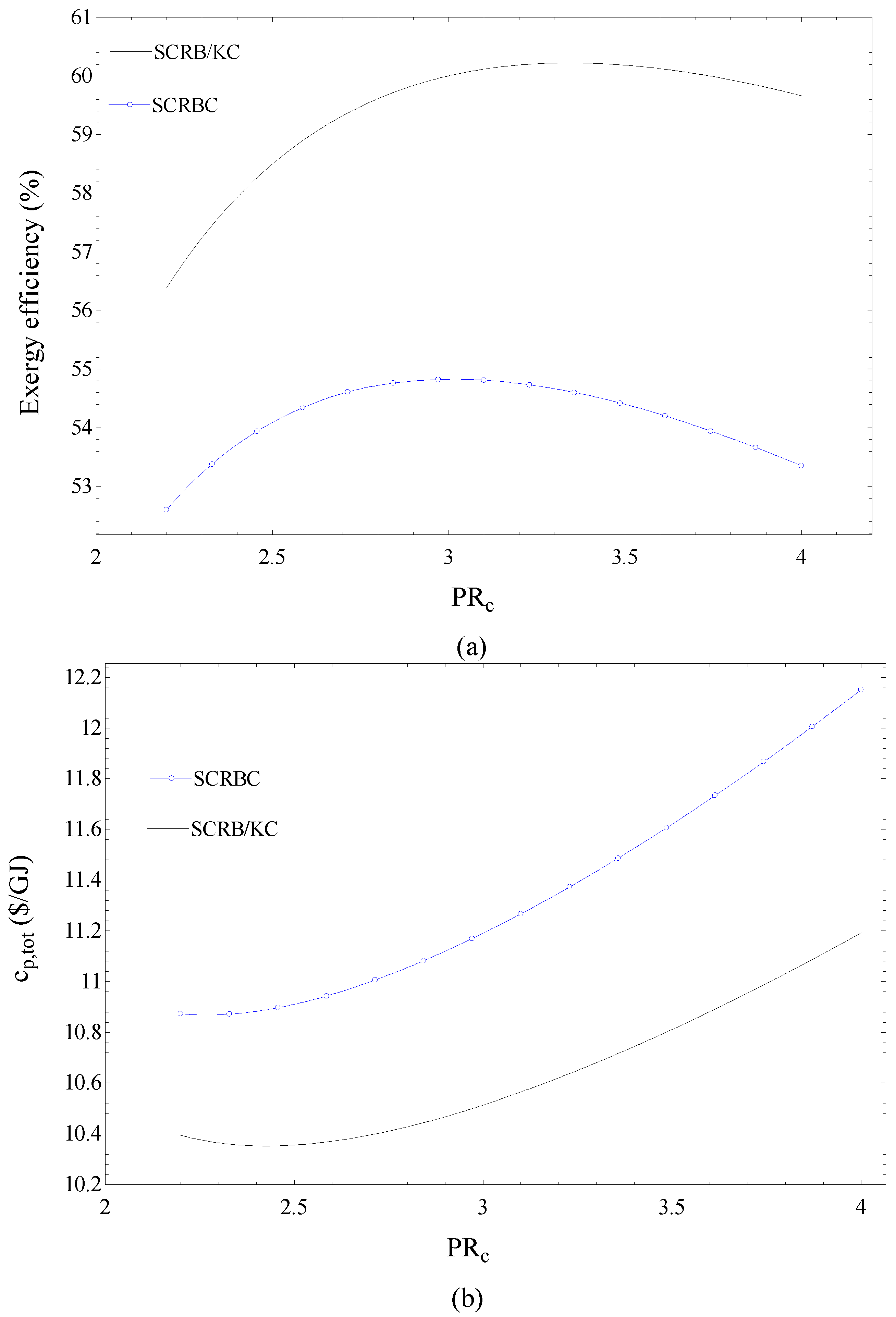

Figure 2a,b shows the effects of the compressor pressure ratio (PR

C) on the exergy efficiency (

) and total product unit cost (c

p,tot) of the SCRBC and the SCRB/KC.

Figure 2a indicates that optimum values exist for PR

C at which the exergy efficiency of the SCRBC or SCRB/KC is maximized. This is justified if we consider that, as the PR

C increases, the net specific work output for the SCRBC increases and the CO

2 mass flow rate decreases, due to the increase in the specific enthalpy difference across the reactor [

2]. The increase in net specific work and the decrease in CO

2 mass flow rate lead to the maximization of the net produced power for the SCRBC as PR

C increases. As the exergy input to the cycle is constant the variation of exergy efficiency with PR

C is justified for the SCRBC. A similar discussion can be made for the SCRB/KC noting that the net specific work of the Kalina cycle increases steadily with increasing PR

C. It is clear in

Figure 2a that at higher PR

C values the exergy efficiency of the SCRB/KC is flatter than that of the SCRBC. This can be explained if we consider that as the PR

C increases the temperature at the inlets of the superheater and pre-cooler1 increase resulting in an increase in the KC exergy input and consequently a higher KC output power. In addition, the increase in the KC power output, because of an increase in PR

C, leads to a higher optimum PR

C for the SCRB/KC compared to the corresponding value for the SCRBC, as shown in

Figure 2a.

It is observed in

Figure 2b that the total product unit cost is minimized at specific values of PR

C for both the SCRBC and the SCRB/KC. This is expected based on Equation (15). However, for both cycles, the optimum PR

C value at which c

p,tot is minimized is less than the corresponding value at which the exergy efficiency is maximized. This can be explained considering the decrease of associated costs with decreasing PR

C. It is seen in

Figure 2 that the differences in optimum values of PR

C for the SCRBC and the SCRB/KC, for maximum exergy efficiency, are higher than the corresponding values for minimum c

p,tot.

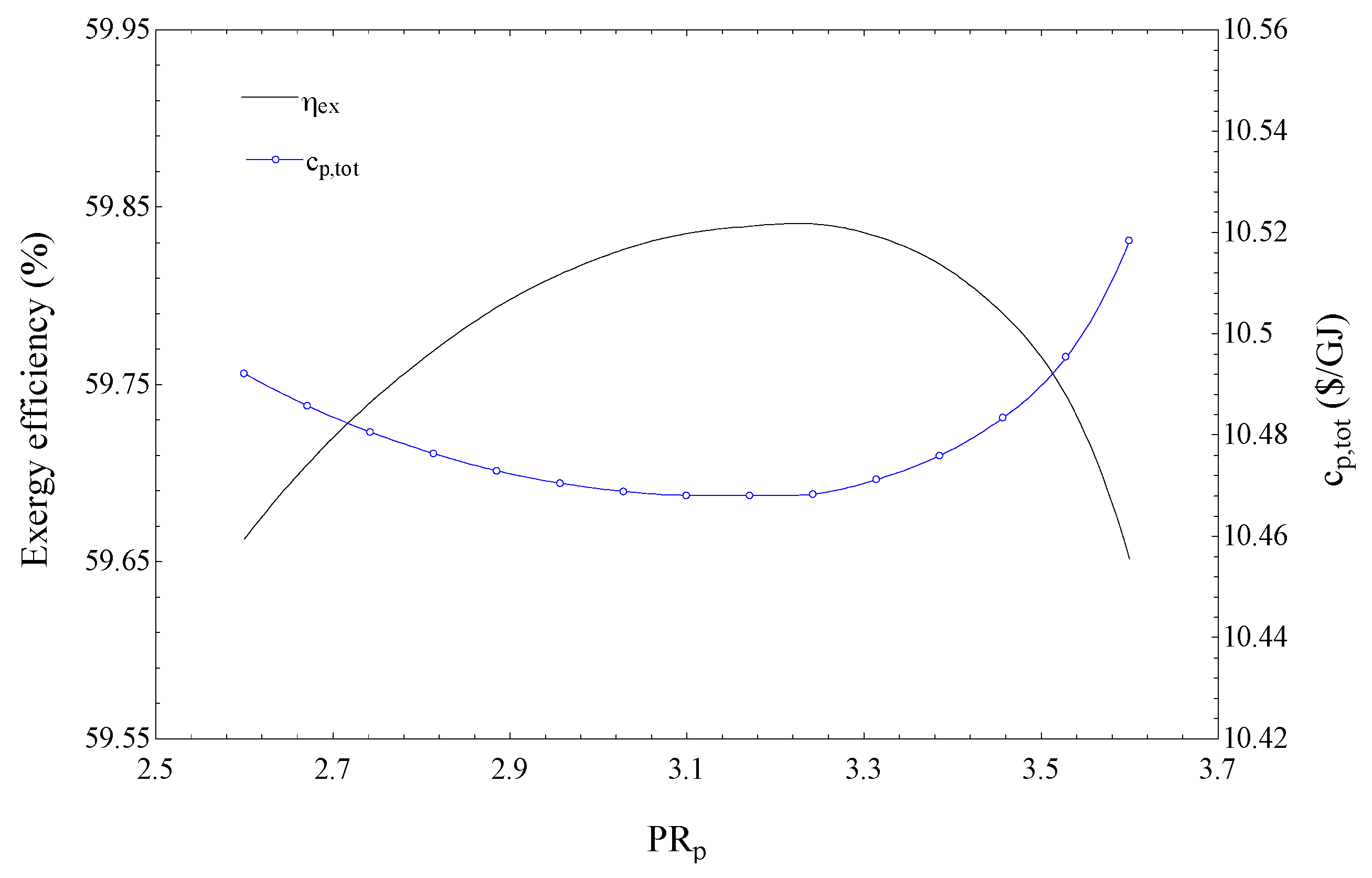

The variation of the exergy efficiency (

) and total product unit cost (c

p,tot) with the pump pressure ratio (PR

P) is shown in

Figure 3, for the SCRB/KC. Although the range of variation for the two parameters is small, the trend is interesting. The value of PR

P at which the exergy efficiency is maximized is seen in

Figure 3 to be the same as that at which the total product unit cost is minimized. This point indicates that, at a given value of PR

P, the changes in c

p,tot are related only to the net produced power for the KC.

The maximization of the SCRB/KC exergy efficiency, as PRb changes, is actually related to the KC performance. This can be explained by noting that an increase in the PRP causes a decrease in the pre-cooler1 outlet vapor mass fraction (q11). This decrease reduces the turbine2 inlet mass flow rate. On the other hand, the increase in PRP brings about a higher specific work for the KC so that the product of the specific work and the mass flow rate is maximized at a specific value of PRP. This maximization leads to the maximization for exergy efficiency and the minimization for the total product unit cost for the SCRB/KC.

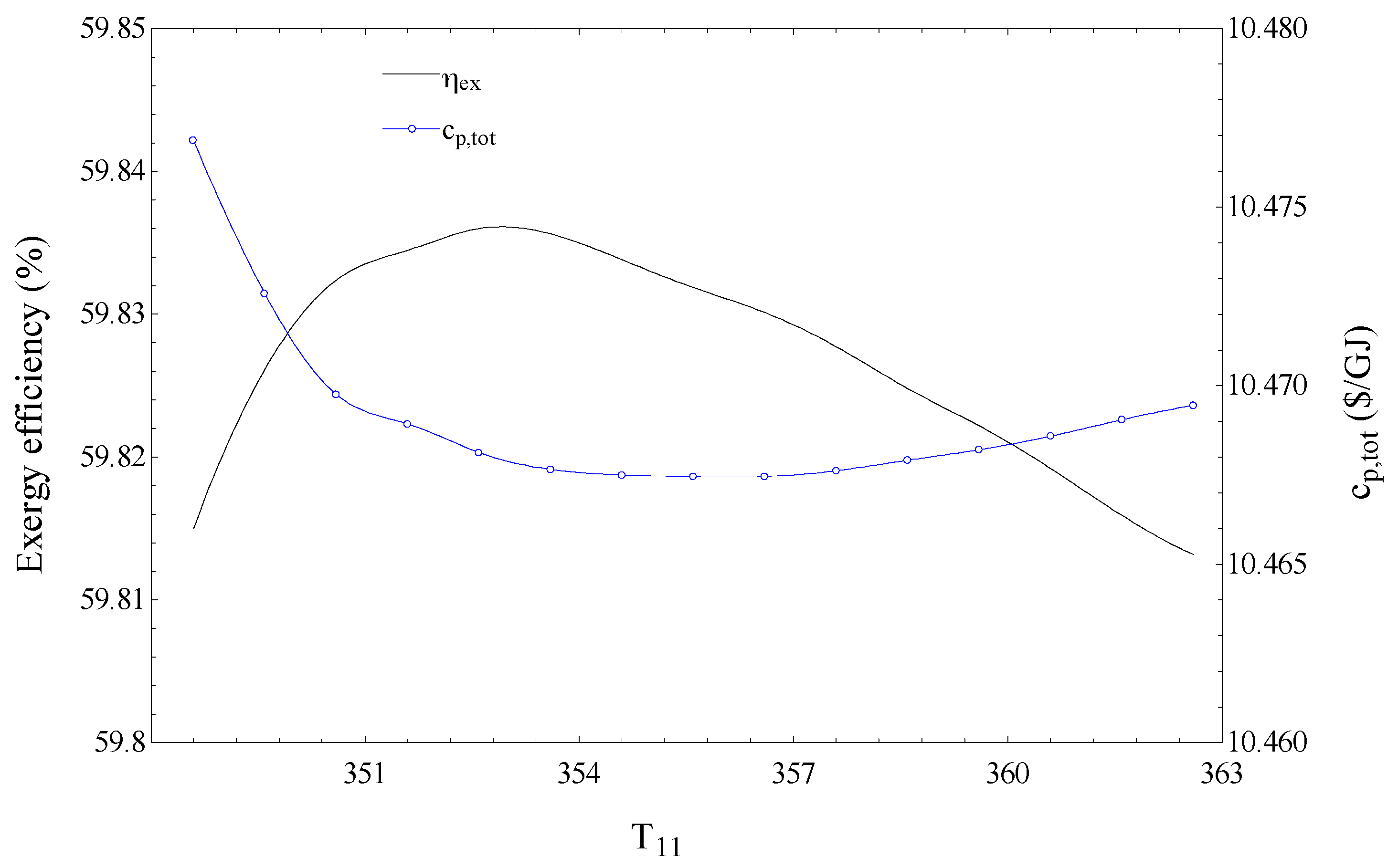

Figure 4 shows the effects on the exergy efficiency (

) and total product unit cost (c

p,tot) of the temperature of the ammonia–water solution at the pre-cooler1 outlet (T

11) for the SCRB/KC. Although

Figure 4 shows that the exergy efficiency is maximized and the total product unit cost is minimized with changing T

11, the variations in the objectives are small.

Note that a higher value of T

11 results in a lower ammonia–water mass flow rate in the KC, but a higher vapor mass fraction (

) in the pre-cooler1 outlet, so that the turbine2 mass flow rate remains almost constant, i.e., the produced power in the KC is almost constant.

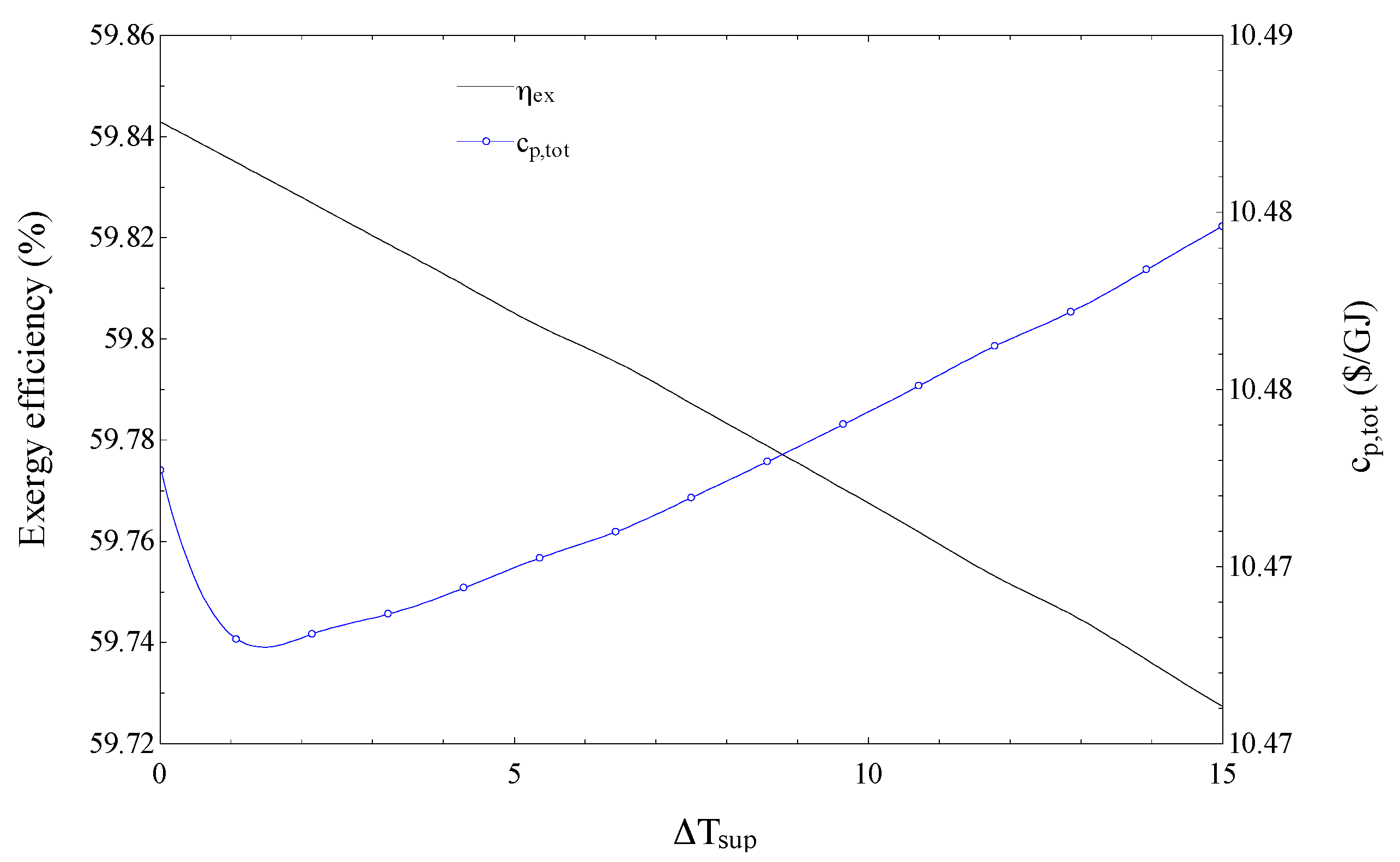

Figure 5 shows the variations in the exergy efficiency and total product unit cost of the SCRB/KC as

changes.

It can be observed in

Figure 5 that, as ΔT

sup increases, the exergy efficiency increases and the total product unit cost is minimized. In fact an increase in the ΔT

sup causes a decrease in the output power of the KC (because of lower heat recovery in the supeheater) and, consequently, the exergy efficiency of the SCRB/KC is reduced. However, the increase in ΔT

sup, brings about a reduction in the superheater capital investment cost rate (

) due to the reduction in the required heat transfer area. Accordingly, as indicated in

Figure 5, there exists an optimum value for ΔT

sup at which the total product unit cost is minimized.

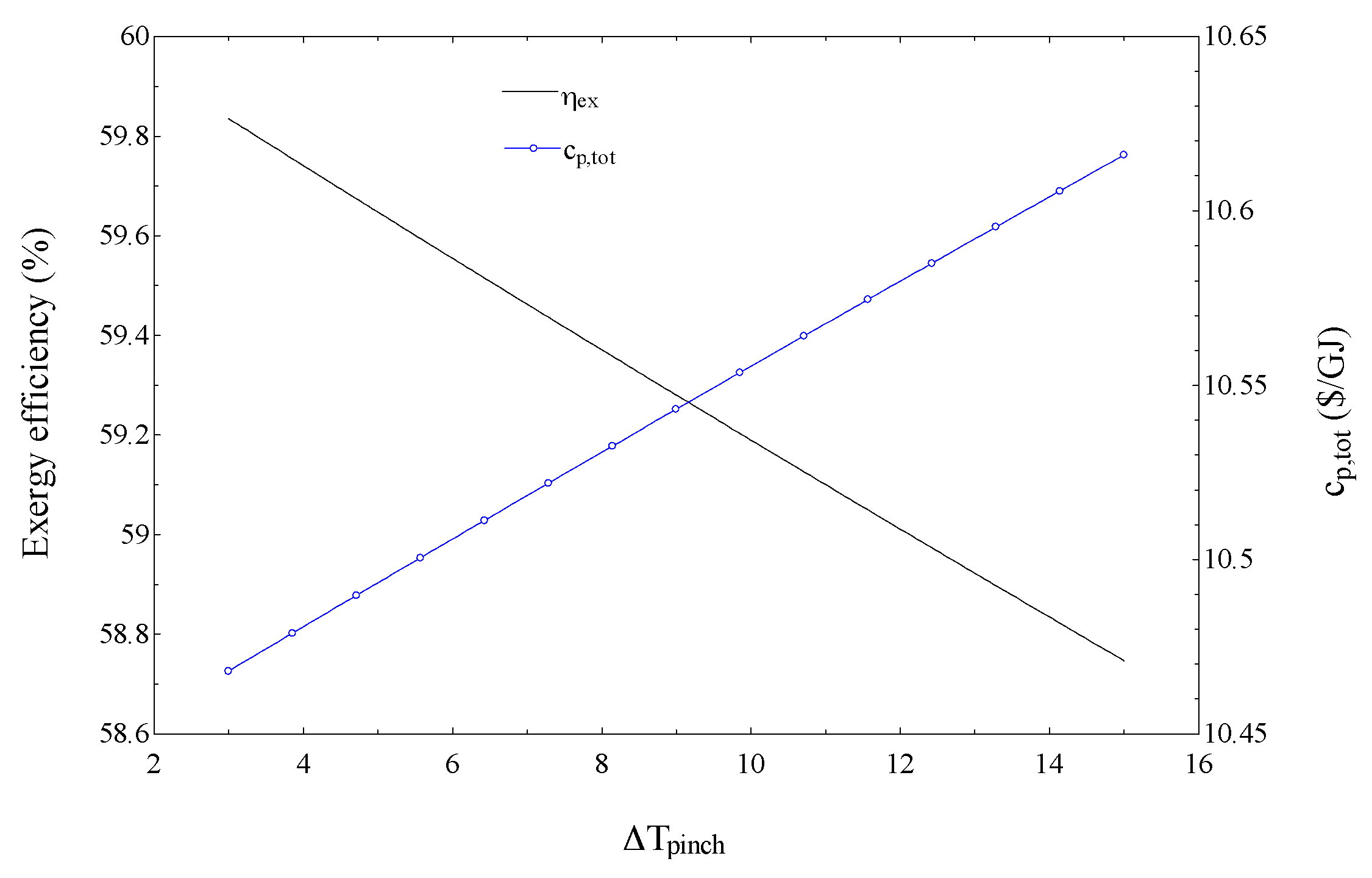

The effects on the exergy efficiency and total product unit cost of the SCRB/KC are shown in

Figure 6 of

in pre-cooler1. Higher exergy efficiency values are obtained for lower ΔT

pinch due to higher values of power generated by the KC. The justification for results in

Figure 6 is similar to that for those in

Figure 5. However the increase in the cost rate associated with the exergy destruction in pre-cooler1 is dominant so that no minimum value is observed for c

p,tot.

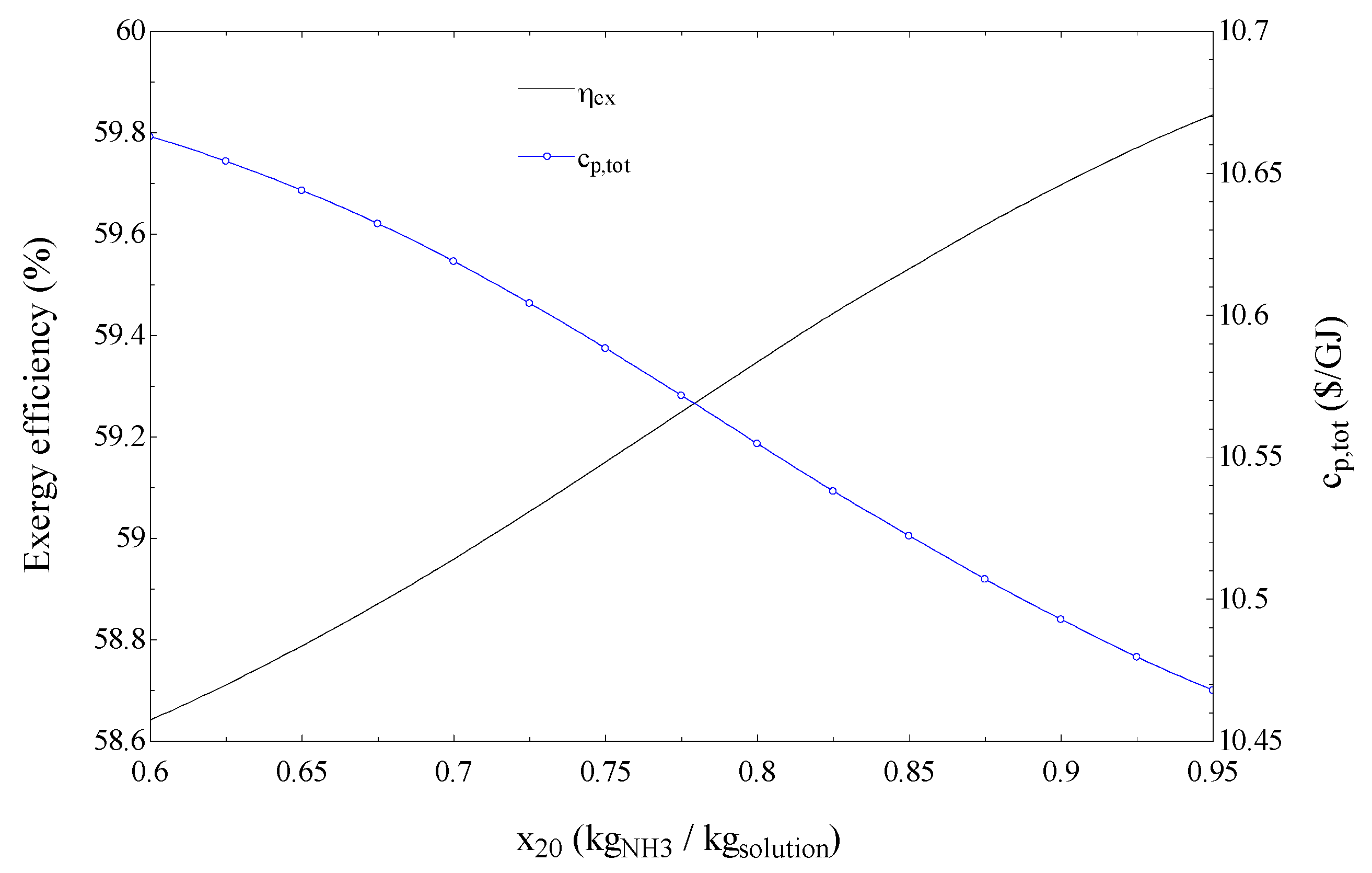

Figure 7 shows the effects of ammonia concentration in the mixture exiting the condenser (X

20) on the exergy efficiency and total product unit cost of the SCRB/KC.

Figure 7 indicates that as X

20 increases the exergy efficiency increases and the total product unit cost decreases. This is justified if we consider that as X

20 increases the exergy destruction in pre-cooler1 and the superheater decreases because of the reduced value of the temperature difference in these two components. Although the reduced value of temperature difference is expected to increase the capital investment cost rate associated with the above-mentioned two components, the increase in produced power is dominant.

Table 7 outlines the thermoeconomic parameters for components of the SCRBC and the SCRB/KC. The sum of

+ is observed in

Table 7 to be highest and second highest for the reactor core and turbine1 in both the proposed systems, respectively. Therefore, the first design changes initially should be applied to these components.

Table 7 also indicates that the exergoeconomic factor is high for these components. This indicates that selecting cheaper components should be suggested for enhancing the economic performance for the systems. However, the extent of improvement in the reactor core is limited. Referring to

Table 7, the third highest

+ value is exhibited by pre-cooler2 in the SCRBC. The very low value of

f for this component suggests that an increase in its capital cost is merited. It is interesting to note that the second highest exergy destruction rate occurs in pre-cooler2 of the SCRBC and the coupling of the KC reduces this exergy destruction. In the KC part of the combined cycle, the highest and second highest values of

+ are associated with turbine2 and the condenser, respectively. Referring to

Table 7, the small value of

f for the condenser suggests it may be appropriate to select a more expensive condenser.